Experimental Research on the Process Parameters of a Novel Low-Load Drill Bit Used for 7000 m Bedrock Sampling Base on Manned Submersible

Abstract

:1. Introduction

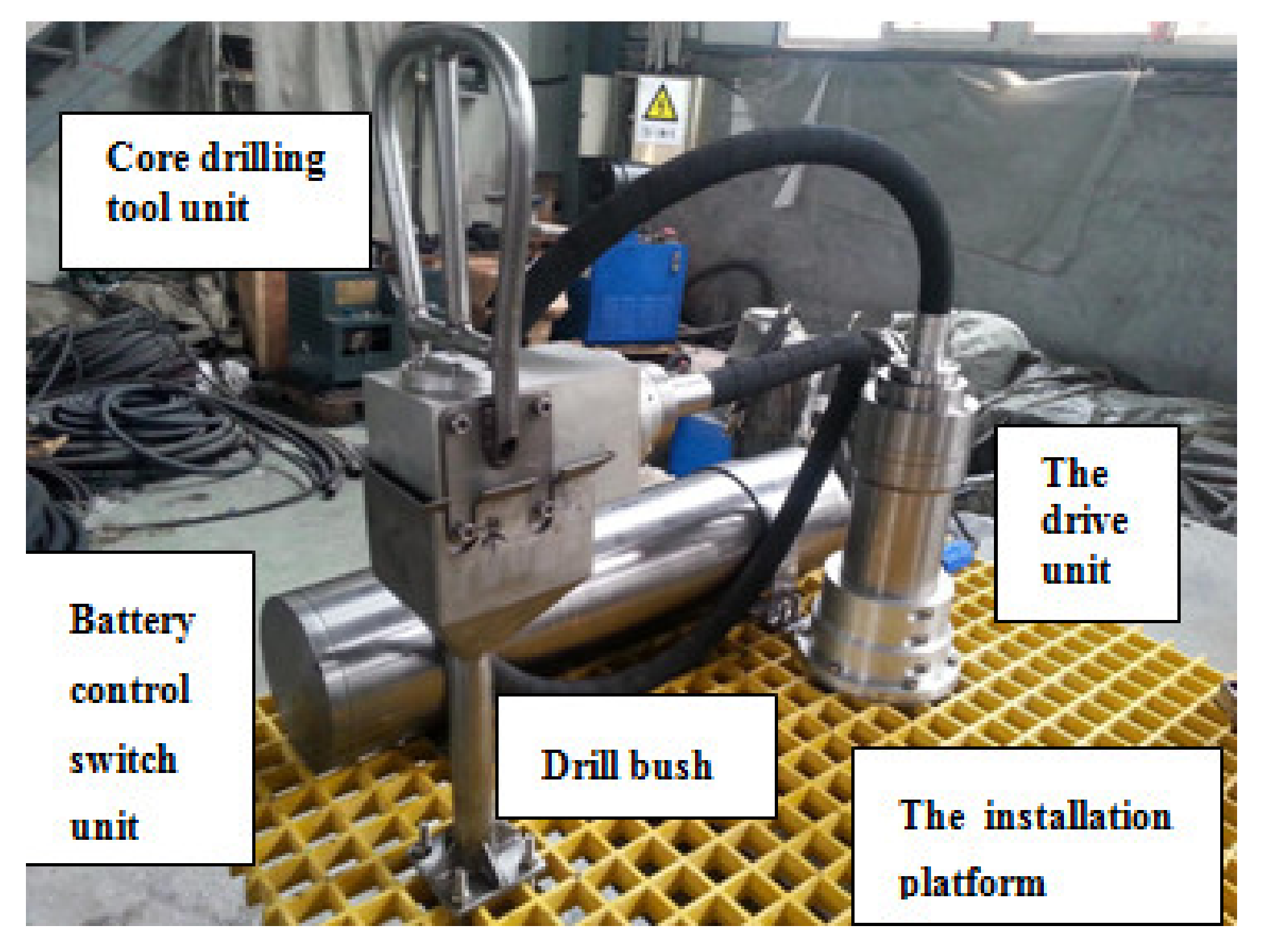

2. Materials and Methods

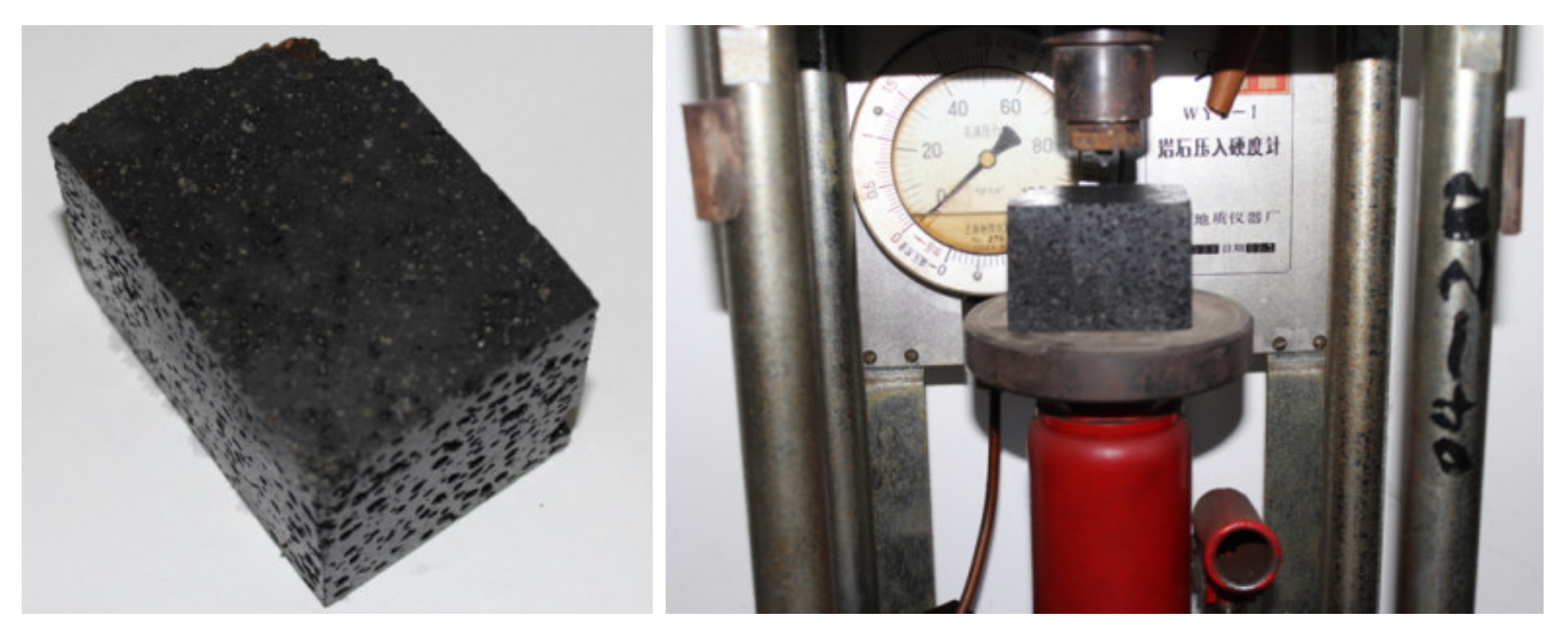

2.1. Bedrock Drillability

2.2. Bedrock Fragmentation Mechanism and Cutting Force Analyses

- (1)

- Determination of minimum drilling pressure.

- (2)

- Determination of Rotary Speed Range.

2.3. Low-Load Drill Bit Design

2.3.1. Design of Negative Rake Angle

2.3.2. Design of Bypass Angle

2.3.3. Exposure Height

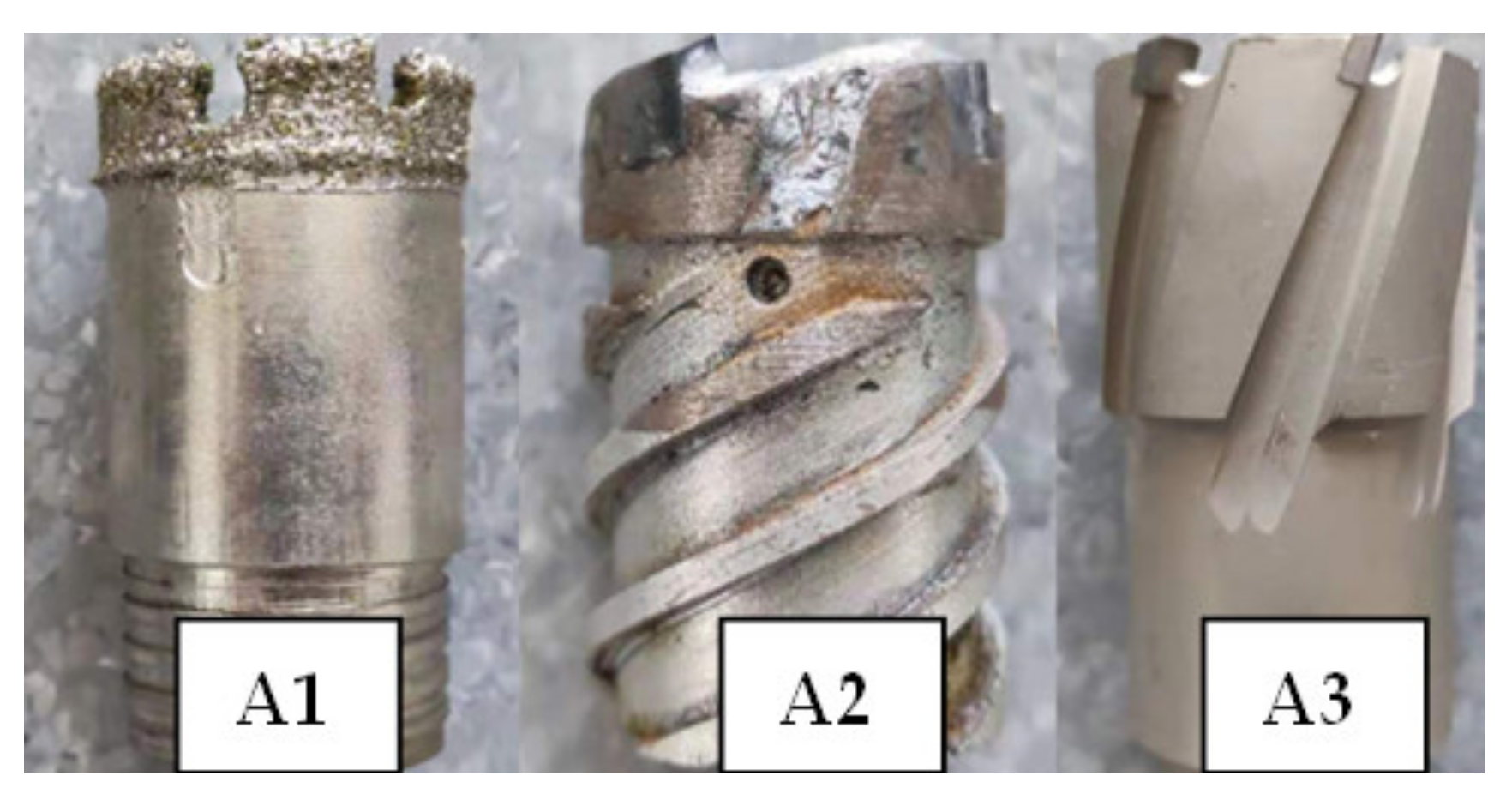

2.4. Drill Bits

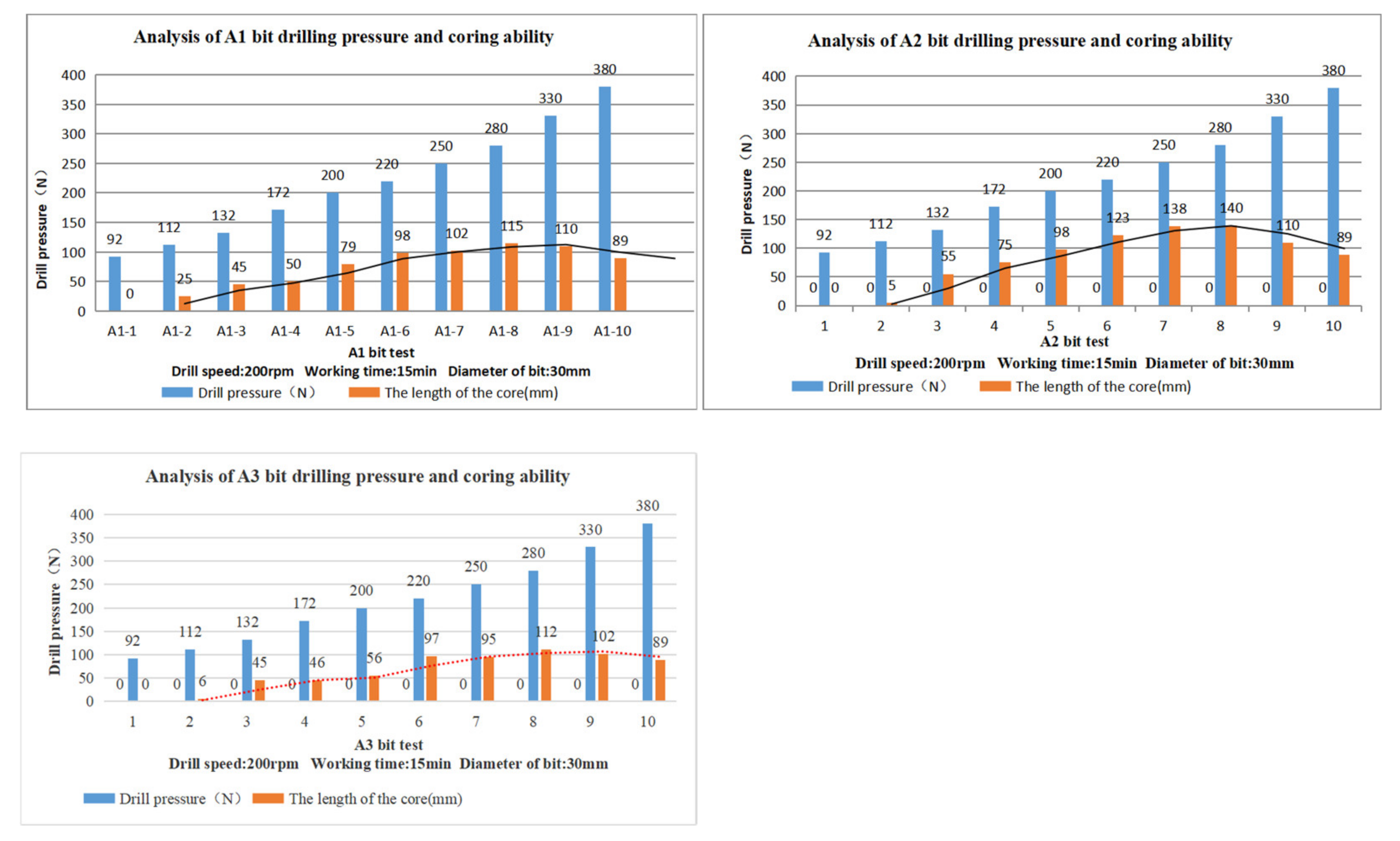

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Reagan, M.K.; Pearce, J.A.; Petronotis, K.; Almeev, R.R.; Avery, A.J.; Carvallo, C.; Chapman, T.; Christeson, G.L.; Ferré, E.C.; Godard, M.; et al. Subduction initiation and ophiolite crust: New insights from IODP drilling. Int. Geol. Rev. 2017, 45, 1–12. [Google Scholar] [CrossRef]

- Ohkubo, S.; Yamazaki, T. Summary of “environmental impact research on marine ecosystem for deep-sea mining” conducted by metal mining agency of Japan. In Proceedings of the ISOPE Ocean Mining Symposium, Tokyo, Japan, 15–19 September 2003; pp. 200–207. [Google Scholar]

- Freudenthal, T.; Wefer, G. Drilling cores on the sea floor with the remote-controlled sea floor drilling rig MeBo. Geosci. Instrum. Methods Data Syst. 2013, 2, 329–337. [Google Scholar] [CrossRef] [Green Version]

- Wumkes, M.A. Development of the U.S. deep coring ice drill. Mem. Natl. Inst. Polar. Res. 1994, 49, 41–51. [Google Scholar]

- Talalay, P.G. Power consumption of deep ice electromechanical drills. Cold Reg. Sci. Technol. 2003, 12, 69–79. [Google Scholar] [CrossRef]

- Shi, X.; Ren, Y.; Tang, J.; Fu, W.; Liu, B. Working Tools Study for JiaoLong Manned Submersible. Mar. Technol. Soc. J. 2019, 53, 56–64. [Google Scholar] [CrossRef]

- Buyan, W.; Guang, Z.; Xiaojun, H. Cobalt-rich Crust Core Sampler Mounted on Human-operated Vehicle. Nonferrous Met. 2009, 61, 138–144. [Google Scholar]

- John, E.; Halkyard, J. Technology for Mining Rich Cobalt Crust from Seamount; Halkyard Company: New York, NY, USA, 1985; pp. 352–367. [Google Scholar]

- White, D.G.; Tietze, R.; Jolly, D.; Hammond, D. Deep ocean ROV operated coring device. In Proceedings of the OCEANS 96 MTS/IEEE Conference Proceedings. The Coastal Ocean—Prospects for the 21st Century, Fort Lauderdale, FL, USA, 23–26 September 1996; pp. 251–252. [Google Scholar]

- Stakes, D.S.; Holloway, G.L.; Tengdin, T.T.; Rajcula, G. First Successful Rotary Diamond Drilling from Submersibles. In Proceedings of the Mastering the Oceans Through Technology, Newport, RI, USA, 26–29 October 1992; pp. 234–239. [Google Scholar]

- Talalay, P.; Fan, X.; Zheng, Z.; Xue, J.; Cao, P.; Zhang, N.; Wang, R.; Yu, D.; Yu, C.; Zhang, Y.; et al. Antitorque systems of electromechanical cable-suspended drills and test results. Ann. Glaciol. 2014, 55, 115–123. [Google Scholar] [CrossRef] [Green Version]

- Zhao, H.; He, Q.; Chen, Q. Research of 7000m Deep-sea Cobalt Sampler. Chin. J. Constr. Mach. 2005, 3, 425–430. [Google Scholar]

- Gao, P.; Xie, Y.; Liu, J. Design of a small bedrock core sampling drill operated by a manipulator of a manned submersible. Mach. Tool Hydraul. 2016, 44, 82–84. [Google Scholar]

- Lu, D.; Ding, Z.; Li, D. Studies and Applications of Cobalt-rich Crust Core Samplers Mounted on “Jiao Long” Manned Submersibles. China Mech. Eng. 2019, 30, 103–107. [Google Scholar]

- Tian, L.; Sheng, Y. The Hai Ma ROV Rich Cobalt Crust Drilling Technology Research. Mech. Electr. Eng. Technol. 2015, 11, 13–15. [Google Scholar]

- Yang, L.; Ding, Z.; Le, D.; Ren, Y. Experimental Study on the Operation of Deep-Sea In-Situ Core Sampling Apparatus. J. Ocean Technol. 2015, 36, 38–42. [Google Scholar]

- Zimmermann, G.; Zang, A. Numerical investigation on stress shadowing in fluid injection-induced fracture propagation in naturally fractured geothermal reservoirs. Bedrock Mech. Bedrock Eng. 2015, 48, 1439–1454. [Google Scholar]

- Gow, A.J.; Meese, D.A. Nature of basal debris in the GISP2 and Byrd ice cores and its relevance to bed processes. Ann. Glaciol. 1996, 22, 134–140. [Google Scholar] [CrossRef] [Green Version]

- Riedel, M.; Conway, K.W. Paleoseismicity Derived from Piston Coring Methods, Explorer and Juan de Fuca Plate Systems; Geological Survey of Canada Current Research: Vancouver, BC, Canada, 2015; pp. 689–696. [Google Scholar]

- Miller, K.A.; Thompson, K.F.; Johnston, P.; Santillo, D. An overview of seabed mining including the current state of development, environmental impacts, and knowledge gaps. Front. Mar. Sci. 2018, 4, 418–425. [Google Scholar] [CrossRef]

- Hein, J.R.; Mizell, K.; Koschinsky, A.; Conrad, T.A. Deep-ocean mineral deposits as a source of critical metals for high-and green-technology applications: Comparison with land-based resources. Ore Geol. Rev. 2013, 51, 1–14. [Google Scholar] [CrossRef]

- Hibbs, L.E.; Flom, D.G. Diamond Compact Cutter Studies for Geothermal Bit Design. J. Press. Vessel. Technol. 1978, 100, 406–416. [Google Scholar] [CrossRef]

- Hill, R. A self-consistent mechanics of composite materials. J. Mech. Phys. Solids 1965, 13, 213–222. [Google Scholar] [CrossRef]

- Tu, H.Z.; Yang, K.H. Drilling Engineering Manual; Geological Press: Beijing, China, 1988; pp. 103–116. [Google Scholar]

- Aoshika, K.; Zaitsu, M. Experimental study of cutting the cobalt-rich manganese crusts. Ocean Bottom 1990, 12, 235–241. [Google Scholar]

| Coring Apparatus | Technical Indicators | Country | Core Parameters |  |

| ALVIN | 5000 m, 35 kg, Hydraulic drive | USA | Collect a bedrock sample of 480 mm in length | |

| Harbor Branch | 7000 m, Hydraulic drive | USA | Multiple bedrock samples can be drilled at one time | |

| APTYC | 5000 m, 1160 mm, 33 kg, Hydraulic drive | Russia | The diameter and length of the core are 21 mm and 80–130 mm. Cores 5 pieces at a time | |

| CONSUB | 3000 m, Hydraulic drive | UK | Specific parameters unknown | |

| ST-1 | 2000 m, Hydraulic drive | France | Can drill into granite, basalt and other hard bedrocks | |

| Shinkai 6500 | 6500 m, Hydraulic drive | Japan | Can drill into granite, basalt and other hard bedrocks and collect a core of 200 mm in length |

| Bedrock Classification | Pressure Hardness Index | Drillability of the Bedrock | |||

|---|---|---|---|---|---|

| Test Value (kgf/cm2) | Calculated Value (kgf/mm2) | ||||

| Cobalt crust | 22 | 22 | 23 | 202.5 | 6 |

| Number | Bit Type | OD/ID (mm) | Matrix Hardness (HRC) |

|---|---|---|---|

| A1 | Impregnated diamond drill bit | 45/30 | 40–50 |

| A2 | New low-load PDC bit | 45/30 | 40–50 |

| A3 | carbide | 45/30 | 40–50 |

| Test Number | Bedrock Category | Parameters and Results of Drilling Test Procedures | Torque (N.CM) | Power Test (W) | Coring Ability | ||||

|---|---|---|---|---|---|---|---|---|---|

| Drilling Pressure (N) | Rotary Speed (rpm) | Drilling Time (min) | Drilling | No-Load | Drilling | Core Length (mm) | Coring Rate (%) Max 140 mm | ||

| 1 | Cobalt crust | 112 | 250 | 15 | 408 | 33 | 43 | 5 | 3.5 |

| 2 | Cobalt crust | 200 | 250 | 15 | 620 | 33 | 130 | 103 | 70 |

| 3 | Cobalt crust | 250 | 250 | 15 | 605 | 33 | 160 | 138 | 98.5 |

| 4 | Cobalt crust | 280 | 250 | 15 | 610 | 33 | 164 | 140 | 100 |

| 5 | Cobalt crust | 380 | 250 | 15 | 634 | 33 | 176 | 125 | 89.3 |

| 6 | Cobalt crust | 280 | 140 | 15 | 404 | 36 | 75 | 100 | 71.4 |

| 7 | Cobalt crust | 280 | 230 | 15 | 613 | 95 | 130 | 127 | 90.7 |

| 8 | Cobalt crust | 280 | 270 | 15 | 621 | 101 | 170 | 140 | 100 |

| 9 | Cobalt crust | 280 | 330 | 15 | 632 | 112 | 175 | 140 | 100 |

| 10 | Cobalt crust | 280 | 390 | 15 | 618 | 123 | 186 | 95 | 67.9 |

| Test Number | Bedrock Category | Parameters and Results of Drilling Test Procedures | Torque (N.CM) | Power Test (W) | Coring Ability | ||||

|---|---|---|---|---|---|---|---|---|---|

| Drilling Pressure (N) | Rotary Speed (rpm) | Drilling Time (min) | Drilling | No-Load | Drilling | Core Length (mm) | Coring Rate(%) Max 140 mm | ||

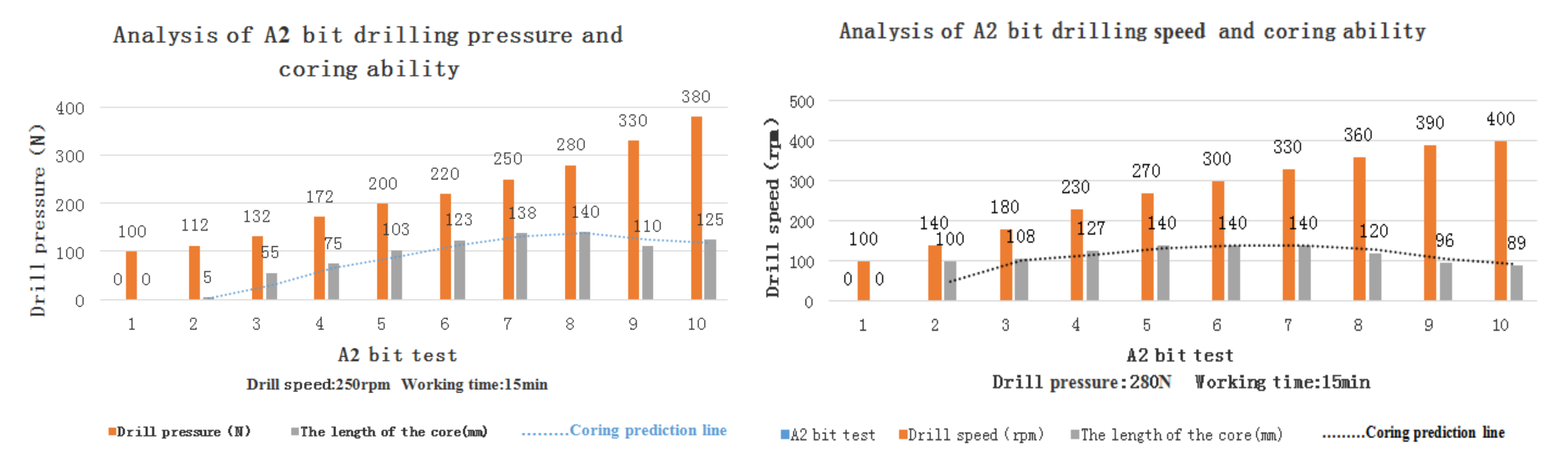

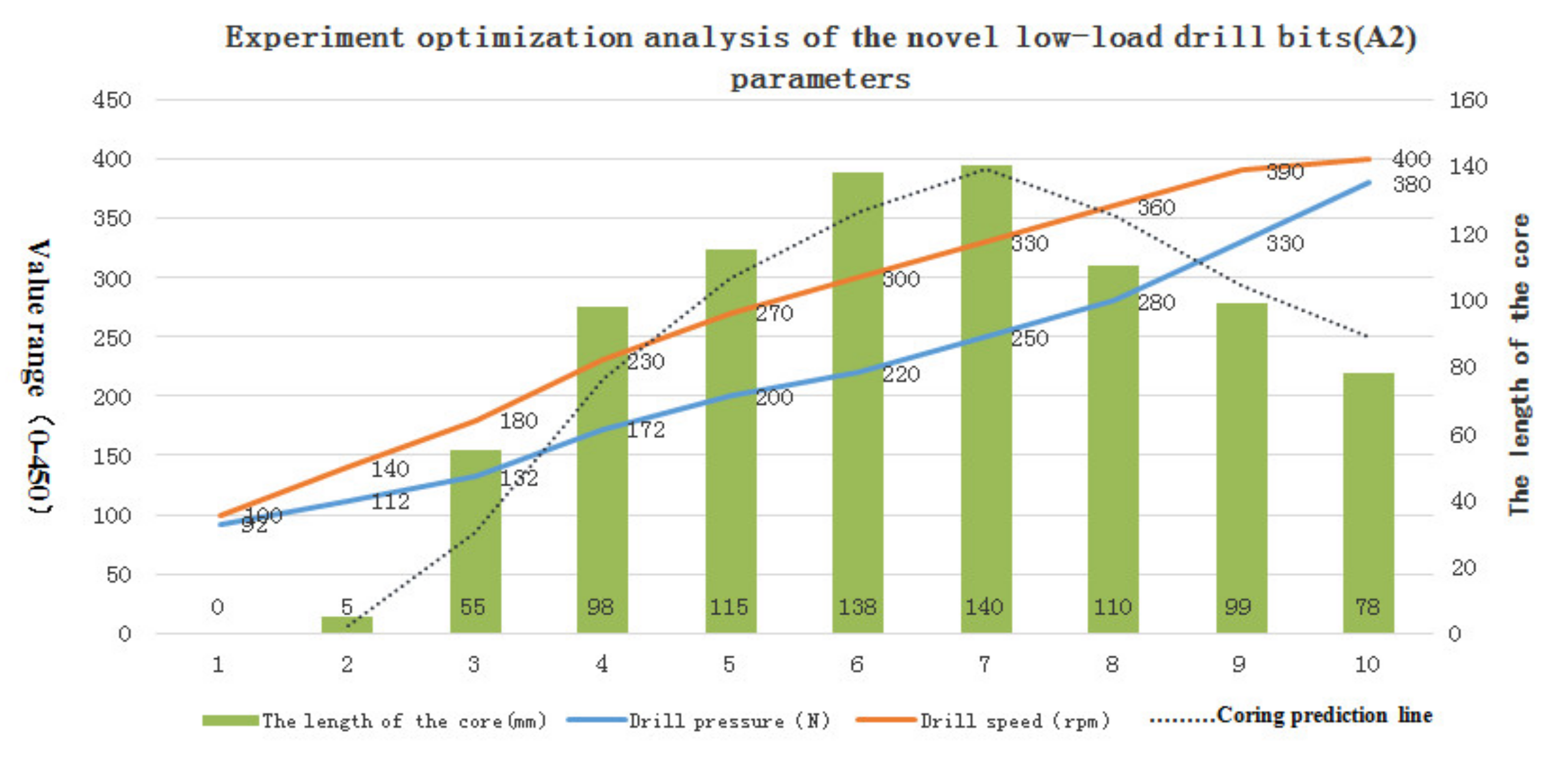

| 1 | Cobalt crust | 92 | 100 | 15 | 256 | 33 | 36 | 0 | 0 |

| 2 | Cobalt crust | 112 | 140 | 15 | 324 | 36 | 40 | 5 | 3.5 |

| 3 | Cobalt crust | 132 | 180 | 15 | 389 | 87 | 76 | 55 | 39.3 |

| 4 | Cobalt crust | 172 | 230 | 15 | 578 | 90 | 121 | 98 | 70 |

| 5 | Cobalt crust | 200 | 270 | 15 | 589 | 101 | 145 | 115 | 82.1 |

| 6 | Cobalt crust | 220 | 300 | 15 | 613 | 107 | 159 | 138 | 98.6 |

| 7 | Cobalt crust | 250 | 330 | 15 | 624 | 112 | 167 | 140 | 100 |

| 8 | Cobalt crust | 280 | 360 | 15 | 638 | 118 | 169 | 110 | 78.6 |

| 9 | Cobalt crust | 330 | 390 | 15 | 641 | 123 | 178 | 99 | 70.7 |

| 10 | Cobalt crust | 380 | 400 | 15 | 617 | 116 | 186 | 78 | 55.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, Y.-G.; Yang, L.; Liu, Y.-J.; Liu, B.-H.; Yu, K.-B.; Zhang, J.-H. Experimental Research on the Process Parameters of a Novel Low-Load Drill Bit Used for 7000 m Bedrock Sampling Base on Manned Submersible. J. Mar. Sci. Eng. 2021, 9, 682. https://doi.org/10.3390/jmse9060682

Ren Y-G, Yang L, Liu Y-J, Liu B-H, Yu K-B, Zhang J-H. Experimental Research on the Process Parameters of a Novel Low-Load Drill Bit Used for 7000 m Bedrock Sampling Base on Manned Submersible. Journal of Marine Science and Engineering. 2021; 9(6):682. https://doi.org/10.3390/jmse9060682

Chicago/Turabian StyleRen, Yu-Gang, Lei Yang, Yan-Jun Liu, Bao-Hua Liu, Kai-Ben Yu, and Jian-Hua Zhang. 2021. "Experimental Research on the Process Parameters of a Novel Low-Load Drill Bit Used for 7000 m Bedrock Sampling Base on Manned Submersible" Journal of Marine Science and Engineering 9, no. 6: 682. https://doi.org/10.3390/jmse9060682