A State-Dependent Constitutive Model for Gas Hydrate-Bearing Sediments Considering Cementing Effect

Abstract

:1. Introduction

2. State-Related Characteristics of GHBS

- (1)

- GHBS may show strain hardening or softening during shearing, and its characteristics depend on Sh, compactness and stress level.

- (2)

- For the deformation characteristics of GHBS, shear shrinkage and dilatancy may occur, which are mainly related to internal states, such as hydrate occurrence mode and Sh.

- (3)

- The cementation of GHBS has an important influence on its characteristics of strength and deformation. With the decline of cementation, it often shows a more obvious phenomenon of softening and dilatancy.

3. State-Dependent Elastoplastic Constitutive Model of GHBS

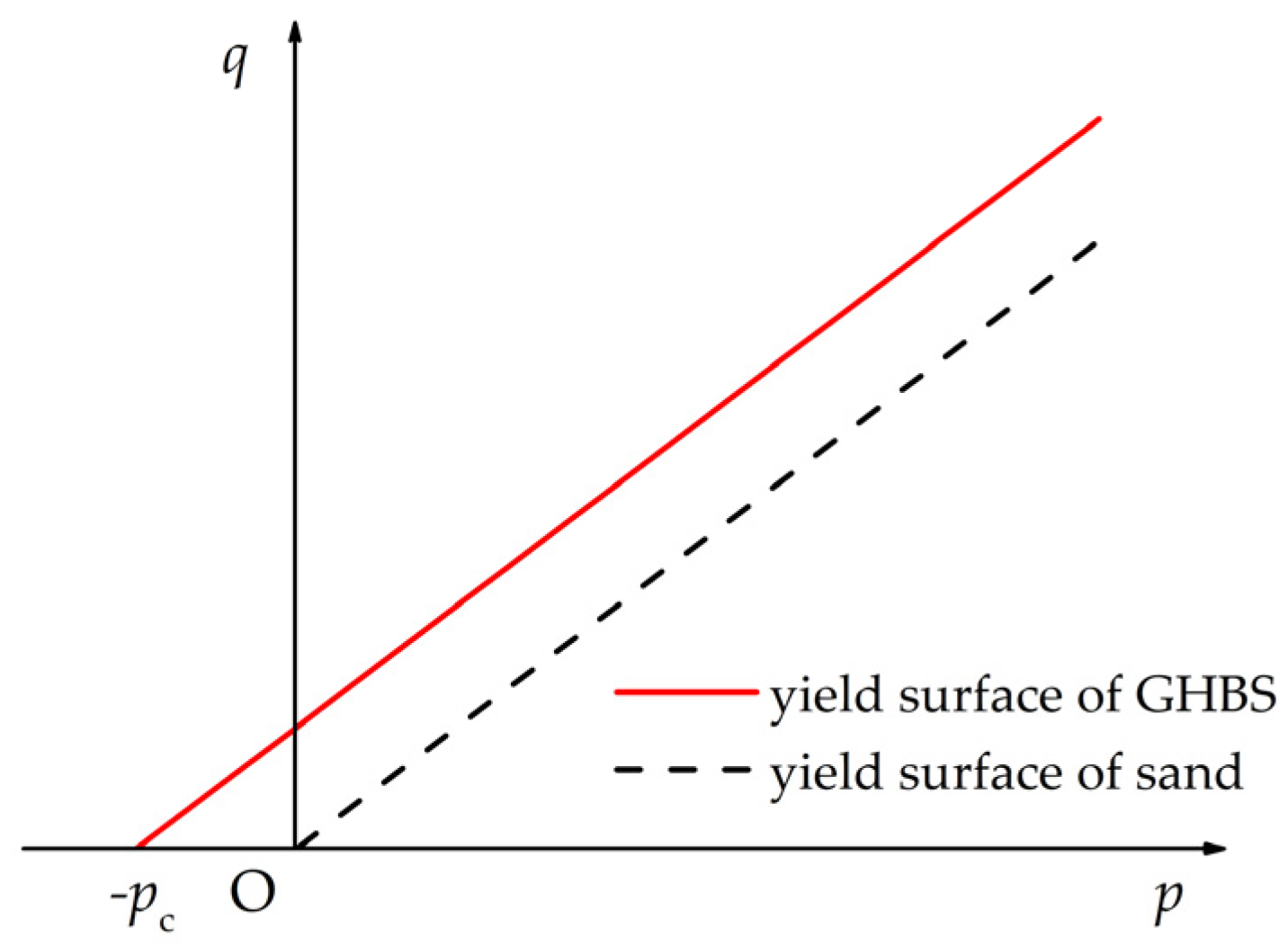

3.1. Yield Function

3.2. Cementation

3.3. State Parameters and Dilatancy

3.4. Hardening Modulus

4. Model Verification

4.1. Model Parameters

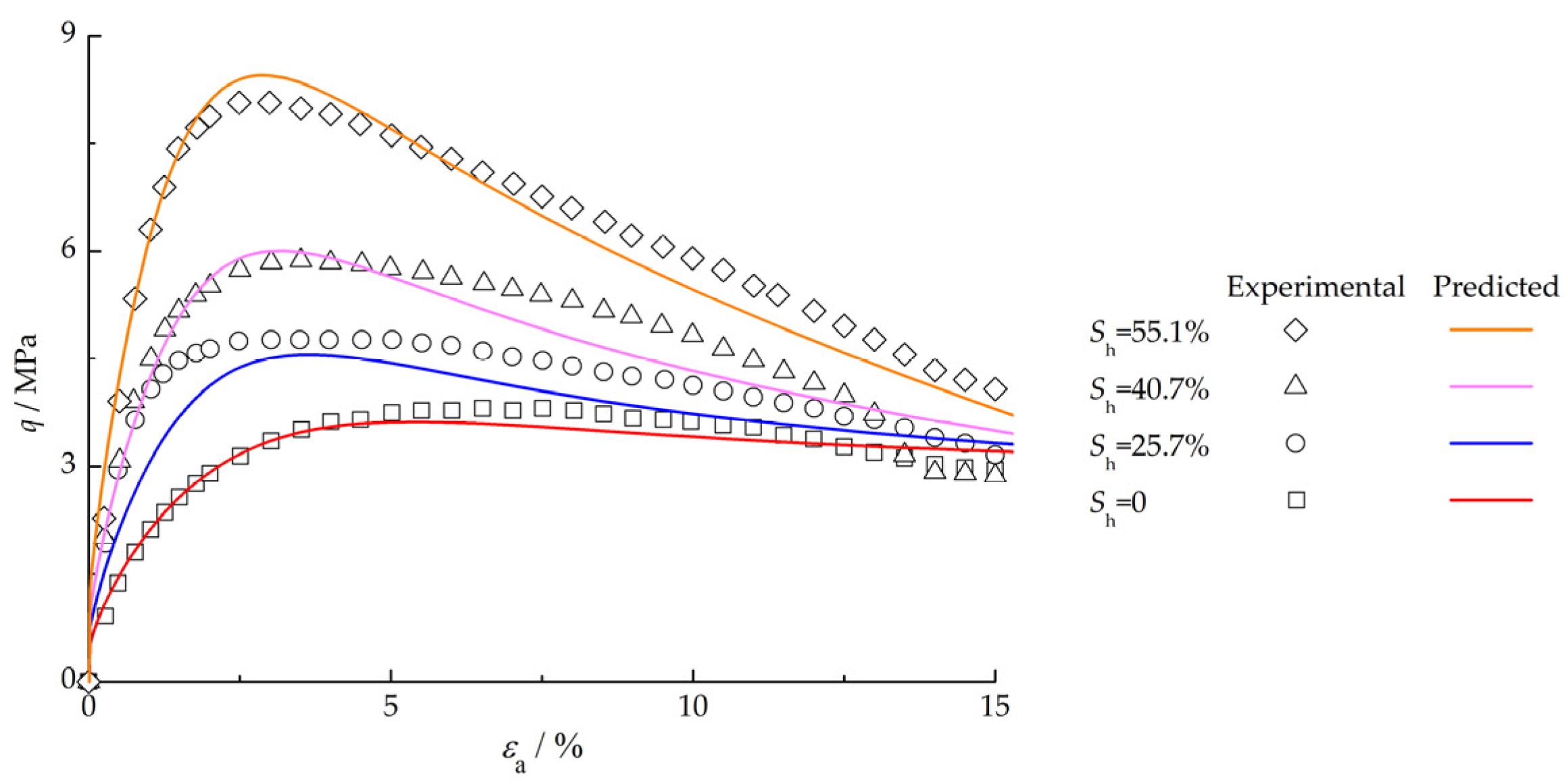

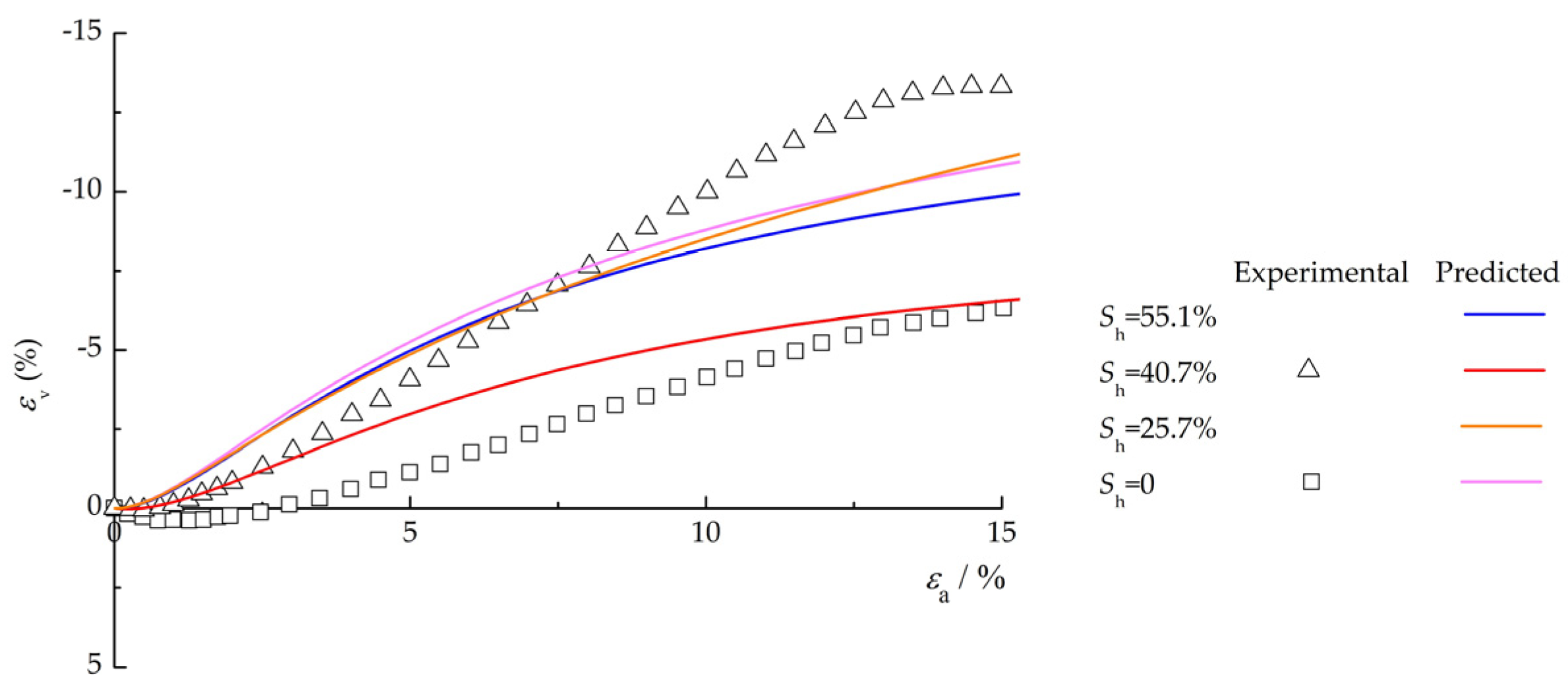

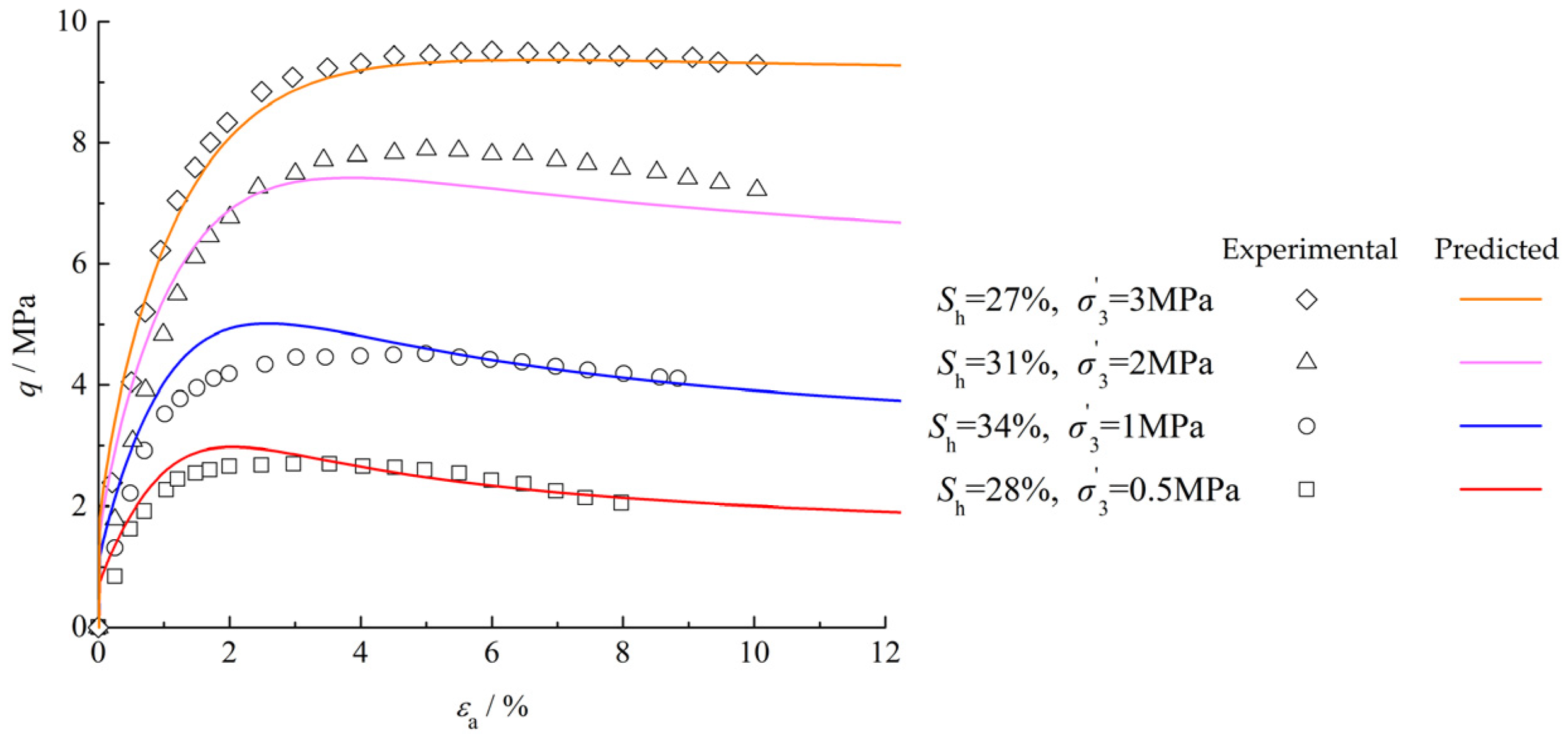

4.2. Model Prediction

5. Conclusions

- (1)

- By summarizing the test rules of GHBS, it is found that GHBS has certain cohesive strength and obvious state-related characteristics. In this paper, GHBS is regarded as a special cementing material, and the sand state correlation model is selected as the basic framework.

- (2)

- By constructing appropriate state parameter expressions, introducing the cementation and its evolutionary pattern and adopting the mixed hardening rule, the state-dependent constitutive model of GHBS is established.

- (3)

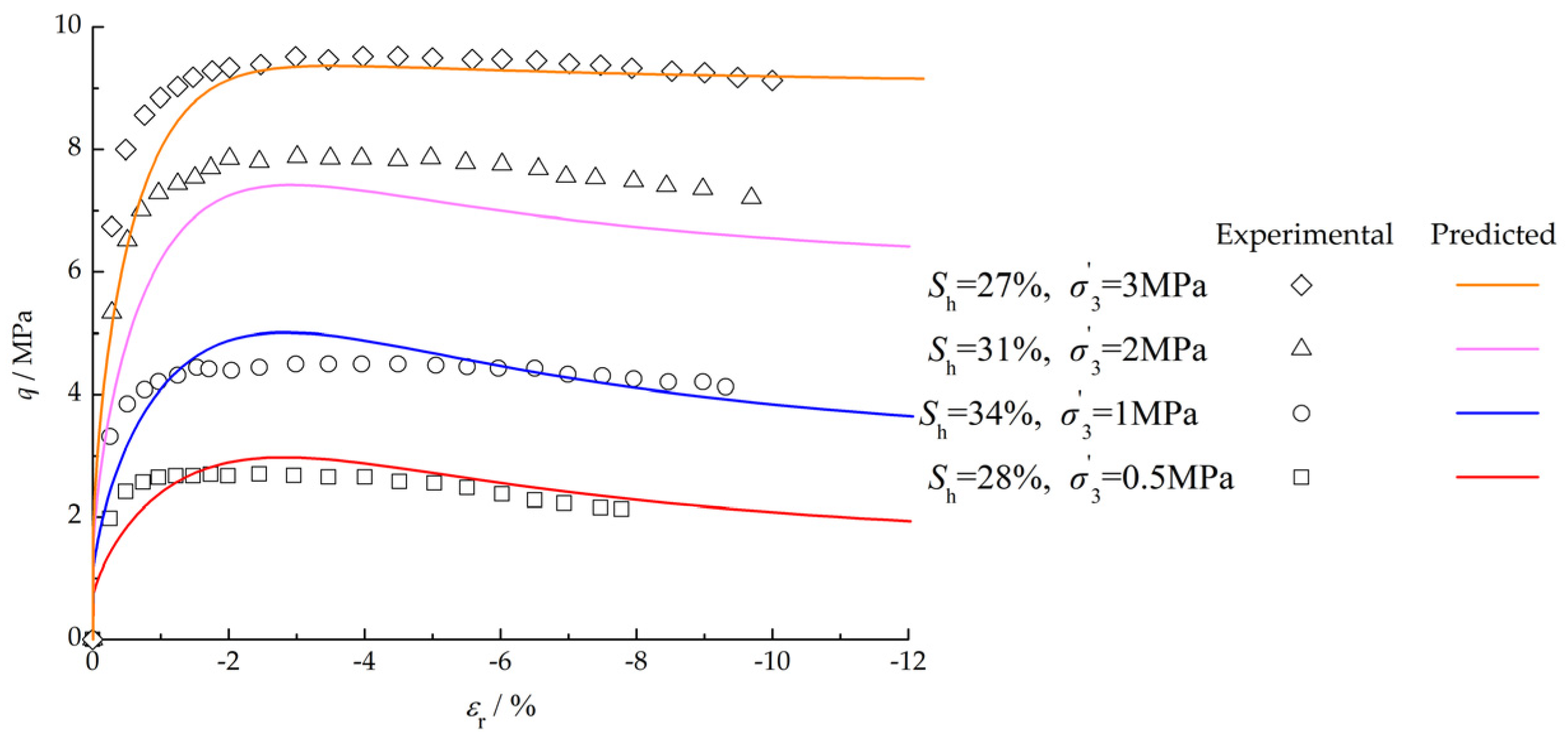

- The comparison between the predicted results using the proposed model and the experimental data shows that the established constitutive model is in good agreement with the experimental data. The model can satisfactorily describe the strain-hardening and strain-softening characteristics of GHBS and can effectively reflect the correlation characteristics of strength and stiffness with hydrate saturation, effective confining pressure and other factors.

Author Contributions

Funding

Conflicts of Interest

References

- Riedel, M.; Spence, G.D.; Chapman, N.R.; Hyndman, R.D. Deep-sea gas hydrates on the northern cascadia margin. Lead. Edge 2001, 20, 87–109. [Google Scholar] [CrossRef]

- Kvenvolden, K. Gas hydrates—Geological perspective and global change. Rev. Geophys. 1993, 31, 173–187. [Google Scholar] [CrossRef]

- Kong, L.; Zhang, Z.F.; Yuan, Q.M.; Liang, Q.Y.; Shi, Y.H.; Lin, J.Q. Multi-factor sensitivity analysis on the stability of submarine hydrate-bearing slope. China Geol. 2018, 1, 367–373. [Google Scholar] [CrossRef]

- Yamamoto, K.; Dallimore, S. Aurora-jogmec-nrcan mallik 2006–2008 gas hydrate research project progress. NETL Methane Hydrate Newslett. 2008, 8, 1–5. [Google Scholar]

- Zhang, X.H.; Lu, X.B.; Liu, L.L. Advances in natural gas hydrate recovery methods. Prog. Geophys. 2014, 29, 858–869. (In Chinese) [Google Scholar] [CrossRef]

- Yamamoto, K.; Terao, Y.; Fujii, T.; Terumichi, I.; Kanno, T. Operational overview of the first offshore production test of methane hydrates in the eastern nankai trough. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–8 May 2014. [Google Scholar]

- Li, B.; Liang, Y.P.; Li, X.S.; Zhou, L. A pilot-scale study of gas production from hydrate deposits with two-spot horizontal well system. Appl. Energy 2016, 176, 12–21. [Google Scholar] [CrossRef]

- Schicks, J.; Spangenberg, E.; Giese, R.; Luzi-Helbing, M.; Priegnitz, M.; Beeskow-Strauch, B. A counter-current heat-exchange reactor for the thermal stimulation of hydrate-bearing sediments. Energies 2013, 6, 3002–3016. [Google Scholar] [CrossRef]

- Liang, Y.P.; Li, X.S.; Li, B. Assessment of gas production potential from hydrate reservoir in qilian mountain permafrost using five-spot horizontal well system. Energies 2015, 8, 10796–10817. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.H.; Tohidi, K.B.; Clennell, B. Micro and macro-scale investigation of cementing characteristics of gas hydrates. In Proceedings of the AAPG Hedberg Research Conference: Natural Gas Hydrates: Energy Resource Potential and Associated Geologic Hazards, Vancouver, BC, Canada, 12–14 September 2004. [Google Scholar]

- Saw, V.; Ahmad, I.; Mandal, A.; Udayabhanu, G.; Laik, S. Methane hydrate formation and dissociation in synthetic seawater. J. Nat. Gas Chem. 2012, 21, 625–632. [Google Scholar] [CrossRef]

- Sultan, N.; Cochonat, P.; Foucher, J.P.; Mienert, J. Effect of gas hydrates melting on seafloor slope instability. Mar. Geol. 2004, 213, 379–401. [Google Scholar] [CrossRef] [Green Version]

- Maslin, M.; Owen, M.J.; Betts, R.; Day, S.; Jones, T.D.; Ridgwell, A. Gas hydrates: Past and future geohazard? Philos. Trans. R. Soc. A 2010, 368, 2369–2393. [Google Scholar] [CrossRef] [PubMed]

- Sanchez, M.; Gai, X.; Santamarina, J.C. A constitutive mechanical model for gas hydrate bearing sediments incorporating inelastic mechanisms. Comput. Geotech. 2017, 84, 28–46. [Google Scholar] [CrossRef] [Green Version]

- Yu, F.; Song, Y.; Liu, W.; Li, Y.; Lam, W. Analyses of stress strain behavior and constitutive model of artificial methane hydrate. J. Pet. Sci. Eng. 2011, 77, 183–188. [Google Scholar] [CrossRef]

- Yan, C.L.; Cheng, Y.F.; Li, M.L.; Han, Z.Y.; Zhang, H.W.; Li, Q.C.; Teng, F.; Ding, J.P. Mechanical experiments and constitutive model of natural gas hydrate reservoirs. Int. J. Hydrog. Energy 2017, 42, 19810–19818. [Google Scholar] [CrossRef]

- Sultan, N. Geomechanical constitutive modelling of gas-hydrate-bearing sediments. In Proceedings of the 7th International Conference on Gas Hydrates (ICGH 2011), Edinburgh, Scotland, UK, 17–21 July 2011. [Google Scholar]

- Yan, R.T.; Wei, C.F.; Wei, H.Z.; Tian, H.-H.; Wu, E.L. A generalized critical state model for gas hydrate-bearing sediments. In Constitutive Modeling of Geomaterials; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Klar, A.; Soga, K.; Ng, M.Y.A. Coupled deformation–flow analysis for methane hydrate extraction. Geotechnique 2010, 60, 765–776. [Google Scholar] [CrossRef]

- Winters, W.J.; Pecher, I.A.; Waite, W.F.; Mason, D.H. Physical properties and rock physics models of sediment containing natural and laboratory-formed methane gas hydrate. Am. Mineral. 2004, 89, 1221–1227. [Google Scholar] [CrossRef]

- Hyodo, M.; Nakata, Y.; Yoshimoto, N.; Ebinuma, T. Basic research on the mechanical behavior of methane hydrate-sediments mixture. Soils Found. 2005, 45, 75–85. [Google Scholar]

- Masui, A.; Haneda, H.; Ogata, Y.; Aoki, K. Effects of methane hydrate formation on shear strength of synthetic methane hydrate sediments. In Proceedings of the International Offshore and Polar Engineering Conference, Seoul, Korea, 19–24 June 2005. [Google Scholar]

- Yun, T.S.; Santamarina, J.C.; Ruppel, C.D. Mechanical properties of sand, silt, and clay containing tetrahydrofuran hydrate. J. Geophys. Res. 2007, 112. [Google Scholar] [CrossRef]

- Miyazaki, K.; Masui, A.; Sakamoto, Y.; Aoki, K.; Tenma, N.; Yamaguchi, T. Triaxial compressive properties of artificial methane-hydrate-bearing sediment. J.Geophys. Res. 2011, 116. [Google Scholar] [CrossRef]

- Ghiassian, H.; Grozic, J.L.H. Strength behavior of methane hydrate bearing sand in undrained triaxial testing. Mar. Pet. Geol. 2013, 43, 310–319. [Google Scholar] [CrossRef]

- Liu, Z.; Dai, S.; Ning, F.; Peng, L.; Wei, H.; Wei, C. Strength estimation for hydrate-bearing sediments from direct shear tests of hydrate-bearing sand and silt. Geophys. Res. Lett. 2018, 45, 715–723. [Google Scholar] [CrossRef]

- Madhusudhan, B.N.; Clayton, C.R.I.; Priest, J.A. The effects of hydrate on the strength and stiffness of some sands. J. Geophys. Res. 2019, 124, 65–75. [Google Scholar] [CrossRef]

- Dong, L.; Li, Y.; Liao, H.; Liu, C.; Chen, Q.; Hu, G.; Liu, L.; Meng, Q. Strength estimation for hydrate-bearing sediments based on triaxial shearing tests. J. Pet. Sci. Eng. 2020, 184, 106478. [Google Scholar] [CrossRef]

- Soga, K.; Lee, S.L.; Ng, M.Y.A.; Klar, A. Characterisation and engineering properties of methane hydrate soils. In Proceedings of the 2nd International Workshop on Characterisation and Engineering Properties of Natural Soils, Singapore, 29 November–1 December 2006. [Google Scholar]

- Li, X.S.; Dafalias, Y.F. Dilatancy for cohesionless soils. Geotechnique 2000, 50, 449–460. [Google Scholar] [CrossRef]

- Sheng, D.; Yao, Y.P.; Carter, J.P. A volume-stress model for sands under isotropic and critical stress states. Can. Geotech. J. 2008, 45, 1639–1645. [Google Scholar] [CrossRef] [Green Version]

- Yao, Y.P.; Liu, L.; Luo, T.; Tian, Y.; Zhang, J.M. Unified hardening (uh) model for clays and sands. Comput. Geotech. 2019, 110, 326–343. [Google Scholar] [CrossRef]

- Poorooshasb, H.; Holubec, I.; Sherbourne, A. Yielding and flow of sand in triaxial compression: Part i. Can. Geotech. J. 2011, 3, 179–190. [Google Scholar] [CrossRef]

- Uchida, S.; Soga, K.; Yamamoto, K. Critical state soil constitutive model for methane hydrate soil. J. Geophys. Res. 2012, 117, B03209. [Google Scholar] [CrossRef]

- Okwananke, A.; Hassanpouryouzband, A.; Farahani, M.V.; Yang, J.; Tohidi, B.; Chuvilin, E.; Istomin, V.; Bukhanov, B. Methane recovery from gas hydrate-bearing sediments: An experimental study on the gas permeation characteristics under varying pressure. J. Pet. Sci. Eng. 2019, 180, 435–444. [Google Scholar] [CrossRef]

- Manzari, M.T.; Dafalias, Y.F. A critical state two-surface plasticity model for sands. Géotechnique 1997, 47, 255–272. [Google Scholar] [CrossRef]

- Wan, R.G.; Guo, P.J. A simple constitutive model for granular soils: Modified stress-dilatancy approach. Comput. Geotech. 1998, 22, 109–133. [Google Scholar] [CrossRef]

- Yoneda, J.; Oshima, M.; Kida, M.; Kato, A.; Konno, Y.; Jin, Y.; Tenma, N. Consolidation and hardening behavior of hydrate-bearing pressure-core sediments recovered from the krishna–godavari basin, offshore india. Mar. Pet. Geol. 2019, 108, 512–523. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| ξ | 0.7 | M | 1.5 |

| λ | 0.0191 | h | 0.0533 |

| ec0 | 0.9344 | m | 3.16 |

| μ | 0.3 | 1944 |

| Parameter | Value |

|---|---|

| k | 0.29 |

| α(MPa) | 7.75 |

| β | 2.90 |

| ac | 4.97 |

| χ | 0.94 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| 2496 | β | 3.49 | |

| k | 0.08 | ac | 1.95 |

| α(MPa) | 7.71 | χ | 1.08 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, Q.; Kong, L.; Xu, R.; Zhao, Y. A State-Dependent Constitutive Model for Gas Hydrate-Bearing Sediments Considering Cementing Effect. J. Mar. Sci. Eng. 2020, 8, 621. https://doi.org/10.3390/jmse8080621

Yuan Q, Kong L, Xu R, Zhao Y. A State-Dependent Constitutive Model for Gas Hydrate-Bearing Sediments Considering Cementing Effect. Journal of Marine Science and Engineering. 2020; 8(8):621. https://doi.org/10.3390/jmse8080621

Chicago/Turabian StyleYuan, Qingmeng, Liang Kong, Rui Xu, and Yapeng Zhao. 2020. "A State-Dependent Constitutive Model for Gas Hydrate-Bearing Sediments Considering Cementing Effect" Journal of Marine Science and Engineering 8, no. 8: 621. https://doi.org/10.3390/jmse8080621