Optimum Arrangement Design of Mastic Ropes for Membrane-Type LNG Tanks Considering the Flatness of Thermal Insulation Panel and Production Cost

Abstract

:1. Introduction

1.1. Research Background

1.2. Related Studies

2. Arrangement Design Method of Mastic Ropes

2.1. LNG Tank Description

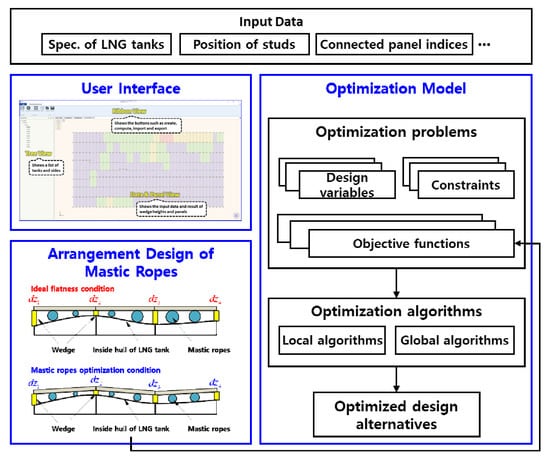

2.2. Formulation of the Optimization Problem

2.2.1. Input Information

2.2.2. Design Variables

2.2.3. Objective Functions

2.2.4. Constraints

2.3. Optimization Algorithm

2.4. Summary of the Proposed Method for Mastic Rope Optimization

| Find | : Design variables | |

| Minimize | , , and | : Objective functions |

| Subject to | , , and | : Constraints |

3. Applications of the Proposed Method

3.1. Prototype Program for the Proposed Method

3.2. Definition of Various Cases with the Proposed Method

- -

- Case 1: H1(X), to minimize the total amount of mastic ropes

- -

- Case 2: H2(X), to minimize the difference between the final heights of the adjacent studs

- -

- Case 3: H3(X), to minimize the standard deviation of the final heights of all studs

3.3. Result and Discussion

4. Conclusions and Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Jeon, S.J.; Jin, B.M.; Kim, Y.J.; Chung, C.H. Consistent thermal analysis procedure of LNG storage tank. Struct. Eng. Mech. 2007, 25, 445–466. [Google Scholar] [CrossRef]

- Chun, M.S.; Kim, M.H.; Kim, W.S.; Kim, S.H.; Lee, J.M. Experimental investigation on the impact behavior of membrane-type LNG carrier insulation system. J. Loss Prev. Process Ind. 2009, 22, 901–907. [Google Scholar] [CrossRef]

- Kim, M.H.; Lee, S.M.; Lee, J.M.; Noh, B.J.; Kim, W.S. Fatigue strength assessment of MARK-III type LNG cargo containment system. Ocean Eng. 2010, 37, 1243–1252. [Google Scholar] [CrossRef]

- Graczyk, M.; Moan, T. Structural response to sloshing excitation in membrane LNG tank. J. Offshore Mech. Arct. Eng. 2010, 133, 021103. [Google Scholar] [CrossRef]

- Kim, B.C.; Yoon, S.H.; Lee, D.G. Pressure resistance of the corrugated stainless steel membranes of LNG carriers. Ocean Eng. 2011, 38, 592–608. [Google Scholar]

- Caprace, J.D.; Bair, F.; Rigo, P. Scantling multi-objective optimisation of a LNG carrier. Mar. Struct. 2010, 23, 288–302. [Google Scholar] [CrossRef]

- Salarkia, M.; Golabi, I.; Amirsalari, B. Optimum Design of Liquified Natural Gas Bi-lobe Tanks using Finite Element, Genetic Algorithm and Neural Network. J. Appl. Comput. Mech. 2020, in press. [Google Scholar] [CrossRef]

- Barclay, J.A.; Corless, A.J.; Nelson, E.H. Optimized LNG Storage Tanks for Fleet-Size Refueling Stations with Local LNG Liquefiers. Adv. Cryog. Eng. 1998, 1199–1206. [Google Scholar]

- Fletcher, R.; de la Maza, E.S. Nonlinear programming and nonsmooth optimization by successive linear programming. Math. Program. 1989, 43, 235–256. [Google Scholar] [CrossRef]

- Arora, J. Introduction to Optimum Design; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Vanderplaats, G.N. Numerical Optimization Techniques for Engineering Design: With Applications; McGraw-Hill: New York, NY, USA, 1984. [Google Scholar]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef] [Green Version]

- Goldberg, E.D. Genetic Algorithms in Search, Optimization, and Machine Learning; Addison-Wesley: Boston, MA, USA, 1989. [Google Scholar]

- Davis, L. Handbook of Genetic Algorithms; Van Nostrand Reinhold: New York, NY, USA, 1991. [Google Scholar]

- Lee, K.-Y.; Roh, M.-I. An Efficient Genetic Algorithm Using Gradient Information for Ship Structural Design Optimization. J. Ship Technol. Res. 2001, 48, 161–170. [Google Scholar]

- Lee, K.-Y.; Roh, M.-I. A Hybrid Optimization Method for Multidisciplinary Ship Design. J. Ship Technol. Res. 2000, 47, 181–185. [Google Scholar]

- Lee, K.-Y.; Roh, M.-I.; Cho, S.H. An Efficient Global-Local Hybrid Optimization Method Using Design Sensitivity Analysis. Int. J. Veh. Des. 2002, 28, 300–317. [Google Scholar] [CrossRef]

- Lee, S.-M. A Study on the Method of Simultaneous Determination of Path and Speed for Ship Route Planning. Master’s Thesis, Seoul National University, Seoul, Korea, 2017. [Google Scholar]

- Kaur, G.; Arora, S. Chaotic Whale Optimization Algorithm. J. Comput. Des. Eng. 2018, 5, 275–284. [Google Scholar] [CrossRef]

- Kohli, M.; Arora, S. Chaotic Grey Wolf Optimization Algorithm for Constrained Optimization Problems. J. Comput. Des. Eng. 2018, 5, 458–472. [Google Scholar] [CrossRef]

- Kyuncu, H.; Ceylan, R. A PSO Based Approach: Scout Particle Swarm Algorithm for Continuous Global Optimization Problems. J. Comput. Des. Eng. 2019, 6, 129–142. [Google Scholar] [CrossRef]

- Jakica, N.; Zanelli, A. Knowledge based Expert System Tool for Optimization of the Complex Glass BIPV System Panel Layout on the Cable Net Structural Skin. Energy Procedia 2015, 78, 2226–2231. [Google Scholar] [CrossRef] [Green Version]

- Cucinotta, F.; Raffaele, M.; Salmeri, F. A Topology Optimization of a Motorsport Safety Device. In International Conference on Design, Simulation, Manufacturing: The Innovation Exchange; Springer: Cham, Switzerland, 2019; pp. 400–409. [Google Scholar]

| Maximum Wedge Height (mm) | Type of Mastic Rope | Sectional Area (mm2) |

|---|---|---|

| e < 7 | C1 | 200 |

| 7 < e < 12 | C2 | 350 |

| 12 < e < 15 | C3 | 430 |

| 15 < e < 20 | C4 | 580 |

| 20 < e < 25 | C5 | 720 |

| Item | Manual Design | Case 1 | Case 2 | Case 3 |

|---|---|---|---|---|

| Number of C1 types | 2 | - | - | - |

| Number of C2 types | 214 | 246 | 232 | 202 |

| Number of C3 types | 86 | 71 | 63 | 93 |

| Number of C4 types | 43 | 27 | 41 | 46 |

| Number of C5 types | 5 | 4 | 12 | 7 |

| Total amount of mastic ropes (H1(X)) | 3895.36 L | 3784.76 L (3% decreased) | 3939.88 L (1% increased) | 3987.48 L (2% increased) |

| Height difference between adjacent studs (H2(X)) | 1.62 mm | 1.58 mm (2% decreased) | 1.25 mm (23% decreased) | 1.41 mm (12% decreased) |

| Standard deviation of all studs (H3(X)) | 8.33 | 7.24 (2% decreased) | 7.06 (15% decreased) | 5.89 (29% decreased) |

| Average wedge height | 10.7 mm | 9.9 mm (8% decreased) | 10.2 mm (5% decreased) | 10.4 mm (3% decreased) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chun, D.-H.; Roh, M.-I.; Ham, S.-H. Optimum Arrangement Design of Mastic Ropes for Membrane-Type LNG Tanks Considering the Flatness of Thermal Insulation Panel and Production Cost. J. Mar. Sci. Eng. 2020, 8, 353. https://doi.org/10.3390/jmse8050353

Chun D-H, Roh M-I, Ham S-H. Optimum Arrangement Design of Mastic Ropes for Membrane-Type LNG Tanks Considering the Flatness of Thermal Insulation Panel and Production Cost. Journal of Marine Science and Engineering. 2020; 8(5):353. https://doi.org/10.3390/jmse8050353

Chicago/Turabian StyleChun, Do-Hyun, Myung-Il Roh, and Seung-Ho Ham. 2020. "Optimum Arrangement Design of Mastic Ropes for Membrane-Type LNG Tanks Considering the Flatness of Thermal Insulation Panel and Production Cost" Journal of Marine Science and Engineering 8, no. 5: 353. https://doi.org/10.3390/jmse8050353