Membrane Distillation Trial on Textile Wastewater Containing Surfactants Using Hydrophobic and Hydrophilic-Coated Polytetrafluoroethylene (PTFE) Membranes

Abstract

1. Introduction

2. Materials and Methods

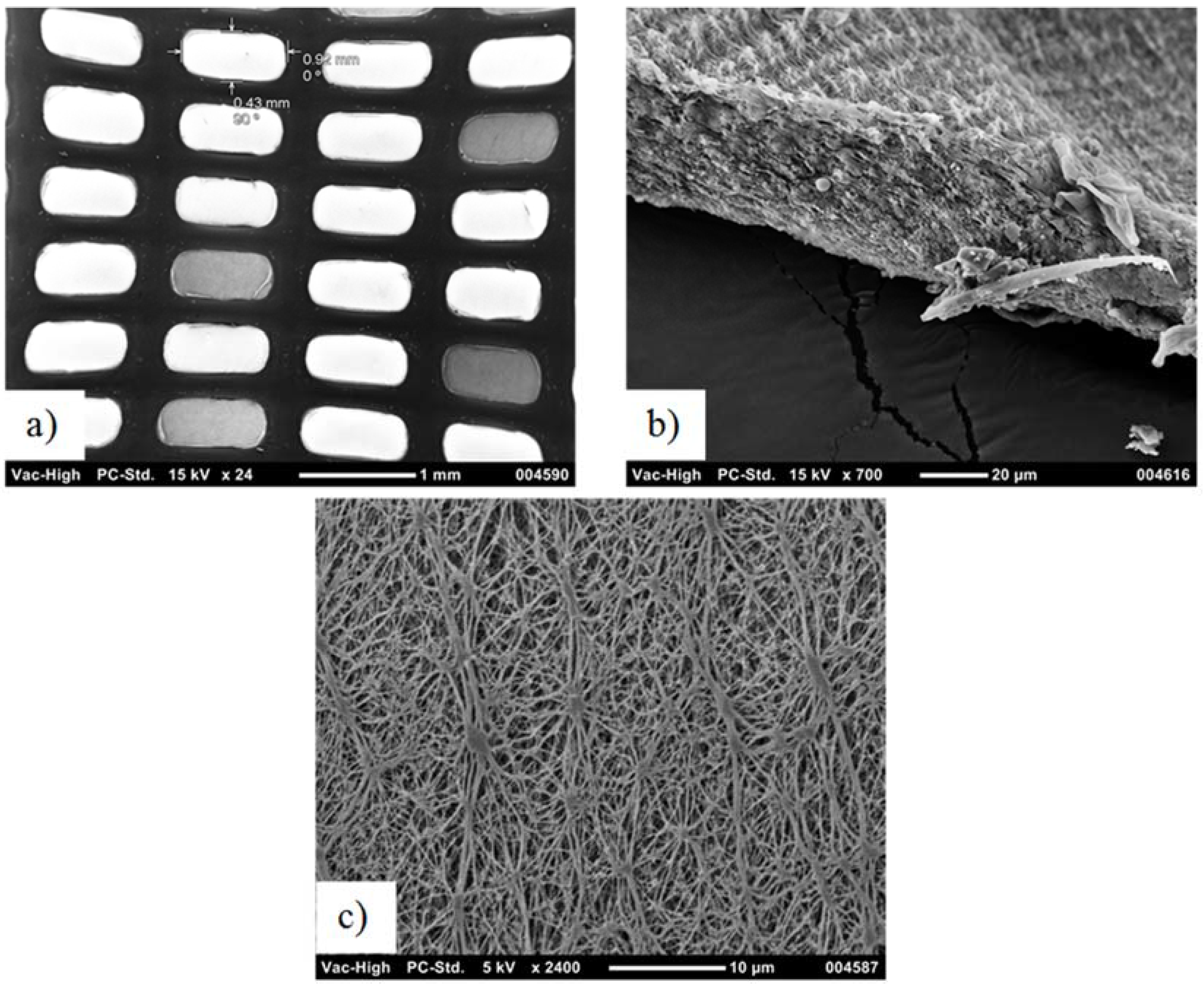

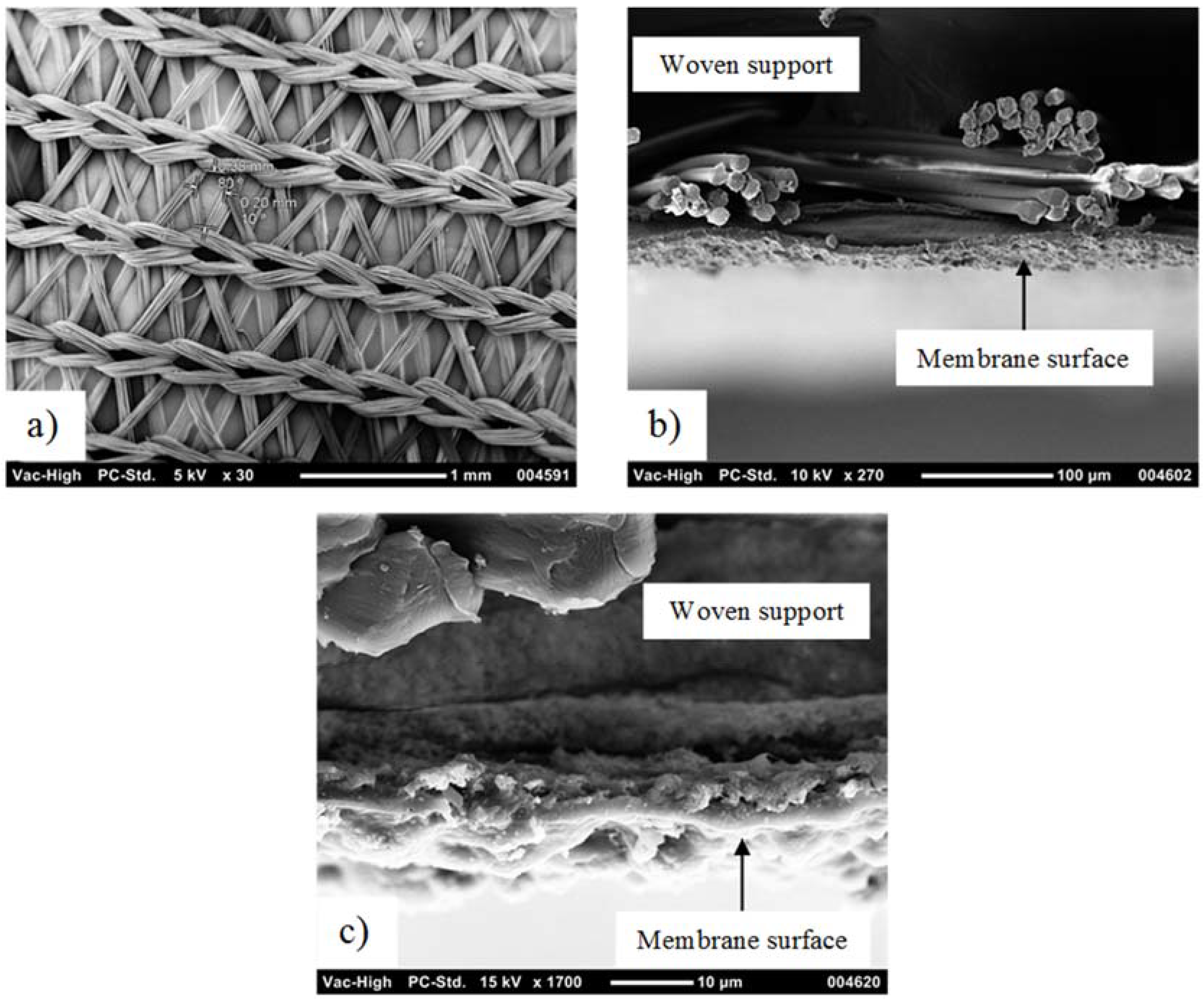

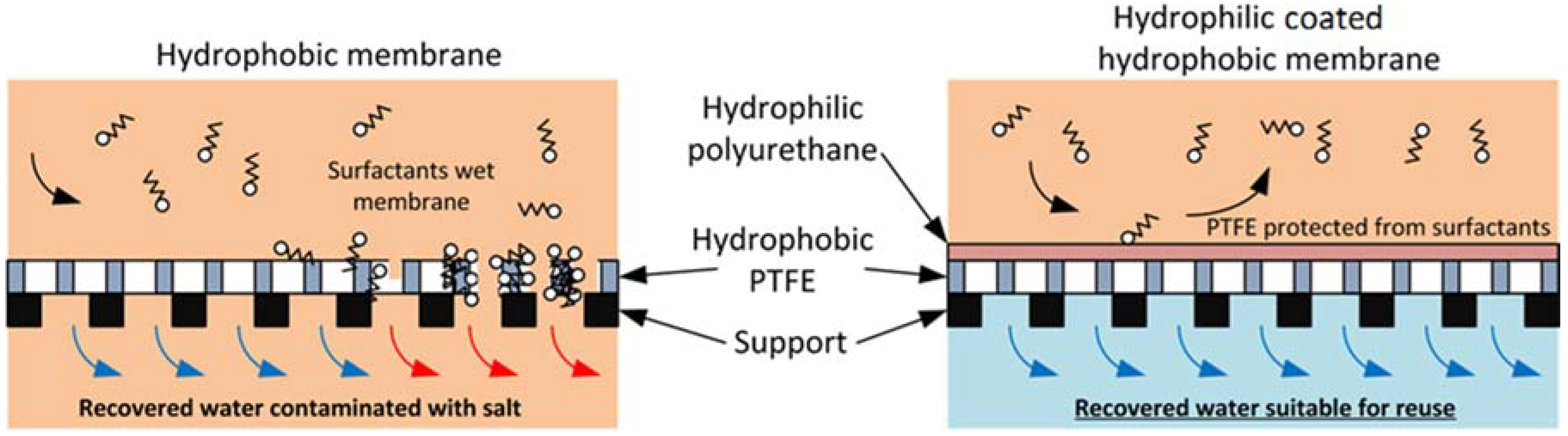

2.1. Membrane and Module

2.2. Site Test Setup

2.3. Water Quality Analyses

2.4. Scanning Electron Microscopy

3. Results and Discussion

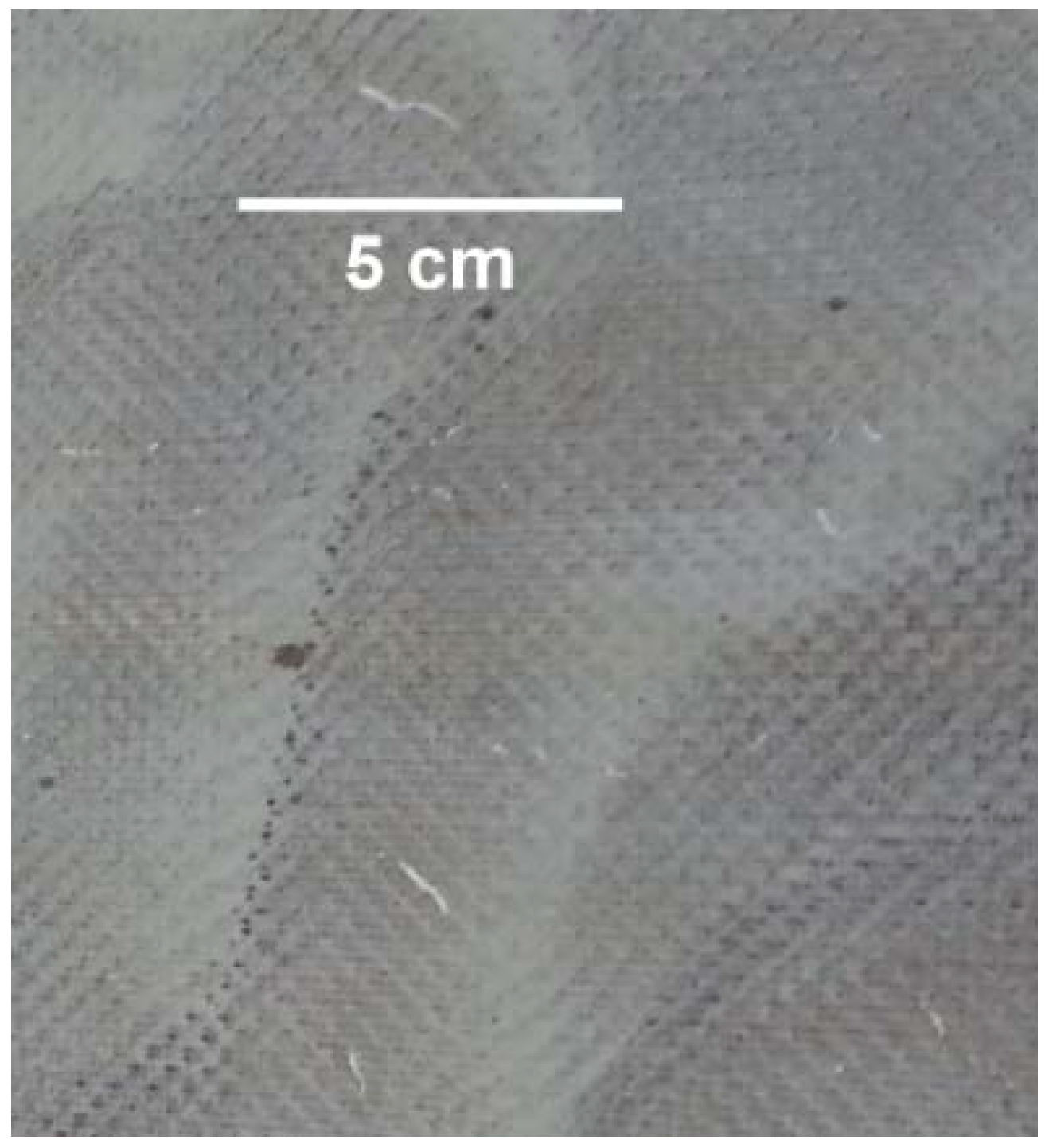

3.1. Membrane Analysis

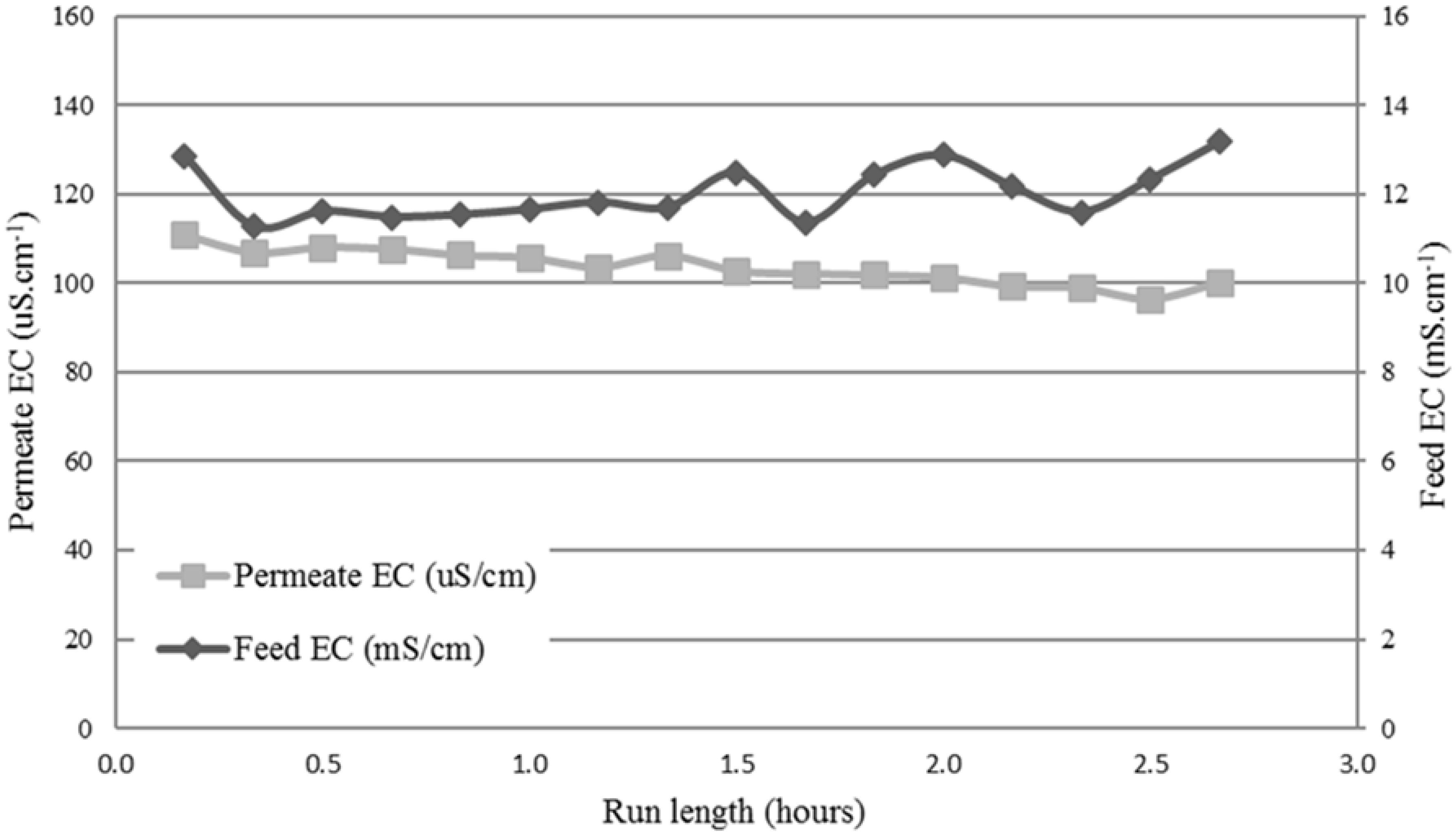

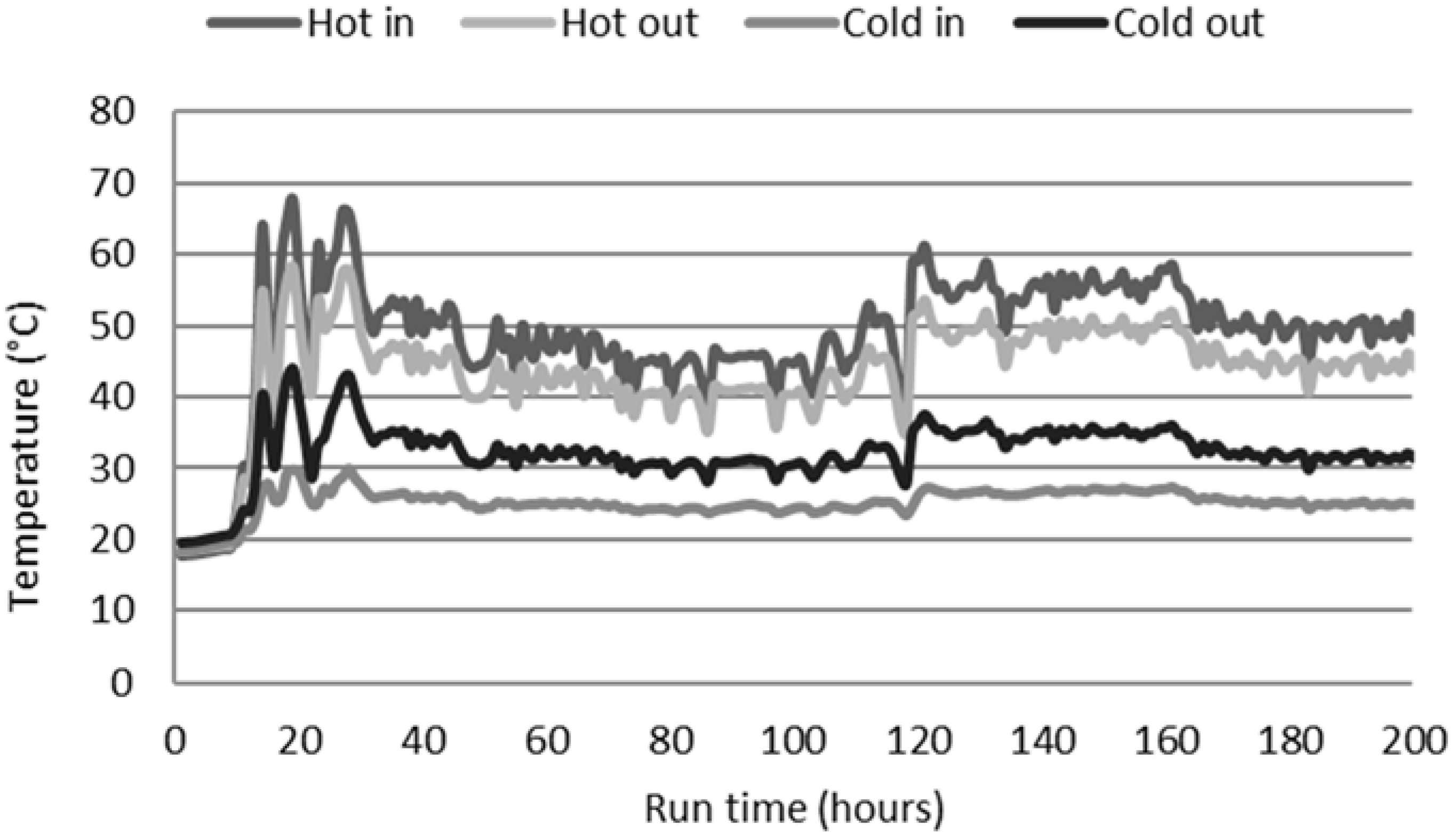

3.2. Initial Plant Performance

3.3. Analysis of Wastewater Used in Trial

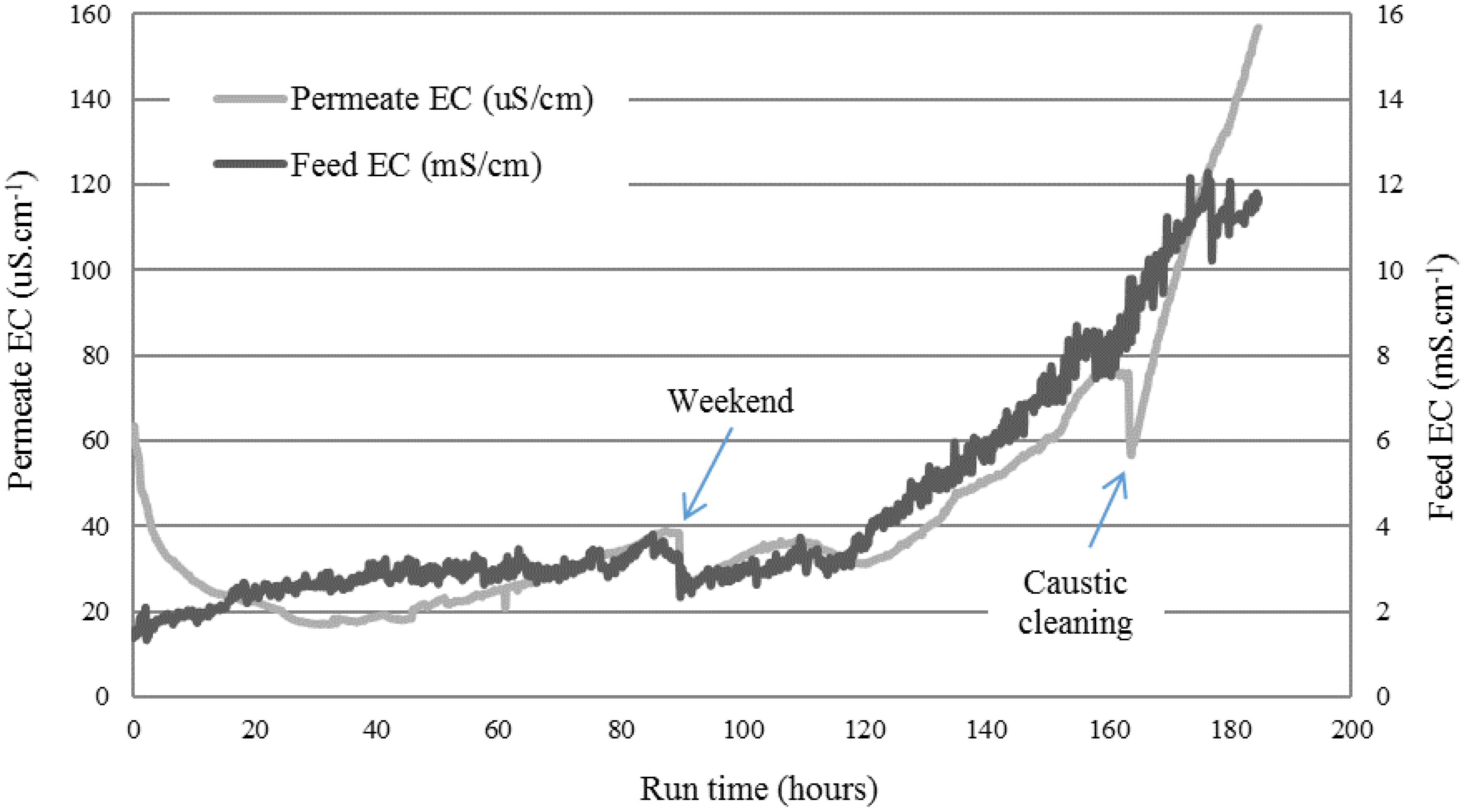

3.4. Performance of Standard Hydrophobic PTFE Membrane

3.5. Performance of Hydrophilic-Coated Hydrophobic PTFE Membrane

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Onsekizoglu, P. Membrane distillation: Principle, advances, limitations and future prospects in food industry. In Distillation-Advances from Modeling to Applications; InTech: Istanbul, Turkey, 2012. [Google Scholar]

- Smolders, K.; Franken, A.C.M. Terminology for membrane distillation. Desalination 1989, 72, 249–262. [Google Scholar] [CrossRef]

- Alkhudhiri, A.; Darwish, N.; Hilal, N. Membrane distillation: A comprehensive review. Desalination 2012, 287, 2–18. [Google Scholar] [CrossRef]

- Ong, Y.K.; Li, F.Y.; Sun, S.-P.; Zhao, B.-W.; Liang, C.-Z.; Chung, T.-S. Nanofiltration hollow fiber membranes for textile wastewater treatment: Lab-scale and pilot-scale studies. Chem. Eng. Sci. 2014, 114, 51–57. [Google Scholar] [CrossRef]

- Vandevivere, P.C.; Bianchi, R.; Verstraete, W. Treatment and reuse of wastewater from the textile wet-processing industry: Review of emerging technologies. J. Chem. Technol. Biotechnol. 1998, 72, 289–302. [Google Scholar] [CrossRef]

- Seif, H.; Malak, M. Textile wastewater treatment. In Proceedings of the Sixth International Water Technology Conference, Alexandria, Egypt, 23–25 March 2001; pp. 608–614. [Google Scholar]

- Volmajer Valh, J.; Majcen Le Marechal, A.; Vajnhandl, S.; Jerič, T.; Šimon, E. Water in the textile industry. In Treatise on Water Science; Wilderer, P., Ed.; Elsevier: Oxford, UK, 2011; pp. 685–706. ISBN 978-0-444-53199-5. [Google Scholar]

- Ellouze, E.; Tahri, N.; Amar, R.B. Enhancement of textile wastewater treatment process using nanofiltration. Desalination 2012, 286, 16–23. [Google Scholar] [CrossRef]

- Dai, T.; Wu, C.; Lv, X.; Wang, X.; Lin, F. Effect of representative foulants to membrane fouling in membrane distillation. Technol. Water Treat. 2012, 8, 4. [Google Scholar]

- Goh, S.; Zhang, J.; Liu, Y.; Fane, A.G. Fouling and wetting in membrane distillation (MD) and MD-bioreactor (MDBR) for wastewater reclamation. Desalination 2013, 323, 39–47. [Google Scholar] [CrossRef]

- Deshmukh, A.; Boo, C.; Karanikola, V.; Lin, S.; Straub, A.P.; Tong, T.; Warsinger, D.M.; Elimelech, M. Membrane distillation at the water-energy nexus: Limits, opportunities, and challenges. Energy Environ. Sci. 2018, 11, 1177–1196. [Google Scholar] [CrossRef]

- Zuo, G.; Wang, R. Novel membrane surface modification to enhance anti-oil fouling property for membrane distillation application. J. Membr. Sci. 2013, 447, 26–35. [Google Scholar] [CrossRef]

- Holmes, D.A. Waterproof breathable fabrics. In Handbook of Technical Textiles; Woodhead Publishing Series in Textiles; Woodhead Publishing: Sawston, UK, 2000; pp. 282–315. ISBN 978-1-85573-385-5. [Google Scholar]

- Mostafa, M.G.; Zhu, B.; Cran, M.; Dow, N.; Milne, N.; Desai, D.; Duke, M. Membrane Distillation of Meat Industry Effluent with Hydrophilic Polyurethane Coated Polytetrafluoroethylene Membranes. Membranes 2017, 7, 55. [Google Scholar] [CrossRef] [PubMed]

- Mansouri, J.; Fane, A.G. Osmotic distillation of oily feeds. J. Membr. Sci. 1999, 153, 103–120. [Google Scholar] [CrossRef]

- Prasad, R.; Sirkar, K.K. Solvent extraction with microporous hydrophilic and composite membranes. AIChE J. 1987, 33, 1057–1066. [Google Scholar] [CrossRef]

- Dow, N.; Duke, M.; Zhang, J.; O’Reilly, T.; Li, J.; Ostarcevic, E.; Atherton, P. Demonstration of solar driven membrane distillation in remote Victoria. In Ozwater’10: 08–10 March 2010, Brisbane: Australia’s National Water Conference and Exhibition; Australian Water Association: Sydney, Australia, 2010; ISBN 978-1-921335-09-9. [Google Scholar]

- Dow, N.; Gray, S.; Li, J.D.; Zhang, J.; Ostarcevic, E.; Liubinas, A.; Atherton, P.; Halliwell, D.; Duke, M. Power station water recycling using membrane distillation-A Plant trial. In OzWater’12; Australian Water Association: Sydney, Australia, 2012. [Google Scholar]

- Dow, N.; Villalobos García, J.; Niadoo, L.; Milne, N.; Zhang, J.; Gray, S.; Duke, M. Demonstration of membrane distillation on textile waste water: Assessment of long term performance, membrane cleaning and waste heat integration. Environ. Sci. Water Res. Technol. 2017, 3, 433–449. [Google Scholar] [CrossRef]

- Van der Bruggen, B.; Curcio, E.; Drioli, E. Process intensification in the textile industry: The role of membrane technology. J. Environ. Manag. 2004, 73, 267–274. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Dow, N.; Duke, M.; Ostarcevic, E.; Li, J.-D.; Gray, S. Identification of material and physical features of membrane distillation membranes for high performance desalination. J. Membr. Sci. 2010, 349, 295–303. [Google Scholar] [CrossRef]

- Martínez, L.; Rodríguez-Maroto, J.M. Characterization of membrane distillation modules and analysis of mass flux enhancement by channel spacers. J. Membr. Sci. 2006, 274, 123–137. [Google Scholar] [CrossRef]

- Gryta, M. Water desalination by membrane distillation. Trends Technol. 2011. [Google Scholar] [CrossRef]

- Kesieme, U.K.; Milne, N.; Aral, H.; Cheng, C.Y.; Duke, M. Economic analysis of desalination technologies in the context of carbon pricing, and opportunities for membrane distillation. Desalination 2013, 323, 66–74. [Google Scholar] [CrossRef]

- Atekwana, E.A.; Atekwana, E.A.; Rowe, R.S.; Werkema, D.D.; Legall, F.D. The relationship of total dissolved solids measurements to bulk electrical conductivity in an aquifer contaminated with hydrocarbon. J. Appl. Geophys. 2004, 56, 281–294. [Google Scholar] [CrossRef]

- Bouroche, A.; Le Bars, M. Techniques de Séparation par Membranes: Vocabulaire Français-Anglais-Allemand Avec Index; Editions Quae: Paris, France, 1994. [Google Scholar]

- Bacchin, P. Principes de base des Technologies à Membranes. In 2ème Ecole d’Eté Franco-Maghrébine “Sciences et Technologies à Membranes”; LGC—Laboratoire de Génie Chimique: Monastir, Tunisia, 2005. [Google Scholar]

- International Finance Centre (IFC). Environmental, Health and Safety Guidelines for Textiles Manufacturing; World Bank Group: Washington, DC, USA, 2007. [Google Scholar]

- Savin, I.-I.; Butnaru, R. Wastewater characteristics in textile finishing mills. Environ. Eng. Manag. J. EEMJ 2008, 7, 859–864. [Google Scholar]

- Hussain, J.; Hussain, I.; Arif, M. Characterization of textile wastewater. Control Pollut. 1970, 20. Available online: http://www.icontrolpollution.com/articles/characterization-of-textile-wastewater-.php?aid=45450 (accessed on 14 June 2018).

- Bisschops, I.; Spanjers, H. Literature review on textile wastewater characterisation. Environ. Technol. 2003, 24, 1399–1411. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.; Hao, Z.; Shen, Z.; Chen, J. Modified modeling of the effect of pH and viscosity on the mass transfer in hydrophobic hollow fiber membrane contactors. J. Membr. Sci. 2005, 250, 269–276. [Google Scholar] [CrossRef]

- Banat, F.; Al-Asheh, S.; Qtaishat, M. Treatment of waters colored with methylene blue dye by vacuum membrane distillation. Desalination 2005, 174, 87–96. [Google Scholar] [CrossRef]

- Gryta, M.; Tomaszewska, M.; Karakulski, K. Wastewater treatment by membrane distillation. Desalination 2006, 198, 67–73. [Google Scholar] [CrossRef]

- Dow, N.; Zhang, J.; Duke, M.; Li, J.; Gray, S.R.; Ostarcevic, E. Membrane Distillation of Brine Wastes; Cooperative Research Centre for Water Quality and Treatment: Adelaide, Australia, 2008. [Google Scholar]

- Yang, X.; Pang, H.; Zhang, J.; Liubinas, A.; Duke, M. Sustainable waste water deammonification by vacuum membrane distillation without pH adjustment: Role of water chemistry. Chem. Eng. J. 2017, 328, 884–893. [Google Scholar] [CrossRef]

- Dumée, L.; Campbell, J.L.; Sears, K.; Schütz, J.; Finn, N.; Duke, M.; Gray, S. The impact of hydrophobic coating on the performance of carbon nanotube bucky-paper membranes in membrane distillation. Desalination 2011, 283, 64–67. [Google Scholar] [CrossRef]

- Liu, C.; Caothien, S.; Hayes, J.; Caothuy, T.; Otoyo, T.; Ogawa, T. Membrane Chemical Cleaning: From Art to Science; Pall Corporation: Port Washington, NY, USA, 2001. [Google Scholar]

| Parameter | Value |

|---|---|

| pH | 7.76 |

| Electrical Conductivity (EC; µS·cm−1) | 976 |

| Total Dissolved Solids (TDS; mg·L−1) | 605 |

| Total Nitrogen (TN; mg·L−1) | 11 |

| Nitrate (NO3−; mg·L−1) | 8 |

| Nitrite (NO2−; mg·L−1) | 0.97 |

| Ammonium (NH4+) (mg·L−1) | 1.12 |

| Chemical Oxygen Demand (COD; mg·L−1) | 2830 |

| Total Phosphorus (TP; mg·L−1) | 3.10 |

| Color | Colored |

| Parameter | Retentate (before Cleaning) | Permeate (before Cleaning) | Rejection (%) |

|---|---|---|---|

| pH | 7.8 | 6.25 | - |

| EC (µS·cm−1) | 3220 | 34.2 | 98.9 |

| TDS (mg·L−1) | 1250 | 14.9 | 98.8 |

| TN (mg·L−1) | 21 | 0.6 | 97.1 |

| NO3− (mg·L−1) | 8 | 0 | 100.0 |

| NO2− (mg·L−1) | 2.23 | 0.02 | 99.1 |

| NH4+ (mg·L−1) | 1.67 | 0.6 | 64.1 |

| COD (mg·L−1) | 3350 | 61 | 98.2 |

| TP (mg·L−1) | 4 | 0.06 | 98.5 |

| Parameter | Retentate (before Cleaning) | Permeate (before Cleaning) | Rejection (%) |

|---|---|---|---|

| pH | 6.21 | 7.86 | - |

| EC (µS·cm−1) | 3650 | 19 | 99.5 |

| TDS (mg·L−1) | 2300 | 11.97 | 99.5 |

| TN (mg·L−1) | 42 | 0.9 | 97.8 |

| NO3− (mg·L−1) | >18 | 13.5 | 25 |

| NO2− (mg·L−1) | 0.749 | 0.025 | 96.7 |

| NH4+ (mg·L−1) | 1 | 0.4 | 60 |

| COD (mg·L−1) | 4335 | 284 | 93.4 |

| TP (mg·L−1) | 15.2 | 0.5 | 96.7 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Villalobos García, J.; Dow, N.; Milne, N.; Zhang, J.; Naidoo, L.; Gray, S.; Duke, M. Membrane Distillation Trial on Textile Wastewater Containing Surfactants Using Hydrophobic and Hydrophilic-Coated Polytetrafluoroethylene (PTFE) Membranes. Membranes 2018, 8, 31. https://doi.org/10.3390/membranes8020031

Villalobos García J, Dow N, Milne N, Zhang J, Naidoo L, Gray S, Duke M. Membrane Distillation Trial on Textile Wastewater Containing Surfactants Using Hydrophobic and Hydrophilic-Coated Polytetrafluoroethylene (PTFE) Membranes. Membranes. 2018; 8(2):31. https://doi.org/10.3390/membranes8020031

Chicago/Turabian StyleVillalobos García, Jesús, Noel Dow, Nicholas Milne, Jianhua Zhang, Leslie Naidoo, Stephen Gray, and Mikel Duke. 2018. "Membrane Distillation Trial on Textile Wastewater Containing Surfactants Using Hydrophobic and Hydrophilic-Coated Polytetrafluoroethylene (PTFE) Membranes" Membranes 8, no. 2: 31. https://doi.org/10.3390/membranes8020031

APA StyleVillalobos García, J., Dow, N., Milne, N., Zhang, J., Naidoo, L., Gray, S., & Duke, M. (2018). Membrane Distillation Trial on Textile Wastewater Containing Surfactants Using Hydrophobic and Hydrophilic-Coated Polytetrafluoroethylene (PTFE) Membranes. Membranes, 8(2), 31. https://doi.org/10.3390/membranes8020031