“Modified” Liquid–Liquid Displacement Porometry and Its Applications in Pd-Based Composite Membranes

Abstract

:1. Introduction

2. Methods, Materials, and Apparatus

2.1. “Modified” Liquid–Liquid Displacement Porometry (MLLDP)

2.2. Materials

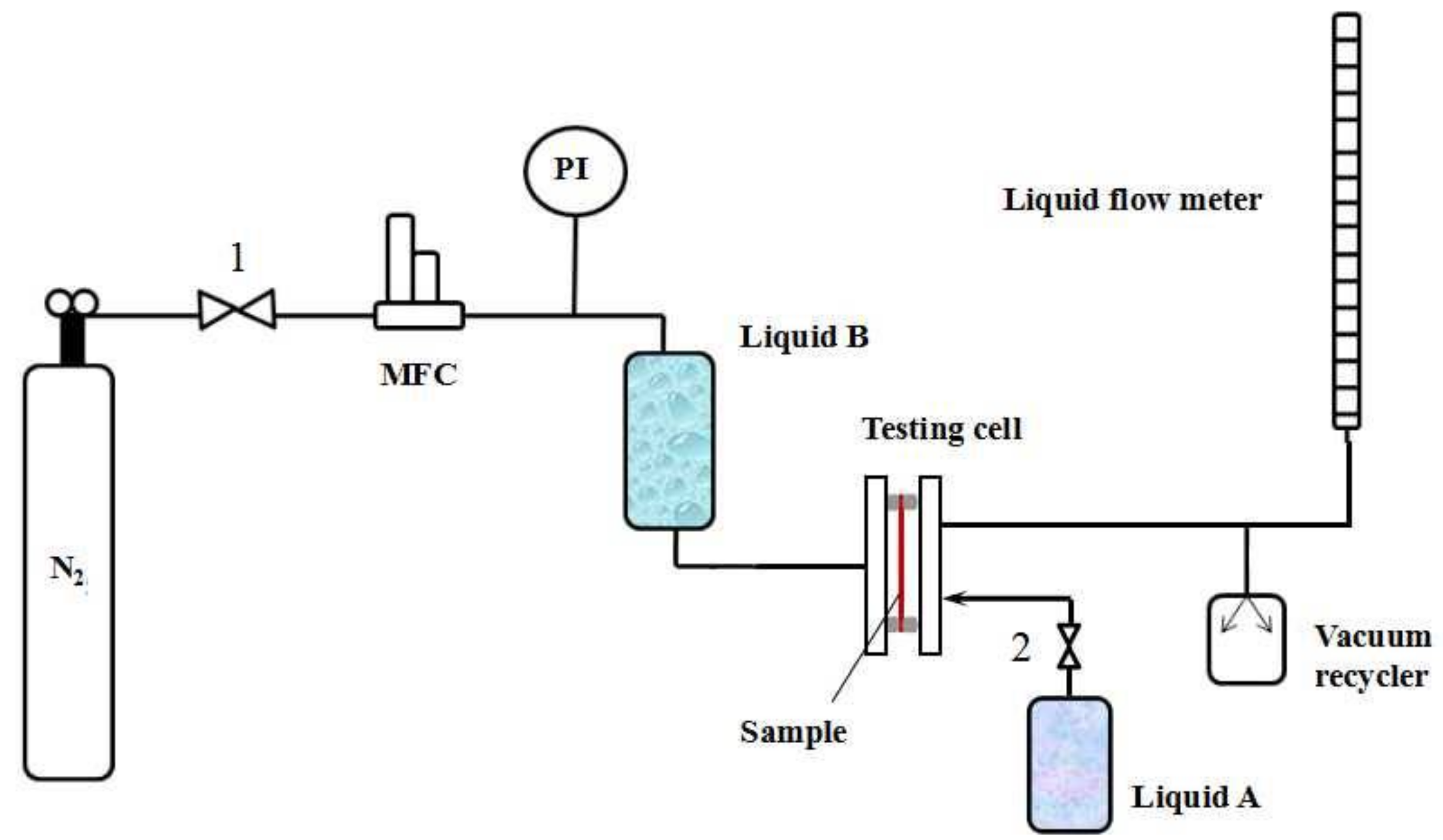

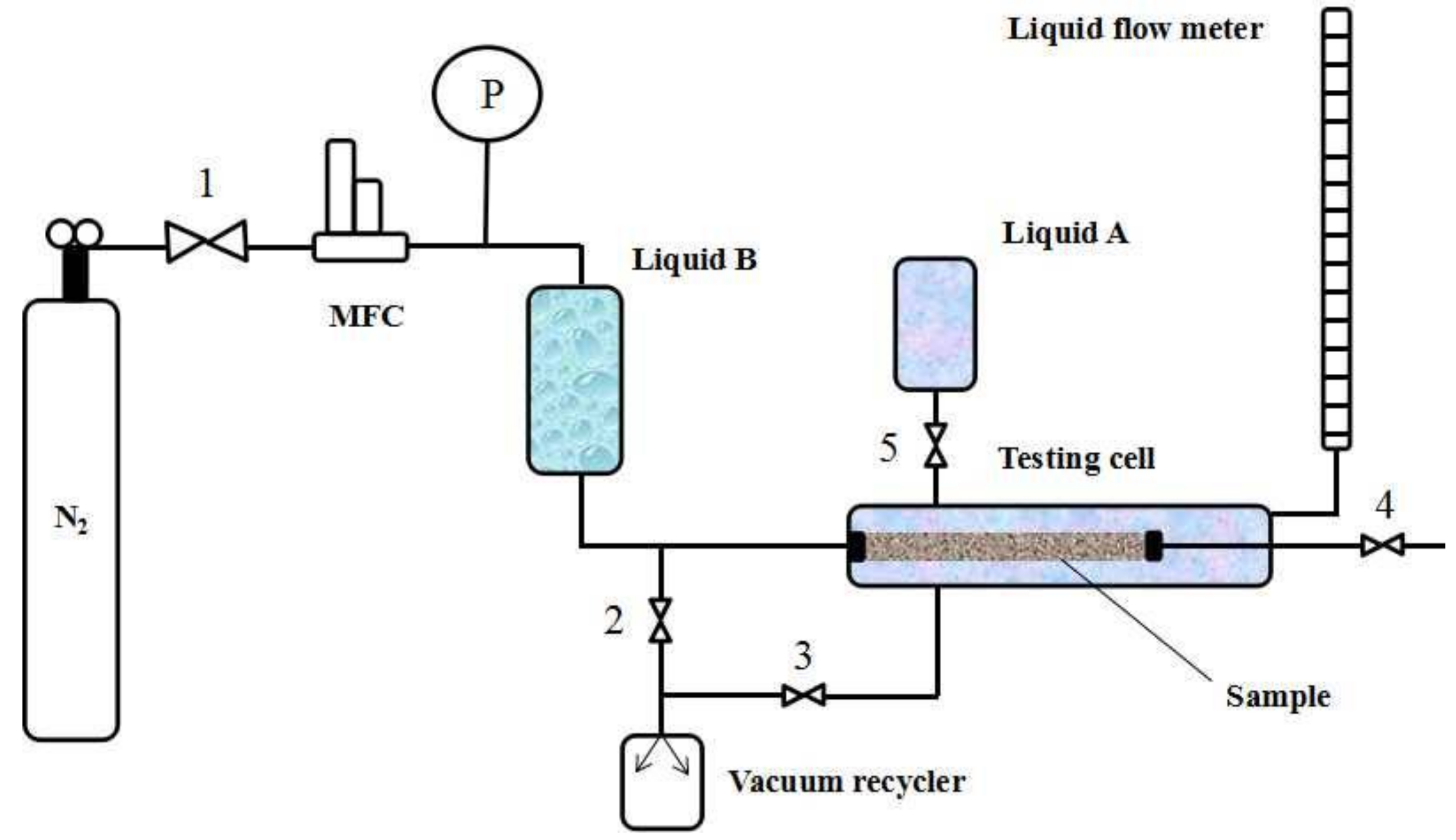

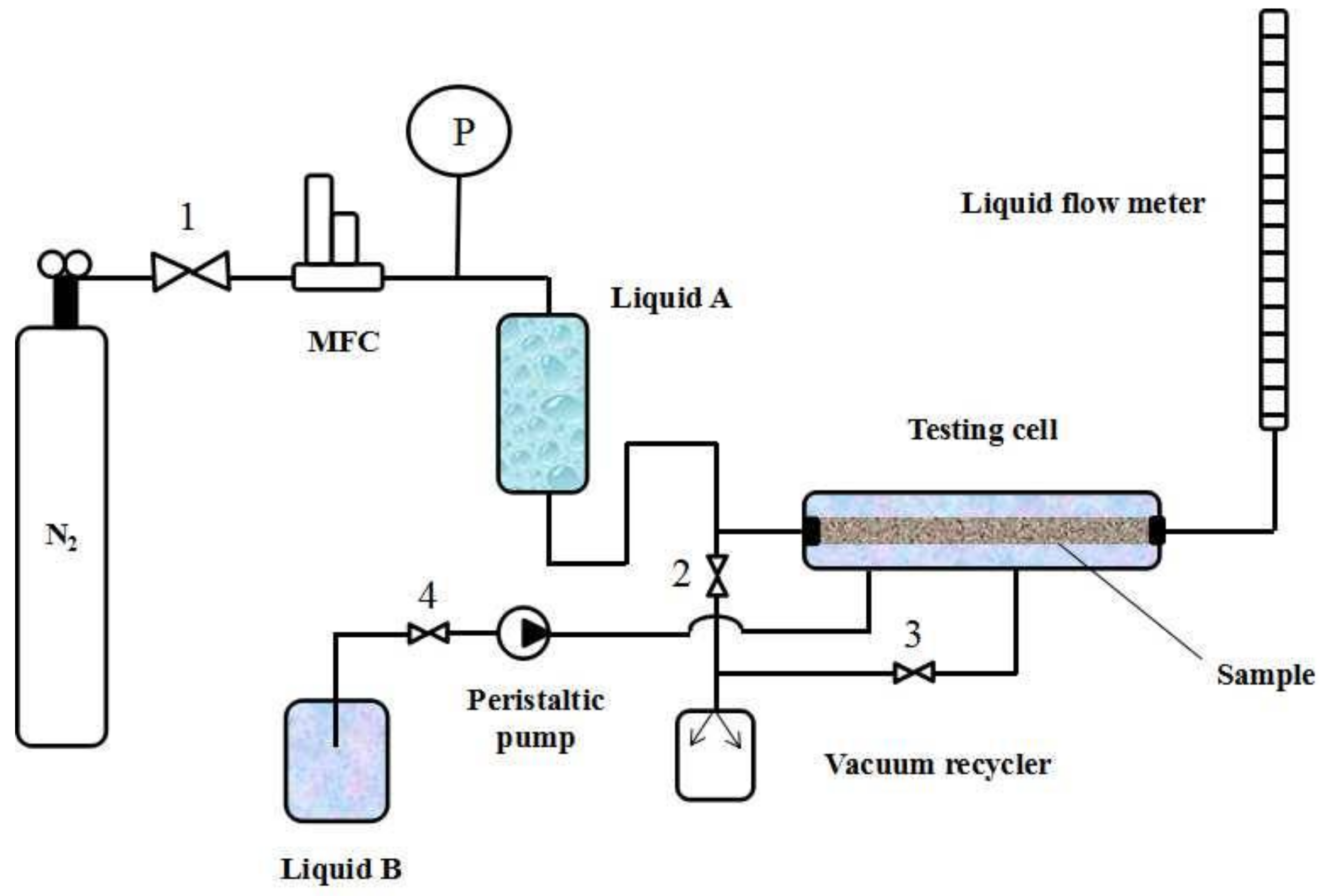

2.3. Apparatus

- Liquid B (acting as penetrating agent) from the reservoir fills the lumen of the sample by opening Valve 4 for a short time;

- The pressure of Liquid B is increased to 3 bar by increasing the N2 gas pressure while applying a negative pressure of −0.8 bar in the shell side by using a vacuum recycler (opening Valve 3) in order to achieve complete wetting of pore tunnels with Liquid B; this step lasts for at least 30 min;

- Liquid A (acting as impregnating agent) from the reservoir is poured into the shell side by opening Valve 5 until the remaining Liquid B on the outer surface of the sample is completely replaced with Liquid A, i.e., until there is no Liquid B observed in the outflow (Liquids A and B can be easily distinguished by color), then Valve 5 is closed; Note that Liquid A is kept under ambient pressure and at a low flow rate below ca. 10 mL/min in order to avoid penetration of Liquid A into membrane pores;

- The pressure of Liquid B increases step by step and a pressure–flux curve can be obtained by monitoring the N2 gas pressure at a step of 0.05–0.1 bar and flux of Liquid B through the pore tunnels (measured by bubble flow meter). The flow rate is recorded until a steady-state flux is achieved. The testing cell is kept at RT during the operation.

- The dry sample is mounted in the testing cell;

- Liquid A (acting as impregnating agent) from the reservoir is poured into the shell side by opening Valve 5 for a short time;

- The sample is impregnated in Liquid A for a period of 30 min to 1 h in order to achieve complete wetting of pore tunnels with Liquid A;

- Liquid B (acting as penetrating agent) from the reservoir fills the lumen of the sample by opening Valve 4 for a short time;

- The pressure of Liquid B increases step by step and a pressure–flux curve can be obtained by monitoring the N2 gas pressure at a step of 0.05–0.1 bar and flux of Liquid B through the pore tunnels (measured by bubble flow meter). The flow rate is recorded until a steady-state flux is achieved. The testing cell is kept at RT during the operation.

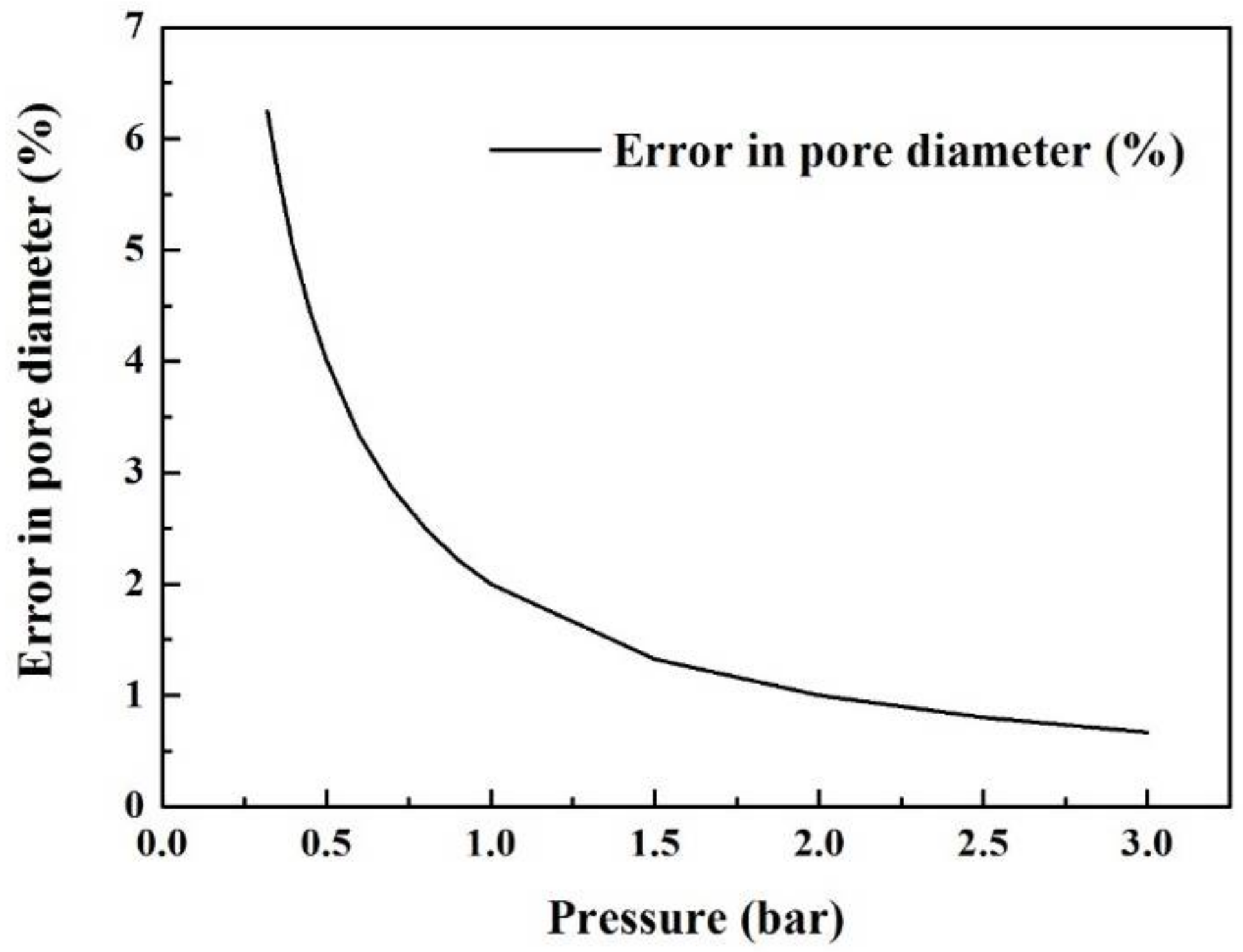

2.4. Error Analysis

3. Results and Discussions

3.1. Standard Membranes

3.1.1. AnoporeTM Membranes (100 nm)

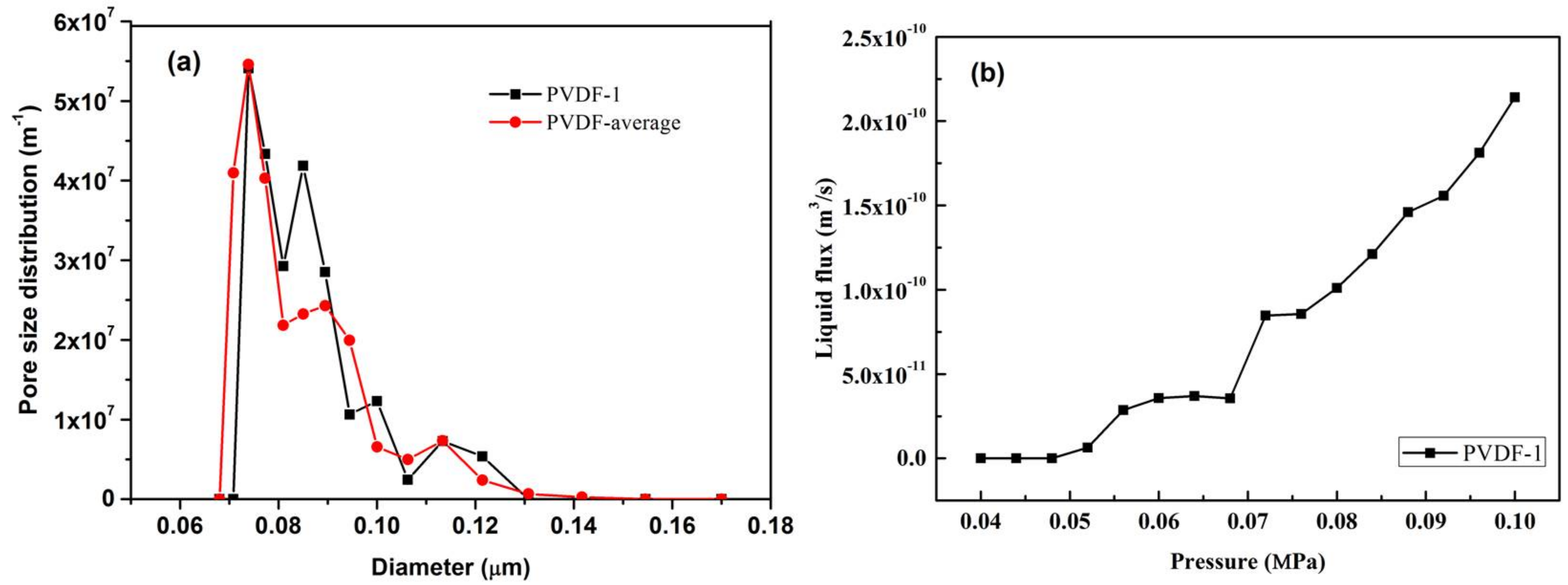

3.1.2. PVDF Membranes (80 nm)

3.2. Tubular Ceramic Substrates for Pd Composite Membranes

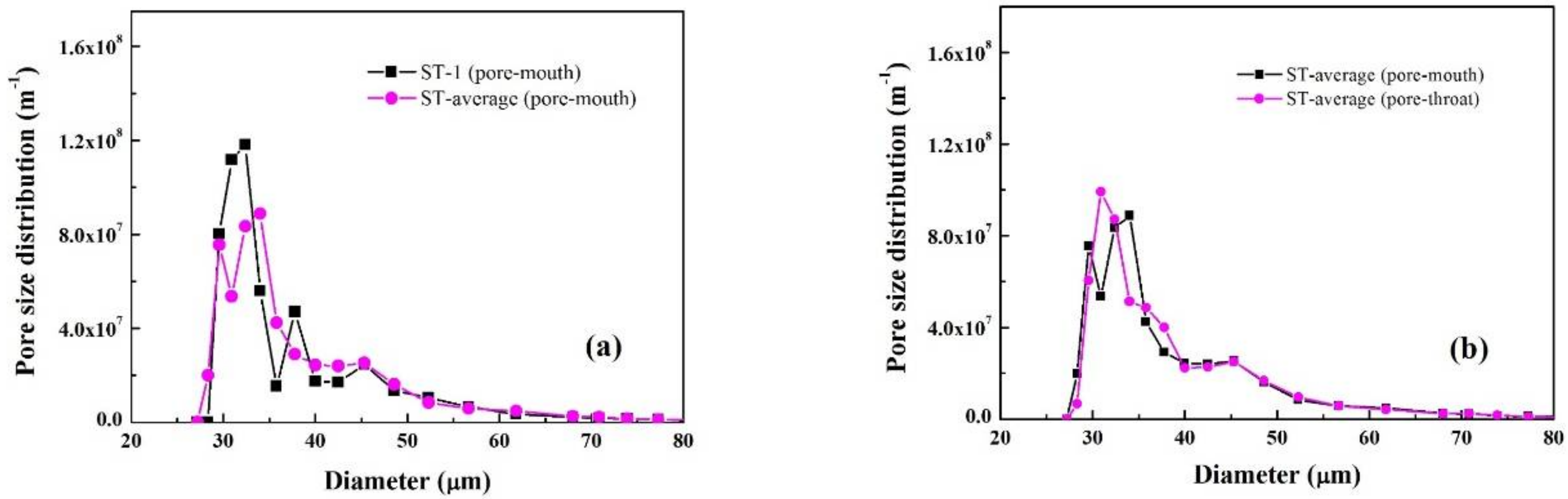

3.2.1. Single Tubular ZrO2/γ-Al2O3/α-Al2O3 Membrane (30 nm)

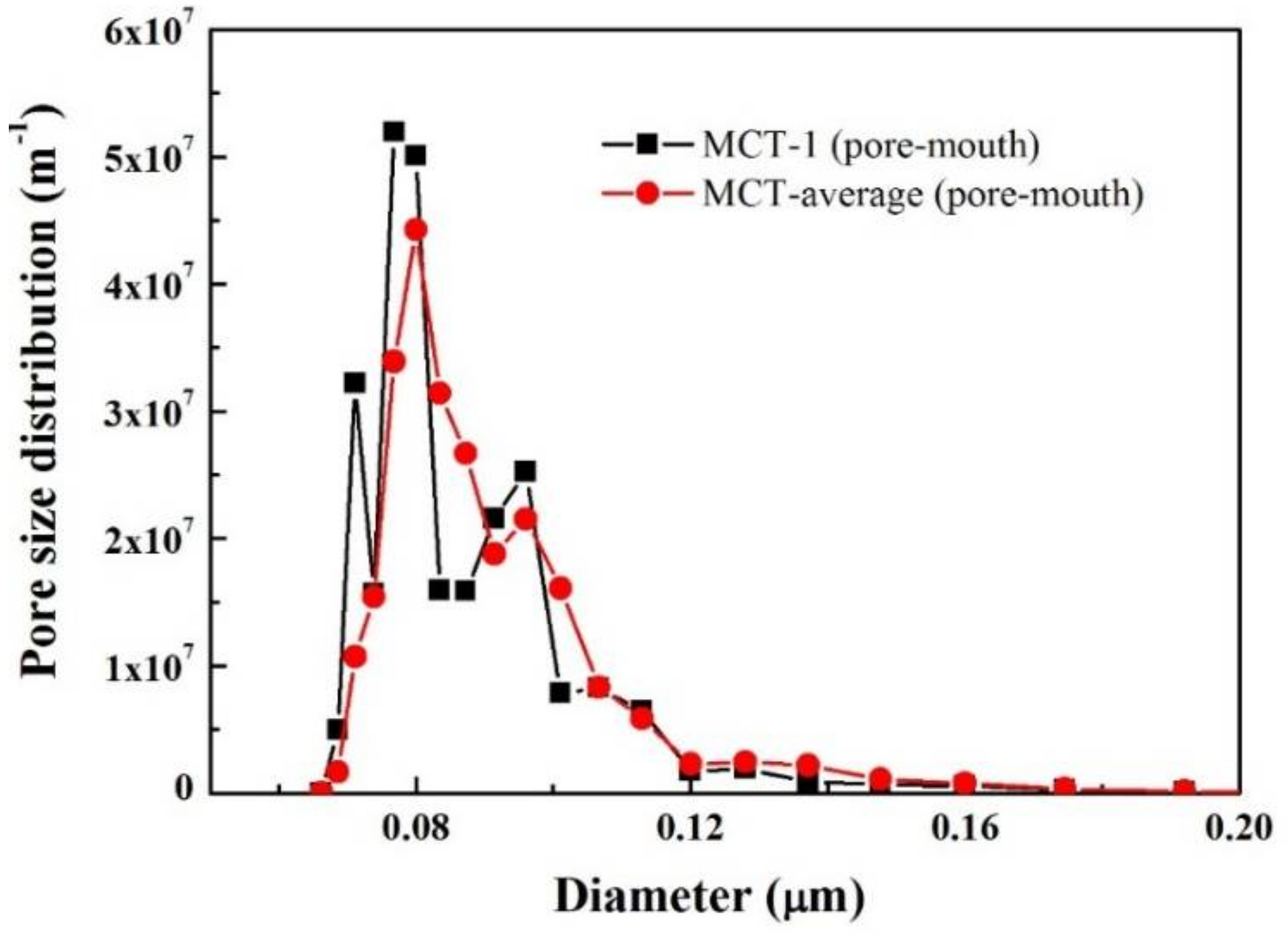

3.2.2. Multichannel Tubular ZrO2/γ-Al2O3/α-Al2O3 Membrane (100 nm)

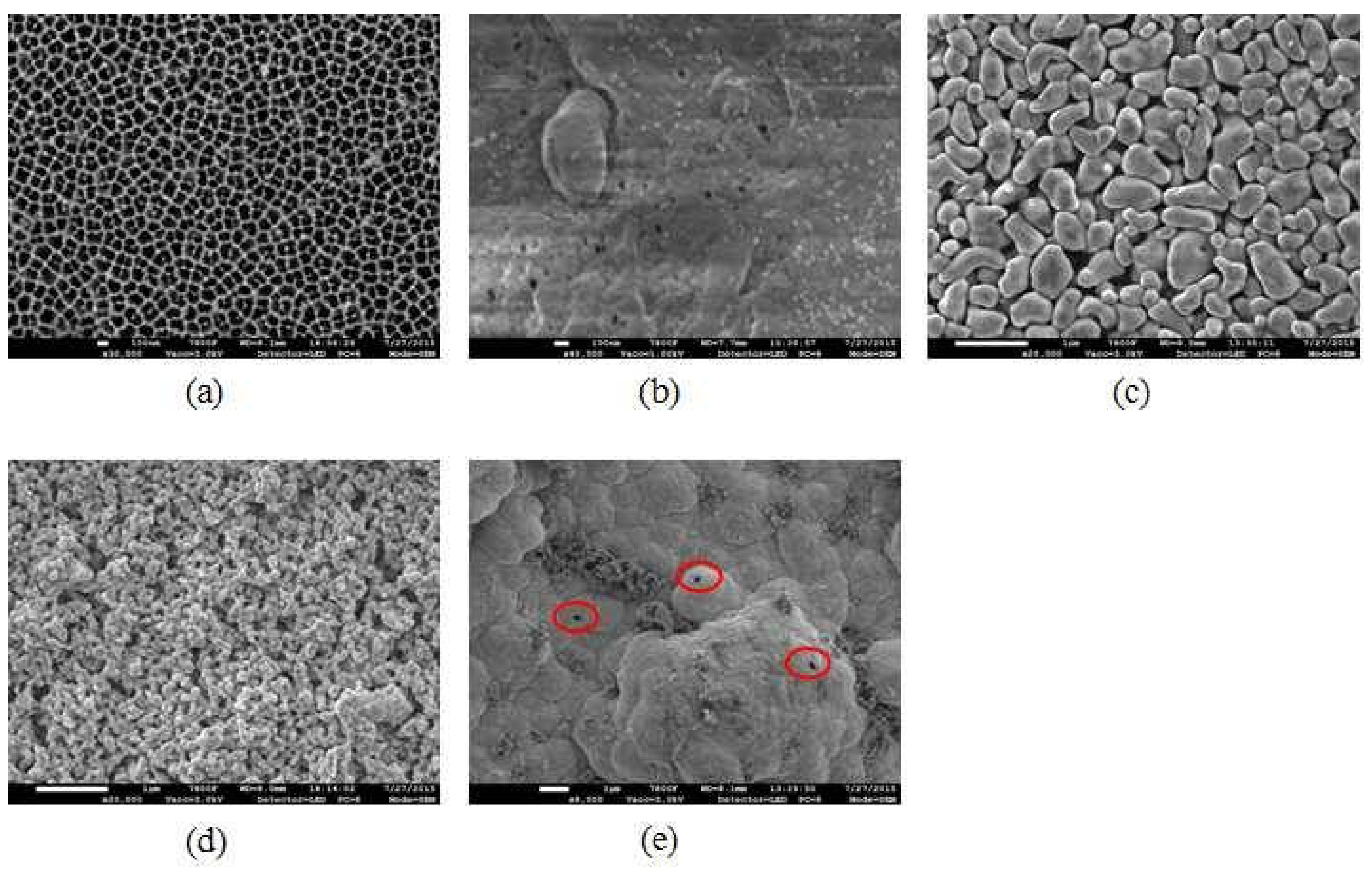

3.3. Defects of a Dense Pd Composite Membrane

3.4. Advantages and Limitations of MLLDP

3.4.1. Advantages of MLLDP

3.4.2. Limitations of MLLDP

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Paglieri, S.N.; Way, J.D. Innovations in palladium membrane research. Sep. Purif. Methods 2002, 31, 1–169. [Google Scholar] [CrossRef]

- Yun, S.; Oyama, S.T. Correlations in palladium membranes for hydrogen separation: A review. J. Membr. Sci. 2011, 375, 28–45. [Google Scholar] [CrossRef]

- Yu, J.; Hu, X.J.; Huang, Y. A modification of the bubble-point method to determine the pore-mouth size distribution of porous materials. Sep. Purif. Technol. 2010, 70, 314–319. [Google Scholar] [CrossRef]

- Ryi, S.K.; Ahn, H.S.; Park, J.S.; Kim, D.W. Pd-Cu alloy membrane deposited on CeO2 modified porous nickel support for hydrogen separation. Int. J. Hydrog. Energy 2014, 39, 4698–4703. [Google Scholar] [CrossRef]

- Zhao, H.B.; Pflanz, K.; Gu, J.H.; Li, A.W.; Stroh, N.; Brunner, H.; Xiong, G.X. Preparation of palladium composite membranes by modified electroless plating procedure. J. Membr. Sci. 1998, 142, 147–157. [Google Scholar] [CrossRef]

- Chi, Y.H.; Yen, P.S.; Jeng, M.S.; Ko, S.T.; Lee, T.C. Preparation of thin Pd membrane on porous stainless steel tubes modified by a two-step method. Int. J. Hydrog. Energy 2010, 35, 6303–6310. [Google Scholar] [CrossRef]

- Jabbari, A.; Ghasemzadeh, K.; Khajavi, P.; Assa, F.; Abdi, M.; Babaluo, A.; Basile, A. Surface modification of α-alumina support in synthesis of silica membrane for hydrogen purification. Int. J. Hydrog. Energy 2014, 39, 18585–18591. [Google Scholar] [CrossRef]

- Tong, J.H.; Su, L.L.; Haraya, K.; Suda, H. Thin and defect-free Pd-based composite membrane without any interlayer and substrate penetration by a combined organic and inorganic process. Chem. Commun. 2006, 1142–1144. [Google Scholar] [CrossRef] [PubMed]

- Zheng, L.; Li, H.; Xu, H.Y. “Defect-free” interlayer with a smooth surface and controlled pore-mouth size for thin and thermally stable Pd composite membranes. Int. J. Hydrog. Energy 2016, 41, 1002–1009. [Google Scholar] [CrossRef]

- Zheng, L.; Li, H.; Xu, T.Y.; Bao, F.; Xu, H.Y. Defect size analysis approach combined with silicate gel/ceramic particles for defect repair of Pd composite membranes. Int. J. Hydrog. Energy 2016, 41, 18522–18532. [Google Scholar] [CrossRef]

- Ye, J.; Dan, G.; Yuan, Q. The preparation of ultrathin palladium membrane. In Key Engineering Materials; Trans Tech Publication: Zürich, Switzerland, 1992; pp. 437–442. [Google Scholar]

- Calvo, J.I.; Bottino, A.; Capannelli, G.; Hernandez, A. Comparison of liquid-liquid displacement porosimetry and scanning electron microscopy image analysis to characterise ultrafiltration track-etched membranes. J. Membr. Sci. 2004, 239, 189–197. [Google Scholar] [CrossRef]

- Krantz, W.B.; Greenberg, A.R.; Kujundzic, E.; Yeo, A.; Hosseini, S.S. Evapoporometry: A novel technique for determining the pore-size distribution of membranes. J. Membr. Sci. 2013, 438, 153–166. [Google Scholar] [CrossRef]

- Reingruber, H.; Zankel, A.; Mayrhofer, C.; Poelt, P. A new in situ method for the characterization of membranes in a wet state in the environmental scanning electron microscope. J. Membr. Sci. 2012, 399, 86–94. [Google Scholar] [CrossRef]

- Ochoa, N.; Pradanos, P.; Palacio, L.; Pagliero, C.; Marchese, J.; Hernandez, A. Pore size distributions based on AFM imaging and retention of multidisperse polymer solutes: Characterisation of polyethersulfone UF membranes with dopes containing different PVP. J. Membr. Sci. 2001, 187, 227–237. [Google Scholar] [CrossRef]

- Calvo, J.; Hernandez, A.; Pradanos, P.; Martınez, L.; Bowen, W. Pore size distributions in microporous membranes ii. Bulk characterization of track-etched filters by air porometry and mercury porosimetry. J. Colloid Interface Sci. 1995, 176, 467–478. [Google Scholar] [CrossRef]

- Cuperus, F.P.; Bargeman, D.; Smolders, C.A. Permporometry—The determination of the size distribution of active pores in UF membranes. J. Membr. Sci. 1992, 71, 57–67. [Google Scholar] [CrossRef]

- Albo, J.; Hagiwara, H.; Yanagishita, H.; Ito, K.; Tsuru, T. Structural characterization of thin-film polyamide reverse osmosis membranes. Ind. Eng. Chem. Res. 2014, 53, 1442–1451. [Google Scholar] [CrossRef]

- Cuperus, F.P.; Bargeman, D.; Smolders, C.A. Critical-points in the analysis of membrane pore structures by thermoporometry. J. Membr. Sci. 1992, 66, 45–53. [Google Scholar] [CrossRef]

- Hernandez, A.; Calvo, J.I.; Pradanos, P.; Tejerina, F. Pore size distributions in microporous membranes. A critical analysis of the bubble point extended method. J. Membr. Sci. 1996, 112, 1–12. [Google Scholar] [CrossRef]

- Gijsbertsen-Abrahamse, A.J.; Boom, R.M.; van der Padt, A. Why liquid displacement methods are sometimes wrong in estimating the pore-size distribution. AIChE J. 2004, 50, 1364–1371. [Google Scholar] [CrossRef]

- Barrett, E.P.; Joyner, L.G.; Halenda, P.P. The determination of pore volume and area distributions in porous substances. I. Computations from nitrogen isotherms. J. Am. Chem. Soc. 1951, 73, 373–380. [Google Scholar] [CrossRef]

- Grabar, P.; Nikitine, S. Sur le diamètre des pores des membranes en collodion utilisées en ultrafiltration. J. Chim. Phys. 1936, 33, 721–741. [Google Scholar] [CrossRef]

- McGuire, K.S.; Lawson, K.W.; Lloyd, D.R. Pore-size distribution determination from liquid permeation through microporous membranes. J. Membr. Sci. 1995, 99, 127–137. [Google Scholar] [CrossRef]

- Piatkiewicz, W.; Rosinski, S.; Lewinska, D.; Bukowski, J.; Judycki, W. Determination of pore size distribution in hollow fibre membranes. J. Membr. Sci. 1999, 153, 91–102. [Google Scholar] [CrossRef]

- Li, H.; Goldbach, A.; Li, W.; Xu, H. PdC formation in ultra-thin Pd membranes during separation of H2/CO mixtures. J. Membr. Sci. 2007, 299, 130–137. [Google Scholar] [CrossRef]

- Albo, J.; Wang, J.; Tsuru, T. Application of interfacially polymerized polyamide composite membranes to isopropanol dehydration: Effect of membrane pre-treatment and temperature. J. Membr. Sci. 2014, 453, 384–393. [Google Scholar] [CrossRef]

- Albo, J.; Wang, J.; Tsuru, T. Gas transport properties of interfacially polymerized polyamide composite membranes under different pre-treatments and temperatures. J. Membr. Sci. 2014, 449, 109–118. [Google Scholar] [CrossRef]

- Hernandez, A.; Calvo, J.I.; Pradanos, P.; Palacio, L.; Rodriguez, M.L.; de Saja, J.A. Surface structure of microporous membranes by computerized sem image analysis applied to anopore filters. J. Membr. Sci. 1997, 137, 89–97. [Google Scholar] [CrossRef]

- Bowen, W.R.; Hilal, N.; Lovitt, R.W.; Williams, P.M. Atomic force microscope studies of membranes: Surface pore structures of cyclopore and anopore membranes. J. Membr. Sci. 1996, 110, 233–238. [Google Scholar] [CrossRef]

| Methods | Equation | Pore Size Information | Ref. | |

|---|---|---|---|---|

| Direct | SEM | - | Pore mouth | [12] |

| AFM | - | Pore mouth | [15] | |

| ESEM | - | Pore mouth | [14] | |

| FESEM | - | Pore mouth | [13] | |

| Indirect | GAD | Kelvin | Average | [16] |

| Permporometry | Kelvin | Pore throat | [17] | |

| Nanopermporometry | Kelvin | Kelvin diameter | [18] | |

| EP | Kelvin | Average | [13] | |

| Thermoporometry | Gibbs–Thompson | Average | [19] | |

| BPM | Young–Laplace | Pore throat | [20] | |

| MBPM | Young–Laplace | Pore mouth | [3] | |

| LLDP | Young–Laplace | Pore throat | [21] | |

| Mercury intrusion porometry | Young–Laplace | Pore throat | [16] | |

| MLLDP | Young–Laplace | Pore mouth | This work | |

| Method | System | Interfacial Tension (mN/m) | Pressure (MPa) Corresponding to Different Pore Diameters (μm) | |||

|---|---|---|---|---|---|---|

| 0.2 | 0.1 | 0.05 | 0.025 | |||

| MBPM | water–nitrogen | 72.8 | 1.45 | 2.91 | 5.82 | 11.64 |

| ethanol–nitrogen | 22.39 | 0.44 | 0.89 | 1.79 | 3.58 | |

| MLLDP | n-amyl alcohol a/water | 4.8 | 0.096 | 0.19 | 0.38 | 0.76 |

| isobutyl alcohol a/water | 1.7 | 0.034 | 0.068 | 0.13 | 0.27 | |

| oil–aqueous phase b/water | 0.35 | 0.007 | 0.014 | 0.028 | 0.056 | |

| Materials | Shape | Geometry | Nominal Pore Size | Liquid System (B/A) | Δp (bar) | Test Rig |

|---|---|---|---|---|---|---|

| AnoporeTM membrane | Planar | O.d.: 7 mm Thickness: 60 μm | 100 nm | Isobutyl alcohol/water | 0.4–1.0 | Figure 3 |

| PVDF membrane | Tubular | O.d.: 1.2 mm I.d.: 0.7 mmL: 40 cm | 80 nm | Isobutyl alcohol/water | 0.4–1.0 | Figure 4 |

| ZrO2/γ-Al2O3/α-Al2O3 membrane | Single tubular | O.d.: 13 mm I.d.: 11 mmL: 5 cm | 30 nm | Isobutyl alcohol/water | 0.6–3.0 | Figure 4 |

| ZrO2/γ-Al2O3/α-Al2O3 membrane | Multi-channel tubular | O.d.: 32 mm Channel i.d.: 4 mmL: 100 cmChannel no.: 19 | 100 nm | n-amyl alcohol/water | 0.4–2.8 | Figure 5 |

| Defects of Pd/ZrO2/Al2O3 membrane | Tubular | O.d.: 13 mm I.d.: 11 mmL: 5 cm | - | Isobutyl alcohol/water | 0.32–3.0 | Figure 4 |

| Types | Membranes | Average | σ | Avg ± σ | |||

|---|---|---|---|---|---|---|---|

| AAO-1 | AAO-2 | AAO-3 | AAO-4 | ||||

| Number-averaged pore mouth (nm) | 80.95 | 80.95 | 89.47 | 85.00 | 84.09 | 3.52 | 84.09 ± 3.52 |

| Methods | Average | Pore Mouth/Pore Throat/Mean Pore Size | Averaged Pore Size (nm) | Ref. |

|---|---|---|---|---|

| EP * | Mass-average | Mean pore size | 94 ± 14 | [13] |

| Number-average | Mean pore size | 69 ± 34 | [13] | |

| FESEM | Number-average | Pore mouth | 87 ± 10 | [13] |

| SEM | Number-average | Pore mouth | 83 ± 26 | [29] |

| LLDP | Mean-flow average | Pore throat | 119 | [29] |

| AFM | Number-average | Pore mouth | 108 ± 26 | [30] |

| MLLDP | Number-average | Pore mouth | 84.09 ± 3.52 | This work |

| Types | Tubes | Average | σ | Avg ± σ | |||||

|---|---|---|---|---|---|---|---|---|---|

| P-1 | P-2 | P-3 | P-4 | P-5 | P-6 | ||||

| Number-averaged pore mouth size (nm) | 73.9 | 70.8 | 73.9 | 80.9 | 77.0 | 77.0 | 75.6 | 3.18 | 75.6 ± 3.18 |

| Types | Repeat Times | Average | σ | avg ± σ | ||

|---|---|---|---|---|---|---|

| ST-1 | ST-2 | ST-3 | ||||

| Number-averaged pore mouth (nm) | 32.38 | 34 | 29.56 | 31.98 | 1.06 | 31.98 ± 1.06 |

| Number-averaged pore throat (nm) | 30.91 | 30.91 | 28.33 | 30.05 | 7.02 | 30.05 ± 7.02 |

| Types | Repeat Times | Average | σ | avg ± σ | ||

|---|---|---|---|---|---|---|

| MCT-1 | MCT-2 | MCT-3 | ||||

| Number-averaged pore mouth (nm) | 76.80 | 83.48 | 80.00 | 80.09 | 2.72 | 80.09 ± 2.72 |

| Types | Repeat Times | Average | σ | avg ± σ | |||||

|---|---|---|---|---|---|---|---|---|---|

| Pd-1 | Pd-2 | Pd-3 | Pd-4 | Pd-5 | Pd-6 | ||||

| Number-averaged defect size (nm) | 24.29 | 24.29 | 25.11 | 24.29 | 24.29 | 24.29 | 24.44 | 0.25 | 24.44 ± 0.25 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, L.; Li, H.; Yu, H.; Kang, G.; Xu, T.; Yu, J.; Li, X.; Xu, H. “Modified” Liquid–Liquid Displacement Porometry and Its Applications in Pd-Based Composite Membranes. Membranes 2018, 8, 29. https://doi.org/10.3390/membranes8020029

Zheng L, Li H, Yu H, Kang G, Xu T, Yu J, Li X, Xu H. “Modified” Liquid–Liquid Displacement Porometry and Its Applications in Pd-Based Composite Membranes. Membranes. 2018; 8(2):29. https://doi.org/10.3390/membranes8020029

Chicago/Turabian StyleZheng, Lei, Hui Li, Haijun Yu, Guodong Kang, Tianying Xu, Jiafeng Yu, Xinzhong Li, and Hengyong Xu. 2018. "“Modified” Liquid–Liquid Displacement Porometry and Its Applications in Pd-Based Composite Membranes" Membranes 8, no. 2: 29. https://doi.org/10.3390/membranes8020029