Low-Energy Membrane Process for Concentration of Stick Water

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Forward Osmosis Apparatus and Measurement Methods

3. Results and Discussion

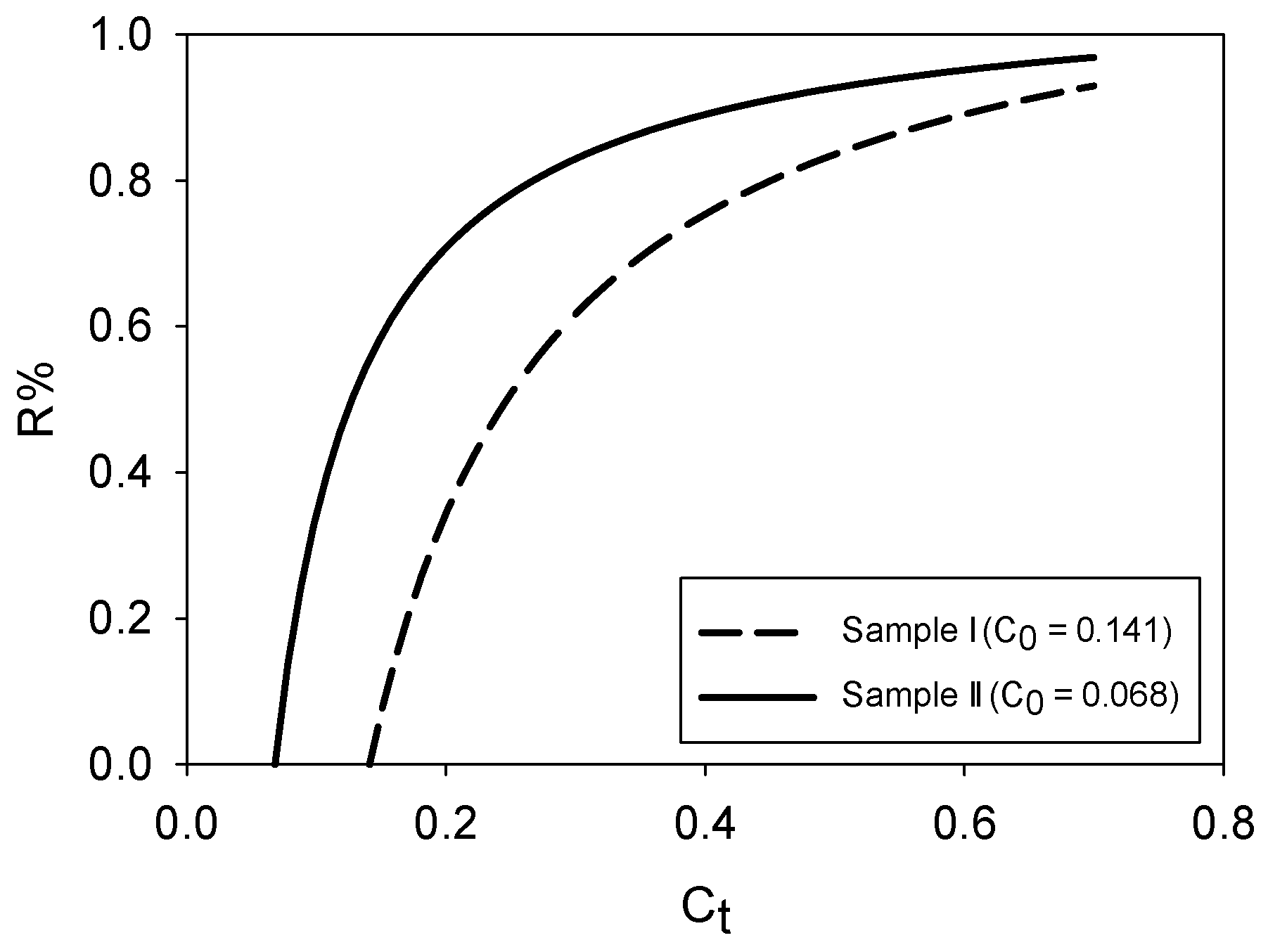

3.1. Impact of Draw Solution Concentration

3.2. Impact of Feed and Draw Solution Stirring Speeds

3.3. Impact of Stick Water Concentration

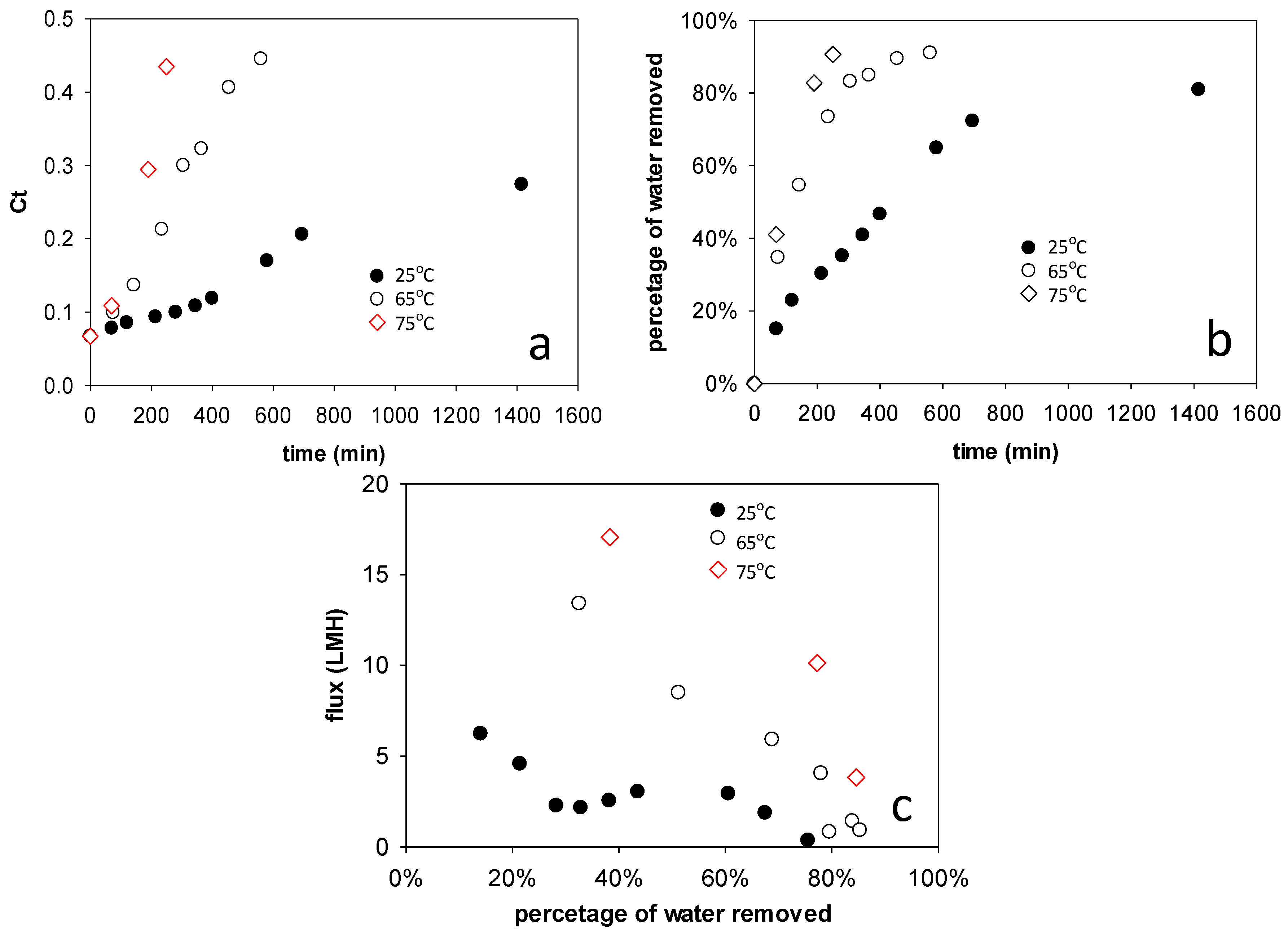

3.4. Impact of Temperature

3.5. Target Stick Water Concentration

3.6. Operating Cost Estimation

- (1)

- Plant output is 24,480 kg stick water per day.

- (2)

- Stick water has a concentration of 6.8 wt % and the goal is to remove 80 wt % of the water either by FO-RO or triple-effect evaporation. No energy is required to heat the feed to 75 °C, as it is available directly from the cooking process at 90–95 °C [1].

- (3)

- (4)

- Operating cost comprises only material cost and energy cost. For FO-RO, the material cost is assumed to be membrane cost only. For RO, a permeability of 2.8 L/m2·h·bar was assumed (Toray 70UB RO membrane), and a feed pressure of 60 bar was assumed. The osmotic pressure of the 1.0 M draw solution is 50 bar, leaving a 10-bar transmembrane pressure driving force to determine the membrane area needed. The energy cost is associated with pumping the feed and pumping costs to regenerate the 1.0 M draw solution using RO to remove water. Thus, FO functions as a pretreatment for RO [17]. This energy cost was determined following the steps outlined by Zhou et al. [18]. A pump efficiency of 60% was assumed. Cleaning was scheduled every 4 days and assumed to be 1 h long. Cleaning cost is usually 15–20% of the operating cost [19]. It was assumed to be 20% in this case. This amount was added to the final column of Table 2.

- (5)

- Thermal evaporation is used as a comparison. Typical figures for steam consumption are 0.60 to 0.65 kg, 0.40 to 0.45 kg and 0.20 to 0.35 kg steam per kilogram water evaporated in double, triple and quadruple effect evaporators [1]. At 1 bar, it takes 2.257 MJ (0.6269 kWh) to generate one kilogram of steam. The approximate cost of power plant operating expenses for electric utilities using fossil steam is $0.036/kWh [20]. Based on these basic data, it should cost about $0.009 of fuel to evaporate one kilogram of water from stick water using triple-effect evaporation.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- FAO (Food and Agriculture Organization). Fishery Industries Division. The Production of Fish Meal and Oil; FAO Fisheries and Aquaculture Technical Paper (142) Rev. 1; FAO: Rome, Italy, 1986; p. 63. [Google Scholar]

- Baeling, P.; Ehnstrom, L. A Process for the Production of Animal Feedstuff from Liquid Raw Materials. WO1983000006 A1, 6 January 1983. [Google Scholar]

- Park, C.W.; Bastian, E.; Farkas, B.; Drake, M.T. The effect of feed solids concentration and inlet temperature on the flavor of spray dried whey protein concentrate. J. Food Sci. 2014, 79, 19–24. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.X.; Wandera, D.; Husson, S.M. Mechanisms and control of fouling during ultrafiltration of high strength wastewater without pretreatment. J. Membr. Sci. 2015, 488, 103–110. [Google Scholar] [CrossRef]

- Mostafa, M.G.; Zhu, B.; Cran, M.; Dow, N.; Milne, N.; Desai, D.; Duke, M. Membrane distillation of meat industry effluent with hydrophilic polyurethane coated polytetrafluoroethylene membranes. Membranes 2017, 7, 55. [Google Scholar] [CrossRef] [PubMed]

- Lutchmiah, K.; Verliefde, A.R.D.; Roest, K.; Rietveld, L.C.; Cornelissen, E.R. Forward osmosis for application in wastewater treatment: A review. Water Res. 2014, 58, 179–197. [Google Scholar] [CrossRef] [PubMed]

- Munshi, F.M.; Church, J.; McLean, R.; Maier, N.; Anwar Sadmani, A.H.M.; Duranceau, S.J.; Lee, W.H. Dewatering algae using an aquaporin-based polyethersulfone forward osmosis membrane. Sep. Purif. Technol. 2018, 204, 154–161. [Google Scholar] [CrossRef]

- Holloway, R.W.; Childress, A.E.; Dennett, K.E.; Cath, T.Y. Forward osmosis for concentration of anaerobic digester centrate. Water Res. 2007, 41, 4005–4014. [Google Scholar] [CrossRef] [PubMed]

- Kwan, S.E.; Bar-Zeev, E.; Elimelech, M. Biofouling in forward osmosis and reverse osmosis: Measurements and mechanisms. J. Membr. Sci. 2015, 493, 703–708. [Google Scholar] [CrossRef]

- McCutcheon, J.R.; Elimelech, M. Influence of concentrative and dilutive internal concentration polarization on flux behavior in forward osmosis. J. Membr. Sci. 2006, 284, 237–247. [Google Scholar] [CrossRef]

- Han, G.; Zhang, S.; Li, X.; Chung, T.-S. Progress in pressure retarded osmosis (PRO) membranes for osmotic power generation. Prog. Polym. Sci. 2015, 51, 1–27. [Google Scholar] [CrossRef]

- Wang, X.; Wang, X.; Xiao, P.; Li, J.; Tian, E.; Zhao, Y.; Ren, Y. High water permeable free-standing cellulose triacetate/graphene oxide membrane with enhanced biofouling and mechanical properties for forward osmosis. Colloids Surf. A Physicochem. Eng. Asp. 2016, 508, 327–335. [Google Scholar] [CrossRef]

- Phuntsho, S.; Hong, S.; Elimelech, M.; Shon, H.K. Osmotic equilibrium in the forward osmosis process: Modelling, experiments and implications for process performance. J. Membr. Sci. 2014, 453, 240–252. [Google Scholar] [CrossRef]

- Zou, S.; Wang, Y.-N.; Wicaksana, F.; Aung, T.; Wong, P.C.Y.; Fane, A.G.; Tang, C.Y. Direct microscopic observation of forward osmosis membrane fouling by microalgae: Critical flux and the role of operational conditions. J. Membr. Sci. 2013, 436, 174–185. [Google Scholar] [CrossRef]

- Korosi, A.; Fabuss, B.M. Viscosity of liquid water from 25 to 150 °C: Measurements in pressurized glass capillary viscometer. Anal. Chem. 1968, 40, 157–162. [Google Scholar] [CrossRef]

- Valladares Linares, R.; Li, Z.; Yangali-Quintanilla, V.; Ghaffour, N.; Amy, G.; Leiknes, T.; Vrouwenvelder, J.S. Life cycle cost of a hybrid forward osmosis—Low pressure reverse osmosis system for seawater desalination and wastewater recovery. Water Res. 2016, 88, 225–234. [Google Scholar] [CrossRef] [PubMed]

- Cath, T.Y.; Childress, A.E.; Elimelech, M. Forward osmosis: Principles, applications, and recent developments. J. Membr. Sci. 2006, 281, 70–87. [Google Scholar] [CrossRef]

- Zhou, J.; Baker, B.O.; Grimsley, C.T.; Husson, S.M. Polishing step purification of high-strength wastewaters by nanofiltration and reverse osmosis. Membranes 2016, 6, 19. [Google Scholar] [CrossRef] [PubMed]

- Regula, C.; Carretier, E.; Wyart, Y.; Gesan-Guiziou, G.; Vincent, A.; Boudot, D.; Moulin, P. Chemical cleaning/disinfection and ageing of organic UF membranes: A review. Water Res. 2014, 56, 325–365. [Google Scholar] [CrossRef] [PubMed]

- Federal Energy Regulatory Commission. FERC form 1, Annual Report of Major Electric Utilities, Licensees and Others via Ventyx Global Energy Velocity Suite, 2016. Available online: https://www.ferc.gov/docs-filing/forms/form-1/data.asp (accessed on 27 May 2018).

- Wandera, D. Suggested Lifetime for HTI CTA Forward Osmosis Membrane. Personal communication to Husson, S.M., 2013. [Google Scholar]

| Stick Water Flow Rate (L·h−1) | Average Membrane Flux (L·m−2·h−1) | Membrane Area (m2) | Temp. (°C) |

|---|---|---|---|

| 1020 | 13.5 | 76 | 75 |

| 1020 | 9.5 | 108 | 65 |

| 1020 | 4 | 256 | 25 |

| Frequency of Membrane Replacement | Membrane Cost ($) | Dry Material Weight (kg) | FO-RO Material Cost $/1000 kg Dry Material | FO-RO Energy Cost $/1000 kg Dry Material | Total FO-RO Cost $/1000 kg Dry Material * |

|---|---|---|---|---|---|

| 3 months | 4860 | 185,760 | 26.2 | 1.3 | 33.0 |

| 6 months | 4860 | 371,520 | 13.1 | 1.3 | 17.3 |

| 12 months | 4860 | 743,040 | 6.6 | 1.3 | 9.5 |

| 24 months | 4860 | 1,486,080 | 3.3 | 1.3 | 5.6 |

| Triple-effect evaporation cost | 0 | 0 | 0 | 24.3 | 24.3 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, J.; Husson, S.M. Low-Energy Membrane Process for Concentration of Stick Water. Membranes 2018, 8, 25. https://doi.org/10.3390/membranes8020025

Zhou J, Husson SM. Low-Energy Membrane Process for Concentration of Stick Water. Membranes. 2018; 8(2):25. https://doi.org/10.3390/membranes8020025

Chicago/Turabian StyleZhou, Jinxiang, and Scott M. Husson. 2018. "Low-Energy Membrane Process for Concentration of Stick Water" Membranes 8, no. 2: 25. https://doi.org/10.3390/membranes8020025