Optimal Water Backwashing Condition in Combined Water Treatment of Alumina Microfiltration and PP Beads

Abstract

:1. Introduction

2. Materials and Methods

2.1. Membranes and Polypropylene (PP) Beads

2.2. Experimental Procedures

2.3. Analytical Methods

2.4. Membrane Recovery Methods

2.5. Resistance-in-Series Filtration Model

3. Results and Discussions

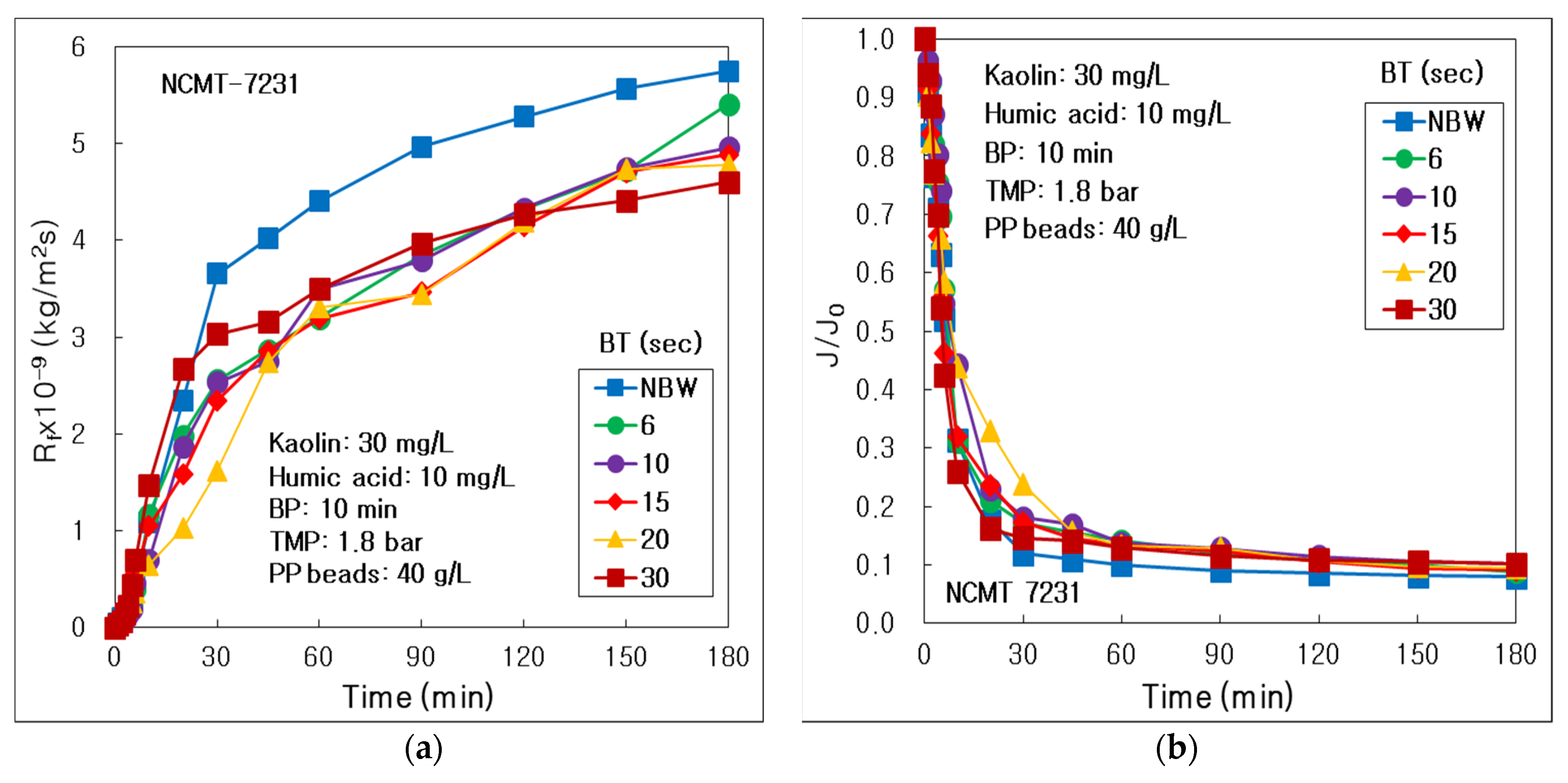

3.1. Influence of Water Backwashing Time (BT) on Membrane Fouling and Treatment Efficiency

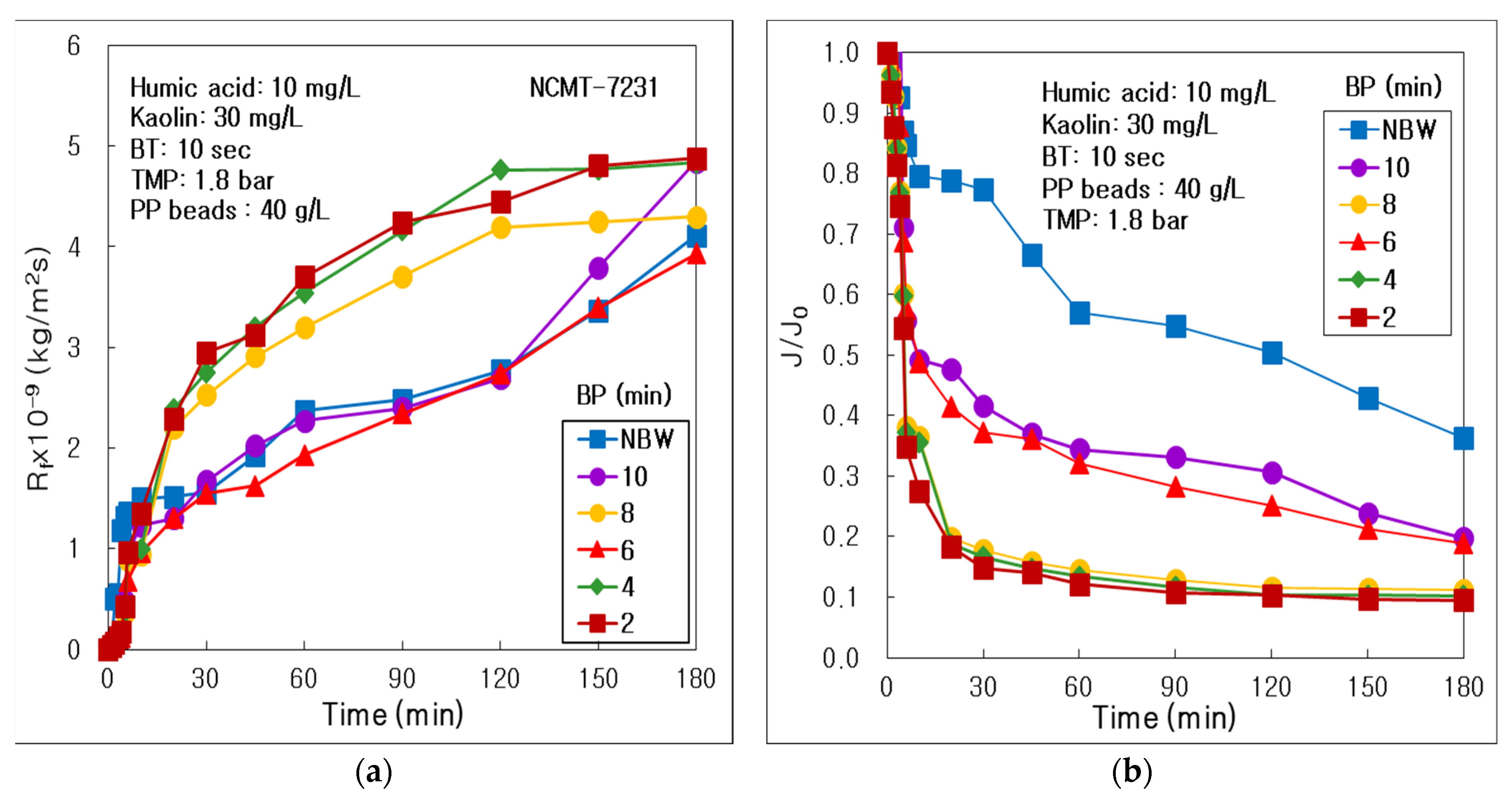

3.2. Influence of Water Backwashing Period (BP) on Membrane Fouling and Treatment Efficiency

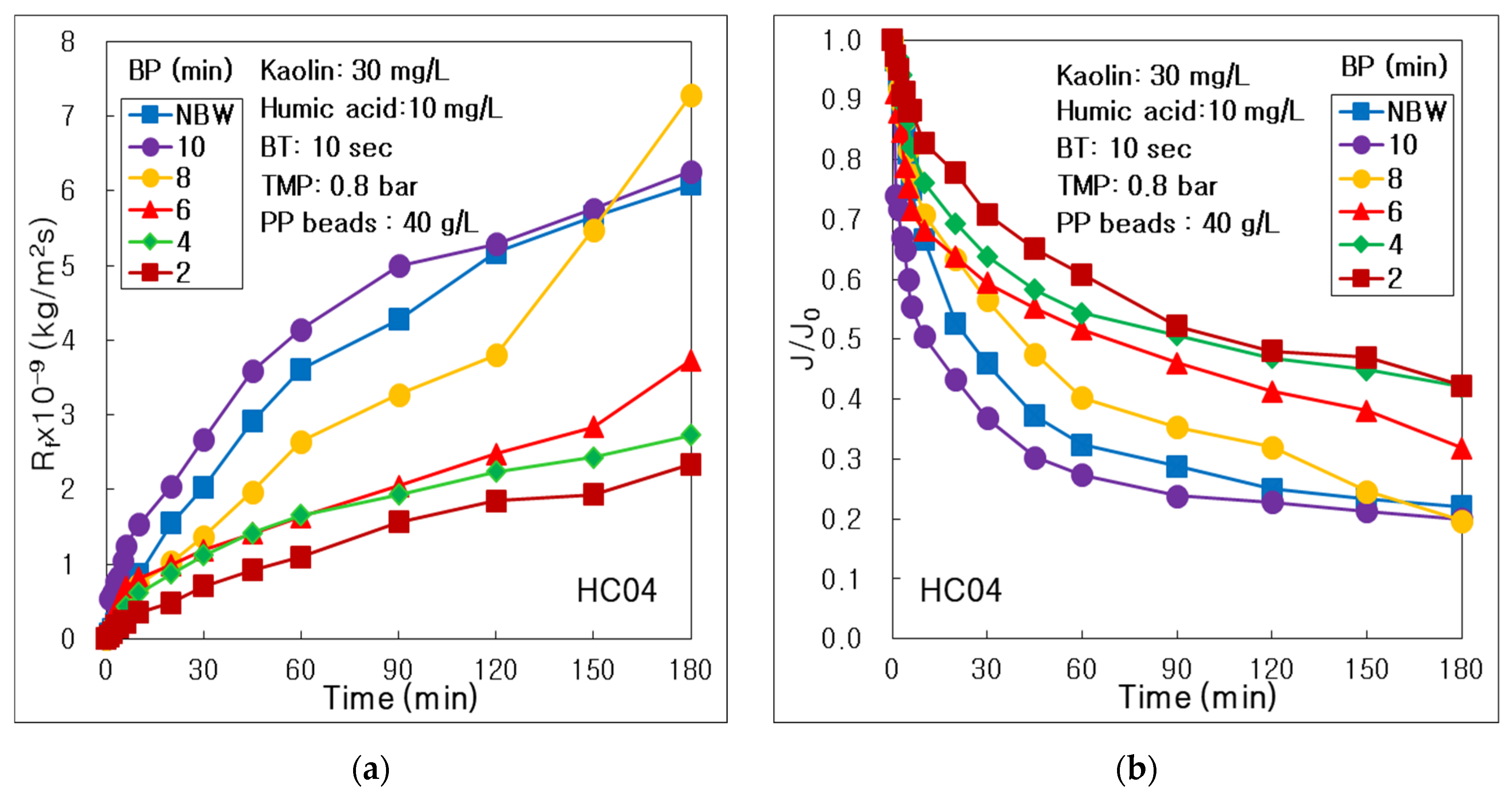

3.3. Influence of Membrane Shape (Tubular or Seven Channel) on Membrane Fouling and Treatment Efficiency

4. Conclusions

- (1)

- The dimensionless permeate flux (J180/J0) after 180 min’s operation at BT 30 s showed the highest value. However, the total treated water volume (VT) had the highest at BT 20 s, because J maintained higher from 10 to 30 min’s operation than those of other BT conditions. Finally, the optimal BT condition could be 20 s in the combined water treatment process, because of the maximum VT in our experimental BT conditions. In the previous work [24], for the combined process of tubular carbon fiber UF and photocatalyst-coated PP beads, the maximum VT could be acquired at BT 30 s, which agreed with this result of the combined process of tubular alumina MF and pure PP beads.

- (2)

- The final Rf (Rf,180) value after 180 min’s operation at BP 2 min was the highest at BP 6 min. Furthermore, the VT showed the highest 3.10 L at BP 6 min. In conclusion, the optimal BP condition could be 6 min, because of the minimum membrane fouling and the maximum total treated volume in this combined water treatment process of tubular alumina MF and PP beads.

- (3)

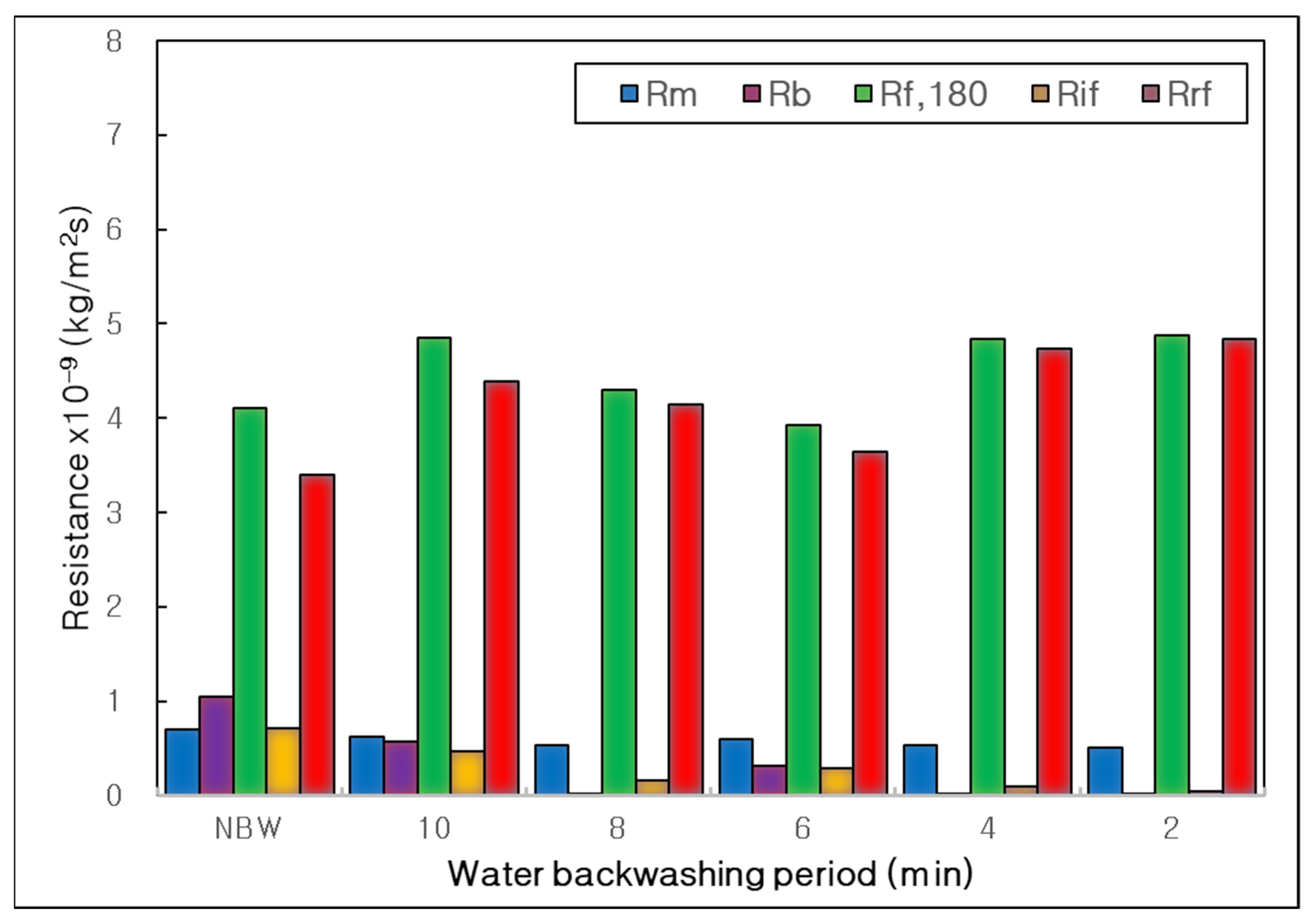

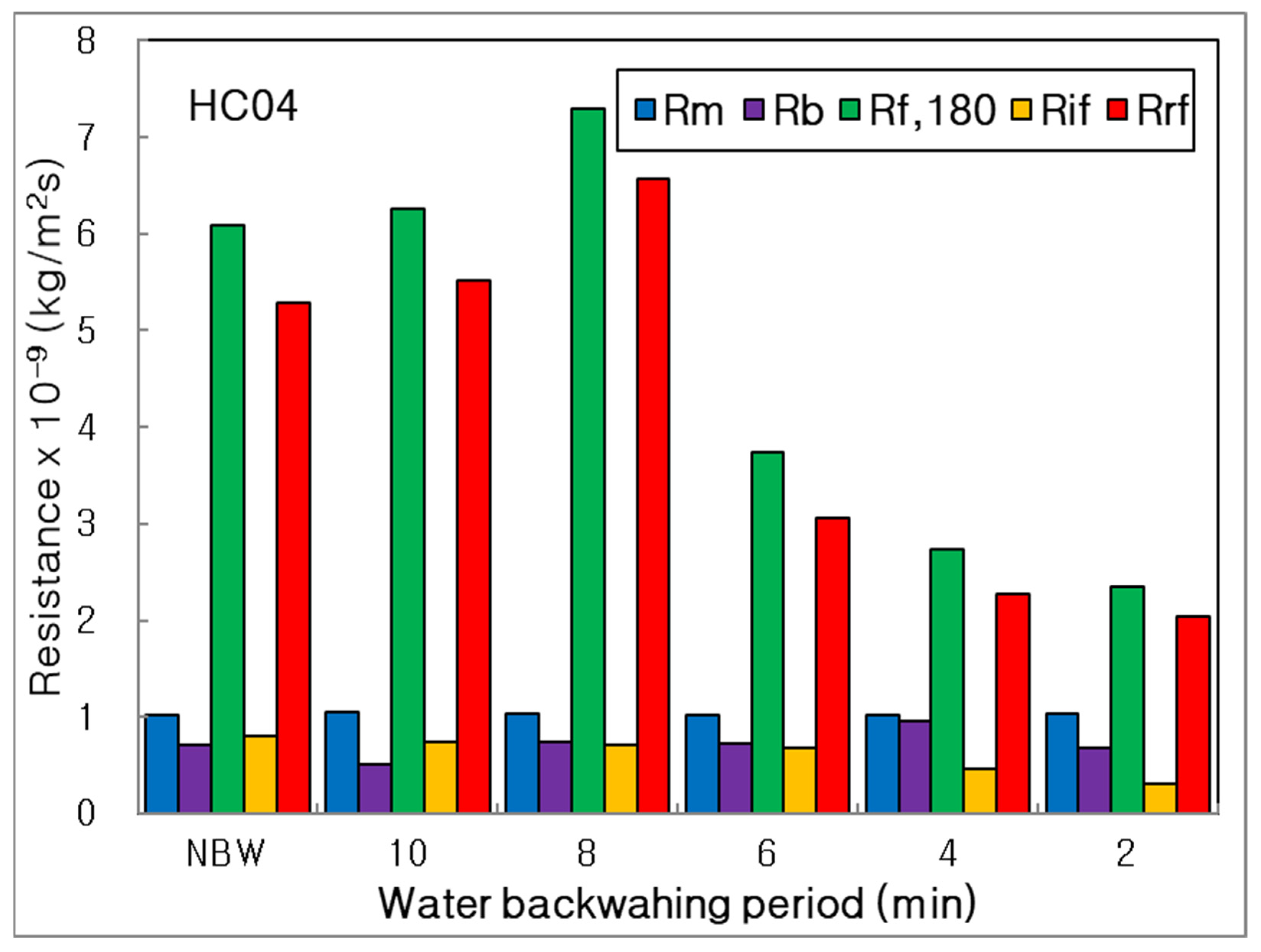

- The resistance of reversible membrane fouling (Rrf) showed a major resistance of total membrane fouling, and that of irreversible membrane fouling (Rif) was a minor one, in the combined process using tubular or seven channel MF. The Rif showed a decreasing trend obviously, as decreasing BP from NBW to 2 min for seven channel MF. It means that the more frequent water backwashing could be more effective to control the membrane fouling, especially irreversible fouling, for seven channel membranes than tubular membranes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Meng, F.G.; Chae, S.R.; Drews, A.; Kraume, M.; Shin, H.S.; Yang, F. Recent advances in membrane bioreactors (MBRs): Membrane fouling and membrane material. Water Res. 2009, 43, 1489–1512. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.X.; Zhang, D.R.; He, Y.; Zhao, X.S.; Bai, R. Modification of membrane surface for anti-biofouling performance: Effect of anti-adhesion and anti-bacterial approaches. J. Membr. Sci. 2010, 346, 121–130. [Google Scholar] [CrossRef]

- Cui, X.; Choo, K.-H. Natural Organic Matter Removal and Fouling Control in Low-Pressure Membrane Filtration for Water Treatment. Environ. Eng. Res. 2014, 19, 1–8. [Google Scholar] [CrossRef]

- Manamperuma, L.D.; Vik, E.A.; Benjamin, M.; Cai, Z.; Skjefstad, J. Effects of a novel adsorbent on membrane fouling by natural organic matter in drinking water treatment. Membranes 2019, 9, 151. [Google Scholar] [CrossRef] [Green Version]

- Gao, Y.; Zhang, Y.; Dudek, M.; Qin, J.; Øye, G.; Østerhus, S.W. A multivariate study of backpulsing for membrane fouling mitigation in produced water treatment. J. Environ. Chem. Eng. 2020, 2020, 104839. [Google Scholar] [CrossRef]

- Cakl, J.; Bauer, I.; Doleček, P.; Mikulášek, P. Effects of backflushing conditions on permeate flux in membrane crossflow microfiltration of oil emulsion. Desalination 2000, 127, 189–198. [Google Scholar] [CrossRef]

- Abadi, S.R.H.; Sebzari, M.R.; Hemati, M.; Rekabdar, F.; Mohammadi, T. Ceramic membrane performance in microfiltration of oily wastewater. Desalination 2011, 265, 222–228. [Google Scholar] [CrossRef]

- Tian, J.; Wu, C.; Yu, H.; Gao, S.; Li, G.; Cui, F.; Qu, F. Applying ultraviolet/persulfate (UV/PS) pre-oxidation for controlling ultrafiltration membrane fouling by natural organic matter (NOM) in surface water. Water Res. 2018, 132, 190–199. [Google Scholar] [CrossRef]

- Marconnet, C.; Houari, A.; Seyer, D.; Djafer, M.; Coriton, G.; Heim, V.; Martino, P.D. Membrane biofouling control by UV irradiation. Desalination 2011, 276, 75–81. [Google Scholar] [CrossRef]

- Kusworo, T.D.; Utomo, D.P. Performance evaluation of double stage process using nano hybrid PES/SiO2-PES membrane and PES/ZnO-PES membranes for oily waste water treatment to clean water. J. Environ. Chem. Eng. 2017, 5, 6077–6086. [Google Scholar] [CrossRef]

- Szymański, K.; Morawski, A.W.; Mozia, S. Surface water treatment in hybrid systems coupling advanced oxidation processes and ultrafiltration using ceramic membrane. Desalinat. Water Treat. 2017, 64, 302–306. [Google Scholar] [CrossRef]

- Hofs, B.; Ogier, J.; Vries, D.; Beerendonk, E.F.; Cornelissen, E.R. Comparison of ceramic and polymeric membrane permeability and fouling using surface water. Sep. Purif. Technol. 2011, 79, 365–374. [Google Scholar] [CrossRef]

- Chen, M.; Heijman, S.G.J.; Rietveld, L.C. State-of-the-art ceramic membranes for oily wastewater treatment: Modification and application. Membranes 2021, 11, 888. [Google Scholar] [CrossRef]

- Liu, P.; Liu, J.; Wang, Z.; Jiao, Y.; Bie, A.; Xia, J. Application of inorganic ceramic membrane in treatment of emulsion wastewater. Oxidat. Commun. 2016, 39, 2753–2757. [Google Scholar]

- Zhang, X.; Fan, L.; Roddick, F.A. Influence of the characteristics of soluble algal organic matter released from Microcystis aeruginosa on the fouling of a ceramic microfiltration membrane. J. Membr. Sci. 2013, 425, 23–29. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Fan, L.; Roddick, F.A. Impact of the interaction between aquatic humic substances and algal organic matter on the fouling of a ceramic microfiltration membrane. Membranes 2018, 8, 7. [Google Scholar] [CrossRef] [Green Version]

- Benito, A.; Penadés, A.; Lliberia, J.L.; Gonzalez-Olmos, R. Degradation pathways of aniline in aqueous solutions during electro-oxidation with BDD electrodes and UV/H2O2 treatment. Chemosph. 2017, 166, 230–237. [Google Scholar] [CrossRef]

- Khuzwayo, Z.; Chirwa, E.M.N. Analysis of catalyst photo-oxidation selectivity in the degradation of polyorganochlorinated pollutants in batch systems using UV and UV/TiO2. South Afr. J. Chem. Eng. 2017, 23, 17–25. [Google Scholar] [CrossRef]

- Milelli, D.; Lemont, F.; Ruffel, L.; Barral, T.; Marchand, M. Thermo- and photo-oxidation reaction scheme in a treatment system using submerged plasma. Chem. Eng. J. 2017, 317, 1083–1091. [Google Scholar] [CrossRef] [Green Version]

- Morgan, A.; Cocca, M.; Vega, K.; Fleischer, A.; Gupta, S.K.; Mehan, M.; Takacs, G.A. Vacuum UV photo-oxidation of poly(ethylene terephthalate). J. Adhes. Sci. Technol. 2017, 31, 2542–2554. [Google Scholar] [CrossRef]

- Semitsoglou-Tsiapou, S.; Templeton, M.R.; Graham, N.J.D.; Hernández Leal, L.; Martijn, B.J.; Royce, A.; Kruithof, J.C. Low pressure UV/H2O2 treatment for the degradation of the pesticides metaldehyde, clopyralid and mecoprop—Kinetics and reaction product formation. Water Res. 2016, 91, 285–294. [Google Scholar] [CrossRef] [PubMed]

- Li, A.; Zhao, X.; Liu, H.; Qu, J. Characteristic transformation of humic acid during photoelectrocatalysis process and its subsequent disinfection byproduct formation potential. Water Res. 2011, 45, 6131–6140. [Google Scholar] [CrossRef] [PubMed]

- Amarsanaa, B.; Park, J.Y. Effect of water back-flushing and PP beads in hybrid water treatment of multi-channel alumina MF and photocatalyst-coated PP beads. Desalinat. Water Treat. 2015, 54, 1457–1469. [Google Scholar] [CrossRef]

- Gang, G.L.; Park, J.Y. Hybrid water treatment process of tubular carbon fiber ultrafiltration and photocatalyst-coated PP beads: Treatment mechanisms and effects of water back-flushing time. Desalinat. Water Treat. 2016, 57, 7721–7732. [Google Scholar] [CrossRef]

- Park, Y.; Park, J.Y. Roles of adsorption and photo-oxidation in hybrid water treatment process of tubular carbon fiber ultrafiltration and PP beads with UV irradiation and water back-flushing. Desalinat. Water Treat. 2017, 61, 20–28. [Google Scholar] [CrossRef]

- Song, S.; Park, Y.; Park, J.Y. Roles of polypropylene beads and pH in hybrid water treatment of carbon fiber membrane and PP beads with water back-flushing. Membr. Water Treat. 2019, 10, 155–163. [Google Scholar] [CrossRef]

- Lee, H.C.; Park, J.Y. Advanced water treatment of high turbidity source by hybrid process of ceramic microfiltration and activated carbon adsorption: Effect of water-back-flushing time and period. Membr. J. 2009, 19, 7–18. [Google Scholar]

| Membrane Model | NCMT-7231 | HC10 |

|---|---|---|

| Pore size (μm) | 0.4 | 0.1 |

| No. of channels | 1 | 7 |

| Outer diameter (mm) | 8 | 20 |

| Inner diameter (mm) | 6 | 4 |

| Length (mm) | 254 | 245 |

| Surface area (cm2) | 47.9 | 215 |

| Cross sectional area of pore (cm2) | 0.283 | 0.880 |

| Flow velocity in channel (cm/s) | 58.9 | 18.9 |

| Reynolds number in channel | 3510 | 751 |

| Material | α-alumina | α-alumina |

| Company | Nanopore Inc. (Korea) | Dongseo Industry (Korea) |

| BT (s) | NBW * | 6 | 10 | 15 | 20 | 30 |

|---|---|---|---|---|---|---|

| Rm × 10−9 (kg/m2s) | 0.484 | 0.490 | 0.489 | 0.484 | 0.493 | 0.495 |

| Rb × 10−9 (kg/m2s) | 0.011 | 0.037 | 0.070 | 0.007 | 0.013 | 0.023 |

| Rf,180 × 10−9 (kg/m2s) | 5.742 | 5.404 | 4.958 | 4.885 | 4.781 | 4.597 |

| Rif × 10−9 (kg/m2s) | 0.247 | 0.214 | 0.086 | 0.147 | 0.117 | 0.136 |

| Rrf × 10−9 (kg/m2s) | 5.495 | 5.190 | 4.873 | 4.739 | 4.663 | 4.461 |

| J0 (L/m2hr) | 1282 | 1207 | 1137 | 1294 | 1255 | 1225 |

| J180 (L/m2hr) | 102 | 107 | 115 | 118 | 120 | 124 |

| J180/J0 | 0.079 | 0.089 | 0.101 | 0.091 | 0.096 | 0.101 |

| VT (L) | 2.43 | 2.76 | 2.80 | 2.88 | 3.13 | 2.60 |

| BT (s) | Turbidity (NTU) | Average Treatment Efficiency (%) | |||

|---|---|---|---|---|---|

| Feed Water | Treated Water | ||||

| Range | Average | Range | Average | ||

| NBW * | 156.0~157.0 | 156.8 | 0.447~0.512 | 0.488 | 99.7 |

| 6 | 153.0~155.0 | 154.2 | 0.668~0.722 | 0.694 | 99.6 |

| 10 | 153.0~155.0 | 154.0 | 0.672~0.725 | 0.694 | 99.5 |

| 15 | 143.0~145.0 | 144.5 | 0.607~0.620 | 0.613 | 99.6 |

| 20 | 147.0~149.0 | 148.0 | 0.611~0.657 | 0.635 | 99.6 |

| 30 | 162.0~163.0 | 162.5 | 0.612~0.684 | 0.635 | 99.6 |

| BT (s) | UV254 Absorbance (cm−1) | Average Treatment Efficiency (%) | |||

|---|---|---|---|---|---|

| Feed Water | Treated Water | ||||

| Range | Average | Range | Average | ||

| NBW * | 0.322~0.324 | 0.323 | 0.038~0.044 | 0.042 | 87.1 |

| 6 | 0.311~0.313 | 0.313 | 0.031~0.038 | 0.035 | 89.0 |

| 10 | 0.317~0.325 | 0.263 | 0.037~0.046 | 0.041 | 87.3 |

| 15 | 0.238~0.303 | 0.246 | 0.040~0.045 | 0.042 | 84.2 |

| 20 | 0.249~0.331 | 0.264 | 0.016~0.023 | 0.020 | 92.4 |

| 30 | 0.341~0.349 | 0.345 | 0.041~0.054 | 0.045 | 86.9 |

| BP (min) | NBW * | 10 | 8 | 6 | 4 | 2 |

|---|---|---|---|---|---|---|

| Rm × 10−9 (kg/m2s) | 0.694 | 0.626 | 0.528 | 0.602 | 0.534 | 0.508 |

| Rb × 10−9 (kg/m2s) | 1.050 | 0.566 | 0.017 | 0.316 | 0.017 | 0.005 |

| Rf,180 × 10−9 (kg/m2s) | 4.112 | 4.849 | 4.299 | 3.931 | 4.834 | 4.877 |

| Rif × 10−9 (kg/m2s) | 0.719 | 0.465 | 0.156 | 0.283 | 0.098 | 0.040 |

| Rrf × 10−9 (kg/m2s) | 3.393 | 4.384 | 4.143 | 3.648 | 4.736 | 4.837 |

| J0 (L/m2hr) | 364 | 533 | 1166 | 692 | 1152 | 1237 |

| J180 (L/m2hr) | 132 | 105 | 131 | 131 | 118 | 118 |

| J180/J0 | 0.363 | 0.197 | 0.112 | 0.189 | 0.102 | 0.095 |

| VT (L) | 3.01 | 2.63 | 2.72 | 3.10 | 2.56 | 2.56 |

| BP (min) | Turbidity (NTU) | Average Treatment Efficiency (%) | |||

|---|---|---|---|---|---|

| Feed Water | Treated Water | ||||

| Range | Average | Range | Average | ||

| NBW * | 41.1~43.5 | 42.2 | 0.623~0.723 | 0.687 | 98.4 |

| 10 | 40.3~43.6 | 41.7 | 0.498~0.612 | 0.547 | 98.7 |

| 8 | 47.4~49.2 | 48.1 | 0.202~0.262 | 0.299 | 99.5 |

| 6 | 45.8~61.3 | 52.6 | 0.091~0.313 | 0.176 | 99.7 |

| 4 | 47.2~51.5 | 49.6 | 0.136~0.239 | 0.173 | 99.7 |

| 2 | 43.6~51.9 | 47.9 | 0.523~0.832 | 0.694 | 98.6 |

| BP (min) | UV254 Absorbance (cm−1) | Average Treatment Efficiency (%) | |||

|---|---|---|---|---|---|

| Feed Water | Treated Water | ||||

| Range | Average | Range | Average | ||

| NBW * | 0.226~0.236 | 0.234 | 0.017~0.019 | 0.018 | 92.4 |

| 10 | 0.221~0.249 | 0.236 | 0.012~0.018 | 0.015 | 93.7 |

| 8 | 0.021~0.304 | 0.299 | 0.011~0.022 | 0.017 | 94.3 |

| 6 | 0.247~0.351 | 0.315 | 0.013~0.036 | 0.021 | 93.4 |

| 4 | 0.211~0.341 | 0.289 | 0.021~0.029 | 0.024 | 91.6 |

| 2 | 0.288~0.315 | 0.297 | 0.009~0.038 | 0.018 | 93.8 |

| BP (min) | NBW * | 10 | 8 | 6 | 4 | 2 |

|---|---|---|---|---|---|---|

| Rm × 10−9 (kg/m2s) | 1.019 | 1.052 | 1.041 | 1.025 | 1.019 | 1.030 |

| Rb × 10−9 (kg/m2s) | 0.710 | 0.511 | 0.748 | 0.720 | 0.962 | 0.682 |

| Rf,180 × 10−9 (kg/m2s) | 6.086 | 6.264 | 7.287 | 3.733 | 2.732 | 2.342 |

| Rif × 10−9 (kg/m2s) | 0.797 | 0.741 | 0.717 | 0.673 | 0.456 | 0.309 |

| Rrf × 10−9 (kg/m2s) | 5.288 | 5.523 | 6.571 | 3.060 | 2.276 | 2.033 |

| J0 (L/m2hr) | 163 | 181 | 158 | 162 | 142 | 165 |

| J180 (L/m2hr) | 36 | 36 | 31 | 52 | 60 | 70 |

| J180/J0 | 0.221 | 0.200 | 0.197 | 0.319 | 0.420 | 0.422 |

| VT (L) | 3.60 | 3.28 | 3.98 | 4.95 | 4.83 | 5.79 |

| BP (min) | Turbidity (NTU) | Average Treatment Efficiency (%) | |||

|---|---|---|---|---|---|

| Feed Water | Treated Water | ||||

| Range | Average | Range | Average | ||

| NBW * | 56.9~61.5 | 59.3 | 0.506~0.637 | 0.567 | 99.1 |

| 10 | 56.5~61.1 | 58.5 | 0.482~0.658 | 0.557 | 99.1 |

| 8 | 67.2~72.8 | 69.8 | 0.674~0.867 | 0.752 | 99.1 |

| 6 | 72.8~75.1 | 73.9 | 0.601~0.735 | 0.677 | 99.1 |

| 4 | 68.2~71.8 | 70.0 | 0.574~0.689 | 0.647 | 99.1 |

| 2 | 76.4~78.2 | 77.2 | 0.632~0.963 | 0.805 | 99.0 |

| BP (min) | UV254 Absorbance (cm−1) | Average Treatment Efficiency (%) | |||

|---|---|---|---|---|---|

| Feed Water | Treated Water | ||||

| Range | Average | Range | Average | ||

| NBW * | 0.524~0.631 | 0.578 | 0.097~0.127 | 0.111 | 80.8 |

| 10 | 0.441~0.513 | 0.482 | 0.081~0.114 | 0.096 | 80.2 |

| 8 | 0.583~0.608 | 0.598 | 0.108~0.120 | 0.114 | 80.9 |

| 6 | 0.584~0.624 | 0.609 | 0.089~0.121 | 0.107 | 82.4 |

| 4 | 0.541~0.609 | 0.577 | 0.098~0.119 | 0.108 | 81.2 |

| 2 | 0.524~0.584 | 0.560 | 0.101~0.122 | 0.111 | 80.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, H.; Yoon, G.; Kim, M.; Park, J.Y. Optimal Water Backwashing Condition in Combined Water Treatment of Alumina Microfiltration and PP Beads. Membranes 2022, 12, 92. https://doi.org/10.3390/membranes12010092

Cho H, Yoon G, Kim M, Park JY. Optimal Water Backwashing Condition in Combined Water Treatment of Alumina Microfiltration and PP Beads. Membranes. 2022; 12(1):92. https://doi.org/10.3390/membranes12010092

Chicago/Turabian StyleCho, Hyungmin, Gihoon Yoon, Minjae Kim, and Jin Yong Park. 2022. "Optimal Water Backwashing Condition in Combined Water Treatment of Alumina Microfiltration and PP Beads" Membranes 12, no. 1: 92. https://doi.org/10.3390/membranes12010092