Experimental Study of a Heat Pump for Simultaneous Cooling and Desalination by Membrane Distillation

Abstract

:1. Introduction

1.1. Principles of membrane distillation

1.2. Membrane Distillation and Heat Sources

1.2.1. Solar Energy

1.2.2. Geothermal Energy

1.2.3. Waste Heat

1.3. Heat Pumps for Desalination

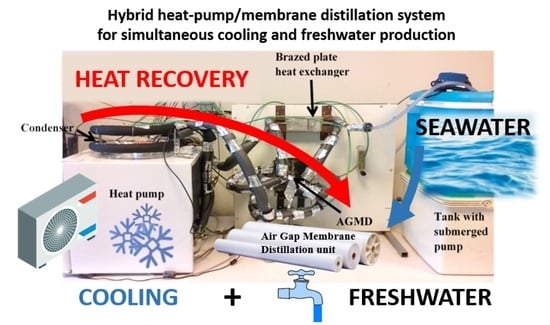

2. Materials and Methods: Heat Pump and AGMD

2.1. Heat Pump

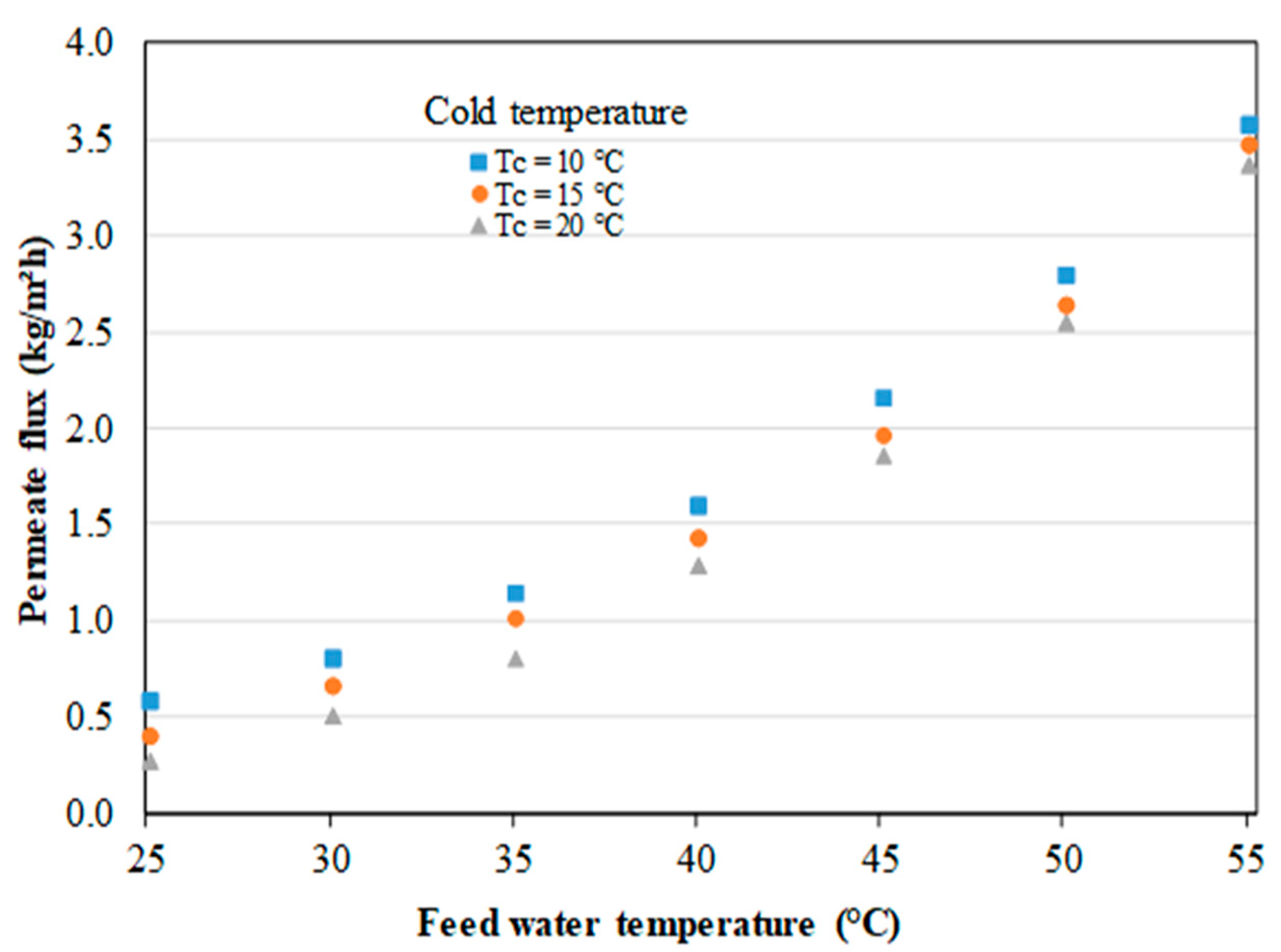

2.2. Air Gap Membrane Distillation Cell

2.3. Description of the Experimental Coupling Setup

2.3.1. Refrigerant Circuit

2.3.2. Hydraulic Circuit

2.4. Performance Analysis

3. Results and Discussion

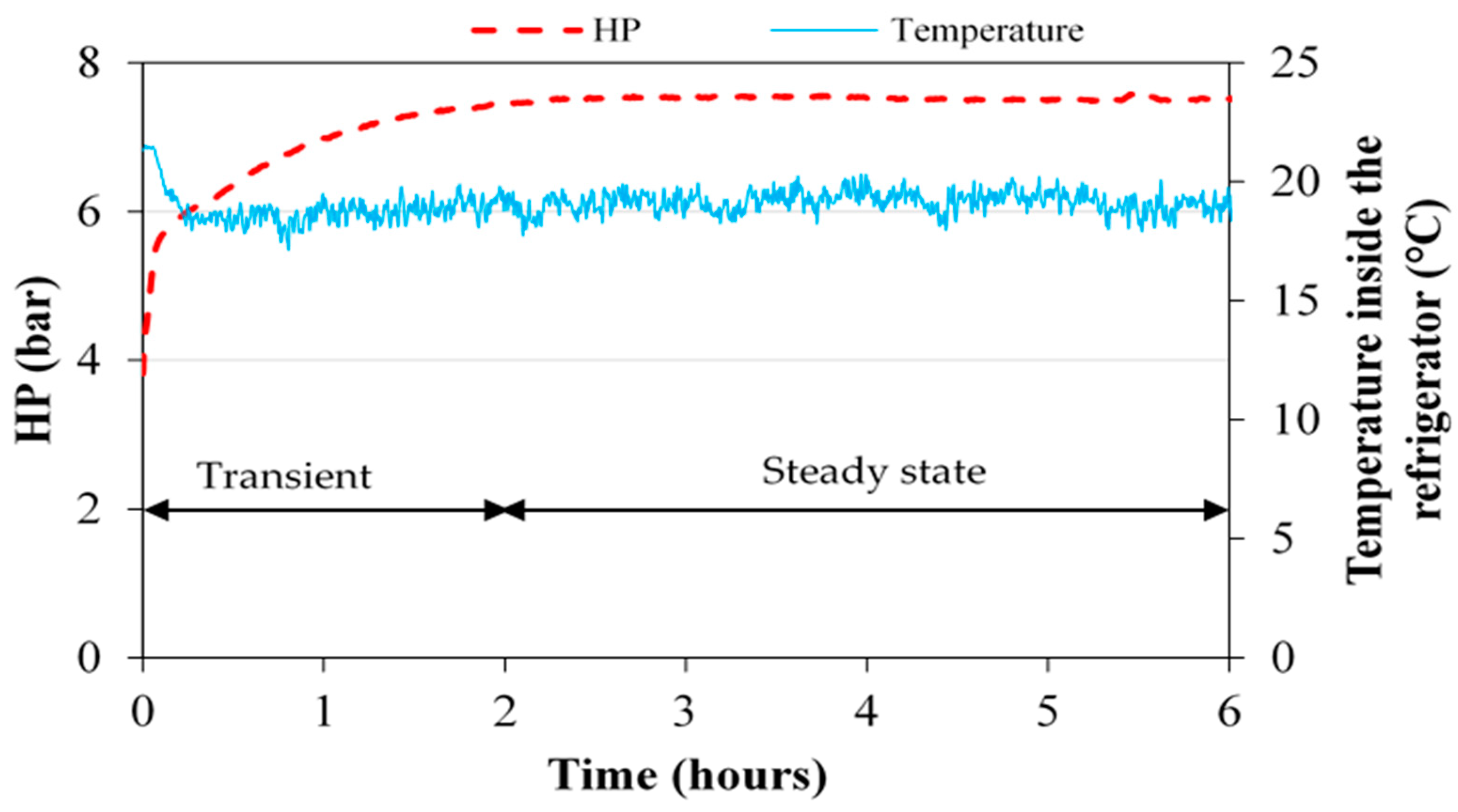

3.1. Continuous Compressor Operation (Door Wide Open)

3.1.1. Dynamic Evolution of High Pressure

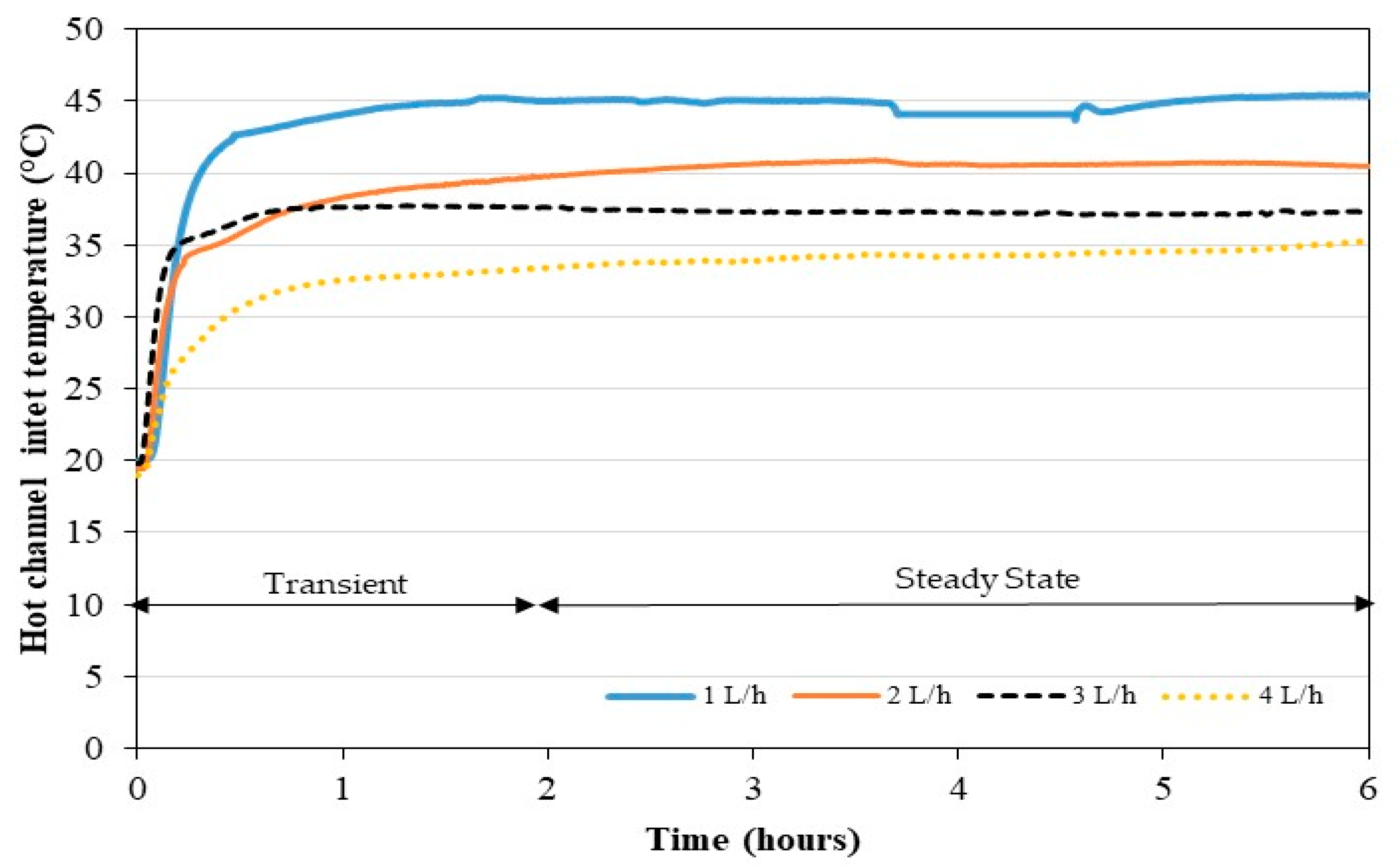

3.1.2. Effect of Flow Rate on Hot Channel Inlet Temperature and Permeate Flux in the Continuous Mode

3.1.3. Energy Analysis in Continuous Mode

3.2. Controlled Compressor Operation (Door Is Closed)

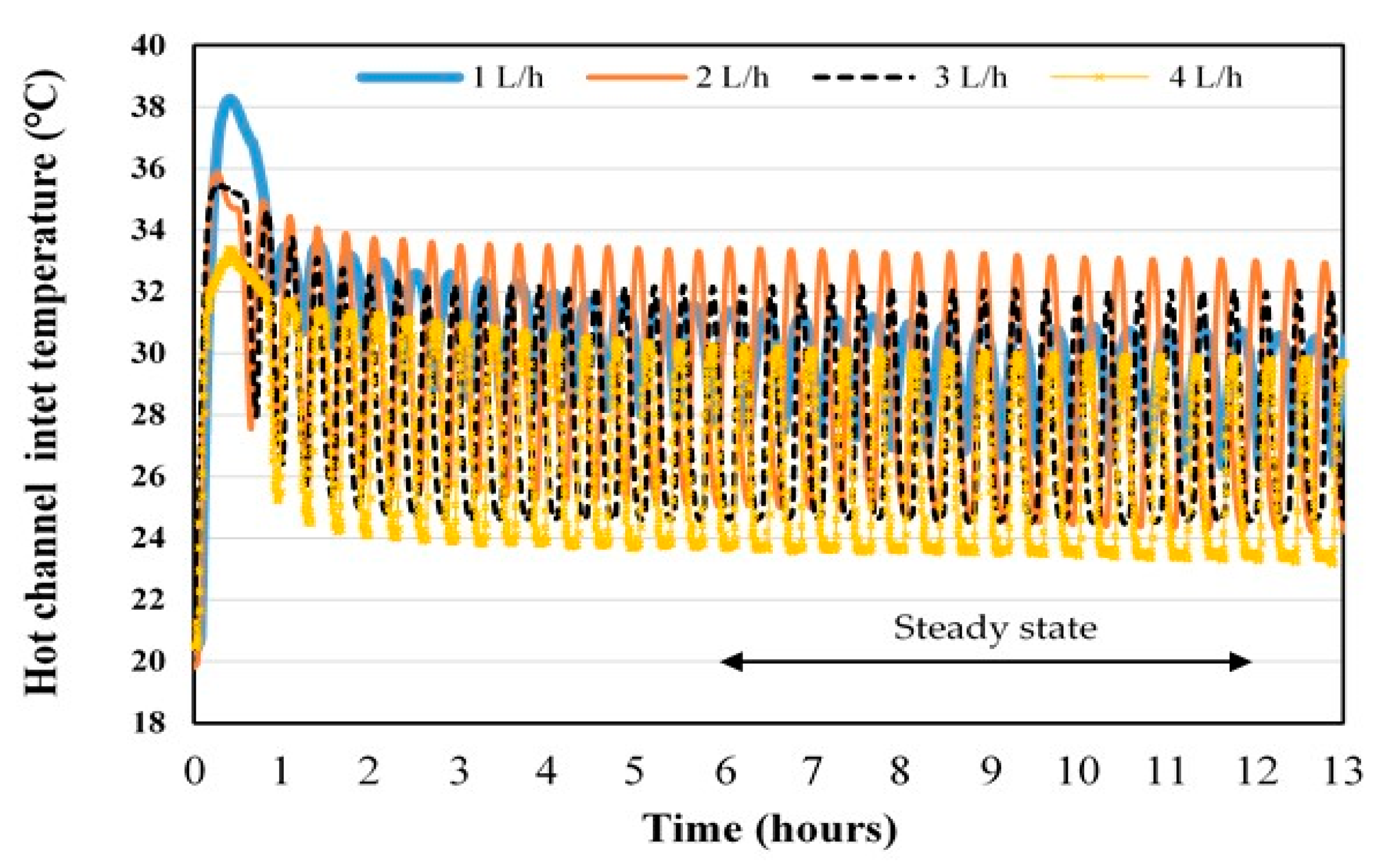

3.2.1. Evolution of the Air Temperature inside the Refrigerator Cabinet

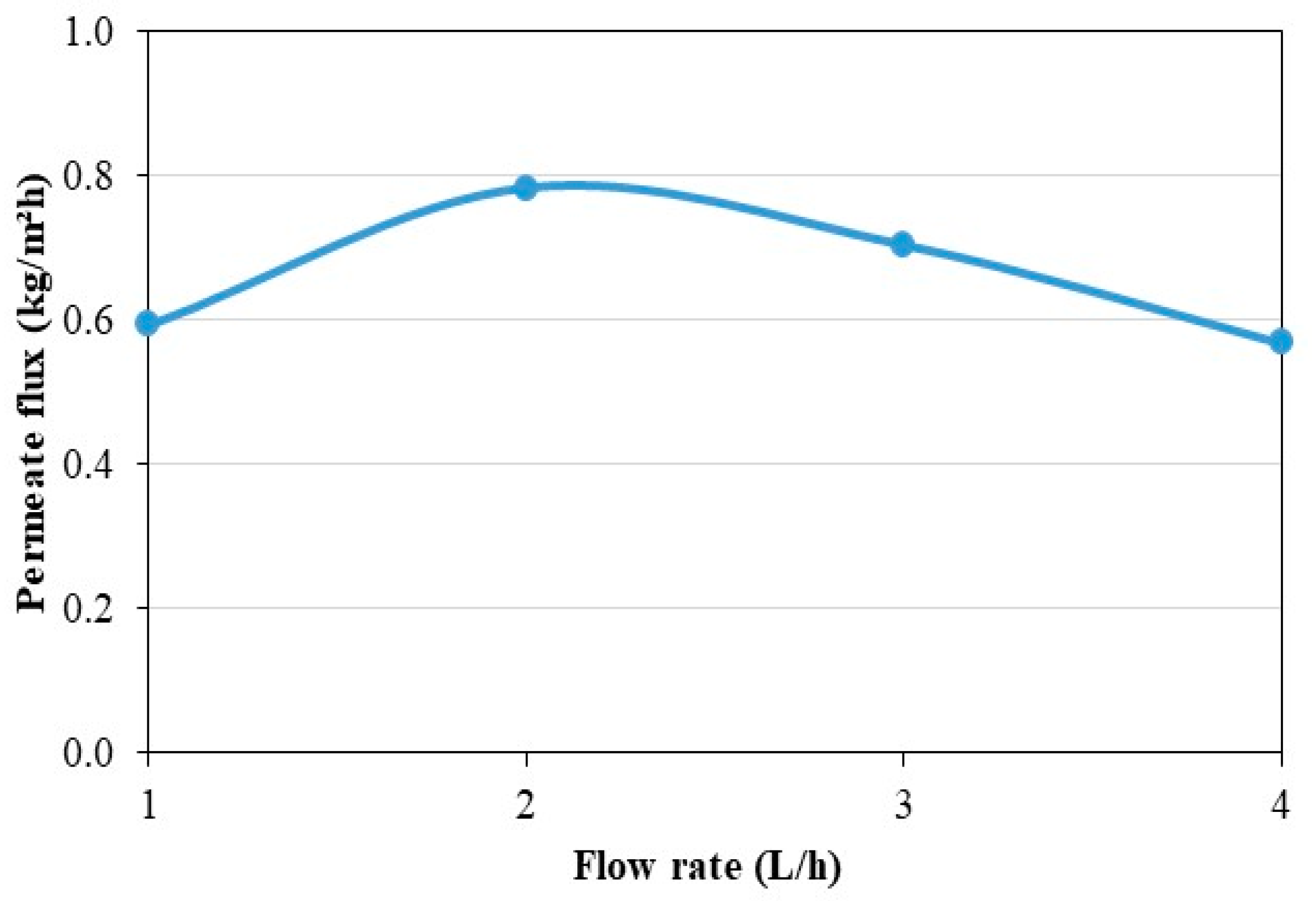

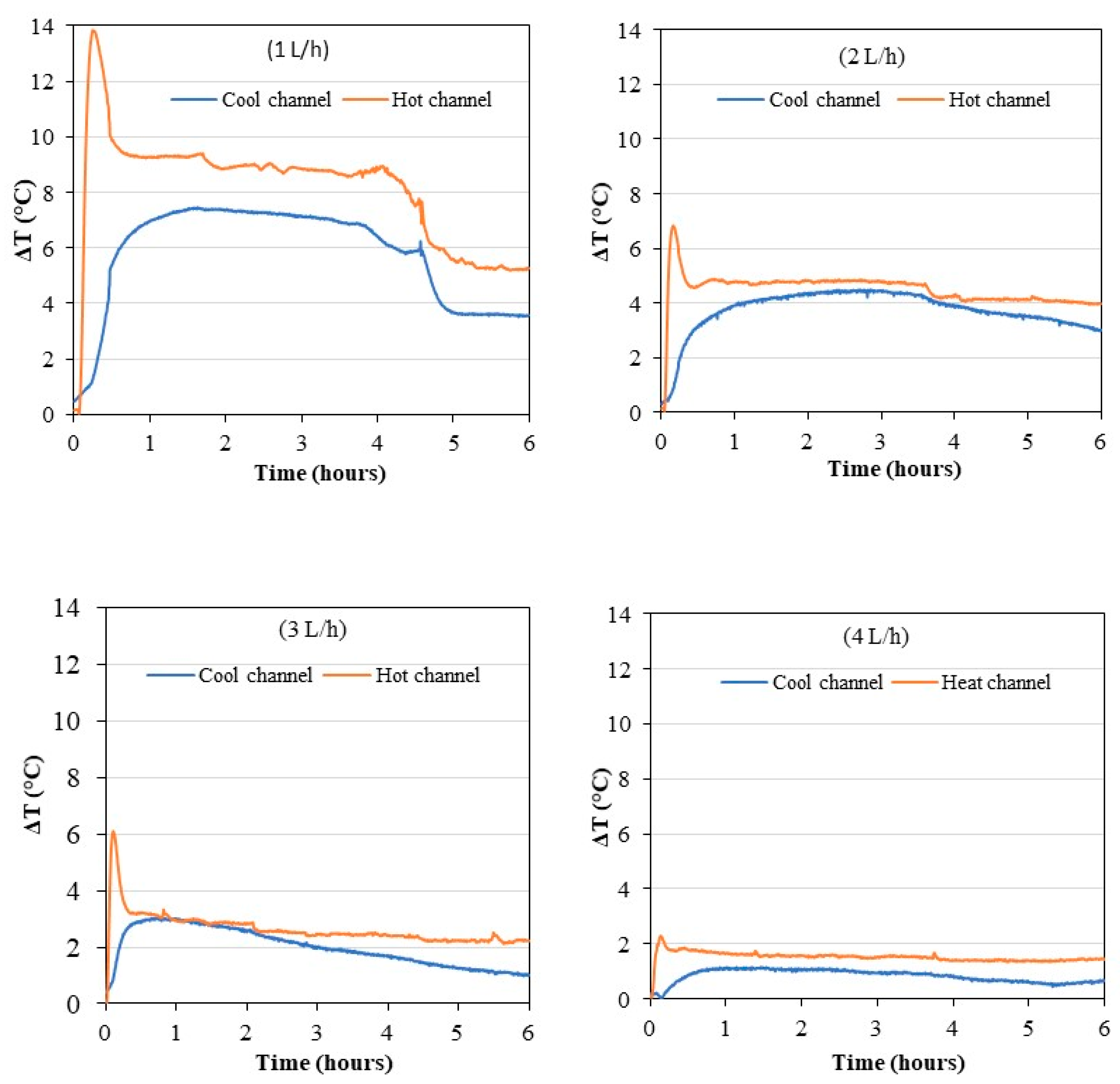

3.2.2. Effect of the Flow Rate on the Hot Channel Inlet Temperature and the Permeate Flux in Controlled Mode

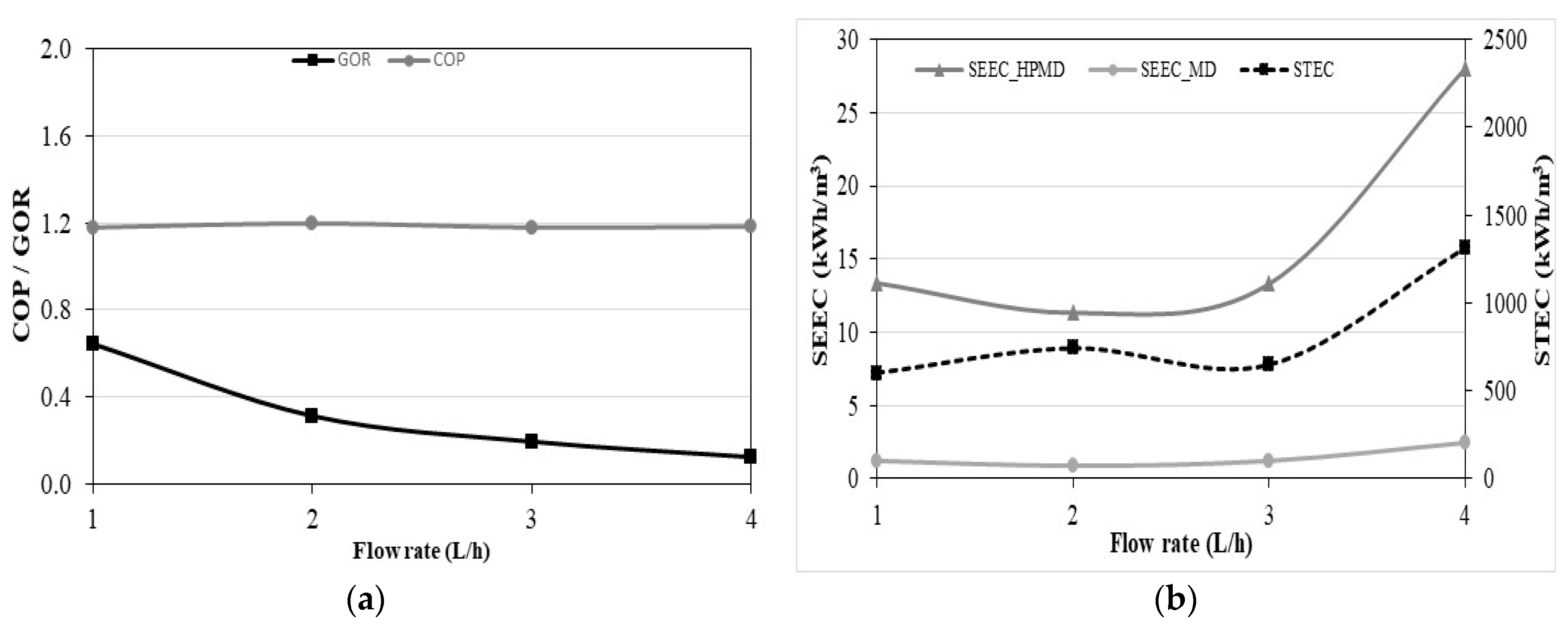

3.2.3. Energy Analysis in Controlled Mode

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AGMD | air gap membrane distillation |

| DCMD | direct contact membrane distillation |

| HP | heat pump |

| HPMD | heat pump and membrane distillation |

| MD | membrane distillation |

| PLA | polylactic acid |

| PGMD | permeate gap membrane distillation |

| SGMD | sweeping gas membrane distillation |

| VMD | vacuum membrane distillation |

| Variables: | |

| cp | Specific heat capacity (kJ/kg K) |

| COP | Coefficient of performance (-) |

| Δ | difference |

| Density (kg/m3) | |

| FFR | Feed flow rate (m3/s) |

| GOR | Gained output ratio (-) |

| h | Enthalpy (kJ/kg) |

| m | mass (kg) |

| PF | Permeate flux (kg/m²h) |

| SEEC | specific electric energy consumption (kWh/m3) |

| STEC | specific thermal energy consumption (kWh/m3) |

| T | temperature (K) |

| t | time (h) |

| mechanical power (W) | |

| Subscripts: | |

| c | cold |

| cd | condenser |

| elec | electric |

| ev | evaporator |

| f | feed |

| h | hot |

| in | inlet |

| nom | nominal |

| out | oulet |

| p | permeate |

| v | vaporization |

References

- Ren, Z.; Paevere, P.; Grozev, G.; Egan, S.; Anticev, J. Assessment of end-use electricity consumption and peak demand by Townsville’s housing stock. Energ. Policy 2013, 61, 888–893. [Google Scholar] [CrossRef]

- Hunt, J.D.; Weber, N.D.A.B.; Zakeri, B.; Diaby, A.T.; Byrne, P.; Filho, W.L.; Schneider, P.S. Deep seawater cooling and desalination: Combining seawater air conditioning and desalination. Sustain. Cities Soc. 2021, 74, 103257. [Google Scholar] [CrossRef]

- Byrne, P.; Fournaison, L.; Delahaye, A.; Oumeziane, Y.A.; Serres, L.; Loulergue, P.; Szymczyk, A.; Mugnier, D.; Malaval, J.-L.; Bourdais, R.; et al. A review on the coupling of cooling, desalination and solar photovoltaic systems. Renew. Sustain. Energy Rev. 2015, 47, 703–717. [Google Scholar] [CrossRef]

- Nassrullaha, H.; Anisa, S.F.; Hashaikeha, R.; Hilal, N. Energy for desalination: A state-of-the-art review. Desalination 2020, 491, 114569. [Google Scholar] [CrossRef]

- Drioli, E.; Ali, A.; Macedonio, F. Membrane distillation: Recent developments and perspectives. Desalination 2015, 356, 56–84. [Google Scholar] [CrossRef]

- Larbot, A.; Gazagnes, L.; Krajewski, S.; Bukowska, M.; Kujawski, W. Water desalination using ceramic membrane distillation. Desalination 2004, 168, 367–372. [Google Scholar] [CrossRef]

- Mericq, J.-P.; Laborie, S.; Cabassud, C. Vacuum membrane distillation for an integrated seawater desalination process. Desalination Water Treat. 2009, 9, 287–296. [Google Scholar] [CrossRef]

- Gálvez, J.B.; García-Rodríguez, L.; Martín-Mateos, I. Seawater desalination by an innovative solar-powered membrane distillation system: The Medesol project. Desalination 2009, 246, 567–576. [Google Scholar] [CrossRef]

- Diaby, A.T.; Byrne, P.; Loulergue, P.; Balannec, B.; Szymczyk, A.; Maré, T.; Sow, O. Design study of the coupling of an air gap membrane distillation unit to an air conditioner. Desalination 2017, 420, 308–317. [Google Scholar] [CrossRef]

- Khaing, T.-H.; Li, J.; Li, Y.; Wai, N.; Wong, F.-S. Feasibility study on petrochemical wastewater treatment and reuse using a novel submerged membrane distillation bioreactor. Sep. Purif. Technol. 2010, 74, 138–143. [Google Scholar] [CrossRef]

- Yao, M.; Woo, Y.C.; Ren, J.; Tijing, L.; Choi, J.-S.; Kim, S.-H.; Shon, H.K. Volatile fatty acids and biogas recovery using thermophilic anaerobic membrane distillation bioreactor for wastewater reclamation. J. Environ. Manag. 2018, 231, 833–842. [Google Scholar] [CrossRef] [PubMed]

- Laqbaqbi, M.; García-Payo, M.; Khayet, M.; El Kharraz, J.; Chaouch, M. Application of direct contact membrane distillation for textile wastewater treatment and fouling study. Sep. Purif. Technol. 2018, 209, 815–825. [Google Scholar] [CrossRef]

- Tufa, R.A.; Curcio, E.; Brauns, E.; van Baak, W.; Fontananova, E.; Di Profio, G. Membrane distillation and reverse electrodialysis for near-zero liquid discharge and low energy seawater desalination. J. Membr. Sci. 2015, 496, 325–333. [Google Scholar] [CrossRef]

- Xu, J.; Singh, Y.B.; Amy, G.L.; Ghaffour, N. Effect of operating parameters and membrane characteristics on air gap membrane distillation performance for the treatment of highly saline water. J. Membr. Sci. 2016, 512, 73–82. [Google Scholar] [CrossRef] [Green Version]

- Khiter, A.; Balannec, B.; Szymczyk, A.; Arous, O.; Nasrallah, N.; Loulergue, P. Behavior of volatile compounds in membrane distillation: The case of carboxylic acids. J. Membr. Sci. 2020, 612, 118453. [Google Scholar] [CrossRef]

- Loulergue, P.; Balannec, B.; Graët, L.F.-L.; Cabrol, A.; Sayed, W.; Djelal, H.; Amrane, A.; Szymczyk, A. Air-gap membrane distillation for the separation of bioethanol from algal-based fermentation broth. Sep. Purif. Technol. 2018, 213, 255–263. [Google Scholar] [CrossRef]

- Alkhudhiri, A.; Darwish, N.; Hilal, N. Membrane distillation: A comprehensive review. Desalination 2012, 287, 2–18. [Google Scholar] [CrossRef]

- González, D.; Amigo, J.; Suárez, F. Membrane distillation: Perspectives for sustainable and improved desalination. Renew. Sustain. Energy Rev. 2017, 80, 238–259. [Google Scholar] [CrossRef]

- Ma, Q.; Ahmadi, A.; Cabassud, C. Direct integration of a vacuum membrane distillation module within a solar collector for small-scale units adapted to seawater desalination in remote places: Design, modeling and evaluation of a flat-plate equipment. J. Membr. Sci. 2018, 564, 617–633. [Google Scholar] [CrossRef]

- Thomas, N.; Mavukkandy, M.O.; Loutatidou, S.; Arafat, H. Membrane distillation research and implementation: Lessons from the past five decades. Sep. Purif. Technol. 2017, 189, 108–127. [Google Scholar] [CrossRef]

- Khayet, M. Solar desalination by membrane distillation: Dispersion in energy consumption analysis and water production costs (A review). Desalination 2013, 308, 89–101. [Google Scholar] [CrossRef]

- Zaragoza, G.; Andrés-Mañas, J.; Ruiz-Aguirre, A. Commercial scale membrane distillation for solar desalination. NPJ Clean Water 2018, 1, 20. [Google Scholar] [CrossRef] [Green Version]

- Deshmukh, A.; Boo, C.; Karanikola, V.; Lin, S.; Straub, A.; Tong, T.; Warsinger, D.M.; Elimelech, M. Membrane distillation at the water-energy nexus: Limits, opportunities, and challenges. Energy Environ. Sci. 2018, 11, 1177–1196. [Google Scholar] [CrossRef]

- Ahmed, F.E.; Lalia, B.S.; Hashaikeh, R.; Hilal, N. Alternative heating techniques in membrane distillation: A review. Desalination 2020, 496, 114713. [Google Scholar] [CrossRef]

- Glassley, W.E. Geothermal Energy: Renewable Energy and the Environment; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Dickson, M.H.; Fanelli, M. Geothermal Energy: Utilization and Technology; Routledge: Abingdon-on-Thames, UK, 2013. [Google Scholar]

- Lund, J.W.; Boyd, T.L. Direct utilization of geothermal energy 2015—Worldwide review. Geothermics 2016, 60, 66–93. [Google Scholar] [CrossRef]

- Sarbatly, R.; Chiam, C.-K. Evaluation of geothermal energy in desalination by vacuum membrane distillation. Appl. Energy 2013, 112, 737–746. [Google Scholar] [CrossRef]

- Ozbey-Unal, B.; Koseoglu-Imer, D.Y.; Keskinler, B.; Koyuncu, I. Boron removal from geothermal water by air gap membrane distillation. Desalination 2018, 433, 141–150. [Google Scholar] [CrossRef]

- Gude, V.G. Energy storage for desalination processes powered by renewable energy and waste heat sources. Appl. Energy 2015, 137, 877–898. [Google Scholar] [CrossRef]

- Ammar, Y.; Joyce, S.; Norman, R.; Wang, Y.; Roskilly, A.P. Low grade thermal energy sources and uses from the process industry in the UK. Appl. Energy 2012, 89, 3–20. [Google Scholar] [CrossRef]

- Forman, C.; Muritala, I.K.; Pardemann, R.; Meyer, B. Estimating the global waste heat potential. Renew. Sustain. Energy Rev. 2016, 57, 1568–1579. [Google Scholar] [CrossRef]

- Cullen, J.M.; Allwood, J. Theoretical efficiency limits for energy conversion devices. Energy 2010, 35, 2059–2069. [Google Scholar] [CrossRef]

- Xu, Y.; Zhu, B.-K.; Xu, Y.-Y. Pilot test of vacuum membrane distillation for seawater desalination on a ship. Desalination 2006, 189, 165–169. [Google Scholar] [CrossRef]

- Gustafson, R.D.; Hiibel, S.R.; Childress, A.E. Membrane distillation driven by intermittent and variable-temperature waste heat: System arrangements for water production and heat storage. Desalination 2018, 448, 49–59. [Google Scholar] [CrossRef]

- Wahlroos, M.; Pärssinen, M.; Manner, J.; Syri, S. Utilizing data center waste heat in district heating—Impacts on energy efficiency and prospects for low-temperature district heating networks. Energy 2017, 140, 1228–1238. [Google Scholar] [CrossRef]

- Turek, D.; Radgen, P. Optimized data center site selection—Mesoclimatic effects on data center energy consumption and costs. Energy Effic. 2021, 14, 33. [Google Scholar] [CrossRef]

- Hintemann, R.; Hinterholzer, S. Energy consumption of data centers worldwide. How will the Internet become green? In Proceedings of the 6th International Conference on ICT for Sustainability (ICT4S), Lappeenranta, Finland, 10–14 June 2019; Available online: http://ceur-ws.org/Vol-2382/ICT4S2019_paper_16.pdf (accessed on 19 September 2021).

- Ebrahimi, K.; Jones, G.F.; Fleischer, A.S. A review of data center cooling technology, operating conditions and the corresponding low-grade waste heat recovery opportunities. Renew. Sustain. Energy Rev. 2014, 31, 622–638. [Google Scholar] [CrossRef]

- Capozzoli, A.; Primiceri, G. Cooling systems in data centers: State of art and emerging technologies. Energy Procedia 2015, 83, 484–493. [Google Scholar] [CrossRef] [Green Version]

- Al-Karaghouli, A.; Kazmerski, L.L. Energy consumption and water production cost of conventional and renewable-energy-powered desalination processes. Renew. Sustain. Energy Rev. 2013, 24, 343–356. [Google Scholar] [CrossRef]

- Byrne, P. Chapter 4. Advances in air-source heat pump water heaters. In Novel Concepts for Energy-Efficient Water Heating Systems: Theoretical Analysis and Experimental Investigation; Douglas, F.B., Vivaldo, S., Eds.; Nova Science Publishers: Hauppauge, NY, USA, 2013; pp. 93–122. [Google Scholar]

- Byrne, P.; Ghoubali, R.; Diaby, A.T. Chapter 1. Heat pumps for simultaneous heating and cooling. In Heat Pumps: Performance and Applications; Tea, E., Ed.; Nova Science Publishers: Hauppauge, NY, USA, 2018; pp. 1–35. [Google Scholar]

- Tan, Y.Z.; Han, L.; Chew, N.G.P.; Chow, W.H.; Wang, R.; Chew, J.W. Membrane distillation hybridized with a thermoelectric heat pump for energy-efficient water treatment and space cooling. Appl. Energy 2018, 231, 1079–1088. [Google Scholar] [CrossRef]

- Johnson, W.E. Indirect freezing. Desalination 1979, 31, 417–425. [Google Scholar] [CrossRef]

- Slesarenko, V.V. Heat pumps as a source of heat energy for desalination of seawater. Desalination 2001, 139, 405–410. [Google Scholar] [CrossRef]

- Diaby, A.T.; Byrne, P.; Maré, T. Simulation of heat pumps for simultaneous heating and cooling using CO2. Int. J. Refrig. 2019, 106, 616–627. [Google Scholar] [CrossRef]

- Khalifa, A.; Lawal, D.; Antar, M.; Khayet, M. Experimental and theoretical investigation on water desalination using air gap membrane distillation. Desalination 2015, 376, 94–108. [Google Scholar] [CrossRef]

- Byrne, P. Energy Efficiency of Heat Pumps for Simultaneous Heating and Cooling. Mémoire d’Habilitation à Diriger des Re-Cherches. Available online: https://hal.archives-ouvertes.fr/tel-03239929/document (accessed on 19 September 2021).

- Karabelas, A.J.; Koutsou, C.P.; Kostoglou, M.; Sioutopoulos, D.C. Analysis of specific energy consumption in reverse osmosis desalination processes. Desalination 2018, 431, 15–21. [Google Scholar] [CrossRef]

- Najib, A.; Orfi, J.; Alansary, H.; Ali, E. Assessing the impact of operating conditions on the energy and exergy efficiency for multi-effect vacuum membrane distillation systems. Water 2021, 13, 1500. [Google Scholar] [CrossRef]

- Bouguecha, S.; Dhahbi, M. Fluidised bed crystalliser and air gap membrane distillation as a solution to geothermal water desal-ination. Desalination 2002, 152, 237–244. [Google Scholar] [CrossRef]

- Izquierdo-Gil, M.A.; Garcıa-Payo, M.C.; Fernandez-Pineda, C. Air gap membrane distillation of sucrose aqueous solutions. J. Membr. Sci. 1999, 155, 291–307. [Google Scholar] [CrossRef]

- Khalifa, A.E.; Alawad, S.M. Air gap and water gap multistage membrane distillation for water desalination. Desalination 2018, 437, 175–183. [Google Scholar] [CrossRef]

- Andrés-Mañas, J.; Ruiz-Aguirre, A.; Acién, F.; Zaragoza, G. Assessment of a pilot system for seawater desalination based on vacuum multi-effect membrane distillation with enhanced heat recovery. Desalination 2018, 443, 110–121. [Google Scholar] [CrossRef]

- Ong, C.L.; Escher, W.; Paredes, S.; Khalil, A.; Michel, B. A novel concept of energy reuse from high concentration photovoltaic thermal (HCPVT) system for desalination. Desalination 2012, 295, 70–81. [Google Scholar] [CrossRef]

- Zaragoza, G.; Ruiz-Aguirre, A.; Guillén-Burrieza, E. Efficiency in the use of solar thermal energy of small membrane desalina-tion systems for decentralized water production. Appl. Energy 2014, 130, 491–499. [Google Scholar] [CrossRef]

- Khalifa, A.E.; Alawad, S.M.; Antar, M.A. Parallel and series multistage air gap membrane distillation. Desalination 2017, 417, 69–76. [Google Scholar] [CrossRef]

| MD Technique | Acronym | Advantages | Drawbacks |

|---|---|---|---|

| Direct contact | DCMD | Simplicity | Higher wettability |

| Air gap | AGMD | Simplicity, Low wettability | Lower permeate flux |

| Sweeping gas | SGMD | High permeate flux | External water condensation (additional device) |

| Vacuum | VMD | High permeate flux | External water condensation (additional device) |

| Permeate gap | PGMD | Simplicity | Higher wettability |

| Value | Sensor/Measurement Method | Uncertainties |

|---|---|---|

| Pressure sensors | Johnson Controls | ±1% |

| Temperature | Type K Thermocouple | ±0.5 °C |

| Precision scales | Adam Nimbus | 0.01 g |

| Flow rate | Variable area flowmeter | 10% |

| Power | Current transformer | ±1% |

| Flow Rate (L/h) | Average Hot Feed Temperature (°C) | Average Temperature Difference (K) |

|---|---|---|

| 1 | 30.29 | 4.20 |

| 2 | 29.3 | 7.00 |

| 3 | 28.08 | 6.60 |

| 4 | 26.90 | 6.40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Diaby, A.T.; Byrne, P.; Loulergue, P.; Sow, O.; Maré, T. Experimental Study of a Heat Pump for Simultaneous Cooling and Desalination by Membrane Distillation. Membranes 2021, 11, 725. https://doi.org/10.3390/membranes11100725

Diaby AT, Byrne P, Loulergue P, Sow O, Maré T. Experimental Study of a Heat Pump for Simultaneous Cooling and Desalination by Membrane Distillation. Membranes. 2021; 11(10):725. https://doi.org/10.3390/membranes11100725

Chicago/Turabian StyleDiaby, Ahmadou Tidiane, Paul Byrne, Patrick Loulergue, Ousmane Sow, and Thierry Maré. 2021. "Experimental Study of a Heat Pump for Simultaneous Cooling and Desalination by Membrane Distillation" Membranes 11, no. 10: 725. https://doi.org/10.3390/membranes11100725