Microintaglio Printing for Soft Lithography-Based in Situ Microarrays

Abstract

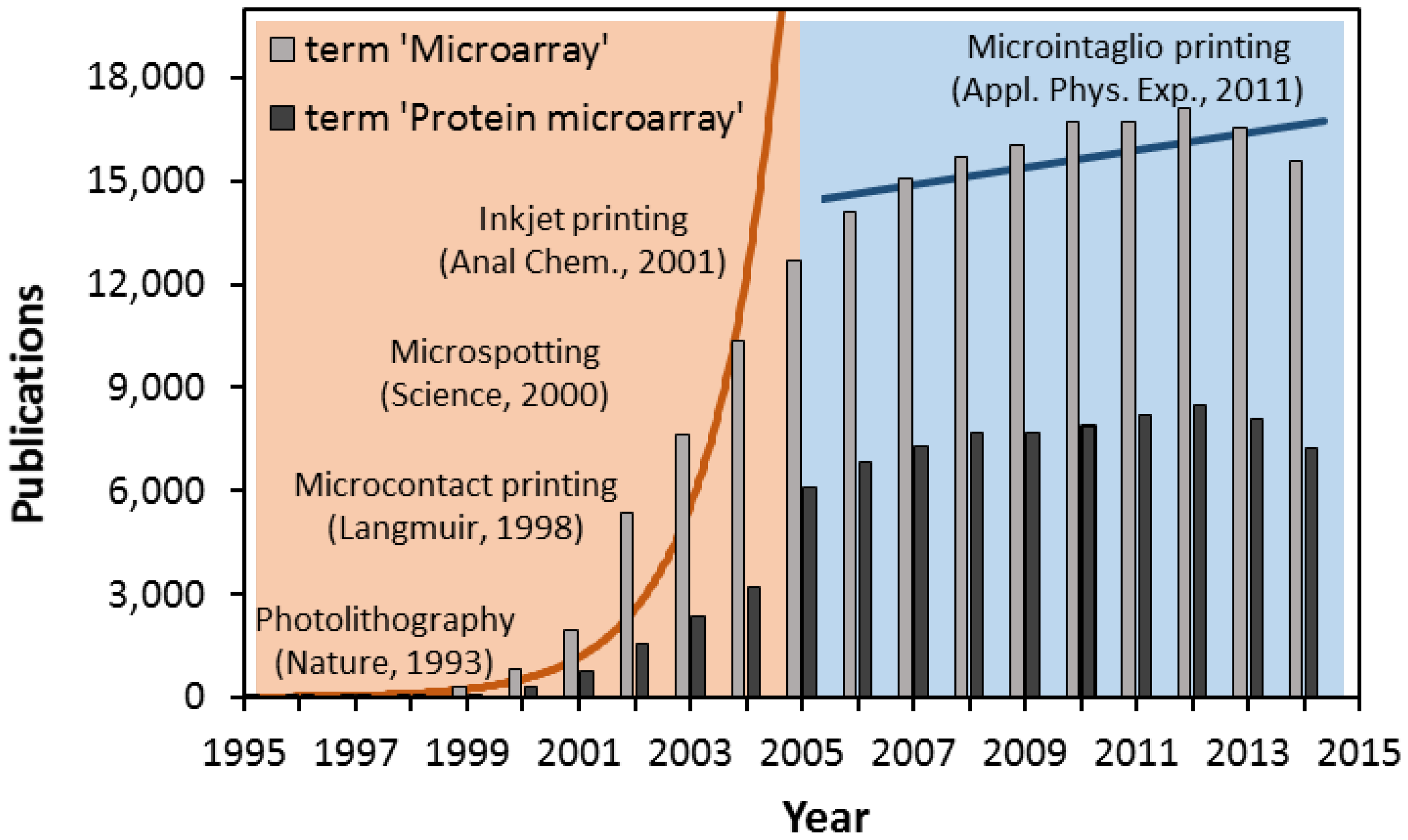

:1. Introduction

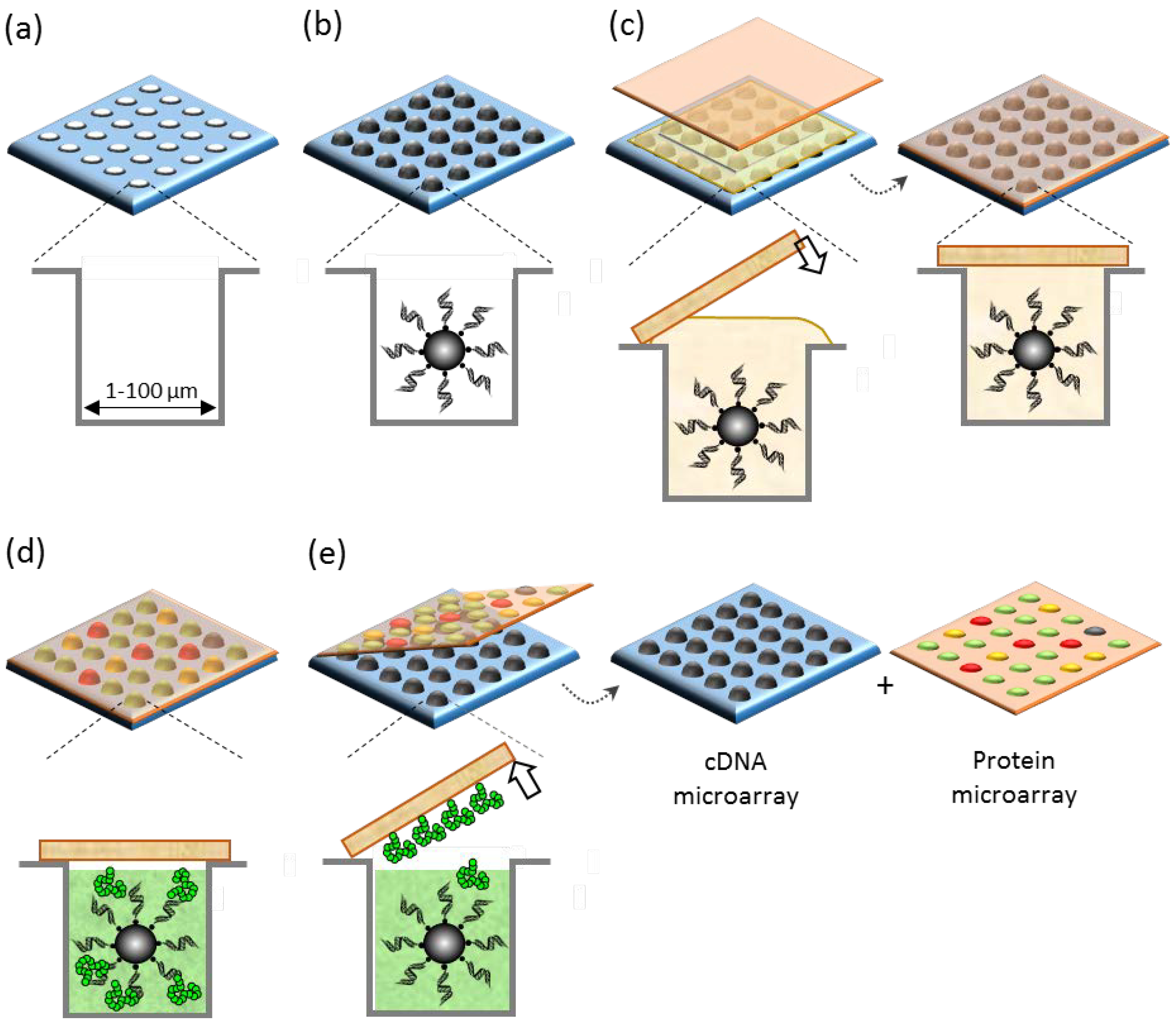

2. Concept of Microintaglio Printing

2.1. Fabrication of Arrays of Microchambers

2.2. Self-Organization and Arraying of Precursors of Biomolecular Ink

2.3. In Situ Synthesis and Patterning of Microarrays

3. Microintaglio Printing-Based Biomolecular Microarrays

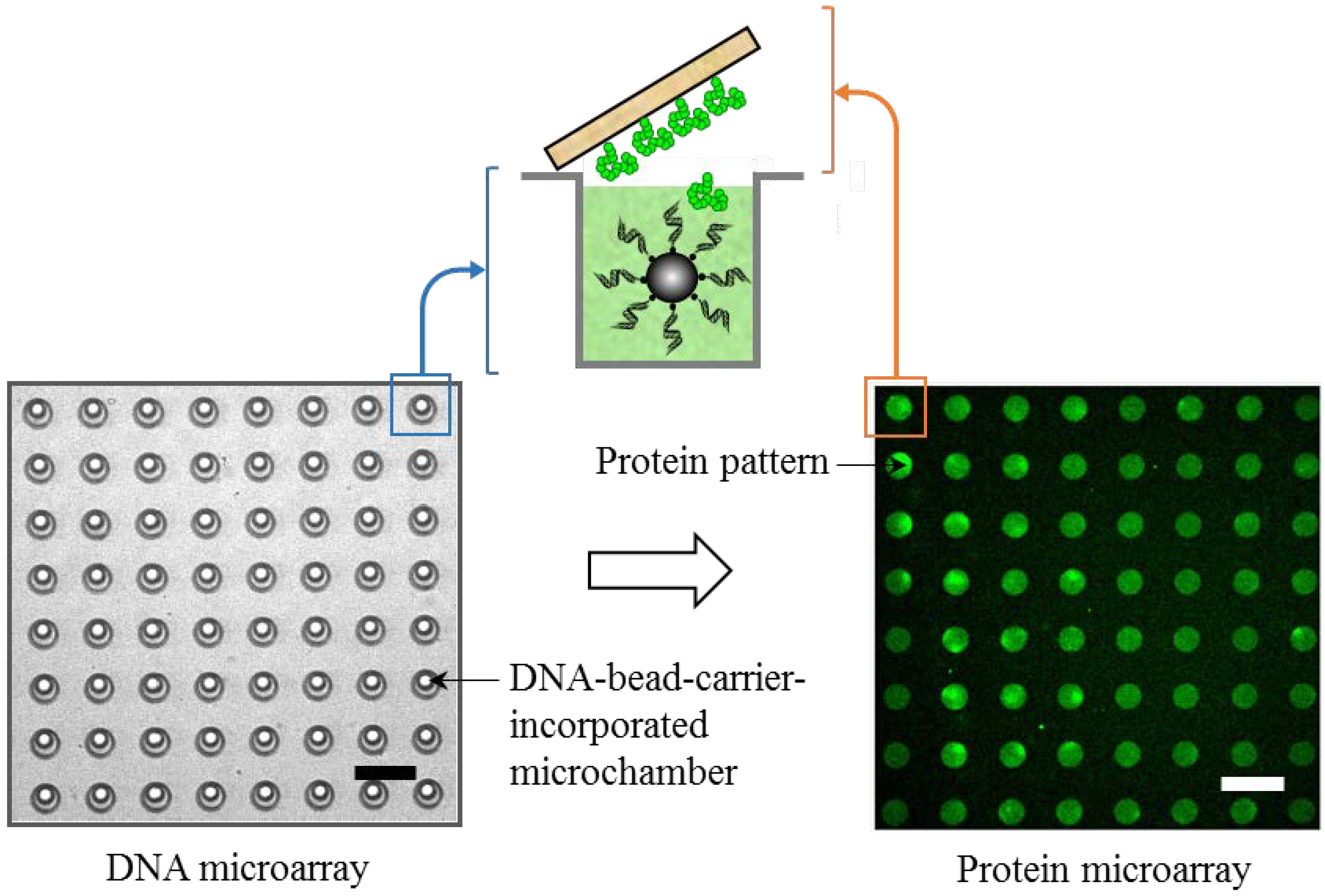

3.1. Printing and Arraying of Ready-To-Print Biomolecular Ink

3.2. Printing and Arraying of In Situ-Synthesized Biomolecular Ink

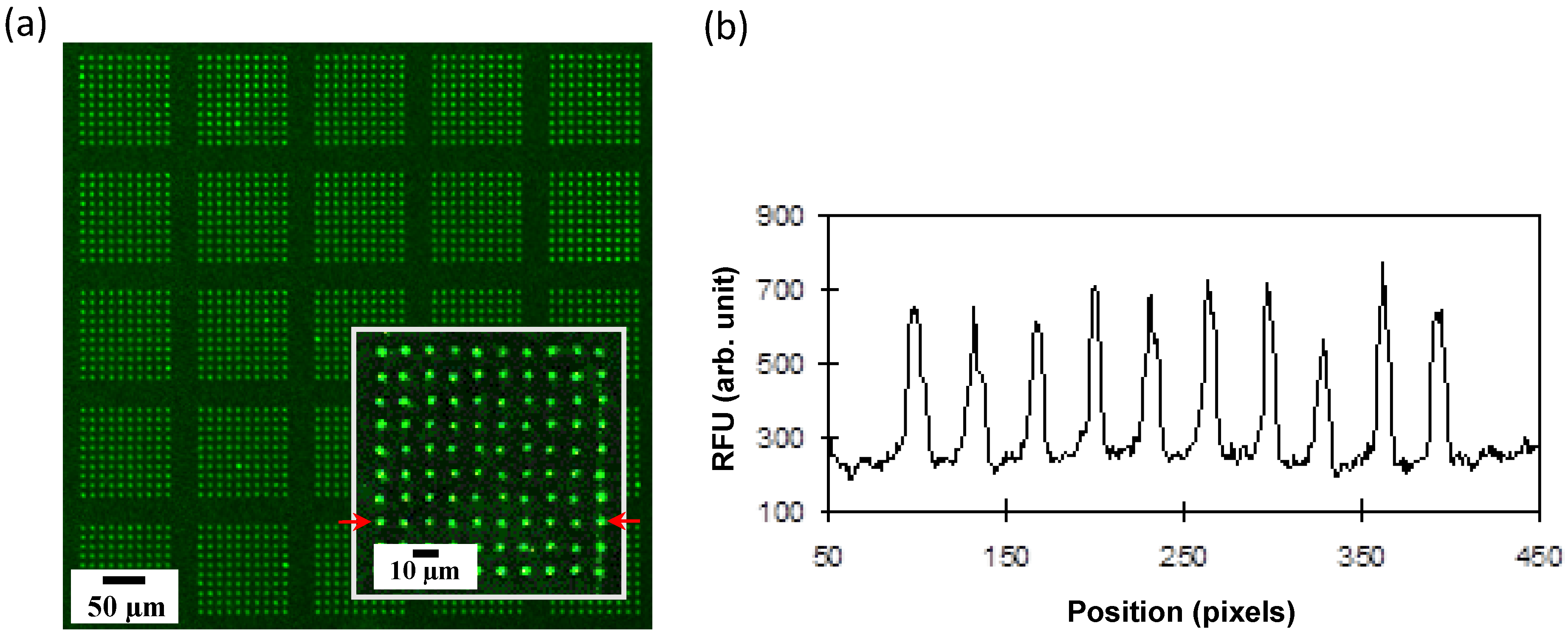

3.3. Instrument-Free Arraying of “Kilo-Giga”-Dense Microarrays with High Resolution

4. Outlook and Future Direction of µIP

Acknowledgments

Conflicts of Interest

References

- Brown, P.O.; Botstein, D. Exploring the new world of the genome with DNA microarrays. Nat. Genet. 1999, 21, 33–37. [Google Scholar] [CrossRef] [PubMed]

- Hoheisel, J.D. Microarray technology: Beyond transcript profiling and genotype analysis. Nat. Rev. Genet. 2006, 3, 200–210. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.R.; Magee, D.M.; Gaster, R.S.; la Baer, J.; Wang, S.X. Emerging protein array technologies for proteomics. Expert Rev. Proteomics 2013, 10, 65–75. [Google Scholar] [CrossRef] [PubMed]

- Delehanty, J.B. Printing functional protein microarrays using piezoelectric capillaries. Methods Mol. Biol. 2004, 264, 135–143. [Google Scholar] [PubMed]

- Branch, D.W.; Corey, J.M.; Weyhenmeyer, J.A.; Brewer, G.J.; Wheeler, B.C. Microstamp patterns of biomolecules for high-resolution neuronal networks. Med. Biol. Eng. Comput. 1998, 36, 135–141. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Whitesides, G.M. Features of gold having micrometer to centimeter dimensions can be formed through a combination of stamping with an elastomeric stamp and an alkanethiol “ink” followed by chemical etching. Appl. Phys. Lett. 1993, 63, 2002–2004. [Google Scholar] [CrossRef]

- MacBeath, G.; Schreiber, S.L. Printing proteins as microarrays for high-throughput function determination. Science 2000, 289, 1760–1763. [Google Scholar] [PubMed]

- Allain, L.R.; Askari, M.; Stokes, D.L.; Vo-Dinh, T. Microarray sampling-platform fabrication using bubble-jet technology for a biochip system. Fresenius J. Anal. Chem. 2001, 371, 146–150. [Google Scholar] [CrossRef] [PubMed]

- Ringeisen, B.R.; Wu, P.K.; Kim, H.; Piqué, A.; Auyeung, R.Y.; Young, H.D.; Chrisey, D.B.; Krizman, D.B. Picoliter-scale protein microarrays by laser direct write. Biotechnol. Prog. 2002, 18, 1126–1129. [Google Scholar] [CrossRef] [PubMed]

- Okamoto, T.; Suzuki, T.; Yamamoto, N. Microarray fabrication with covalent attachment of DNA using Bubble Jet technology. Nat. Biotechnol. 2000, 18, 438–441. [Google Scholar] [PubMed]

- Cai, Y.; Ocko, B.M. Large-scale fabrication of protein nanoarrays based on nanosphere lithography. Langmuir 2005, 21, 9274–9279. [Google Scholar] [CrossRef] [PubMed]

- Dixit, C.K.; Kumar, A.; Kaushik, A. Nanosphere lithography-based platform for developing rapid and high sensitivity microarray systems. Biochem. Biophys. Res. Commun. 2012, 423, 473–477. [Google Scholar] [CrossRef] [PubMed]

- Barbulovic-Nad, I.; Lucente, M.; Sun, Y.; Zhang, M.; Wheeler, A.R.; Bussmann, M.A. Bio-microarray fabrication techniques—A review. Crit. Rev. Biotechnol. 2006, 26, 237–259. [Google Scholar] [CrossRef] [PubMed]

- Auburn, R.P.; Kreil, D.P.; Meadows, L.A.; Fischer, B.; Matilla, S.S.; Russell, S. Robotic spotting of cDNA and oligonucleotide microarrays. Trends Biotechnol. 2005, 23, 374–379. [Google Scholar] [CrossRef] [PubMed]

- Xia, Y.; Whitesides, G.M. Soft Lithography. Angew. Chem. Int. Ed. 1998, 37, 550–575. [Google Scholar] [CrossRef]

- Rolland, J.P.; Hagberg, E.C.; Denison, G.M.; Carter, K.R.; DeSimone, J.M. High resolution soft lithography: Enabling materials for nanotechnologies. Angew. Chem. Int. Ed. Engl. 2004, 43, 5796–5799. [Google Scholar] [CrossRef] [PubMed]

- Fodor, S.P.; Read, J.L.; Pirrung, M.C.; Stryer, L.; Lu, A.T.; Solas, D. Light-directed, spatially addressable parallel chemical synthesis. Science 1991, 251, 767–773. [Google Scholar] [CrossRef] [PubMed]

- Pirrung, M.C. How to make a DNA chip. Angew. Chem. Int. Ed. 2002, 41, 1276–1289. [Google Scholar] [CrossRef]

- Lockhart, D.J.; Dong, H.; Byrne, M.C.; Follettie, M.T.; Gallo, M.V.; Chee, M.S.; Mittmann, M.; Wang, C.; Kobayashi, M.; Horton, H.; et al. Expression monitoring by hybridization to high-density oligonucleotide arrays. Nat. Biotech. 1996, 14, 1675–1680. [Google Scholar] [CrossRef] [PubMed]

- Quan, J.; Saaem, I.; Tang, N.; Ma, S.; Negre, N.; Gong, H.; White, K.P.; Tian, J. Parallel on-chip gene synthesis and application to optimization of protein expression. Nat. Biotechnol. 2011, 29, 449–452. [Google Scholar] [CrossRef] [PubMed]

- Biyani, M.; Osawa, T.; Nemoto, N.; Ichiki, T. Microintaglio printing of biomolecules and its application to in situ production of messenger ribonucleic acid display microarray. Appl. Phys. Express 2011, 4, 047001. [Google Scholar] [CrossRef]

- Biyani, M.; Moriyasu, J.; Tanaka, Y.; Sato, S.; Ueno, S.; Ichiki, T. Microintaglio printing of in Situ synthesized proteins enables rapid printing of high-density protein microarrays directly from dna microarrays. Appl. Phys. Express 2013, 6, 087001. [Google Scholar] [CrossRef]

- Biyani, M.; Shiono, H.; Ichiki, T. Japan Patent Application. Patent 2012-70654, 1 March 2012. [Google Scholar]

- Biyani, M.; Sato, S.; Fujita, T.; Akagi, T.; Ichiki, T. Kilo-to-giga DNA microarray for high-density protein microarray on-demand. In Proceedings of the 14th International Conference on Miniaturized Systems for Chemistry and Life Sciences, Groningen, The Netherlands, 3–7 October 2010; pp. 734–736.

- Diehl, F.; Li, M.; He, Y.; Kinzler, K.W.; Vogelstein, B.; Dressman, D. BEAMing: Single-molecule PCR on microparticles in water-in-oil emulsions. Nat. Methods 2006, 3, 551–559. [Google Scholar] [CrossRef] [PubMed]

- Sato, S.; Biyani, M.; Akagi, T.; Ichiki, T. On-chip synthesis of mutant GFP library using ultra-large self-aligned DNA-bound beads microarray. In Proceedings of the 15th International Conference on Miniaturized Systems for Chemistry and Life Sciences, Seattle, WA, USA, 2–6 October 2011; Landers, J.P., Herr, A., Juncker, D., Pamme, N., Blenvenue, J., Eds.; pp. 765–767.

- Seetharaman, S.; Zivarts, M.; Sudarsan, N.; Breaker, R.R. Immobilized RNA switches for the analysis of complex chemical and biological mixtures. Nat. Biotechnol. 2001, 19, 336–341. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Crooks, R.M. Parallel fabrication of RNA microarrays by mechanical transfer from a DNA master. Anal. Chem. 2007, 79, 8994–8999. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Nakamoto, K.; Niwa, O.; Corn, R.M. On-chip synthesis of RNA aptamer microarrays for multiplexed protein biosensing with SPR imaging measurements. Langmuir 2012, 28, 8281–8285. [Google Scholar] [CrossRef] [PubMed]

- Kobayashi, R.; Biyani, M.; Ueno, S.; Kumal, S.R.; Kuramochi, H.; Ichiki, T. Temperature-controlled microintaglio printing for high-resolution micropatterning of RNA molecules. Biosens. Bioelectron. 2015, 67, 115–120. [Google Scholar] [CrossRef] [PubMed]

- Biyani, M.; Osawa, T.; Nemoto, N.; Ichiki, T. One-to-one gene-encoded functional protein microarray. In Proceedings of the Twelfth International Conference on Miniaturized Systems for Chemistry and Life Sciences, San Diego, CA, USA, 12–16 October 2008; pp. 1781–1783.

- Biyani, M.; Nemoto, N.; Ichiki, T. DNA-linked protein array for high-throughput proteomics: From spatially unknown DNA arrays to identifiable protein arrays. NANO Life 2010, 1, 33–43. [Google Scholar] [CrossRef]

- Toepke, M.W.; Beebe, D.J. PDMS absorption of small molecules and consequences in microfluidic applications. Lab. Chip 2006, 6, 1484–1486. [Google Scholar] [CrossRef] [PubMed]

- Biyani, M.; Tanaka, Y.; Sato, S.; Ueno, S.; Ichiki, T. Evaluation of poly(dimethylsiloxane) microreactors for pattern size miniaturization of microintaglio-printing-based protein microarray. Jpn. J. Appl. Phys. 2014, 53. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biyani, M.; Ichiki, T. Microintaglio Printing for Soft Lithography-Based in Situ Microarrays. Microarrays 2015, 4, 311-323. https://doi.org/10.3390/microarrays4030311

Biyani M, Ichiki T. Microintaglio Printing for Soft Lithography-Based in Situ Microarrays. Microarrays. 2015; 4(3):311-323. https://doi.org/10.3390/microarrays4030311

Chicago/Turabian StyleBiyani, Manish, and Takanori Ichiki. 2015. "Microintaglio Printing for Soft Lithography-Based in Situ Microarrays" Microarrays 4, no. 3: 311-323. https://doi.org/10.3390/microarrays4030311