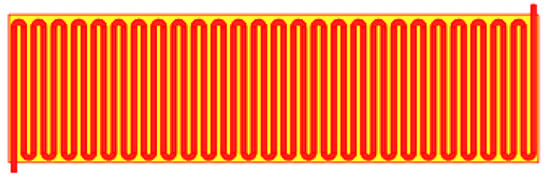

As mentioned in this work, by means of numerical simulations, five designs of bipolar plate geometries of fuel cells were made and compared to different air flow fields adjacent to a PEMFC oxygen cathode. Based on the obtained results, we can mention that in Designs 1 and 2 (

Figure 2), the flow rate observed was very slow at the square corners when the flow changed direction abruptly (

Figure 2A). In this sense, it is possible to suppose that the water of the system could accumulate in the mentioned corners, and consequently, an uneven distribution of gas and current can be observed. A region of very slow flow velocity was not observed when the direction of flow gradually changed (

Figure 2B).

Figure 2C,D presents the electric current distributions at a high potential of a high cathode (0.8 V).

Figure 3 shows the variation of electric current in the axis, and the electric current gradually decreased along the axis and with the maximum value near the input. Several reports showed the comparisons of designs in terms of pressure drop with the increase in the Reynolds number (Equation (9)). According to Boddu [

31] and Rivas [

32], for the square serpentine geometries (Design 1) the pressure drops are higher compared to the designs with curves (Design 2). A large pressure drop leads to inefficient fuel cell performance. In addition, because the lack of fuel is more likely to occur in Design 1, Design 2 was selected as the standard to be modified to create Design 3; see

Figure 1C. The mass fraction distributions were more uniform in Designs 4 and 5 than in Designs 1, 2, and 3. With a cathode overpotential of 0.66 V, the final mass fraction of oxygen in the gas diffusion layer was slightly below 0.123 in Design 3. In contrast, in Designs 4 and 5, the final oxygen mass fractions were slightly higher than 0.137. In

Figure 6, the current density distributions for Designs 3–5 can be observed under a cell voltage of 0.52 V, and the highest current density was obtained at the input where the oxygen concentration was the highest.

Figure 6 clearly shows that the electrical current density at the output was lower in Design 3, and consequently, less efficient cell performance was expected. Designs 4 and 5 produced more uniform distributions of electric current density over the porous cathode than Design 3. Therefore, Designs 4 and 5 can offer higher yields. At low electrical demands, the performance of all fuel cells was governed by the kinetics of the electrode (Equation (6)). In this case, the differences between the gas distribution designs were minimal. The performance of Design 3 became limited in mass transport. With higher electrical demands, the performance of Design 3 deteriorated further (

Table 5). With an overpotential of 0.82 V, the total current (1811 mA) was significantly less than the total electric current for Design 5 (2127 mA). The distributions of the oxygen mass fraction for Designs 3–5 are shown in

Figure 5. These appeared to be more uniform in Design 4 or 5 than in Designs 1, 2, and 3. Barreras [

9] and Rivas [

33] showed that the profiles of current density exhibited better distributions with the re-direct pattern design, to produce a more efficient fuel cell. Our results were in agreement with those presented by this author. On the other hand, Rivas [

33] observed poor current distributions with parallel flow fields.

Figure 6 shows the current density distributions for Designs 3–5, for which the cell voltage fell below 0.52 V (that is, 0.66 V of cathode over potential). The highest current density was obtained at the entrance where the oxygen concentration was the highest.

Figure 6 clearly shows that the electrical current density at the output was lower in Design 3, and consequently, less efficient cell performance was expected. With an overpotential of 0.82 V, the total current was 1811 mA. It was significantly lower than the total electric current for Design 5 (2127 mA).

Drendel [

34] proposed that the external power generation and energy efficiency were considered as indices for PEM performance. The main results established in this work: five designs with different channel shapes and gas flow patterns, were simulated numerically using computational fluid dynamics (CFD). Using this approach, it was possible to conceive of, detail, and analyze each design. The electrical current distributions of the two different serpentine channels with square or rounded flow bends were tested. We can mention some studies that we relied on to arrive at our results. P.Havaej [

35] utilized a two-phase, multicomponent, transient, and three-dimensional model for simulating the performance of the PEMFC. In the first step, the best longitudinal catalyst loading distribution was found. In the second step, several lateral distributions were superimposed on the noted longitudinal catalyst loading distribution, and the performance of the PEMFC was evaluated for each distribution. Numerical results showed 3.1% enhancement for the longitudinal catalyst loading distributions. Um [

36], through simulation, was able to detail the cell current density response to a step-change in cell voltage.

By studying bipolar plates with different flow channel configurations, through computational modeling of fluid dynamics, a comparison was able to made of the pressure drop characteristics for different flow channel designs. The results showed that with a greater number of parallel channels and smaller sizes, a more effective contact surface area can be achieved along with a decrease in pressure drop. The correlations of these coefficients of the input region will be useful for the fuel cell simulation model. Xun Zhu [

37] analyzed different geometry configurations of collective flow plates using CDF and found for microchannels with different cross-section geometries, the detachment time, detachment diameter, and the removal time of water droplets increased in this sequence: triangle < trapezoid < rectangle with a curved bottom wall < rectangle < upside-down trapezoid. The detachment time for semicircle channel was longer than the rectangle, while its detachment diameter was smaller and the removal time shorter than the rectangle. Yan [

38], by simulating the flow channels, better uniformity in the current density distribution along the width of the cell could be attained. In other cases, the researchers showed real applications mainly for the automotive sector in hybrid vehicles or applications in the electronics industry such as telephony, computing, and instruments for research and development [

33]. Zamora, using ANSYS

®v14, simulated the behavior of the relevant variables in a fuel cell (pressure, volume, mass flow) in eight different geometry configurations in bipolar plates. More uniform results were obtained in a geometry configuration with grooves [

39], and the simulation reduced the time for laboratory-scale experimentation. In our own case, we carried out an application at the laboratory level applying polymeric materials for the manufacture of bipolar plates and the construction of a stack, achieving results similar to those obtained in commercial fuel cells, our contribution resulted in a decrease in the number of components (screws), since the manufactured cells were sealed with the same material as the bipolar plates. In most of the cases mentioned, the study was limited to the simulation of the plates and their different geometries [

39]. Peng [

40], through the design of experiments (DOE) method and an optimization method known as adoptive simulation (ASA), proposed an optimization model of the flow channel section design for a hydroformed metal bipolar plate. The optimization results showed that the optimal dimension values for the depth of the channel, the width of the channel, the width of the rib, and the transition radius were 0.5, 1.0, 1.6, and 0.5 mm, respectively, with the greatest reaction efficiency (79%) and acceptable formability (1.0). Kong developed a model capturing the key geometric parameters and their interrelationship, which were required to derive explicit expressions of the key electrode parameters in fuel cells [

41].