Approximation of Non-Linear Stress–Strain Curve for GFRP Tensile Specimens by Inverse Method

Abstract

:1. Introduction

2. Experiment and FEA Setup

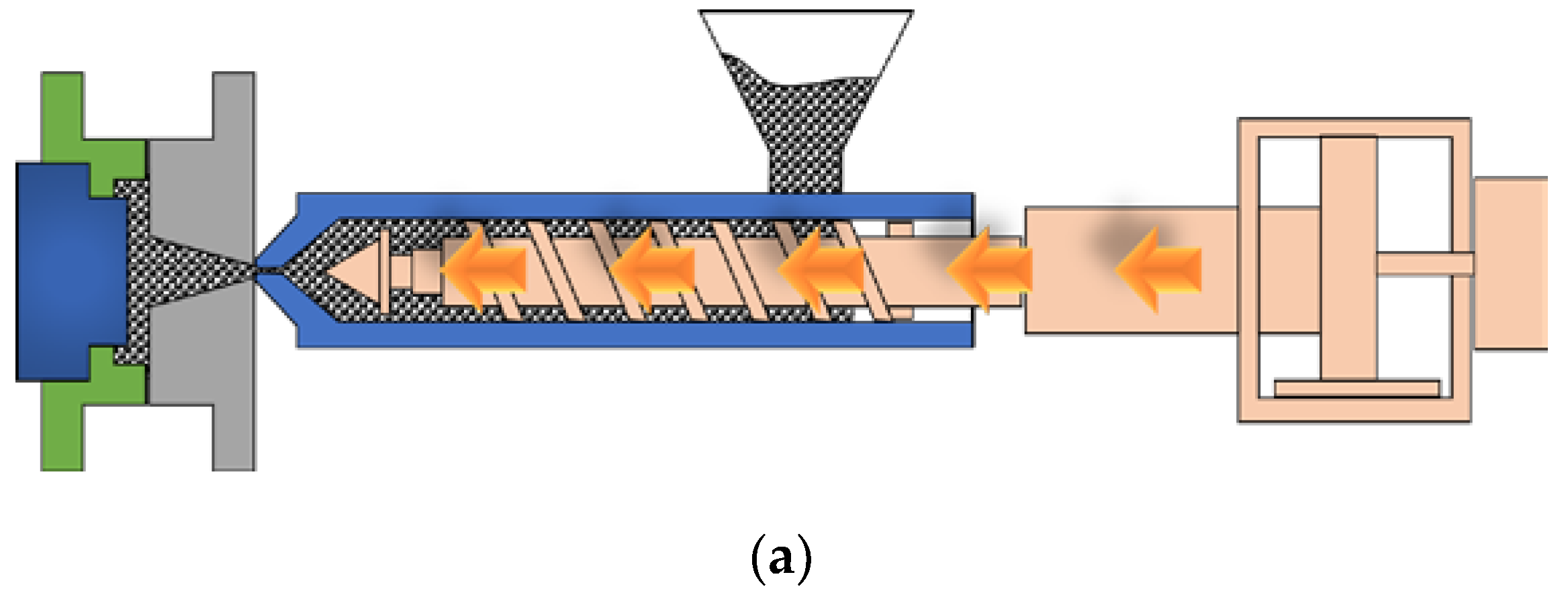

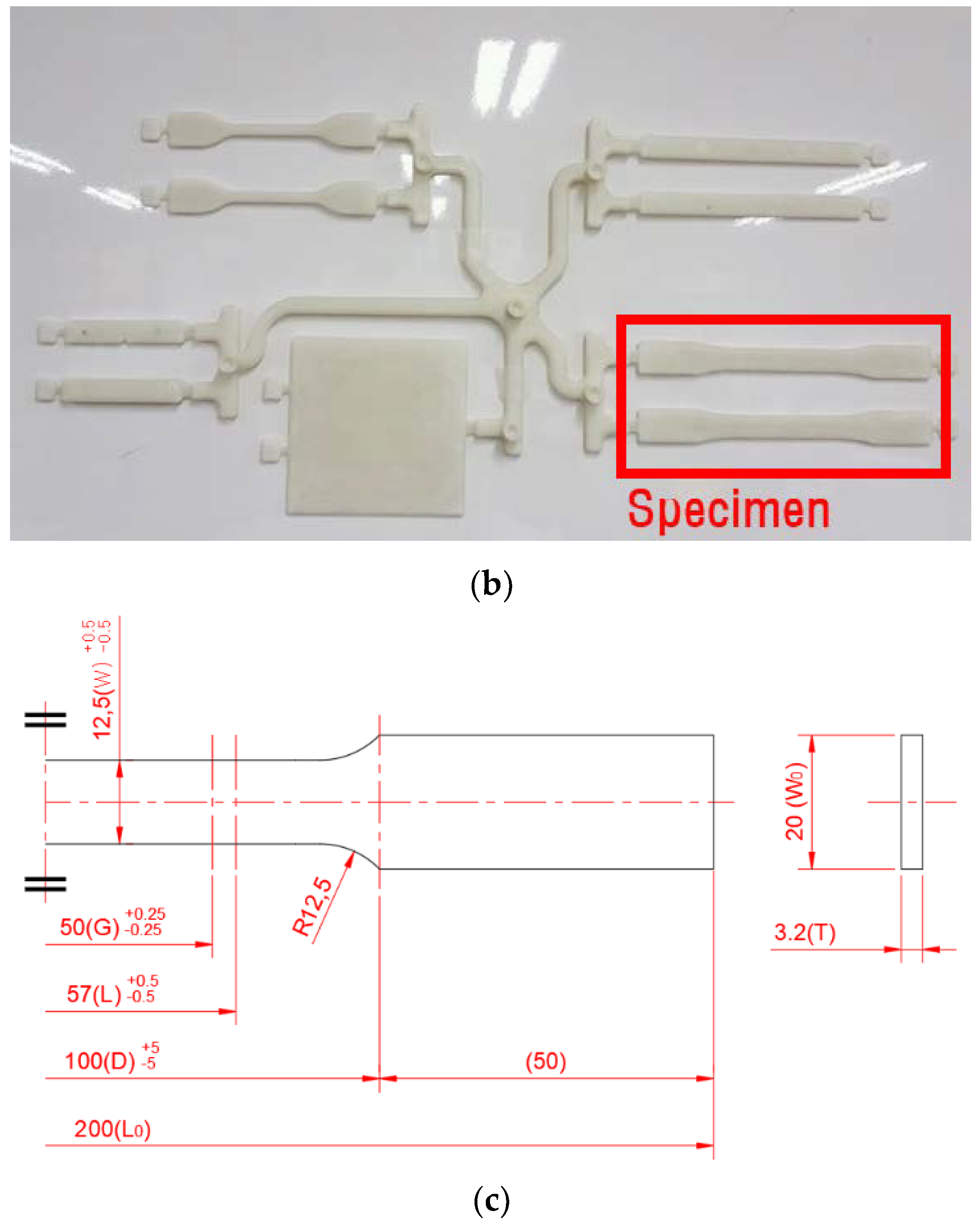

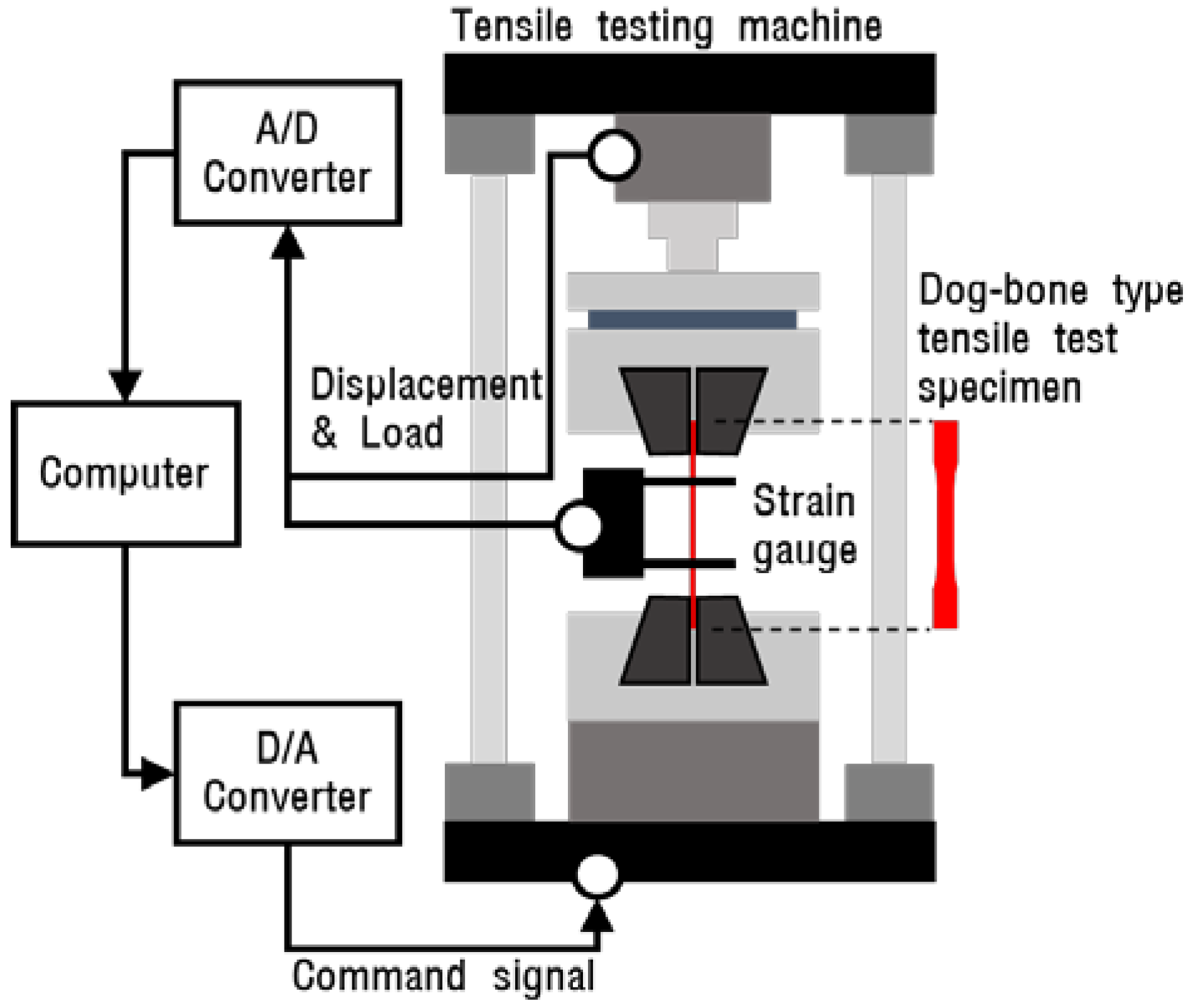

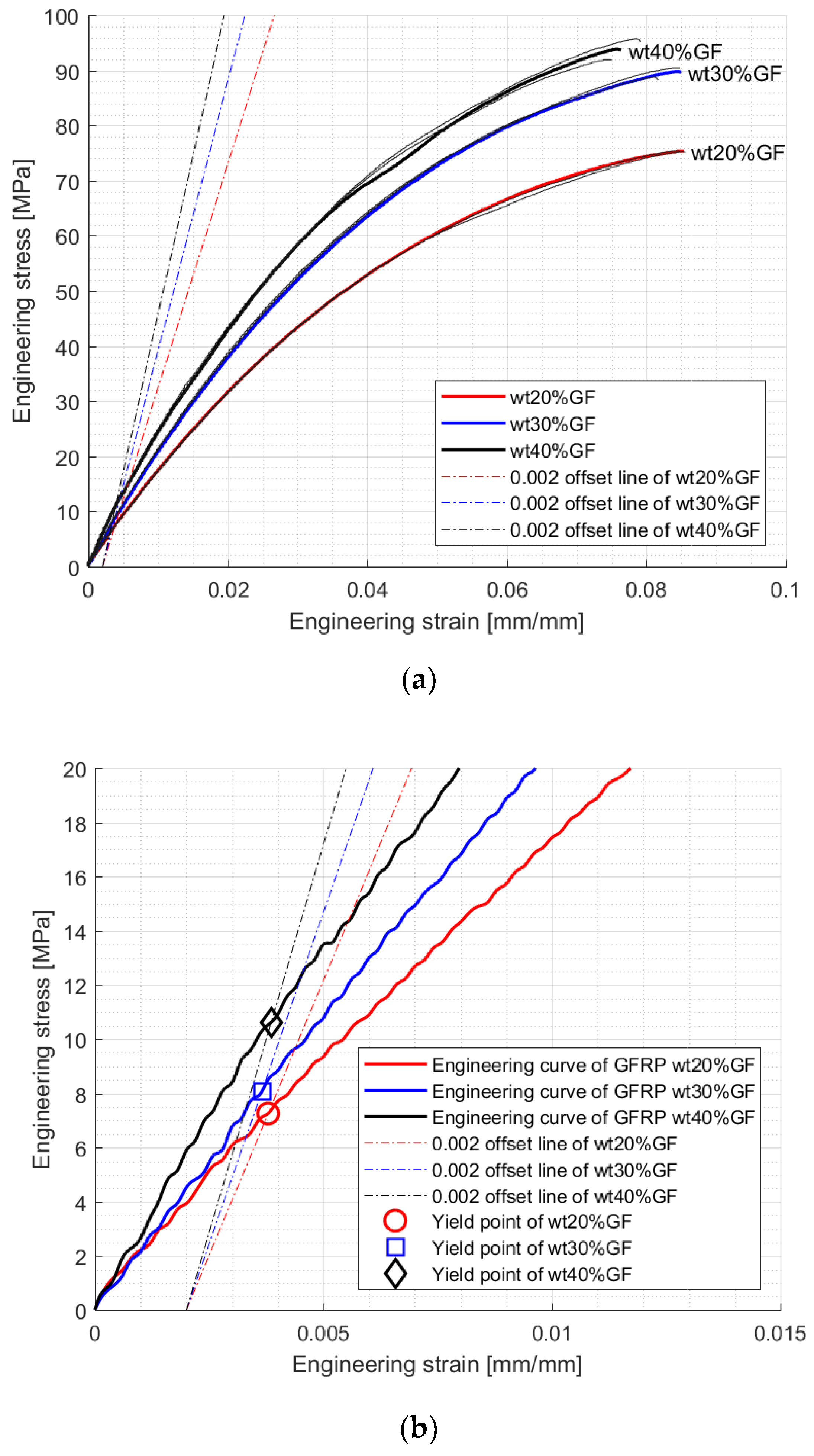

2.1. Experimental Setup (ASTM D638-14)

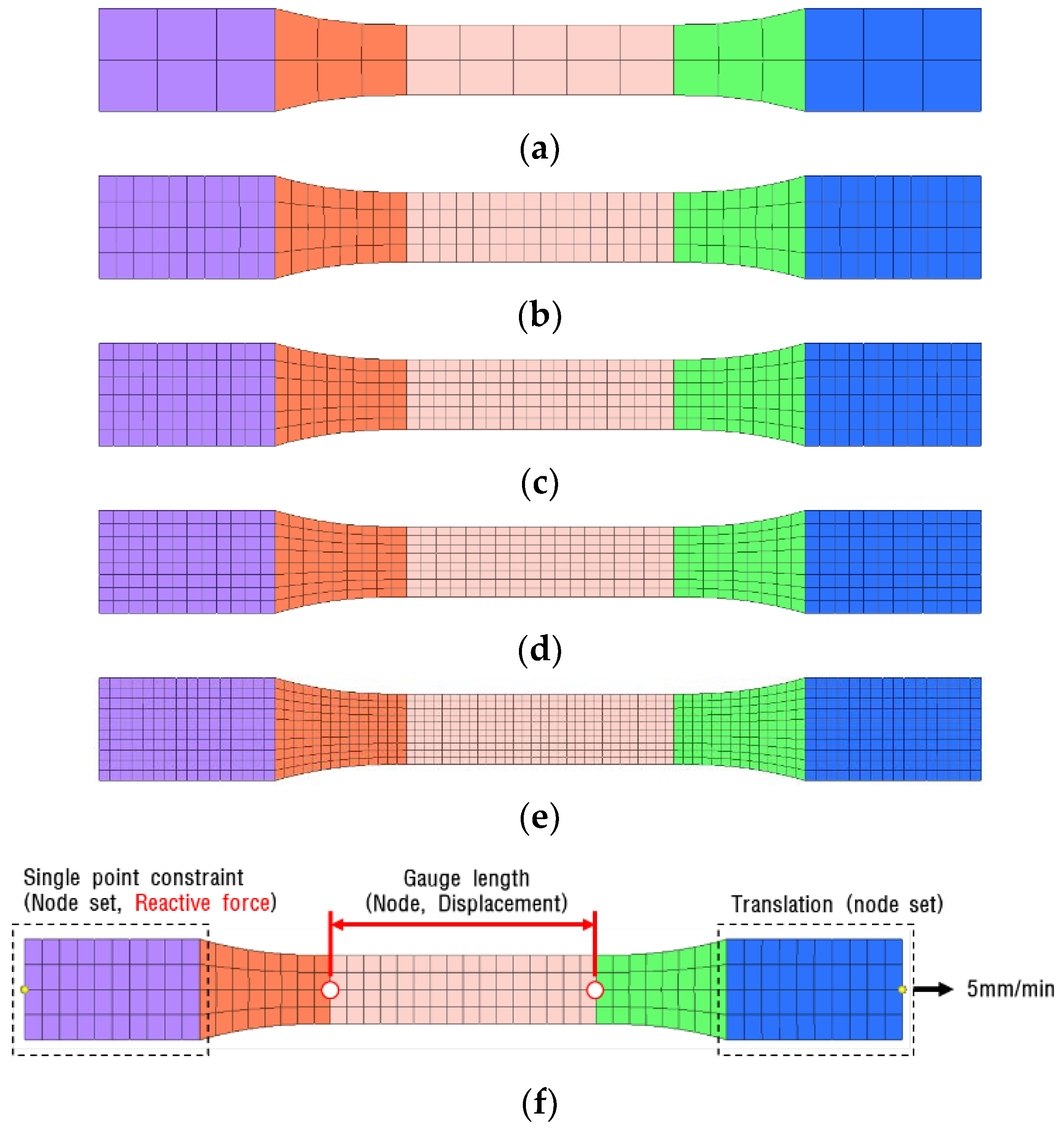

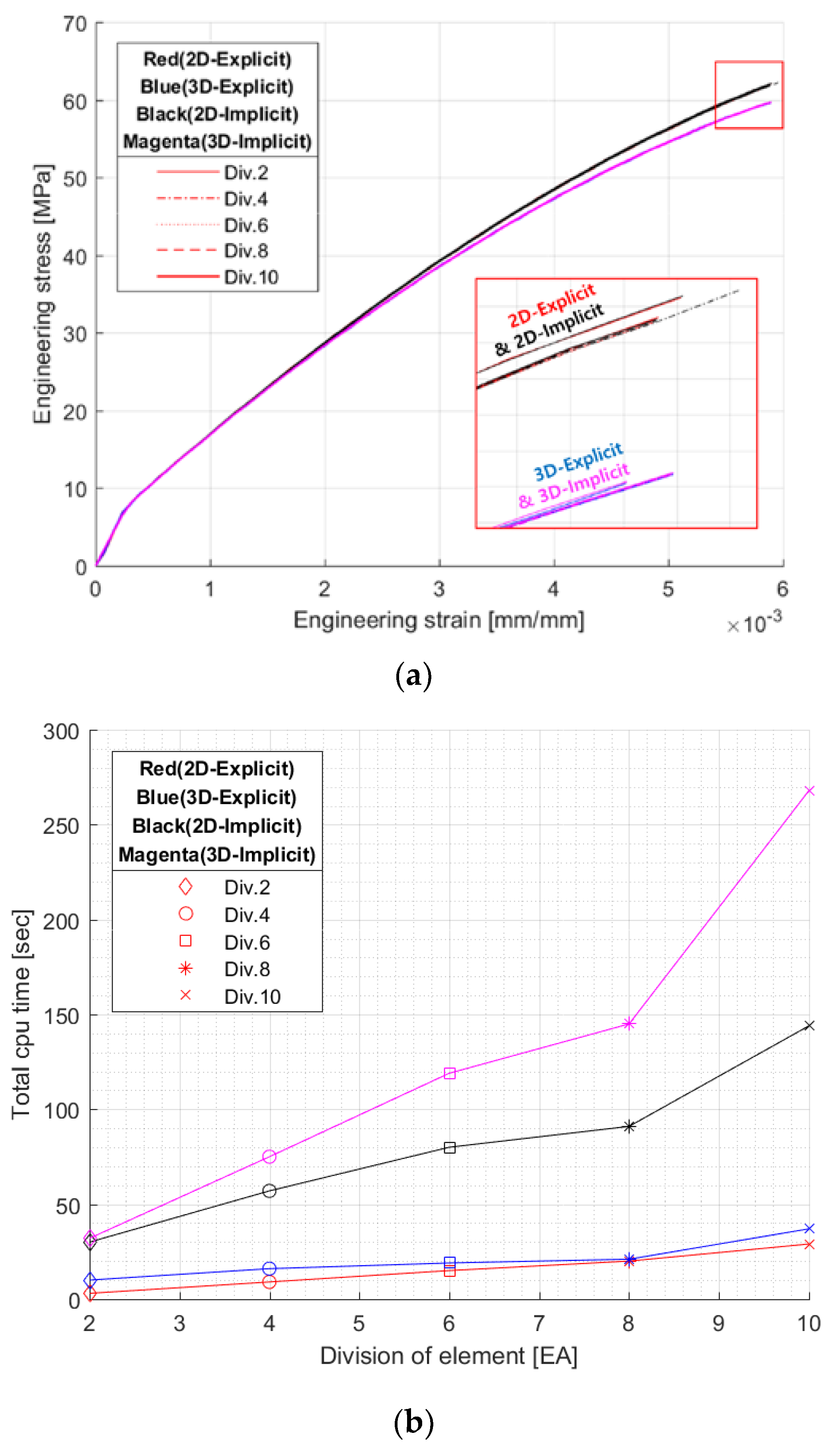

2.2. Finite Element Analysis Setup

2.3. Inverse Methods

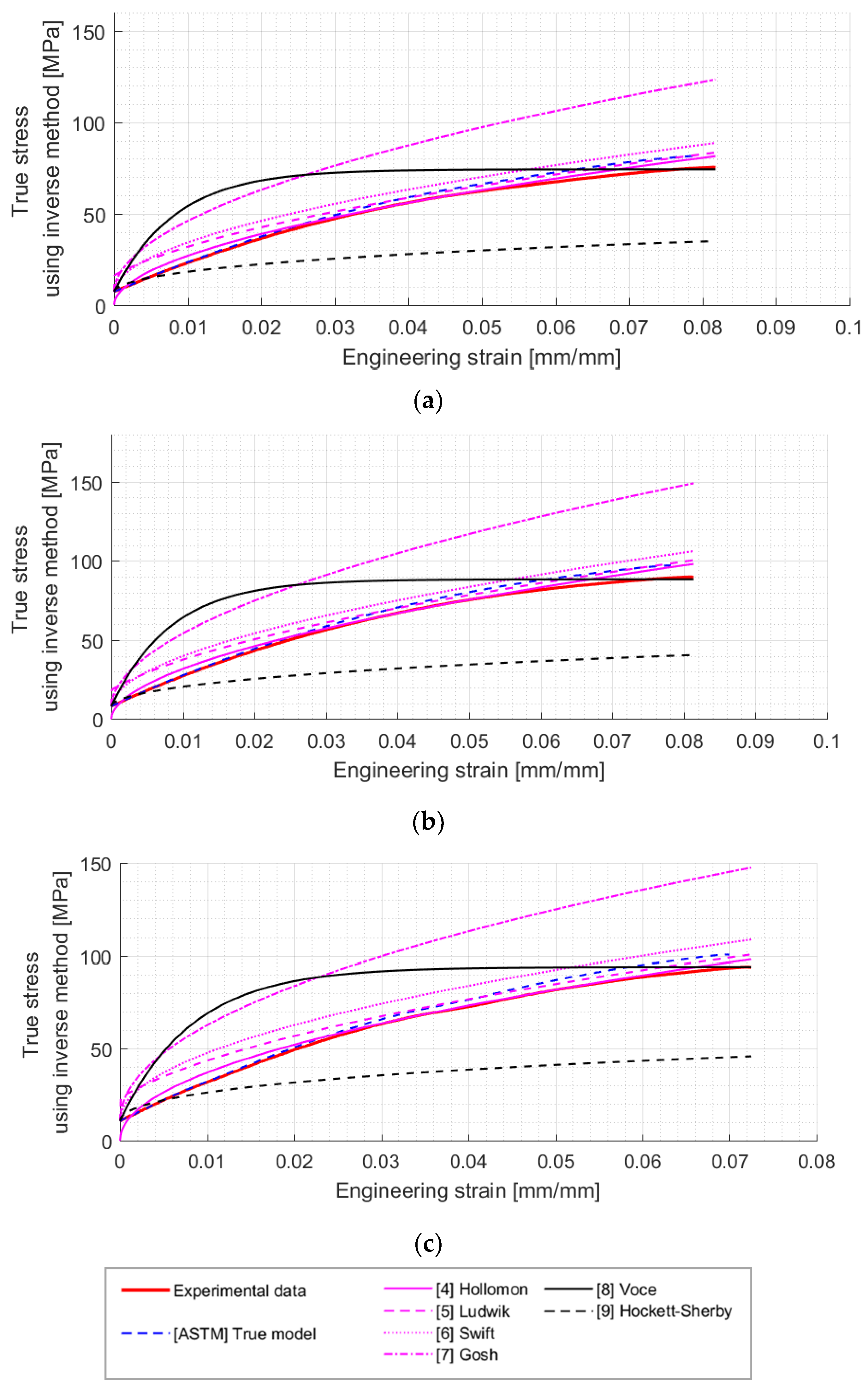

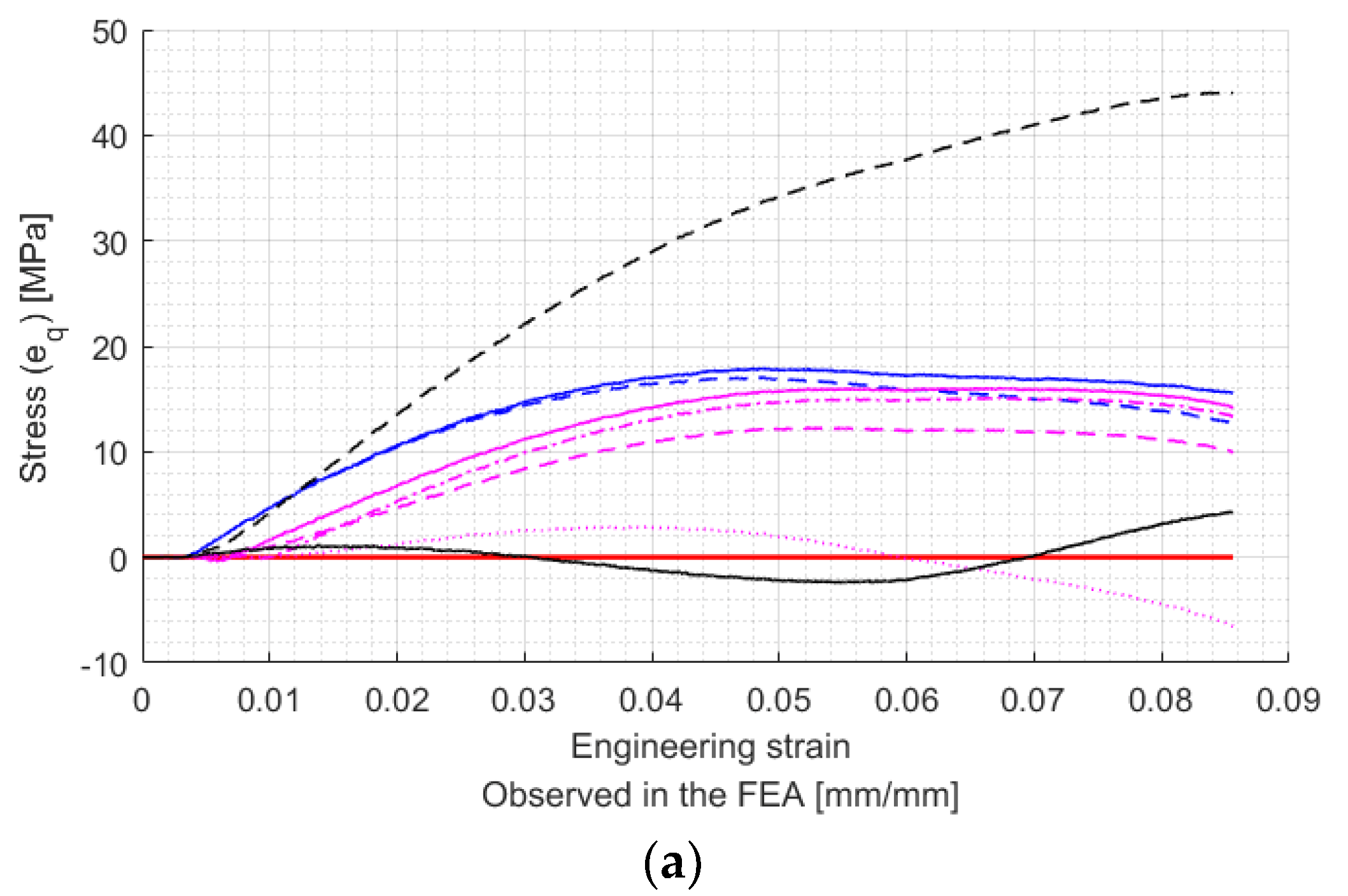

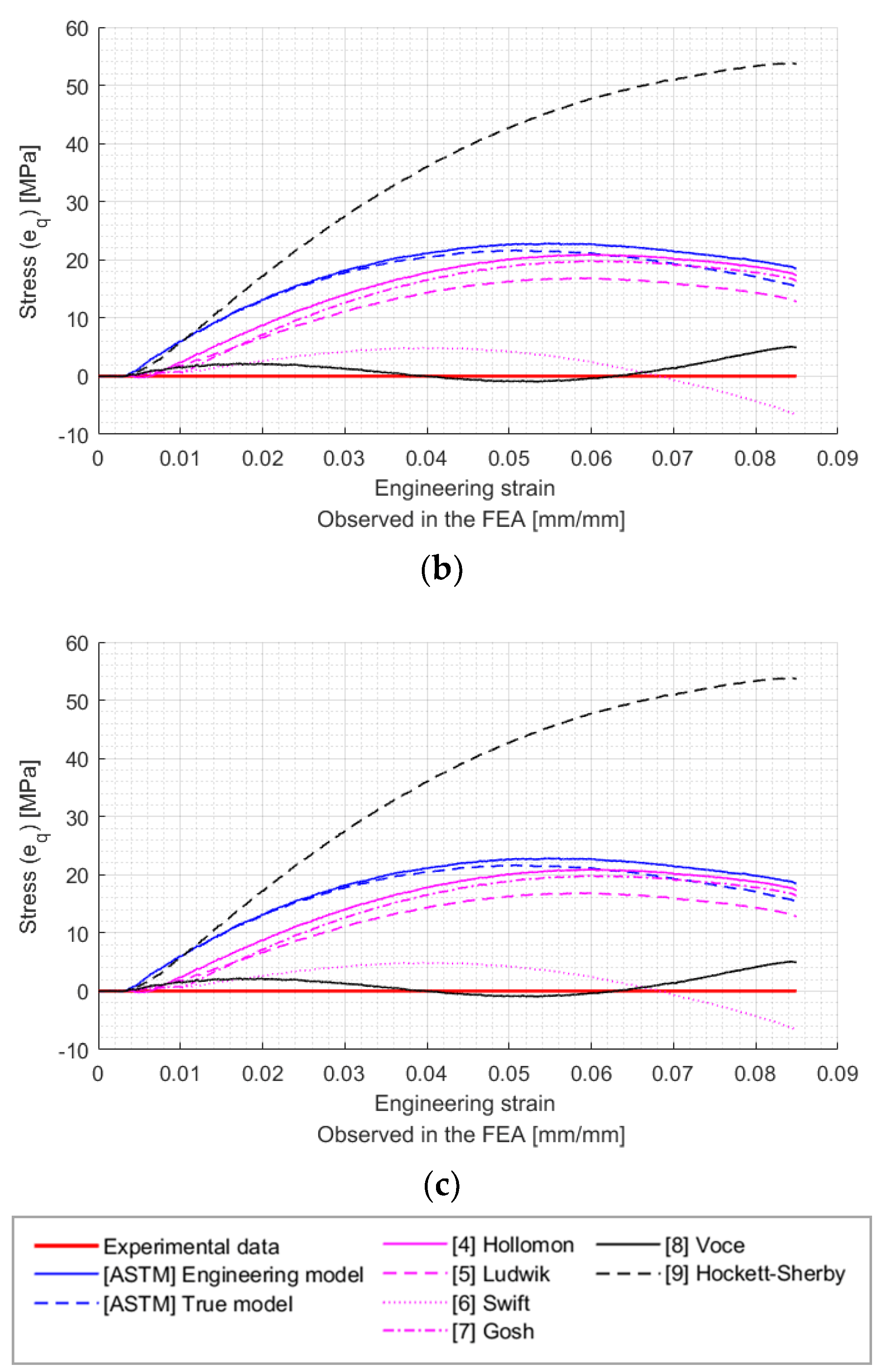

3. Optimization of Inverse Methods

Parameter Optimization

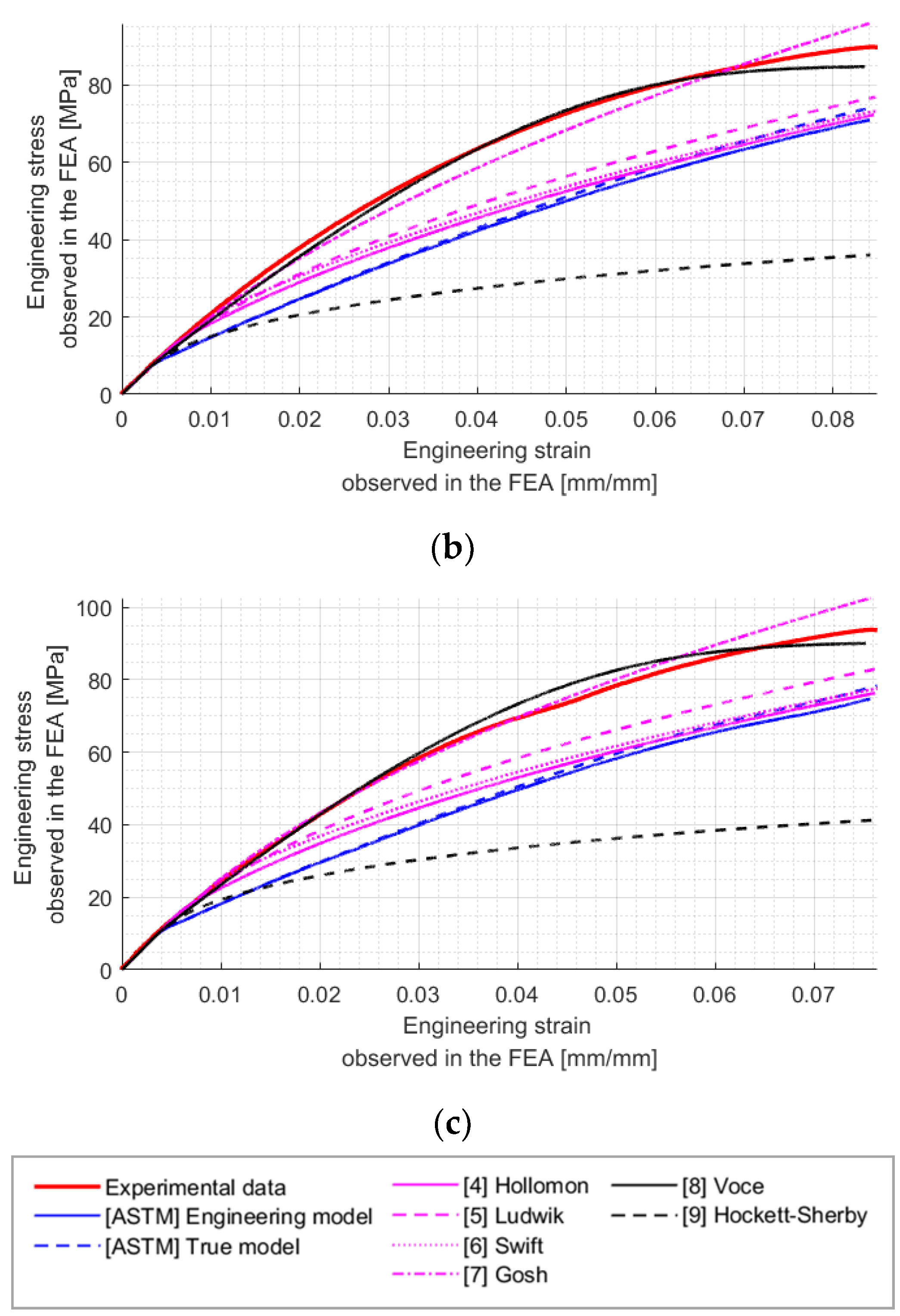

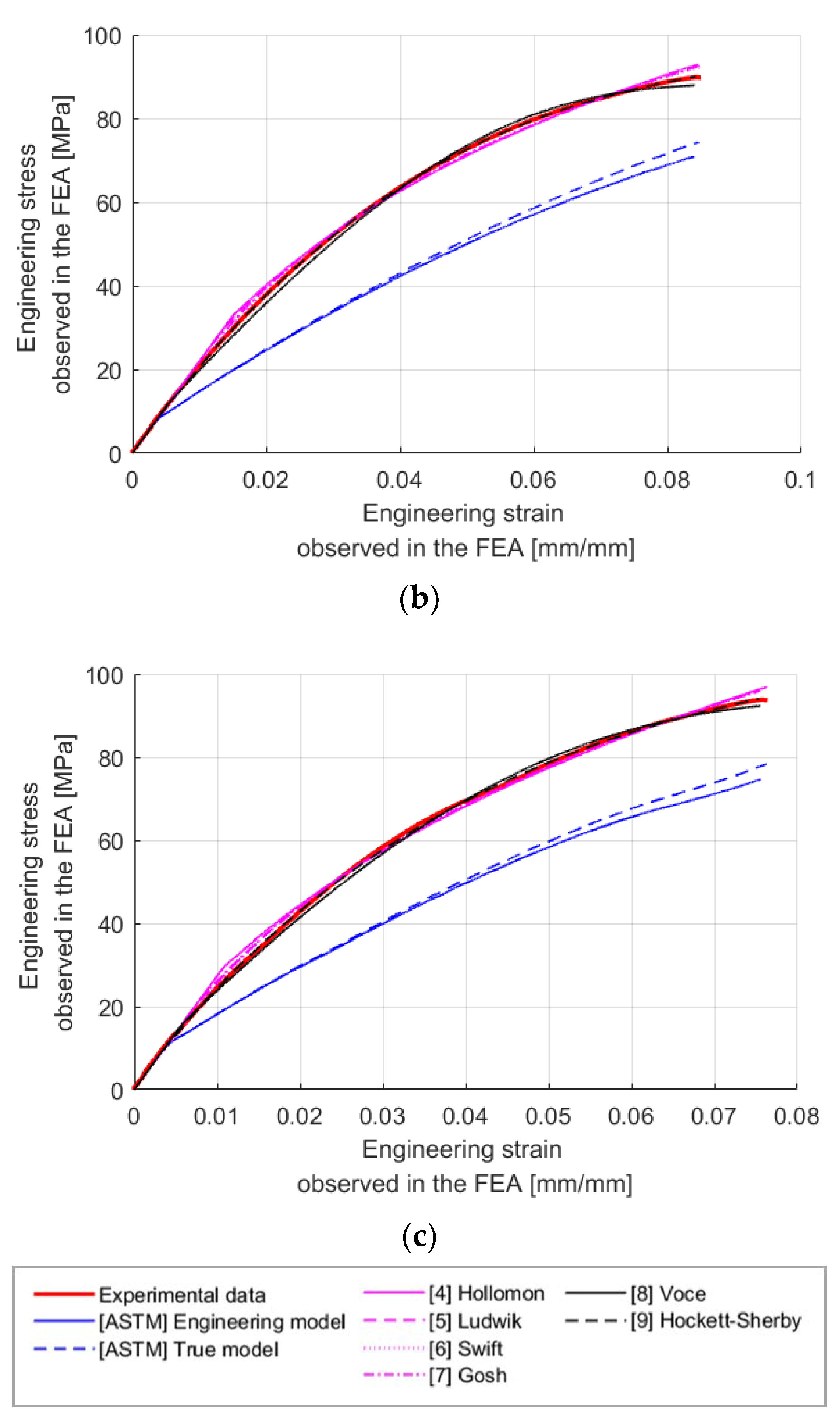

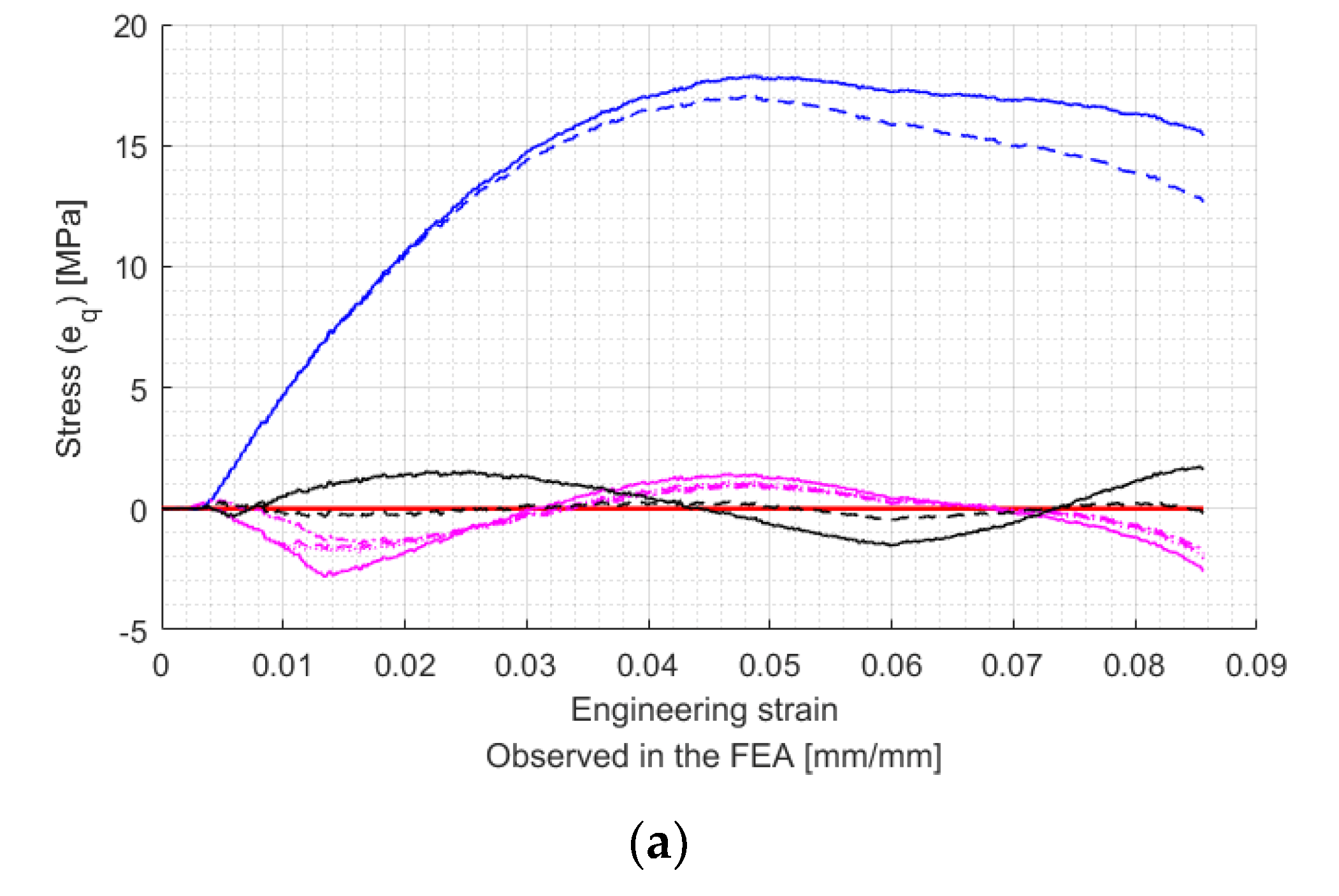

4. Results of Advanced Inverse Method

4.1. Advanced Inverse Method

4.2. Simulation and Optimization

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Center width of tensile specimen | |

| Total width of tensile specimen | |

| Thickness of tensile specimen | |

| Length of tensile specimen | |

| Total length of tensile specimen | |

| Gauge length = Original distance between gage marks | |

| Increment of distance between gage marks | |

| Displacement in FEA | |

| Radius | |

| Reactive force | |

| Engineering stress in experiment of ASTM D638-14 | |

| Engineering strain in experiment of ASTM D638-14 | |

| True stress in experiment of ASTM D638-14 | |

| Engineering stress in FEA | |

| Engineering strain in FEA | |

| Maximum number of data points that express stress–strain | |

| Order of data that express stress-strain, | |

| Sequential stress values of the stress–strain curve derived from FEA | |

| Sequential stress values of the stress–strain curve derived from an experiment | |

| E | Young’s modulus |

| Poisson’s ratio | |

| Yield stress | |

| Yield strain | |

| Maximum number of material properties | |

| Value that expresses the order of a material property, | |

| Equation number of the inverse method, | |

| Difference in the experiment and analysis for the engineering stress | |

| Average of the differences between the experiment and the analysis | |

| Average of the differences between the experiment and the analysis for the entire material properties | |

| Material parameter of inverse model | |

| Material parameter of advanced model | |

| Maximum number of material parameters by inverse method | |

| Value that expresses the order of a material parameter |

References

- Carlo, B.N.; Andrea, T.; Raaele, C.; Giovanni, B.; Davide, S.P. Assessment of residual elastic properties of a damaged composite plate with combined damage index and finite element methods. Appl. Sci. 2019, 9, 2579. [Google Scholar]

- Mazzon, E.; Habas-Ul, A.; Habas, J.P. Lightweight rigid foams from highly reactive epoxy resins derived from vegetable oil for automotive applications. Eur. Polym. J. 2015, 68, 546–557. [Google Scholar] [CrossRef]

- Hwang, Y.J.; Kang, S.K.; Kim, J.B.; Lee, S.S.; Choi, C.G.; Son, J.H. Topology optimal design for lightweight shape of the vehicle mechanical component. J. Korean Soc. Precis. Eng. 2003, 20, 177–184. [Google Scholar]

- Ishikawa, T.; Amaoka, K.; Masubuchi, Y.; Yamamoto, T.; Yamamoto, A.; Arai, M.; Takahashi, J. Overview of automotive structural composites technology developments in Japan. Compos. Sci. Technol. 2018, 155, 221–246. [Google Scholar] [CrossRef]

- Katunin, A.; Sul, P.; Łasica, A.; Dragan, K.; Krukiewicz, K.; Turczyn, R. Damage resistance of CSA-doped PANI/epoxy CFRP composite during passing the artificial lightning through the aircraft rivet. Eng. Fail. Anal. 2017, 82, 116–122. [Google Scholar] [CrossRef]

- Mouritz, A.P. Advances in understanding the response of fibre-based polymer composites to shock waves and explosive blasts. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105502. [Google Scholar] [CrossRef]

- Talha Junaid, M.; Elbana, A.; Altoubat, S.; Al-Sadoon, Z. Experimental study on the effect of matrix on the flexural behavior of beams reinforced with Glass Fiber Reinforced Polymer (GFRP) bars. Compos. Struct. 2019, 222, 110930. [Google Scholar]

- Yuan, Y.; Niu, K.; Wang, Z. Compressive strength prediction of fibre reinforced polymer composites under lateral disturbance. Polym. Test. 2019, 78, 105952. [Google Scholar] [CrossRef]

- Henning, F.; Kärger, L.; Dörr, D.; Schirmaier, F.J.; Seuffert, J.; Bernath, A. Fast processing and continuous simulation of automotive structural composite components. Compos. Sci. Technol. 2019, 171, 261–279. [Google Scholar] [CrossRef]

- Stewart, R. Lightweighting the automotive market. Reinf. Plast. 2009, 53, 14–16. [Google Scholar] [CrossRef]

- Hwang, Y.K.; Eun, I.U.; Lee, C.M.; Seo, Y.W. Development of Lightweight Moving Table for Linear Motor using Composite Materials. J. Korean Soc. Precis. Eng. 2010, 27, 7–13. [Google Scholar]

- You, H.Y.; Park, S.H. Warpage analysis of a door carrier plate in the injection molding considering the characteristics of LFT. J. Korea Acad. Ind. Coop. Soc. 2013, 14, 3625–3630. [Google Scholar]

- Seon, G.; Makeev, A.; Schaefer, J.D.; Justusson, B. Measurement of interlaminar tensile strength and elastic properties of composites using open-hole compression testing and digital image correlation. Appl. Sci. 2019, 9, 2647. [Google Scholar] [CrossRef]

- Hohe, J.; Beckmann, C.; Paul, H. Modeling of uncertainties in long fiber reinforced thermoplastics. Mater. Des. 2015, 66, 390–399. [Google Scholar] [CrossRef]

- Ünal, O.; Demir, F.; Uygunoglua, T. Fuzzy logic approach to predict stress–strain curves of steel fiber-reinforced concretes in compression. Build. Environ. 2007, 42, 3589–3595. [Google Scholar] [CrossRef]

- Zhao, K.; Wang, L.; Chang, Y.; Yan, J. Identification of post-necking stress–strain curve for sheet metals by inverse method. Mech. Mater. 2016, 92, 107–118. [Google Scholar] [CrossRef]

- Flayeh, A.H.; Toopchi-Nezhad, H.; TahamouliRoudsari, M. The use of fiberglass textile-reinforced mortar (TRM) jacketing system to enhance the load capacity and confinement of concrete columns. In Proceedings of the 2018 2nd International Conference for Engineering Technology and Sciences of Al-Kitab (ICETS), Karkuk, Iraq, 4–6 December 2018; pp. 66–71. [Google Scholar]

- Zhang, Z.L.; Hauge, M.; Odegard, J.; Thaulow, C. Determining material true stress-strain curve from tensile specimens with rectangular cross-section. Int. J. Solids Struct. 1999, 36, 3497–3516. [Google Scholar] [CrossRef]

- Kim, J.H.; Serpantie, A.; Barlat, F.; Pierron, F.; Lee, M.G. Characterization of the post-necking strain hardening behavior using the virtual fields method. Int. J. Solids Struct. 2013, 50, 3829–3842. [Google Scholar] [CrossRef] [Green Version]

- Joun, M.S.; Eom, J.G.; Lee, M.C. A new method for acquiring true stress–strain curves over a large range of strains using a tensile test and finite element method. Mech. Mater. 2008, 40, 586–593. [Google Scholar] [CrossRef]

- Kamaya, M.; Kawakubo, M. A procedure for determining the true stress–strain curve over a large range of strains using digital image correlation and finite element analysis. Mech. Mater. 2011, 43, 243–253. [Google Scholar] [CrossRef]

- Dziallach, S.; Bleck, W.; Blumbach, M.; Hallfeldt, T. Sheet metal testing and flow curve determination under multiaxial conditions. Adv. Eng. Mater. 2007, 9, 987–994. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Tensile Properties of Plastics; ASTM D638-14; ASTM: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Hollomon, J.H. Tensile deformations. Trans. Metall. Soc. AIME 1945, 162, 268–290. [Google Scholar]

- Ludwik, P. Elemente der Technologischen Mechanik; Springer: Berlin, Germany, 1909. [Google Scholar]

- Swift, H.W. Plastic instability under plane stress. J. Mech. Phys. Solids 1952, 1, 1–18. [Google Scholar] [CrossRef]

- Gosh, A.K. Tensile instability and necking in materials with strain hardening and strain-rate hardening. Acta Metall. 1977, 25, 1413–1424. [Google Scholar] [CrossRef]

- Voce, E. The relationship between stress and strain for homogeneous deformation. J. Inst. Met. 1948, 74, 537–562. [Google Scholar]

- Hockett, J.E.; Sherby, O.D. Large strain deformation of polycrystalline metals at low homologous temperatures. J. Mech. Phys. Solids 1975, 23, 87–98. [Google Scholar] [CrossRef]

- ASTM. Tensile Strain-Hardening Exponents (N-Values) of Metallic Sheet Materials; ASTM E646-16; ASTM: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Cook, R.D.; Nachtsheim, C.J. A comparison of algorithms for constructing exact D-optimal designs. Technometrics 1980, 22, 315–324. [Google Scholar] [CrossRef]

- Kim, Y.S.; Pham, Q.T.; Kim, C.I. New stress-strain model for identifying plastic deformation behavior of sheet materials. J. Korean Soc. Precis. Eng. 2017, 34, 273–279. [Google Scholar] [CrossRef]

- Lee, D.W.; Cho, S.S. Tension estimation of tire using neural networks and DOE. J. Korean Soc. Precis. Eng. 2011, 28, 814–820. [Google Scholar]

- Doh, J.H.; Lee, J.S. Approximate multi-objective optimization of a wall-mounted monitor bracket arm considering strength design conditions. Trans. Korean Soc. Mech. Eng. A 2015, 39, 535–541. [Google Scholar] [CrossRef]

| Symbols | Units | wt 20% GF | wt 30% GF | wt 40% GF |

|---|---|---|---|---|

| MPa | 4082.40 | 4833.49 | 5717.59 | |

| - | 0.35 | 0.38 | 0.4 | |

| MPa | 7.25 | 8.08 | 10.62 | |

| - | 0.0038 | 0.0037 | 0.0039 | |

| 1.05 | 1.11 | 1.21 | ||

| MPa | 75.33 | 89.72 | 93.83 |

| No. | Eq. | Applied S–S Curve Model | ||||

|---|---|---|---|---|---|---|

| wt 20% GF | wt 30% GF | wt 40% GF | ||||

| 1 | 1 | ASTM Engineering model | 13.54 | 17.00 | 15.75 | 15.43 |

| 2 | 3 | ASTM True model | 12.62 | 15.97 | 14.67 | 14.42 |

| 3 | 4 | Hollomon | 11.37 | 14.41 | 12.77 | 12.85 |

| 4 | 5 | Ludwik | 8.50 | 11.43 | 8.29 | 9.41 |

| 5 | 6 | Swift | 10.33 | 13.28 | 11.38 | 11.66 |

| 6 | 7 | Gosh | 1.87 | 2.85 | 2.06 | 2.26 |

| 7 | 8 | Voce | 1.32 | 1.39 | 1.91 | 1.54 |

| 8 | 9 | Hockett–Sherby | 26.59 | 33.03 | 30.51 | 30.05 |

| No. | Eq. | Applied S-S Curve Model | ||||

|---|---|---|---|---|---|---|

| wt 20% GF | wt 30% GF | wt 40% GF | ||||

| 1 | 1 | ASTM Engineering model | 13.54 | 17.00 | 15.75 | 15.43 |

| 2 | 3 | ASTM True model | 12.62 | 15.97 | 14.67 | 14.42 |

| 3 | 4 | Hollomon | 0.96 | 1.20 | 1.18 | 1.11 |

| 4 | 5 | Ludwik | 0.68 | 1.09 | 0.82 | 0.86 |

| 5 | 6 | Swift | 0.57 | 0.77 | 0.71 | 0.69 |

| 6 | 7 | Gosh | 0.73 | 0.95 | 0.91 | 0.86 |

| 7 | 8 | Voce | 0.85 | 0.97 | 0.87 | 0.90 |

| 8 | 9 | Hockett–Sherby | 0.17 | 0.06 | 0.29 | 0.17 |

| 9 | 19 | Kim–Tuan | 0.12 | 0.16 | 0.32 | 0.20 |

| 10 | 20 | Swift–Voce | 0.11 | 0.15 | 0.29 | 0.18 |

| 11 | 21 | Ludwik–Voce | 0.38 | 0.26 | 0.45 | 0.36 |

| 12 | 22 | Swift Hockett–Sherby | 1.25 | 0.18 | 0.39 | 0.61 |

| 13 | 23 | Ludwik Hockett–Sherby | 0.18 | 0.21 | 0.38 | 0.26 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, D.S.; Kim, Y.S.; Jeon, E.S. Approximation of Non-Linear Stress–Strain Curve for GFRP Tensile Specimens by Inverse Method. Appl. Sci. 2019, 9, 3474. https://doi.org/10.3390/app9173474

Shin DS, Kim YS, Jeon ES. Approximation of Non-Linear Stress–Strain Curve for GFRP Tensile Specimens by Inverse Method. Applied Sciences. 2019; 9(17):3474. https://doi.org/10.3390/app9173474

Chicago/Turabian StyleShin, Dong Seok, Young Shin Kim, and Euy Sik Jeon. 2019. "Approximation of Non-Linear Stress–Strain Curve for GFRP Tensile Specimens by Inverse Method" Applied Sciences 9, no. 17: 3474. https://doi.org/10.3390/app9173474