Effect of Steel Casing on Vertical Bearing Characteristics of Steel Tube-Reinforced Concrete Piles in Loess Area

Abstract

:1. Introduction

2. Methodology

2.1. Purpose of the Test

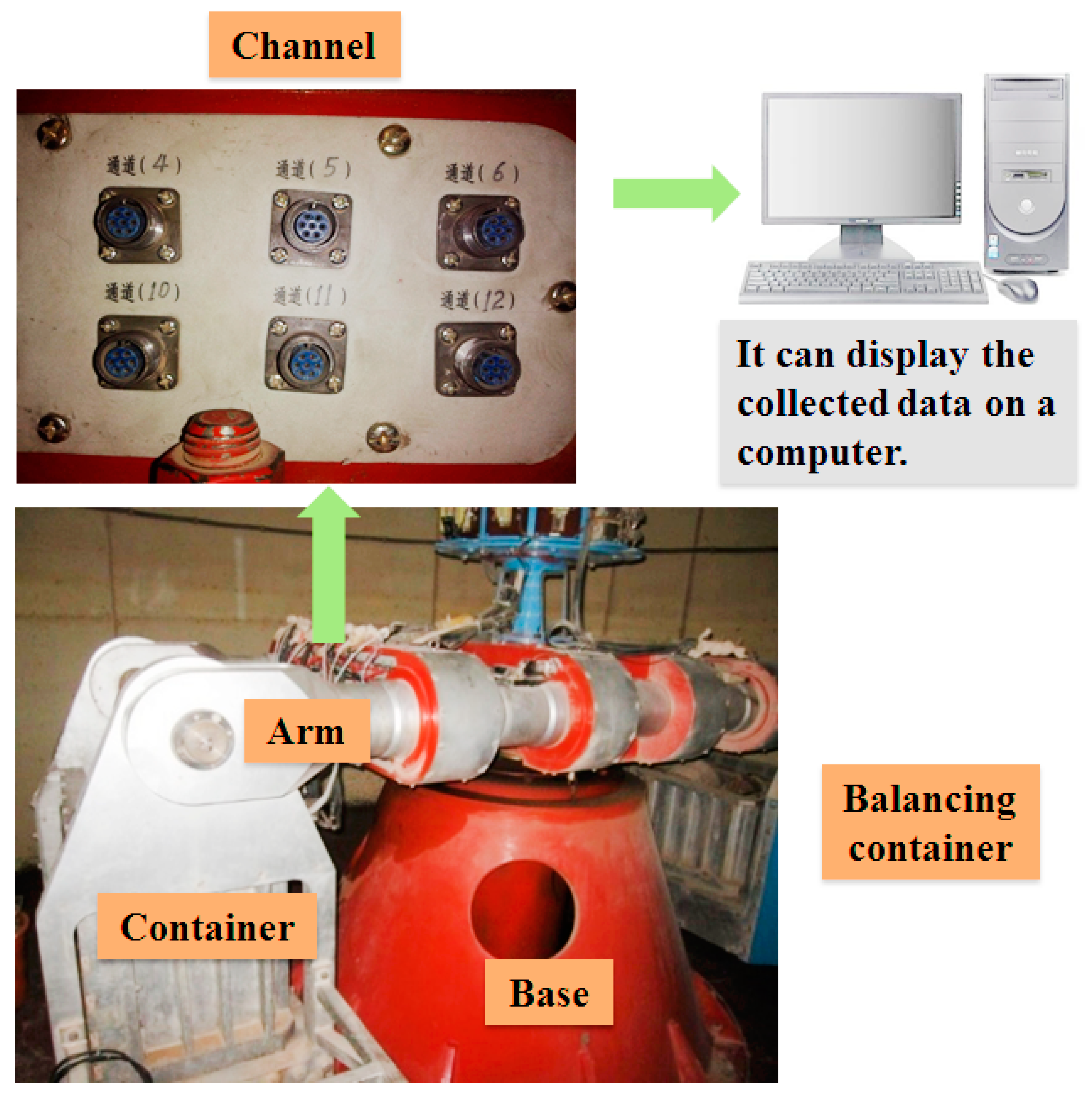

2.2. Centrifuge Equipment

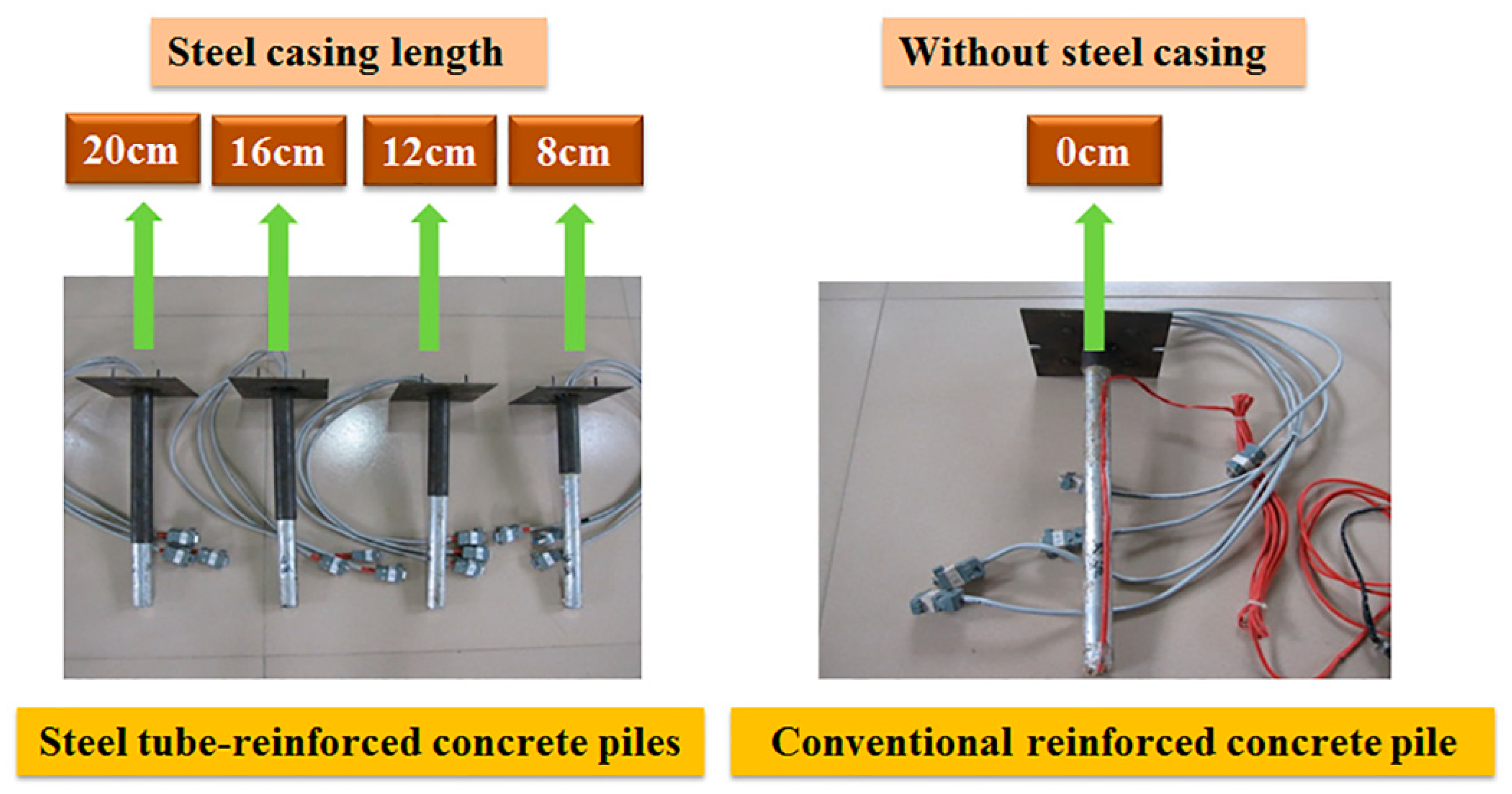

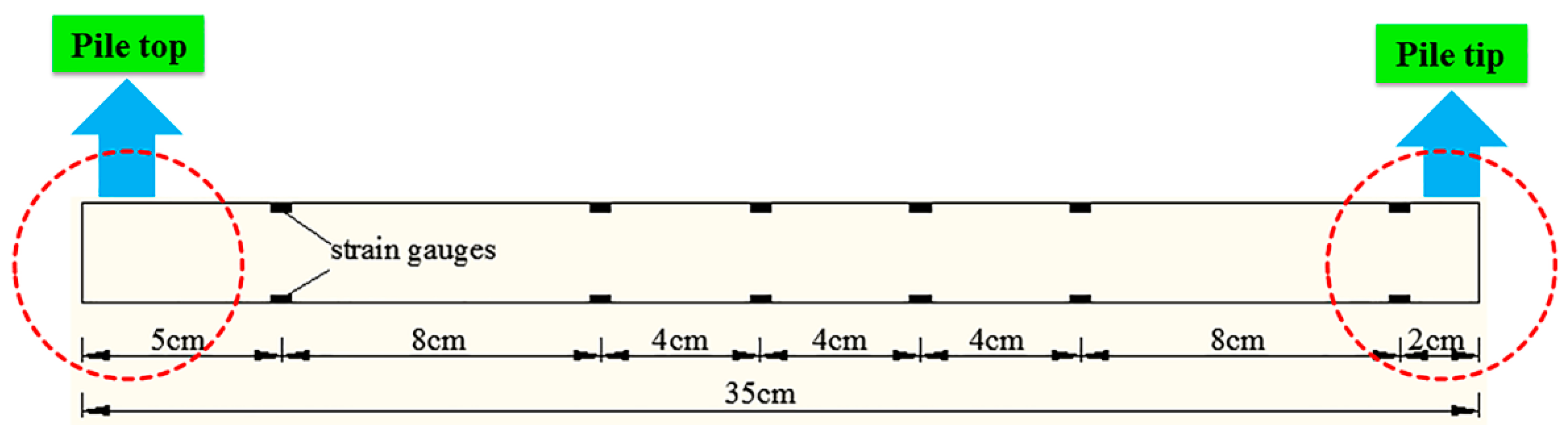

2.3. Model Pile

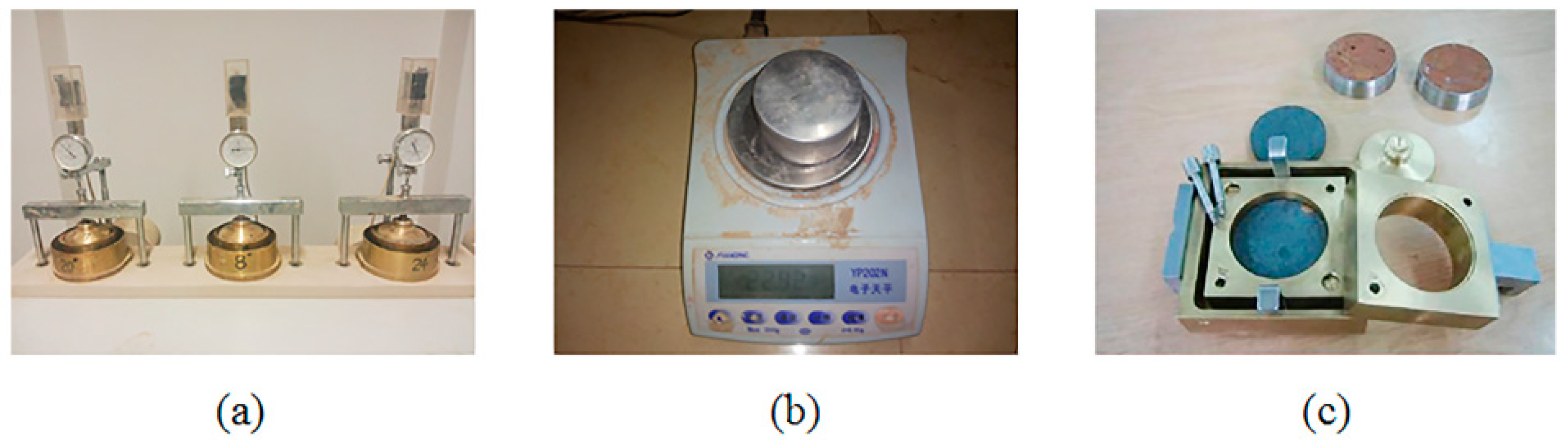

2.4. Physical Properties of Loess

2.5. Test Procedure

- In order to ensure that the density of soil in the container is consistent, a certain mass of soil is compressed into a certain volume. In this study, the soil density is 1.7 g/cm3; each layer of the soil is compressed to 2 cm, because the container length is 70 cm; width is 36 cm; and each layer of the soil is compressed to 5040 cm3, so it can be calculated that each layer requires a soil mass of 8568 g. First, 8568 g of soil was weighed and placed in plastic bags, then a shovel was used to spread the soil evenly into the container, and finally a vibrator was used to compress the soil to 2 cm; the operation was repeated 20 times and the soil was filled to 40 cm high. Then the hole was drilled according to the pile position; the position of the model piles are shown in Figure 7. The depth of the hole was 30 cm; the aperture was slightly smaller than the pile diameter, so that the shaft resistance between the pile and soil was closer to the actual value. Finally, the pile was pressed into the hole.

- The container was put into the centrifuge by hoisting machine.

- First, the displacement meter was mounted on the inverse force frame to measure top displacement. Then the reverse force frame was fastened to the container by bolts. Finally, strain gauges, earth pressure cells and the displacement meter were connected with the centrifuge channel, which can obtain the data from the computer.

- Five minutes preliminary operation at the 100 g level was conducted.

- The test data was transferred to the computer.

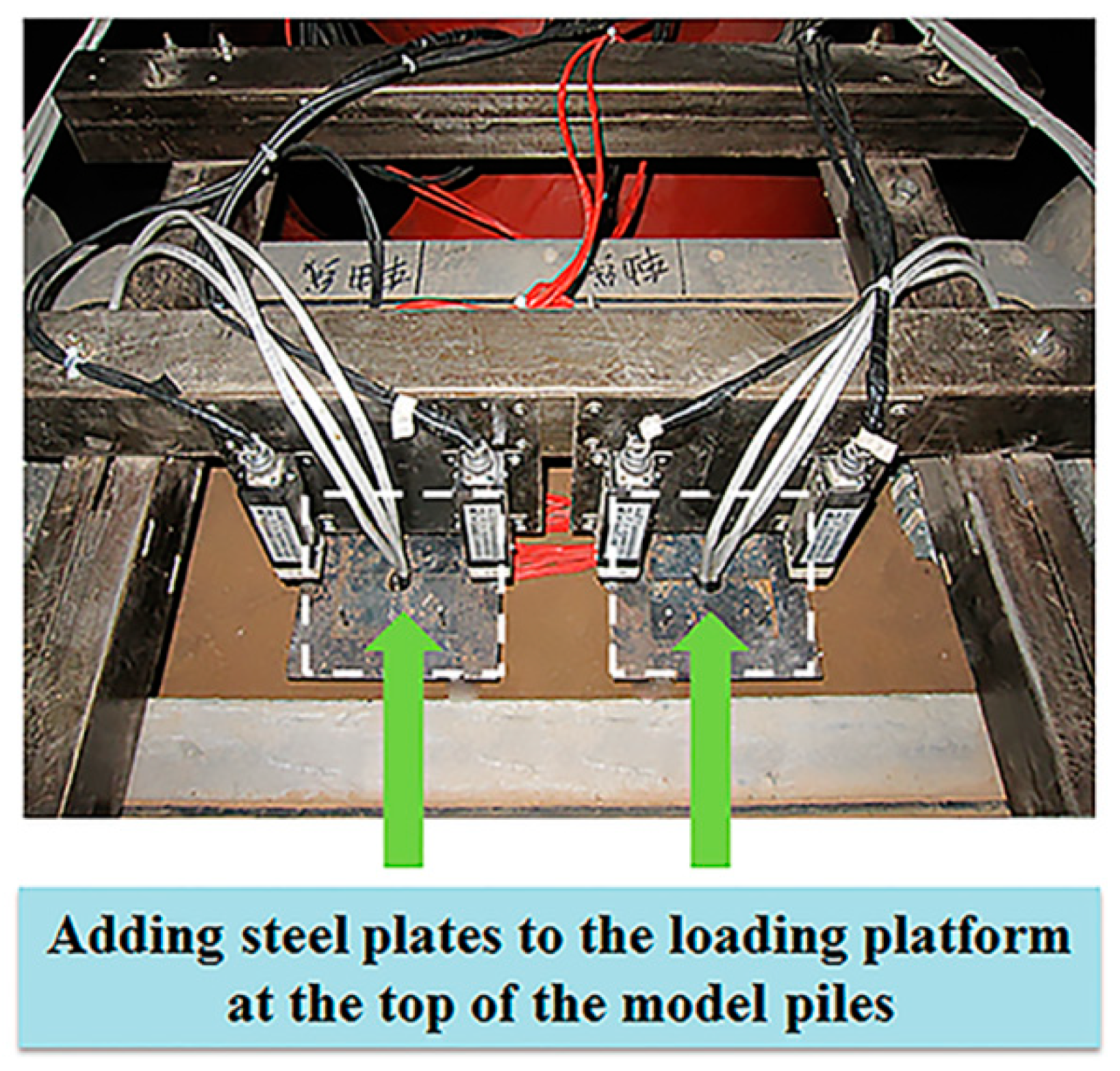

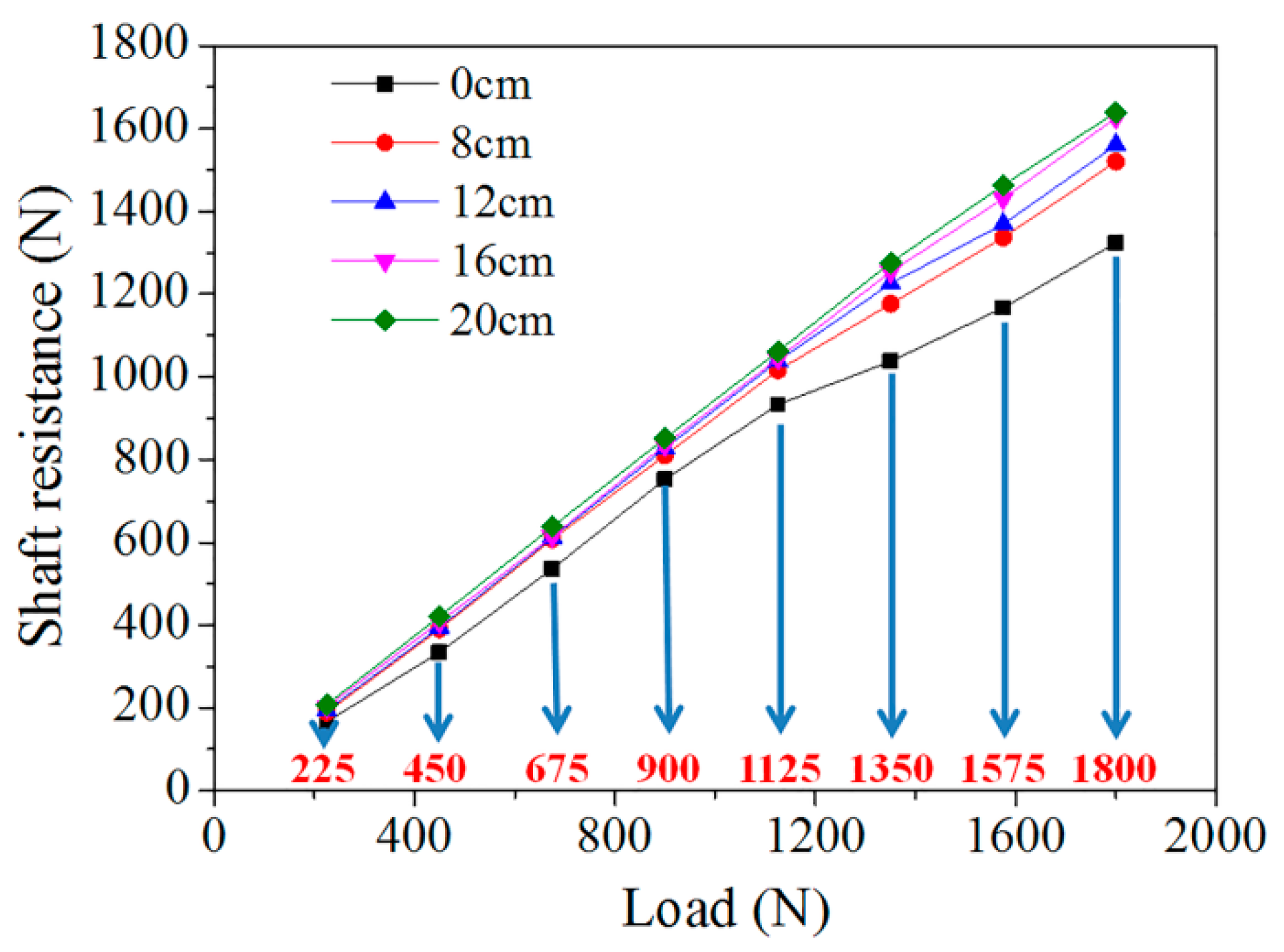

- Load was increased after one load ended, and then the steps above were repeated. Vertical loading was achieved by adding steel plates to the loading platform at the top of the model pile, and the vertical loading was divided into eight levels; the weight of the loading platform itself can be considered as the first stage load, the loading size is 225 N, 450 N, 675 N, 900 N, 1125 N, 1350 N, 1575 N, and 1800 N. The loading device is shown in Figure 8.

3. Results and Discussion

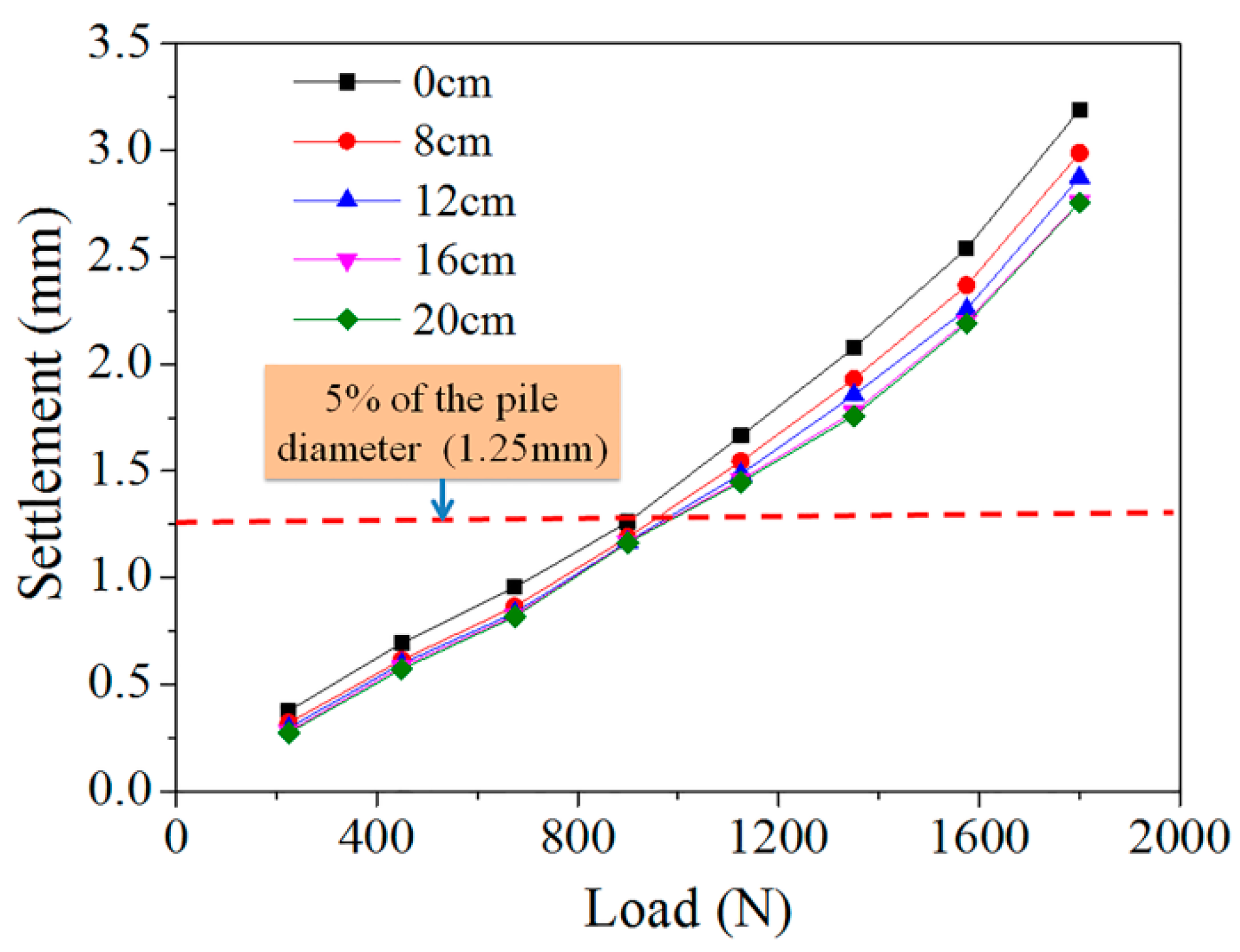

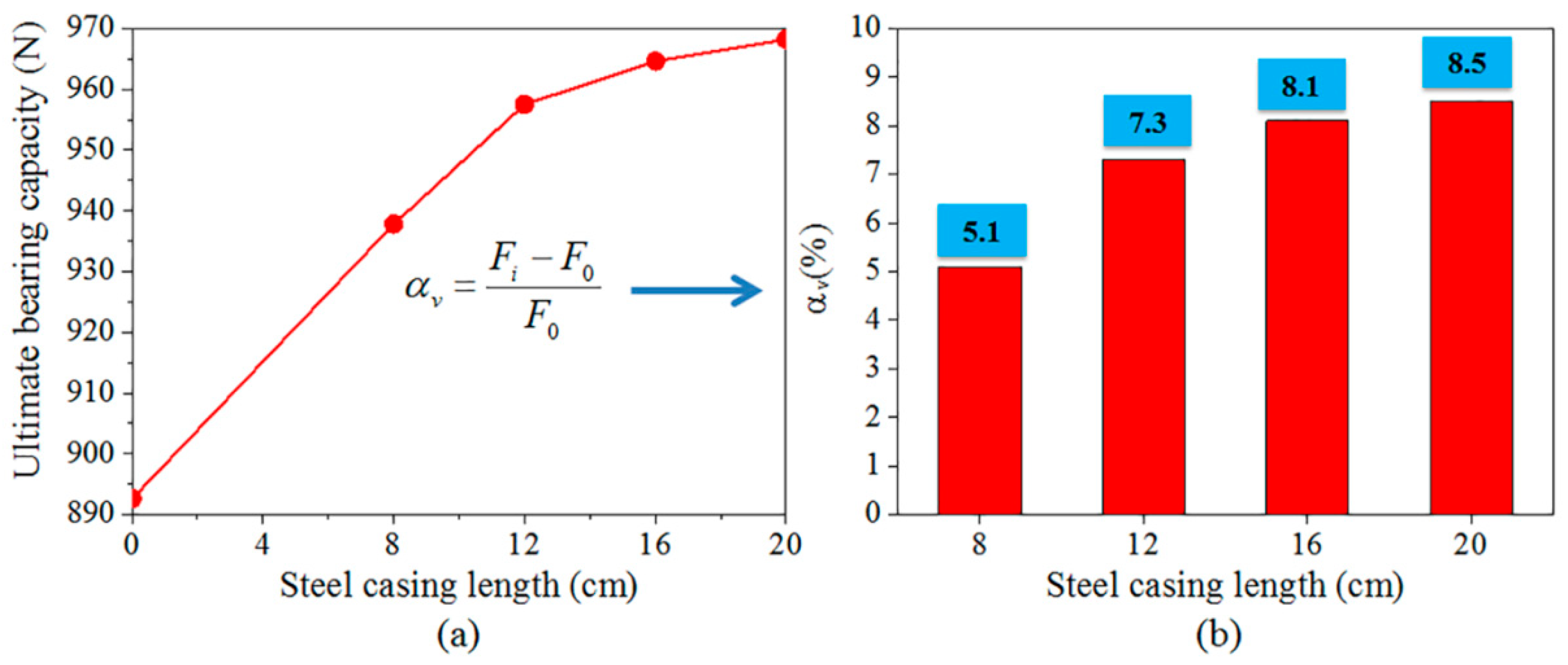

3.1. Effect of Steel Casing on Bearing Capacity

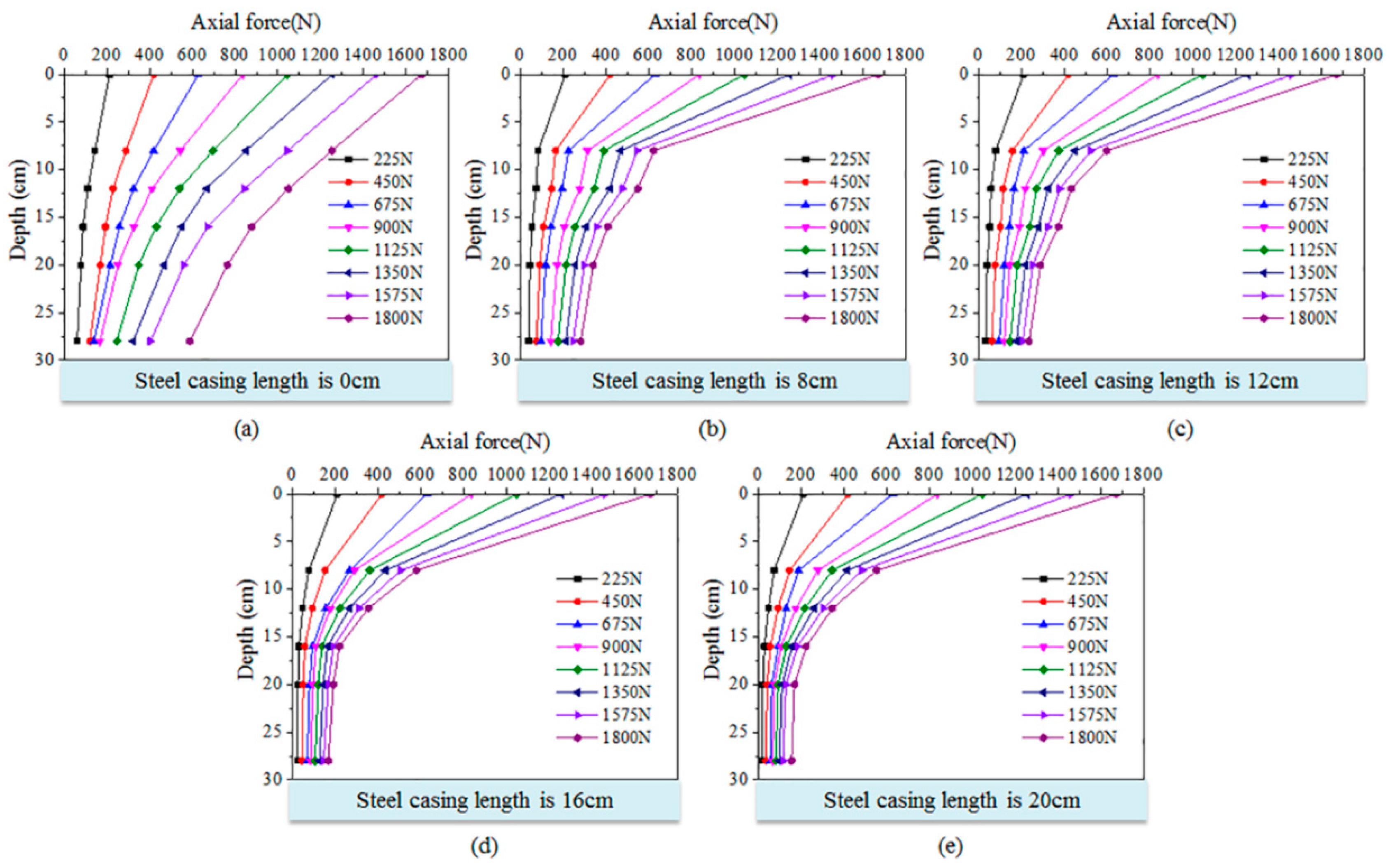

3.2. Effect of Steel Casing on Axial Force

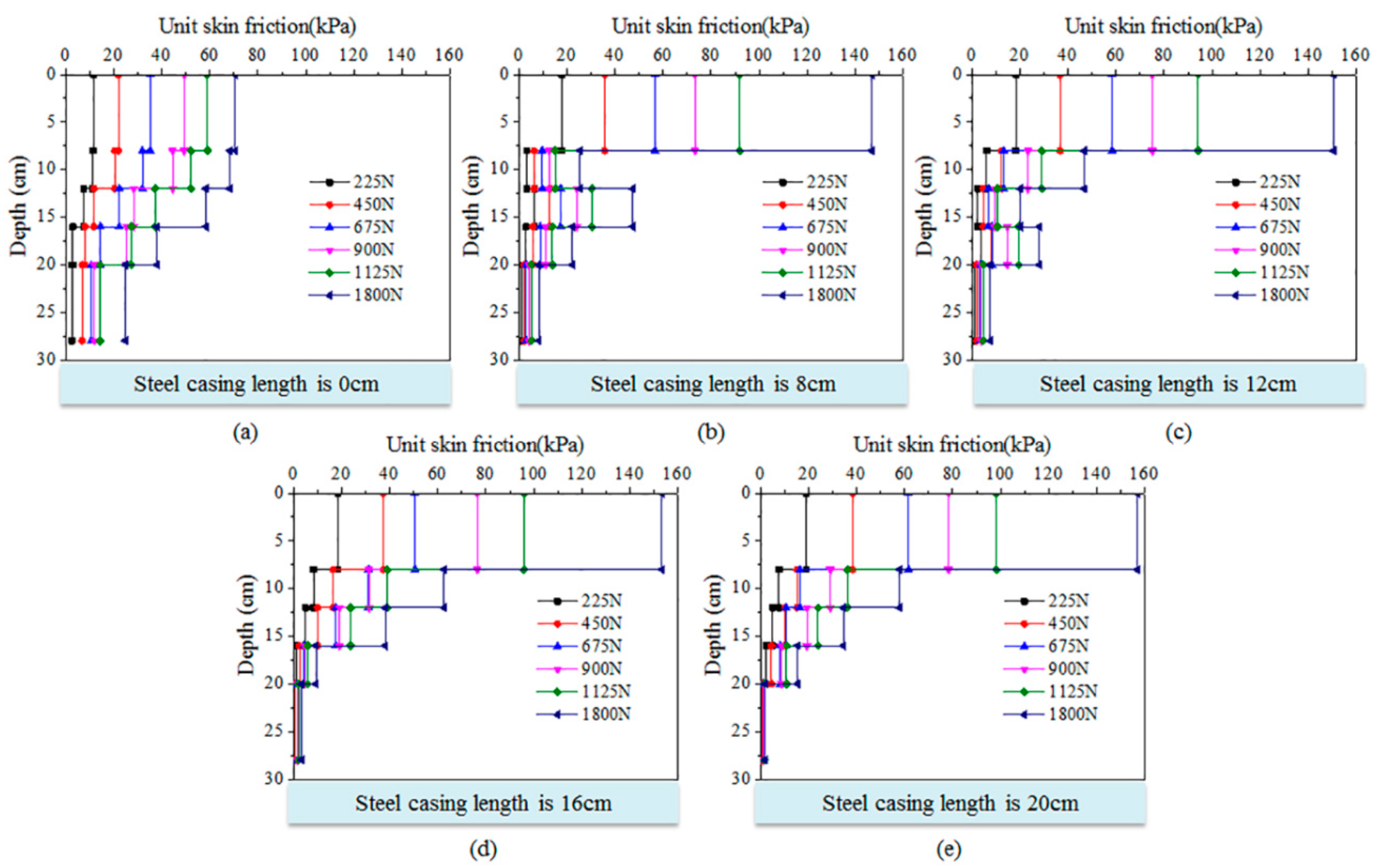

3.3. Effect of Steel Casing on Unit Skin Friction

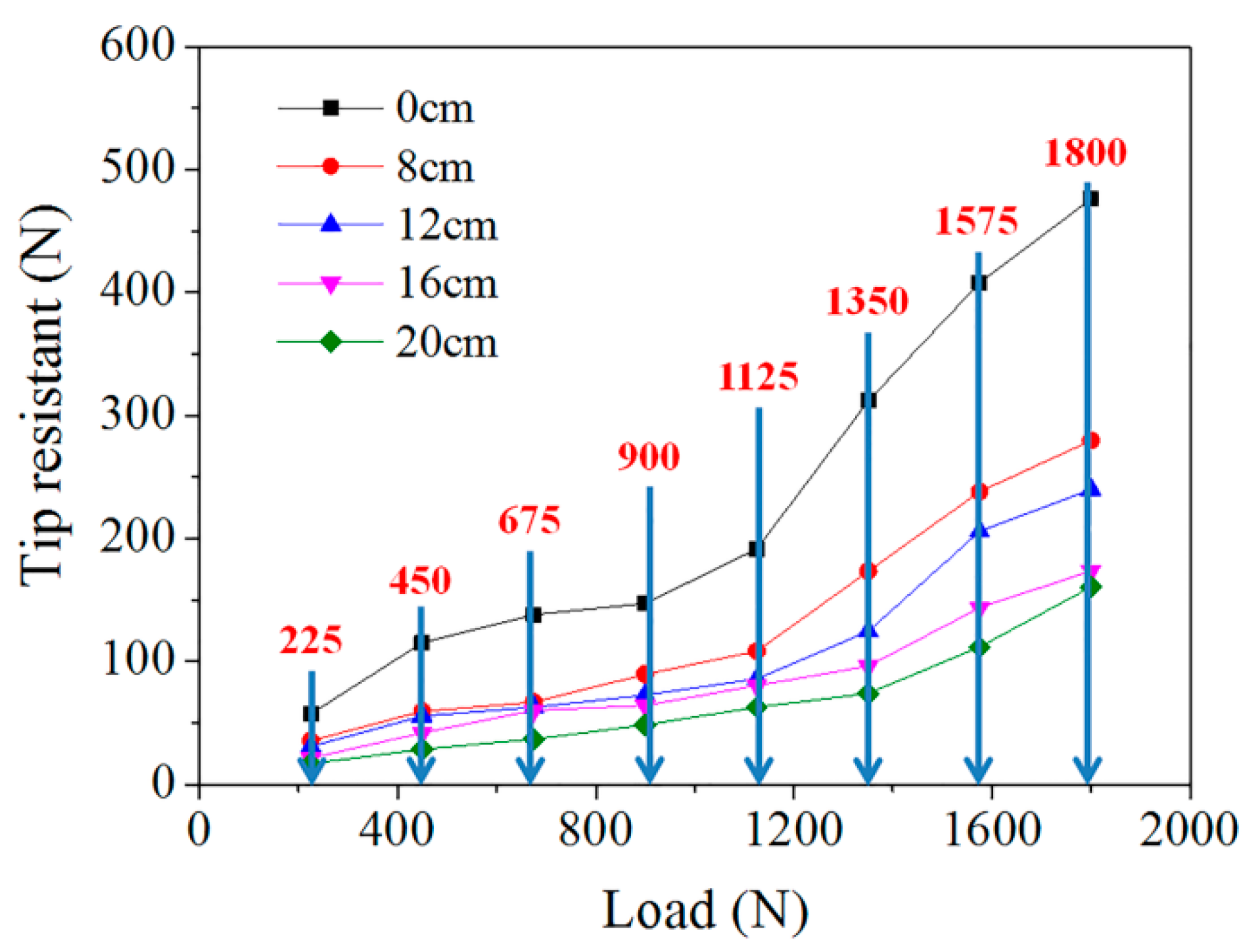

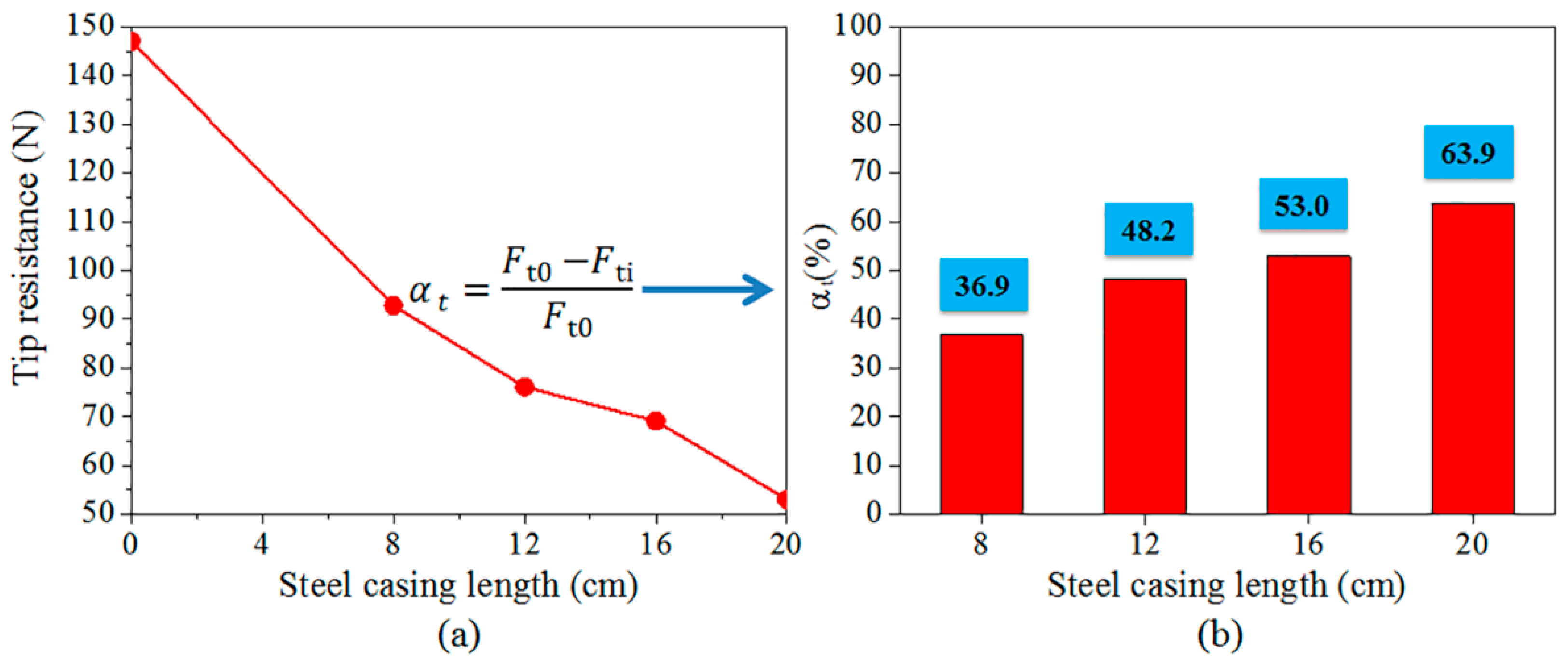

3.4. Effect of Steel Casing on Tip Resistance

3.5. Effect of Steel Casing on Shaft Resistance

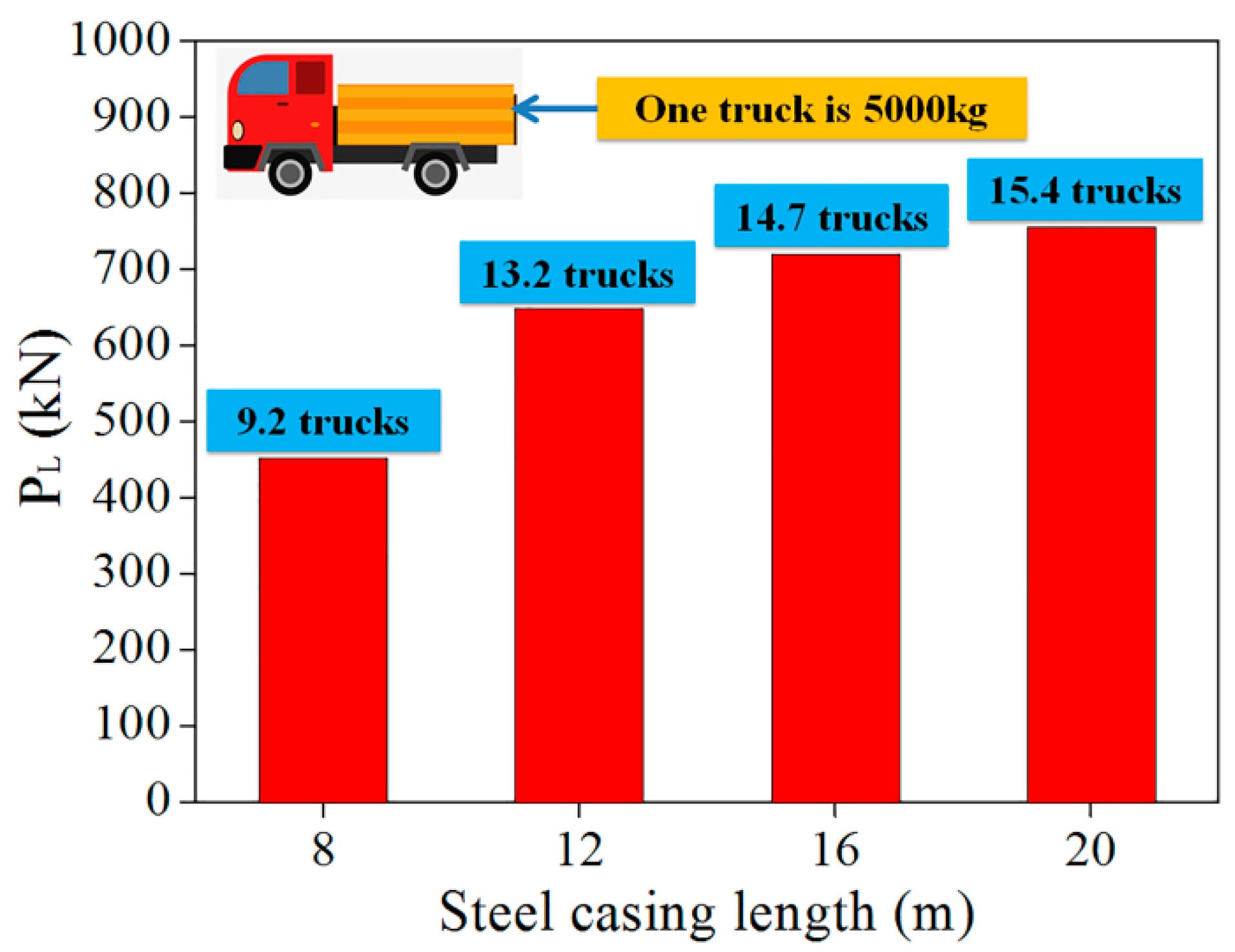

3.6. Advantages of Steel Casing in Pile Foundation Engineering

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lai, J.; Liu, H.; Qiu, J.; Fan, H.; Zhang, Q.; Hu, Z.; Wang, J. Stress analysis of CFG pile composite foundation in consolidating saturated mine tailings dam. Adv. Mater. Sci. Eng. 2016, 2016, 1–12. [Google Scholar] [CrossRef]

- Lai, J.; Liu, H.; Qiu, J.; Chen, J. Settlement analysis of saturated tailings dam treated by CFG pile composite foundation. Adv. Mater. Sci. Eng. 2016, 2016, 1–10. [Google Scholar] [CrossRef]

- Lai, J.; Mao, S.; Qiu, J.; Fan, H.; Zhang, Q.; Hu, Z.; Chen, J. Investigation progresses and applications of fractional derivative model in geotechnical engineering. Math. Probl. Eng. 2016, 2016, 9183296:1–9183296:15. [Google Scholar] [CrossRef]

- Duan, L.; Zhang, Y.; Lai, J. Influence of Ground Temperature on Shotcrete-to-Rock Adhesion in Tunnels: A Review. Adv. Mater. Sci. Eng. 2019, 2019, 8709087:1–8709087:12. [Google Scholar] [CrossRef]

- Zhou, Z.; Dong, Y.; Jiang, P.; Han, D.; Liu, T. Calculation of Pile Side Friction by Multiparameter Statistical Analysis. Adv. Mater. Sci. Eng. 2019, 2019, 2638520:1–2638520:12. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, L.; Chen, Y. Analysis of compression pile response using a softening model, a hyperbolic model of skin friction, and a bilinear model of end resistance. J. Eng. Mech. 2014, 140, 102–111. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, S.; Zhang, S.; Zhang, J.; Wang, K. Simplified non-linear approaches for response of a single pile and pile groups considering progressive deformation of pile–soil system. Soils Found. 2016, 56, 473–484. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, Z. A simplified nonlinear approach for single pile settlement analysis. Can. Geotech. J. 2012, 49, 1256–1265. [Google Scholar] [CrossRef]

- Lee, C.W.; Kim, Y.S.; Park, S.Y. Development of prebored screw pile method and evaluation of its bearing characteristics. Mar. Georesour. Geotec. 2016, 34, 42–56. [Google Scholar] [CrossRef]

- Zhou, J.; Gong, X.; Wang, K.; Zhang, R.; Yan, T. A model test on the behavior of a static drill rooted nodular pile under compression. Mar. Georesour. Geotec. 2016, 34, 293–301. [Google Scholar] [CrossRef]

- Sun, H.; Wang, Q.P.; Zhang, P.; Zhong, Y.J.; Yue, X.B. Spatiotemporal Characteristics of Tunnel Traffic Accidents in China from 2001 to Present. Adv. Civ. Eng. 2019, 4536414, 1–16. [Google Scholar] [CrossRef]

- Ai, Z.Y.; Chen, Y.F.; Jiang, X.B. Behavior of laterally and vertically loaded piles in multi-layered transversely isotropic soils. Appl. Math. Model 2017. [Google Scholar] [CrossRef]

- Aslani, F.; Uy, B.; Tao, Z.; Mashiri, F. Behaviour and design of composite columns incorporating compact high-strength steel plates. J. Constr. Steel Res. 2015, 107, 94–110. [Google Scholar] [CrossRef]

- Aslani, F.; Uy, B.; Tao, Z.; Mashiri, F. Predicting the axial load capacity of high-strength concrete filled steel tubular columns. Steel Compos. Struct. 2015, 19, 967–993. [Google Scholar] [CrossRef]

- Montuori, R.; Piluso, V. Analysis and modelling of CFT members: Moment curvature analysis. Thin Wall. Struct. 2015, 86, 157–166. [Google Scholar] [CrossRef]

- Lai, J.; Qiu, J.; Fan, H.; Zhang, Q.; Hu, Z.; Wang, J.; Chen, J. Fiber bragg grating sensors-based in situ monitoring and safety assessment of loess tunnel. J. Sensors 2016, 2016, 8658290:1–8658290:10. [Google Scholar] [CrossRef]

- Gaaver, K.E. Geotechnical properties of Egyptian collapsible soils. Alex. Eng. J. 2012, 51, 205–210. [Google Scholar] [CrossRef] [Green Version]

- Momeni, M.; Shafiee, A.; Heidari, M.; Jafari, M.K.; Mahdavifar, M.R. Evaluation of soil collapse potential in regional scale. Nat. Hazards 2012, 64, 459–479. [Google Scholar] [CrossRef]

- Kalantari, B. Foundations on collapsible soils: A review. Proc. Inst. Civil Eng-Frensic Eng. 2013, 166, 57–63. [Google Scholar] [CrossRef]

- Qian, Z.; Lu, X.; Yang, W.; Cui, Q. Behaviour of micropiles in collapsible loess under tension or compression load. Geomech. Eng. 2014, 7, 477–493. [Google Scholar] [CrossRef]

- Noorzad, R.; Pakniat, H. Investigating the effect of sample disturbance, compaction and stabilization on the collapse index of soils. Environ. Earth Sci. 2016, 75. [Google Scholar] [CrossRef]

- Gao, X.; Wang, J.; Zhu, X. Static load test and load transfer mechanism study of squeezed branch and plate pile in collapsible loess foundation. J. Zhejiang Univ-sci. A 2007, 8, 1110–1117. [Google Scholar] [CrossRef]

- Wang, L.; Sun, J.; Huang, X.; Xu, S.; Shi, Y.; Qiu, R.; Zhang, Z. A field testing study on negative skin friction along piles induced by seismic subsidence of loess. Soil Dyn. Earthq. Eng. 2011, 31, 45–58. [Google Scholar] [CrossRef]

- Zhang, Y.; Yao, Y.; Ma, A.; Liu, C. In situ tests on improvement of collapsible loess with large thickness by down-hole dynamic compaction pile. Eur. J. Environ. Civ. En. 2017, 1–15. [Google Scholar] [CrossRef]

- Xing, H.; Liu, L. Field tests on influencing factors of negative skin friction for pile foundations in collapsible loess regions. Int. J. Civ. Eng. 2018, 16, 1–10. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhu, S.; Kong, X.; Lei, J.; Liu, T. Optimization Analysis of Settlement Parameters for Postgrouting Piles in Loess Area of Shaanxi, China. Adv. Civ. Eng. 2019, 2019, 7085104:1–7085104:11. [Google Scholar] [CrossRef]

- Naggar, M.H.E.; Sakr, M. Evaluation of axial performance of tapered piles from centrifuge tests. Can. Geotech. J. 2000, 37, 1295–1308. [Google Scholar] [CrossRef]

- Lee, M.; Bae, K.T.; Lee, I.W.; Yoo, M. Cyclic p-y Curves of Monopiles in Dense Dry Sand Using Centrifuge Model Tests. Appl. Sci. 2019, 9, 1641. [Google Scholar] [CrossRef]

- Im, E.S.; Kim, T.H. Lateral earth pressure acting on underground retaining structure in clay ground under embankment based on centrifuge model tests. KSCE J. Civ. Eng. 2004, 8, 387–396. [Google Scholar] [CrossRef]

- Jang, Y.S.; Kim, Y.S. Centrifugal model behavior of laterally loaded suction pile in sand. KSCE J. Civ. Eng. 2013, 17, 980–988. [Google Scholar] [CrossRef]

- Wang, C.; Zhou, S.; Guo, P.; Wang, B. Experimental analysis on settlement controlling of geogrid-reinforced pile-supported embankments on collapsible loess in high-speed railway. Int. J. Pavement Eng. 2014, 15, 867–878. [Google Scholar] [CrossRef]

- Wang, C.; Wang, B.; Guo, P.; Zhou, S. Experimental analysis on settlement controlling of geogrid-reinforced pile-raft-supported embankments in high-speed railway. Acta Geotech. 2014, 15, 231–242. [Google Scholar] [CrossRef]

- China Institute of Water Resources and Hydropower. Code of Geotechnical Centrifuge Model Tests; DL/T 5012-1999; CIWRH: Beijing, China, 1999. (In Chinese) [Google Scholar]

- Li, L.; Huang, J.; Han, B. Centrifugal Investigation of Excavation Adjacent to Existing Composite Foundation. J. Perform. Constr. Fac. 2018, 32. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Technical Code for Testing of Building Foundation Piles; JGJ106-2014; China Architecture & Building Press: Beijing, China, 2014.

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Chinese Technical Code for Building Pile Foundations; JGJ94-2008; China Architecture & Building Press: Beijing, China, 2008.

- Peng, J.; Li, X.; Fan, W.; Chen, Z.; Su, S.; Song, Y.; Lu, Q.; Deng, Y.; Chen, L.; Sun, P. Classification and development pattern of caves in the loess plateau. Earth Sci. Front 2007, 14, 234–244. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, L.; Chen, J.; Qu, C. Analysis and discussion of several issues of pile foundation construction in karst region of Tangshan. Chin. J. Geotech. Eng. 2011, 33, 318–323. [Google Scholar]

| Parameter | Ratio |

|---|---|

| Length | 1∶n |

| Displacement | 1∶n |

| Diameter | 1∶n |

| Stress and strain | 1∶1 |

| Area | 1∶n 2 |

| Force | 1∶n 2 |

| g Level | Pile Length L | Outside Diameter D | Thickness T | Young′s modulus E (GPa) | |||

|---|---|---|---|---|---|---|---|

| Model (mm) | Proto-Type (m) | Model (mm) | Proto-Type (m) | Model (mm) | Proto-Type (m) | ||

| 100 | 350 | 35 | 25 | 2.5 | 2 | 0.2 | 63.3 |

| g Level | Length L | Outside Diameter D | Thickness t | Young′s modulus E (GPa) | |||

|---|---|---|---|---|---|---|---|

| Model (cm) | Proto-Type (m) | Model (mm) | Proto-Type (m) | Model (mm) | Proto-Type (m) | ||

| 100 | 20 | 20 | 30 | 3 | 2 | 0.2 | 164 |

| 16 | 16 | ||||||

| 12 | 12 | ||||||

| 8 | 8 | ||||||

| Name | Density (g/cm3) | Compressive Modulus (MPa) | Moisture Content ω (%) | Cohesion c (kPa) | Internal Friction Angle φ (°) |

|---|---|---|---|---|---|

| Loess | 1.7 | 26.9 | 13.5 | 27 | 21 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, Z.; Hu, H.; Dong, Y.; Wang, F.; Jia, M.; Zhao, Y.; He, J. Effect of Steel Casing on Vertical Bearing Characteristics of Steel Tube-Reinforced Concrete Piles in Loess Area. Appl. Sci. 2019, 9, 2874. https://doi.org/10.3390/app9142874

Feng Z, Hu H, Dong Y, Wang F, Jia M, Zhao Y, He J. Effect of Steel Casing on Vertical Bearing Characteristics of Steel Tube-Reinforced Concrete Piles in Loess Area. Applied Sciences. 2019; 9(14):2874. https://doi.org/10.3390/app9142874

Chicago/Turabian StyleFeng, Zhongju, Haibo Hu, Yunxiu Dong, Fuchun Wang, Minghui Jia, Yawan Zhao, and Jingbin He. 2019. "Effect of Steel Casing on Vertical Bearing Characteristics of Steel Tube-Reinforced Concrete Piles in Loess Area" Applied Sciences 9, no. 14: 2874. https://doi.org/10.3390/app9142874