Performance of InGaN/GaN Light Emitting Diodes with n-GaN Layer Embedded with SiO2 Nano-Particles

Abstract

:1. Introduction

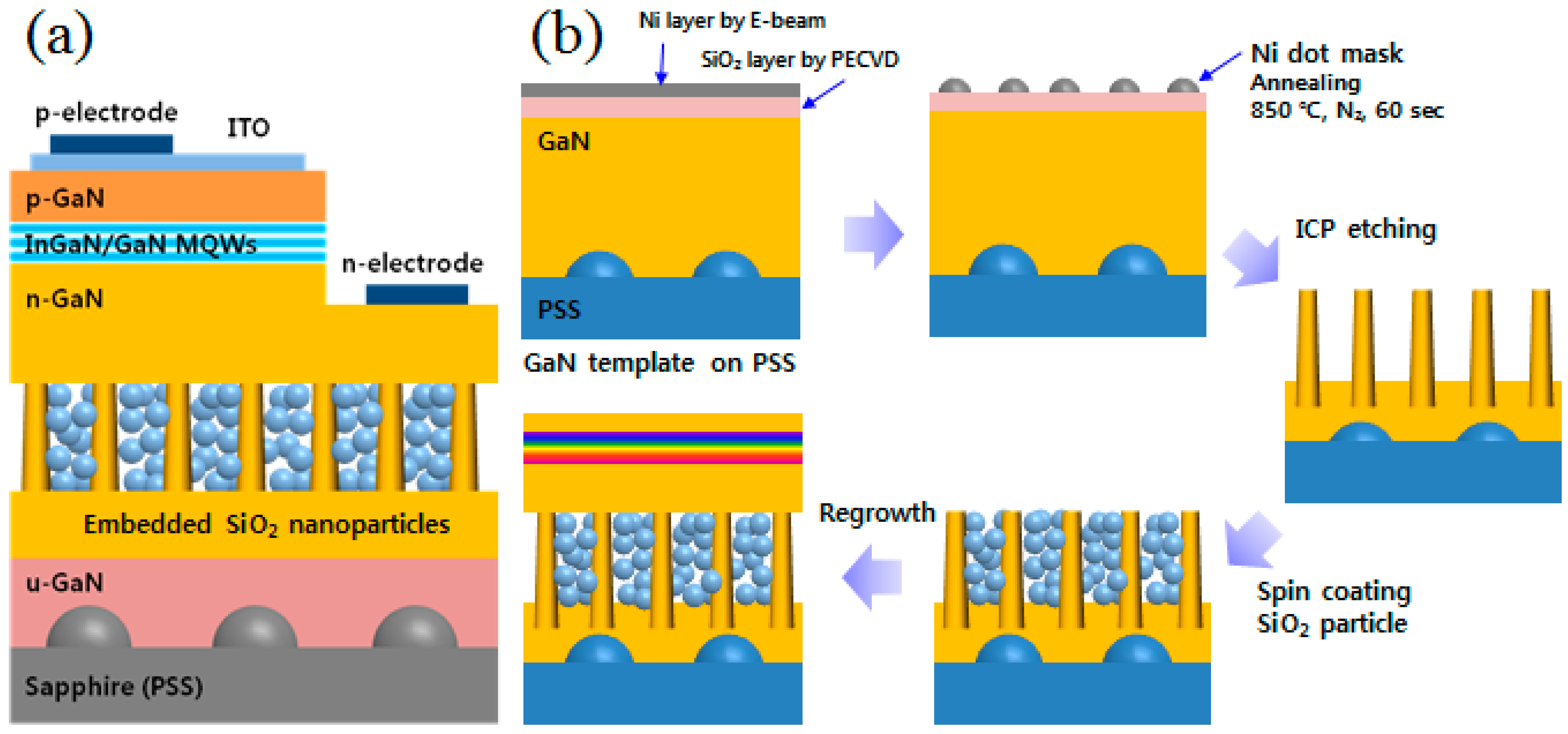

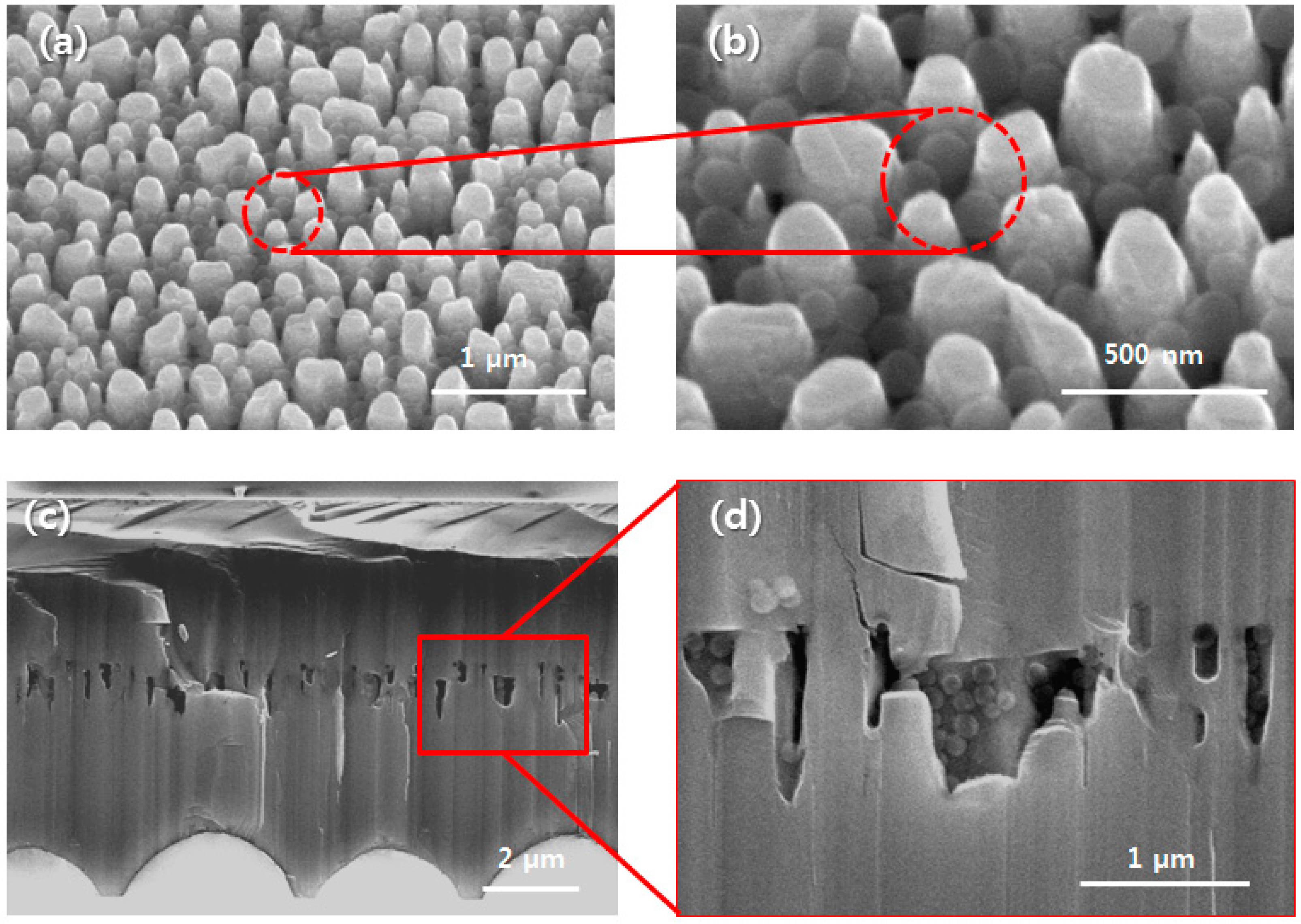

2. Experiment

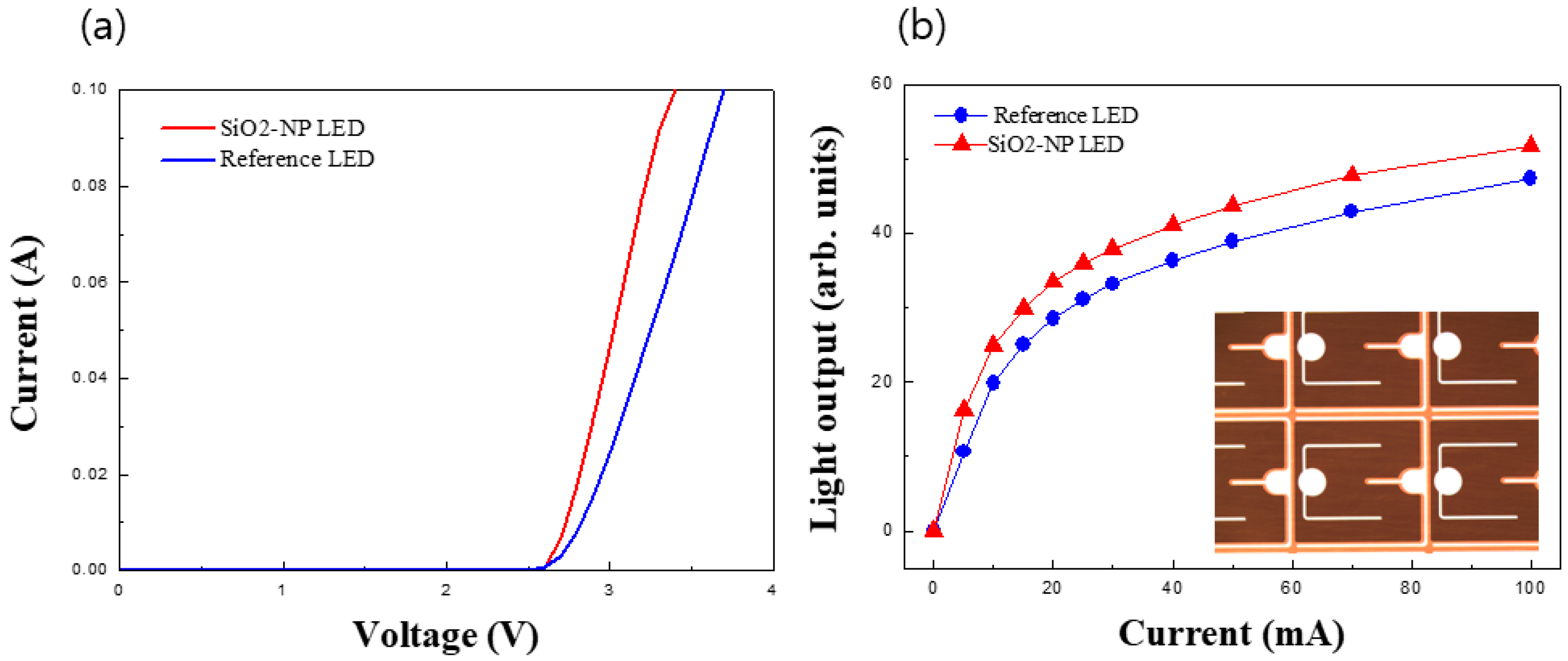

3. Experimental Results

4. Simulation and Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A: 3-D FDTD Simulation Conditions

Appendix B: Dislocation Density Comparison

Appendix C: Light Extraction Efficiency Comparison

References

- DenBaars, S.P.; Feezell, D.; Kelchner, K.; Pimputkar, S.; Pan, C.; Tanaka, C.S.; Zhao, Y.; Pfaff, N.; Farrell, R.; Iza, M.; et al. Development of gallium-nitride-based light-emitting diodes (LEDs) and laser diodes for energy-efficient lighting and displays. Acta Mater. 2013, 61, 945–951. [Google Scholar] [CrossRef]

- Robertso, J. Diamond-like amorphous carbon. Mater. Sci. Eng. Rep. 2002, 37, 129–281. [Google Scholar] [CrossRef] [Green Version]

- Jeon, D.W.; Jang, L.W.; Cho, H.S.; Kwon, K.S.; Dong, M.J.; Polyakov, A.Y.; Ju, J.W.; Chung, T.H.; Baek, J.H.; Lee, I.-H. Enhanced optical output performance in InGaN/GaN light-emitting diode embedded with SiO2 nanoparticles. Opt. Express 2014, 22, 21454–21459. [Google Scholar] [CrossRef] [PubMed]

- Kim, B.; Jang, S.; Kim, S.; Kim, Y.; Lee, J.; Byun, D. Epitaxial Lateral Overgrowth of GaN on Sapphire Substrate Using High-Dose N+-Ion-Implantation. J. Electrochem. Soc. 2010, 157, H1132–H1134. [Google Scholar] [CrossRef]

- Son, J.H.; Kim, J.U.; Song, Y.H.; Kim, B.J.; Ryu, C.J.; Lee, J.L. Design Rule of Nanostructures in Light-Emitting Diodes for Complete Elimination of Total Internal Reflection. Adv. Mater. 2012, 24, 2259–2262. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.G.; Kim, H.K.; Kim, H.Y.; Ryu, J.H.; Kang, J.H.; Han, N.; Uthirakumar, P.; Hong, C.H. Impact of two-floor air prism arrays as an embedded reflector for enhancing the output power of InGaN/GaN light emitting diodes. Appl. Phys. Lett. 2009, 95, 221110. [Google Scholar] [CrossRef]

- Cho, C.Y.; Kwon, M.K.; Park, I.K.; Hong, S.H.; Kim, J.J.; Park, S.E.; Kim, S.T.; Park, S.J. High-efficiency light-emitting diode with air voids embedded in lateral epitaxially overgrown GaN using a metal mask. Opt. Express 2011, 19, A943–A948. [Google Scholar] [CrossRef] [PubMed]

- Park, Y.J.; Kang, J.H.; Kim, H.Y.; Lysak, V.V.; Chandramohan, S.; Ryu, J.H.; Kim, H.K.; Han, N.; Jeong, H.; Jeong, M.S.; et al. Enhanced light emission in blue light-emitting diodes by multiple Mie scattering from embedded silica nanosphere stacking layers. Opt. Express 2011, 19, 23429–23435. [Google Scholar] [CrossRef] [PubMed]

- Fujii, T.; Gao, Y.; Sharma, R.; Hu, E.L.; DenBaars, S.P.; Nakamura, S. Increase in the extraction efficiency of GaN-based light-emitting diodes via surface roughening. Appl. Phys. Lett. 2004, 84, 855. [Google Scholar] [CrossRef]

- Pan, J.W.; Wang, C.S. Light extraction efficiency of GaN-based LED with pyramid texture by using ray path analysis. Opt. Express 2012, 20, A630–A640. [Google Scholar] [CrossRef] [PubMed]

- Lee, T.X.; Gao, K.F.; Chien, W.T.; Sun, C.C. Light extraction analysis of GaN-based light-emitting diodes with surface texture and/or patterned substrate. Opt. Express 2007, 15, 6670–6676. [Google Scholar] [CrossRef] [PubMed]

- Kang, J.H.; Ryu, J.H.; Kim, H.K.; Kim, H.Y.; Han, N.; Park, Y.J.; Uthirakumar, P.; Hong, C.H. Comparison of various surface textured layer in InGaN LEDs for high light extraction efficiency. Opt. Express 2011, 19, 3637–3647. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.H.; Wu, Y.C.S.; Liao, W.C.; Lin, B.W. Improved crystal quality and performance of GaN-based light-emitting diodes by decreasing the slanted angle of patterned sapphire. Appl. Phys. Lett. 2010, 96, 051109. [Google Scholar] [CrossRef]

- Xu, S.R.; Li, P.X.; Jiang, J.C.T.; Ma, J.J.; Lin, Z.Y.; Hao, Y. Threading dislocation annihilation in the GaN layer on cone patterned sapphire substrate. J. Alloy. Compd. 2014, 614, 360–363. [Google Scholar] [CrossRef]

- Ko, D.; Yoon, J.; Seo, J. Patterned substrates enhance LED light extraction. LEDs Magazine, 22 July 2014; 53–58. [Google Scholar]

- Lysak, V.V.; Kang, J.H.; Hong, C.H. Conical air prism arrays as an embedded reflector for high efficient InGaN/GaN light emitting diodes. Appl. Phys. Lett. 2013, 102, 061114. [Google Scholar] [CrossRef]

- Kim, J.; Woo, H.; Joo, K.; Tae, S.; Park, J.; Moon, D.; Park, S.H.; Jang, J.; Cho, Y.; Park, J.; et al. Less strained and more efficient GaN light-emitting diodes with embedded silica hollow nanospheres. Sci. Rep. 2013, 3, 3201. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chiu, C.H.; Yen, H.H.; Chao, C.L.; Li, Z.Y.; Yu, P.; Kuo, H.C.; Lu, T.C.; Wang, S.C.; Lau, K.M.; Cheng, S.J. Nanoscale epitaxial lateral overgrowth of GaN-based light-emitting diodes on a SiO2 nanorod-array patterned sapphire template. Appl. Phys. Lett. 2008, 93, 081108. [Google Scholar] [CrossRef]

- Wuu, D.S.; Wang, W.K.; Wen, K.S.; Huang, S.C.; Lin, S.H.; Huang, S.Y.; Lin, C.F. Defect reduction and efficiency improvement of near-ultraviolet emitters via laterally overgrown GaN on a GaN/patterned sapphire template. Appl. Phys. Lett. 2006, 89, 161105. [Google Scholar] [CrossRef]

- Park, J.M.; Oh, J.K.; Kwon, K.W.; Kim, Y.H.; Jo, S.S.; Lee, J.K.; Ryu, S.W. Improved light output of photonic crystal light-emitting diode fabricated by anodized aluminum oxide nano-patterns. IEEE Photon. Technol. Lett. 2008, 20, 321–323. [Google Scholar] [CrossRef]

- Kuo, C.H.; Chang, L.C.; Chou, H.M. Current spreading improvement in GaN-based light-emitting diode grown on nano-rod GaN template. IEEE Photon. Technol. Lett. 2012, 24, 608–610. [Google Scholar] [CrossRef]

- Jeon, D.W.; Choi, W.M.; Shin, H.J.; Yoon, S.M.; Choi, J.Y.; Jang, L.W.; Lee, I.-H. Nanopillar InGaN/GaN light emitting diodes integrated with homogeneous multilayer grapheme electrodes. J. Mater. Chem. 2011, 21, 17688–17692. [Google Scholar] [CrossRef]

- Shim, J.I.; Ryu, H.Y. Explanation of the efficiency droop in InGaN multiple quantum well light-emitting diodes by the reduced radiative recombination probability. In Proceedings of the 2010 SPIE Photonic West, San Francisco, CA, USA, 23–28 January 2010; pp. 7617–7619. [Google Scholar] [CrossRef]

- Mukai, T.; Nakamura, S. Ultraviolet InGaN and GaN Single-Quantum-Well-Structure Light-Emitting Diodes Grown on Epitaxially Laterally Overgrown GaN Substrates. J. Appl. Phys. 1999, 38, 5735. [Google Scholar] [CrossRef]

- Polyakov, A.Y.; Smirnov, N.B.; Yakimov, E.B.; Cho, H.S.; Baek, J.H.; Turutin, A.V.; Shemerov, I.V.; Kondratyev, E.S.; Lee, I.-H. Deep Electron Traps Responsible for Higher Quantum Efficiency in Improved GaN/InGaN Light Emitting Diodes Embedded with SiO2 Nanoparticles. ECS Solid State Sci. Technol. 2016, 5, Q274–Q277. [Google Scholar] [CrossRef]

- Lee, I.-H.; Polyakov, A.Y.; Smirnov, N.B.; Shchemerov, I.V.; Lagov, P.B.; Zinov’ev, R.A.; Yakimov, E.B.; Shcherbachev, K.D.; Pearton, S.J. Point defects controlling non-radiative recombination in GaN blue light emitting diodes: Insights from radiation damage experiments. J. Appl. Phys. 2017, 122, 115704. [Google Scholar] [CrossRef]

- Chiu, C.H.; Lin, C.C.; Han, H.V.; Liu, C.Y.; Chen, Y.H.; Lan, Y.P.; Yu, P.; Kuo, H.C.; Lu, T.C.; Wang, S.C.; et al. High efficiency GaN-based light-emitting diodes with embedded air voids/SiO2 nanomasks. Nanotechnology 2012, 23, 045303. [Google Scholar] [CrossRef] [PubMed]

| IQE [%] a) | At 20 mA | At 100 mA |

|---|---|---|

| Reference LED | 88.7 | 84 |

| SiO2 NP LED | 91.2 | 87.8 |

| Light Output Increase a) | 13.5% |

| IQE Increase | 4.5% |

| LEE Increase | 8.6% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yom, H.-S.; Yang, J.-K.; Polyakov, A.Y.; Lee, I.-H. Performance of InGaN/GaN Light Emitting Diodes with n-GaN Layer Embedded with SiO2 Nano-Particles. Appl. Sci. 2018, 8, 1574. https://doi.org/10.3390/app8091574

Yom H-S, Yang J-K, Polyakov AY, Lee I-H. Performance of InGaN/GaN Light Emitting Diodes with n-GaN Layer Embedded with SiO2 Nano-Particles. Applied Sciences. 2018; 8(9):1574. https://doi.org/10.3390/app8091574

Chicago/Turabian StyleYom, Hong-Seo, Jin-Kyu Yang, Alexander Y. Polyakov, and In-Hwan Lee. 2018. "Performance of InGaN/GaN Light Emitting Diodes with n-GaN Layer Embedded with SiO2 Nano-Particles" Applied Sciences 8, no. 9: 1574. https://doi.org/10.3390/app8091574