Leachability and Stability of Hexavalent-Chromium-Contaminated Soil Stabilized by Ferrous Sulfate and Calcium Polysulfide

Abstract

1. Introduction

2. Materials and Methods

2.1. Cr(VI) Contaminated Soil Preparation

2.2. Stabilized of Cr(VI) Contaminated Soil

3. Test Methods

4. Results and Discussion

4.1. pH of Stabilized Soils

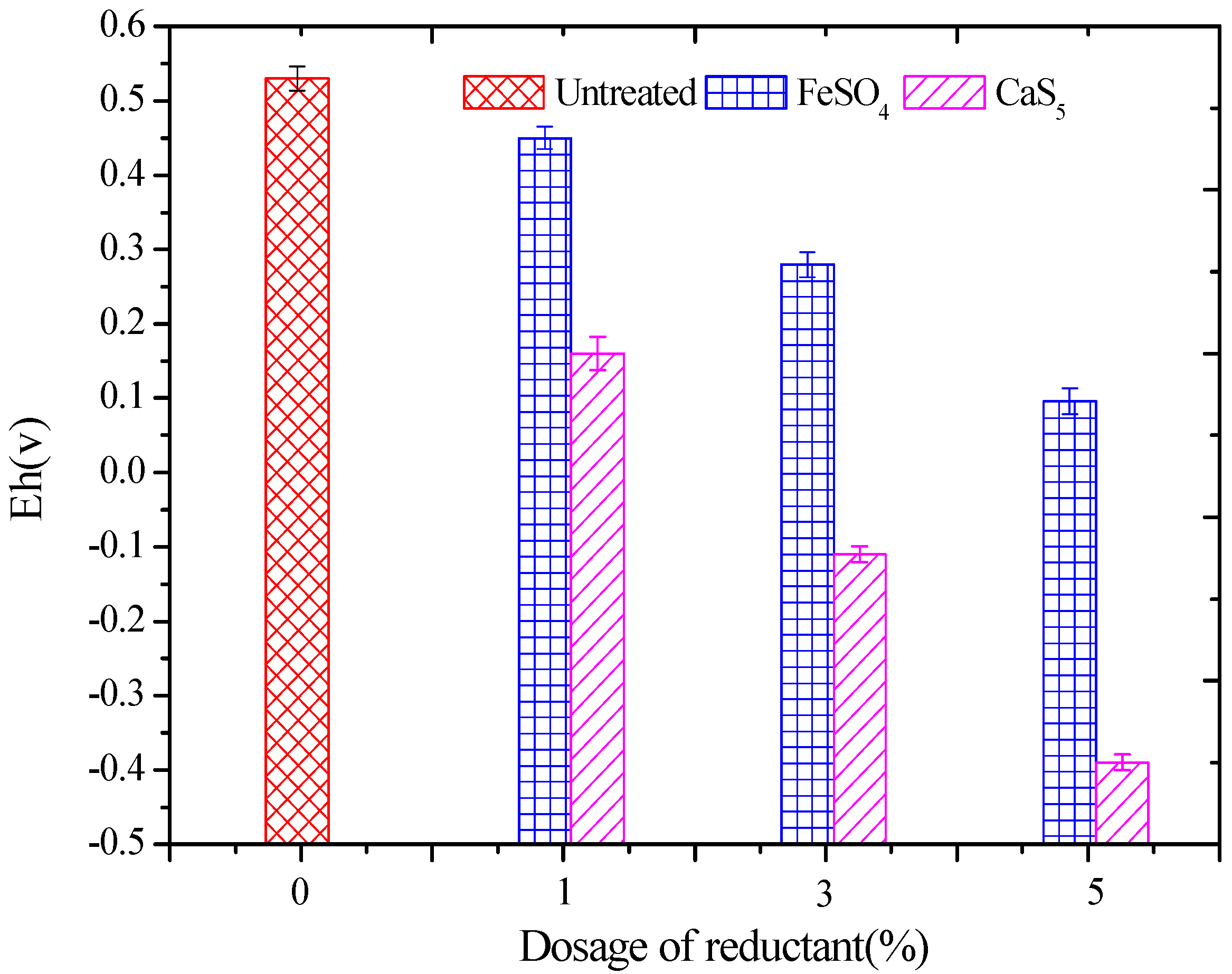

4.2. Redox Potential of Stabilized Soils

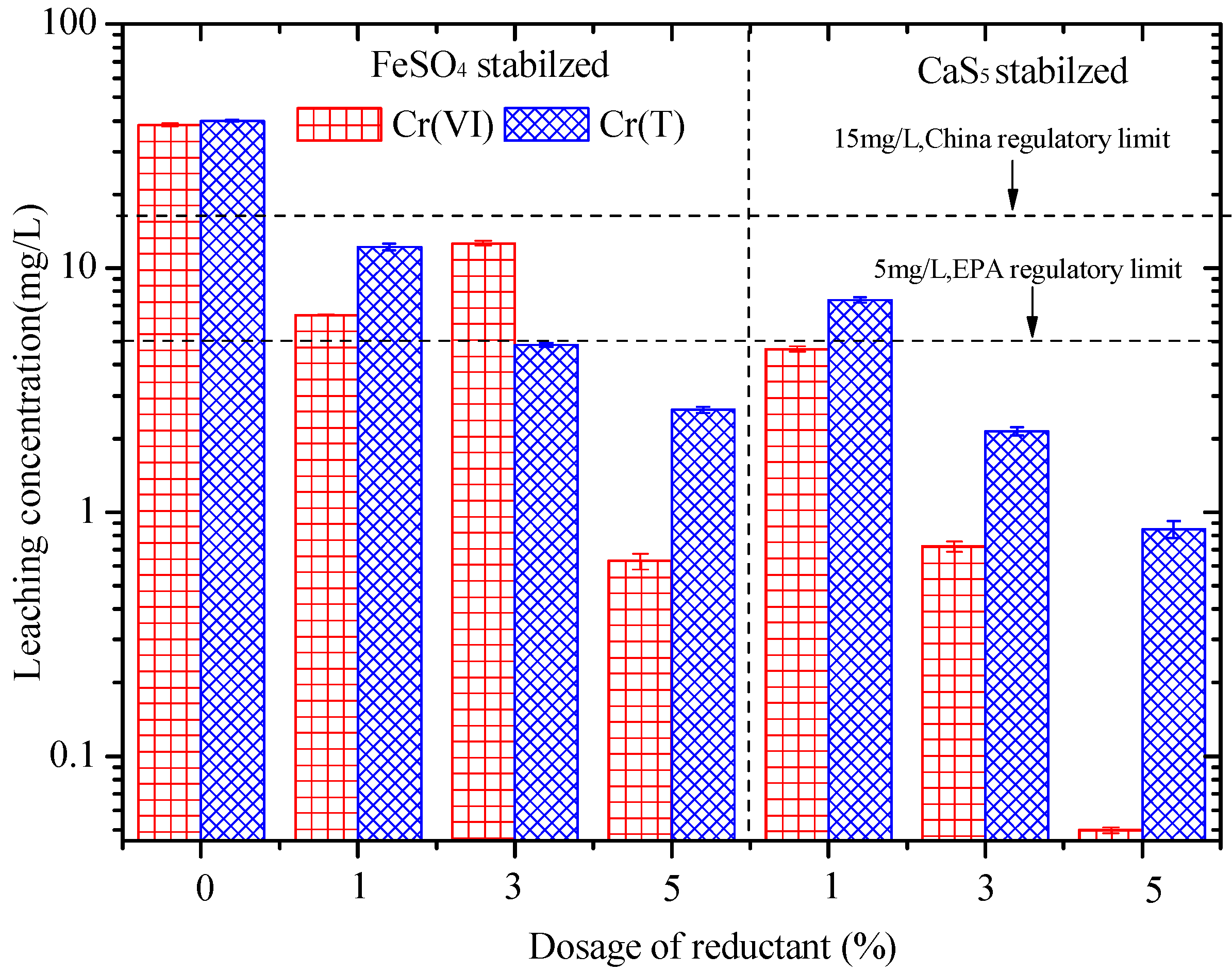

4.3. Leachability of Cr/Cr(VI) from Contaminated Soil in TCLP Leaching

4.4. Bioaccessibility of Cr/Cr(VI) from Contaminated Soil

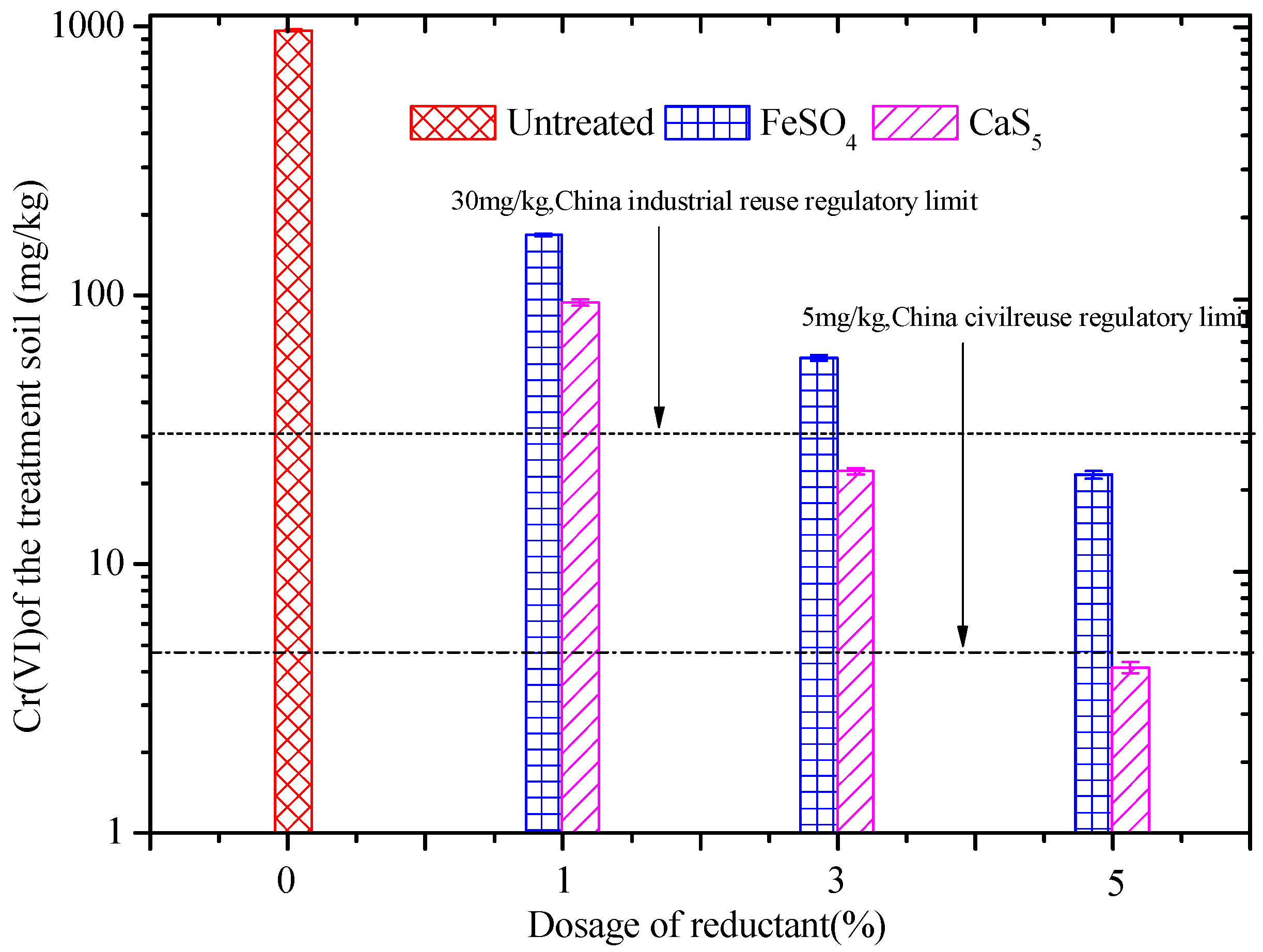

4.5. Cr(VI) Content in Soils before and after Stabilization

4.6. Species Distribution of Cr in Soils before and after Stabilization

4.7. Probable Immobilization Mechanism of Cr

4.8. Conclusions

- The pH and redox potential of the CaS5-stabilized soils were better than those of the FeSO4-stabilized soils regardless of CaS5 dosage. The concentrations of Cr(VI) and Cr leached from the stabilized soils with FeSO4 were larger than those of CaS5 at the same dosage. The Cr(VI) content in the stabilized soils was decreased with the increase in FeSO4 and CaS5 dosages, and that in the CaS5-stabilized soils decreased more noticeably compared with that in the FeSO4-stabilized soils at the same dosage. This finding reflected that CaS5 presented a better effect than FeSO4 in the stabilization of Cr(VI) and Cr.

- The leached Cr(VI)/Cr from the SBET leaching test was considerably larger than that from TCLP leaching due to the difference in the stabilization mechanism and the pH of the leaching solutions. The bioaccessibility risk of Cr in the FeSO4-stabilized soils was higher than that in the CaS5-stabilized soils due to the difference in stabilization mechanisms of Cr(VI) between FeSO4 and CaS5.

- The differences in the leachability, bioaccessibility, and toxicity of Cr(VI) and Cr in the FeSO4- and CaS5-stabilized soils were attributed to the changes in mineral composition. For the FeSO4-stabilized soil, the Cr(VI) was mainly converted to Cr(OH)3 and CrxFe1−x(OH)3. For the CaS5-stabilized soil, the Cr(VI) was reducted to Cr(III) and formed ettringite and sulfur. The Cr(III) was retained in the crystal structures of ettringite and sulfur through anion exchange.

Author Contributions

Funding

Conflicts of Interest

References

- Yin, W.; Li, Y.; Wu, J.; Chen, G.; Jiang, G.; Li, P.; Gu, J.; Liang, H.; Liu, C. Enhanced Cr (VI) removal from groundwater by Fe0-H2O system with bio-amended iron corrosion. J. Hazard. Mater. 2017, 332, 42–50. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Xu, X.; Liu, J.; Wu, K.; Gu, C.; Shao, G.; Chen, S.; Chen, G.; Huo, X. The hazard of chromium exposure to neonates in Guiyu of China. Sci. Total Environ. 2008, 403, 99–104. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Xia, J. Chromium contamination accident in China: Viewing environment policy of China. Environ. Sci. Technol. 2011, 45, 8605–8606. [Google Scholar] [CrossRef] [PubMed]

- Dong, X.; Ma, L.Q.; Gress, J.; Harris, W.; Li, Y. Enhanced Cr (VI) reduction and As (III) oxidation in ice phase: Important role of dissolved organic matter from biochar. J. Hazard. Mater. 2014, 267, 62–70. [Google Scholar] [CrossRef] [PubMed]

- Megharaj, M.; Avudainayagam, S.; Naidu, R. Toxicity of hexavalent chromium and its reduction by bacteria isolated from soil contaminated with tannery waste. Curr. Microbiol. 2003, 47, 0051–0054. [Google Scholar] [CrossRef] [PubMed]

- Dermatas, D.; Chrysochoou, M.; Moon, D.H.; Grubb, D.G.; Wazne, M.; Christodoulatos, C. Ettringite-induced heave in chromite ore processing residue (COPR) upon ferrous sulfate treatment. Environ. Sci. Technol. 2006, 40, 5786–5792. [Google Scholar] [CrossRef] [PubMed]

- Chrysochoou, M.; Johnston, C.P. Polysulfide speciation and reactivity in chromate-contaminated soil. J. Hazard. Mater. 2015, 281, 87–94. [Google Scholar] [CrossRef] [PubMed]

- Di Palma, L.; Gueye, M.T.; Petrucci, E. Hexavalent chromium reduction in contaminated soil: A comparison between ferrous sulphate and nanoscale zero-valent iron. J. Hazard. Mater. 2015, 281, 70–76. [Google Scholar] [CrossRef] [PubMed]

- Seaman, J.C.; Bertsch, P.M.; Schwallie, L. In situ Cr (VI) reduction within coarse-textured, oxide-coated soil and aquifer systems using Fe (II) solutions. Environ. Sci. Technol. 1999, 33, 938–944. [Google Scholar] [CrossRef]

- Buerge, I.J.; Hug, S.J. Influence of mineral surfaces on chromium (VI) reduction by iron (II). Environ. Sci. Technol. 1999, 33, 4285–4291. [Google Scholar] [CrossRef]

- Chrysochoou, M.; Johnston, C.P.; Dahal, G. A comparative evaluation of hexavalent chromium treatment in contaminated soil by calcium polysulfide and green-tea nanoscale zero-valent iron. J. Hazard. Mater. 2012, 201, 33–42. [Google Scholar] [CrossRef] [PubMed]

- Wazne, M.; Jagupilla, S.C.; Moon, D.H.; Jagupilla, S.C.; Christodoulatos, C.; Kim, M.G. Assessment of calcium polysulfide for the remediation of hexavalent chromium in chromite ore processing residue (COPR). J. Hazard. Mater. 2007, 143, 620–628. [Google Scholar] [CrossRef] [PubMed]

- Chrysochoou, M.; Ferreira, D.R.; Johnston, C.P. Calcium polysulfide treatment of Cr (VI)-contaminated soil. J. Hazard. Mater. 2010, 179, 650–657. [Google Scholar] [CrossRef] [PubMed]

- Petrucci, E.; Montanaro, D.; Merli, C. Sequential extraction analysis provides decision-making tools for the use of contaminated sediments. Chem. Ecol. 2011, 27, 107–118. [Google Scholar] [CrossRef]

- Zimmerman, A.J.; Weindorf, D.C. Heavy metal and trace metal analysis in soil by sequential extraction: A review of procedures. Int. J. Anal. Chem. 2010, 2010, 387803. [Google Scholar] [CrossRef] [PubMed]

- Li, J.S.; Xue, Q.; Wang, P.; Zhang, T.T.; Zhao, Y. Comparison of solidification/stabilization of lead contaminated soil between magnesia–phosphate cement and ordinary portland cement under the same dosage. Environ. Prog. Sustain. Energy 2016, 35, 88–94. [Google Scholar] [CrossRef]

- Wang, P.; Xue, Q.; Li, J.S.; Zhang, T.T. Effects of pH on leaching behavior of compacted cement solidified/stabilized lead contaminated soil. Environ. Prog. Sustain. Energy 2016, 35, 149–155. [Google Scholar] [CrossRef]

- Zhang, D.; Kong, H.; Wu, D.; He, S.; Hu, Z.; Hu, X. Remediation of chromite ore processing residue by pyrolysis process with sewage sludge. Bioresour. Technol. 2009, 100, 2874–2877. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Fang, Z.; Liang, B.; Tsang, E.P. Remediation of hexavalent chromium contaminated soil by stabilized nanoscale zero-valent iron prepared from steel pickling waste liquor. Chem. Eng. J. 2014, 247, 283–290. [Google Scholar] [CrossRef]

- Wang, Y.; Fang, Z.; Kang, Y.; Tsang, E.P. Immobilization and phytotoxicity of chromium in contaminated soil remediated by CMC-stabilized nZVI. J. Hazard. Mater. 2014, 275, 230–237. [Google Scholar] [CrossRef] [PubMed]

- Du, J.; Lu, J.; Wu, Q.; Jing, C. Reduction and immobilization of chromate in chromite ore processing residue with nanoscale zero-valent iron. J. Hazard. Mater. 2012, 215, 152–158. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Li, X.; Zhou, Q.; Peng, Z.; Liu, G.; Qi, T. Remediation of chromite ore processing residue by hydrothermal process with starch. Process Saf. Environ. Prot. 2011, 89, 179–185. [Google Scholar] [CrossRef]

- Jagupilla, S.C.; Moon, D.H.; Wazne, M.; Christodoulatos, C.; Kim, M.G. Effects of particle size and acid addition on the remediation of chromite ore processing residue using ferrous sulfate. J. Hazard. Mater. 2009, 168, 121–128. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Evett, J.B. Soil Properties, Testing, Measurement, and Evaluation, 5th ed.; Prentice-Hall: New York, NY, USA, 2002. [Google Scholar]

- United States Environmental Protection Agency (US EPA). Method 3050 B: Acid Digestion of Sediments, Sludges and Soils; US EPA: Washington, DC, USA, 1996.

- ASTM International. D4972-01, Standard Test Method for pH of Soils; ASTM International: West Conshohocken, PA, USA, 2001. [Google Scholar]

- United States Environmental Protection Agency. Toxicity Characteristic Leaching Procedure, Method 1311; United States Environmental Protection Agency: Washington, DC, USA, 1992.

- US EPA. Estimation of Relative Bioavailability of Lead in Soil and Soil-Like Materials Using In Vivo and In Vitro Methods; Office of Solid Waste and Emergency Response (OSWER), US EPA: Washington, DC, USA, 2007; Volume 9285, pp. 7–77.

- Oomen, A.G.; Hack, A.; Minekus, M.; Zeijdner, E.; Cornelis, C.; Schoeters, G.; Verstraete, W.; Van de Wiele, T.; Wragg, J.; Rompelberg, C.J.; et al. Comparison of five in vitro digestion models to study the bioaccessibility of soil contaminants. Environ. Sci. Technol. 2002, 36, 3326–3334. [Google Scholar] [CrossRef] [PubMed]

- U.S. Environmental Protection Agency. Alkaline Digestion for Hexavalentchromium, Method 3060A; U.S. Environmental Protection Agency: Washington, DC, USA, 1996.

- U.S. Environmental Protection Agency. Chromium, Hexavalent (Colorimetric), Method 7196A; U.S. Environmental Protection Agency: Washington, DC, USA, 1992.

- Rauret, G.; Lopez-Sanchez, J.F.; Sahuquillo, A.; Rubio, R.; Davidson, C.; Ure, A.; Quevauviller, P. Improvement of the BCR three step sequential extraction procedure prior to the certification of new sediment and soil reference materials. J. Environ. Monit. 1999, 1, 57–61. [Google Scholar] [CrossRef] [PubMed]

- Choppala, G.; Kunhikrishnan, A.; Seshadri, B.; Park, J.H.; Bush, R.; Bolan, N. Comparative sorption of chromium species as influenced by pH, surface charge and organic matter content in contaminated soils. J. Geochem. Explor. 2018, 184, 255–260. [Google Scholar] [CrossRef]

- GB/T5085.3. Identification Standards for Hazardous Wastes-Identification for Extraction Toxicity; Ministry of Environmental Protection of the People’s Republic of China: Beijing, China, 2007.

- GB15618. Environmental Quality Standards Soils; Ministry of Environmental Protection of the People’s Republic of China: Beijing, China, 2008.

- Kostarelos, K.; Rao, E.; Reale, D.; Moon, D.H. Reduction of Cr (VI) to Cr (III) in artificial, contaminated soil using ferrous sulfate heptahydrate and sodium thiosulfate. Pract. Period. Hazard. Toxic Radioact. Waste Manag. 2009, 13, 135–139. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, J.; Wang, L.; Chen, J.; Hou, H.; Yang, J.; Lu, X. Long-term stability of FeSO4 and H2SO4 treated chromite ore processing residue (COPR): Importance of H+ and SO42−. J. Hazard. Mater. 2017, 321, 720–727. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Zhou, M.; Wu, X.; Han, Y.; Geng, J.; Wang, T.; Wan, S.; Hou, H. Reductive solidification/stabilization of chromate in municipal solid waste incineration fly ash by ascorbic acid and blast furnace slag. Chemosphere 2017, 182, 76–84. [Google Scholar] [CrossRef] [PubMed]

- Graham, M.C.; Farmer, J.G.; Anderson, P.; Paterson, E.; Hillier, S.; Lumsdon, D.G.; Bewley, R.J. Calcium polysulfide remediation of hexavalent chromium contamination from chromite ore processing residue. Sci. Total Environ. 2006, 364, 32–44. [Google Scholar] [CrossRef] [PubMed]

- Jacobs, J.A.; Testa, S.M. Overview of chromium (VI) in the Environment: Background and history. In Chromium (VI) Handbook; CRC Press: Boca Raton, FL, USA, 2005; pp. 1–21. [Google Scholar]

- Yang, J.K.; Barnett, M.O.; Jardine, P.M.; Basta, N.T.; Casteel, S.W. Adsorption, sequestration, and bioaccessibility of As (V) in soils. Environ. Sci. Technol. 2002, 36, 4562–4569. [Google Scholar] [CrossRef] [PubMed]

- Jardine, P.M.; Stewart, M.A.; Barnett, M.O.; Basta, N.T.; Brooks, S.C.; Fendorf, S.; Mehlhorn, T.L. Influence of soil geochemical and physical properties on chromium (VI) sorption and bioaccessibility. Environ. Sci. Technol. 2013, 47, 11241–11248. [Google Scholar] [CrossRef] [PubMed]

| Items | Raw Soil | Chromium-Contaminated Soil | |

|---|---|---|---|

| Physicochemical properties | Water content/% | 20.78 | --- |

| pH | 8.53 | 7.76 | |

| Specific gravity | 2.72 | 2.79 | |

| Liquid limit/% | 41.63 | 40.18 | |

| Plastic limit/% | 21.84 | 21.33 | |

| Mn (mg/kg) | 798.36 | 797.48 | |

| C.E.C (meq/100 g) | 9.12 | 9.87 | |

| Mechanical properties | Optimum moisture content/% | 19.53 | 18.95 |

| Maximum dry density/(g/cm3) | 1.72 | 1.73 | |

| Brunauer-Emmett-Teller specific surface Area (m2/g) | 30.74 | 29.62 | |

| Grain-size distribution (%) | Clay content (<0.005 mm) | 4.62 | 3.23 |

| Silt content (0.005–0.075 mm) | 74.29 | 71.76 | |

| Sand content (0.075–2 mm) | 21.09 | 25.01 | |

| Chemical composition (%) | Al2O3 | 22.12 | 21.67 |

| SiO2 | 64.2 | 64.37 | |

| K2O | 2.78 | 2.85 | |

| CaO | 1.43 | 1.42 | |

| TiO2 | 0.84 | 0.86 | |

| MnO | 0.12 | 0.13 | |

| Fe2O3 | 8.51 | 8.59 | |

| Cr2O3 | --- | 0.11 |

| Test No. | Reductant | Dosage (%) |

|---|---|---|

| 1 | FeSO4 | 0 |

| 2 | FeSO4 | 1 |

| 3 | FeSO4 | 3 |

| 4 | FeSO4 | 5 |

| 5 | CaS5 | 0 |

| 6 | CaS5 | 1 |

| 7 | CaS5 | 3 |

| 8 | CaS5 | 5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, T.-T.; Xue, Q.; Wei, M.-L. Leachability and Stability of Hexavalent-Chromium-Contaminated Soil Stabilized by Ferrous Sulfate and Calcium Polysulfide. Appl. Sci. 2018, 8, 1431. https://doi.org/10.3390/app8091431

Zhang T-T, Xue Q, Wei M-L. Leachability and Stability of Hexavalent-Chromium-Contaminated Soil Stabilized by Ferrous Sulfate and Calcium Polysulfide. Applied Sciences. 2018; 8(9):1431. https://doi.org/10.3390/app8091431

Chicago/Turabian StyleZhang, Ting-Ting, Qiang Xue, and Ming-Li Wei. 2018. "Leachability and Stability of Hexavalent-Chromium-Contaminated Soil Stabilized by Ferrous Sulfate and Calcium Polysulfide" Applied Sciences 8, no. 9: 1431. https://doi.org/10.3390/app8091431

APA StyleZhang, T.-T., Xue, Q., & Wei, M.-L. (2018). Leachability and Stability of Hexavalent-Chromium-Contaminated Soil Stabilized by Ferrous Sulfate and Calcium Polysulfide. Applied Sciences, 8(9), 1431. https://doi.org/10.3390/app8091431