The Effect of TiC Additive on Mechanical and Electrical Properties of Al2O3 Ceramic

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

- (1)

- a-Al2O3 corundum A16SG (Alcoa, New York, NY, USA), with an average particle diameter of d50 = 0.53 µm,

- (2)

- TiC (Plasmotherm, Moscow, Russia), with 99.5% purity and an average particle diameter of d50 = 0.6 μm.

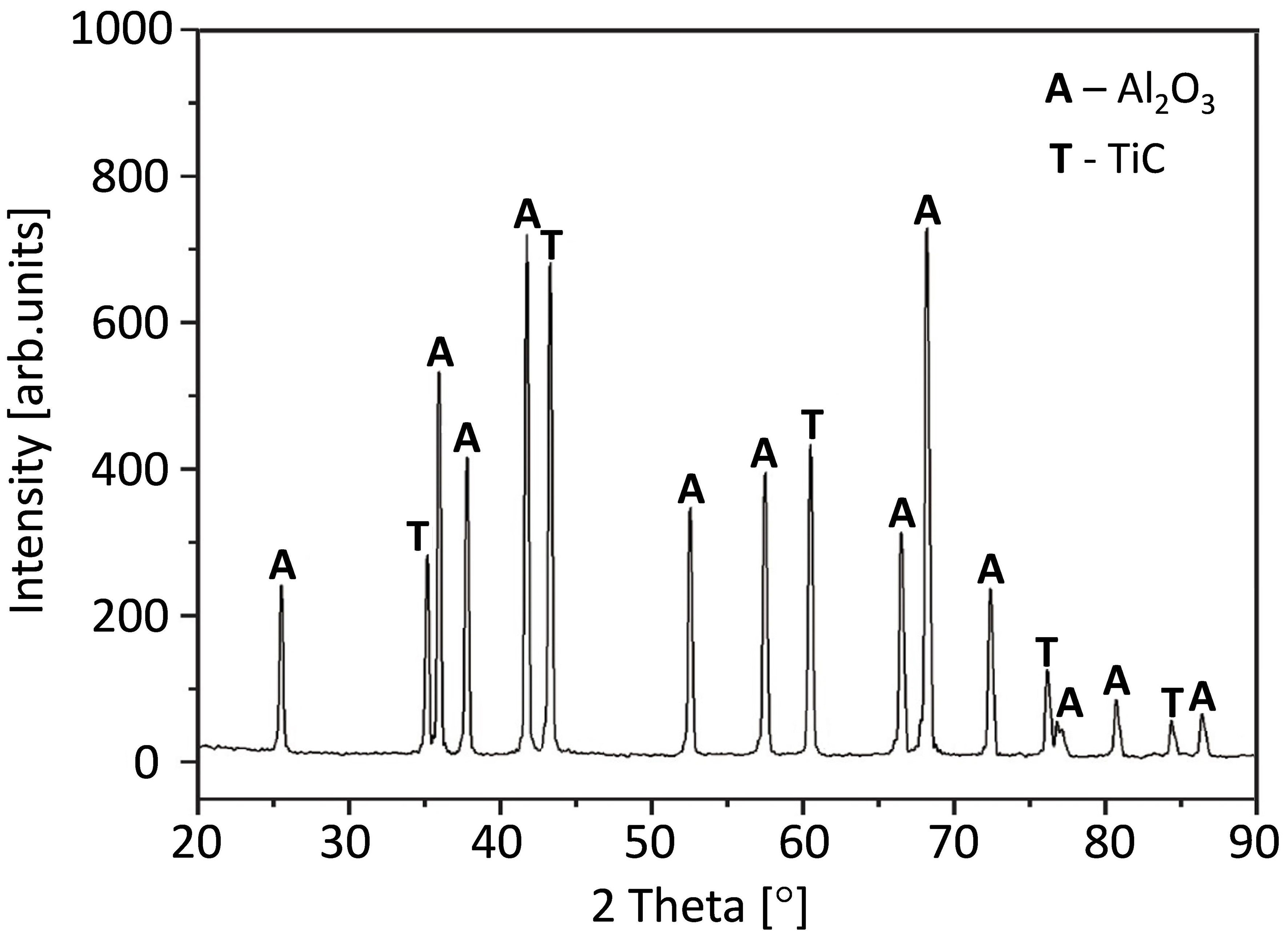

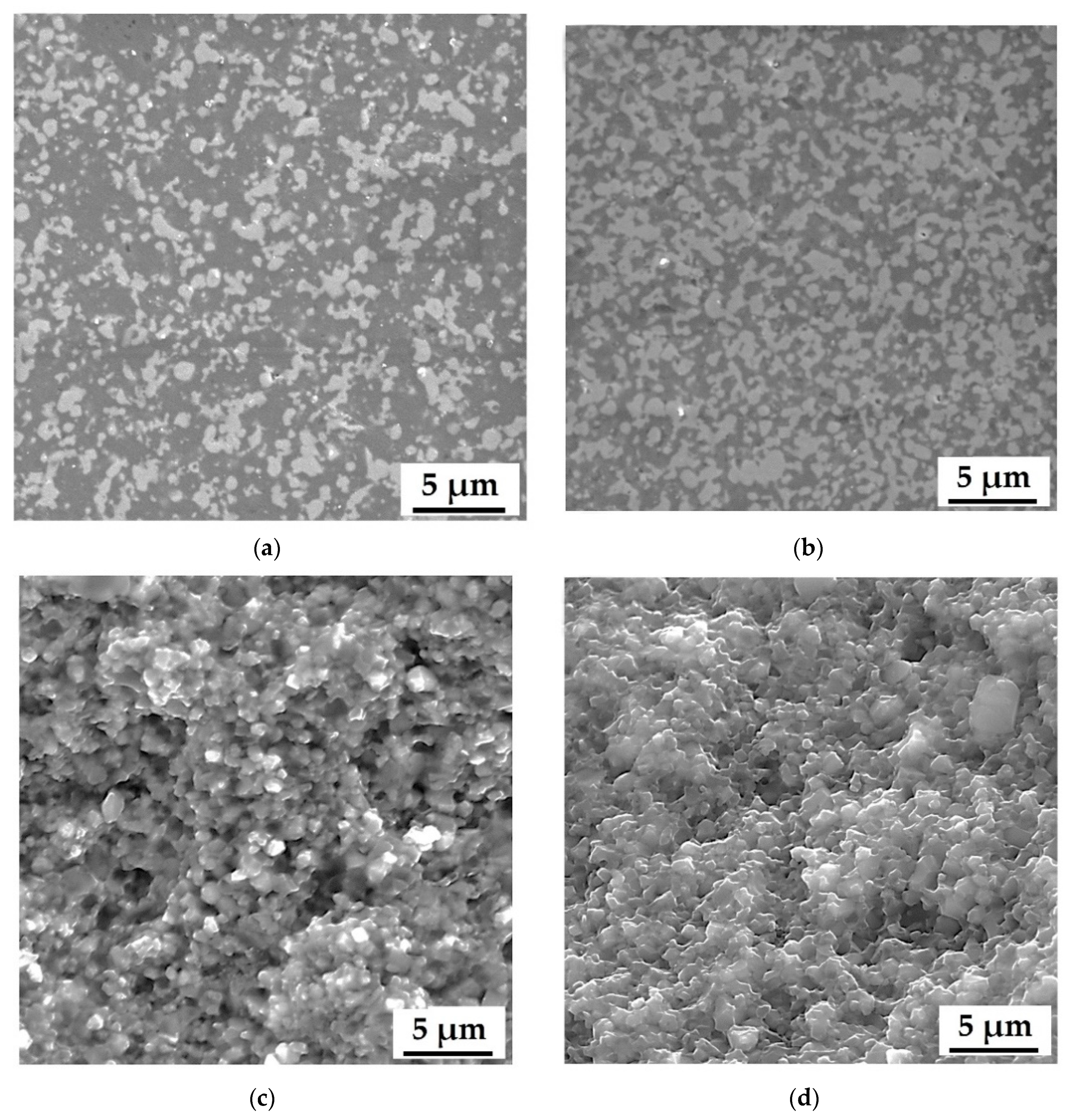

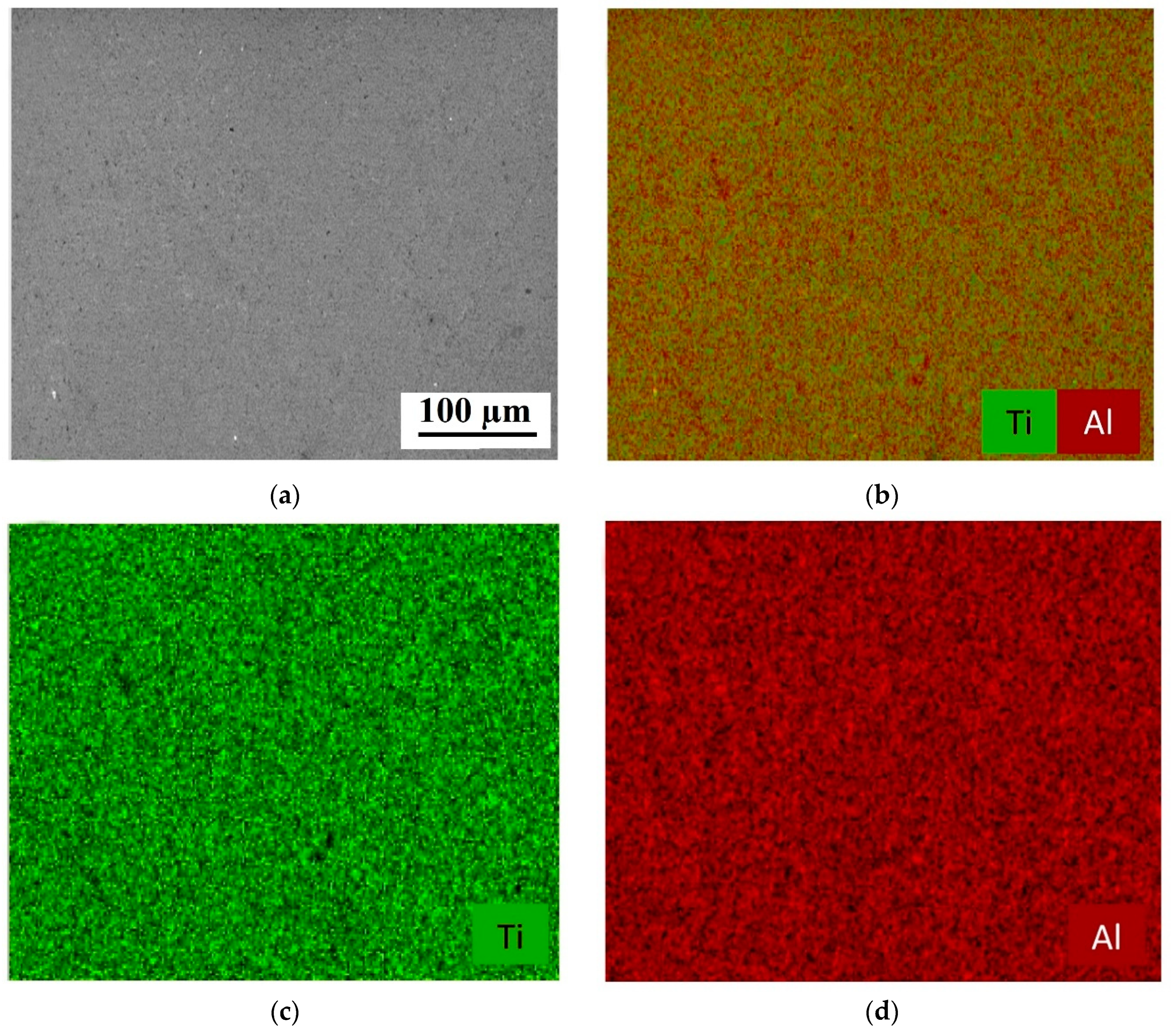

3. Results

3.1. Characterization of the Samples and their Mechanical Properties

3.2. Electrical Properties and Electrical Discharge Machining of the Samples

4. Discussion

4.1. Characterization of the Samples and its Mechanical Properties

4.2. Electrical Properties and Electrical Discharge Machining of the Samples

5. Conclusions

6. Patents

- Grigoriev, S.N.; Torrecillas, R.; Diaz Rodrigez, A.L.; Solis Pinargote, N.W.; Okunkova, A.A.; Volosova, M.A.; Peretyagin, P.Y.; Vladimirov, Y.G.; Loktev, M.A. Device for producing products from composite powders; RU2555303C1; Date 07.10.2015.

- Grigoriev, S.N.; Torrecillas, R.; Diaz Rodrigez, A.L.; Solis Pinargote, N.W.; Okunkova, A.A.; Volosova, M.A.; Peretyagin, P.Y.; Vladimirov, Y.G.; Loktev, M.A. The method of obtaining nanocomposite from ceramic powder; RU2544942C1; Date 20.03.2015.

- Grigoriev, S.N.; Volosova, M.A.; Okunkova, A.A. A method of manufacturing a shaped cutter; RU 2491156; Date 27.08.2013.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, J.; Li, J.; Xu, C. Interaction of the cutting tools and the ceramic-reinforced metal matrix composites during micro-machining: A review. CIRP J. Manuf. Sci. Technol. 2004, 7, 55–70. [Google Scholar] [CrossRef]

- Kumar, A.S.; Durai, A.R.; Sornakumar, T. Machinability of hardened steel using alumina-based ceramic cutting tools. Int. J. Refract. Met. H 2003, 21, 109–117. [Google Scholar] [CrossRef]

- Gevorkyan, E.; Lavrynenko, S.; Rucki, M.; Siemiatkowski, Z.; Kislitsa, M. Ceramic cutting tools out of nanostructured refractory compounds. Int. J. Refract. Met. H 2017, 68, 142–144. [Google Scholar] [CrossRef]

- Wang, D.; Xue, C.; Cao, Y.; Cao, Y.; Zhao, J. Fabrication and cutting performance of an Al2O3/TiC/TiN ceramic cutting tool in turning of an ultra-high-strength steel. Int. J. Adv. Manuf. Technol. 2017, 91, 1967–1976. [Google Scholar] [CrossRef]

- Laine, R.M.; Marchal, J.C.; Sun, H.P.; Pan, X.Q. Nano-α-Al2O3 by liquid-feed flame spray pyrolysis. Nat. Mater. 2006, 5, 710–712. [Google Scholar] [CrossRef] [PubMed]

- Kolodiazhnyi, T.; Annino, G.; Spreitzer, M.; Taniguchi, T.; Freer, R.; Azough, F.; Panariello, A.; Fitzpatrick, W. Development of Al2O3–TiO2 composite ceramics for high-power millimeter-wave applications. Acta Mater. 2009, 57, 3402–3409. [Google Scholar] [CrossRef]

- Bartolomé, J.F.; Smirnov, A.; Kurland, H.-D.; Grabow, J.; Müller, F.A. New ZrO2/Al2O3 nanocomposite fabricated from hybrid nanoparticles prepared by CO2 laser co-vaporization. Sci. Rep. UK 2016, 6, 20589. [Google Scholar] [CrossRef]

- Smirnov, A.; Bartolomé, J.F.; Moya, J.S.; Kern, F.; Gadow, R. Dry reciprocating sliding wear behaviour of alumina–silicon carbide nanocomposite fabricated by ceramic injection molding. J. Eur. Ceram. Soc. 2011, 31, 469–474. [Google Scholar] [CrossRef]

- Evans, A.G. Perspective on the development of high-toughness ceramics. J. Am. Ceram. Soc. 1990, 73, 187–206. [Google Scholar] [CrossRef]

- Boatemaa, L.; Bosch, M.; Farle, A.-S.; Bei, G.-P.; van der Zwaag, S.; Sloof, W.G. Autonomous high-temperature healing of surface cracks in Al2O3 containing Ti2AlC particles. J. Am. Ceram. Soc. 2018, 101, 5684–5693. [Google Scholar] [CrossRef]

- Ercenk, E.; Guven, B.; Yilmaz, S. Crystallization kinetics of machinable glass ceramics produced from volcanic basalt rock. J. Non-Cryst. Solids 2018, 498, 262–271. [Google Scholar] [CrossRef]

- Song, Q.; Zhang, Z.-H.; Hu, Z.-Y.; Yin, S.-P.; Wang, H.; Wang, H.; Cheng, X.-W. Fully dense B4C ceramics fabricated by spark plasma sintering at relatively low temperature. Mater. Res. Express 2018, 5, 105201. [Google Scholar] [CrossRef]

- Li, L.; Pu, S.; Liu, Y.; Zhao, L.; Ma, J.; Li, J. High-purity disperse alpha-Al2O3 nanoparticles synthesized by high-energy ball milling. Adv. Powder Technol. 2018, 29, 2194–2203. [Google Scholar] [CrossRef]

- Ghouli, S.; Ayatollahi, M.R.; Bushroa, A.R. Fracture characterization of ceria partially stabilized zirconia using the GMTSN criterion. Eng. Fract. Mech. 2018, 199, 647–657. [Google Scholar] [CrossRef]

- Diaz, L.A.; Montes-Moran, M.A.; Peretyagin, P.Y.; Vladimirov, Y.G.; Okunkova, A.; Moya, J.S.; Torrecillas, R. Zirconia-alumina-nanodiamond composites with gemological properties. J. Nanopart. Res. 2014, 16, 2257. [Google Scholar] [CrossRef]

- Smirnov, A.; Bartolomé, J.F.; Kurland, H.-D.; Grabow, J.; Müller, F.A. Design of a new zirconia-alumina-Ta micro-nanocomposite with unique mechanical properties. J. Eur. Ceram. Soc. 2016, 99, 3205–3209. [Google Scholar] [CrossRef]

- Gutiérrez-González, C.F.; Suarez, M.; Pozhidaev, S.; Rivera, S.; Peretyagin, P.; Solís, W.; Díaz, L.A.; Fernandez, A.; Torrecillas, R. Effect of TiC addition on the mechanical behavior of Al2O3–SiC whiskers composites obtained by SPS. J. Eur. Ceram. Soc. 2016, 36, 2149–2152. [Google Scholar] [CrossRef]

- Ighodaro, O.L.; Okoli, O.I. Fracture toughness enhancement for alumina systems: A Review. Int. J. Appl. Ceram. Technol. 2008, 5, 313–323. [Google Scholar] [CrossRef]

- Kumar, R.; Chaubey, A.K.; Maity, T.; Prashanth, K.G. Mechanical and Tribological Properties of Al2O3-TiC Composite Fabricated by Spark Plasma Sintering Process with Metallic (Ni, Nb) Binders. Metals 2018, 8, 50. [Google Scholar] [CrossRef]

- Godin, N.; Reynaud, P.; R’Mili, M.; Fantozzi, G. Identification of a Critical Time with Acoustic Emission Monitoring during Static Fatigue Tests on Ceramic Matrix Composites: Towards Lifetime Prediction. Appl. Sci. 2016, 6, 43. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Krapostin, A.A. Multilayer composite nanoscale coatings as a method to increase reliability and tool life of cutting tools made of mixed ceramic Al2O3-TiC. Mech. Ind. 2016, 17, 704. [Google Scholar] [CrossRef]

- Grigoriev, S.; Metel, A. Plasma- and beam-assisted deposition methods. In Nanostructured Thin Films and Nanodispersion Strengthened Coatings; Voevodin, A.A., Shtansky, D.V., Levashov, E.A., Moore, J.J., Eds.; Kluwer Academic Publishers: New York, NY, USA; Boston, MA, USA; Dordrecht, The Netherlands; London, UK; Moscow, Russia, 2004; pp. 147–154, ISBN 9781402022227 (online), ISBN 9781402022203 (print). [Google Scholar]

- Farooqui, M.N.; Patil, N.G. A perspective on shaping of advanced ceramics by electro discharge machining. Procedia Manuf. 2018, 20, 65–72. [Google Scholar] [CrossRef]

- Kumar, C.S.; Patel, S.K. Effect of WEDM surface texturing on Al2O3/TiCN composite ceramic tools in dry cutting of hardened steel. Ceram. Int. 2018, 44, 2510–2523. [Google Scholar] [CrossRef]

- Ninz, P.; Landfried, R.; Kern, F.; Gadow, R. Electrical discharge machining of metal doped Y-TZP/TiC nanocomposites. J. Eur. Ceram. Soc. 2015, 35, 4031–4037. [Google Scholar] [CrossRef]

- Selvarajan, L.; Rajavel, J.; Prabakaran, V.; Sivakumar, B.; Jeeva, G. A review paper on EDM parameter of composite material and industrial demand material machining. Mater. Today 2018, 5, 5506–5513. [Google Scholar] [CrossRef]

- Smirnov, A.; Peretyagin, P.; Bartolomé, J.F. Wire electrical discharge machining of 3Y-TZP/Ta ceramic-metal composites. J. Alloys Compd. 2018, 739, 62–68. [Google Scholar] [CrossRef]

- Díaz, L.A.; Fernández, A.; Okunkova, A.; Solís, W.; Peretyagin, P.; Gotor Martínez, F.J.; Torrecillas, R. Electro conductive alumina nanocomposites from different alumina-carbides mixtures. Matec. Web Conf. 2016, 65, 02003. [Google Scholar] [CrossRef]

- Ji, R.; Liu, Y.; Diao, R.; Xu, C.; Li, X.; Cai, B.; Zhang, Y. Influence of electrical resistivity and machining parameters on electrical discharge machining performance of engineering ceramics. PLoS ONE 2014, 9, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Lóh, N.J.; Simão, L.; Jiusti, J.; De Noni Jr., A.; Montedo, O.R.K. Effect of temperature and holding time on the densification of alumina obtained by two-step sintering. Ceram. Int. 2017, 43, 8269–8275. [Google Scholar] [CrossRef]

- Tamura, Y.; Moshtaghioun, B.M.; Gomez-Garcia, D.; Rodríguez, A.D. Spark plasma sintering of fine-grained alumina ceramics reinforced with alumina whiskers. Ceram. Int. 2017, 43, 658–663. [Google Scholar] [CrossRef]

- Gao, L.; Hong, J.S.; Miyamoto, H.; Torre, S.D.D.L. Bending strength and microstructure of Al2O3 ceramics densified by spark plasma sintering. J. Eur. Ceram. Soc. 2000, 20, 2149–2152. [Google Scholar] [CrossRef]

- Lee, M.; Borom, M.P. Rapid rate sintering of Al2O3-TiC composites for cutting-tool applications. Adv. Ceram. Mater. 1988, 3, 38–44. [Google Scholar] [CrossRef]

- Pourali, Z.; Sovizi, M.R.; Yaftian, M.R.; Yaftian, M.R.; Amiri, Z.; Emami, S.M.; Shahed, H.E. Microstructures and Mechanical Behavior of Ti3SiC2/Al2O3-Ni Composites Synthesized by Pulse Discharge Sintering. J. Mater. Eng. Perform. 2018, 27, 3600–3609. [Google Scholar] [CrossRef]

- Sun, S.; Xu, Q. Fabricating a Novel Intragranular Microstructure for Al2O3/GdAlO3 Ceramic Composites. Materials 2018, 11, 1879. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Zielke, P.; Van Nong, N.; Pirou, S.; Reolon, R.; Si, X.; Simonsen, S.B.; Norby, P.; Lühmann, H.; Bensch, W.; et al. Hydrothermal Synthesis, Characterization, and Sintering Behavior of Core-Shell Particles: A Principle Study on Lanthanum Strontium Cobaltite Coated with Nanosized Gadolinium Doped Ceria. Ceramics 2018, 1, 246–260. [Google Scholar] [CrossRef]

- Jin, Y.; Han, M.-K.; Kim, S.-J. Na-Doping Effects on Thermoelectric Properties of Cu2−xSe Nanoplates. Appl. Sci. 2018, 8, 12. [Google Scholar] [CrossRef]

- Ning, J.; Wu, D.; Zhao, D. Synthesis and Thermoelectric Properties of TiO2/Cu2SnSe3 Composites. Appl. Sci. 2017, 7, 1043. [Google Scholar] [CrossRef]

- Alleno, E. Review of the Thermoelectric Properties in Nanostructured Fe2Val. Metals 2018, 8, 864. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, L.; Liu, X.; Chen, Q.; Xu, Y. Effect of Zr Addition on the Microstructure and Mechanical Properties of CoCrFeNiMn High-Entropy Alloy Synthesized by Spark Plasma Sintering. Entropy 2018, 20, 810. [Google Scholar] [CrossRef]

- Viswanathan, V.; Laha, T.; Balani, K.; Agarwal, A.; Seal, S. Challenges and advances in nanocomposite processing techniques. Mater. Sci. Eng. R 2006, 54, 121–285. [Google Scholar] [CrossRef]

- Suárez, M.; Fernández, A.; Menéndez, J.L.; Torrecillas, R.; Kessel, H.U.; Hennicke, J.; Kirchner, R.; Kessel, T. Challenges and opportunities for spark plasma sintering: A key technology for a new generation of materials. Sinter. Appl. 2013, 13, 319–342. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, J.; Jiang, W. Recent development in reactive synthesis of nanostructured bulk materials by spark plasma sintering. Int. J. Refract. Met. H 2013, 39, 103–112. [Google Scholar] [CrossRef]

- Grigoriev, S.; Peretyagin, P.; Smirnov, A.; Solís, W.; Díaz, L.A.; Fernández, A.; Torrecillas, R. Effect of graphene addition on the mechanical and electrical properties of Al2O3-SiCw ceramics. J. Eur. Ceram. Soc 2017, 37, 2473–2479. [Google Scholar] [CrossRef]

- Miranzo, P.; Moya, J.S. Elastic/plastic indentation in ceramics: A fracture toughness determination method. Ceram. Int. 1984, 10, 147–152. [Google Scholar] [CrossRef]

- Smirnov, A.; Bartolomé, J.F. Mechanical properties and fatigue life of ZrO2–Ta composites prepared by hot pressing. J. Eur. Ceram. Soc. 2012, 32, 3899–3904. [Google Scholar] [CrossRef]

- Tseng, W.J.; Kao, W.-H. Preparation of Electrically Conductive Calcium Phosphate Composite Foams by Particle-Stabilized Emulsion Route. Ceramics 2018, 1, 319–328. [Google Scholar] [CrossRef]

- Huang, J.; Her, S.-C.; Yang, X.; Zhi, M. Synthesis and Characterization of Multi-Walled Carbon Nanotube/Graphene Nanoplatelet Hybrid Film for Flexible Strain Sensors. Nanomaterials 2018, 8, 786. [Google Scholar] [CrossRef] [PubMed]

- Xin, B.; Li, S.; Yin, X.; Lu, X. Dynamic Observer Modeling and Minimum-Variance Self-Tuning Control of EDM Interelectrode Gap. Appl. Sci. 2018, 8, 1443. [Google Scholar] [CrossRef]

- Salcedo, A.T.; Arbizu, I.P.; Pérez, C.J.L. Analytical Modelling of Energy Density and Optimization of the EDM Machining Parameters of Inconel 600. Metals 2017, 7, 166. [Google Scholar] [CrossRef]

- Peng, L.M.; Li, Z.; Li, H.; Wang, J.H.; Gong, M. Microstructural characterization and mechanical properties of TiAl-Al2Ti4C2-Al2O3-TiC in situ composites by hot-press-aided reaction synthesis. J. Alloys Compd. 2006, 414, 100–106. [Google Scholar] [CrossRef]

- Yasuoka, M.; Erito, M.E.; Hirao, K.; Kanzaki, S. Effect of Dispersed Particle-Size on Mechanical-Properties of Alumina Non-Oxides Composites. Nippon. Seram Kyo Gak 1993, 101, 889–894. [Google Scholar] [CrossRef]

- Volosova, M.; Grigoriev, S.; Metel, A.; Shein, A. The Role of Thin-Film Vacuum-Plasma Coatings and Their Influence on the Efficiency of Ceramic Cutting Inserts. Coatings 2018, 8, 287. [Google Scholar] [CrossRef]

- Wang, Y.; Luo, F.; Zhou, W.; Zhu, D. Dielectric and Microwave Absorption Properties of TiC-Al2O3/Silica Coatings at High Temperature. J. Electron. Mater. 2017, 46, 5225–5231. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M.; Guclu, T.; Besir, A.; Gokce, E.; Serencam, U. A novel method based on thermal conductivity for material identification in scrap industry: An experimental validation. Measurement 2018, 127, 379–389. [Google Scholar] [CrossRef]

- Kuriachen, B.; Lijesh, K.P.; Kuppan, P. Multi Response Optimization and Experimental Investigations into the Impact of Wire EDM on the Tribological Properties of Ti-6Al-4V. Trans. Indian Inst. Met. 2018, 71, 1329–1339. [Google Scholar] [CrossRef]

- Takahashi, K.; Kagawa, T.; Tanaka, K.; Kihira, H.; Ushioda, K. Reduction of Contact Resistance on Titanium Sheet Surfaces by Formation of Titanium Carbide and Nitride, and Its Stability in Sulfuric Acid Aqueous Solution. Tetsu Hagane 2018, 104, 264–273. [Google Scholar] [CrossRef]

- Metel, A.S.; Grigoriev, S.N.; Melnik, Y.A.; Bolbukov, V.P. Broad beam sources of fast molecules with segmented cold cathodes and emissive grids. Instrum. Exp. Tech. 2012, 55, 122–130. [Google Scholar] [CrossRef]

- Sobol’, O.V.; Andreev, A.A.; Grigoriev, S.N.; Volosova, M.A.; Gorban, V.F. Vacuum-arc multilayer nanostructured TiN/Ti coatings: Structure, stress state, properties. Met. Sci. Heat Treat. 2012, 54, 28–33. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Grigoriev, S.N. Study of cracking mechanisms in multi-layered composite nano-structured coatings. Wear 2017, 378, 43–57. [Google Scholar] [CrossRef]

- Bayer, T.J.M.; Carter, J.J.; Wang, J.-J.; Klein, A.; Chen, L.-Q.; Randall, C.A. Determination of electrical properties of degraded mixed ionic conductors: Impedance studies with applied dc voltage. J. Appl. Phys. 2017, 122, 244101. [Google Scholar] [CrossRef]

- Tijo, D.; Kumari, S.; Masanta, M. Ceramic-metal Composite Coating on Steel Using a Powder Compact Tool Electrode by the Electro-Discharge Coating Process. Silicon 2018, 10, 1625–1637. [Google Scholar]

- Jimenez, M.J.M.; de Oliveira, R.F.; Shimizu, F.M.; Bufon, C.C.; Rodrigues, V.; Gobbi, Â.L.; Piazzetta, M.H.O.; Jr, A.R. Poole-Frenkel emission on functionalized, multilayered-packed reduced graphene oxide nanoplatelets. Nanotechnology 2018, 29, 505703. [Google Scholar] [CrossRef] [PubMed]

- Grigoriev, S.N.; Melnik, Y.A.; Metel, A.S.; Panin, V.V. Broad beam source of fast atoms produced as a result of charge exchange collisions of ions accelerated between two plasmas. Instrum. Exp. Tech. 2009, 52, 602–608. [Google Scholar] [CrossRef]

- Grigoriev, S.; Melnik, Y.; Metel, A. Broad fast neutral molecule beam sources for industrial-scale beam-assisted deposition. Surf. Coat. Technol. 2002, 156, 44–49. [Google Scholar] [CrossRef]

- Wu, T.; Su, J.; Li, Y.; Zhao, H.; Zhang, Y.; Zhang, M.; Wu, B. Wear Resistance Mechanism of Alumina Ceramics Containing Gd2O3. Materials 2018, 11, 2054. [Google Scholar] [CrossRef] [PubMed]

- Metel, A.; Bolbukov, V.; Volosova, M.; Grigoriev, S.; Melnik, Y. Source of metal atoms and fast gas molecules for coating deposition on complex shaped dielectric products. Surf. Coat. Technol. 2013, 225, 34–39. [Google Scholar] [CrossRef]

- Wang, R.; Shi, T.; Zhang, X.; Wang, W.; Wei, J.; Lu, J.; Zhao, X.; Wu, Z.; Cao, R.; Long, S.; et al. Bipolar Analog Memristors as Artificial Synapses for Neuromorphic Computing. Materials 2018, 11, 2102. [Google Scholar] [CrossRef] [PubMed]

- Goodall, P.; Foulkes, M.E.; Ebdon, L. Slurry nebulization inductively coupled plasma spectrometry-the fundamental parameters discussed. Spectrochim. Acta B 1993, 48, 1563–1577. [Google Scholar] [CrossRef]

- Patil, S.P.; Murkute, R.; Shirafkan, N.; Markert, B. Deformation of Stacked Metallic Sheets by Shock Wave Loading. Metals 2018, 8, 679. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Kozochkin, M.P.; Sabirov, F.S.; Kutin, A.A. Diagnostic Systems as Basis for Technological Improvement. Proc. CIRP 2012, 1, 599–604. [Google Scholar] [CrossRef]

- Kozochkin, M.P.; Porvatov, A.N.; Sabirov, F.S. Vibration Testing of Technological Processes in Automated Machining Equipment. Meas. Technol. 2014, 56, 1414–1420. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Sinopalnikov, V.A.; Tereshin, M.V.; Gurin, V.D. Control of parameters of the cutting process on the basis of diagnostics of the machine tool and workpiece. Meas. Technol. 2012, 55, 555–558. [Google Scholar] [CrossRef]

- Ma, L.; Wang, Y.; Di, G. Study on the Microstructure Evolution and Tungsten Content Optimization of 9Cr-3W-3Co Steel. Materials 2018, 11, 2080. [Google Scholar] [CrossRef] [PubMed]

| Material | Density 1 [%ρth] | Flexural Strength 2 σf [MPa] | Hardness HV 2 [GPa] | Fracture Toughness 2 KIc [MPa∙m1/2] |

|---|---|---|---|---|

| Al2O3-30 vol.%TiC composite | 99 | 643 ± 48 | 22.8 ± 0.4 | 7.1 ± 0.3 |

| Al2O3-40 vol.%TiC composite | 99 | 687 ± 39 | 23.3 ± 0.3 | 7.8 ± 0.4 |

| Al2O3-40 vol.%TiC 3 cutting ceramic [51,52,53] | - | ~637.0 | ~13.5–14.0 | 3–5 |

| Material | Electrical Conductivity 1 γ [S∙cm−1] | Electrical Conductivity 2 γ [S∙m−1] | Specific Electrical Resistance 2 R[Ω∙mm2∙m−1] | Specific Electrical Resistance 2 R [Ω·m] |

|---|---|---|---|---|

| Al2O3-30 vol.%TiC composite | 2956.3 ± 9.6 | 295,630 | 3.382 | 3.38 × 10−6 |

| Al2O3-40 vol.%TiC composite | 16,985.2 ± 38.4 | 1,698,520 | 0.589 | 5.89 × 10−7 |

| Al2O3-40 vol.%TiC 3 cutting ceramic [53,54] | 2849.0 | 284,900 | 3.510 | 3.51 × 10−6 |

| TiC 3 [21,22] | 16,667.0 | 1,666,700 | 0.600 | 6.0 × 10−7 |

| CuZn35 3 [55] | 135,135.0 | 13,513,500 | 0.074 | 7.4 × 10−8 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grigoriev, S.N.; Volosova, M.A.; Peretyagin, P.Y.; Seleznev, A.E.; Okunkova, A.A.; Smirnov, A. The Effect of TiC Additive on Mechanical and Electrical Properties of Al2O3 Ceramic. Appl. Sci. 2018, 8, 2385. https://doi.org/10.3390/app8122385

Grigoriev SN, Volosova MA, Peretyagin PY, Seleznev AE, Okunkova AA, Smirnov A. The Effect of TiC Additive on Mechanical and Electrical Properties of Al2O3 Ceramic. Applied Sciences. 2018; 8(12):2385. https://doi.org/10.3390/app8122385

Chicago/Turabian StyleGrigoriev, Sergey N., Marina A. Volosova, Pavel Y. Peretyagin, Anton E. Seleznev, Anna A. Okunkova, and Anton Smirnov. 2018. "The Effect of TiC Additive on Mechanical and Electrical Properties of Al2O3 Ceramic" Applied Sciences 8, no. 12: 2385. https://doi.org/10.3390/app8122385

APA StyleGrigoriev, S. N., Volosova, M. A., Peretyagin, P. Y., Seleznev, A. E., Okunkova, A. A., & Smirnov, A. (2018). The Effect of TiC Additive on Mechanical and Electrical Properties of Al2O3 Ceramic. Applied Sciences, 8(12), 2385. https://doi.org/10.3390/app8122385