Real-Time Strength Monitoring for Concrete Structures Using EMI Technique Incorporating with Fuzzy Logic

Abstract

:1. Introduction

2. Concrete Strength Estimation Using a PZT Sensor

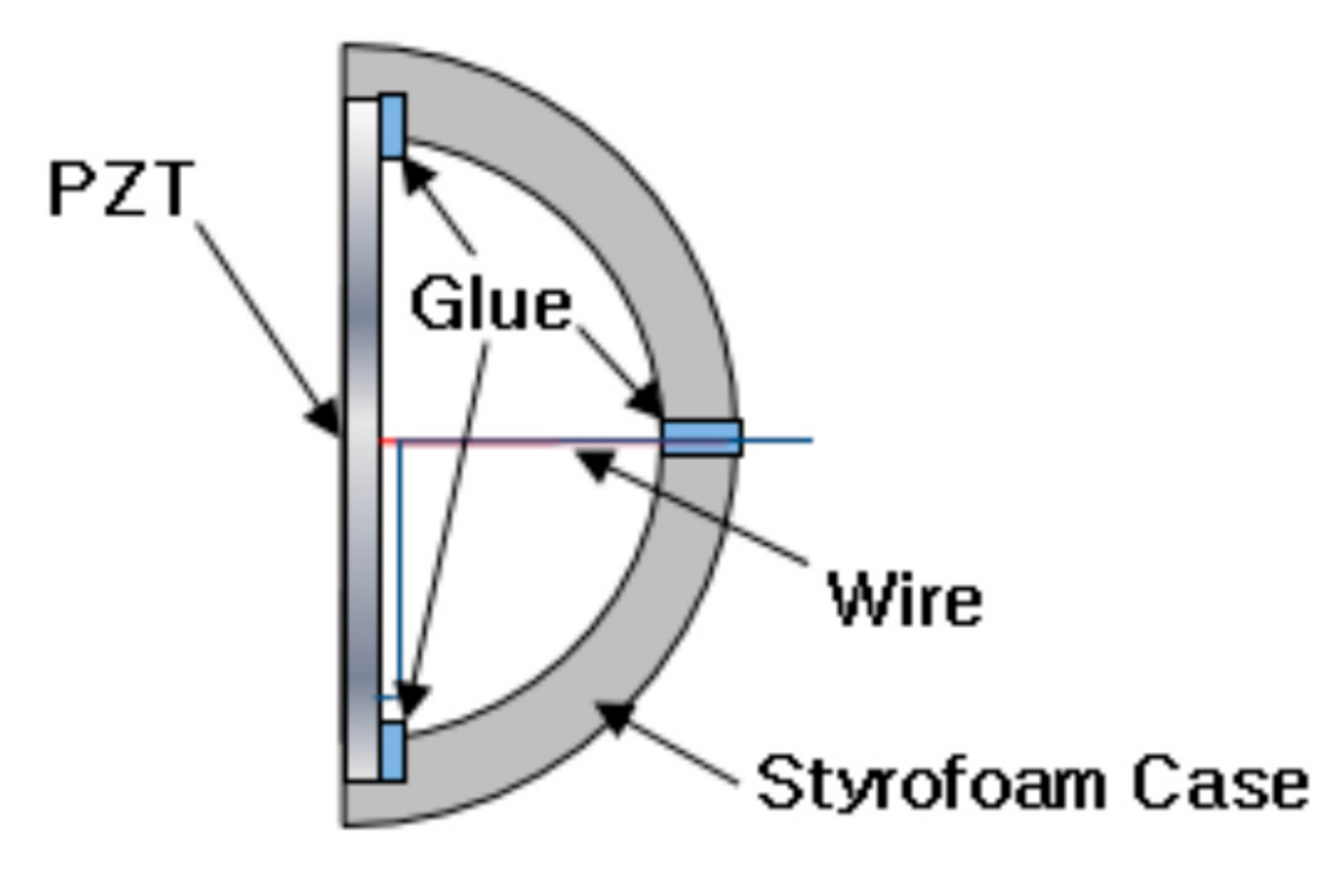

2.1. Piezoelectric Sensor

2.2. Methodology

3. Experimental Study

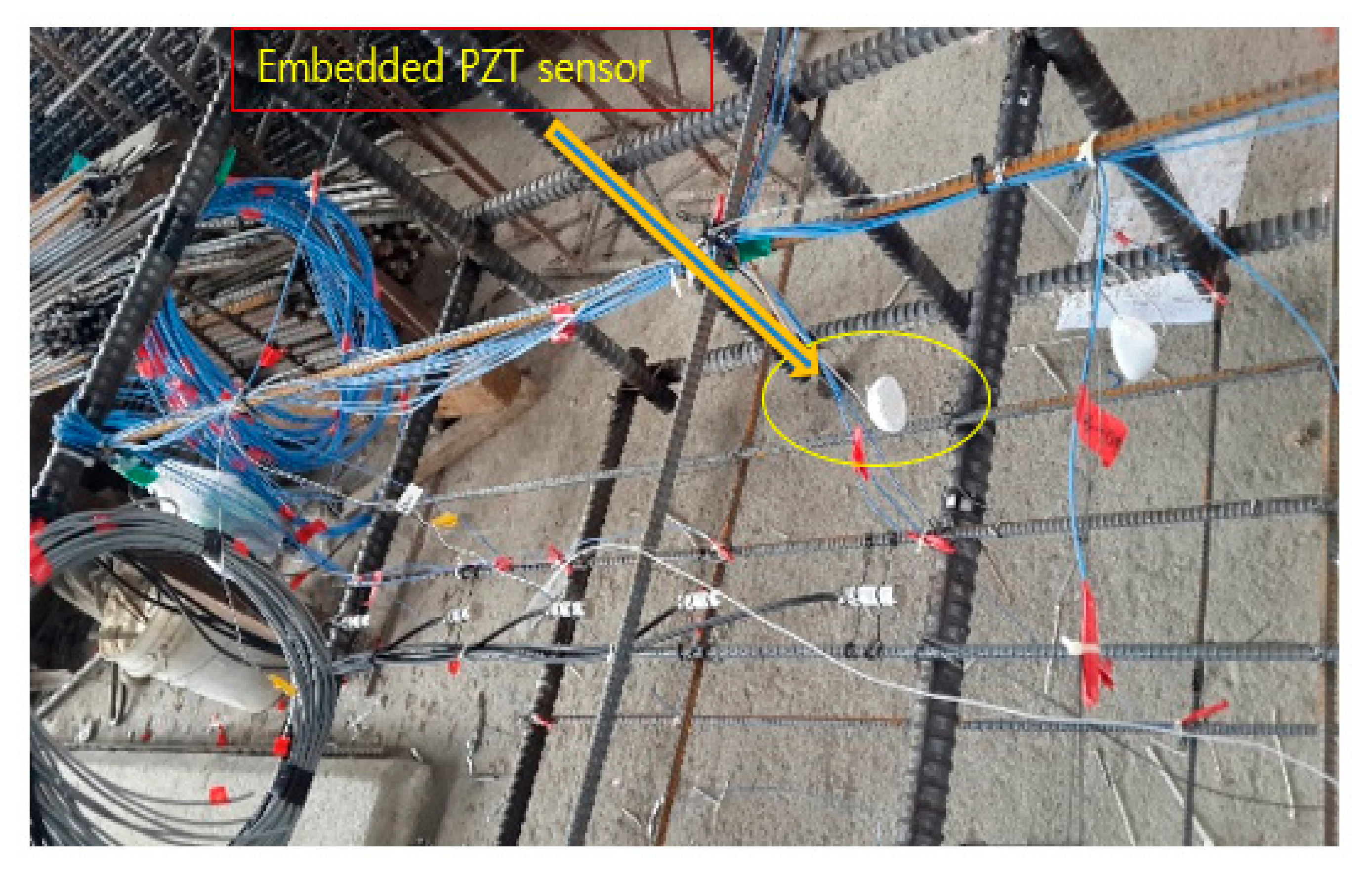

3.1. Specimen Size and Embedded Sensor

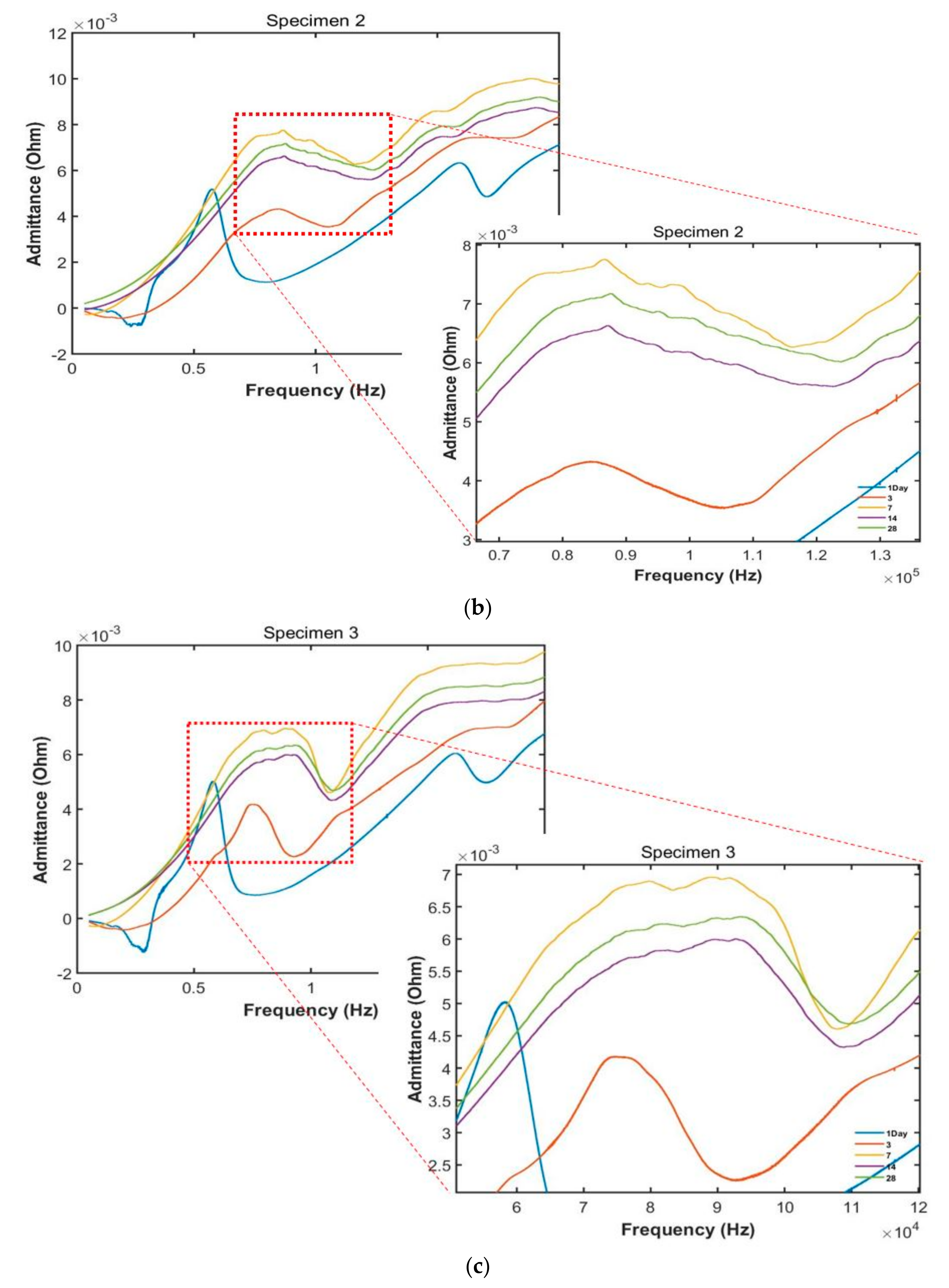

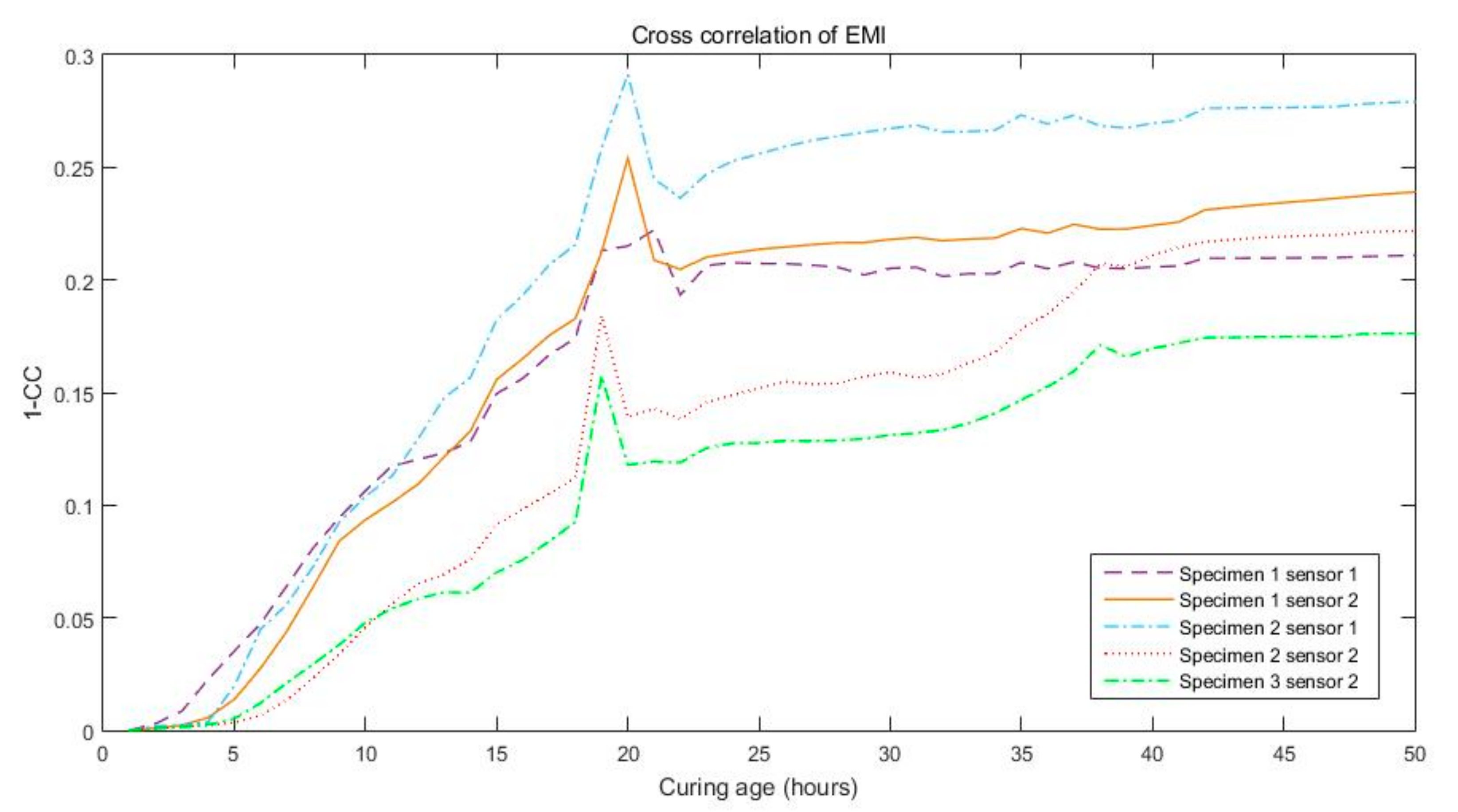

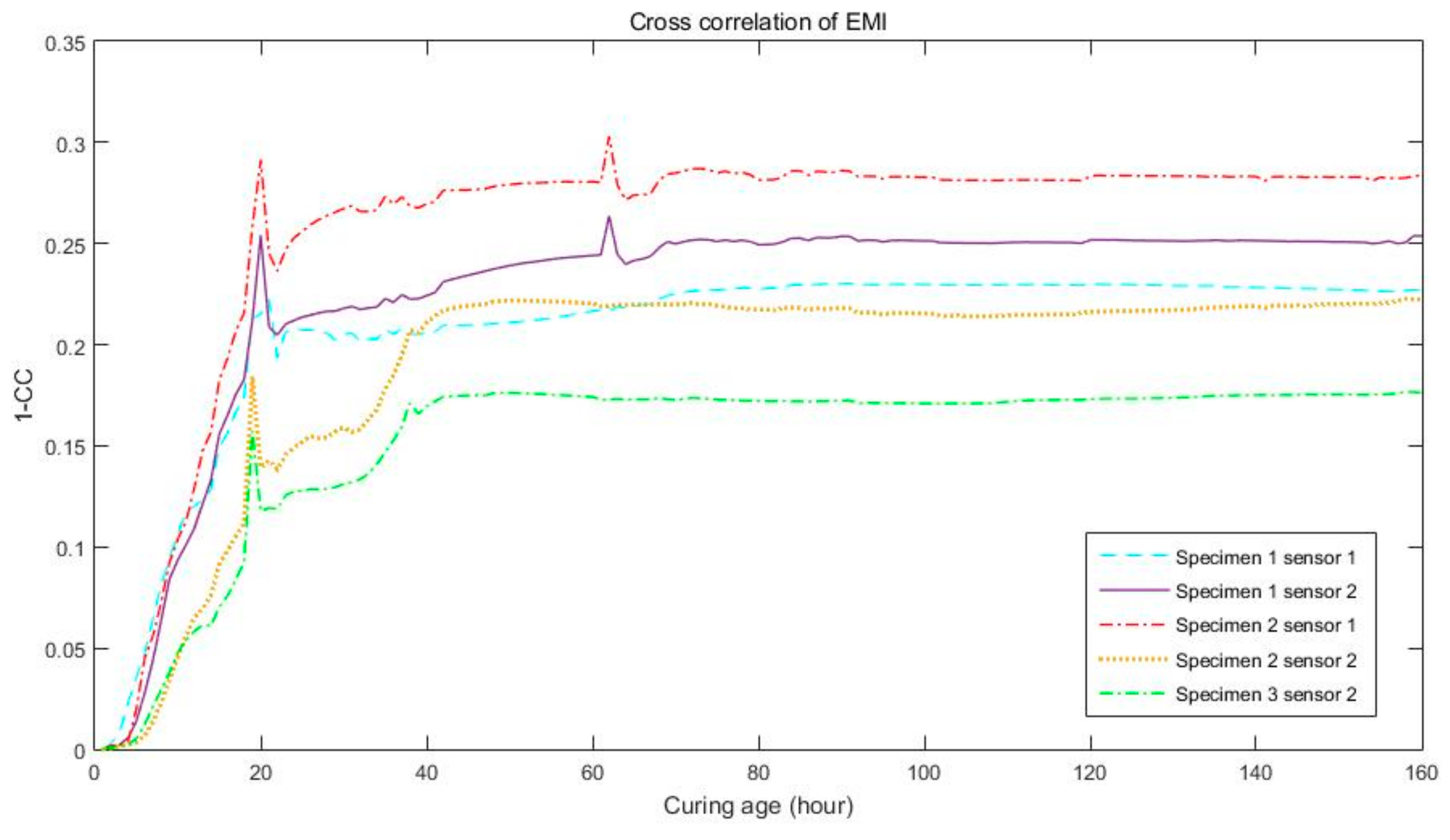

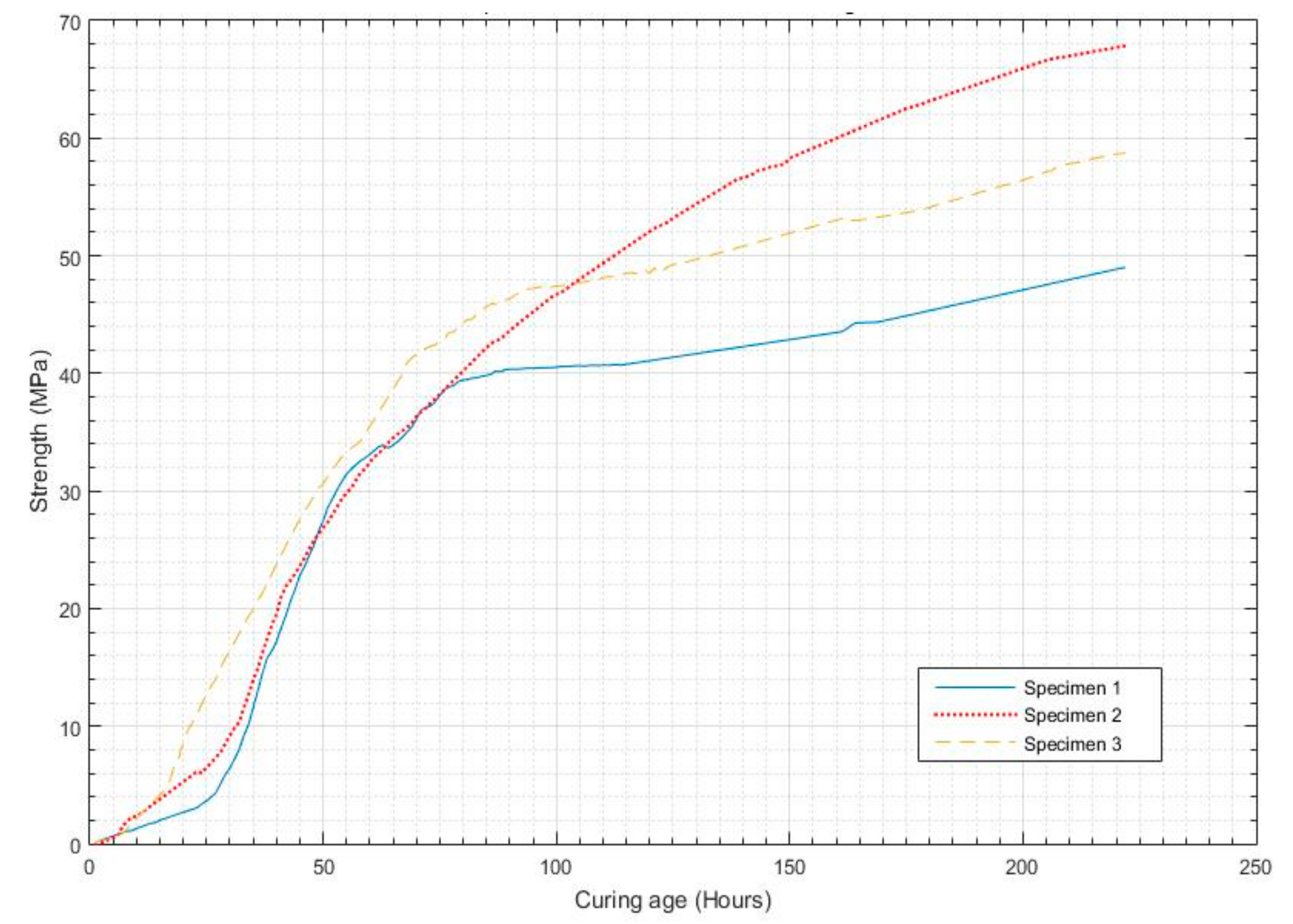

3.2. Results of Ultrasonic Signals and EMI

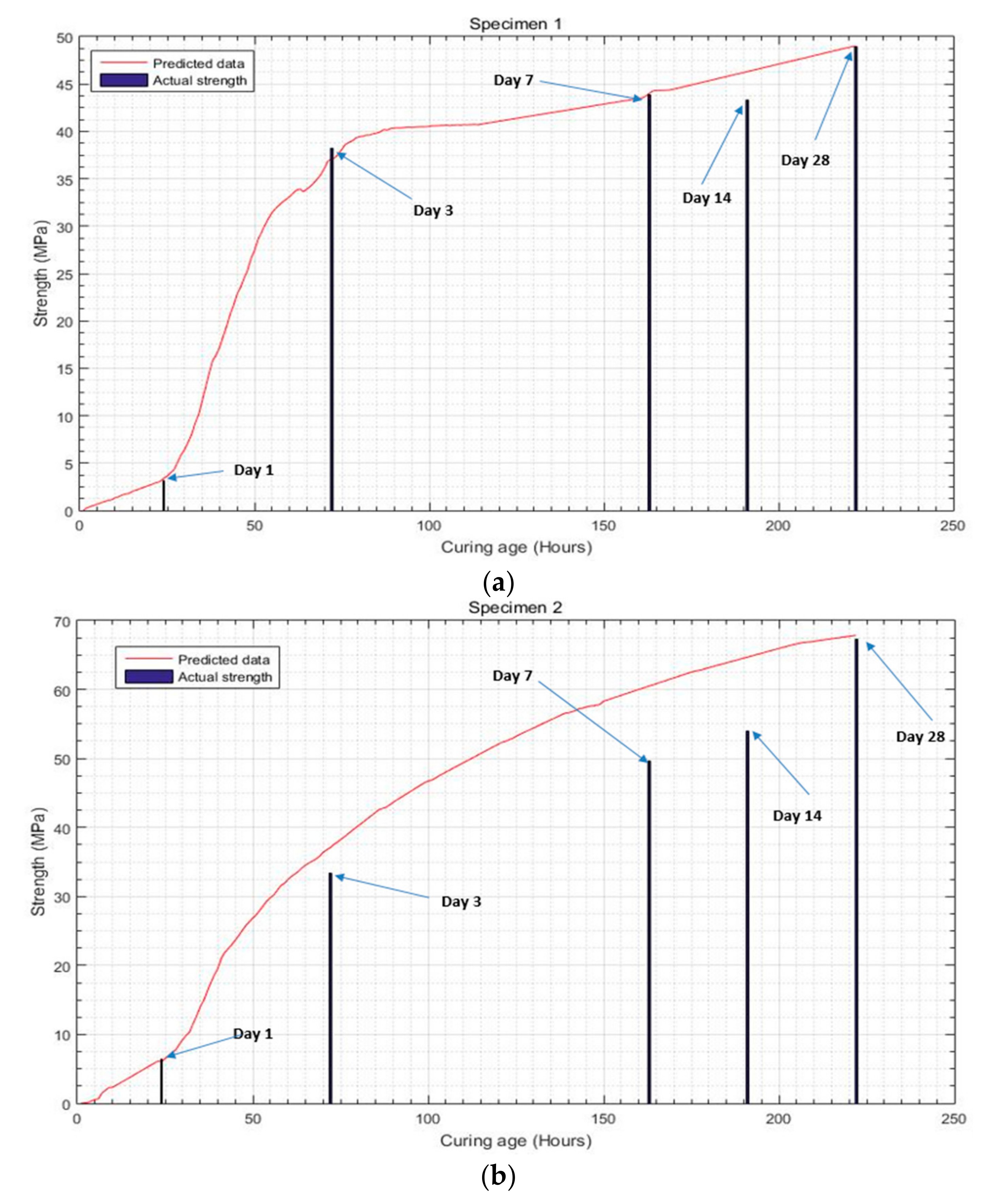

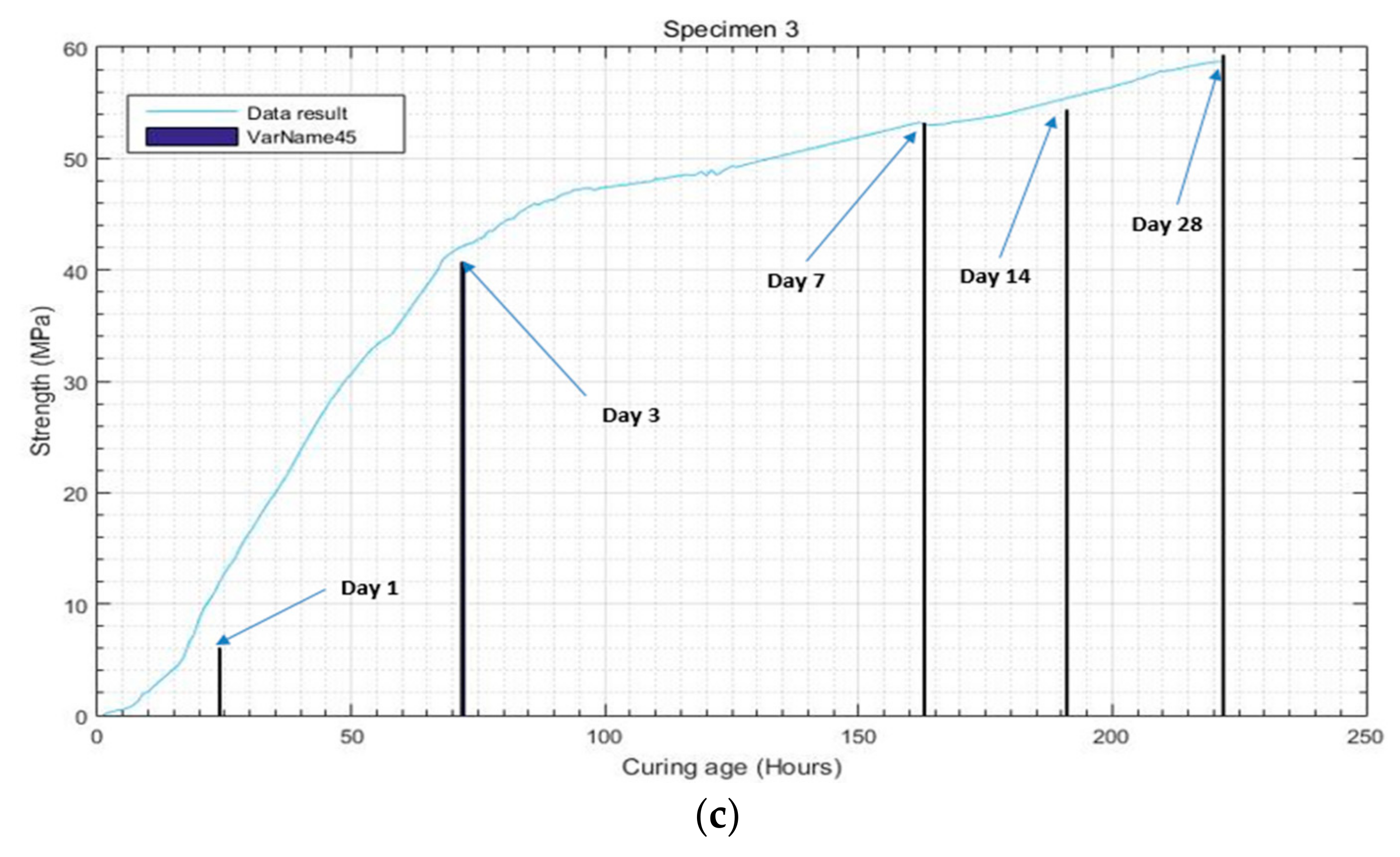

4. Fuzzy Logic Coding and Results

5. Discussion

6. Conclusions

Acknowledgements

Author Contributions

Conflicts of Interest

Abbreviations

| NDT | Non-destructive testing |

| NPP | Nuclear power plant |

| EMI | Electromechanical impedance |

| HSC | High-strength concrete |

| CC | Cross correlation |

| PZT | Piezoelectric materials |

| MPa | Megapascal |

References

- Akindahunsi, A.A.; Uzoegbo, H.C. Strength and Durability Properties of concrete with starch Admixture. Int. J. Concr. Mater. 2015, 9, 323–335. [Google Scholar] [CrossRef]

- Kim, H.S.; Lee, S.H.; Moon, H.Y. Strength properties and durability aspects of high strength concrete using Korean metakaolin. Constr. Build. Mater. 2007, 21, 1229–1237. [Google Scholar] [CrossRef]

- Mirmiran, A.; Wei, Y. Damage assessment of FRP-Encased concrete using ultrasonic pulse velocity. J. Eng. Mech. 2001, 127, 126–135. [Google Scholar] [CrossRef]

- Rizzo, P.; Ni, X.; Nassiri, S.; Vandenbossche, J. A solitary wave-based sensor to monitor the setting of fresh concrete. Sensors 2014, 14, 12568–12584. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gu, H.; Song, G.; Dhonde, H.; Mo, Y.; Yan, S. Concrete early-age strength monitoring using embedded piezoelectric transduces. Smart Mater. Struct. 2006, 15, 1837. [Google Scholar] [CrossRef]

- Phung, Q.T.; Maes, N.; Jacques, D. Current concerns on durability of concrete used in Nuclear Power Plants and Radioactive wasted repositories. In Proceedings of the 4th Congress International de Geotechnique-Ouvrages-Structures (CIGOS 2017), Ho Chi Minh City, Vietnam, 26–27 October 2017; Springer: Singapore, 2017; Volume 8. [Google Scholar]

- Kim, J.; Kim, J.; Shin, K.J.; Lee, H.; Park, S. ANN-based tensile force estimation for pre-stressed tendons of PSC girders using FBG/EM hybrid sensing. Insight 2017, 59, 544–552. [Google Scholar] [CrossRef]

- Lee, C.; Kim, J.; Park, S.; Kim, D.H. Advanced Fatigue Crack Detection using Nonlinear Self-Sensing Impedance Technique for Automated NDE of Metallic Structures. Res. Nondestruct. Eval. 2015, 26, 107–121. [Google Scholar] [CrossRef]

- Kim, J.; Kim, J.W.; Lee, C.; Park, S. Development of embedded EM sensors for estimating tensile forces of PSC girder bridges. Sensors 2017, 17, 1989. [Google Scholar] [CrossRef] [PubMed]

- Park, S.; Inman, J.; Lee, J.; Yun, B. Piezoelectric sensor based health monitoring of railroad track using a two step support vector machine classifier. J. Infrastruct. Syst. 2008, 14, 80–88. [Google Scholar] [CrossRef]

- Lee, C.; Park, S.; Bolander, J.E.; Pyo, S. Monitoring the hardening process of ultra high performance concrete using decomposed modes of guided waves. Constr. Build. Mater. 2017, 163, 267–276. [Google Scholar] [CrossRef]

- Azhar, M.; Ahmed, Z.; Safeer, A.; Mubashir, A. Ultrasonic pulse velocity and rebound hummer testing for nondestructive evaluation of existing concrete structure. Pak. J. Eng. Appl. Sci. 2016, 18, 89–97. [Google Scholar]

- Wang, D.; Song, H.; Zhu, H. Numerical and experimental studies on damage detection of a concrete beam based on PZT admittances and correlation coefficient. Constr. Build. Mater. 2013, 49, 564–574. [Google Scholar] [CrossRef]

- Kim, J.W.; Kim, J.; Park, S.; Oh, T.K. Integrating embedded piezoelectric sensors with continuous wavelet transforms for real-time concrete curing strength monitoring. Struct. Infrastruct. Eng. 2015, 11, 897–903. [Google Scholar] [CrossRef]

- Bhalla, S.; Soh, C.K. Structural health monitoring by piezo-impedance transducers. J. Aerosp. Eng. 2004, 17, 154–165. [Google Scholar] [CrossRef]

- Park, S.; Kim, W.; Lee, C.; Park, K. Impedance-based wireless Debonding condition monitoring of CFRP Laminated Concrete structure. NDT E Int. 2011, 44, 232–238. [Google Scholar] [CrossRef]

- Kim, W.; Lee, C.; Park, S.; Koh, T. Real-time strength development monitoring for concrete structure using wired and wireless electro-mechanical impedance techniques. KSCE J. Civ. Eng. 2013, 17, 1432–1436. [Google Scholar] [CrossRef]

- Park, S.; Yun, C.-B.; Inman, D.J. Structural health monitoring using Electro-mechanical Impedance Sensors. J. Fatique Fract. Eng. Mater. Struct. 2008, 31, 714–724. [Google Scholar] [CrossRef]

- Park, S.; Ahmad, S.; Yun, C.-B.; Roh, Y. Multi crack detection of concrete structure using impedance based structural health monitoring technology. J. Exp. Mech. 2006, 46, 609–618. [Google Scholar] [CrossRef]

- Hu, X.; Zhu, H.; Wang, D. A study of concrete slab damage detection based on the electromechincal impedance method. Sensors 2014, 14, 19897–19909. [Google Scholar] [CrossRef] [PubMed]

- Maeder, M.; Damjanovic, D.; Setter, N. Lead Free Piezoelectric Materials. J. Electroceram. 2004, 13, 385–392. [Google Scholar] [CrossRef]

- Sherrit, S.; Mukherjee, B.K. Characterization of Piezoelectric Materials for Transducers. Available online: http://arxiv.org/ftp/arxiv/papers/0711/0711.2657.pdf (accessed on 24 May 2017).

- Voutetaki, M.E.; Papadopoulos, N.A.; Angeli, G.M.; Providakis, C.P. Investigation of a new experimental method for damage assessment of RC beam failing in shear using piezoelectric transducers. Eng. Struct. 2016, 114, 226–240. [Google Scholar] [CrossRef]

- Basu, P.; Labbe, P.; Naus, D. Nuclear Power Plant Concrete Structures. Proceedings of 22nd Conference on Structural Mechanics in Reactor Technology, San Francisco, CA, USA, 18–23 August 2013. [Google Scholar]

| APC Materials 850 WEB Series | ||

|---|---|---|

| Size | Thickness | 0.508 mm |

| Diameter | 30.00 mm | |

| Piezoelectric charge constant, 10−12 | d33 | 400 |

| d31 | −175 | |

| Electromechanical coupling factor of the material | k33 | 0.72 |

| k31 | 0.36 | |

| Specimen No | W/C % | Unit Weight kg/m3 | AD % | AE % | Temperature for Curing, °C | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| W | C | FA | GGBS | SF | S | G | |||||

| 1 | 40 | 162 | 324 | 81 | 0 | 0 | 722 | 965 | 0 | 0 | 5 |

| 2 | 34 | 155 | 328 | 0 | 228 | 0 | 717 | 723 | 0.9 | 0.8 | 20 |

| 3 | 34 | 155 | 137 | 0 | 296 | 23 | 724 | 966 | 0.007 | 0.005 | 40 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, S.-K.; Tareen, N.; Kim, J.; Park, S.; Park, I. Real-Time Strength Monitoring for Concrete Structures Using EMI Technique Incorporating with Fuzzy Logic. Appl. Sci. 2018, 8, 75. https://doi.org/10.3390/app8010075

Choi S-K, Tareen N, Kim J, Park S, Park I. Real-Time Strength Monitoring for Concrete Structures Using EMI Technique Incorporating with Fuzzy Logic. Applied Sciences. 2018; 8(1):75. https://doi.org/10.3390/app8010075

Chicago/Turabian StyleChoi, Sang-Ki, Najeebullah Tareen, Junkyeong Kim, Seunghee Park, and Innjoon Park. 2018. "Real-Time Strength Monitoring for Concrete Structures Using EMI Technique Incorporating with Fuzzy Logic" Applied Sciences 8, no. 1: 75. https://doi.org/10.3390/app8010075

APA StyleChoi, S.-K., Tareen, N., Kim, J., Park, S., & Park, I. (2018). Real-Time Strength Monitoring for Concrete Structures Using EMI Technique Incorporating with Fuzzy Logic. Applied Sciences, 8(1), 75. https://doi.org/10.3390/app8010075