Metallic, 3D-Printed, K-Band-Stepped, Double-Ridged Square Horn Antennas

Abstract

:Featured Application

Abstract

1. Introduction

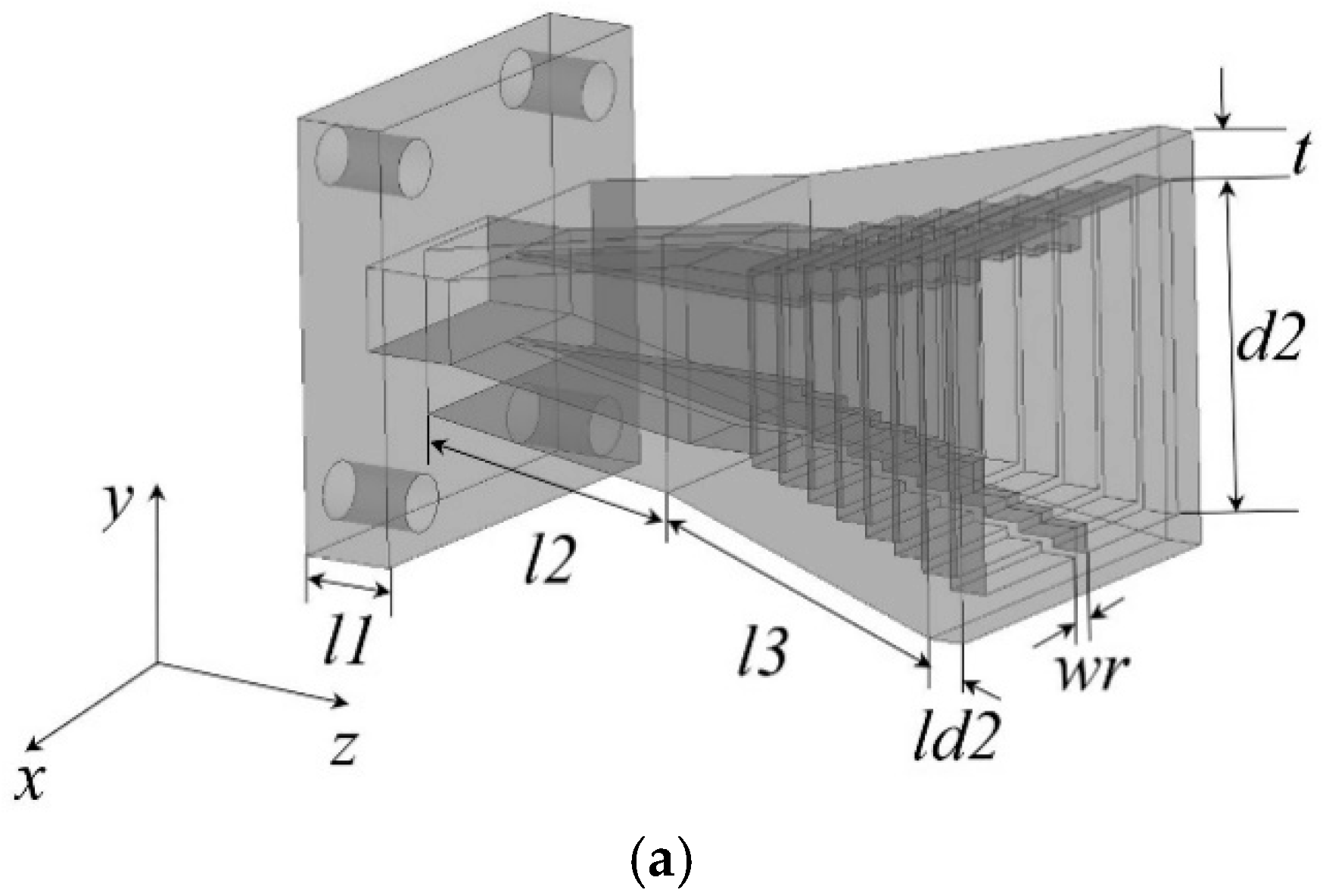

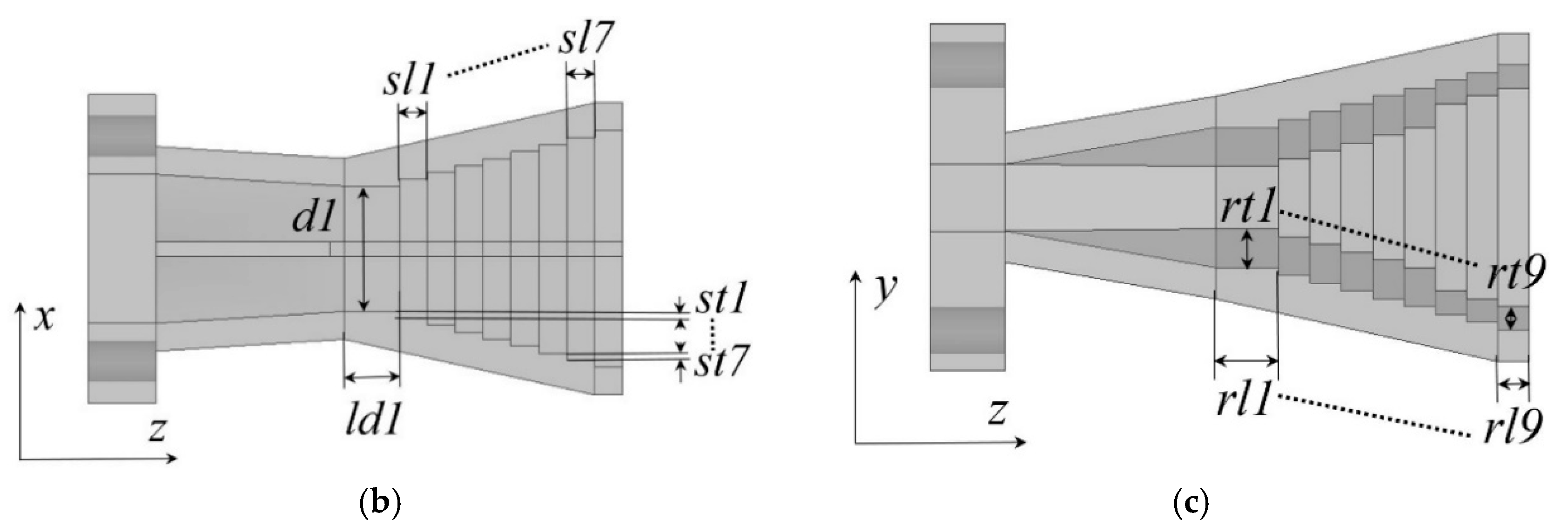

2. Design and Fabrication of the Antennas

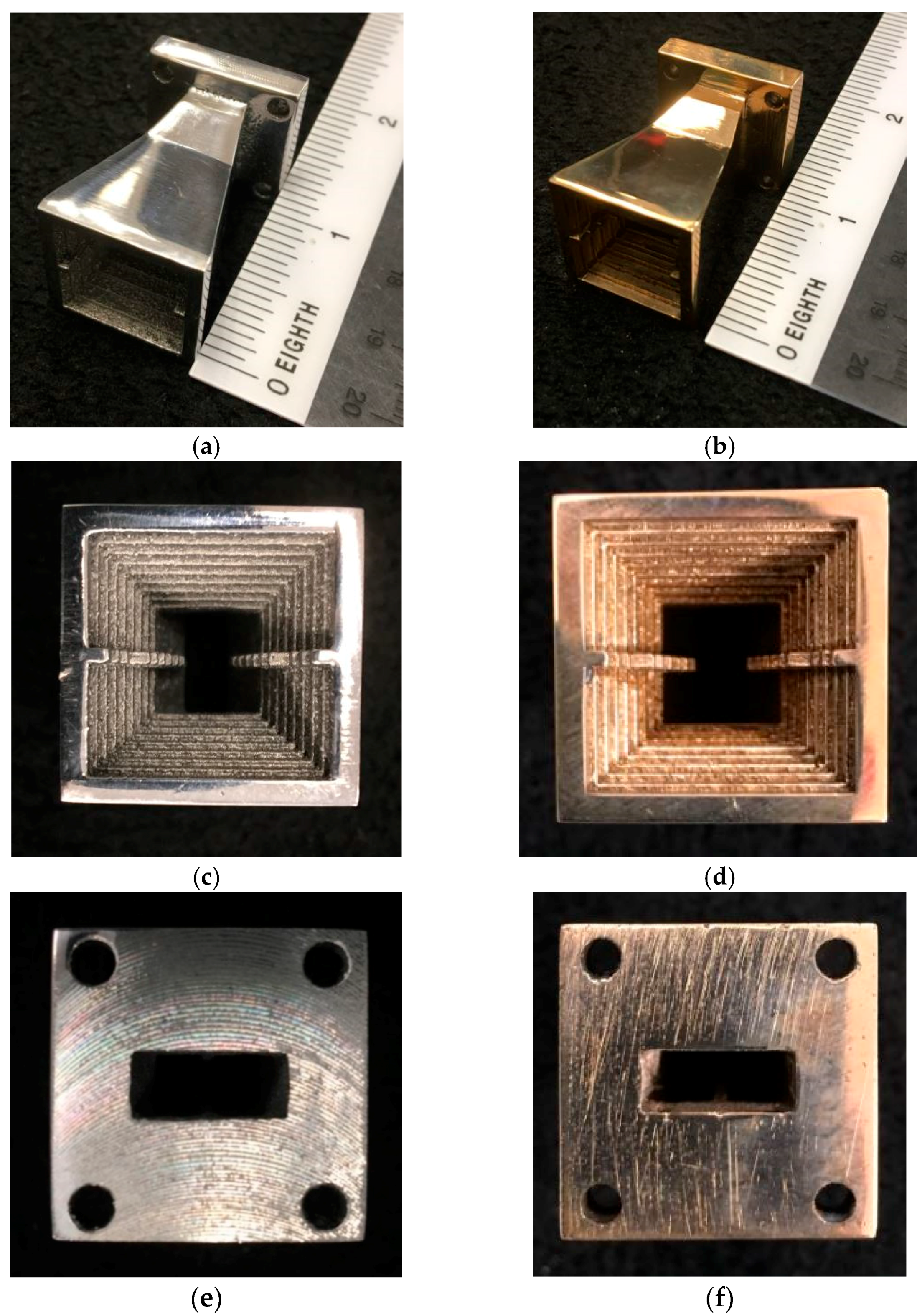

3. Characterization of the Antenna

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hull, C. Apparatus for Production of Three-Dimensional Objects by Stereolithography. U.S. Patent 4575330, 11 March 1986. [Google Scholar]

- Deckard, C.; Beaman, J.; Darrah, J. Selective Laser Sintering with Layerwise Cross-Scanning. U.S. Patent 5155324, 13 October 1992. [Google Scholar]

- Crump, S. Apparatus and Method for Creating Three-Dimensional Objects. U.S. Patent 5121329, 9 June 1992. [Google Scholar]

- Gonzales, A.; Kaneko, K.; Kojima, T.; Asayama, S.; Uzawa, Y. Terahertz corrugated horns (1.25–1.57 THz): Design, Gaussian modeling, and measurements. IEEE Trans. Terahertz Sci. Technol. 2016, 7, 42–52. [Google Scholar]

- Tajima, T.; Song, H.J.; Ajito, K.; Yaita, M.; Kukutsu, N. 300-GHz step-profiled corrugated horn antennas integrated in LTCC. IEEE Trans. Antennas Propag. 2014, 62, 5437–5444. [Google Scholar] [CrossRef]

- Timbie, P.; Grade, J.; van der Veide, D.; Maffei, B.; Pisano, G. Stereolithographed MM-wave corrugated horn antennas. In Proceedings of the 36th International Conference on Infrared, Millimeter and Terahertz Waves (IRMMW-THz), Houston, TX, USA, 2–7 October 2011; pp. 1–3. [Google Scholar]

- Chieh, J.C.; Dick, B.; Loui, S.; Rockway, J.D. Development of a Ku-band corrugated conical horn using 3-D print technology. IEEE Antennas Wirel. Propag. Lett. 2014, 13, 201–204. [Google Scholar] [CrossRef]

- Von Bieren, A.; De Rijk, E.; Ansermet, J.P.; Macor, A. Monolithic metal-coated plastic components for MM-wave applications. In Proceedings of the 39th International Conference on Infrared, Millimeter, and Terahertz Waves (IRMMW-THz), Tucson, TX, USA, 14–19 September 2014; pp. 1–2. [Google Scholar]

- Garcia, C.R.; Rumpf, R.C.; Tsang, H.H.; Barton, J.H. Effects of extreme surface roughness on 3D printed horn antenna. Electron. Lett. 2013, 49, 734–736. [Google Scholar] [CrossRef]

- Zhang, B.; Linnér, P.; Karnfelt, C.; Tam, P.L.; Södervall, U.; Zirath, H. Attempt of the metallic 3D printing technology for millimeter-wave antenna implementations. In Proceedings of the Asia-Pacific Microwave Conference (APMC), Nanjing, China, 6–9 December 2015; pp. 1–3. [Google Scholar]

- Zhang, B.; Zhan, Z.; Cao, Y.; Gulan, H.; Linnér, P.; Sun, J.; Zwick, T.; Zirath, H. Metallic 3D printed antennas for millimeter- and submillimeter-wave applications. IEEE Trans. Terahertz Sci. Technol. 2016, 6, 592–600. [Google Scholar] [CrossRef]

- Zhang, B.; Guo, Y.X.; Zirath, H.; Zhang, Y.P. Investigation on 3-D-printing technologies for millimeterwave and Terahertz applications. Proc. IEEE 2017, 105, 723–736. [Google Scholar] [CrossRef]

- Gordon, A.J.; Novotny, D.R.; Francis, M.H.; Wittmann, R.C.; Butler, M.L.; Curtin, A.E.; Guerrieri, J.R.; Periasamy, L.; Gasiewski, A.J. An all metal, 3-D-printed CubeSat feed horn: An assessment of performance conducted at 118.7503 GHz using a robotic antenna range. IEEE Antennas Propag. Mag. 2017, 59, 96–102. [Google Scholar] [CrossRef]

- Ignatenko, M.; Simakauskas, B.; Notaros, M.; Filipovic, D.S. A phase center-stabilized K/Ka/V band linearly-polarized horn for Luneberg lenses. IEEE Antennas Wirel. Propag. Lett. 2017, 16, 2726–2729. [Google Scholar] [CrossRef]

| Parameters | (mm) | Parameters | (mm) | Parameters | (mm) | Parameters | (mm) |

|---|---|---|---|---|---|---|---|

| d1 | 9 | d2 | 17 | l1 | 4.83 | l2 | 13.73 |

| l3 | 18.87 | ld1 | 4 | ld2 | 2 | rl1 | 4 |

| rl2 | 2 | rl3 | 2 | rl4 | 2 | rl5 | 2 |

| rl6 | 2 | rl7 | 2 | rl8 | 2 | rl9 | 2 |

| rt1 | 0.5 | rt2 | 0.5 | rt3 | 0.5 | rt4 | 0.5 |

| rt5 | 0.5 | rt6 | 1.5 | rt7 | 0.5 | rt8 | 0.5 |

| rt9 | 0.5 | sl1 | 2 | sl2 | 2 | sl3 | 2 |

| sl4 | 2 | sl5 | 2 | sl6 | 2 | sl7 | 2 |

| st1 | 0.5 | st2 | 0.5 | st3 | 0.5 | st4 | 0.5 |

| st5 | 0.5 | st6 | 0.5 | st7 | 0.5 | t | 2 |

| wr | 1 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Guo, Y.-X.; Sun, H.; Wu, Y. Metallic, 3D-Printed, K-Band-Stepped, Double-Ridged Square Horn Antennas. Appl. Sci. 2018, 8, 33. https://doi.org/10.3390/app8010033

Zhang B, Guo Y-X, Sun H, Wu Y. Metallic, 3D-Printed, K-Band-Stepped, Double-Ridged Square Horn Antennas. Applied Sciences. 2018; 8(1):33. https://doi.org/10.3390/app8010033

Chicago/Turabian StyleZhang, Bing, Yong-Xin Guo, Hucheng Sun, and Yanjie Wu. 2018. "Metallic, 3D-Printed, K-Band-Stepped, Double-Ridged Square Horn Antennas" Applied Sciences 8, no. 1: 33. https://doi.org/10.3390/app8010033