Laser Irradiation Responses of a Single-Crystal Diamond Produced by Different Crystal Growth Methods

Abstract

:1. Introduction

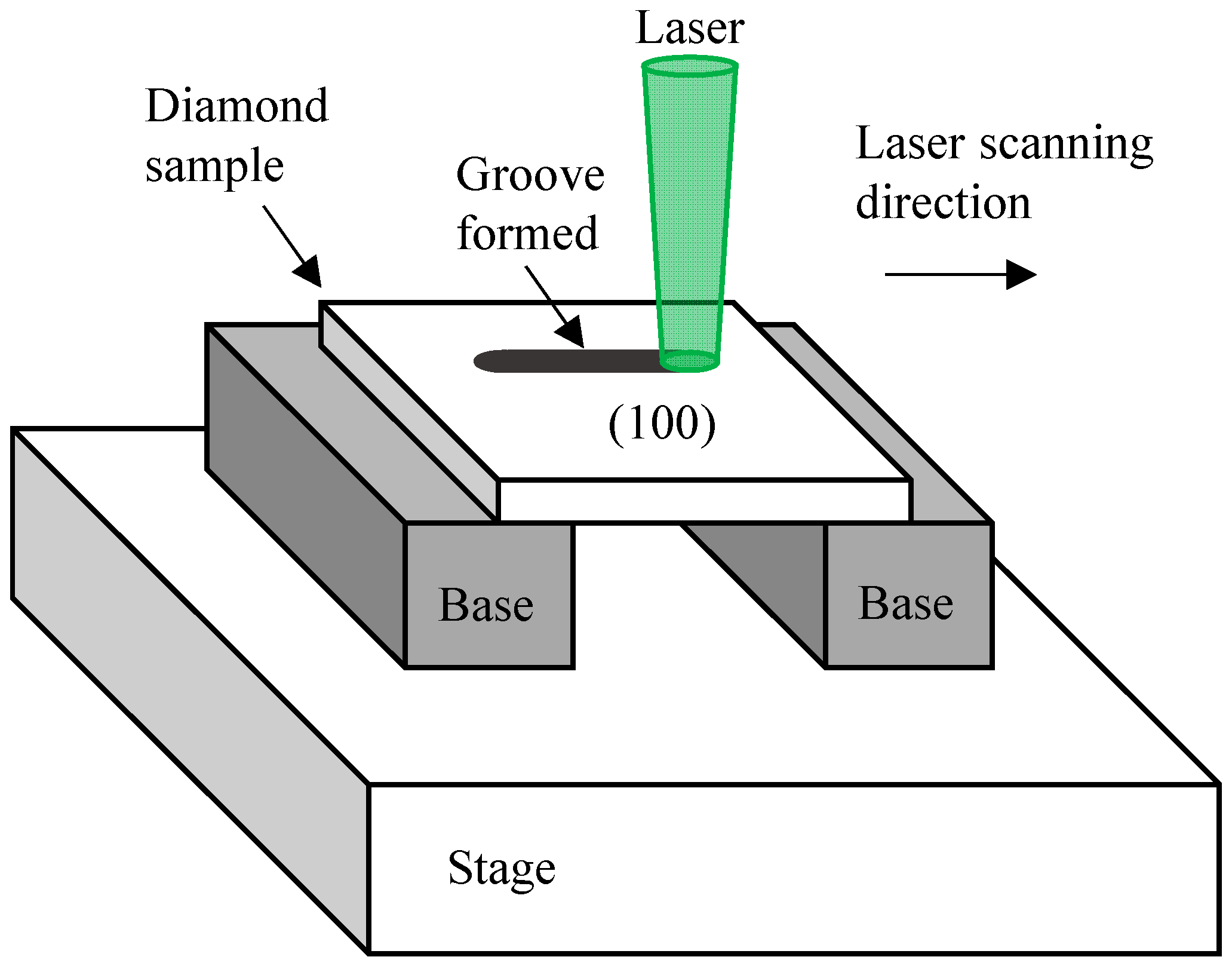

2. Materials and Methods

3. Results

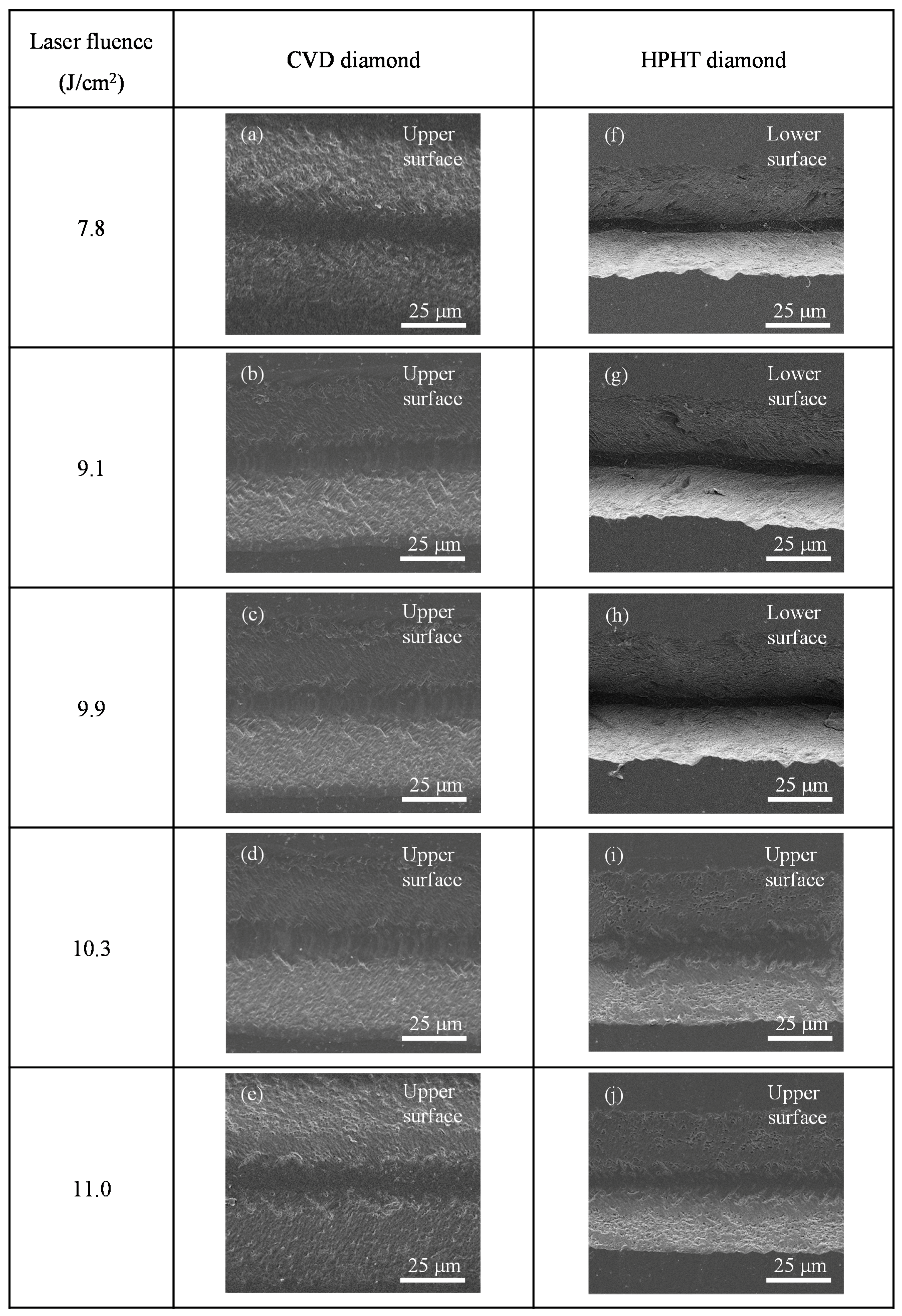

3.1. Groove Formation Behaviour

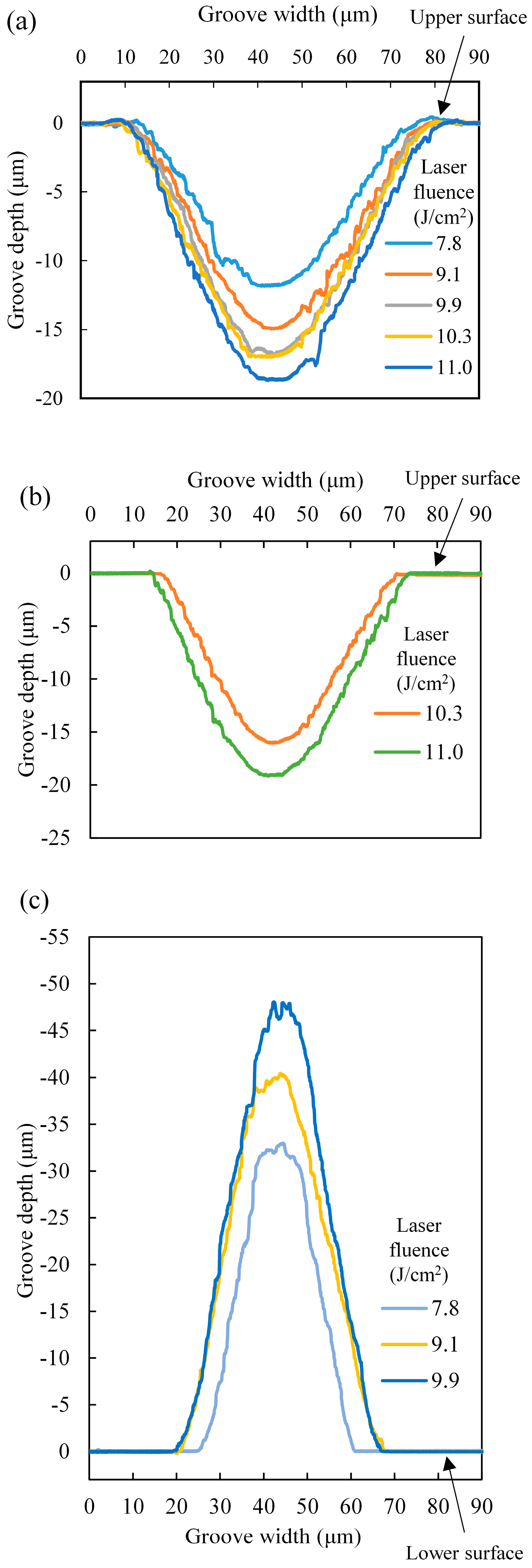

3.2. Groove Cross-Sectional Profile

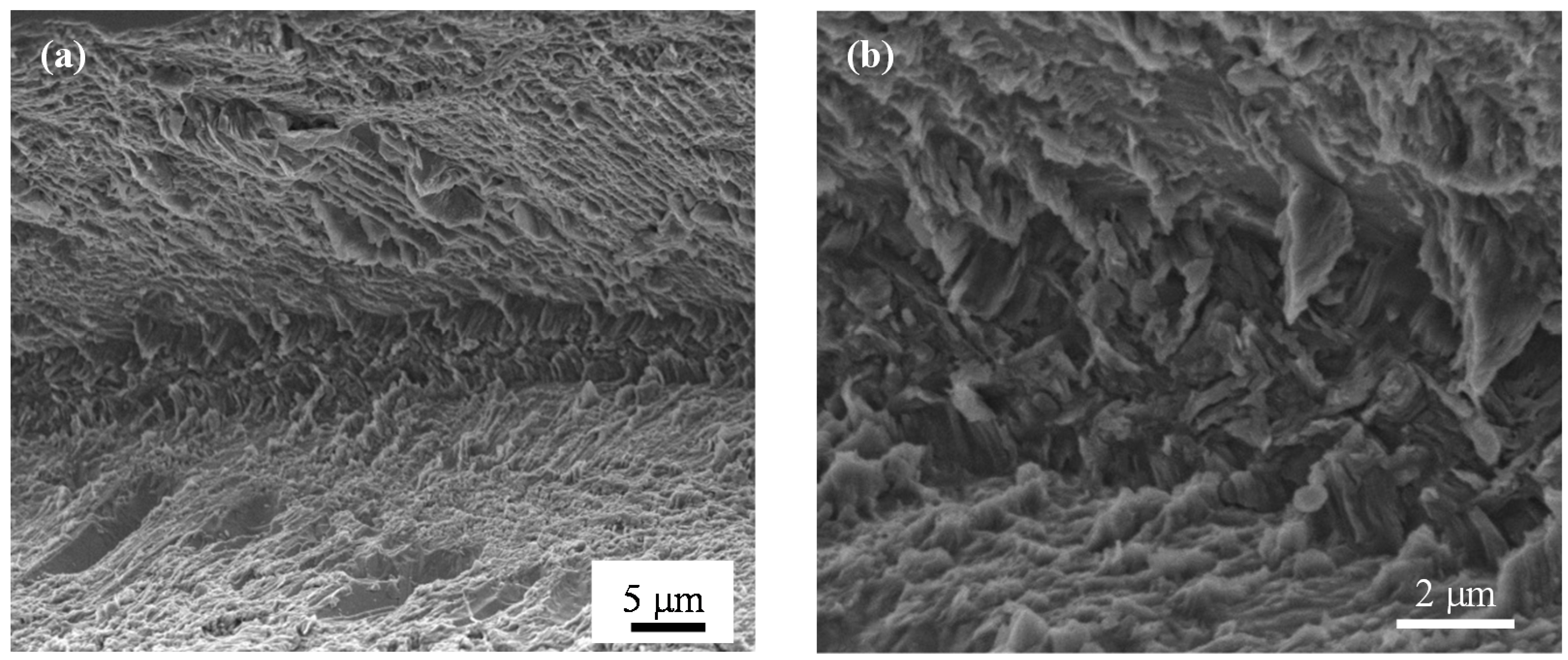

3.3. Debris Cloud Formation

4. Discussion

4.1. Machining Thresholds

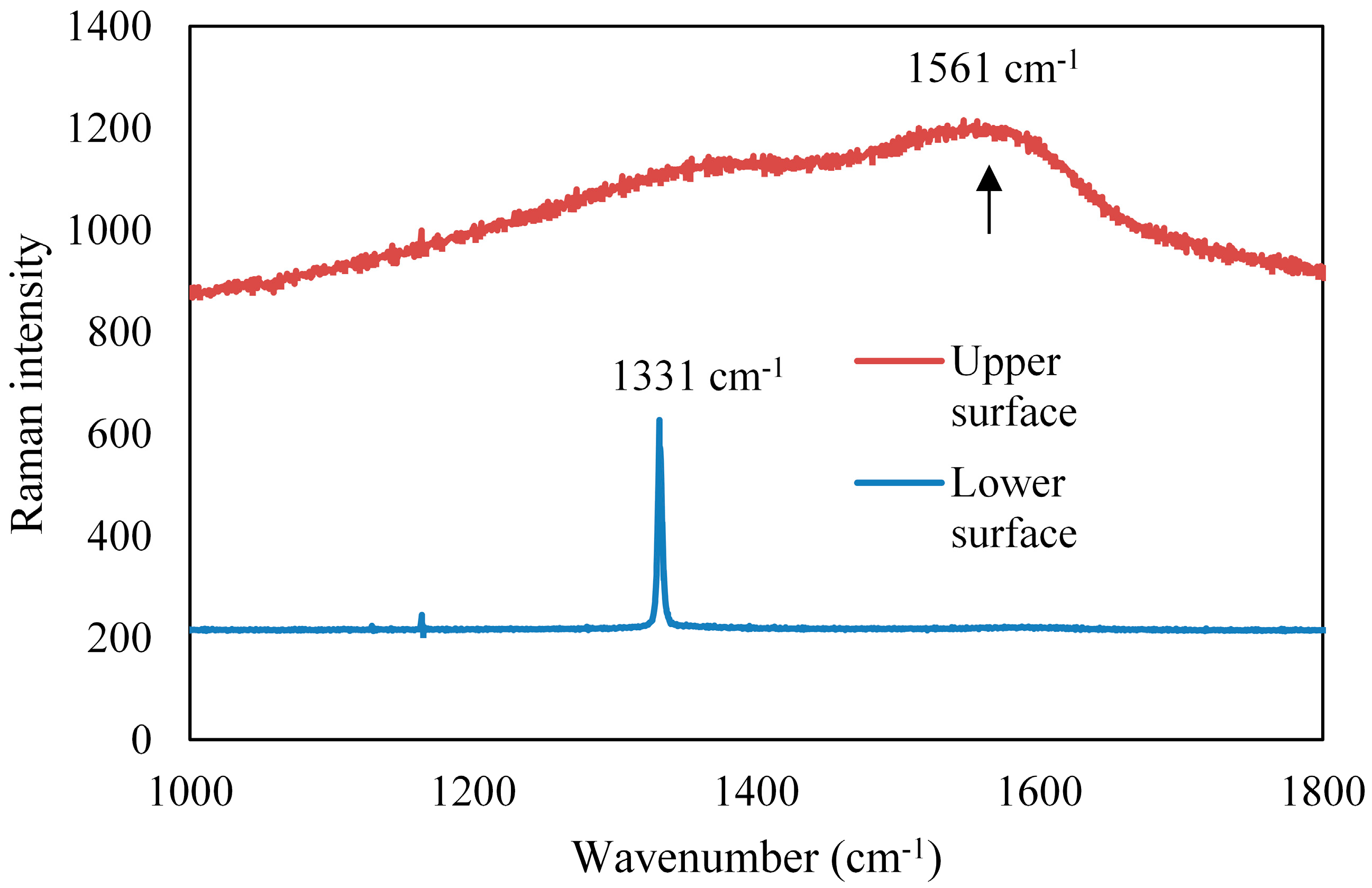

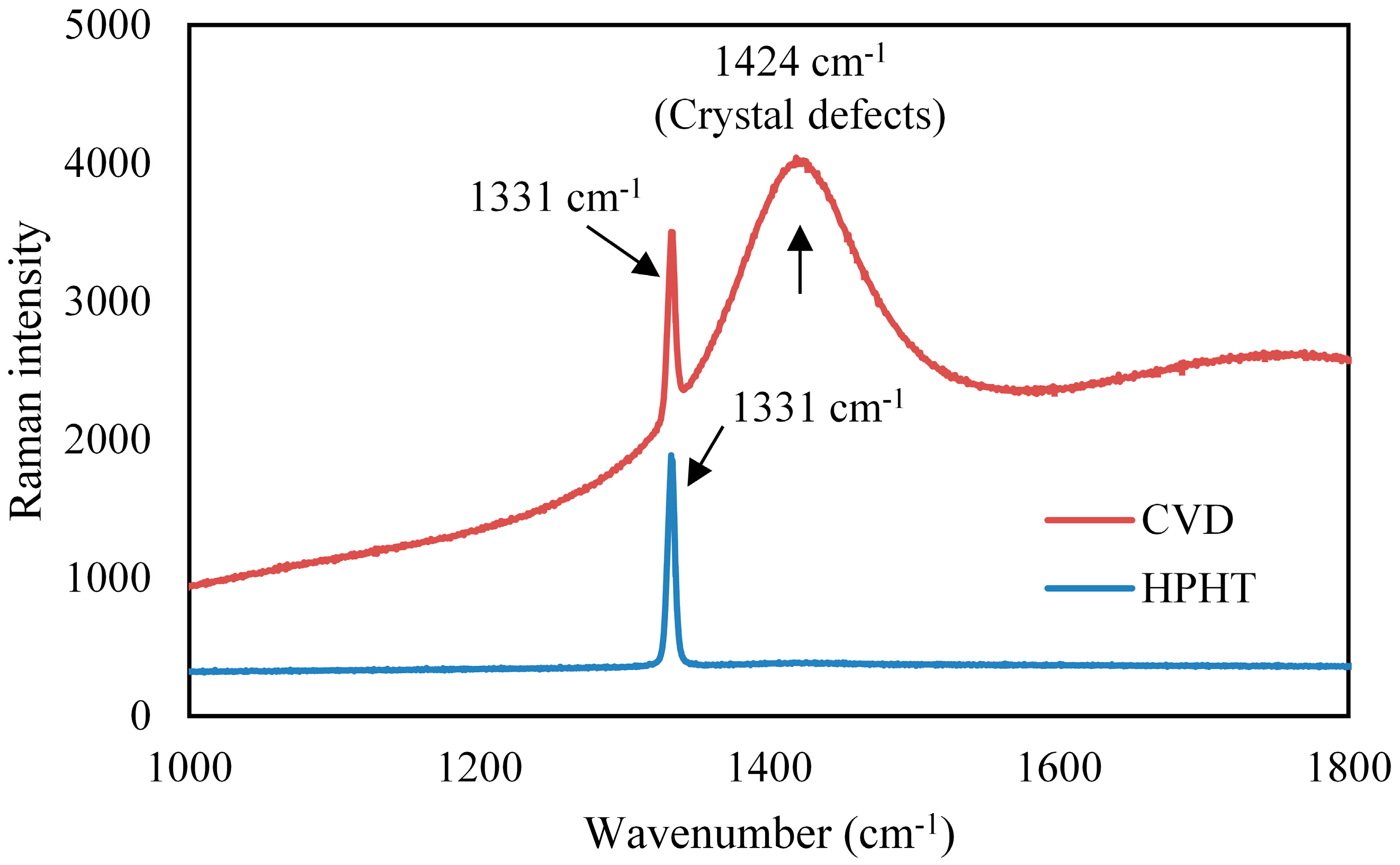

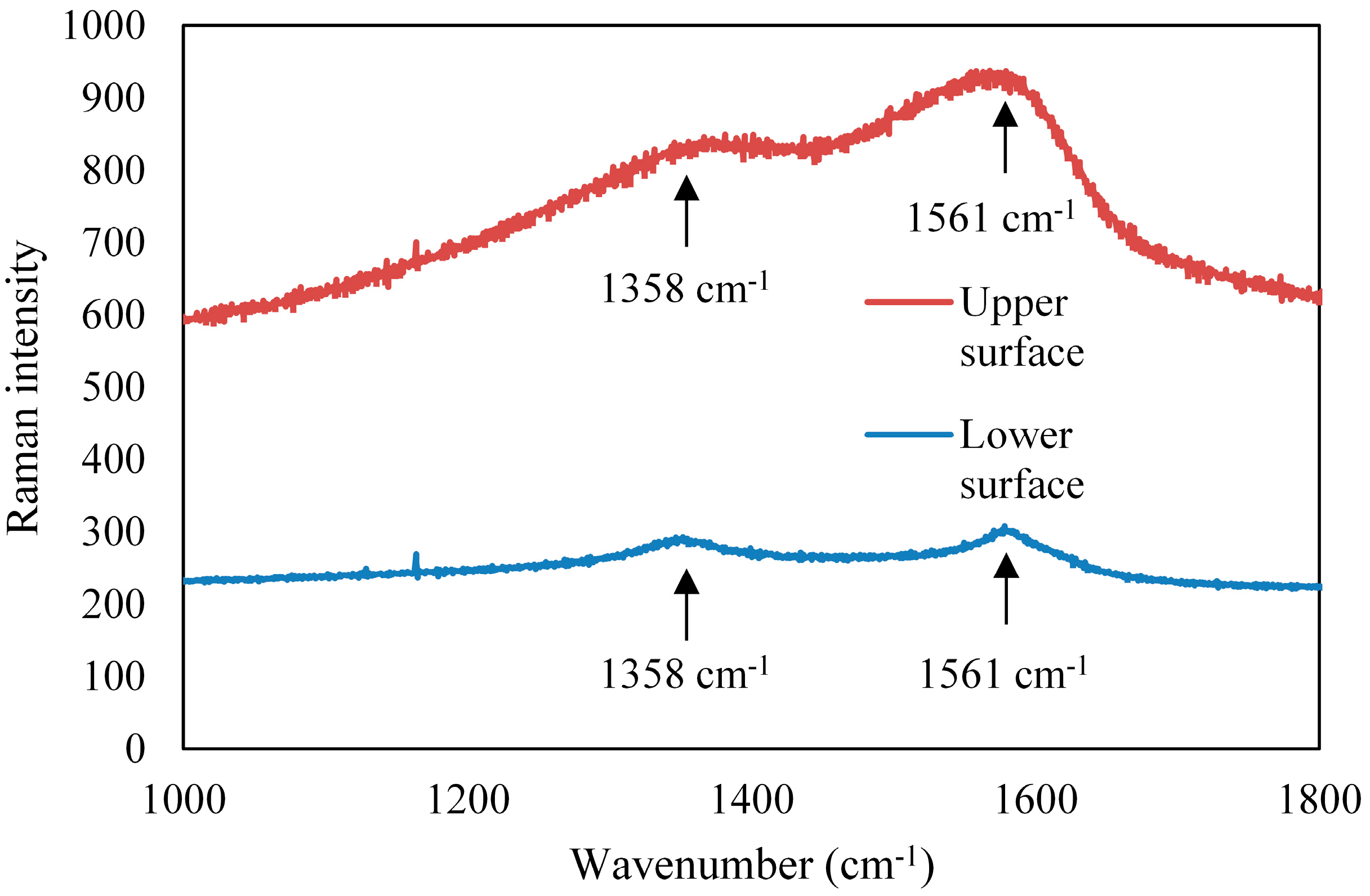

4.2. Material Structural Change

5. Conclusions

- (1)

- The transmission rate of HPHT diamond to the present laser beam is 75.7%, lower than that of CVD diamond (83.9%).

- (2)

- For both HPHT and CVD diamond, destructive interference takes place on the upper surface at a sufficiently high laser fluence, leading to direct ablation of smooth grooves.

- (3)

- For HPHT diamond, at a laser fluence lower than the machining threshold for the upper surface, laser passes through the upper surface and material removal only takes place on the lower surface of due to constructive interference of the laser, resulting in spalling of material and formation of sharp grooves with rough bottoms.

- (4)

- There is significant deposition of debris containing sp2 bonding on the area surrounding the groove on the upper surface, while no such deposition was found on the lower surface. For the latter, the laser comes into contact with a limited amount to oxygen in the grooves, thus oxidation, which greatly reduces the onset temperature of crystal structure change, cannot take place, and limited sp2 bonds are produced.

Author Contributions

Conflicts of Interest

References

- Konrad, W.; Claus, D.; Marcel, H.; Christian, W. Laser Prepared Cutting Tools. Phys. Procedia 2012, 39, 240–248. [Google Scholar] [CrossRef]

- Plano, L.S.G. Growth of CVD Diamond for Electronic Applications. In Diamond: Electronic Properties and Applications, 1st ed.; Pan, L.S., Kania, D.R., Eds.; Springer: New York, NY, USA, 1995; pp. 61–138. [Google Scholar]

- Tabor, D. Mohs’s Hardness Scale—A Physical Interpretation. Proc. Phys. Soc. Lond. B 1954, 67, 249–257. [Google Scholar] [CrossRef]

- Field, J.E.; Pickles, C.S.J. Strength, fracture and friction properties of diamond. Diam. Relat. Mater. 1996, 5, 625–634. [Google Scholar] [CrossRef]

- Berman, R. Physical Properties of Diamond; Clarendon Press: London, UK, 1965; pp. 140–154. [Google Scholar]

- Konov, V.I. Laser in micro and nanoprocessing of diamond materials. Laser Photonics Rev. 2012, 6, 739–766. [Google Scholar] [CrossRef]

- Dumitru, G.; Romano, V.; Weber, H.P.; Sentis, M.; Marine, W. Femtosecond ablation of ultrahard materials. Appl. Phys. A Mater. Sci. Process. 2002, 74, 729–739. [Google Scholar] [CrossRef]

- Kononenko, T.V.; Komlenok, M.S.; Pashinin, V.P.; Pimenov, S.M.; Konov, V.I.; Neff, M.; Romano, V.; Lüthy, W. Femtosecond laser microstructuring in the bulk of diamond. Diam. Relat. Mater. 2009, 18, 196–199. [Google Scholar] [CrossRef]

- Ramanathan, D.; Molian, P.A. Micro- and Sub-Micromachining of Type IIa Single Crystal Diamond Using a Ti:Sapphire Femtosecond Laser. J. Manuf. Sci. Eng. 2002, 124, 389–396. [Google Scholar] [CrossRef]

- Preuss, S.; Stuke, M. Subpicosecond ultraviolet laser ablation of diamond: Nonlinear properties at 248 nm and time-resolved characterization of ablation dynamics. Appl. Phys. Lett. 1995, 67, 338–340. [Google Scholar] [CrossRef]

- Mathis, A.; Courvoisier, F.; Froehly, L.; Furfaro, L.; Jacquot, M.; Lacourt, P.A.; Dudley, J.M. Micromachining along a curve: Femtosecond laser micromachining of curved profiles in diamond and silicon using accelerating beams. Appl. Phys. Lett. 2012, 101, 99–102. [Google Scholar] [CrossRef] [Green Version]

- Wu, Q.; Ma, Y.; Fang, R.; Liao, Y.; Yu, Q.; Chen, X.; Wang, K. Femtosecond laser-induced periodic surface structure on diamond film. Appl. Phys. Lett. 2003, 82, 1703–1705. [Google Scholar] [CrossRef]

- Rehman, Z.U.; Janulewicz, K.A. Structural transformation of monocrystalline diamond driven by ultrashort laser pulses. Diam. Relat. Mater. 2016, 70, 194–200. [Google Scholar] [CrossRef]

- Takayama, N.; Yan, J. Mechanisms of micro-groove formation on single-crystal diamond by a nanosecond pulsed laser. J. Mater. Process. Technol. 2017, 243, 299–311. [Google Scholar] [CrossRef]

- Iakoubovshii, K.; Stesmans, A. Chemical vapour deposition diamond studied by optical and electron spin resonance techniques. J. Phys. Condens. Matter 2002, 14, R467–R499. [Google Scholar] [CrossRef]

- Lee, K.C.; Sussman, B.J.; Nunn, J.; Lorenz, V.O.; Reim, K.; Jaksch, D.; Walmsley, I.A.; Spizzirri, P.; Prawer, S. Comparing phonon dephasing lifetimes in diamond using Transient Coherent Ultrafast Phonon Spectroscopy. Diam. Relat. Mater. 2010, 19, 1289–1295. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Dong, L.H.; Wang, D.S.; Dong, Y.H. Study of HPHT single crystal diamond as precision cutting tool material. Precis. Eng. 2012, 36, 162–167. [Google Scholar] [CrossRef]

- Mildren, R.P. Intrinsic optical properties of diamond. In Optical Engineering of Diamond; Mildren, R.P., Rabeau, J.R., Eds.; Wiley-VCH Verlag GmbH & Co.: Weinheim, Germany, 2013; pp. 1–3. [Google Scholar]

- Dubey, A.K.; Yadava, V. Laser beam machining—A review. Int. J. Mach. Tools Manuf. 2008, 48, 609–628. [Google Scholar] [CrossRef]

- Paschotta, R. Beam quality deterioration of lasers caused by intracavity beam distortions. Opt. Express 2006, 14, 6069–6074. [Google Scholar] [CrossRef] [PubMed]

- Young, M. Optics and Lasers: Including Fibers and Optical Waveguides, 5th ed.; Springer: Berlin/Heidelberg, Germany, 2000; pp. 5–8. [Google Scholar]

- Anthony, T.R. Reverse Laser Drilling. U.S. Patent 4,473,737, 25 September 1984. [Google Scholar]

- Philipp, H.; Taft, E. Optical Properties of Diamond in the Vacuum Ultraviolet. Phys. Rev. 1962, 127, 159–161. [Google Scholar] [CrossRef]

- Zaitsev, A.M. Optical Properties of Diamond: A Data Handbook; Springer: Berlin/Heidelberg, Germany, 2001; pp. 13–17. [Google Scholar]

- Körner, C.; Mayerhofer, R.; Hartmann, M.; Bergmann, H.W. Physical and material aspects in using visible laser pulses of nanosecond duration for ablation. Appl. Phys. A 1996, 63, 123–131. [Google Scholar] [CrossRef]

- Hasselman, D.P.H. Unified Theory of Thermal Shock Fracture Initiation and Crack Propagation in Brittle Ceramics. J. Am. Ceram. Soc. 1969, 52, 600–604. [Google Scholar] [CrossRef]

- Rothschild, M.; Arnone, C.; Ehrlich, D.J. Excimer-laser etching of diamond and hard carbon films by direct writing and optical projection. J. Vac. Sci. Technol. B Microelectron. Process. Phenom. 1986, 4, 310–314. [Google Scholar] [CrossRef]

- Spriggs, G.E. Properties of diamond and cubic boron nitride. In Powder Metallurgy Data. Refractory, Hard and Intermetallic Materials; Beiss, P., Ruthardt, R., Warlimont, H., Eds.; Springer: Berlin/Heidelberg, Germany, 2002; pp. 118–139. [Google Scholar]

- Telling, R.; Pickard, C.; Payne, M.; Field, J. Theoretical strength and cleavage of diamond. Phys. Rev. Lett. 2000, 84, 5160–5163. [Google Scholar] [CrossRef] [PubMed]

- Ihlemann, J.; Wolff, B.; Simon, P. Nanosecond and femtosecond excimer laser ablation of fused silica. Appl. Phys. A Solids Surf. 1992, 54, 363–368. [Google Scholar] [CrossRef]

- Kononenko, V.V.; Kononenko, T.V.; Pimenov, S.M.; Sinyavskii, M.N.; Konov, V.I.; Dausinger, F. Effect of the pulse duration on graphitisation of diamond during laser ablation. Quantum Electron. 2005, 35, 252–256. [Google Scholar] [CrossRef]

- Jeschke, H.O.; Garcia, M.E.; Bennemann, K.H. Theory for the ultrafast ablation of graphite films. Phys. Rev. Lett. 2001, 87, 015003. [Google Scholar] [CrossRef] [PubMed]

- Medvedev, N.; Jeschke, H.O.; Ziaja, B. Nonthermal graphitization of diamond induced by a femtosecond X-ray laser pulse. Phys. Rev. B Condens. Matter Mater. Phys. 2013, 88, 224304. [Google Scholar] [CrossRef]

- Seal, M. The Effect of Surface Orientation on the Graphitization of Diamond. Phys. Status Solidi B 1963, 3, 658–664. [Google Scholar] [CrossRef]

- Evans, T.; James, P.F. A Study of the Transformation of Diamond to Graphite. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1964, 277, 260–269. [Google Scholar] [CrossRef]

- Davies, G.; Evans, T. Graphitization of diamond at zero pressure and at a high pressure. Proc. R. Soc. Lond. A 1972, 328, 413–427. [Google Scholar] [CrossRef]

- Kuznetsov, V.L.; Zilberberg, I.L.; Butenko, Y.V.; Chuvilin, A.L.; Segall, B. Theoretical study of the formation of closed curved graphite-like structures during annealing of diamond surface. J. Appl. Phys. 1999, 86, 863–870. [Google Scholar] [CrossRef]

- Narayan, J.; Bhaumik, A. Novel phase of carbon, ferromagnetism, and conversion into diamond. J. Appl. Phys. 2015, 118, 215303. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Wavelength (nm) | 532 |

| Pulse width (ns) | 15.6 |

| Repetition frequency (kHz) | 1 |

| Power (mW) | 450, 515, 560, 590, 625 |

| Fluence on upper surface (J/cm2) | 7.8, 9.1, 9.9, 10.3, 11.0 |

| Scanning speed (mm/s) | 1 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Takayama, N.; Yan, J. Laser Irradiation Responses of a Single-Crystal Diamond Produced by Different Crystal Growth Methods. Appl. Sci. 2017, 7, 815. https://doi.org/10.3390/app7080815

Takayama N, Yan J. Laser Irradiation Responses of a Single-Crystal Diamond Produced by Different Crystal Growth Methods. Applied Sciences. 2017; 7(8):815. https://doi.org/10.3390/app7080815

Chicago/Turabian StyleTakayama, Nozomi, and Jiwang Yan. 2017. "Laser Irradiation Responses of a Single-Crystal Diamond Produced by Different Crystal Growth Methods" Applied Sciences 7, no. 8: 815. https://doi.org/10.3390/app7080815