Evaluation of Mechanical Properties of Recycled Material for Utilization in Asphalt Mixtures

Abstract

:1. Introduction

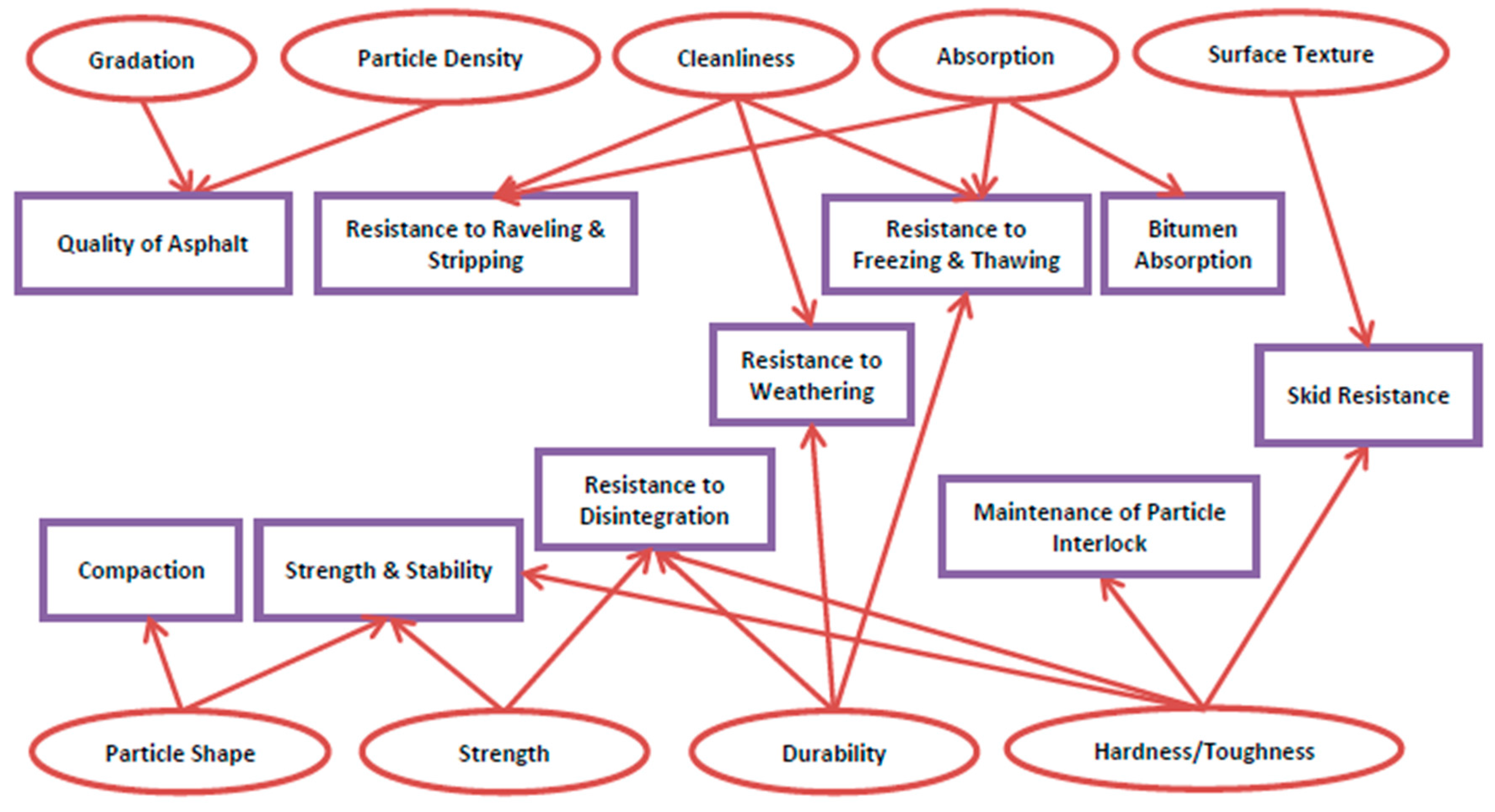

2. Aggregate Properties and Their Relationship to Asphalt Performance

3. Experimental Work

3.1. Materials

3.2. Laboratory Tests

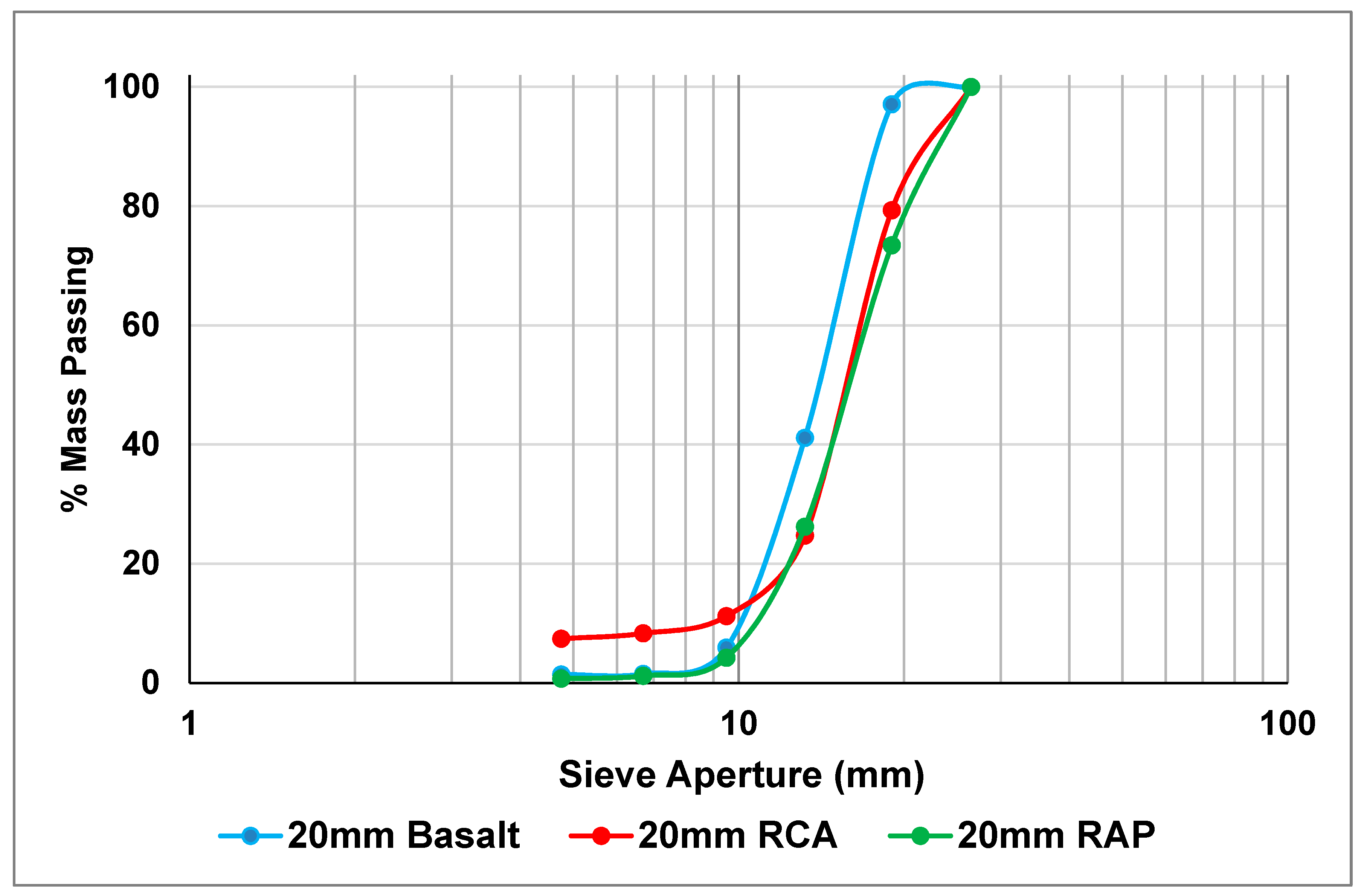

3.2.1. Particle Size Distribution Test

3.2.2. Particle Shape Test

3.2.3. Flakiness Index Test

3.2.4. Particle Density and Water Absorption Test

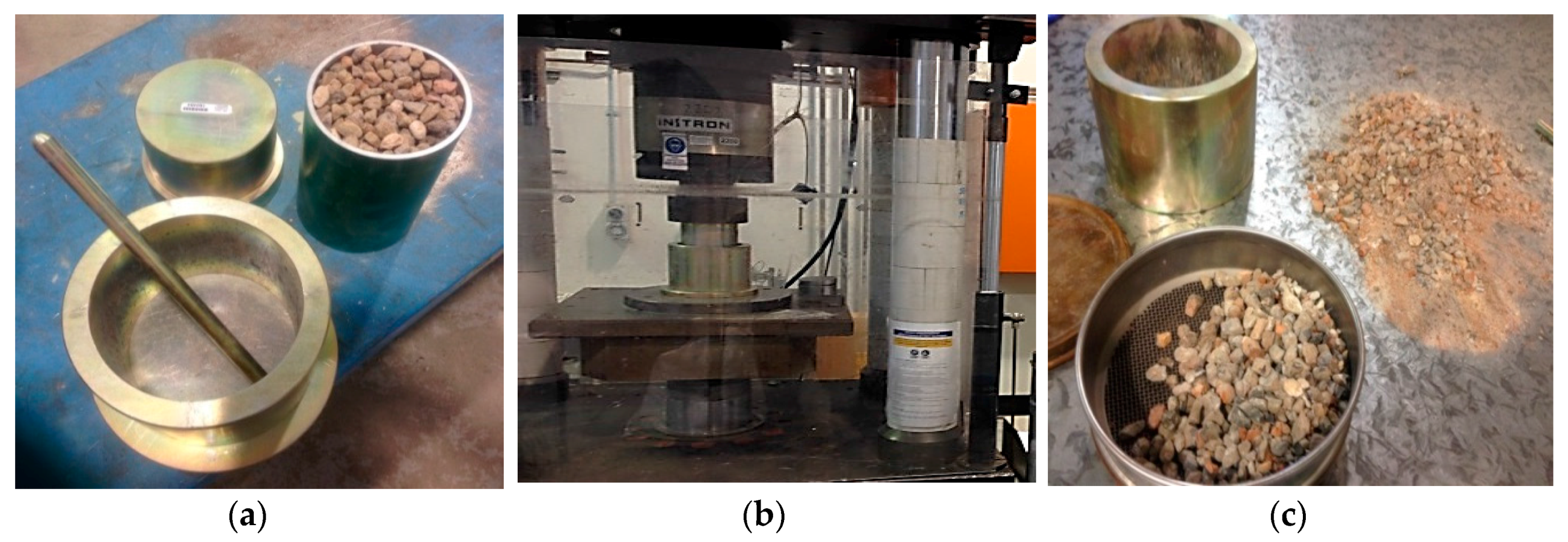

3.2.5. Crushing Value Test

3.2.6. Weak Particle Test

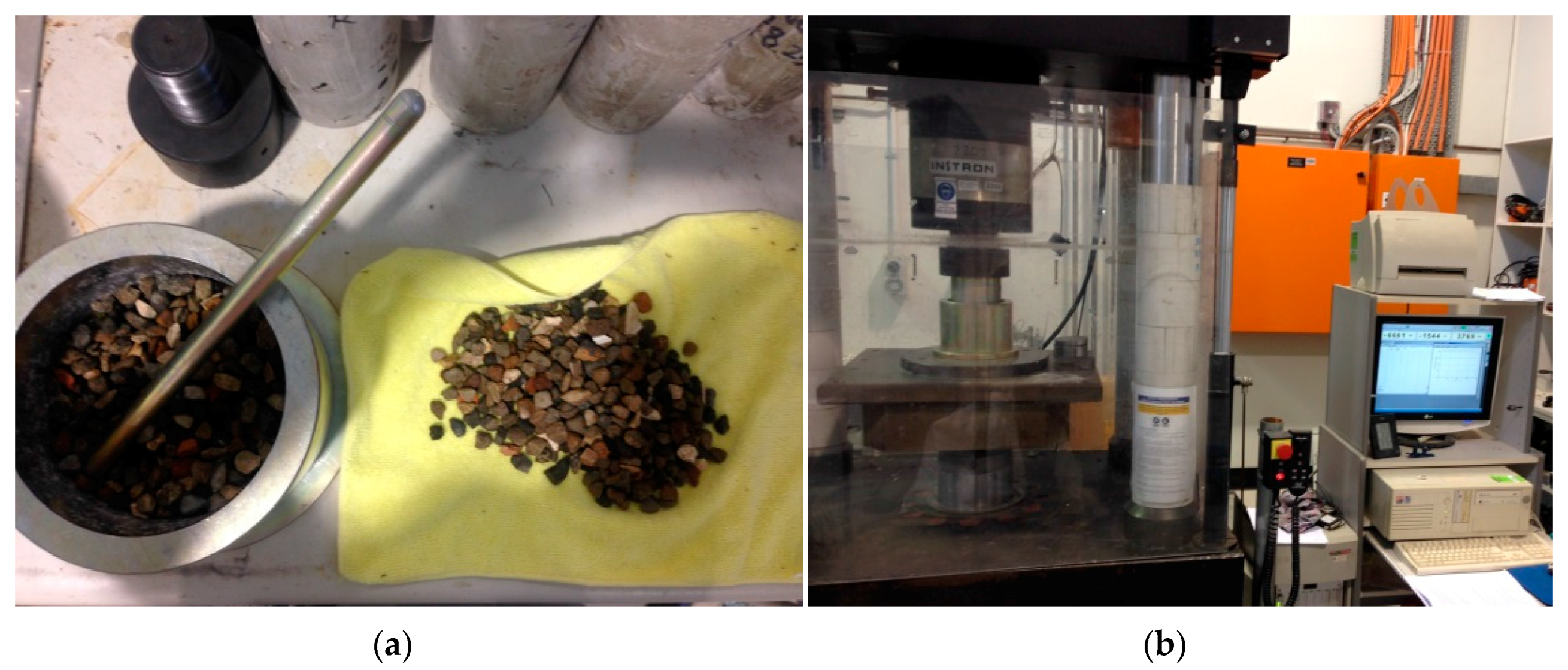

3.2.7. Wet/Dry Strength Variation Test

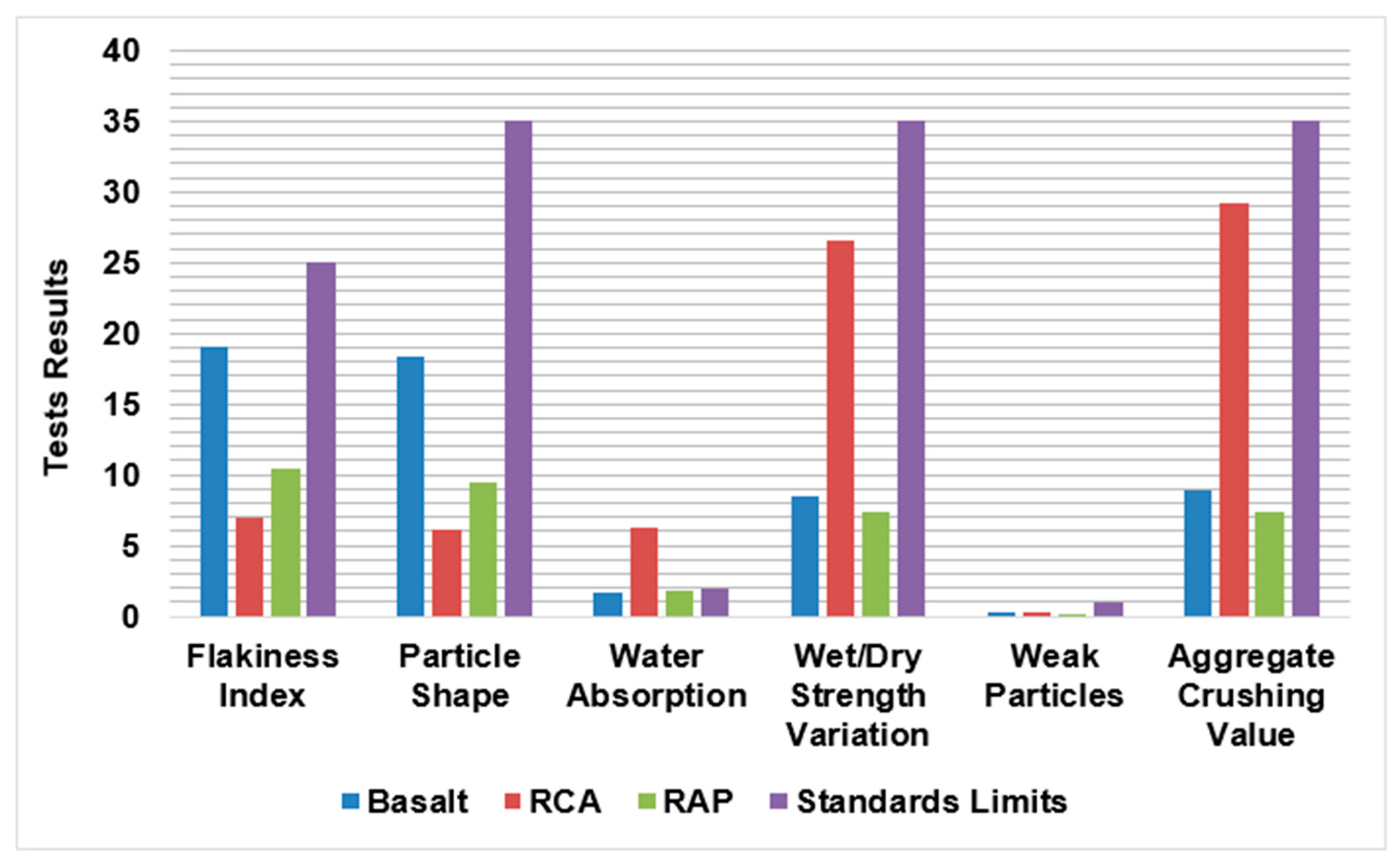

3.3. Results and Discussions

4. Conclusions

- (1)

- RCA has lower value of flaky and misshapen particles in comparison with RAP and basalt. This implies that asphalt mixtures containing a certain amount of RCA can have better workability, deformation resistance and compaction.

- (2)

- RCA exhibits comparatively more absorption and wet/dry strength variation than conventional aggregate and RAP, while the results of other tests show that RCA still meets the requirements for aggregate in asphalt mixtures. Cracks and adhering mortar and cement paste can be significant reasons for the high water absorbtion of RCA which needs to be compensated for during mix design.

- (3)

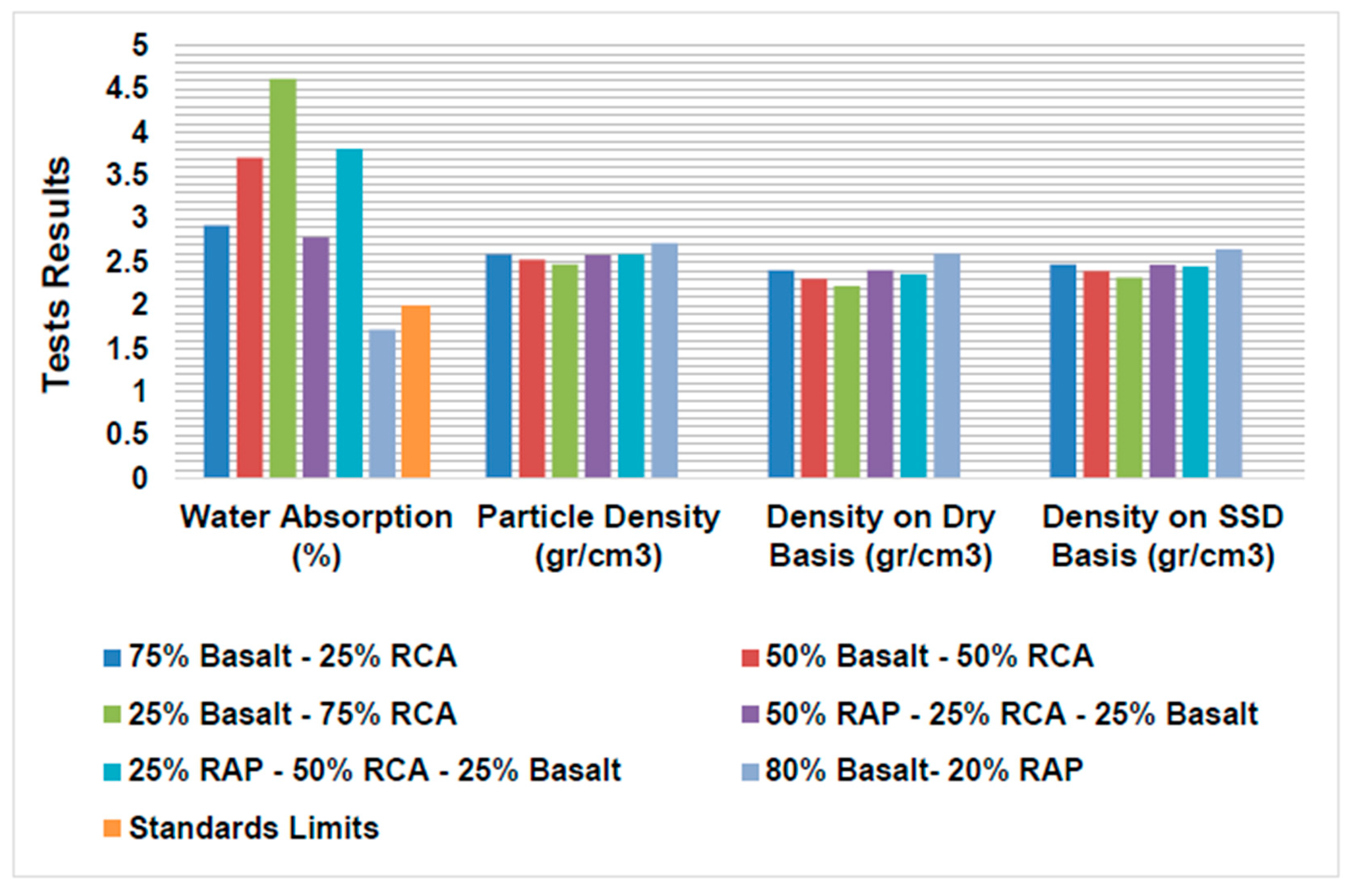

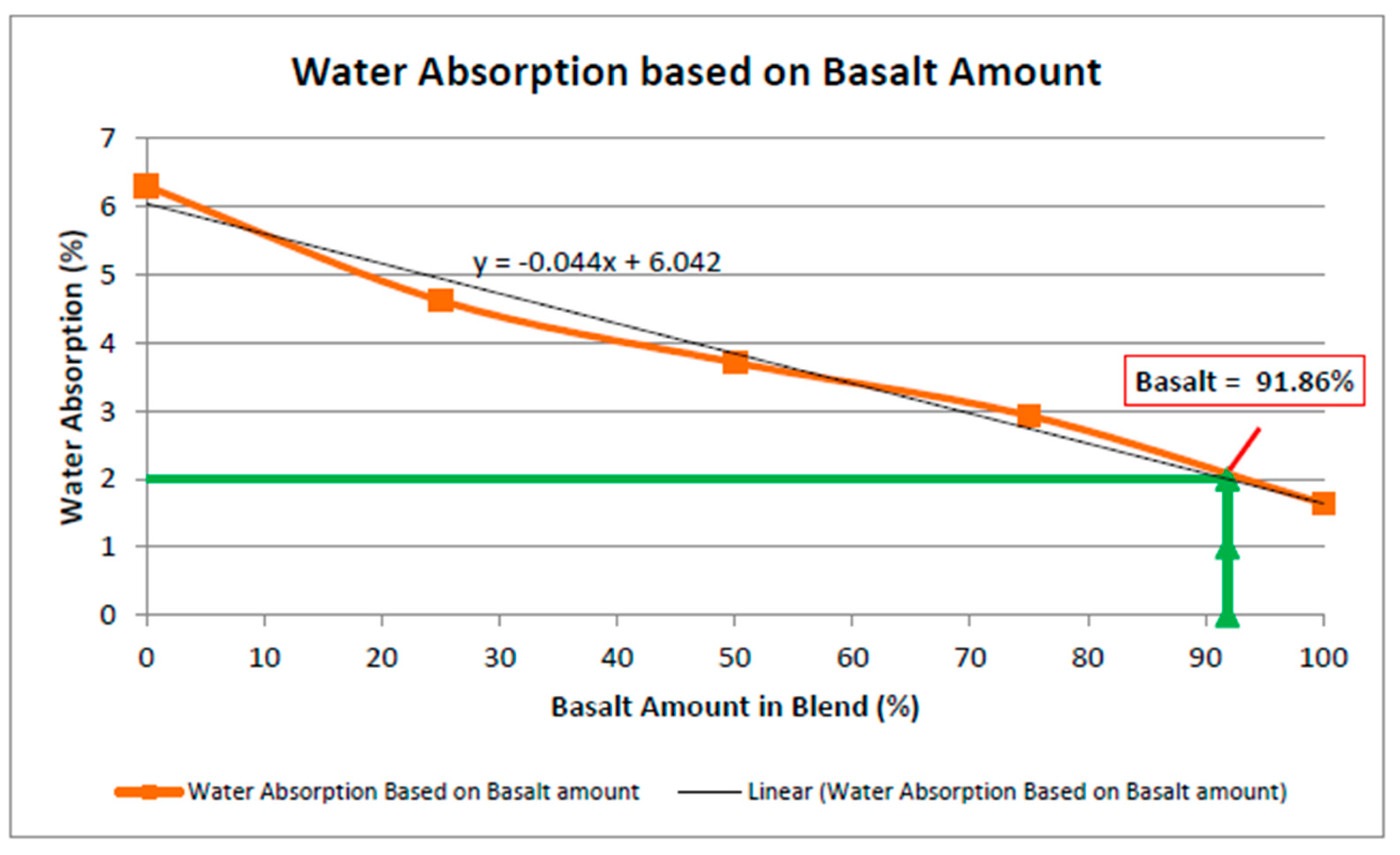

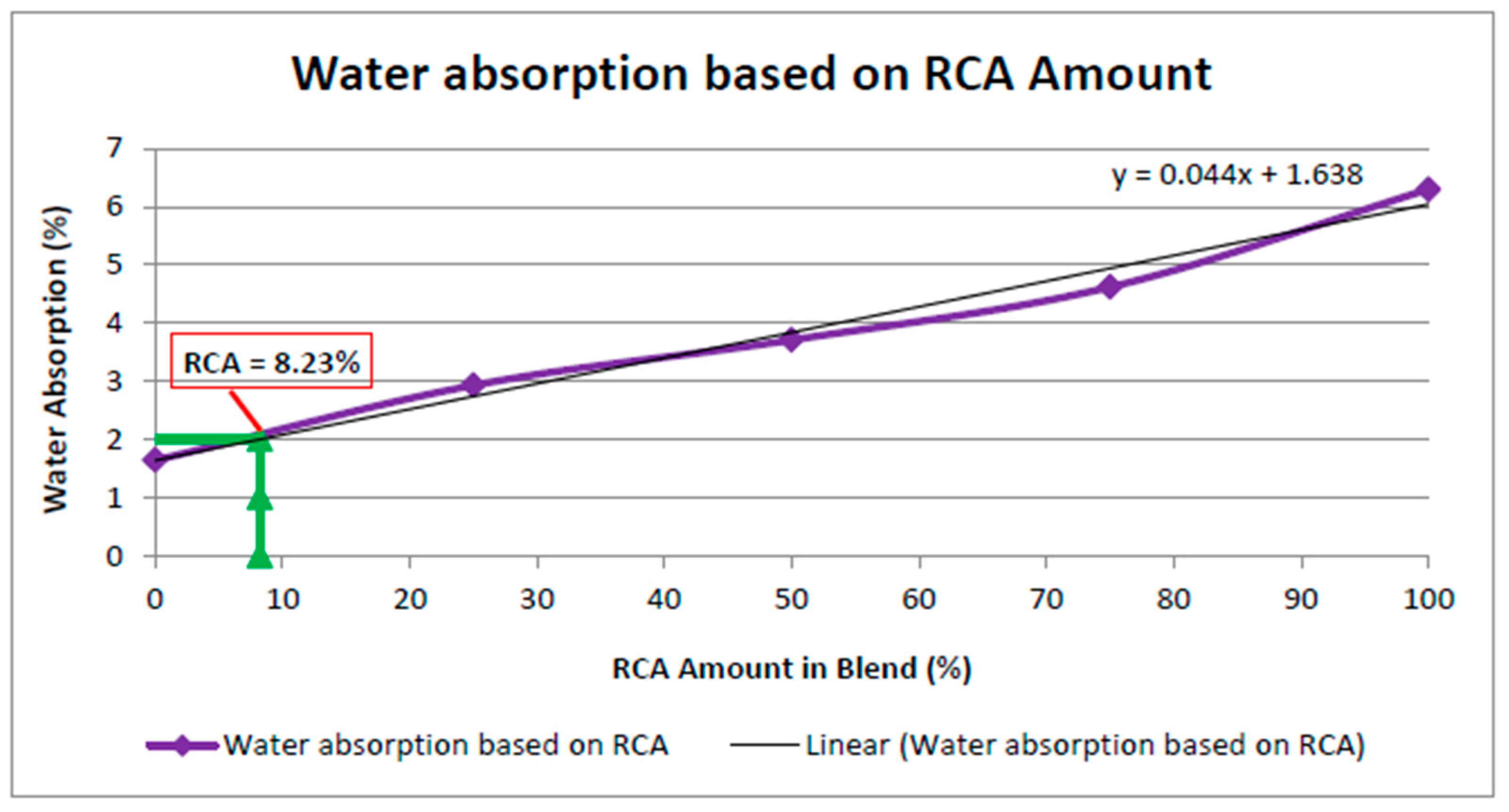

- The results of water absorption and particle density test on different mix of coarse aggregates revealed that RCA increase will increase water absorption of the mixture. Therefore, the selection of optimum combination of RCA and other aggregates is required to satisfy the relevant standards requirements.

- (4)

- (5)

- Since, according to Austroads (2014), the aggregates with water absorption of between 2% and 4% of their mass should be carefully examined by other tests [59]. This standard limit will allow further investigation of the application of up to 50% of RCA in mixtures because based on the water absorption results, it can be observed that the combination of 25% RCA and 75% basalt would provide water absorption of 2.93%, and the combination of 50% RCA and 50% basalt would provide water absorption of 3.71%, which are still in the range of aggregates that require further research for their water absorption properties.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Karlsson, R.; Isacsson, U. Material-Related Aspects of Asphalt Recycling-State-of-the-Art. J. Mater. Civ. Eng. 2006, 18, 81–92. [Google Scholar] [CrossRef]

- Huang, Y.; Bird, R.; Heidrich, O. A Review of the Use of Recycled Solid Waste Materials in Asphalt Pavements. Resour. Conserv. Recycl. 2007, 52, 58–73. [Google Scholar] [CrossRef]

- Widyatmoko, I. Mechanistic-Empirical Mixture Design for Hot Mix Asphalt Pavement Recycling. Constr. Build. Mater. 2008, 22, 77–87. [Google Scholar] [CrossRef]

- Ahmedzadeh, P.; Sengoz, B. Evaluation of steel slag coarse aggregate in hot mix asphalt concrete. J. Hazard. Mater. 2009, 165, 300–305. [Google Scholar] [CrossRef] [PubMed]

- Rafi, M.M.; Qadir, A.; Siddiqui, S.H. Experimental Testing of Hot Mix Asphalt Mixture Made of Recycled Aggregates. Waste Manag. Res. 2011, 29, 1316–1326. [Google Scholar] [CrossRef] [PubMed]

- Khan, I.; Gundaliya, P.J. Utilization of Waste Polyethylene Materials in Bituminous Concrete Mix for Improved Performance of Flexible Pavements. J. Appl. Res. 2012, 1, 85–86. [Google Scholar]

- Menaria, Y.; Sankhla, R. Use of Waste Plastic in Flexible Pavements-Green Roads. Open J. Civ. Eng. 2015, 5, 299–311. [Google Scholar] [CrossRef]

- Chandh, K.A.; Akhila, S. A Laboratory Study on Effect of Plastic on Bitumen. Int. J. Sci. Res. 2016, 5, 1406–1409. [Google Scholar]

- Tabsh, S.W.; Abdelfatah, A.S. Influence of Recycled Concrete Aggregates on Strength Properties of Concrete. Constr. Build. Mater. 2009, 23, 1163–1167. [Google Scholar] [CrossRef]

- Mills-Beale, J.; You, Z. The Mechanical Properties of Asphalt Mixtures with Recycled Concrete Aggregates. Constr. Build. Mater. 2010, 24, 230–235. [Google Scholar] [CrossRef]

- Chen, M.; Lin, J.; Wu, S. Potential of Recycled Fine Aggregates Powder as Filler in Asphalt Mixture. Constr. Build. Mater. 2011, 25, 3909–3914. [Google Scholar] [CrossRef]

- Silva, H.M.; Oliveira, J.R.; Jesus, C.M. Are totally recycled hot mix asphalt a sustainable alternative for road paving? Resour. Conserv. Recycl. 2012, 60, 38–48. [Google Scholar] [CrossRef]

- Vavrik, W.R.; Harrell, M.J.; Gillen, S.L. Achieving Perpetual Pavement through Staged Construction. In Proceedings of the International Conference of Perpetual Pavements, Ohio University, Athens, OH, USA, 30 September 2009. [Google Scholar]

- Zaniewski, J.P.; Srinivasan, G. Evaluation of Indirect Tensile Strength to Identify Asphalt Concrete Rutting Potential. In Asphalt Technology Program; West Virginia University: West Virginia, WV, USA, 2004; Volume 3, pp. 154–196. [Google Scholar]

- Husain, N.M.D.; Karim, M.R.; Mahmud, H.B.; Koting, S. Effects of Aggregate Gradation on the Physical Properties of Semiflexible Pavement. Adv. Mater. Sci. Eng. 2014, 2014, 1–8. [Google Scholar] [CrossRef]

- Al-Mosawe, H.; Thom, N.; Airey, G.; Al-Bayati, A. Effect of Aggregate Gradation on the Stiffness of Asphalt Mixtures. Int. J. Pavement Eng. Asphalt Technol. 2015. [Google Scholar] [CrossRef]

- Kandhal, P.S.; Cooley, L.A. National Cooperative Highway Research Program Report 464: The Restricted Zone in the Superpave Aggregate Gradation Specification. In National Cooperative Highway Research Program; National Research Council: Washington, DC, WA, USA, 2001. [Google Scholar]

- Arabani, M.; Azarhoosh, A.R. The Effect of Recycled Concrete Aggregate and Steel Slag on the Dynamic Properties of Asphalt Mixtures. Constr. Build. Mater. 2011, 35, 1–7. [Google Scholar] [CrossRef]

- Jony, H.; Al-Rubaie, M.; Jahad, I. The Effect of Using Glass Powder Filler on Hot Asphalt Concrete Mixtures Properties. Eng. Technol. J. 2011, 29, 44–57. [Google Scholar]

- Pereira, P.; Oliveira, J.; Picado-Santos, L. Mechanical Characterization of Hot Mix Recycled Materials. Int. J. Pavement Eng. 2004, 5, 211–220. [Google Scholar] [CrossRef]

- Fulton, B. Use of Recycled Glass in Pavement Aggregate. In Proceedings of the 23rd Australian Road Research Board International Conference, Adelaide, Australia, 30 July–1 August 2008. [Google Scholar]

- Finkle, I.; Ksaibati, K. Recycled Glass Utilization in Highway Construction. In Proceedings of the Transportation Research Board 86th Annual Meeting, University of Wyoming, Laramie, WY, USA, 21–25 January 2007. [Google Scholar]

- Wong, Y.D.; Sun, D.D.; Lai, D. Value-Added Utilisation of Recycled Concrete in Hot-Mix Asphalt. Waste Manag. 2007, 27, 294–301. [Google Scholar] [CrossRef] [PubMed]

- Paranavithana, S.; Mohajerani, A. Effects of Recycled Concrete Aggregates on Properties of Asphalt Concrete. Resour. Conserv. Recycl. 2006, 48, 1–12. [Google Scholar] [CrossRef]

- Motter, J.S.; Miranda, L.F.R.; Bernucci, L.L.B. Performance of Hot Mix Asphalt Concrete Produced with Coarse Recycled Concrete Aggregate. J. Civ. Eng. 2014, 27. [Google Scholar] [CrossRef]

- Pérez, I.; Pasandin, A.R.; Medina, L. Hot Mix Asphalt Using C&D Waste as Coarse Aggregates. Mater. Des. 2012, 36, 840–846. [Google Scholar]

- Silva, C.A.R.S. Study of Recycled Aggregate from Civil Construction in Bituminous Mixtures for Urban Roads. Master’s Dissertation, Federal University of Ouro Preto, Minas Gerais, Brazil, November 2009. [Google Scholar]

- Zhu, J.; Wu, S.; Zhong, J.; Wang, D. Investigation of Asphalt Mixture Containing Demolition Waste Obtained from Earthquake-Damage Buildings. Constr. Build. Mater. 2012, 29, 466–475. [Google Scholar] [CrossRef]

- Zulkati, A.; Wong, Y.D.; Sun, D.D. Mechanistic Performance Of Asphalt-Concrete Mixture Incorporating Coarse Recycled Concrete Aggregate. J. Mater. Civ. Eng. 2013, 10, 1299–1305. [Google Scholar] [CrossRef]

- Arulrajah, A.J.; Piratheepan, M.W.B.; Sivakugan, N. Geotechnical Characteristics of Recycled Crushed Brick Blends for Pavement Subbase Applications. Can. Geotech. J. 2012, 49, 796–811. [Google Scholar] [CrossRef]

- Bennert, T.; Papp, W.J.; Maher, A.; Gucunski, N. Utilization of Construction and Demolition Debris under Traffic-Type Loading in Base and Subbase Applications. Transp. Res. Rec. 2000. [Google Scholar] [CrossRef]

- Blankenagel, B.J. Characterization of Recycled Concrete for Use as Pavement Base Material. Master’s Thesis, Brigham Young University, Provo, UT, USA, 20 August 2005. [Google Scholar]

- Conceicao, F.D.; Motta, R.D.S.; Vasconcelos, K.L.; Bernucci, L. Laboratory Evaluation of Recycled Construction and Demolition Waste for Pavements. Constr. Build. Mater. 2011, 25, 2972–2979. [Google Scholar]

- Jayakody, S.; Gallage, C.; Kumar, A. Assessment of Recycled Concrete Aggregates as a Pavement Material. Geomech. Eng. 2014, 6, 235–248. [Google Scholar]

- Jiménez, J.R.; Ayuso, J.; Agrela, F.; López, M.; Galvín, A.P. Utilization of Unbound Recycled Aggregates from Selected CDW in Unpaved Rural Roads. J. Resour. Conser. Recycl. 2012, 58, 88–97. [Google Scholar] [CrossRef]

- Papp, W.J.; Maher, M.H.; Bennet, T.A.; Gucunski, N. Behavior of construction and demolition debris in base and subbase applications. In Recycled Materials in Geotechnical Applications; Vipulanandan, C., Elton, D.J., Eds.; American Society of Civil Engineers: Reston, VA, USA, 1998; pp. 122–136. ISBN 0784403872. [Google Scholar]

- Nataatmadja, A.; Tan, Y.L. Resilient Response of Recycled Concrete Road Aggregates. J. Transp. Eng. 2001. [Google Scholar] [CrossRef]

- Celauro, C.; Benardo, C.; Gabriele, B. Production of Innovative, Recycled and High-Performance Asphalt for Road Pavements. Resour. Conser. Recycl. J. 2010, 54, 337–347. [Google Scholar] [CrossRef]

- Hossain, M.; Metcalf, D.G.; Scofield, L.A. Performance of Recycled Asphalt Concrete Overlays in Southwestern Arizona. Transp. Res. Rec. 1993, 1427, 30–37. [Google Scholar]

- Rebbechi, J.; Green, M. Going Green: Innovations in Recycling Asphalt. In Proceedings of the AAPA, Queensland, QLD, Australia, 13–16 September 2015. [Google Scholar]

- Berthelot, C.; Haichert, R.; Podborochynski, D.; Wandzura, C.; Taylor, B.; Gunther, D. Mechanistic Laboratory Evaluation and Field Construction of Recycled Concrete Materials for Use in Road Substructures. Transp. Res. Board 2010. [Google Scholar] [CrossRef]

- Wu, S.; Zhu, J.; Zhong, J.; Wang, D. Influence of Demolition Waste Used as Recycled Aggregate on Performance of Asphalt Mixture. Road Mater. Pavement Des. 2013, 14, 679–688. [Google Scholar] [CrossRef]

- Dahir, S.A. Review of Aggregate Selection Criteria for Improved Wear Resistance and Skid Resistance of Bituminous Surfaces. J. Test. Eval. 1979, 7, 245–253. [Google Scholar]

- Brown, E.R.; McRae, J.L.; Crawley, A.B. Effect of Aggregate on Performance of Bituminous Concrete. In ASTM STP 1016; American Society for Testing and Materials: West Conshohocken, PA, USA, 1989; pp. 34–63. [Google Scholar]

- Brown, E.R.; Bassett, C.E. Effects of Maximum Aggregate Size on Rutting Potential and Other Properties of Asphalt-Aggregate Mixtures. In Transportation Research Record; Transportation Research Board: Washington, DC, USA, 1990; pp. 107–119. [Google Scholar]

- Button, J.W.; Perdomo, D.; Lytton, R.L. Influence of Aggregate on Rutting in Asphalt Concrete Pavements. In Transportation Research Record; Transportation Research Board: Washington, DC, USA, 1990; pp. 141–152. [Google Scholar]

- Elliot, R.P.; Ford, M.C.; Ghanim, M.; Tu, Y.F. Effect of Aggregate Gradation Variation on Asphalt Concrete Mix Properties. In Transportation Research Record; Transportation Research Board: Washington, DC, USA, 1991; pp. 52–60. [Google Scholar]

- Krutz, N.C.; Sebaaly, P.E. The Effects of Aggregate Gradation on Permanent Deformation of Asphalt Concrete. In Proceedings of the Asphalt Paving Technology, Austin, TX, USA, 22–24 March 1993. [Google Scholar]

- Oduroh, P.K.; Mahboub, K.C.; Anderson, R.M. Flat and Elongated Aggregates in Superpave Regime. J. Mater. Civ. Eng. 2000, 12, 124–130. [Google Scholar] [CrossRef]

- Chen, J.S.; Liao, M.S. Evaluation of Internal Resistance in Hot-Mix Asphalt (HMA) Concrete. Constr. Build. Mater. J. 2002, 16, 313–319. [Google Scholar] [CrossRef]

- Sengoz, B.; Onsori, A.; Topal, A. Effect of Aggregate Shape on the Surface Properties of Flexible Pavement, KSCE. J. Civ. Eng. 2014, 18. [Google Scholar] [CrossRef]

- Masad, E.; Rezaei, A.; Chowdhury, A.; Harris, P. Predicting Asphalt Mixture Resistance Based on Aggregate Characteristics. In Aggregate Resistance to Polishing and Its Relationship to Skid Resistance Project; National Technical Information Service: Springfield, VA, USA, 2009. [Google Scholar]

- Wu, Z.; King, W. Development of Surface Friction Guidelines for LADOTD. In LTRC Project No. 09-2B; Louisiana State University: Baton Rouge, LA, USA, April 2011. [Google Scholar]

- Marinho, M.N. Analysis of Mechanical Performance of Hot Mixed Asphaltic Concrete Produced with Recycled Coarse Concrete Aggregate. Master’s Dissertation, Federal University of Pernambuco, Recife, Brazil, July 2011. [Google Scholar]

- Mohajerani, A. A Study of Relationships between Polished Aggregate Friction Value, Aggregate Crushing Value, and Point Load Strength Index. Aust. Geomech. 1997, 1997, 62–65. [Google Scholar]

- Prowell, B.D.; Zhang, J.; Brown, E.R. Aggregate Properties and the Performance of Superpave Designed Hot Mix Asphalt. In National Cooperative Highway Research Program Report 539; National Research Council: Washington, DC, USA, 2005. [Google Scholar] [CrossRef]

- Dickinson, E.J. Bituminous Roads in Australia; Australian Road Research Board: Melbourne, MEL, Australia, 1984. [Google Scholar]

- Masad, E.; Al-Rousan, T.; Button, J.; Little, D. Test Methods for Characterizing Aggregate Shape, Texture, and Angularity. In National Cooperative Highway Research Program Report 555; National Research Council: Washington, DC, USA, 2007. [Google Scholar]

- Guide to Pavement Technology Part 4B: Asphalt, Austroads. 2014. Available online: https://www.onlinepublications.austroads.com.au/items/AGPT04B-1 (accessed on 31 June 2014).

| Property | Test Method | Test Name |

|---|---|---|

| Gradation and particle size distribution | AS 1141.11.1 | Particle Size Distribution (Sieving Method) |

| Flakiness index of aggregate | AS 1141.15 | Flakiness Index |

| Proportion of misshapen particles | AS 1141.14 | Particle Shape by proportional calliper |

| Water absorption of aggregate | AS1141.6.1 | Particle Density and Water Absorption of coarse aggregate |

| Variation in strength of aggregate in wet/dry condition | AS 1141.22 | Wet/Dry Strength Variation |

| Particle density of aggregate | AS 1141.6.1 | Particle Density and Water Absorption of coarse aggregate |

| Strength and crushing value of aggregate | AS 1141.21 | Aggregate Crushing Value |

| Percentage of weak particles in coarse aggregate | AS 1141.32 | Weak particles (including clay lumps, soft and friable particles) in coarse aggregates |

| Sample Number | Misshapen Particles (%) | Australian Standards Misshapen Percentage Limits (%) | ||

|---|---|---|---|---|

| RCA | RAP | Basalt | ||

| Sample 1 | 5.3 | 12.0 | 19.4 | 35% (max) For heavy and very heavy traffic |

| Sample 2 | 6.2 | 7.7 | 18.3 | |

| Sample 3 | 7.0 | 8.7 | 17.3 | |

| Average Misshapen Particles Percentage (%) | 6.2 | 9.5 | 18.3 | |

| Sample Number | Flakiness Index (%) | Australian Standards Flakiness Index Limits (%) | ||

|---|---|---|---|---|

| RCA | RAP | Basalt | ||

| Sample 1 | 5.6 | 12.8 | 21.3 | 25% (max) For heavy and very heavy traffic |

| Sample 2 | 8.1 | 10.1 | 21.1 | |

| Sample 3 | 7.1 | 8.4 | 14.7 | |

| Average Flakiness Index (%) | 6.9 | 10.4 | 19.0 | |

| Sample Name | Apparent Particle Density (g/cm3) | Particle Density on a Dry Basis (g/cm3) | Particle Density on a SSD Basis (g/cm3) | Water Absorption (%) | Australian Standards Limits for Water Absorption (%) |

|---|---|---|---|---|---|

| RCA 1 | 2.375 | 2.211 | 2.352 | 6.39 | 2% (max) For heavy and very heavy traffic |

| RCA 2 | 2.375 | 2.211 | 2.352 | 6.39 | |

| RCA 3 | 2.361 | 2.214 | 2.349 | 6.12 | |

| Average Values for RCA | 2.370 | 2.212 | 2.351 | 6.30 | |

| RAP 1 | 2.539 | 2.422 | 2.468 | 1.89 | |

| RAP 2 | 2.544 | 2.437 | 2.479 | 1.72 | |

| RAP 3 | 2.540 | 2.433 | 2.475 | 1.73 | |

| Average Values for RAP | 2.541 | 2.431 | 2.474 | 1.78 | |

| Basalt 1 | 2.635 | 2.528 | 2.568 | 1.60 | |

| Basalt 2 | 2.630 | 2.521 | 2.562 | 1.64 | |

| Basalt 3 | 2.654 | 2.542 | 2.584 | 1.67 | |

| Average Values for Basalt | 2.640 | 2.530 | 2.571 | 1.64 |

| Sample Name | Apparent Particle Density (g/cm3) | Particle Density on a Dry Basis (g/cm3) | Particle Density on a SSD Basis (g/cm3) | Water Absorption (%) | |

|---|---|---|---|---|---|

| 75% Basalt and 25% RCA | 1 | 2.579 | 2.394 | 2.466 | 2.98 |

| 2 | 2.589 | 2.406 | 2.476 | 2.94 | |

| 3 | 2.601 | 2.420 | 2.489 | 2.88 | |

| Average Values for 75% Basalt and 25% RCA | 2.590 | 2.407 | 2.477 | 2.93 | |

| 50% Basalt and 50% RCA | 1 | 2.520 | 2.296 | 2.385 | 3.86 |

| 2 | 2.535 | 2.322 | 2.406 | 3.62 | |

| 3 | 2.527 | 2.313 | 2.397 | 3.65 | |

| Average Values for 50% Basalt and 50% RCA | 2.527 | 2.310 | 2.396 | 3.71 | |

| 25% Basalt and 75% RCA | 1 | 2.477 | 2.224 | 2.326 | 4.57 |

| 2 | 2.471 | 2.207 | 2.313 | 4.84 | |

| 3 | 2.480 | 2.234 | 2.333 | 4.44 | |

| Average Values for 25% Basalt and 75% RCA | 2.476 | 2.222 | 2.324 | 4.62 | |

| 80% Basalt and 20% RAP | 1 | 2.727 | 2.607 | 2.651 | 1.68 |

| 2 | 2.719 | 2.600 | 2.644 | 1.68 | |

| 3 | 2.724 | 2.596 | 2.643 | 1.80 | |

| Average Values for 80% Basalt and 20% RAP | 2.723 | 2.601 | 2.646 | 1.72 | |

| 25% Basalt and 25% RCA and 50% RAP | 1 | 2.579 | 2.411 | 2.476 | 2.70 |

| 2 | 2.581 | 2.401 | 2.471 | 2.89 | |

| 3 | 2.585 | 2.412 | 2.479 | 2.78 | |

| Average Values for 25% Basalt and 25% RCA and50% RAP | 2.582 | 2.408 | 2.475 | 2.79 | |

| 25% Basalt and 50% RCA and 25% RAP | 1 | 2.606 | 2.380 | 2.466 | 3.63 |

| 2 | 2.592 | 2.356 | 2.447 | 3.85 | |

| 3 | 2.596 | 2.355 | 2.447 | 3.94 | |

| Average Values for 25% Basalt and 50% RCA and 25% RAP | 2.598 | 2.364 | 2.453 | 3.81 | |

| Sample Number | Crushing Value (%) | Australian Standards Aggregate Crushing Value Limits (%) | ||

|---|---|---|---|---|

| RCA | RAP | Basalt | ||

| Sample 1 | 29.53 | 7.04 | 9.32 | 35% (max) For heavy and very heavy traffic |

| Sample 2 | 28.88 | 7.76 | 8.51 | |

| Average Crushing Value (%) | 29.21 | 7.40 | 8.91 | |

| Sample Number | Weak Particles (%) | Australian Standards Aggregate Crushing Value Limits (%) | ||

|---|---|---|---|---|

| RCA | RAP | Basalt | ||

| Sample 1 | 0.21 | 0.05 | 0.29 | 1% (max) For heavy and very heavy traffic |

| Sample 2 | 0.25 | 0.03 | 0.16 | |

| Average Weak Particles Percentage (%) | 0.23 | 0.04 | 0.23 | |

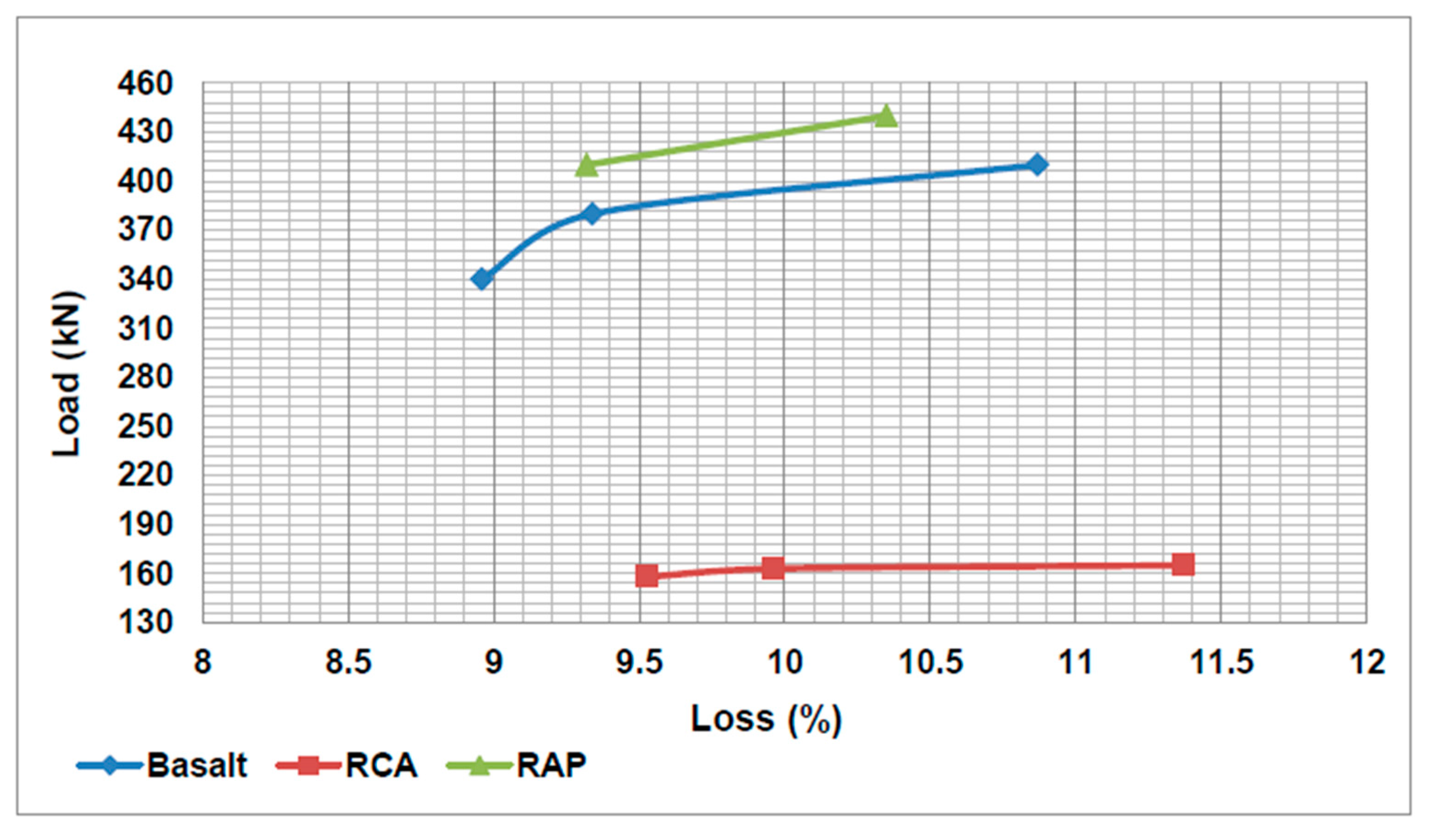

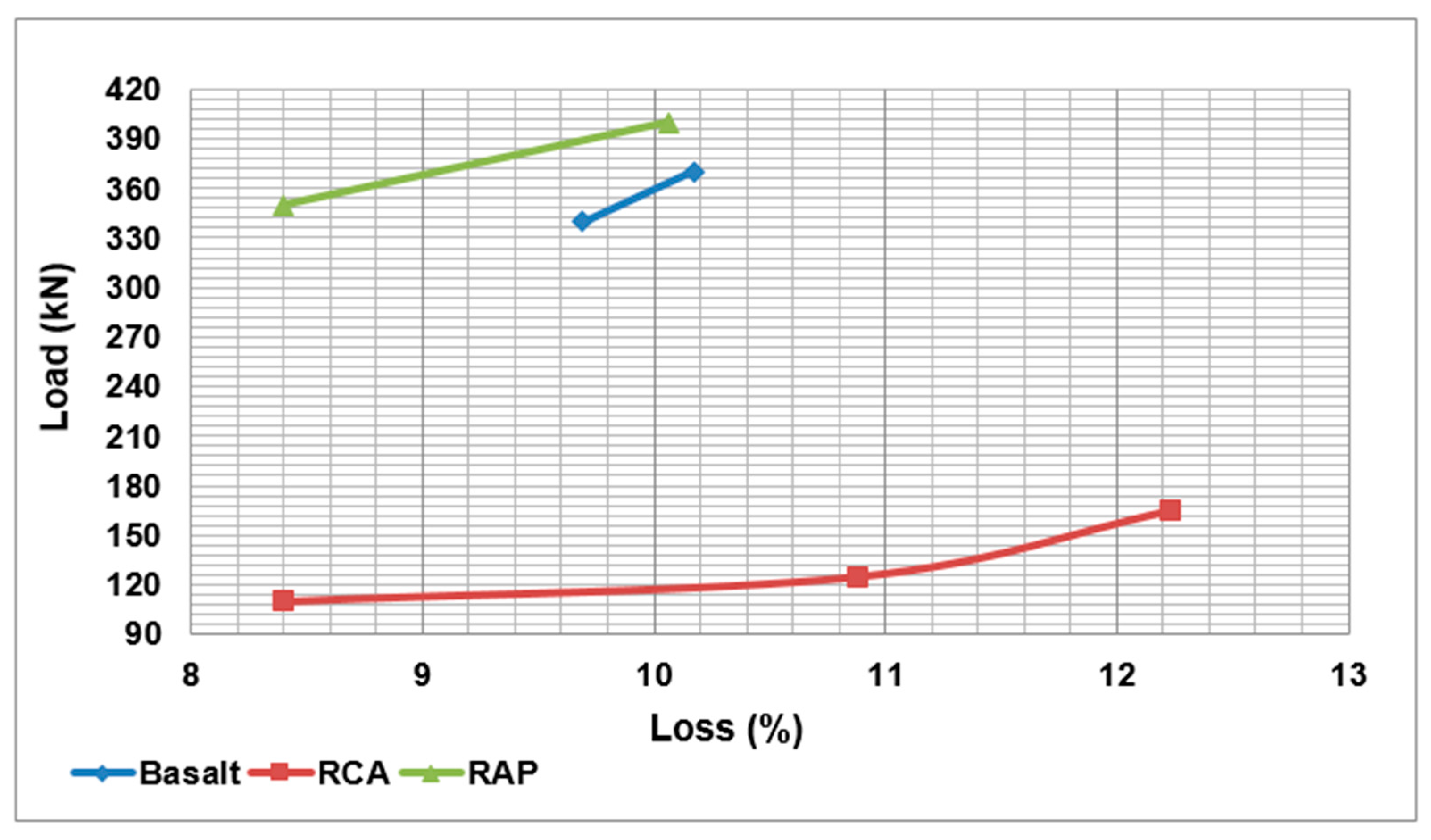

| Material | Dry Strength, D (kN) | Wet Strength, W (kN) | Wet/Dry Strength Variation (%) | Australian Standards Wet/Dry Strength Limits (%) |

|---|---|---|---|---|

| RCA | 163.1 | 119.7 | 26.6 | 35% (max) For heavy and very heavy traffic |

| RAP | 429.8 | 398.2 | 7.4 | |

| Basalt | 392.9 | 359.4 | 8.5 |

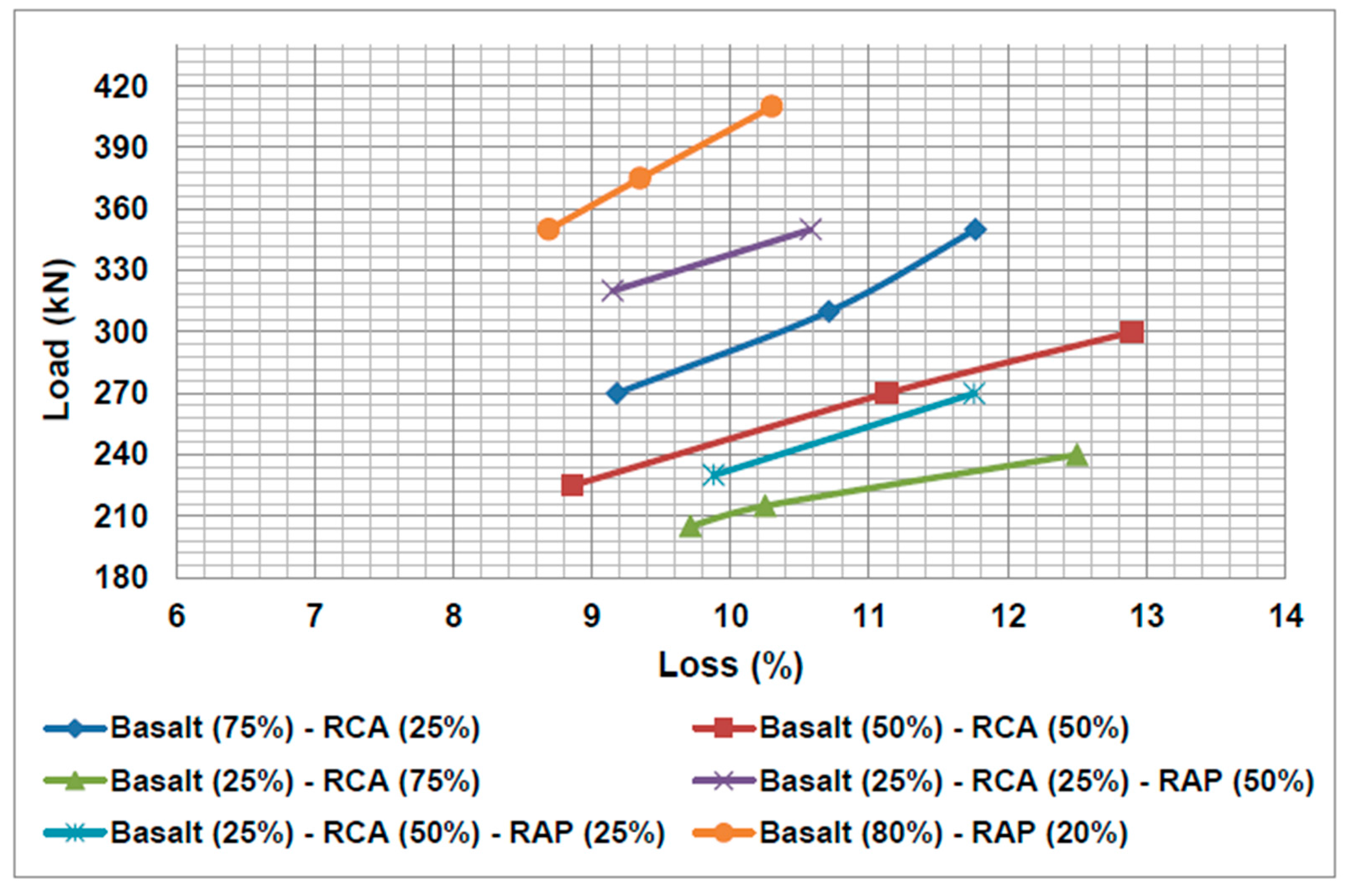

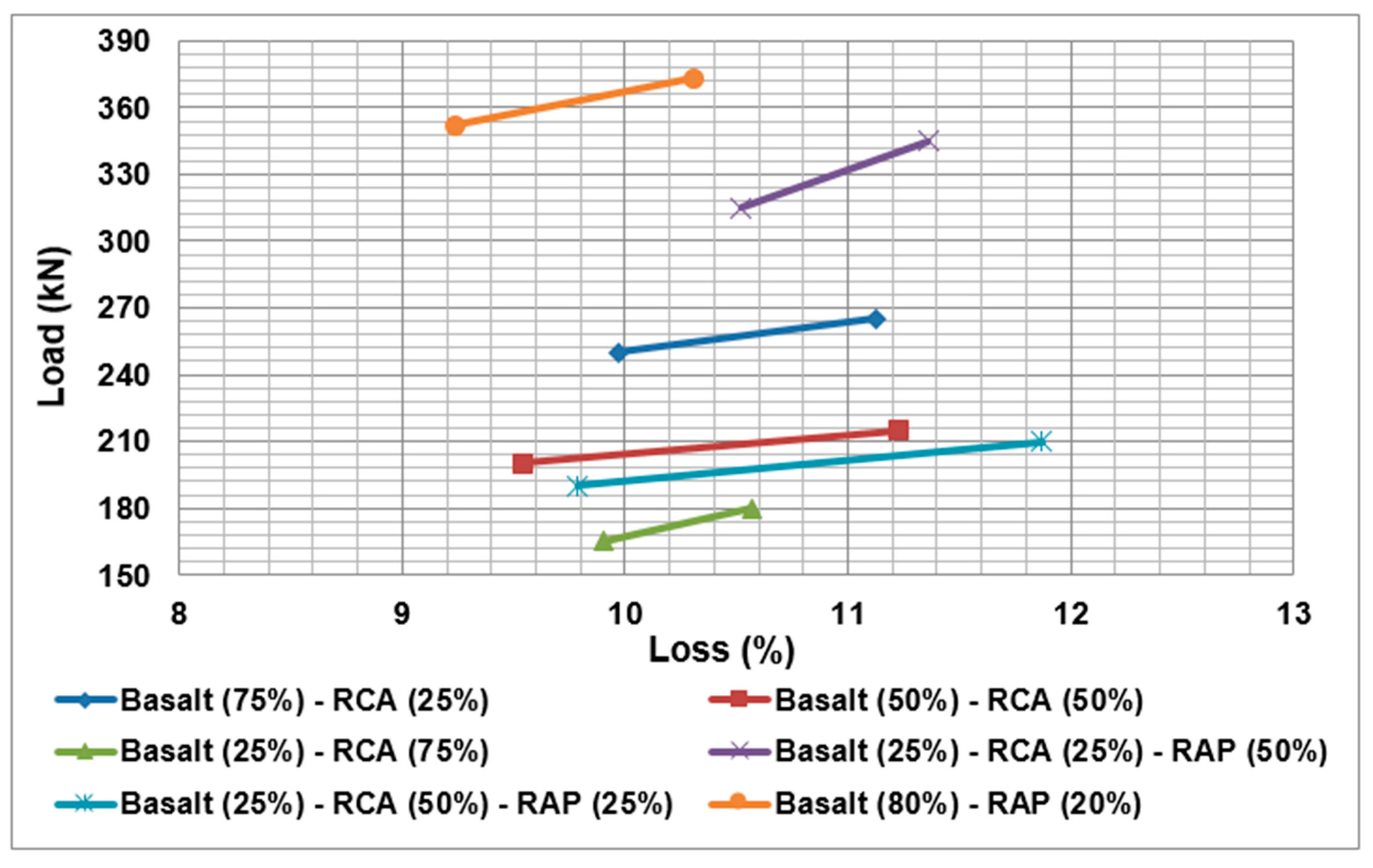

| Material | Dry Strength, D (kN) | Wet Strength, W (kN) | Wet/Dry Strength Variation (%) | Australian Standards Wet/Dry Strength Limits (%) |

|---|---|---|---|---|

| Basalt (75%) and RCA (25%) | 291.4 | 250.4 | 14.1 | 35% (max) For heavy and very heavy traffic |

| Basalt (50%) and RCA (50%) | 247.6 | 204.1 | 17.6 | |

| Basalt (25%) and RCA (75%) | 210.4 | 167.2 | 20.5 | |

| Basalt (80%) and RAP (20%) | 398.9 | 366.9 | 8.0 | |

| Basalt (25%), RCA (25%) and RAP (50%) | 337.8 | 296.4 | 12.3 | |

| Basalt (25%), RCA (50%) and RAP (25%) | 232.6 | 192 | 17.5 |

| Test | Test Method | Aggregate | Typical Limit Based on Australian Standards | ||

|---|---|---|---|---|---|

| RCA | RAP | Basalt | |||

| Particle Distribution Test | AS 1141.11.1 | As presented in relevant Figures and Tables | - | ||

| Flakiness Index Test | AS 1141.15 | 6.91 | 10.42 | 19.03 | 25% (max) |

| Particle Shape Test | AS 1141.14 | 6.16 | 9.47 | 18.34 | 35% (max) |

| Water Absorption | AS 1141.6.1 | 6.30 | 1.78 | 1.64 | 2% (max) |

| Particle Density | AS 1141.6.1 | 2.370 | 2.541 | 2.640 | - |

| Particle Density on Dry Basis | AS 1141.6.1 | 2.212 | 2.431 | 2.530 | - |

| Particle Density on SSD Basis | AS 1141.6.1 | 2.351 | 2.474 | 2.571 | - |

| Aggregate Crushing Value | AS 1141.21 | 29.21 | 7.40 | 8.91 | 35% (max) |

| Weak Particles | AS 1141.32 | 0.23 | 0.04 | 0.23 | 1% (max) |

| Wet/Dry Strength Test | AS 1141.22 | 26.6 | 7.4 | 8.5 | 35% (max) |

| Wet Strength | AS 1141.22 | 119.7 | 398.2 | 359.2 | 150 kN (min) |

| Dry Strength | AS 1141.22 | 163.1 | 429.8 | 392.9 | - |

| Mix | Test Method | Water Absorption | Particle Density | Wet/Dry Strength Variation |

|---|---|---|---|---|

| Basalt (75%), RCA (25%) | AS 1141.15 | 2.93 | 2.590 | 14.1 |

| Basalt (50%), RCA (50%) | AS 1141.14 | 3.71 | 2.527 | 17.6 |

| Basalt (25%), RCA (75%) | AS 1141.6.1 | 4.62 | 2.476 | 20.5 |

| Basalt (80%), RAP (20%) | AS 1141.6.1 | 1.72 | 2.723 | 8.0 |

| Basalt (25%), RCA (25%), RAP (50%) | AS 1141.21 | 2.79 | 2.582 | 12.3 |

| Basalt (25%), RCA (50%), RAP (25%) | AS 1141.32 | 3.81 | 2.598 | 17.5 |

| Mix | Coefficient of Variation | Standard Deviation |

|---|---|---|

| Basalt (100%) + RCA (0%) | 2.14 | 0.035 |

| Basalt (75%) + RCA (25%) | 1.71 | 0.050 |

| Basalt (50%) + RCA (50%) | 3.52 | 0.131 |

| Basalt (25%) + RCA (75%) | 4.42 | 0.204 |

| Basalt (0%) + RCA (100%) | 2.47 | 0.156 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tahmoorian, F.; Samali, B.; Tam, V.W.Y.; Yeaman, J. Evaluation of Mechanical Properties of Recycled Material for Utilization in Asphalt Mixtures. Appl. Sci. 2017, 7, 763. https://doi.org/10.3390/app7080763

Tahmoorian F, Samali B, Tam VWY, Yeaman J. Evaluation of Mechanical Properties of Recycled Material for Utilization in Asphalt Mixtures. Applied Sciences. 2017; 7(8):763. https://doi.org/10.3390/app7080763

Chicago/Turabian StyleTahmoorian, Farzaneh, Bijan Samali, Vivian W.Y. Tam, and John Yeaman. 2017. "Evaluation of Mechanical Properties of Recycled Material for Utilization in Asphalt Mixtures" Applied Sciences 7, no. 8: 763. https://doi.org/10.3390/app7080763