Impact of Cryogenic Condition and Drill Diameter on Drilling Performance of CFRP

Abstract

:1. Introduction

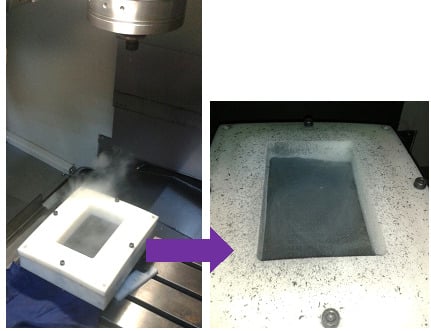

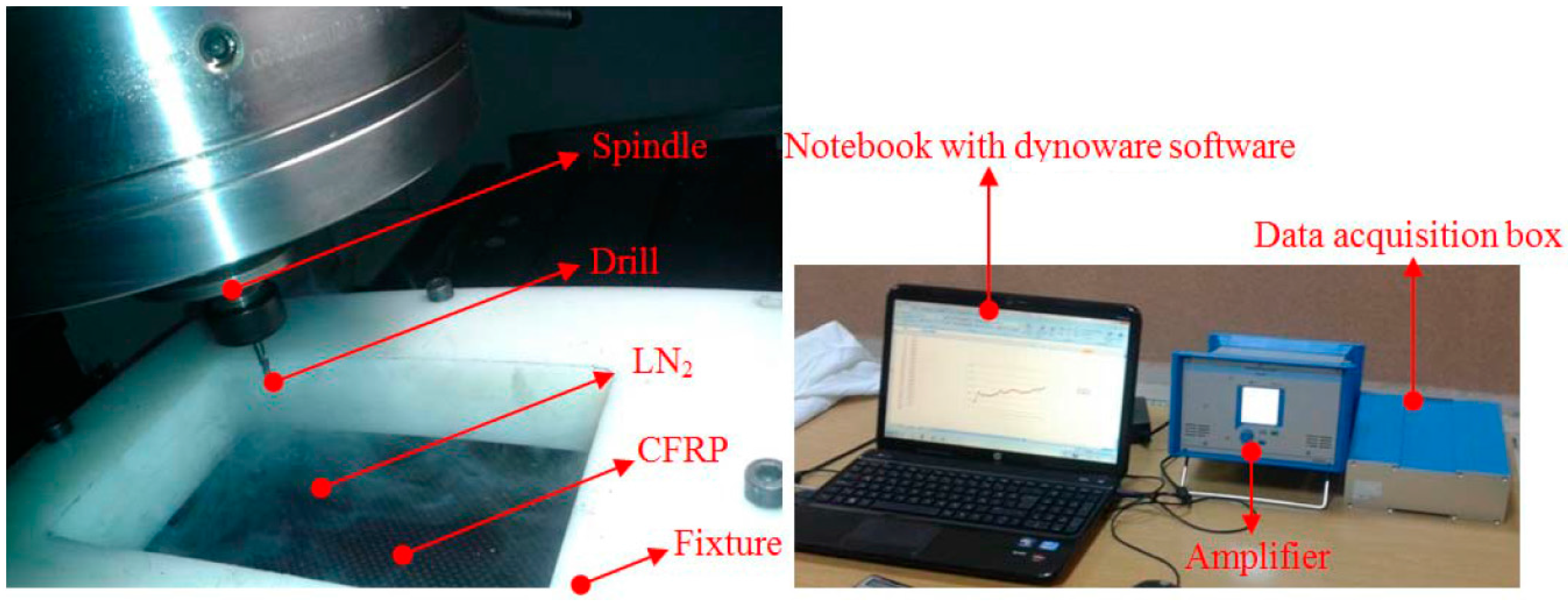

2. Materials and Methods

3. Results and Discussion

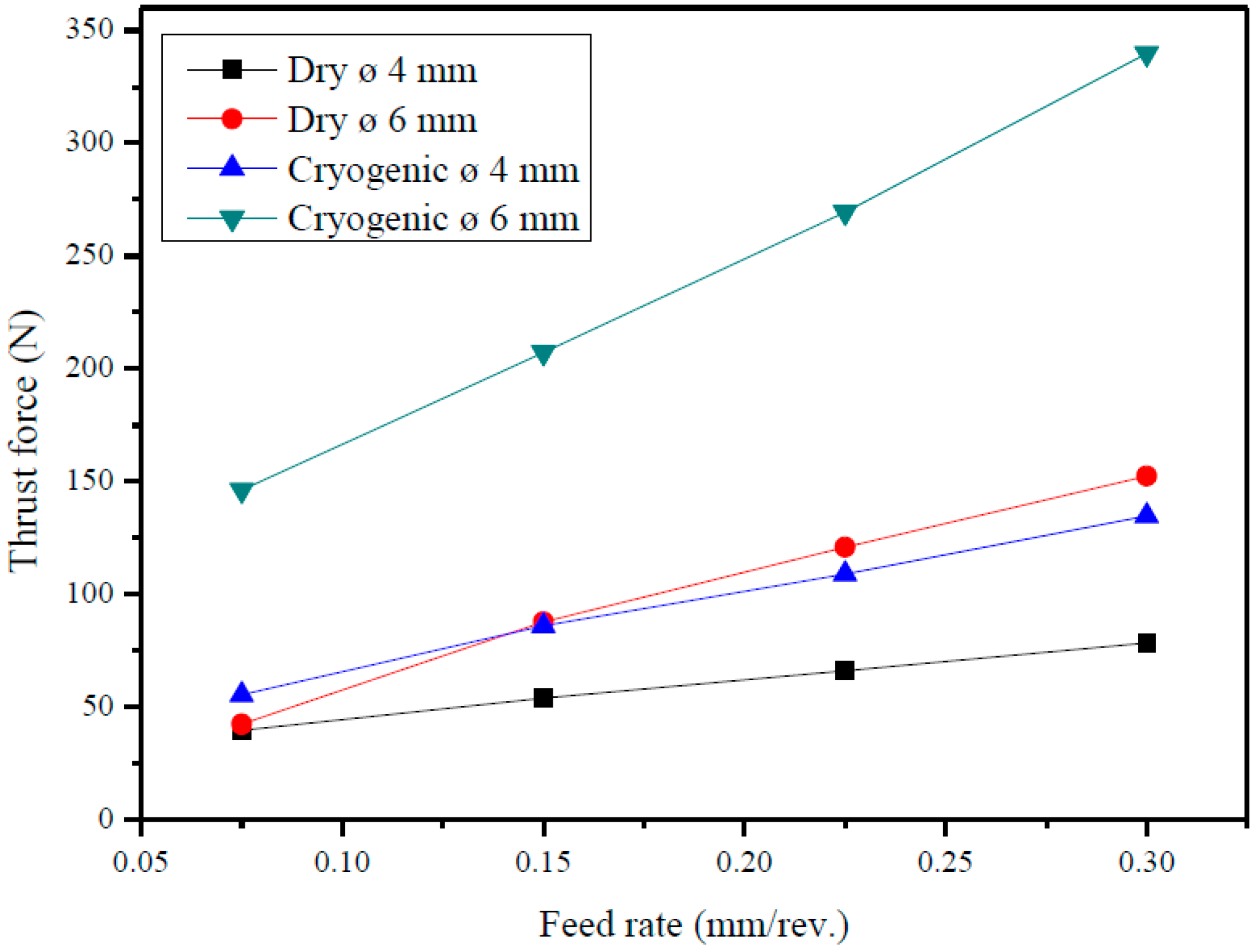

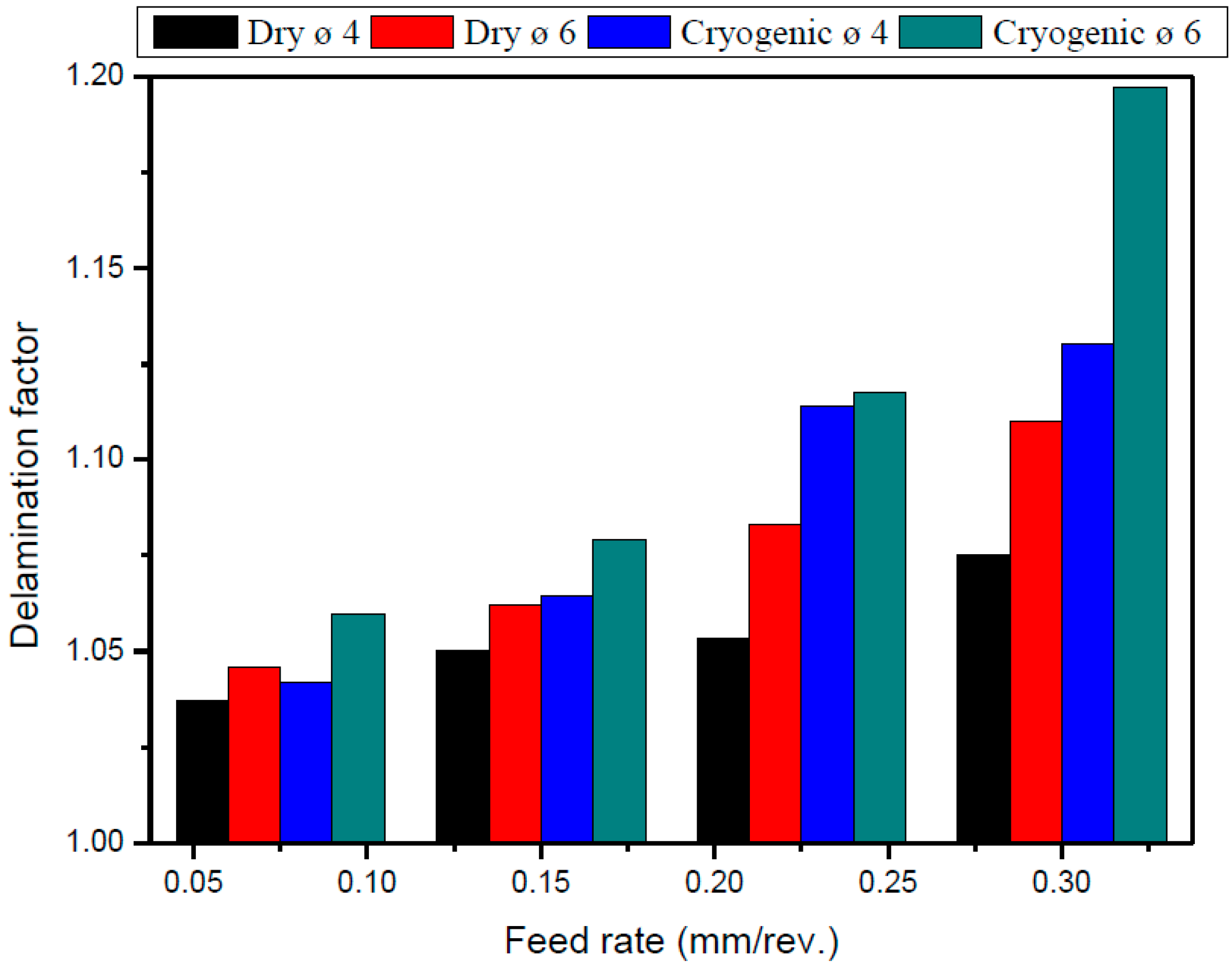

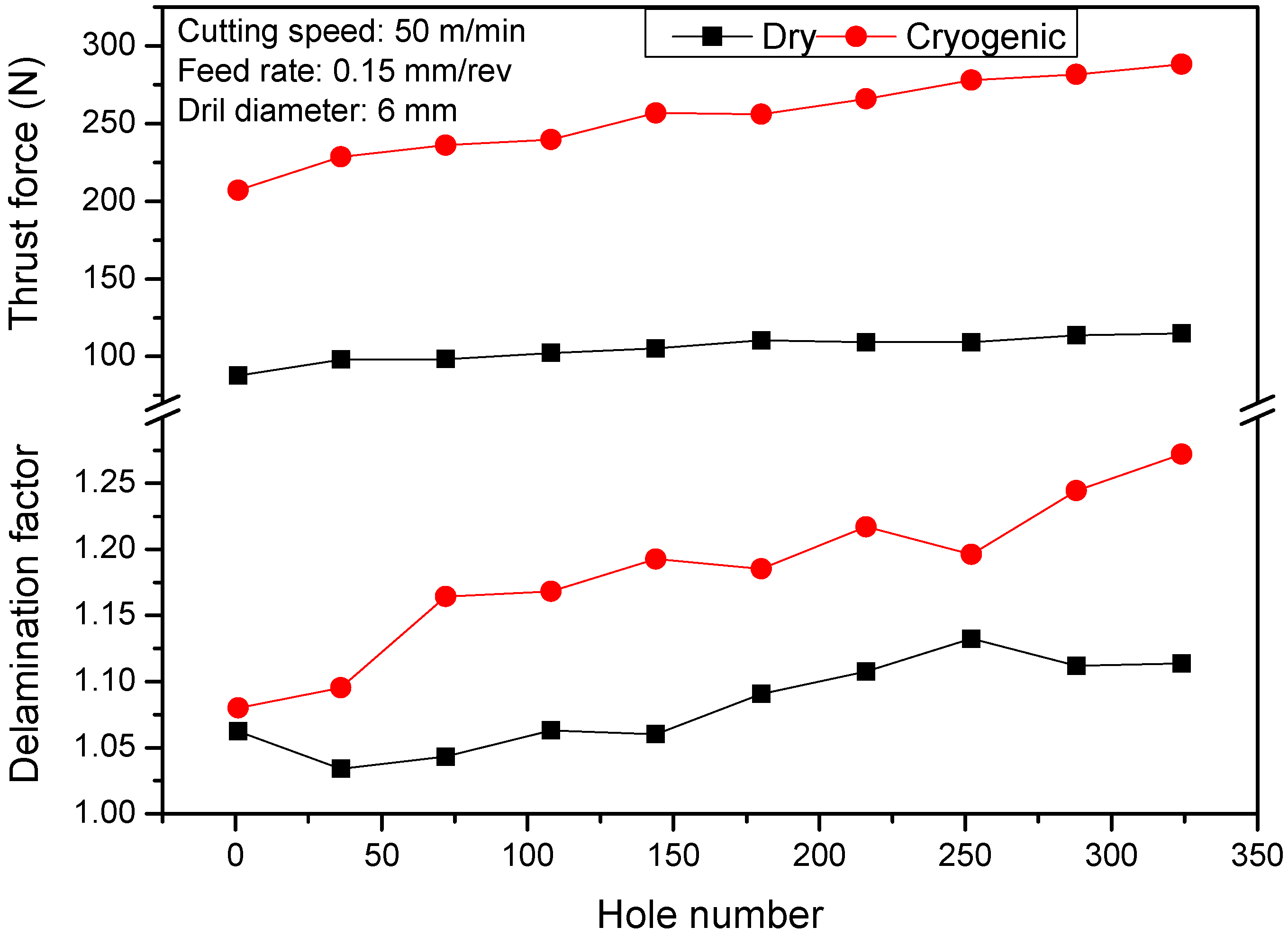

3.1. Evaluation of Thrust Force and Delamination Factor

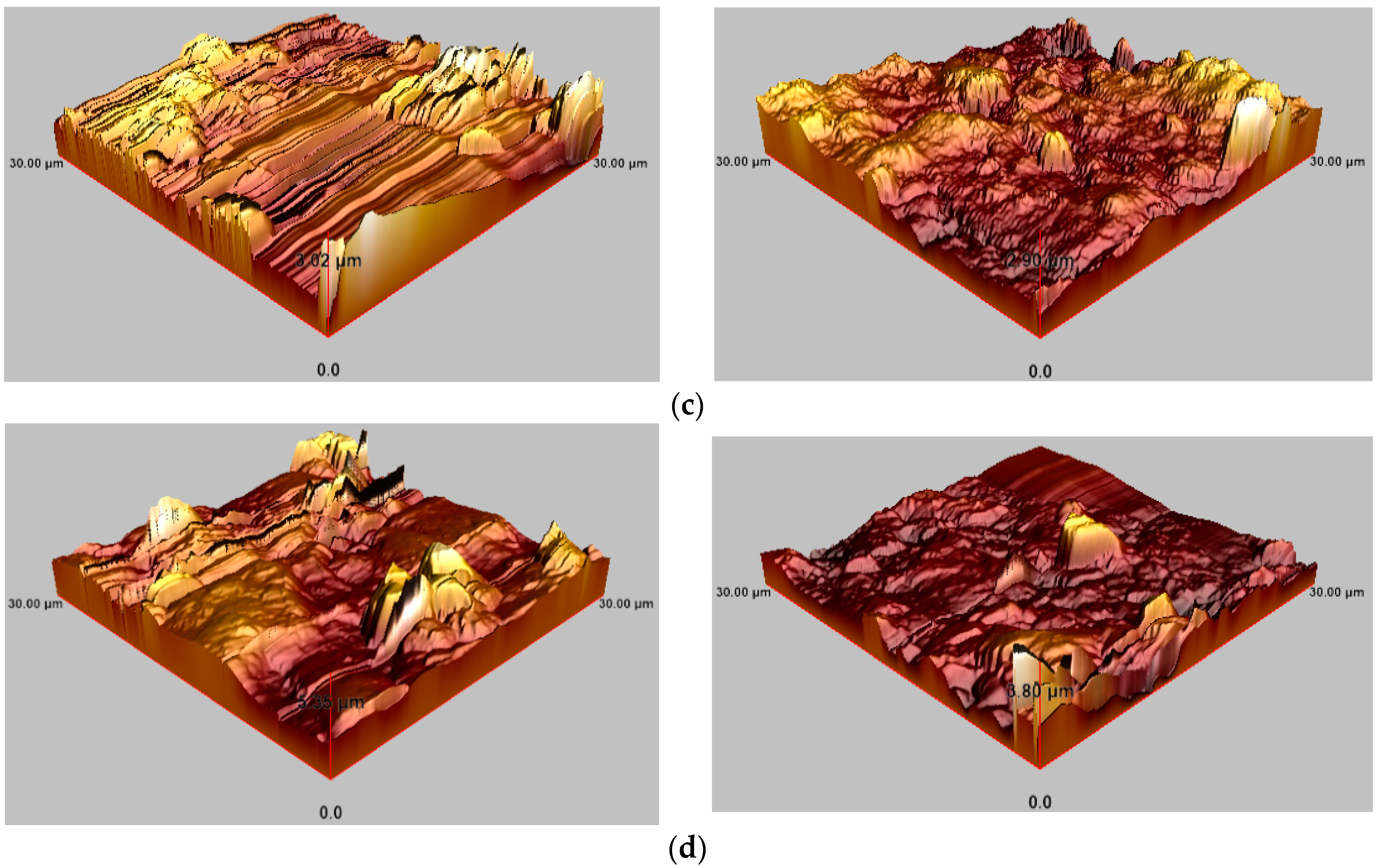

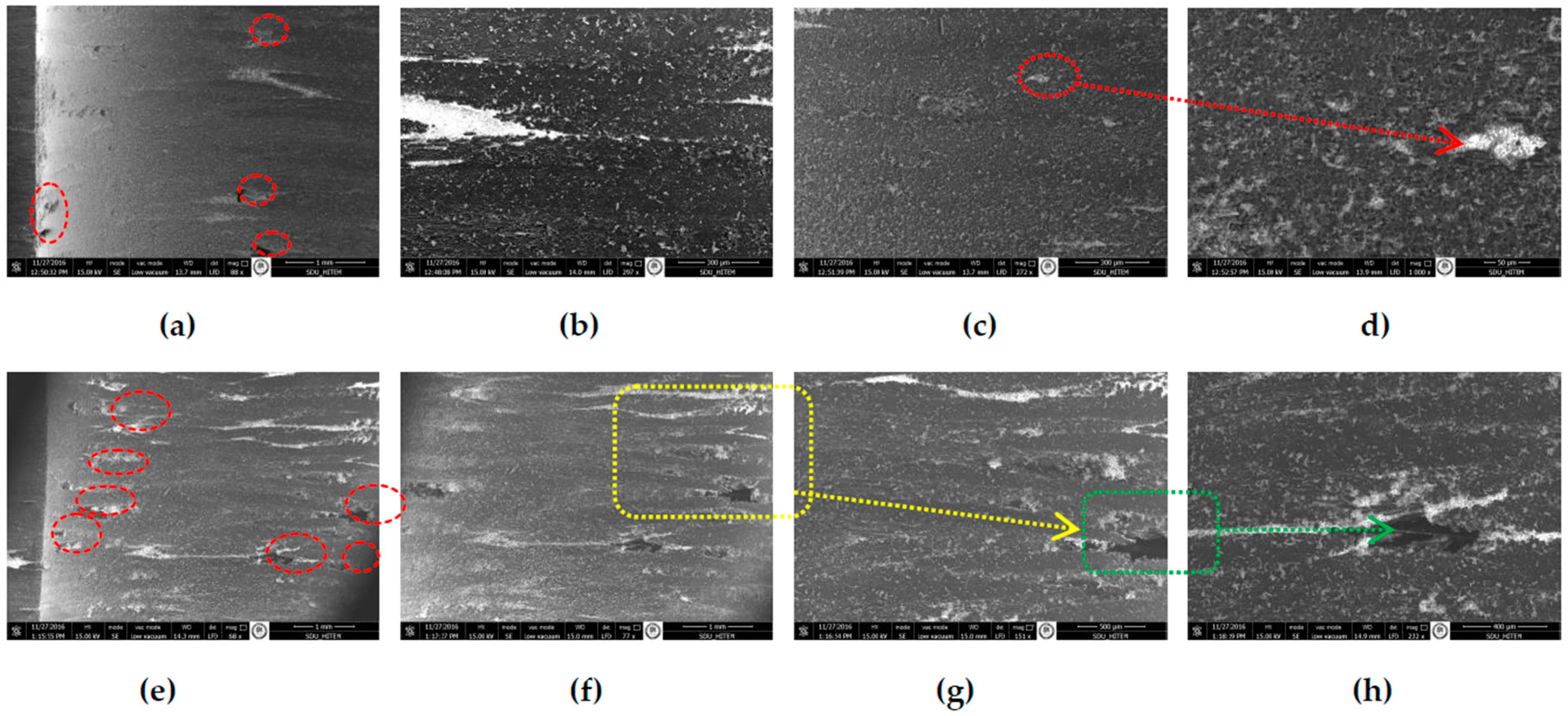

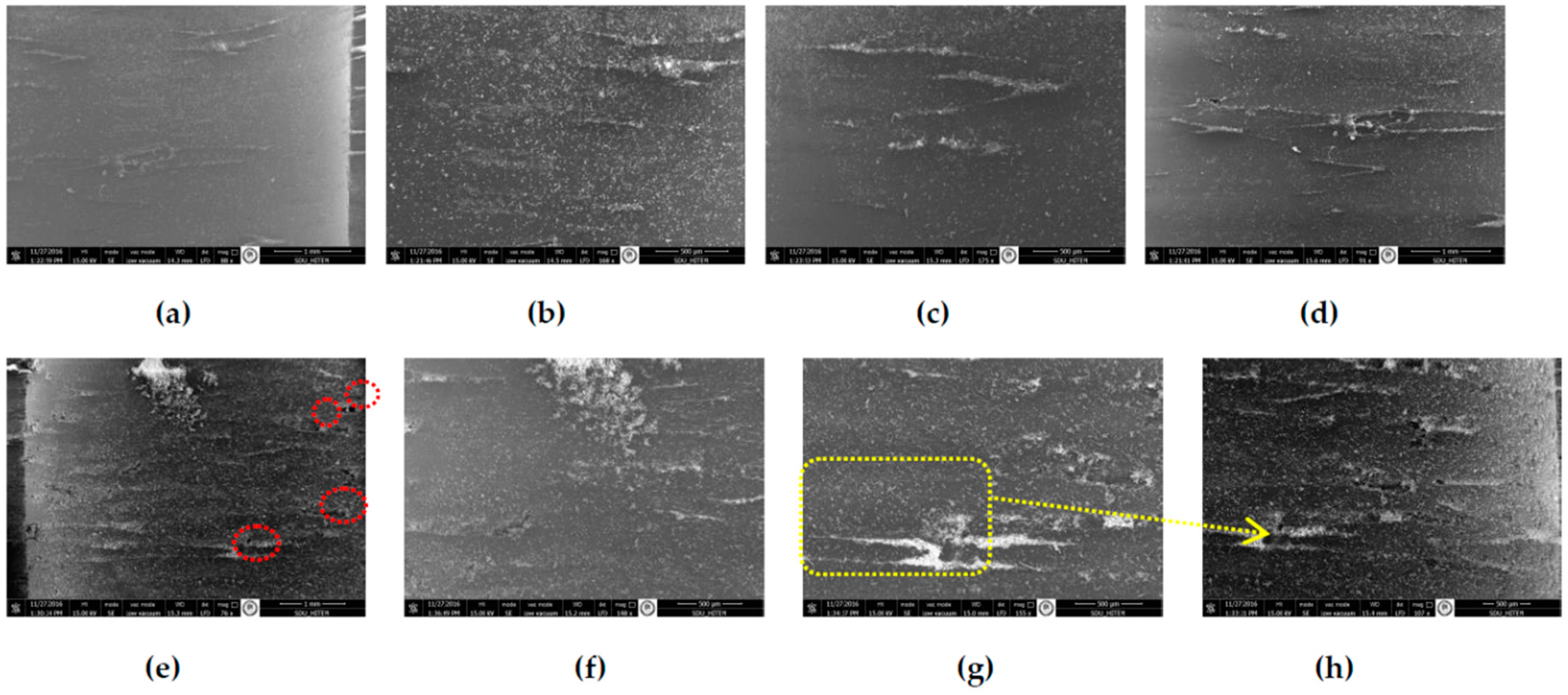

3.2. Observation from the SEM and AFM

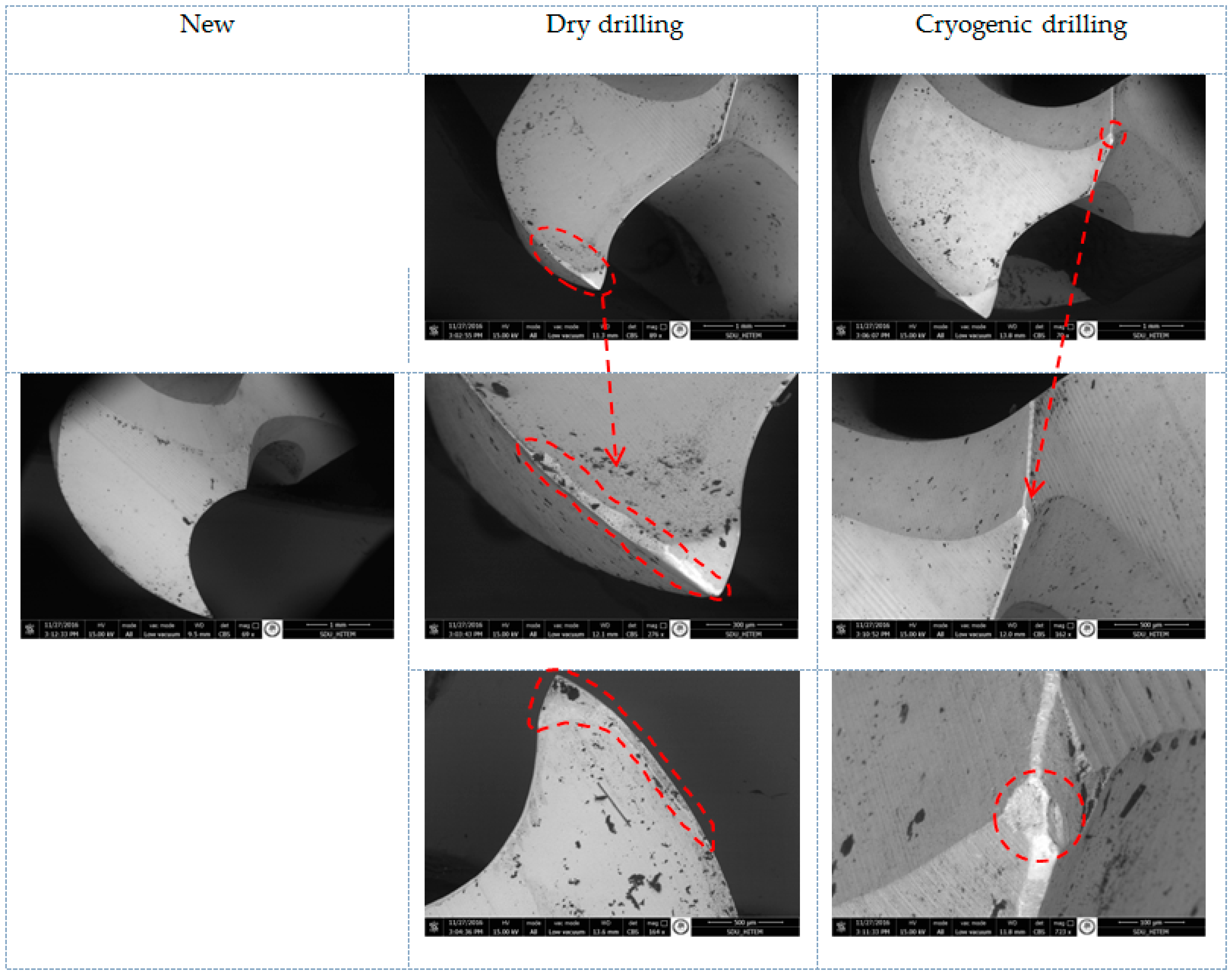

3.3. Tool Wear

4. Results

- When CFRP is exposed to excessive cold under cryogenic conditions, the temperature of the material decreases extremely. This decrease in the temperature leads to an increase in Young modulus and tensile strength and also makes the material stiffer, more brittle, and fragile. As materials are highly resistant to deformation at low temperatures, the thrust forces generated during the drilling of CFRP in cryogenic conditions are larger when compared with dry conditions.

- The high temperatures that occurred in the dry drilling of CFRP may cause several problems if temperatures in the cutting zone surpass the glass transition temperature of the matrix. As using a cryogenic coolant prevents temperature increase in the cutting zone and provides lubrication, less damaged, smoother, and higher quality surfaces were obtained under cryogenic conditions.

- Owing to the fact that the temperature increase in the cutting zone is small under cryogenic conditions, there is less tool wear compared to dry conditions.

- According to the results of this study, 4 mm diameter drills performed better than 6 mm diameter drills in all tested cases. Smaller diameter drill bits should thus be chosen unless there is a restriction in terms of design.

- Using cryogenic coolant is profitable when drilling CFRP since it enhances machining efficiency by reducing heat occurrence in the cutting zone during machining, rapidly transferring heat from the cutting zone and allowing high-speed machining.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Xu, J.Y.; An, Q.L.; Chen, M. A comparative evaluation of polycrystalline diamond drills in drilling high-strength T800S/250F CFRP. Compos. Struct. 2014, 117, 71–82. [Google Scholar] [CrossRef]

- Erkan, Ö.; Işık, B.; Çiçek, A.; Kara, F. Prediction of damage factor in end milling of glass fibre reinforced plastic composites using artificial neural network. Appl. Compos. Mater. 2013, 20, 517–536. [Google Scholar] [CrossRef]

- Karpat, Y.; Bahtiyar, O.; Deger, B.; Kaftanoglu, B. A mechanistic approach to investigate drilling of UD-CFRP laminates with PCD drills. CIRP Ann.-Manuf. Technol. 2014, 63, 81–84. [Google Scholar] [CrossRef]

- Khashaba, U.A.; El-Sonbaty, I.A.; Selmy, A.I.; Megahed, A.A. Machinability analysis in drilling woven GFR/epoxy composites: Part I—Effect of machining parameters. Compos. Part A Appl. Sci. Manuf. 2010, 41, 391–400. [Google Scholar] [CrossRef]

- El-Sonbaty, I.; Khashaba, U.A.; Machaly, T. Factors affecting the machinability of GFR/epoxy composites. Compos. Struct. 2004, 63, 329–338. [Google Scholar] [CrossRef]

- Srinivasan, T.; Palanikumar, K.; Rajagopal, K.; Latha, B. Optimization of delamination factor in drilling GFR-polypropylene composites. Mater. Manuf. Process. 2017, 32, 226–233. [Google Scholar] [CrossRef]

- Tsao, C.C.; Hocheng, H. Taguchi analysis of delamination associated with various drill bits in drilling of composite material. Int. J. Mach. Tool Manuf. 2004, 44, 1085–1090. [Google Scholar] [CrossRef]

- Herbert, M.A.; Shetty, D.; Vijay, G.; Shetty, R. Evaluation of drilling induced delamination of carbon fiber reinforced polymer composite using solid carbide drills. Eur. Sci. J. ESJ 2014, 10, 279–292. [Google Scholar]

- Palanikumar, K.; Srinivasan, T.; Rajagopal, K.; Latha, B. Thrust force analysis in drilling glass fiber reinforced/polypropylene (GFR/PP) composites. Mater. Manuf. Process. 2016, 31, 581–586. [Google Scholar] [CrossRef]

- Wstawska, I.; Ślimaka, K. The influence of cooling techniques on cutting forces and surface roughness during cryogenic machining of titanium alloys. Arch. Mech. Technol. Mater. 2016, 36, 12–17. [Google Scholar] [CrossRef]

- Percin, M.; Aslantas, K.; Ucun, I.; Kaynak, Y.; Cicek, A. Micro-drilling of Ti-6Al-4V alloy: The effects of cooling/lubricating. Precis. Eng. 2016, 45, 450–462. [Google Scholar] [CrossRef]

- Ahmed, L.S.; Kumar, M.P. Cryogenic drilling of Ti-6Al-4V alloy under liquid nitrogen cooling. Mater. Manuf. Process. 2016, 31, 951–959. [Google Scholar] [CrossRef]

- Islam, M.N.; Boswell, B. Effect of cooling methods on hole quality in drilling of aluminium 6061-6T. IOP Conf. Ser. Mater. Sci. Eng. 2016, 114, 012022. [Google Scholar] [CrossRef]

- Kheireddine, A.; Ammouri, A.; Lu, T.; Dillon, O., Jr.; Hamade, R.; Jawahir, I. An experimental and numerical study of the effect of cryogenic cooling on the surface integrity of drilled holes in AZ31B Mg alloy. Int. J. Adv. Manuf. Technol. 2015, 78, 269–279. [Google Scholar] [CrossRef]

- Govindaraju, N.; Ahmed, L.S.; Kumar, M.P. Experimental investigations on cryogenic cooling in the drilling of AISI 1045 steel. Mater. Manuf. Process. 2014, 29, 1417–1421. [Google Scholar] [CrossRef]

- Murthy, N.H.; Krishna, M. Performance analysis of cryogenically treated carbide drills in drilling white cast iron. Int. J. Appl. Eng. Res. 2010, 1, 553. [Google Scholar]

- Xia, T.; Kaynak, Y.; Arvin, C.; Jawahir, I.S. Cryogenic cooling-induced process performance and surface integrity in drilling CFRP composite material. Int. J. Adv. Manuf. Technol. 2016, 82, 605–616. [Google Scholar] [CrossRef]

- Giasin, K.; Ayvar-Soberanis, S.; Hodzic, A. Evaluation of cryogenic cooling and minimum quantity lubrication effects on machining glare laminates using design of experiments. J. Clean. Prod. 2016, 135, 533–548. [Google Scholar] [CrossRef]

- Giasin, K.; Ayvar-Soberanis, S.; Hodzic, A. The effects of minimum quantity lubrication and cryogenic liquid nitrogen cooling on drilled hole quality in glare fibre metal laminates. Mater. Des. 2016, 89, 996–1006. [Google Scholar] [CrossRef]

- Singh, A.K.; Panda, S.S.; Pal, S.K.; Chakraborty, D. Predicting drill wear using an artificial neural network. Int. J. Adv. Manuf. Technol. 2006, 28, 456–462. [Google Scholar] [CrossRef]

- Kaplan, Y.; Okay, Ş.; Motorcu, A.R.; Nalbant, M. Investigation of the effects of machining parameters on the thrust force and cutting torque in the drilling of AISI D2 and AISI D3 cold work tool steels. Indian J. Eng. Mater. Sci. 2014, 21, 128–138. [Google Scholar]

- Rajamurugan, T.V.; Shanmugam, K.; Palanikumar, K. Mathematical model for predicting thrust force in drilling of GFRP composites by multifaceted drill. Indian J. Sci. Technol. 2013, 6, 5316–5324. [Google Scholar]

- Xu, J.Y.; An, Q.L.; Cai, X.J.; Chen, M. Drilling machinability evaluation on new developed high-strength T800S/250F CFRP laminates. Int. J. Precis. Eng. Manuf. 2013, 14, 1687–1696. [Google Scholar] [CrossRef]

- Amuthakkannan, P.; Manikandan, V.; Uthayakumar, M. Analysis of delamination in drilling of basalt fiber reinforced polymer composites. Mater. Phys. Mech. 2015, 24, 1–8. [Google Scholar]

- Kaynak, Y. Evaluation of machining performance in cryogenic machining of Inconel 718 and comparison with dry and MQL machining. Int. J. Adv. Manuf. Technol. 2014, 72, 919–933. [Google Scholar] [CrossRef]

- Ishida, T.; Noma, K.; Kakinuma, Y.; Aoyama, T.; Hamada, S.; Ogawa, H.; Higaino, T. Helical milling of carbon fiber reinforced plastics using ultrasonic vibration and liquid nitrogen. Procedia CIRP 2014, 24, 13–18. [Google Scholar] [CrossRef]

- Xu, J.Y.; Mkaddem, A.; El Mansori, M. Recent advances in drilling hybrid FRP/Ti composite: A state-of-the-art review. Compos. Struct. 2016, 135, 316–338. [Google Scholar] [CrossRef]

- Poulachon, G.; Outeiro, J.; Ramirez, C.; André, V.; Abrivard, G. Hole surface topography and tool wear in CFRP drilling. Procedia CIRP 2016, 45, 35–38. [Google Scholar] [CrossRef]

- Isbilir, O.; Ghassemieh, E. Comparative study of tool life and hole quality in drilling of CFRP/titanium stack using coated carbide drill. Mach. Sci. Technol. 2013, 17, 380–409. [Google Scholar] [CrossRef]

- Lin, T.R.; Shyu, R.F. Improvement of tool life and exit burr using variable feeds when drilling stainless steel with coated drills. Int. J. Adv. Manuf. Technol. 2000, 16, 308–313. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Basmaci, G.; Yoruk, A.S.; Koklu, U.; Morkavuk, S. Impact of Cryogenic Condition and Drill Diameter on Drilling Performance of CFRP. Appl. Sci. 2017, 7, 667. https://doi.org/10.3390/app7070667

Basmaci G, Yoruk AS, Koklu U, Morkavuk S. Impact of Cryogenic Condition and Drill Diameter on Drilling Performance of CFRP. Applied Sciences. 2017; 7(7):667. https://doi.org/10.3390/app7070667

Chicago/Turabian StyleBasmaci, Gültekin, A. Said Yoruk, Ugur Koklu, and Sezer Morkavuk. 2017. "Impact of Cryogenic Condition and Drill Diameter on Drilling Performance of CFRP" Applied Sciences 7, no. 7: 667. https://doi.org/10.3390/app7070667