Shunt Damping Vibration Control Technology: A Review

Abstract

:1. Introduction

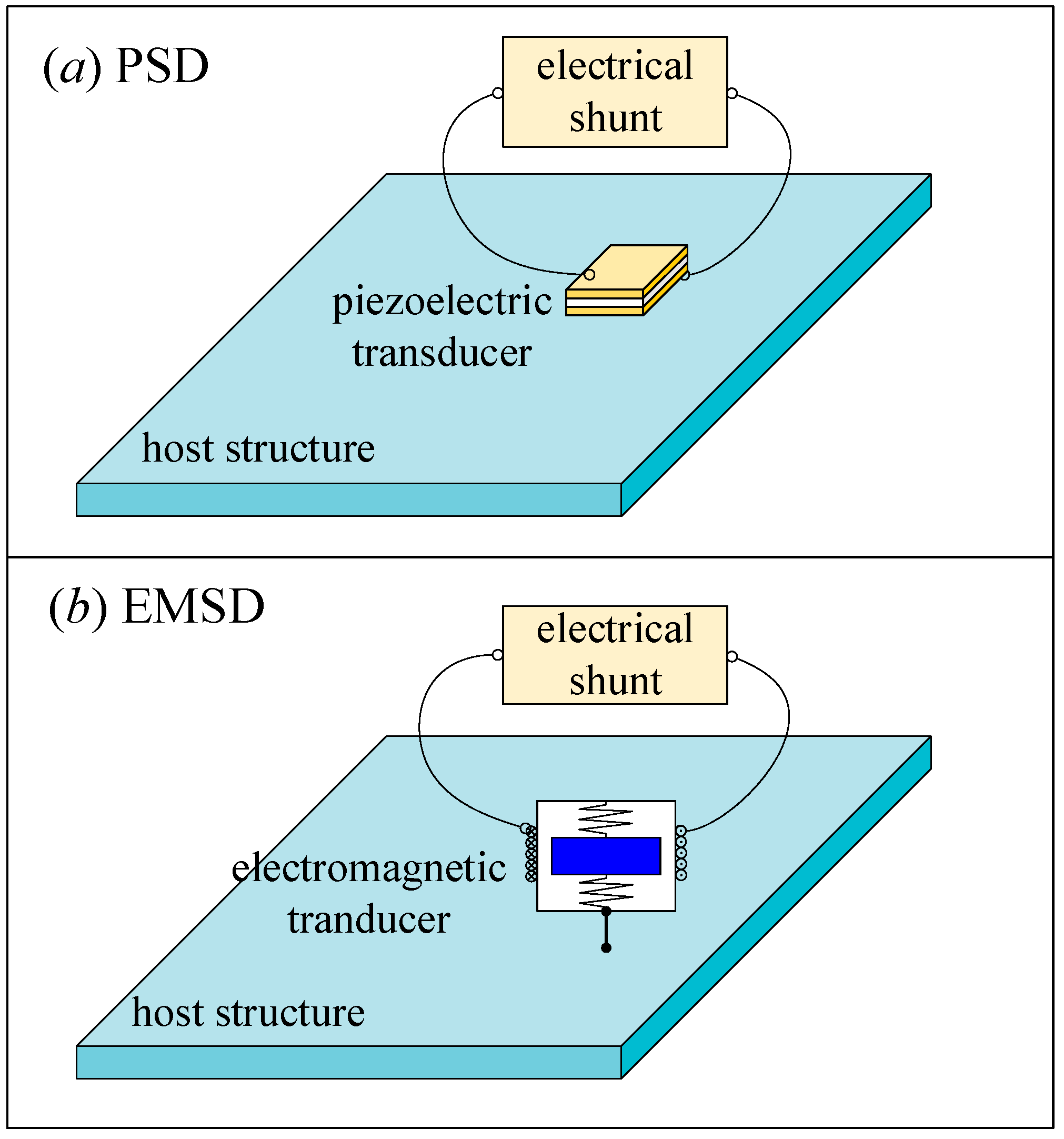

2. Fundamentals of the Piezoelectric and Electromagnetic Transducers

2.1. Piezoelectric Transducer

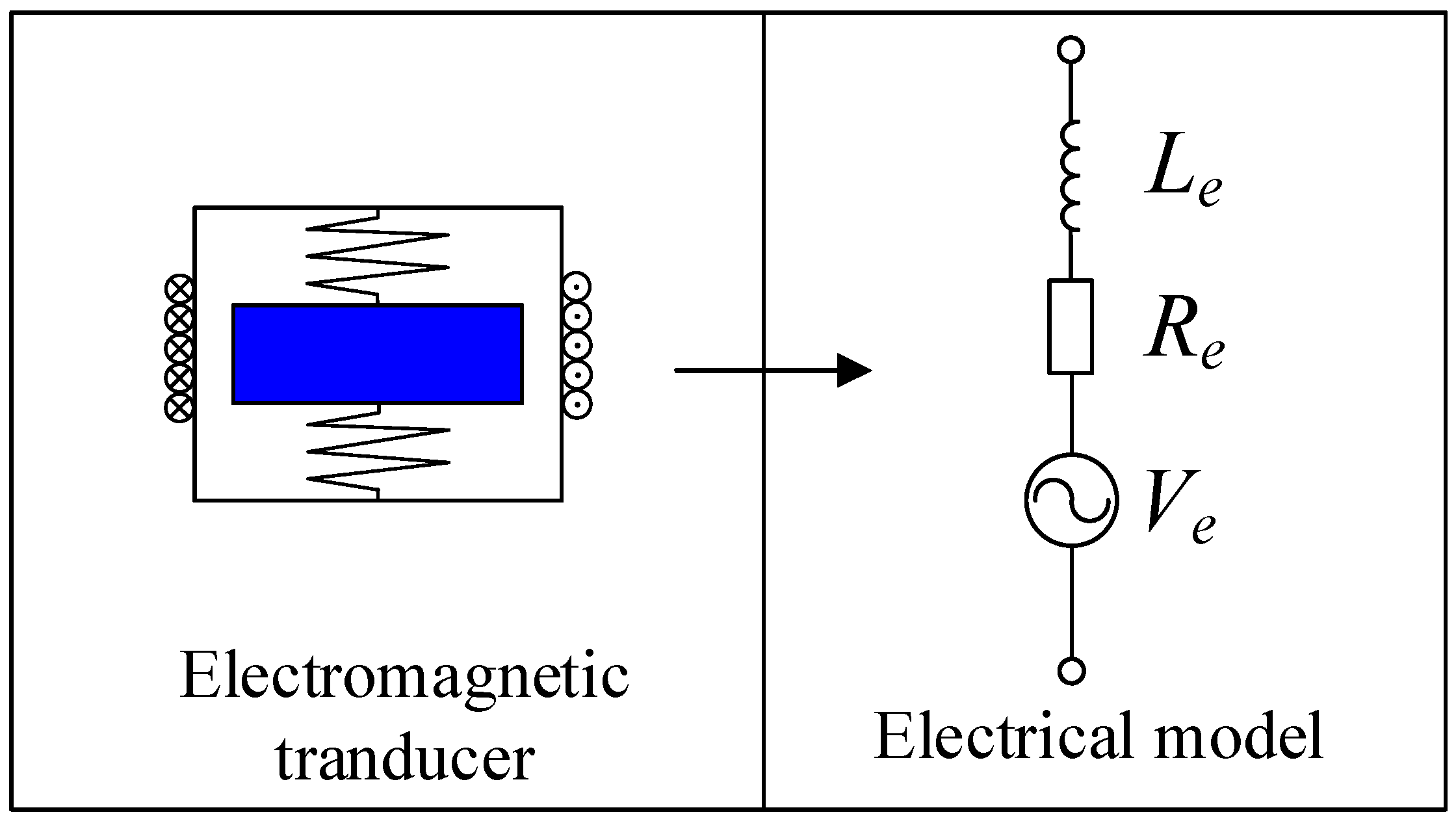

2.2. Electromagnetic Transducer

2.3. Governing Equations of the Coupled System

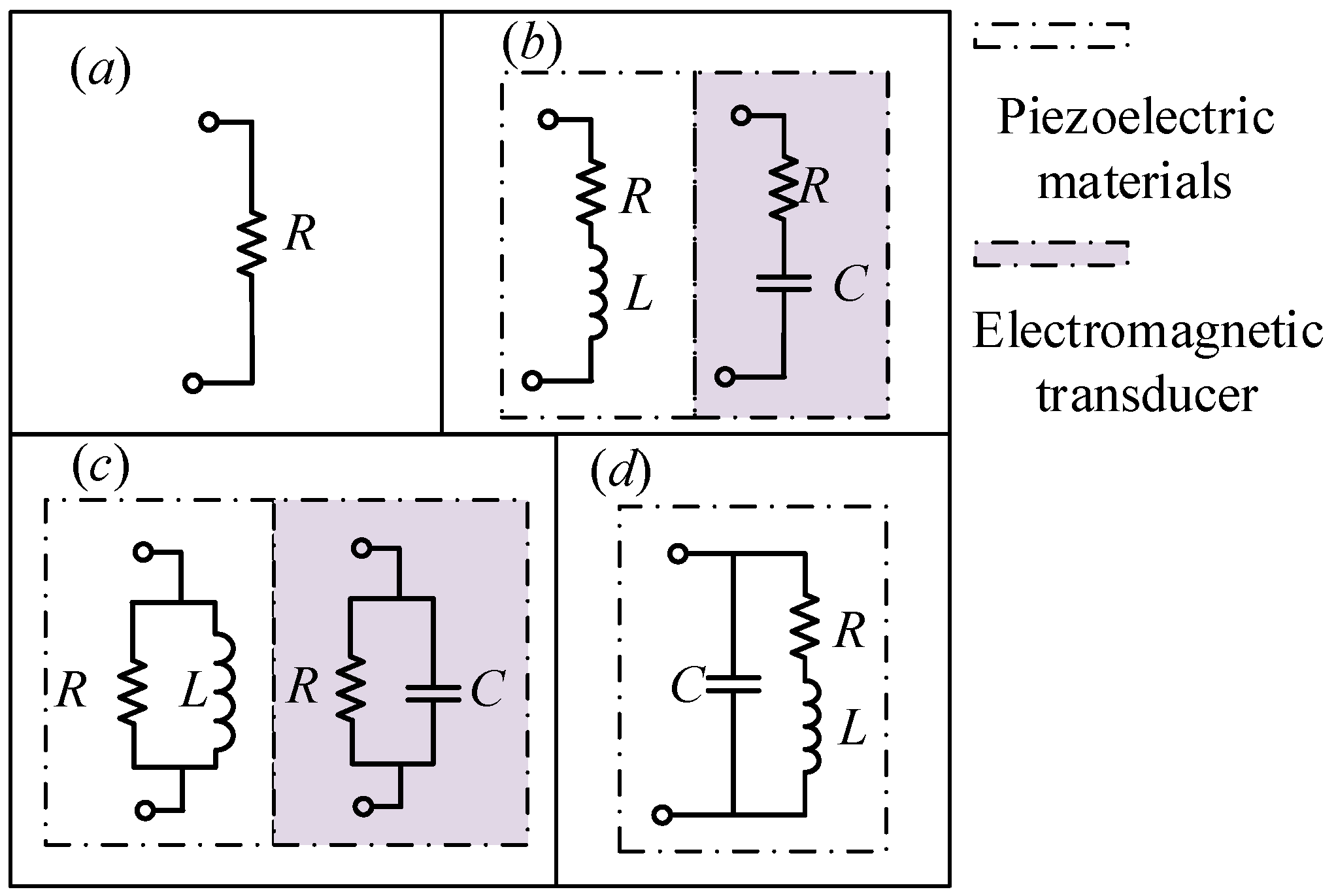

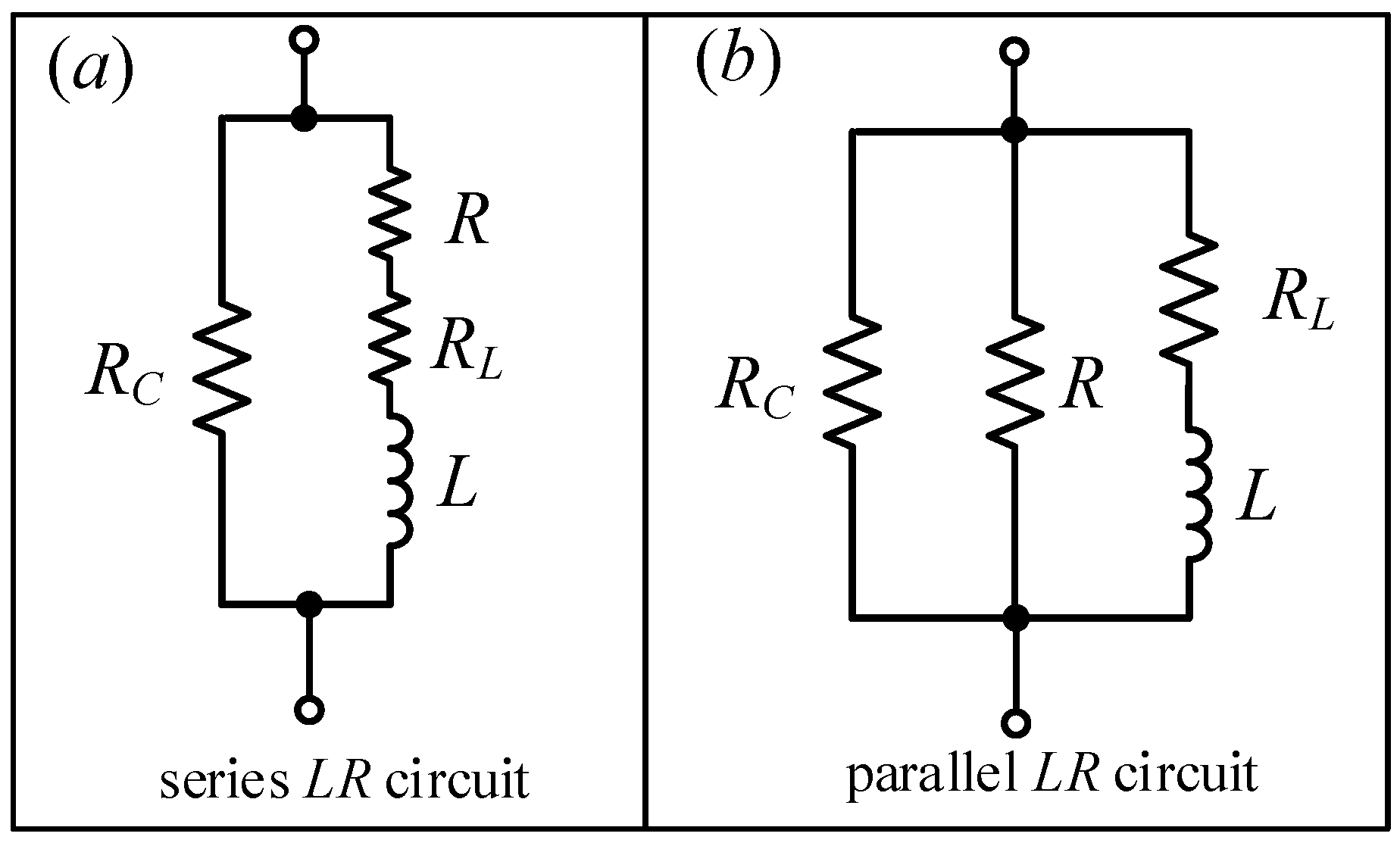

3. Passive Shunt

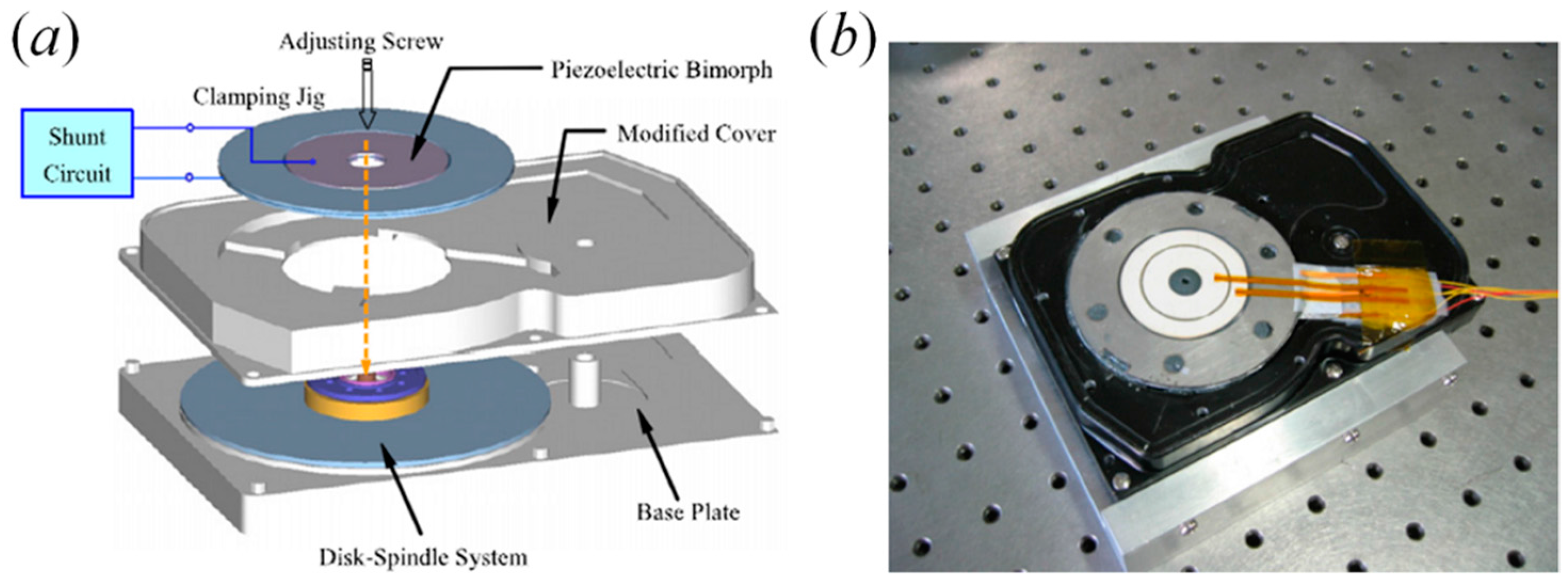

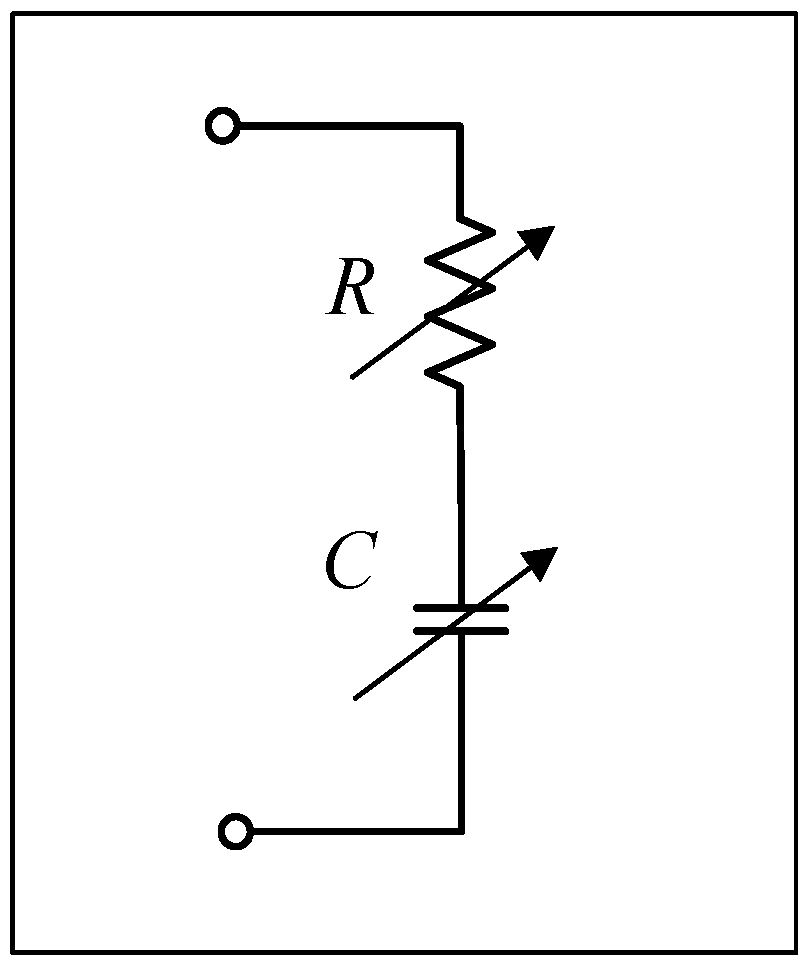

3.1. Single Modal Vibration Control

3.2. Multimodal Vibration Control

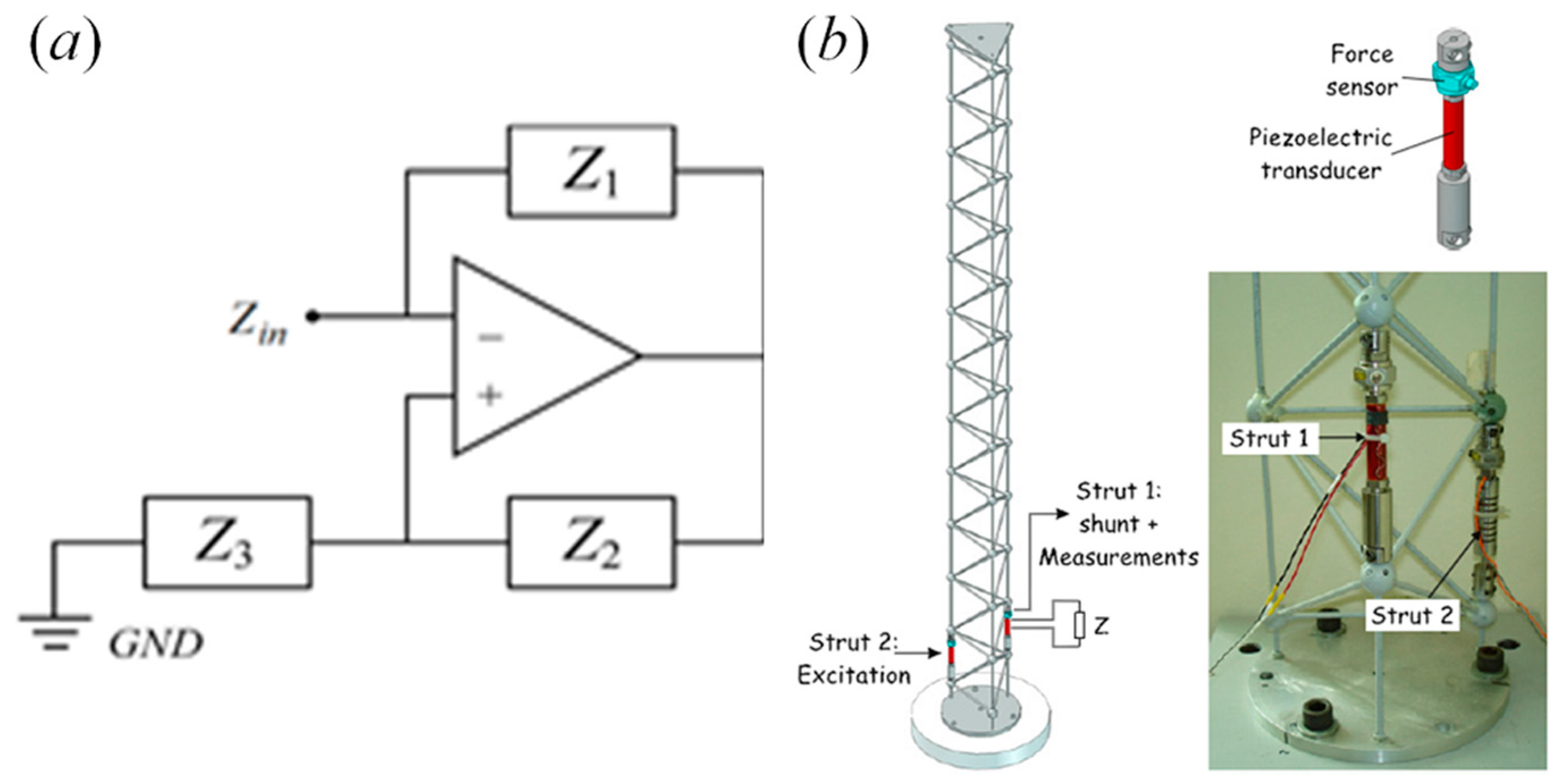

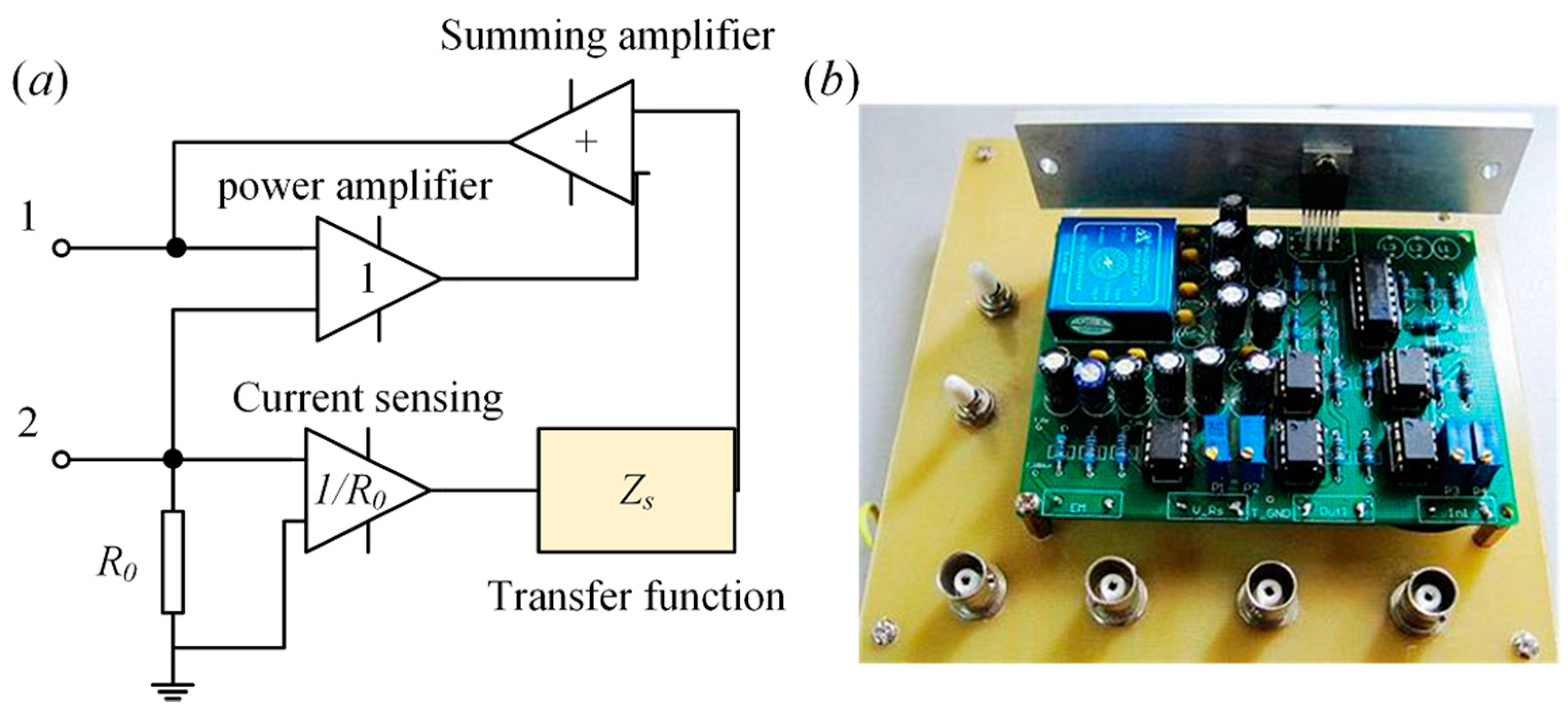

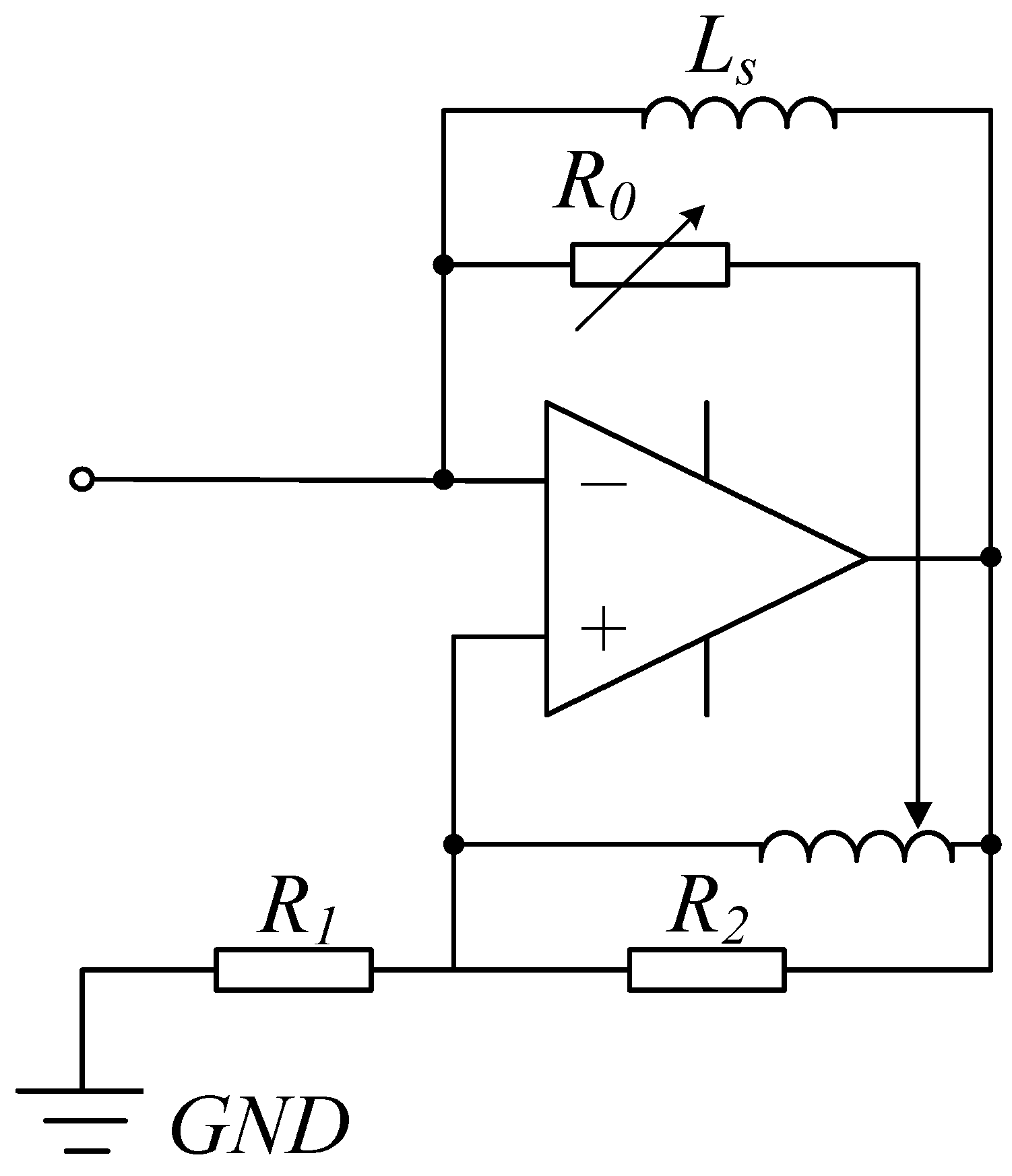

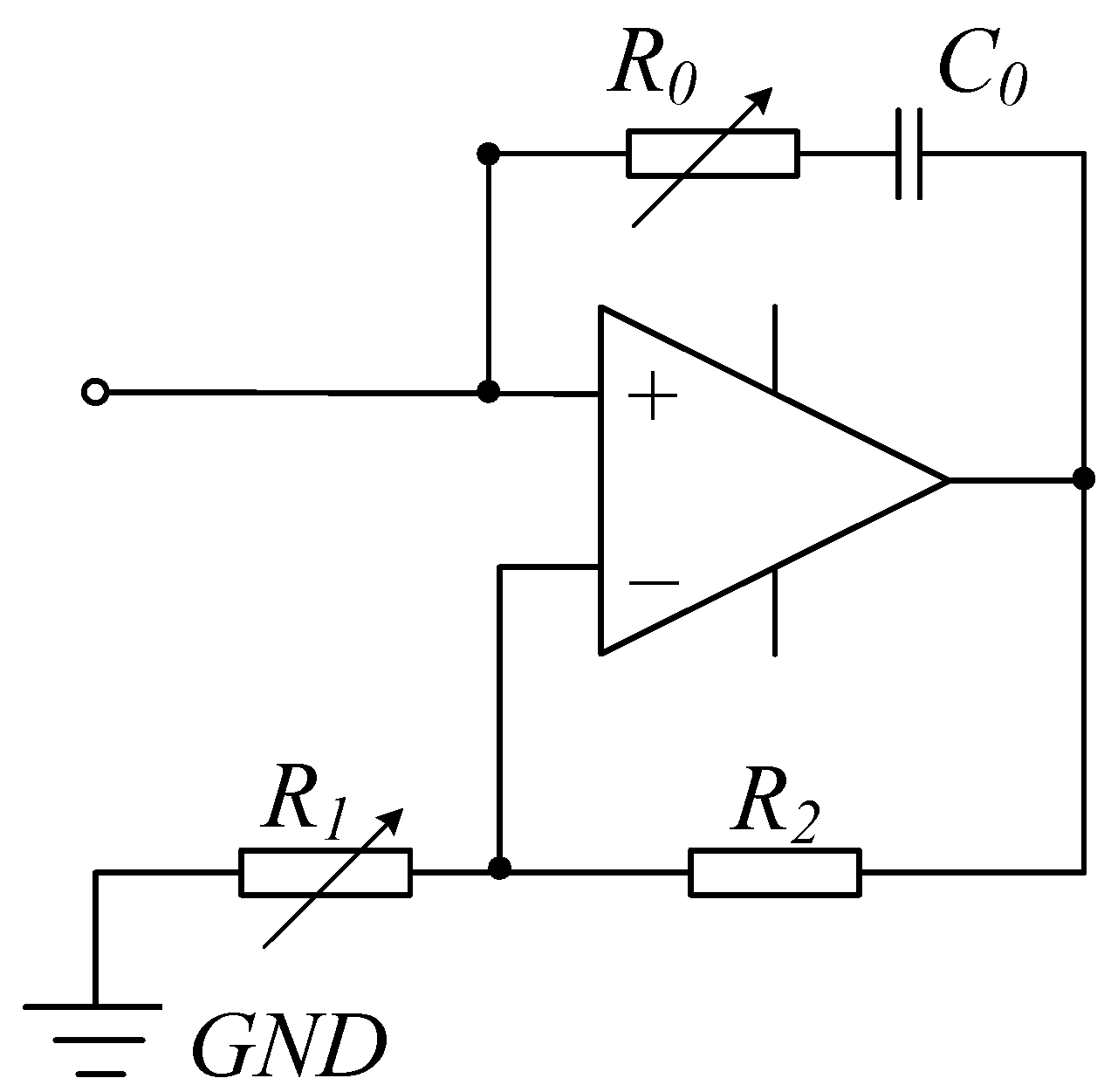

4. Active Shunt

5. Nonlinear Shunt

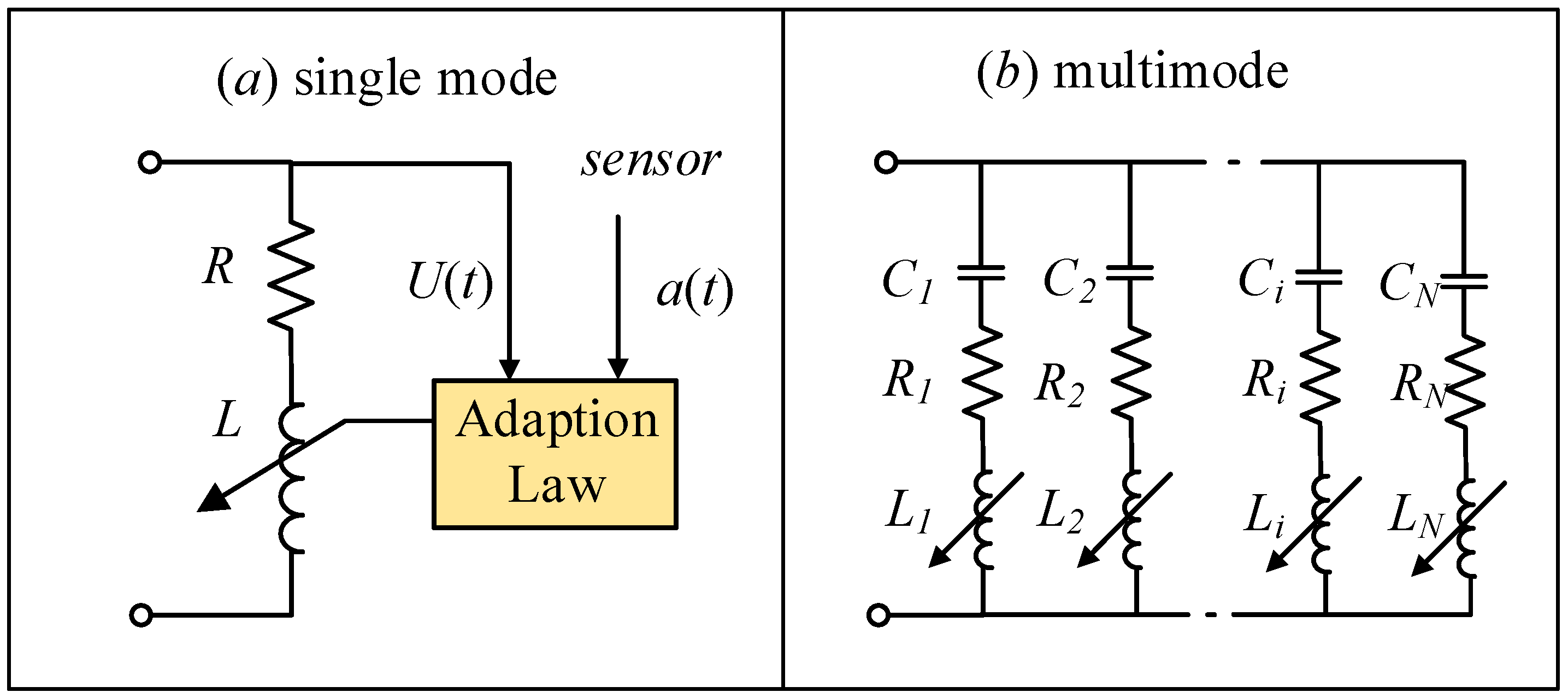

6. Adaptive Shunt

7. Challenges in Shunt Damping Vibration Control

7.1. Noise and Acoustic Control

7.2. Dual-Functional Energy Harvesting and Shunt Damping

8. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Jiang, Z.; Christenson, R.E. A fully dynamic magneto-rheological fluid damper model. Smart Mater. Struct. 2012, 21, 065002. [Google Scholar] [CrossRef]

- Song, G.; Sethi, V.; Li, H.N. Vibration control of civil structures using piezoceramic smart materials: A review. Eng. Struct. 2006, 28, 1513–1524. [Google Scholar] [CrossRef]

- Vautier, B.J.G.; Moheimani, S.O.R. Vibration reduction of resonant structures using charge controlled piezoelectric actuators. Electron. Lett. 2003, 39, 1036–1038. [Google Scholar] [CrossRef]

- Moheimani, S.O.R.; Vautier, B.J.G. Resonant control of structural vibration using charge-driven piezoelectric actuators. IEEE Trans. Control Syst. Technol. 2005, 13, 1021–1035. [Google Scholar] [CrossRef]

- Rodriguez-Fortun, J.M.; Orus, J.; Alfonso, J.; Gimeno, F.B.; Jose, A.; Castellanos, J.A. Flatness-Based Active Vibration Control for Piezoelectric Actuators. IEEE/ASME Trans. Mech. 2013, 18, 221–229. [Google Scholar] [CrossRef]

- Damanpack, A.R.; Bodaghi, M.; Aghdam, M.M.; Shakeri, M. On the vibration control capability of shape memory alloy composite beams. Compos. Struct. 2014, 110, 325–334. [Google Scholar] [CrossRef]

- Song, G.; Ma, N.; Li, H.-N. Applications of shape memory alloys in civil structures. Eng. Struct. 2006, 28, 1266–1274. [Google Scholar] [CrossRef]

- Ebrahimi, B.; Khamesee, M.B.; Golnaraghi, F. Eddy current damper feasibility in automobile suspension: Modeling, simulation and testing. Smart Mater. Struct. 2009, 18, 015017. [Google Scholar] [CrossRef]

- Chen, J.Y.; Zhou, J.B.; Meng, G.; Zhang, W.M. Evaluation of Eddy-Current Effects on Diamagnetic Bearings for Microsystems. IEEE Trans. Ind. Electron. 2009, 56, 964–972. [Google Scholar] [CrossRef]

- Beek, T.V.; Pluk, K.; Jansen, H.; Lomonova, E. Optimisation and measurement of eddy current damping in a passive tuned mass damper. IET Electr. Power Appl. 2016, 10, 641–648. [Google Scholar] [CrossRef]

- Bae, J.-S.; Kwak, M.K.; Inman, D.J. Vibration suppression of a cantilever beam using eddy current damper. J. Sound Vib. 2005, 284, 805–824. [Google Scholar] [CrossRef]

- Balas, M.J. Direct velocity feedback control of large space structures. J. Guid. Control Dynam. 1979, 2, 252–253. [Google Scholar] [CrossRef]

- Lieh, J. Semiactive and Active Suspensions for Vehicle Ride Control Using Velocity Feedback. J. Vib. Control 1997, 3, 201–212. [Google Scholar] [CrossRef]

- Ǻström, K.J.; Hägglund, T. PID Controllers: Theory, Design, and Tuning; Instrument Society of America: Research Triangle Park, NC, USA, 1995. [Google Scholar]

- Khot, S.; Yelve, N.P.; Tomar, R.; Desai, S.; Vittal, S. Active vibration control of cantilever beam by using PID based output feedback controller. J. Vib. Control 2012, 18, 366–372. [Google Scholar] [CrossRef]

- Snyder, S.D.; Tanaka, N. On feedforward active control of sound and vibration using vibration error signals. J. Acoust. Soc. Am. 1993, 94, 2181–2193. [Google Scholar] [CrossRef]

- Su, T.; Ishida, M.; Hori, T. Suppression control method for torque vibration of three-phase HB-type stepping motor utilizing feedforward control. IEEE Trans. Ind. Electron. 2002, 49, 896–904. [Google Scholar] [CrossRef]

- Alma, M.; Martinez, J.J.; Landau, I.D.; Buche, G. Design and Tuning of Reduced Order H-Infinity Feedforward Compensators for Active Vibration Control. IEEE Trans. Control Syst. Technol. 2012, 20, 554–561. [Google Scholar] [CrossRef]

- Peng, F.; Ng, A.; Hu, Y.-R. Actuator placement optimization and adaptive vibration control of plate smart structures. J. Intell. Mater. Syst. Struct. 2005, 16, 263–271. [Google Scholar] [CrossRef]

- Ma, K.; Ghasemi-Nejhad, M.N. Adaptive Control of Flexible Active Composite Manipulators Driven by Piezoelectric Patches and Active Struts With Dead Zones. IEEE Trans. Control Syst. Technol. 2008, 16, 897–907. [Google Scholar]

- Kwak, M.; Sciulli, D. Fuzzy-logic based vibration suppression control experiments on active structures. J. Sound Vib. 1996, 191, 15–28. [Google Scholar] [CrossRef]

- Han, J.-H.; Lee, I. Optimal placement of piezoelectric sensors and actuators for vibration control of a composite plate using genetic algorithms. Smart Mater. Struct. 1999, 8, 257. [Google Scholar] [CrossRef]

- Sun, J.; Poo, A.N.; Chew, C.M.; Ang, M.H.; Hong, G.S. Optimization of Mechatronic Design Quotient Using Genetic Algorithm in Vibration Controllers for Flexible Beams. J. Vib. Control 2009, 15, 1603–1626. [Google Scholar] [CrossRef]

- Itoh, K.; Iwasaki, M.; Matsui, N. Optimal design of robust vibration suppression controller using genetic algorithms. IEEE Trans. Ind. Electron. 2004, 51, 947–953. [Google Scholar] [CrossRef]

- Madkour, A.; Hossain, M.A.; Dahal, K.P.; Yu, H. Intelligent Learning Algorithms for Active Vibration Control. IEEE Trans. Syst. Man Cybern. C (Appl. Rev.) 2007, 37, 1022–1033. [Google Scholar] [CrossRef]

- Viana, F.A.C.; Kotinda, G.I.; Rade, D.A.; Steffen, V., Jr. Tuning dynamic vibration absorbers by using ant colony optimization. Comput. Struct. 2008, 86, 1539–1549. [Google Scholar] [CrossRef]

- Forward, R.L. Electronic damping of vibrations in optical structures. Appl. Opt. 1979, 18, 690–697. [Google Scholar] [CrossRef] [PubMed]

- Hollkamp, J.J. Multimodal passive vibration suppression with piezoelectric materials and resonant shunts. J. Intell. Mater. Syst. Struct. 1994, 5, 49–57. [Google Scholar] [CrossRef]

- Hagood, N.W.; von Flotow, A. Damping of structural vibrations with piezoelectric materials and passive electrical networks. J. Sound Vib. 1991, 146, 243–268. [Google Scholar] [CrossRef]

- Behrens, S.; Fleming, A.J.; Moheimani, S.O.R. Passive vibration control via electromagnetic shunt damping. IEEE/ASME Trans. Mech. 2005, 10, 118–122. [Google Scholar] [CrossRef]

- Behrens, S.; Fleming, A.J.; Moheimani, S.O.R. Ieee Electromagnetic shunt damping. In Proceedings of the 2003 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (Aim 2003), Kobe, Japan, 20–24 July 2003; Volumes 1 and 2, pp. 1145–1150. [Google Scholar]

- Hollkamp, J.J.; Starchville, T.F. A self-tuning piezoelectric vibration absorber. J. Intell. Mater. Syst. Struct. 1994, 5, 559–566. [Google Scholar] [CrossRef]

- Moheimani, S.O.R. A survey of recent innovations in vibration damping and control using shunted piezoelectric transducers. IEEE Trans. Control Syst. Technol. 2003, 11, 482–494. [Google Scholar] [CrossRef]

- Cheng, T.H.; Oh, I.K. A current-flowing electromagnetic shunt damper for multi-mode vibration control of cantilever beams. Smart Mater. Struct. 2009, 18, 095036. [Google Scholar] [CrossRef]

- Fleming, A.J.; Behrens, S.; Moheimani, S.O.R. Synthetic impedance for implementation of piezoelectric shunt-damping circuits. Electron. Lett. 2000, 36, 1525–1526. [Google Scholar] [CrossRef]

- Fleming, A.; Moheimani, S. Adaptive piezoelectric shunt damping. Smart Mater. Struct. 2003, 12, 36–48. [Google Scholar] [CrossRef]

- De Marneffe, B.; Preumont, A. Vibration damping with negative capacitance shunts: Theory and experiment. Smart Mater. Struct. 2008, 17, 035015. [Google Scholar] [CrossRef]

- Ji, H.L.; Qiu, J.H.; Cheng, J.; Inman, D. Application of a negative capacitance circuit in synchronized switch damping techniques for vibration suppression. J. Vib. Acoust. 2011, 133, 041015. [Google Scholar] [CrossRef]

- Fukada, E.; Date, M.; Sekigawa, K. Vibration Control by Magnetostrictive Actuator Coupled with Negative Inductance Circuits. Jpn. J. Appl. Phys. 2003, 42, 7124. [Google Scholar] [CrossRef]

- Scheidler, J.J.; Asnani, V.M.; Dapino, M.J. Design and testing of a dynamically-tuned magnetostrictive spring with electrically controlled stiffness. In Proceedings of the SPIE 9433, Industrial and Commercial Applications of Smart Structures Technologies, San Diego, CA, USA, 8 March 2015. [Google Scholar]

- Scheidler, J.J.; Asnani, V.M.; Dapino, M.J. Dynamically tuned magnetostrictive spring with electrically controlled stiffness. Smart Mater. Struct. 2016, 25, 035007. [Google Scholar] [CrossRef]

- Adriaens, H.J.; De Koning, W.L.; Banning, R. Modeling piezoelectric actuators. IEEE/ASME Trans. Mech. 2000, 5, 331–341. [Google Scholar] [CrossRef]

- Fuller, C.; Elliott, S.J.; Nelson, P.R. Active Vibration Control. In Handbook of Noise and Vibration Control; Acadamic Press: San Diego, CA, USA, 1996; pp. 770–784. [Google Scholar]

- Gandhi, M.V.; Thompson, B. Smart Materials and Structures; Chapman &Hall: London, UK, 1992. [Google Scholar]

- Fleming, A.J. Synthesis and Implementation of Sensor-Less Shunt Controllers for Piezoelectric and Electromagnetic Vibration Control; The University of Newcastle: Callaghan, Australia, 2004. [Google Scholar]

- Dosch, J.J.; Inman, D.J.; Garcia, E. A self-sensing piezoelectric actuator for collocated control. J. Intell. Mater. Syst. Struct. 1992, 3, 166–185. [Google Scholar] [CrossRef]

- Giovanni, C. A critical analysis of electric shunt circuits employed in piezoelectric passive vibration damping. Smart Mater. Struct. 2001, 10, 1059. [Google Scholar]

- Sodano, H.A.; Bae, J.-S.; Inman, D.J.; Keith Belvin, W. Concept and model of eddy current damper for vibration suppression of a beam. J. Sound Vib. 2005, 288, 1177–1196. [Google Scholar] [CrossRef]

- Ebrahimi, B.; Khamesee, M.B.; Golnaraghi, M.F. Design and modeling of a magnetic shock absorber based on eddy current damping effect. J. Sound Vib. 2008, 315, 875–889. [Google Scholar] [CrossRef]

- Zuo, L.; Chen, X.; Nayfeh, S. Design and analysis of a new type of electromagnetic damper with increased energy density. J. Vib. Acoust. 2011, 133, 041006. [Google Scholar] [CrossRef]

- Furlani, E.P. Permanent Magnet and Electromechanical Devices; Mayergoyz, I., Ed.; Acdemic Press: New York, NY, USA, 2001. [Google Scholar]

- Niu, H.P.; Zhang, X.N.; Xie, S.L.; Wang, P.P. A new electromagnetic shunt damping treatment and vibration control of beam structures. Smart Mater. Struct. 2009, 18, 045009. [Google Scholar] [CrossRef]

- Yan, B.; Zhang, X.N.; Niu, H.P. Design and test of a novel isolator with negative resistance electromagnetic shunt damping. Smart Mater. Struct. 2012, 21, 035003. [Google Scholar] [CrossRef]

- Niederberger, D.; Behrens, S.; Fleming, A.J.; Moheimani, S.O.R.; Morari, M. Adaptive electromagnetic shunt damping. IEEE/ASME Trans. Mech. 2006, 11, 103–108. [Google Scholar] [CrossRef]

- Yan, B.; Zhang, X.N.; Niu, H.P. Vibration isolation of a beam via negative resistance electromagnetic shunt dampers. J. Intell. Mater. Syst. Struct. 2012, 23, 665–673. [Google Scholar] [CrossRef]

- Zhang, X.N.; Niu, H.P.; Yan, B. A novel multimode negative inductance negative resistance shunted electromagnetic damping and its application on a cantilever plate. J. Sound Vib. 2012, 331, 2257–2271. [Google Scholar] [CrossRef]

- Sodano, H.A.; Bae, J.S.; Inman, D.J.; Belvin, W.K. Improved concept and model of eddy current damper. J. Vib. Acoust. 2006, 128, 294–302. [Google Scholar] [CrossRef]

- Ebrahimi, B.; Khamesee, M.B.; Golnaraghi, F. Permanent magnet configuration in design of an eddy current damper. Microsyst. Technol. 2010, 16, 19–24. [Google Scholar] [CrossRef]

- Zuo, L.; Scully, B.; Shestani, J.; Zhou, Y. Design and characterization of an electromagnetic energy harvester for vehicle suspensions. Smart Mater. Struct. 2010, 19, 045003. [Google Scholar] [CrossRef]

- Yan, B.; Zhang, X.; Luo, Y.; Zhang, Z.; Xie, S.; Zhang, Y. Negative impedance shunted electromagnetic absorber for broadband absorbing: Experimental investigation. Smart Mater. Struct. 2014, 23, 125044. [Google Scholar] [CrossRef]

- Yan, B.; Luo, Y.; Zhang, X. Structural multimode vibration absorbing with electromagnetic shunt damping. J. Vib. Control 2016, 22, 1604–1617. [Google Scholar] [CrossRef]

- Harris, C.M.; Piersol, A.G. Harris’ Shock and Vibration Handbook; McGraw-Hill: New York, NY, USA, 2002. [Google Scholar]

- Meirovitch, L. Fundamentals of Vibrations; Waveland Press: Long Grove, IL, USA, 2010. [Google Scholar]

- Den Hartog, J.P. Mechanical Vibrations; Courier Corporation: North Chelmsford, MA, USA, 1985. [Google Scholar]

- Neubauer, M.; Oleskiewicz, R.; Popp, K.; Krzyzynski, T. Optimization of damping and absorbing performance of shunted piezo elements utilizing negative capacitance. J. Sound Vib. 2006, 298, 84–107. [Google Scholar] [CrossRef]

- Kim, J.-S.; Jeong, U.-C.; Seo, J.-H.; Kim, Y.-D.; Lee, O.-D.; Oh, J.-E. Structure borne noise control of a clamped panel using shunt damping system. Sens. Actuators A Phys. 2015, 233, 330–348. [Google Scholar] [CrossRef]

- Kandagal, S.B. KartikVenkatraman Structural vibration control using resistively shunted piezoceramics. Struct. Eng. Mech. 2002, 14, 521–542. [Google Scholar] [CrossRef]

- Jaehwan, K.; Yeon-Ho, R.; Seung-Bok, C. New shunting parameter tuning method for piezoelectric damping based on measured electrical impedance. Smart Mater. Struct. 2000, 9, 868. [Google Scholar]

- Inoue, T.; Ishida, Y.; Sumi, M. Vibration suppression using electromagnetic resonant shunt damper. J. Vib. Acoust. 2008, 130, 041003. [Google Scholar] [CrossRef]

- Kozlowski, M.V.; Cole, D.G.; Clark, R.L. A comprehensive study of the RL series resonant shunted piezoelectric: A feedback controls perspective. J. Vib. Acoust. 2011, 133, 011012. [Google Scholar] [CrossRef]

- Soltani, P.; Kerschen, G.; Tondreau, G.; Deraemaeker, A. Piezoelectric vibration damping using resonant shunt circuits: An exact solution. Smart Mater. Struct. 2014, 23, 125014. [Google Scholar] [CrossRef]

- Lim, S.C.; Choi, S.B. Vibration control of an HDD disk-spindle system utilizing piezoelectric bimorph shunt damping: I. Dynamic analysis and modeling of the shunted drive. Smart Mater. Struct. 2007, 16, 891–900. [Google Scholar] [CrossRef]

- Lim, S.C.; Choi, S.B. Vibration control of an HDD disk-spindle system using piezoelectric bimorph shunt damping: II. Optimal design and shunt damping implementation. Smart Mater. Struct. 2007, 16, 901–908. [Google Scholar] [CrossRef]

- Schoeftner, J.; Irschik, H. Passive damping and exact annihilation of vibrations of beams using shaped piezoelectric layers and tuned inductive networks. Smart Mater. Struct. 2009, 18, 125008. [Google Scholar] [CrossRef]

- Wu, S.-Y. Piezoelectric shunts with a parallel R-L circuit for structural damping and vibration control. In Proceedings of the SPIE 2720, Smart Structures and Materials 1996: Passive Damping and Isolation, San Diego, CA, USA, 25 February 1996. [Google Scholar]

- Park, C.H. Dynamics modelling of beams with shunted piezoelectric elements. J. Sound Vib. 2003, 268, 115–129. [Google Scholar] [CrossRef]

- Nguyen, C.H.; Pietrzko, S.J. FE analysis of a PZT-actuated adaptive beam with vibration damping using a parallel R–L shunt circuit. Finite Elem. Anal. Des. 2006, 42, 1231–1239. [Google Scholar] [CrossRef]

- Li, N. Virtual piezoelectric vibration absorber with LR parallel shunt circuit. In Advanced Mechanical Design; Trans Tech Publications: Zurich, Switzerland, 2012; pp. 1165–1168. [Google Scholar]

- Guo, K.; Jiang, J. Independent modal resonant shunt for multimode vibration control of a truss-cored sandwich panel. Int. J. Dyn. Control 2014, 2, 326–334. [Google Scholar] [CrossRef]

- Sun, H.; Yang, Z.; Li, K.; Li, B.; Xie, J.; Wu, D.; Zhang, L. Vibration suppression of a hard disk driver actuator arm using piezoelectric shunt damping with a topology-optimized PZT transducer. Smart Mater. Struct. 2009, 18, 065010. [Google Scholar] [CrossRef]

- Yamada, K.; Matsuhisa, H.; Utsuno, H.; Sawada, K. Optimum tuning of series and parallel LR circuits for passive vibration suppression using piezoelectric elements. J. Sound Vib. 2010, 329, 5036–5057. [Google Scholar] [CrossRef]

- Høgsberg, J.; Krenk, S. Balanced calibration of resonant shunt circuits for piezoelectric vibration control. J. Intell. Mater. Syst. Struct. 2012, 23, 1937–1948. [Google Scholar] [CrossRef]

- Krenk, S.; Høgsberg, J.B. A Family of Resonant Vibration Control Formats. In Proceedings of the 5th European Conference on Structural Control, Genoa, Italy, 18–20 June 2012. [Google Scholar]

- Krenk, S.; Høgsberg, J. Optimal resonant control of flexible structures. J. Sound Vib. 2009, 323, 530–554. [Google Scholar] [CrossRef]

- Krenk, S.; Hogsberg, J. Equal modal damping design for a family of resonant vibration control formats. J. Vib. Control 2013, 19, 1294–1315. [Google Scholar] [CrossRef]

- Høgsberg, J.; Krenk, S. Calibration of piezoelectric RL shunts with explicit residual mode correction. J. Sound Vib. 2017, 386, 65–81. [Google Scholar] [CrossRef]

- Wu, S.-Y. Method for multiple mode piezoelectric shunting with single PZT transducer for vibration control. J. Intell. Mater. Syst. Struct. 1998, 9, 991–998. [Google Scholar] [CrossRef]

- Wu, S.-Y. Method for multiple-mode shunt damping of structural vibration using a single PZT transducer. In Proceedings of the 5th Annual International Symposium on Smart Structures and Materials, San Diego, CA, USA, 1–5 March 1998. [Google Scholar]

- Behrens, S.; Moheimani, S.R. Current flowing multiple-mode piezoelectric shunt dampener. In Proceedings of the SPIE’s 9th Annual International Symposium on Smart Structures and Materials, San Diego, CA, USA, 17–21 March 2002. [Google Scholar]

- Behrens, S.; Moheimani, S.R.; Fleming, A. Multiple mode current flowing passive piezoelectric shunt controller. J. Sound Vib. 2003, 266, 929–942. [Google Scholar] [CrossRef]

- Fleming, A.J.; Moheimani, S.O.R. Improved current and charge amplifiers for driving piezoelectric loads, and issues in signal processing design for synthesis of shunt damping circuits. J. Intell. Mater. Syst. Struct. 2004, 15, 77–92. [Google Scholar] [CrossRef]

- Fleming, A.J.; Behrens, S.; Moheimani, S.O.R. Reducing the inductance requirements of piezoelectric shunt damping systems. Smart Mater. Struct. 2003, 12, 57–64. [Google Scholar] [CrossRef]

- Vasques, C.M.A. Improved passive shunt vibration control of smart piezo-elastic beams using modal piezoelectric transducers with shaped electrodes. Smart Mater. Struct. 2012, 21, 125003. [Google Scholar] [CrossRef]

- Fleming, A.J.; Behrens, S.; Moheimani, S.O.R. IEEE Active LQR and H2 shunt control of electromagnetic transducers. In Proceedings of the 42nd IEEE Conference on Decision and Control, Maui, HI, USA, 9–12 December 2003; pp. 2294–2299. [Google Scholar]

- Fleming, A.J.; Moheimani, S.R. Control orientated synthesis of high-performance piezoelectric shunt impedances for structural vibration control. IEEE Trans. Control Syst. Technol. 2005, 13, 98–112. [Google Scholar] [CrossRef]

- Wu, S.-Y. Broadband piezoelectric shunts for passive structural vibration control. In Proceedings of the SPIE’s 8th Annual International Symposium on Smart Structures and Materials, Newport Beach, CA, USA, 4 March 2001. [Google Scholar]

- Merrill, J. Theory of the negative impedance converter. Bell Syst. Tech. J. 1951, 30, 88–109. [Google Scholar] [CrossRef]

- Behrens, S.; Fleming, A.J.; Moheimani, S.O.R. A broadband controller for shunt piezoelectric damping of structural vibration. Smart Mater. Struct. 2003, 12, 18–28. [Google Scholar] [CrossRef]

- Park, C.H.; Park, H.C. Multiple-Mode Structural Vibration Control Using Negative Capacitive Shunt Damping. J. Mech. Sci. Technol. 2003, 17, 1650–1658. [Google Scholar] [CrossRef]

- Manzoni, S.; Moschini, S.; Redaelli, M.; Vanali, M. Vibration attenuation by means of piezoelectric transducer shunted to synthetic negative capacitance. J. Sound Vib. 2012, 331, 4644–4657. [Google Scholar] [CrossRef]

- Mokrani, B.; Rodrigues, G.; Ioan, B.; Bastaits, R.; Preumont, A. Synchronized switch damping on inductor and negative capacitance. J. Intell. Mater. Syst. Struct. 2012, 23, 2065–2075. [Google Scholar] [CrossRef]

- Beck, B.S.; Cunefare, K.A.; Collet, M. The power output and efficiency of a negative capacitance shunt for vibration control of a flexural system. Smart Mater. Struct. 2013, 22, 065009. [Google Scholar] [CrossRef]

- Qureshi, E.M.; Shen, X.; Chang, L. Power output and efficiency of a negative capacitance and inductance shunt for structural vibration control under broadband excitation. Int. J. Aeronaut. Space Sci. 2015, 16, 223–246. [Google Scholar] [CrossRef]

- Salloum, R.; Heuss, O.; Götz, B.; Mayer, D. Optimally tuned resonant negative capacitance for piezoelectric shunt damping based on measured electromechanical impedance. In Proceedings of the SPIE 9433, Industrial and Commercial Applications of Smart Structures Technologies 2015, San Diego, CA, USA, 8 March 2015. [Google Scholar]

- Necasek, J.; Vaclavik, J.; Marton, P. Digital synthetic impedance for application in vibration damping. Rev. Sci. Instrum. 2016, 87, 024704. [Google Scholar] [CrossRef] [PubMed]

- Alessandro, S.; Guglielmo, S.A.; Guy, R.; Geert, S. A 2-collinear-DoF strut with embedded negative-resistance electromagnetic shunt dampers for spacecraft micro-vibration. Smart Mater. Struct. 2017, 26, 045031. [Google Scholar]

- McDaid, A.J.; Mace, B.R. A self-tuning electromagnetic vibration absorber with adaptive shunt electronics. Smart Mater. Struct. 2013, 22, 105013. [Google Scholar] [CrossRef]

- Yan, B.; Zhang, X.; Luo, Y. Investigation of negative resistance shunt damping for the vibration control of a plate. Int. J. Appl. Electrom. 2014, 45, 93–100. [Google Scholar]

- Date, M.; Kutani, M.; Sakai, S. Electrically controlled elasticity utilizing piezoelectric coupling. J. Appl. Phys. 1999, 87, 863–868. [Google Scholar] [CrossRef]

- Mokrý, P.; Fukada, E.; Yamamoto, K. Noise shielding system utilizing a thin piezoelectric membrane and elasticity control. J. Appl. Phys. 2003, 94, 789–796. [Google Scholar] [CrossRef]

- Mokrý, P.; Fukada, E.; Yamamoto, K. Sound absorbing system as an application of the active elasticity control technique. J. Appl. Phys. 2003, 94, 7356–7362. [Google Scholar] [CrossRef]

- Fukada, E.; Date, M.; Kimura, K.; Okubo, T.; Kodama, H.; Mokry, P.; Yamamoto, K. Sound isolation by piezoelectric polymer films connected to negative capacitance circuits. IEEE. Trans. Dielectr. Electr. Insul. 2004, 11, 328–333. [Google Scholar] [CrossRef]

- Sluka, T.; Mokry, P. Feedback control of piezoelectric actuator elastic properties in a vibration isolation system. Ferroelectrics 2007, 351, 51–61. [Google Scholar] [CrossRef]

- Sluka, T.; Kodama, H.; Fukada, E.; Mory, P. Sound shielding by a piezoelectric membrane and a negative capacitor with feedback control. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2008, 55, 1859–1866. [Google Scholar] [CrossRef] [PubMed]

- Steiger, K.; Mokrý, P. Finite element analysis of the macro fiber composite actuator: Macroscopic elastic and piezoelectric properties and active control thereof by means of negative capacitance shunt circuit. Smart Mater. Struct. 2015, 24, 025026. [Google Scholar] [CrossRef]

- Davis, C.L.; Lesieutre, G.A.; Dosch, J.J. Tunable electrically shunted piezoceramic vibration absorber. In Proceedings of the SPIE 3045, Smart Structures and Materials 1997: Passive Damping and Isolation, San Diego, CA, USA, 3 March 1997. [Google Scholar]

- Cunefare, K.A.; De Rosa, S.; Sadegh, N.; Larson, G. State-switched absorber for semi-active structural control. J. Intell. Mater. Syst. Struct. 2000, 11, 300–310. [Google Scholar] [CrossRef]

- Clark, W.W. Vibration control with state-switched piezoelectric materials. J. Intell. Mater. Syst. Struct. 2000, 11, 263–271. [Google Scholar] [CrossRef]

- Corr, L.R.; Clark, W.W. A novel semi-active multi-modal vibration control law for a piezoceramic actuator. J. Vib. Acoust. 2003, 125, 214–222. [Google Scholar] [CrossRef]

- Qureshi, E.M.; Shen, X.; Chen, J. Vibration control laws via shunted piezoelectric transducers: A review. Int. J. Aeronaut. Space Sci. 2014, 15, 1–19. [Google Scholar] [CrossRef]

- Christopher Robert, K.; Jeffrey, K. Adaptive Synchronized Switch Damping on an Inductor: A Self-Tuning Switching Law. Smart Mater. Struct. 2016. acceped. [Google Scholar]

- Han, X.; Neubauer, M.; Wallaschek, J. Improved piezoelectric switch shunt damping technique using negative capacitance. J. Sound Vib. 2013, 332, 7–16. [Google Scholar] [CrossRef]

- Niederberger, D.; Morari, M.; Pietrzko, S.J. Adaptive resonant shunted piezoelectric devices for vibration suppression. In Proceedings of the SPIE 5056, Smart Structures and Materials 2003: Smart Structures and Integrated Systems, San Diego, CA, USA, 5 August 2003. [Google Scholar]

- Niederberger, D.; Fleming, A.; Moheimani, S.R.; Morari, M. Adaptive multi-mode resonant piezoelectric shunt damping. Smart Mater. Struct. 2004, 13, 1025. [Google Scholar] [CrossRef]

- McDaid, A.J.; Mace, B.R. A Robust Adaptive Tuned Vibration Absorber Using Semi-Passive Shunt Electronics. IEEE Trans. Ind. Electron. 2016, 63, 5069–5077. [Google Scholar] [CrossRef]

- Kodejska, M.; Mokry, P.; Linhart, V.; Vaclavik, J.; Sluka, T. Adaptive Vibration Suppression System: An Iterative Control Law for a Piezoelectric Actuator Shunted by a Negative Capacitor. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2012, 59, 2785–2796. [Google Scholar] [CrossRef] [PubMed]

- Gripp, J.A.B.; Góes, L.C.S.; Heuss, O.; Scinocca, F. An adaptive piezoelectric vibration absorber enhanced by a negative capacitance applied to a shell structure. Smart Mater. Struct. 2015, 24, 125017. [Google Scholar] [CrossRef]

- Ahmadian, M.; Jeric, K.M. On the application of shunted piezoceramics for increasing acoustic transmission loss in structures. J. Sound Vib. 2001, 243, 347–359. [Google Scholar] [CrossRef]

- Kim, J.; Lee, J.-K. Broadband transmission noise reduction of smart panels featuring piezoelectric shunt circuits and sound-absorbing material. J. Acoust. Soc. Am. 2002, 112, 990–998. [Google Scholar] [CrossRef] [PubMed]

- Fleming, A.J.; Niederberger, D.; Moheimani, S.O.R.; Morari, M. Control of Resonant Acoustic Sound Fields by Electrical Shunting of a Loudspeaker. IEEE Trans. Control Syst. Techol. 2007, 15, 689–703. [Google Scholar] [CrossRef]

- Kim, J.; Jung, Y.-C. Broadband noise reduction of piezoelectric smart panel featuring negative-capacitive- converter shunt circuit. J. Acoust. Soc. Am. 2006, 120, 2017–2025. [Google Scholar] [CrossRef]

- Kodama, H.; Date, M.; Yamamoto, K.; Fukada, E. A study of sound shielding control of curved piezoelectric sheets connected to negative capacitance circuits. J. Sound Vib. 2008, 311, 898–911. [Google Scholar] [CrossRef]

- Lissek, H.; Boulandet, R.; Fleury, R. Electroacoustic absorbers: Bridging the gap between shunt loudspeakers and active sound absorption. J. Acoust. Soc. Am. 2011, 129, 2968–2978. [Google Scholar] [CrossRef] [PubMed]

- Černík, M.; Mokrý, P. Sound reflection in an acoustic impedance tube terminated with a loudspeaker shunted by a negative impedance converter. Smart Mater. Struct. 2012, 21, 115016. [Google Scholar] [CrossRef]

- Zhang, Y.; Chan, Y.-J.; Huang, L. Thin broadband noise absorption through acoustic reactance control by electro-mechanical coupling without sensor. J. Acoust. Soc. Am. 2014, 135, 2738–2745. [Google Scholar] [CrossRef] [PubMed]

- Tao, J.; Jing, R.; Qiu, X. Sound absorption of a finite micro-perforated panel backed by a shunted loudspeaker. J. Acoust. Soc. Am. 2014, 135, 231–238. [Google Scholar] [CrossRef] [PubMed]

- Shen, W.; Zhu, S.; Zhu, H.; Xu, Y.-L. Electromagnetic energy harvesting from structural vibrations during earthquakes. Smart Struct. Syst. 2016, 18, 449–470. [Google Scholar] [CrossRef]

- Lesieutre, G.A.; Ottman, G.K.; Hofmann, H.F. Damping as a result of piezoelectric energy harvesting. J. Sound Vib. 2004, 269, 991–1001. [Google Scholar] [CrossRef]

- Renno, J.M.; Daqaq, M.F.; Inman, D.J. On the optimal energy harvesting from a vibration source. J. Sound Vib. 2009, 320, 386–405. [Google Scholar] [CrossRef]

- Wilhelm, J.; Rajamani, R. Methods for Multimodal Vibration Suppression and Energy Harvesting Using Piezoelectric Actuators. J. Vib. Acoust. 2009, 131, 011001. [Google Scholar] [CrossRef]

- Zhu, S.; Shen, W.-A.; Xu, Y.-L. Linear electromagnetic devices for vibration damping and energy harvesting: Modeling and testing. Eng. Struct. 2012, 34, 198–212. [Google Scholar] [CrossRef]

- Harne, R.L. Development and testing of a dynamic absorber with corrugated piezoelectric spring for vibration control and energy harvesting applications. Mech. Syst. Signal Process. 2013, 36, 604–617. [Google Scholar] [CrossRef]

- Zuo, L.; Cui, W. Dual-Functional Energy-Harvesting and Vibration Control: Electromagnetic Resonant Shunt Series Tuned Mass Dampers. J. Vib. Acoust. 2013, 135, 051018. [Google Scholar] [CrossRef] [PubMed]

- Vaclavik, J.; Mokry, P. Measurement of mechanical and electrical energy flows in the semiactive piezoelectric shunt damping system. J. Intell. Mater. Syst. Struct. 2012, 23, 527–533. [Google Scholar] [CrossRef]

- Vaclavik, J.; Kodejska, M.; Mokry, P. Wall-plug efficiency analysis of semi-active piezoelectric shunt damping systems. J. Vib. Control 2016, 22, 2582–2590. [Google Scholar] [CrossRef]

- Ottman, G.K.; Hofmann, H.F.; Bhatt, A.C.; Lesieutre, G.A. Adaptive piezoelectric energy harvesting circuit for wireless remote power supply. IEEE Trans. Power Electron. 2002, 17, 669–676. [Google Scholar] [CrossRef]

- Rahimi, A.; Zorlu, O.; Muhtaroglu, A.; Kulah, H. Fully Self-Powered Electromagnetic Energy Harvesting System With Highly Efficient Dual Rail Output. IEEE Sens. J. 2012, 12, 2287–2298. [Google Scholar] [CrossRef]

- Zhang, S.; Yan, B.; Luo, Y.; Miao, W.; Xu, M. An Enhanced Piezoelectric Vibration Energy Harvesting System with Macro Fiber Composite. Shock Vib. 2015, 2015, 916870. [Google Scholar] [CrossRef]

- Yan, B.; Zhang, S.; Zhang, X.; Wang, C.; Wu, C. Self-powered electromagnetic energy harvesting for the low power consumption electronics: Design and experiment. Int. J. Appl. Electromagn. Mech. 2017, 1–11. [Google Scholar] [CrossRef]

- Pérez-Díaz, J.; Valiente-Blanco, I.; Cristache, C. Z-Damper: A New Paradigm for Attenuation of Vibrations. Machines 2016, 4, 12. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, B.; Wang, K.; Hu, Z.; Wu, C.; Zhang, X. Shunt Damping Vibration Control Technology: A Review. Appl. Sci. 2017, 7, 494. https://doi.org/10.3390/app7050494

Yan B, Wang K, Hu Z, Wu C, Zhang X. Shunt Damping Vibration Control Technology: A Review. Applied Sciences. 2017; 7(5):494. https://doi.org/10.3390/app7050494

Chicago/Turabian StyleYan, Bo, Ke Wang, Zifan Hu, Chuanyu Wu, and Xinong Zhang. 2017. "Shunt Damping Vibration Control Technology: A Review" Applied Sciences 7, no. 5: 494. https://doi.org/10.3390/app7050494