3.1. Impact of Heat Exchanger Effectiveness on Cycle Performance

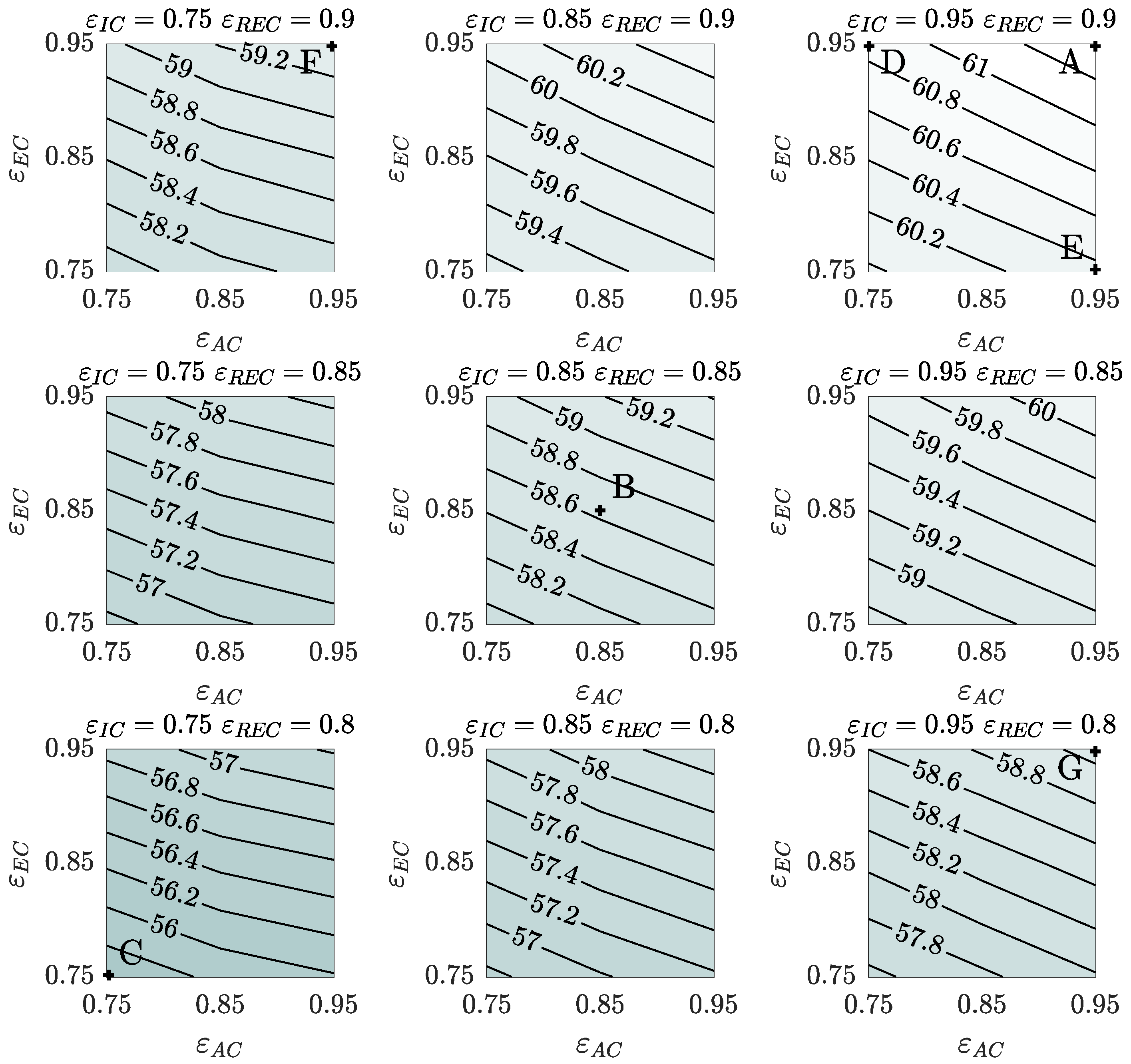

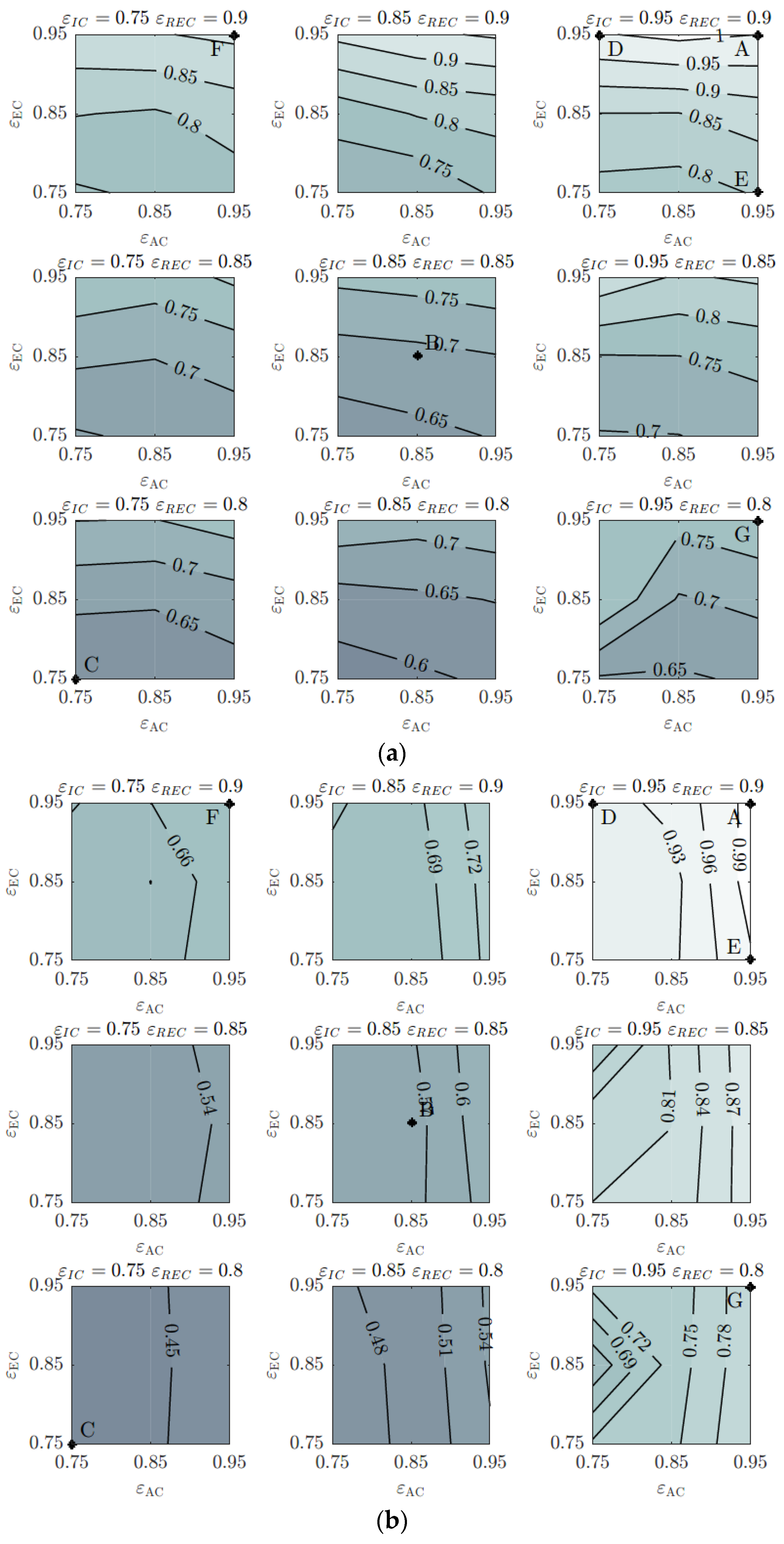

The impact of heat exchanger effectiveness on the cycle thermal efficiency is shown in

Figure 3, for constant

OPR of 40 and pinch temperature difference in the saturator of 5 K. The

x-axis and

y-axis of the contour plots are, respectively, the aftercooler and economizer effectiveness, and the contour lines show the estimated cycle thermal efficiency. Moving vertically and horizontally through the contour plots, the effectiveness of the recuperator and intercooler vary respectively. Therefore, the top-right point of the top-right contour corresponds to the cycle

shown in

Table 4.

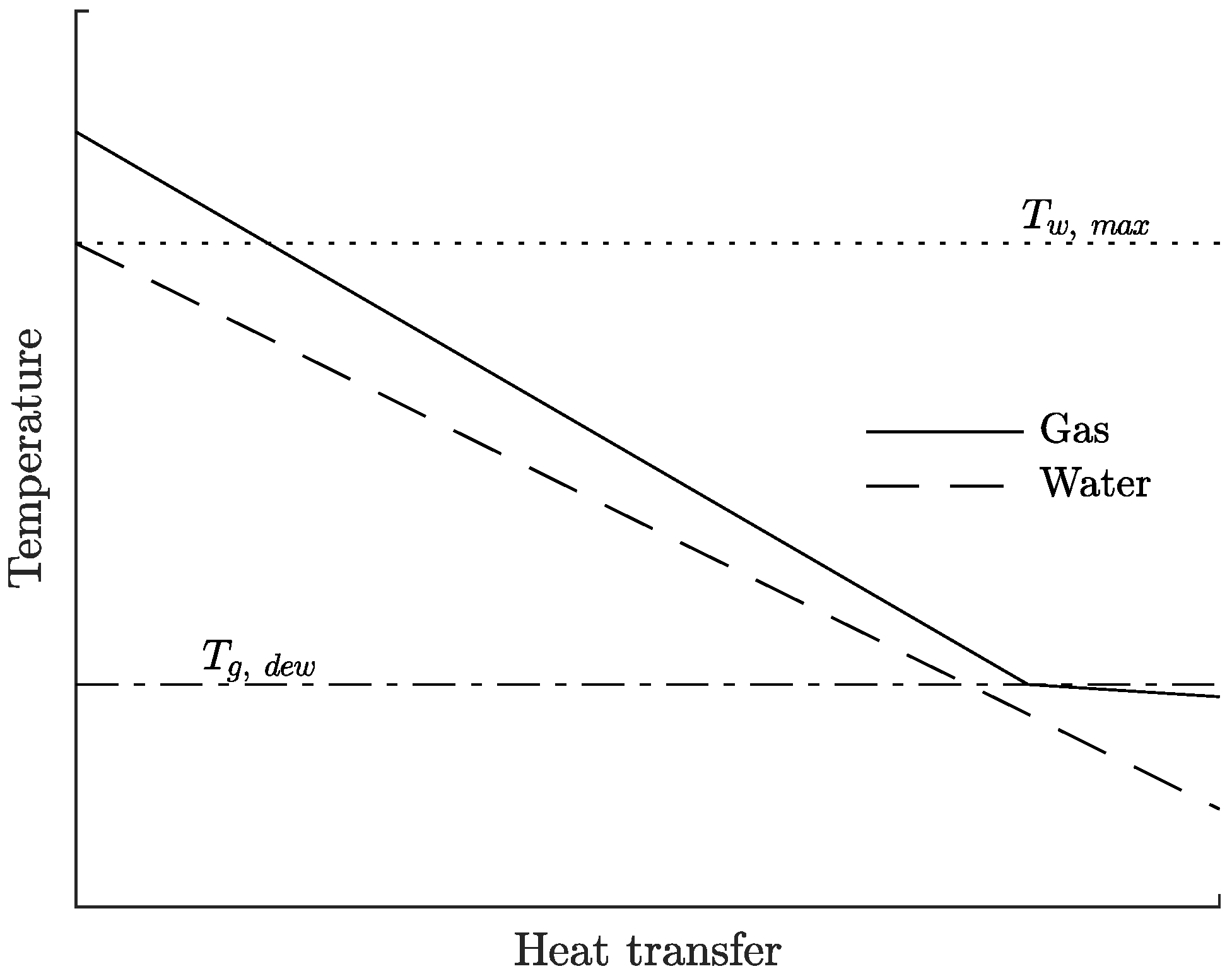

In all contours with intercooler effectiveness of 0.75 (left column of contours in

Figure 3), there is a change in in the variation rate of the thermal efficiency when the

falls below 0.85. This is due to the notably high value of aftercooler heat capacity ratio

= 0.95 for aftercooler effectiveness of 0.95 and 0.85, which it decreases to

= 0.64 when the effectiveness of the aftercooler is 0.75, in order for the outlet water temperature to remain within the limits imposed to avoid steaming in the saturator (

).

The dependency between the thermal efficiency and the heat exchanger effectiveness remains linear when changing the effectiveness of all heat exchangers together. The comparison between cycles and highlights the impact of the recuperator effectiveness and results in a reduction of 2.28 pp in cycle thermal efficiency when recuperator effectiveness becomes 0.8 from 0.9. The impact of intercooler effectiveness is shown by comparing cycle against . A reduction in from 0.95 to 0.75 causes a reduction of 2 pp in the cycle thermal efficiency. The impact of the aftercooler and economizer is shown by the comparison of the cycle with the cycle , and of with the cycle , with, respectively, a reduction of 0.48 pp and 1 pp on the thermal efficiency. The combined effect of the reduction in effectiveness of all the heat exchangers is shown by the comparison of the cycle with the cycle and with, respectively, a drop of 2.7 pp and 5.5 pp in thermal efficiency.

Figure 4 shows the effect of the heat exchanger effectiveness on the absolute humidity at the inlet of the combustion chamber for constant values of

OPR (40) and saturator pinch temperature difference (5 K). The maximum absolute humidity in the design space is 24.6%, which ensures stable combustion in a modern combustion chamber as discussed by Göke in [

30].

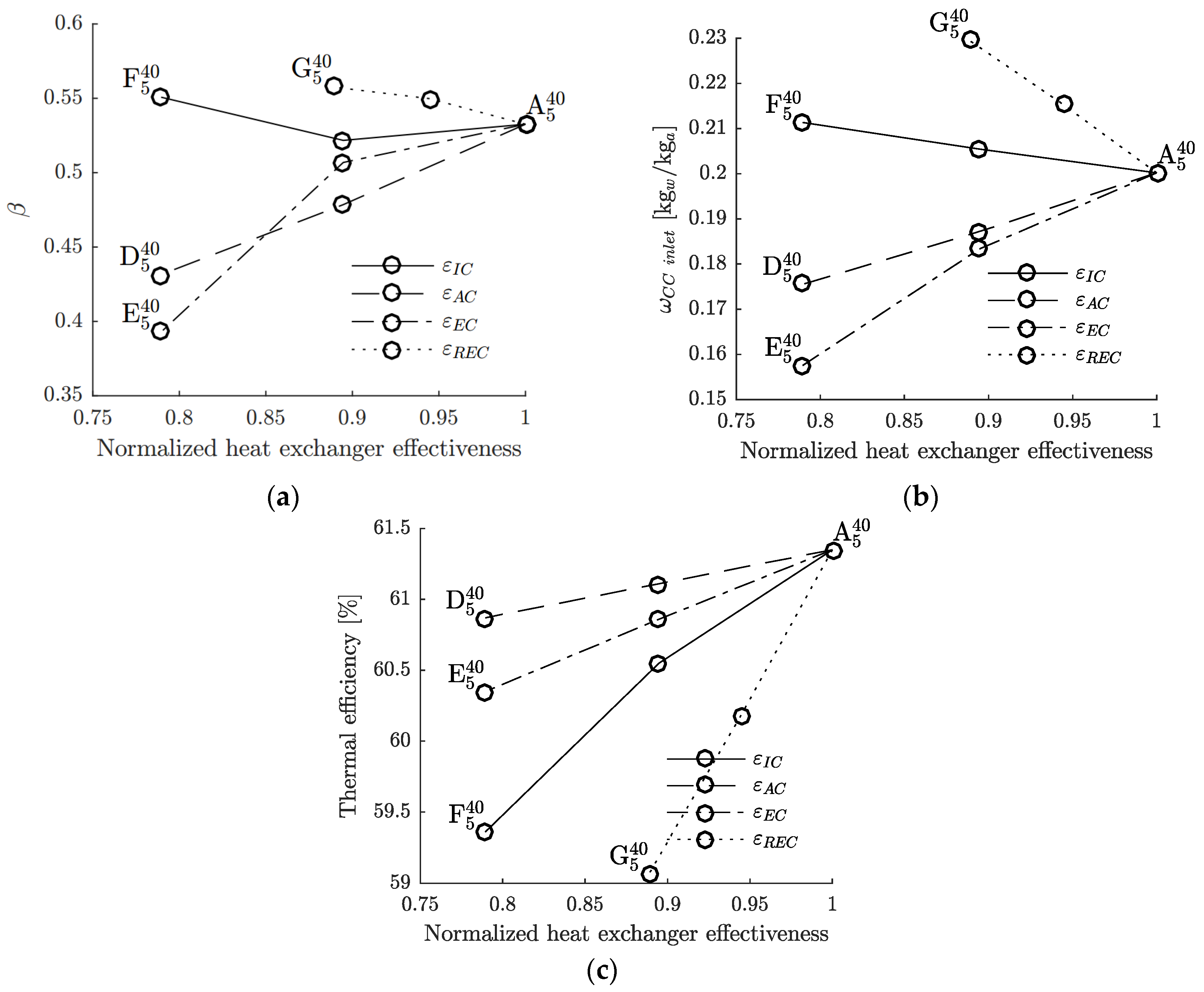

The impact of heat exchanger effectiveness on the optimized saturator bypass ratio, on the consequent absolute humidity (

ω) at the inlet of the combustion chamber and on cycle thermal efficiency is illustrated in

Figure 5 for constant

OPR = 40 and

= 5 K.

The reduction in effectiveness of the aftercooler and economizer has an impact on the amount of heat and mass transfer that occurs in the saturator and, therefore, on the thermal efficiency of the cycle. For an aftercooler effectiveness of 0.75 (

→

—see

Figure 5), the water mass flow in the saturator is reduced by 0.5% while a 1.2% reduction is observed in its temperature (

across the range). The temperature of the gas at the inlet of the saturator increases by 13.8%, reducing the temperature leap in the saturator and, therefore, the heat and mass transfer that occurs within the device. Hence, the fraction of gas that bypasses the saturator (

) decreases by 19% (

Figure 5a) and the humidity at the inlet of the combustion chamber also decreases from 20% to 18% (

Figure 5b). The reduction in heat recuperated at low temperature in the cycle, due to the aftercooler, affects the thermal efficiency of the cycle, with a 0.48 pp reduction between cycles

and

(

Figure 5c).

When the economizer effectiveness reduces from 0.95 to 0.75 (

→

—see

Figure 5), the mass flow of the water heated in the heat exchanger falls by 22%, whereas the water outlet temperature falls only by 0.3%—i.e.,

increases. As for the aftercooler, the saturator bypass

decreases by 26% as shown in (

Figure 5a) and the humidity at the inlet of the combustion chamber decreases from 20% to 15.7% (

Figure 5b). This reduction in heat recuperated in the cycle at low temperature, as for the aftercooler, entails a decrease in thermal efficiency of 1 pp between cycles

and

(

Figure 5c).

The effectiveness of the intercooler affects the amount of waste heat that is recuperated both at high and low temperatures within the cycle. When

becomes 0.75 from 0.95 (

→

—see

Figure 5), the total amount of water injected in the saturator increases by 10% due to the increase of heat available in the gas at the inlet of the economizer—i.e., the temperature at the outlet of the recuperator on the hot side increases due to the increase in temperature of the gas at the inlet of the cold side. Therefore, the mass flow ratio of gas that bypasses the saturator decreases by 2% (

Figure 5a) and the humidity at the inlet of the combustion chamber increases by 5% (

Figure 5b). This highlights the importance of the intercooling process, since it not only reduces the compression work required but also the heat extracted from the gas between the two compressors is partly recovered in the saturator and not rejected entirely as in most common intercooled gas turbines. Thus, the reduction of the effectiveness of the intercooler from 0.95 to 0.75 entails a reduction of 2 pp in the cycle thermal efficiency (

→

—see

Figure 5c).

The recuperator is the heat exchanger whose effectiveness change has the most severe effects on the thermal efficiency of the cycle, with a reduction of 2.28 pp in thermal efficiency when it is reduced to 0.8 from 0.9 (

→

—see

Figure 5), due to the reduction of high quality heat recovery—i.e., heat recovery at high temperature—within the cycle. Nevertheless, this reduction in recuperator effectiveness results in higher enthalpy gas at the inlet of the economizer and entails 22% higher amount of heat transfer in the latter heat exchanger. Therefore, the water mass flow injected into the saturator increases by 10%, the mass flow ratio of gas that bypasses the saturator decreases—i.e.,

increases by 4.7% as shown in

Figure 5a—and the humidity at the inlet of the combustion chamber increases from 20% to 23% (

Figure 5b).

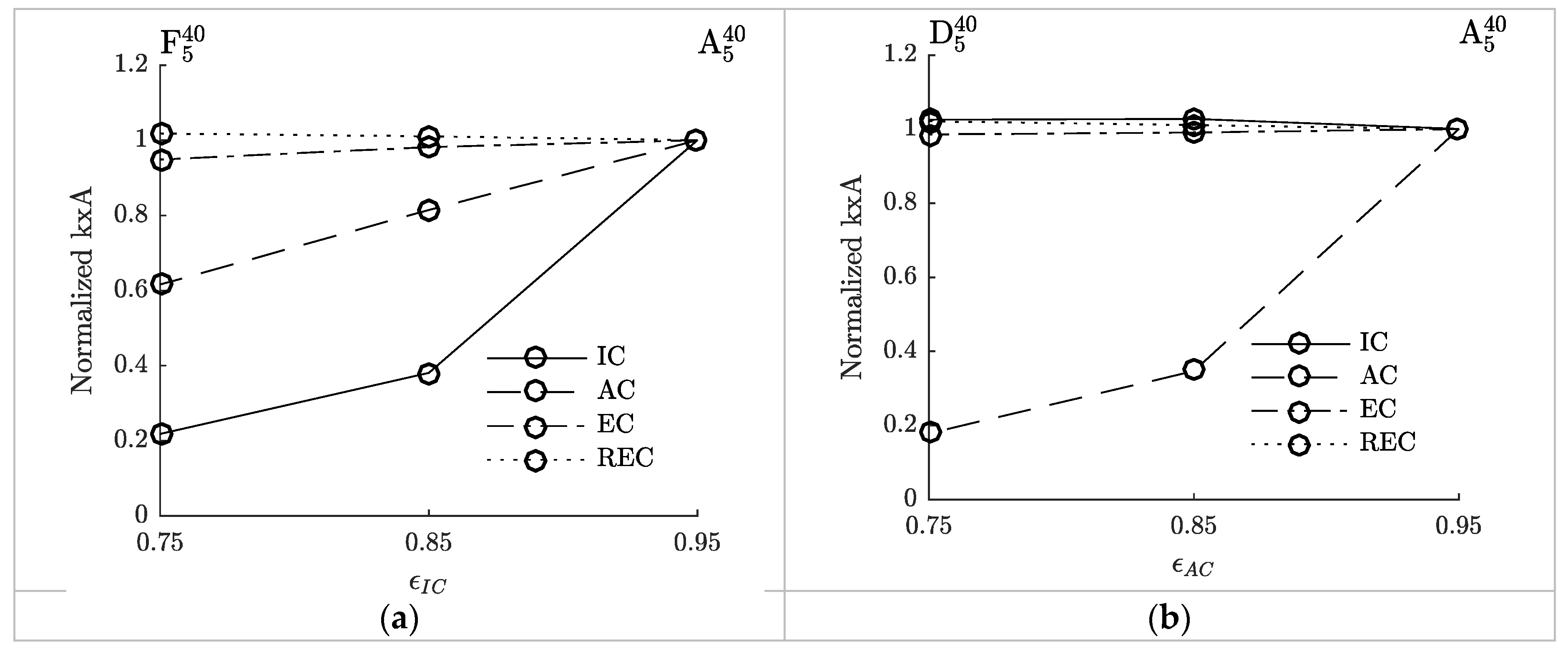

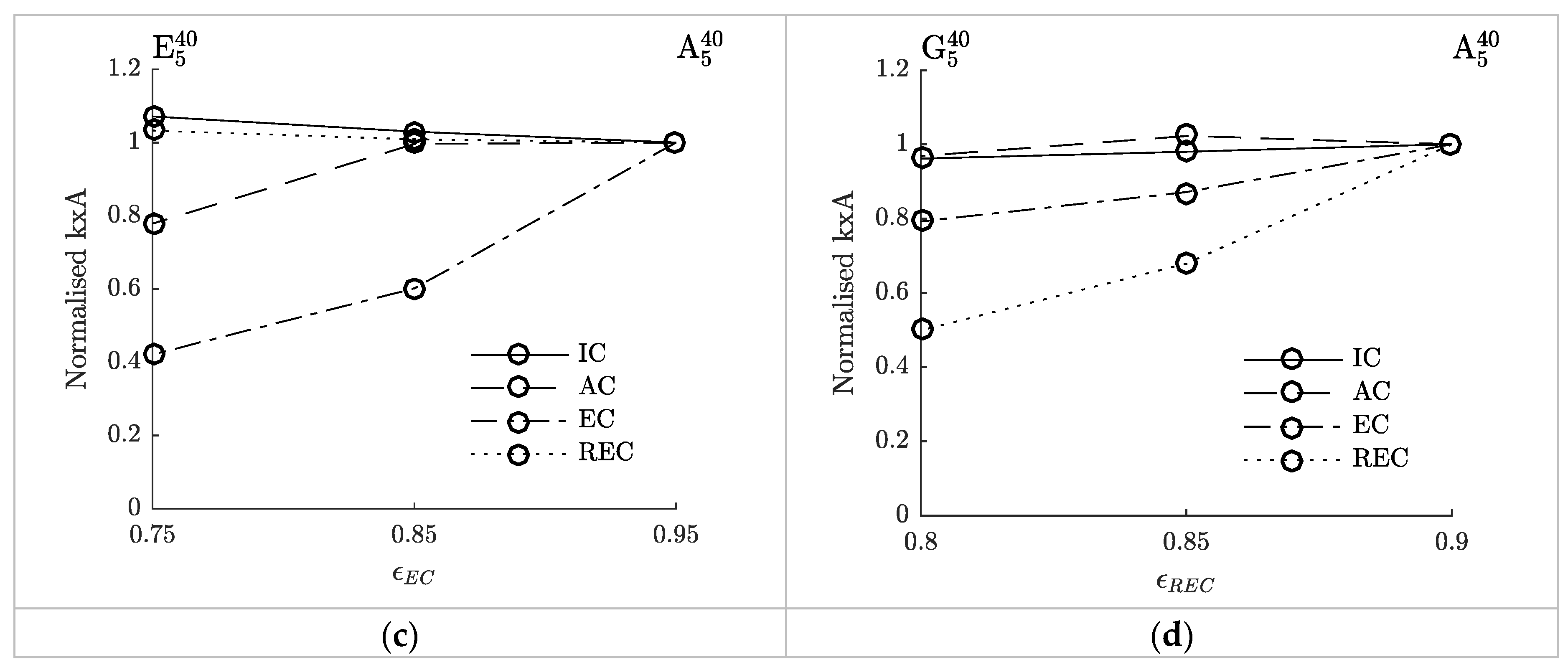

Figure 6 shows the impact of the heat exchanger effectiveness on the heat transfer coefficient times the heat transfer area (

k ×

A) of each heat exchanger for constant

OPR (40) and saturator pinch temperature difference (5 K). For similar inlet conditions, the variation in

k ×

A of a heat exchanger is a useful parameter to evaluate the impact of the of the cycle “design vector” on the variation in size independently from the design choices in sizing the heat exchanger. Nonetheless,

k ×

A should not be used to evaluate the differences in size between intercooler, aftercooler, economizer and recuperator due to the different inlet conditions of the two flows—i.e., different heat transfer coefficients. The values of

k ×

A for each heat exchanger are normalized using the values of the reference cycle

which is reported in

Table 5.

The heat exchangers that are mostly affected by the reduction in effectiveness are the intercooler and aftercooler, with a reduction of

k ×

A respectively of 79% (

→

—see

Figure 6a) and of 82% (

→

—see

Figure 6b) in relative terms when reducing the effectiveness of the latter from 0.95 to 0.75.

The variation of effectiveness of a heat exchanger, however, has a knock-on effect on the

k ×

A of the remaining heat exchangers. The aftercooler

k ×

A is strongly affected by the variation of the intercooler and economizer effectiveness with a 38.5% and 22% reduction when reducing

and

become 0.75 from 0.95 (

→

in

Figure 6a and

→

Figure 6c). In addition, the

k ×

A of the economizer is strongly affected by the variation of the effectiveness of the recuperator (

→

) with a reduction of 21%. No knock-on effect on the recuperator and intercooler

k ×

A was found by effectiveness changes of the rest of the heat exchangers.

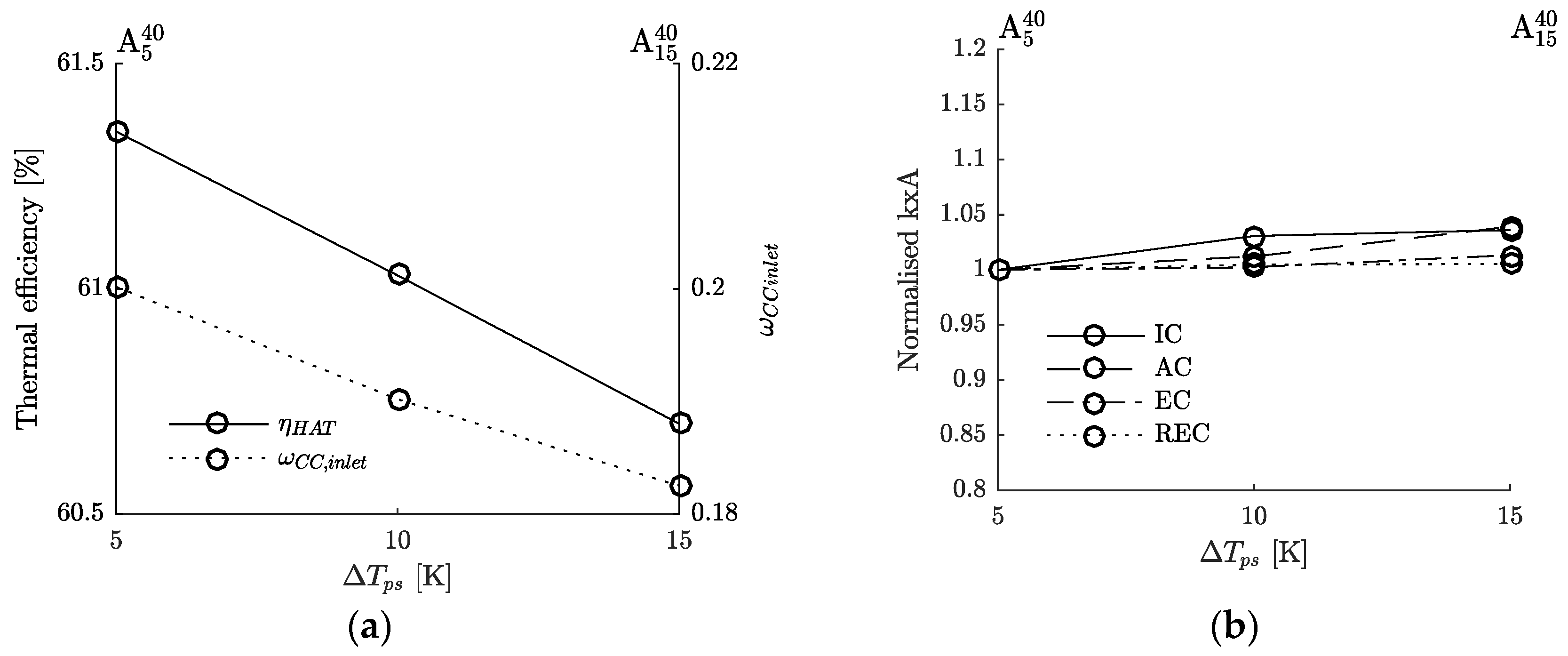

The increase of the saturator pinch temperature difference

from 5 K to 15 K (

→

) has a linear effect on the thermal efficiency and on the absolute humidity of the air at the inlet of the combustion chamber (

Figure 7a), with a reduction in thermal efficiency of 0.64 pp from the baseline cycle. The

k ×

A of all heat exchangers are not significantly affected by the pinch temperature difference in the saturator (

Figure 7b) with a maximum increase of 4% in intercooler

k ×

A for

= 15 K. The increases in

k ×

A (cycle

→

) are attributed to the 3.2% higher gas mass flow requirement to produce the prescribed power output of 40 MW triggered by the lower water content in the hot section of the power plant.

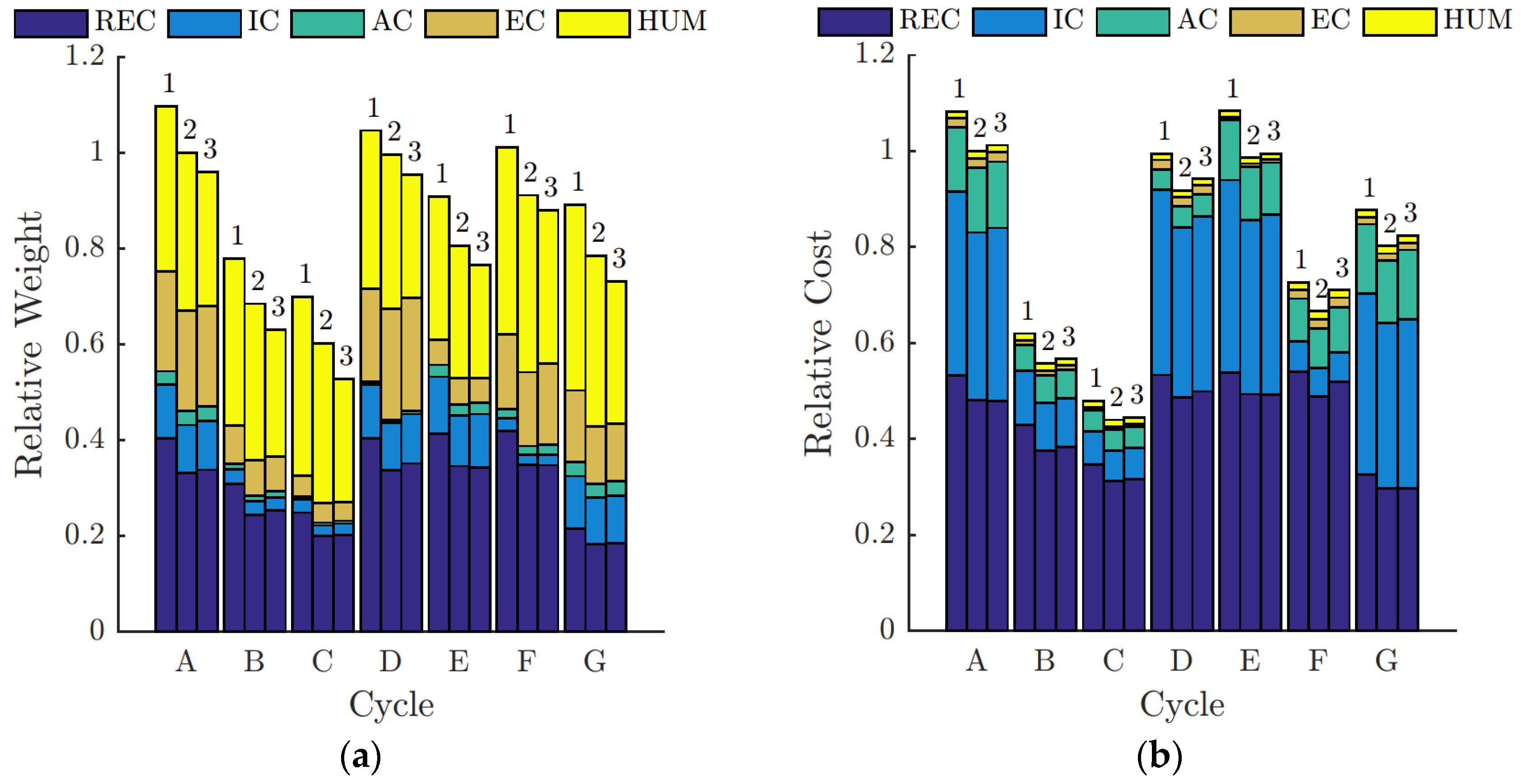

3.3. Heat Exchanger Size and Cost Analysis

The breakdown of the total weight and cost for the heat exchanger configurations are highlighted in

Figure 9. Cycles

,

, and

(see

Table 3) show the variation when the effectiveness of all heat exchangers vary together. On the other hand, cycles

,

,

, and

show the effect of reducing the technology level of one heat exchanger at a time. The reference cycle (

) has been used to normalize the weight and cost of the components. The total reference weight of all heat exchangers is estimated up to 47.76 tones, whereas the reference cost estimate is 4.2 m USD. These estimates are broadly in accordance with the cost estimates previously presented by Jonsson and Yan [

1] for a power plant of 55.1 MW (3.8 m USD updated to 2015). It is important to highlight that the thermal efficiency achieved by the reference cycle (61.4%) is 11.9 pp higher than the one reported by Jonsson and Yan in [

1], which partially justifies the discrepancy in the heat exchanger acquisition cost estimate.

For cycle

, the recuperator is the heaviest component—33.12% of the total weight—followed by the humidifier, the economizer, the intercooler, and finally the aftercooler—with relative contributions to the overall power plant weight of 33.01%, 20.96%, 9.98%, 2.94%, respectively. Although the economizer and the humidifier are among the heaviest components, their contribution to the overall cost of the system was found to be approximately 3% (

Figure 9). In terms of heat exchanger cost, the recuperator is the most expensive heat exchanger—48.11% of the total cost, followed by the intercooler, the aftercooler, the economizer, and finally the saturator—with relative contributions to the overall cycle cost of 34.95%, 13.43%, 1.99%, and 1.52%, respectively.

Reducing the

OPR from 40 to 30 increases the total weight across a range between 5% and 10% depending upon the cycle technology level (

Figure 9a), and the total cost by 8% in all cases (

Figure 9b). The observed increment in heat exchanger weight is primarily driven by the recuperator and the economizer due to the excess of available heat downstream the power turbine that needs to be managed by these two components whose size is further increased by the higher flow rate requirement of this low

OPR cycle. As a result, the size increase of the recuperator primarily drives the increase in the estimated acquisition cost of the system. It is worth noting that when the

OPR becomes 30 from 40, the humidifier is 7% less expensive, driven by the need for thinner shell walls. However, an increase in weight is observed as the required material for packing increases by 12% compared to the baseline case to facilitate the larger enthalpy flux. Finally, although the reduction of the

OPR to 30 increases the weight and the cost of the components, it is associated with a reduction in the overall thermal efficiency of the system by 0.7 pp.

When the becomes 15 K from 5 K, the size, and, consequently, the weight and cost of all the heat exchangers increases due to the demand of a higher mass flow to achieve the required power output. The saturator is the only component whose weight and cost reduce as it becomes shorter. Except for , which increases its total weight compared with , the reduction in the weight of the humidifier outbalances the increment in the weight of the heat exchangers, but not the increment in the cost. When the pinch point temperature is increased to 15 K, the total acquisition cost of the system marginally increases by around 3% while the thermal efficiency falls by approximately 0.45 pp.

The comparison of cycles

,

, and

(

Figure 9), where the effectiveness of all the heat exchangers is reduced at the same time, shows the exponential relationship between the technology level of the components, and their weight and cost. When the effectiveness of the heat exchangers increases from 0.75 to 0.85 (

→

), the total weight increases by 14% and the total cost by 28%. For a further effectiveness increase to 0.95 (

→

), the weight rises by 46% and the cost by 80% with respect to the baseline cycle. On the other hand, the thermal efficiency shows a quasi-linear correlation with the cycle design parameters. From

to

the efficiency rises by 2.8 pp, and from

to

an increase of 2.7 pp is observed (

Figure 3).

Considering each heat exchanger separately, between cycles and , the intercooler is the component that undergoes the largest variation in weight, manifesting a reduction of 77%. The economizer shows a reduction of 65% with regards to its reference cost, followed by the aftercooler with a reduction of 60%, and, finally, the recuperator with a reduction of 40%. On the other hand, the intercooler is the component that suffers the largest reduction in cost—82% of its reference cost, followed by the economizer, the aftercooler, and the recuperator—70%, 67%, and 35%, respectively. This demonstrates that the variations in the total weight of the heat exchangers and the variations in cost are linearly related, as the changes in cost are directly correlated with the variations in weight of each component.

Moreover, when comparing cycles

,

,

, and

with

, it can be seen that the reduction of the technology level of a heat exchanger has a knock-on effect on the remaining heat exchangers of the system (see

Figure 9). The aftercooler is the heat exchanger that experiences the largest reduction in weight and cost—88% and 87%, respectively. In addition, both the weight and cost of the aftercooler are cut by 39% when the effectiveness of the intercooler is reduced from 0.95 to 0.75 (

→

). However, both the weight and cost of the aftercooler are cut by 39% and 17%, respectively, when the effectiveness of the economizer is reduced from 0.95 to 0.75 (

→

).

The weight and cost of the economizer is reduced by 43% and 14%, respectively, when the recuperator effectiveness is changed from 0.9 to 0.8 (→). Hence, the design of the power plant must account for the impact of the technology level of one of the components on the design, cost, and weight of the remaining heat exchangers.

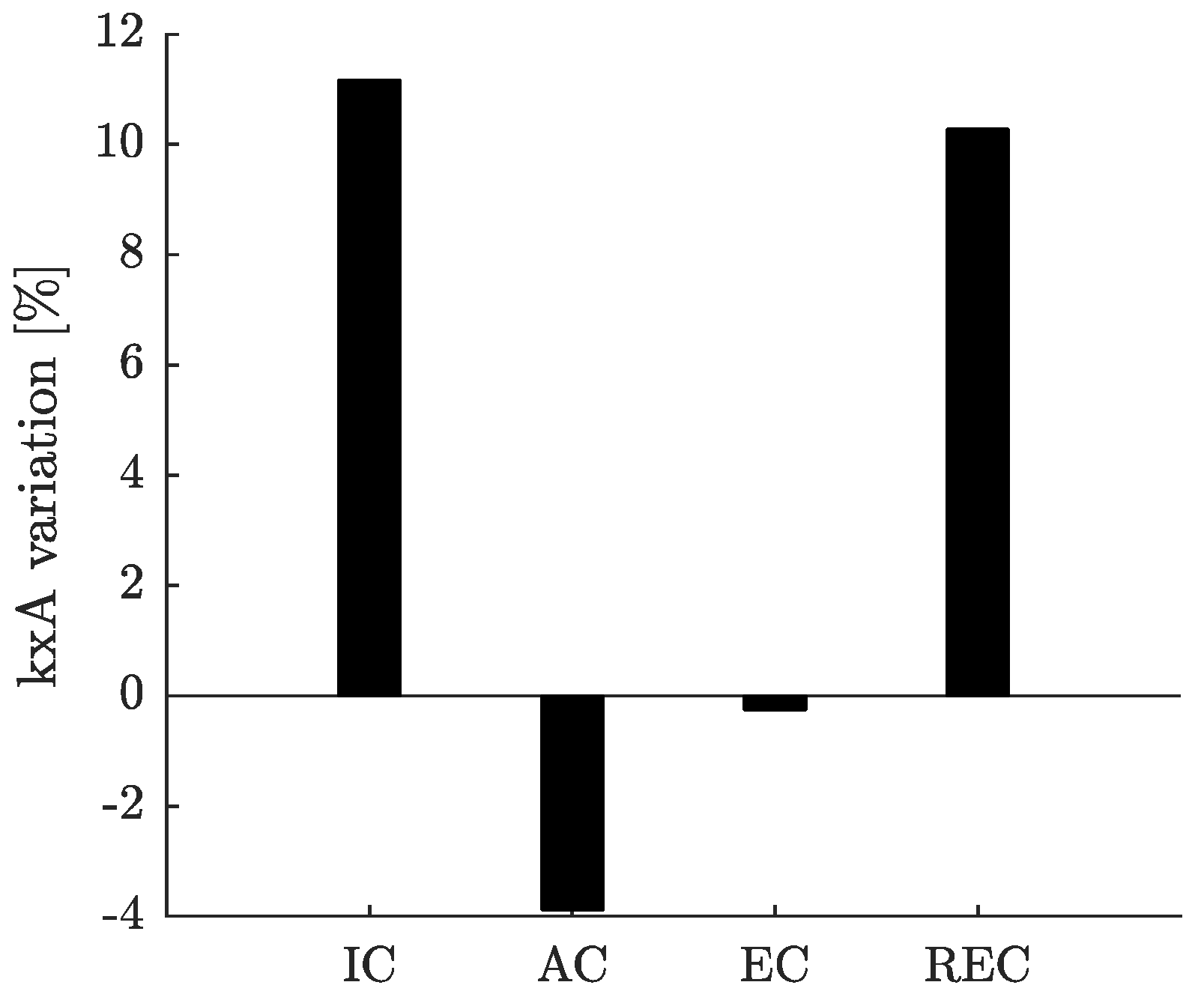

The overall system estimated acquisition cost and weight is shown in

Figure 10 normalized against the baseline cycle

metrics. In terms of total weight, the change produced by the economizer and the recuperator—20% and 22% of the reference weight, respectively—is an order of magnitude higher than the changes produced by the intercooler, or the aftercooler—9%, and 1%, respectively. On the other hand, the changes produced by the intercooler, the recuperator, and the aftercooler—34%, 20%, and 8% of the reference cost, respectively—are one order of magnitude higher than the ones the economizer can create which is around 2%. In addition, from the contours illustrated in

Figure 3 and

Figure 10b, it can be demonstrated that the most efficient way to reduce the total cost of the heat exchangers is to reduce the effectiveness of the aftercooler. The ratio of the percentage variation in cost to the variation in thermal efficiency

is 17—i.e., the cost drops by 17% per percentage point drop of thermal efficiency, whereas, when reducing the effectiveness of the intercooler, recuperator and economizer, these ratios become 16, 9 and 1, respectively.