Study of the Preparation and Dielectric Property of PP/SMA/PVDF Blend Material

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of PP/PVDF and PP/SMA/PVDF Multiple Blends of Each Composition

2.3. Instrumental Analysis

3. Result and Discussion

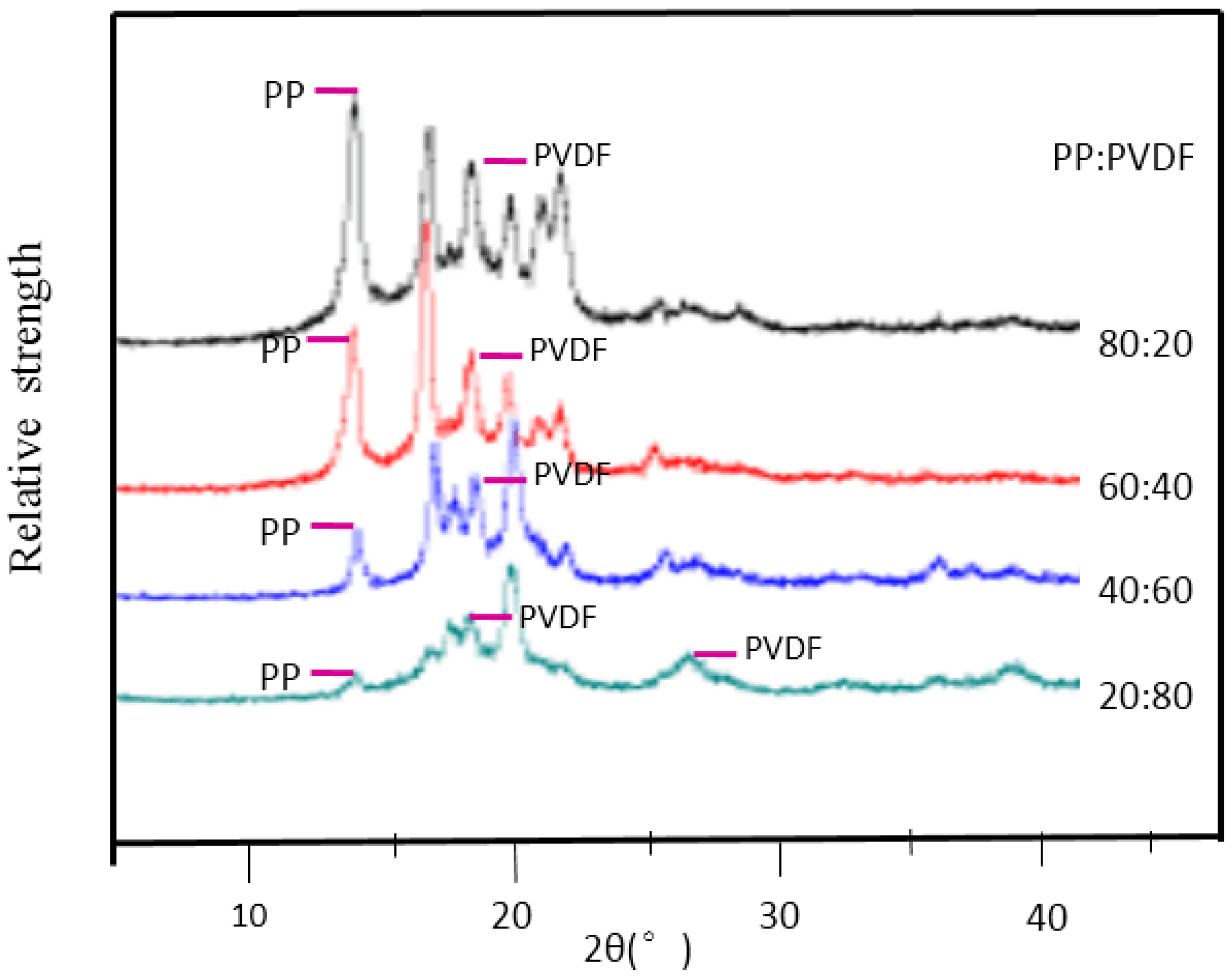

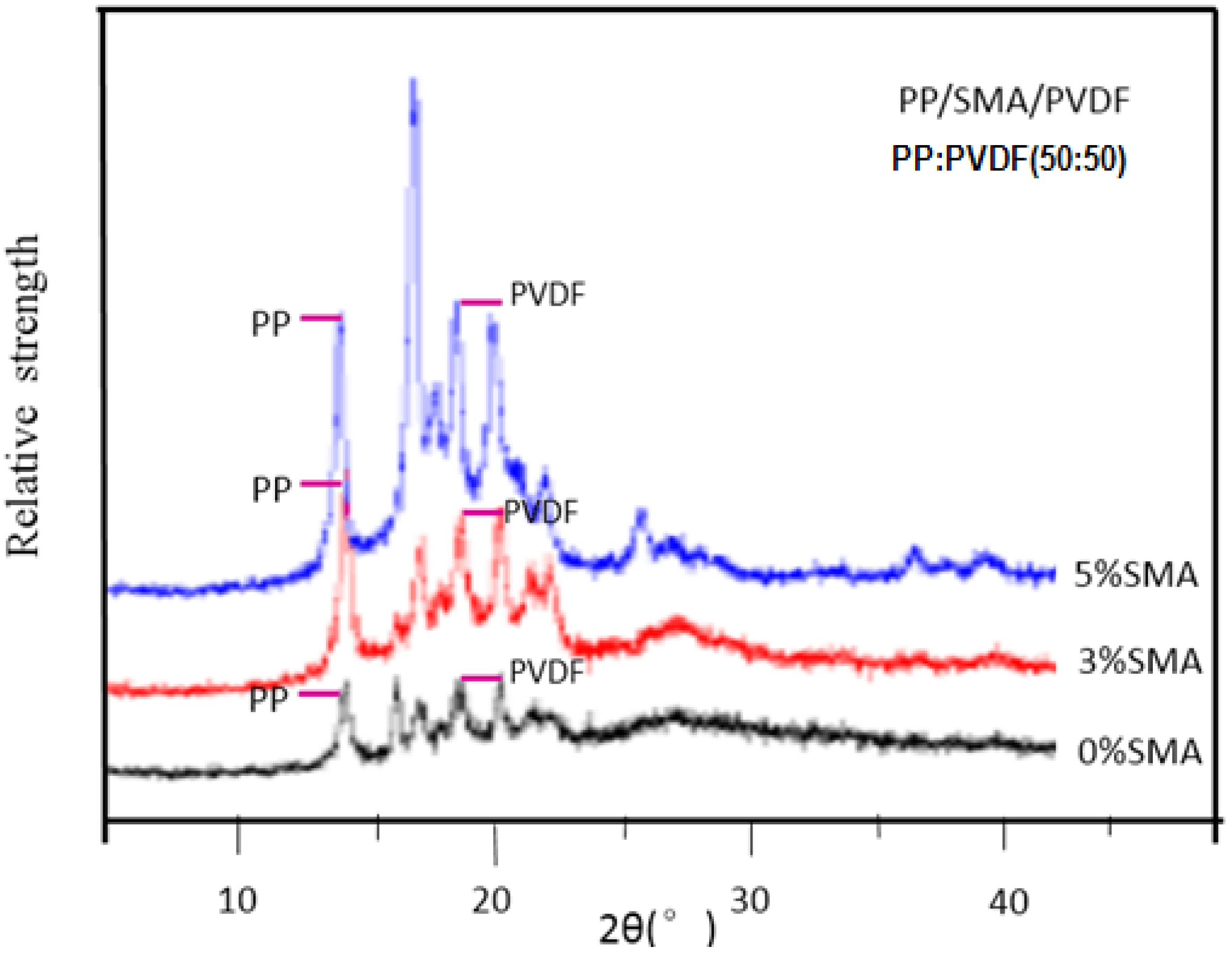

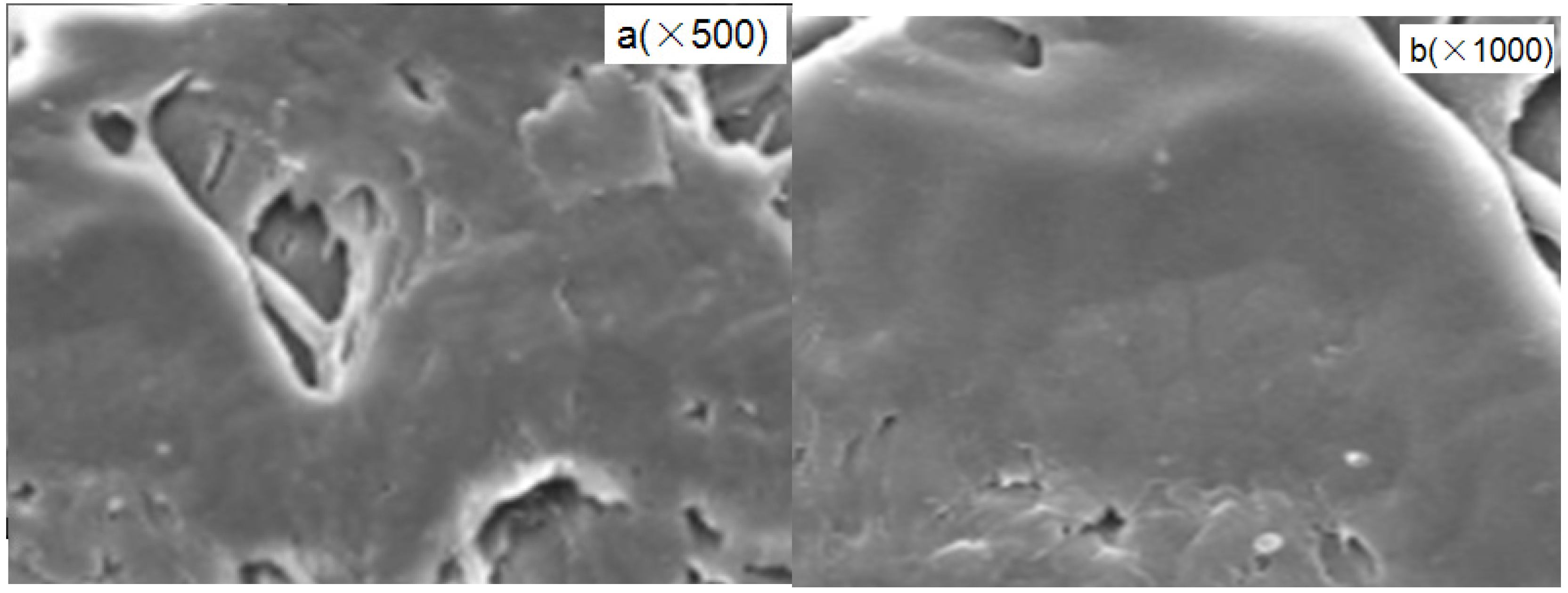

3.1. Structure Analysis

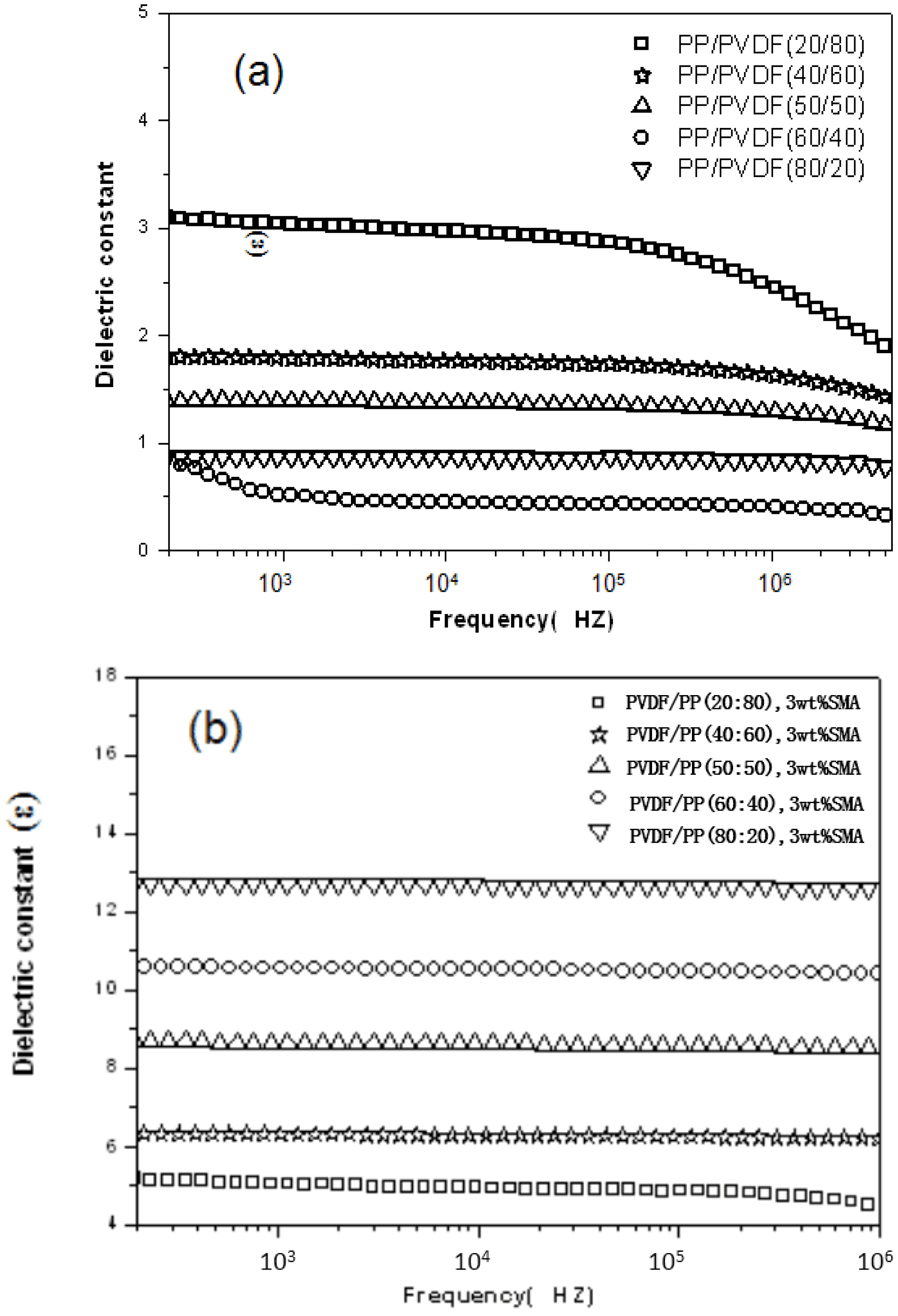

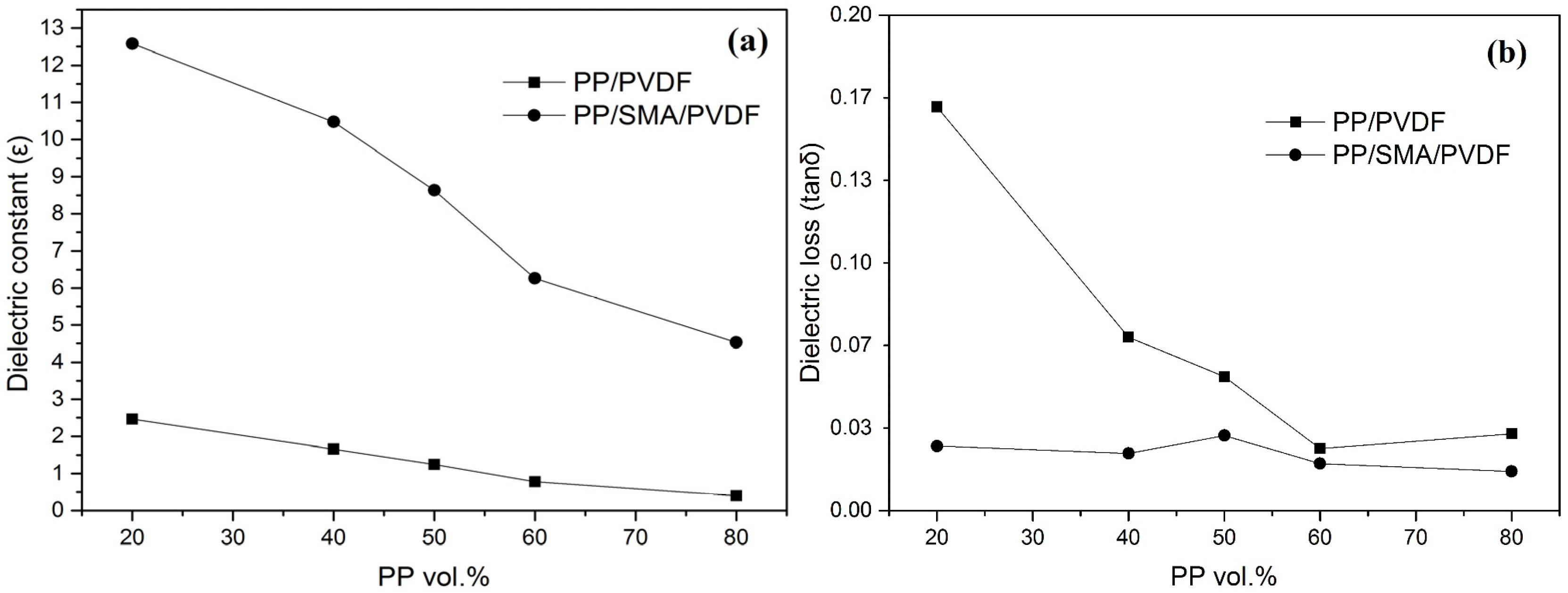

3.2. Dielectric Properties

4. Conclusions

Acknowledgment

Author Contributions

Conflicts of Interest

References

- Zhang, Q.M.; Li, H.F.; Poh, M. An all organic composite actuator material with a high dielectric constant. Nature 2002, 419, 284–287. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Pei, J.Z. High dielectric performance of polyamide 11/poly(vinylidene fluoride) blend films induced by interfacial glycidyl methacrylate. Polym. Sci. 2015, 57, 792–798. [Google Scholar] [CrossRef]

- Zhu, G.M.; Xin, W.L. Present status of polymer blending. Modif. Plast. Sci. Technol. 2002, 2, 42–46. [Google Scholar]

- Li, R.; Wang, C.C.; Wang, P.Z.; Pei, J.Z. Preparation of a novel flow improver and its viscosity-reducing effect on bitumen. Fuel 2016, 181, 935–941. [Google Scholar] [CrossRef]

- Dang, Z.M.; Zhang, Y.H.; Tjong, S.C. Dependence of dielectric behavior on the physical property of fillers in the polymer matrix composites. Synth. Met. 2004, 146, 79–84. [Google Scholar] [CrossRef]

- Scaccabarozzi, A.D.; Stingelin, N. Semiconducting: Insulating polymer blends for optoelectronic applications—A review of recent advances. J. Mater. Chem. A 2014, 2, 10818–10824. [Google Scholar] [CrossRef]

- Houghton, T.; Vanjaria, J.; Yu, H. Conductive and stretchable silver-polymer blend for electronic applications. In Proceedings of the Electronic Components and Technology Conference, Las Vegas, NV, USA, 8 August 2016. [Google Scholar]

- Li, R.; Xiong, C.X.; Kuang, D.L.; Dong, L.J.; Lei, Y.A. Polyamide 11/Poly(vinylidene fluoride) blends as novel flexible materials for capacitors. Macromol. Rapid Commun. 2008, 29, 1449–1454. [Google Scholar] [CrossRef]

- Kuang, D.L.; Li, R.; Pei, J.Z. Polyamide 11/poly(vinylidene fluoride)/vinyl acetate maleic anhydride copolymer as novel blends flexible materials for capacitors. Polymers 2014, 6, 2146–2156. [Google Scholar] [CrossRef]

- Li, R.; Chen, Z.X.; Pei, J.Z. High dielectric performance of polyamide 66/poly(vinylidenefluoride) flexible blends induced by interfacial copolymer for capacitors. Polymers 2016, 8, 2. [Google Scholar] [CrossRef]

- Wang, J.W.; Wang, Y.; Wang, F.; Li, S.Q. A large enhancement in dielectric properties of poly(vinylidene fluoride) based all-organic nanocomposite. Polymers 2009, 50, 679–684. [Google Scholar] [CrossRef]

- Zhao, X.B.; Du, L. Compatibility and phase separation of polymer blends. Chin. Polym. Bull. 2001, 4, 75–80. [Google Scholar]

- Murayama, N.; Nakamura, K.; Obara, H.; Obara, H.; Segawa, M. The strong piezoelectricity in polyvinylidenefluroide (PVDF). Ultrasonics 1976, 14, 15–24. [Google Scholar] [CrossRef]

- Alcock, B.; Cabrera, N.O.; Barkoula, N.M.; Segawa, M. The mechanical properties of unidirectional all-polypropylene composites. Compos. Part A 2006, 37, 716–726. [Google Scholar] [CrossRef]

- Dang, Z.M.; Yan, W.T.; Xu, H.P. Novel high-dielectric-permittivity poly(vinylidene fluoride)/polypropylene blend composites: The influence of the poly(vinylidene fluoride) concentration and compatibilizer. J. Appl. Polym. Sci. 2007, 105, 3649–3655. [Google Scholar] [CrossRef]

- Zhao, J.; Yin, X.; Shi, J.; Zhao, X.D.; Wang, X.Y. Effect of the mixing on the dielectric constant of poly(vinylidene fluoride)/isotactic polypropylene blends. Sci. Adv. Mater. 2013, 5, 505–511. [Google Scholar] [CrossRef]

- Yuan, X.; Chung, T.C. Cross-linking effect on dielectric properties of polypropylene thin films and applications in electric energy storage. Appl. Phys. Lett. 2011. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Pei, J.; Li, R. Study of the Preparation and Dielectric Property of PP/SMA/PVDF Blend Material. Appl. Sci. 2017, 7, 389. https://doi.org/10.3390/app7040389

Chen Z, Pei J, Li R. Study of the Preparation and Dielectric Property of PP/SMA/PVDF Blend Material. Applied Sciences. 2017; 7(4):389. https://doi.org/10.3390/app7040389

Chicago/Turabian StyleChen, Zixuan, Jianzhong Pei, and Rui Li. 2017. "Study of the Preparation and Dielectric Property of PP/SMA/PVDF Blend Material" Applied Sciences 7, no. 4: 389. https://doi.org/10.3390/app7040389