Gear Wear Process Monitoring Using a Sideband Estimator Based on Modulation Signal Bispectrum

Abstract

:1. Introduction

2. Theoretical Basis for Gear Wear Monitoring

2.1. Gear Vibration Signal Model for Tooth Wear

2.2. Modulation Signal Bispectrum-based Sideband Estimation

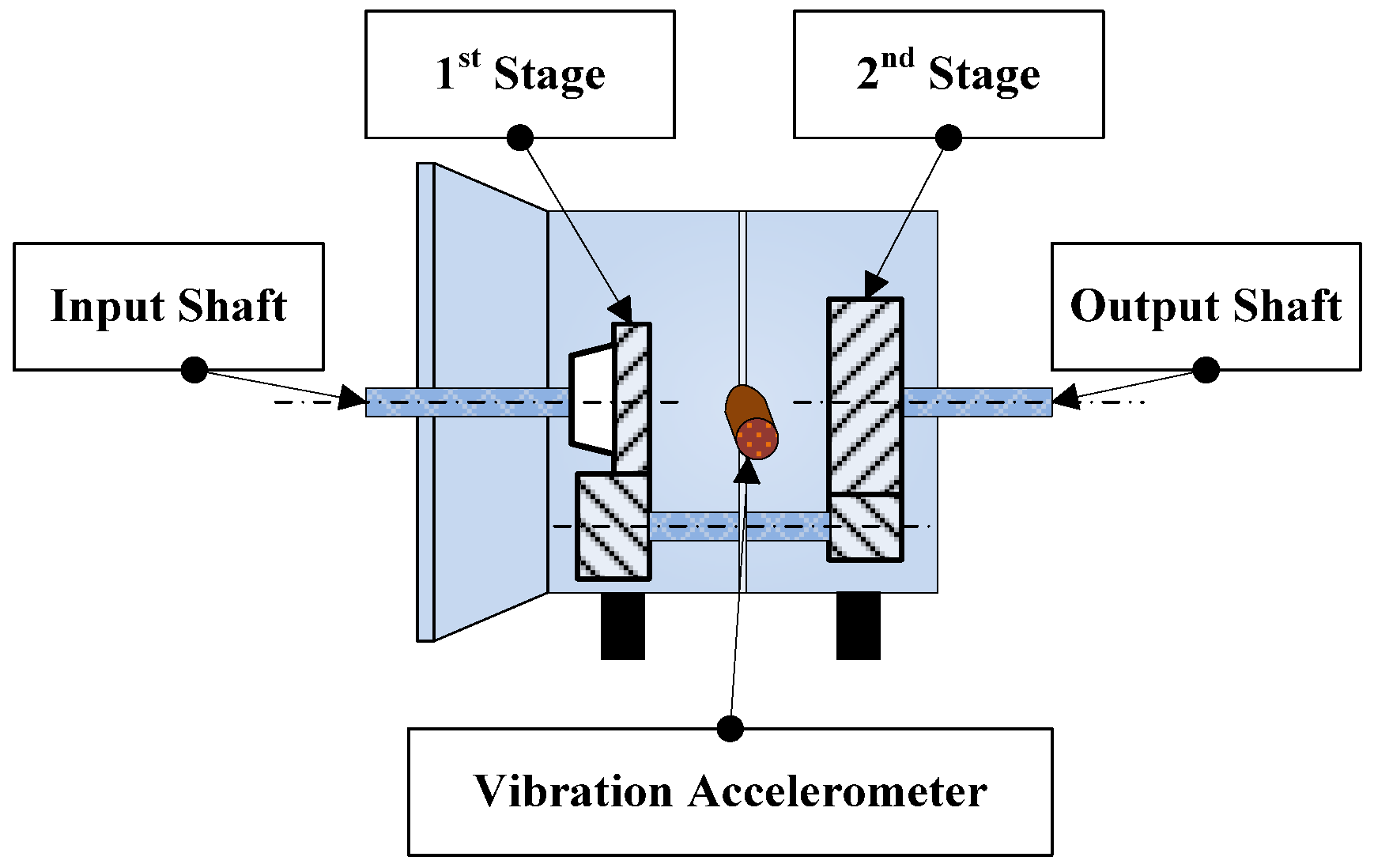

3. Experiment Setup and Procedure

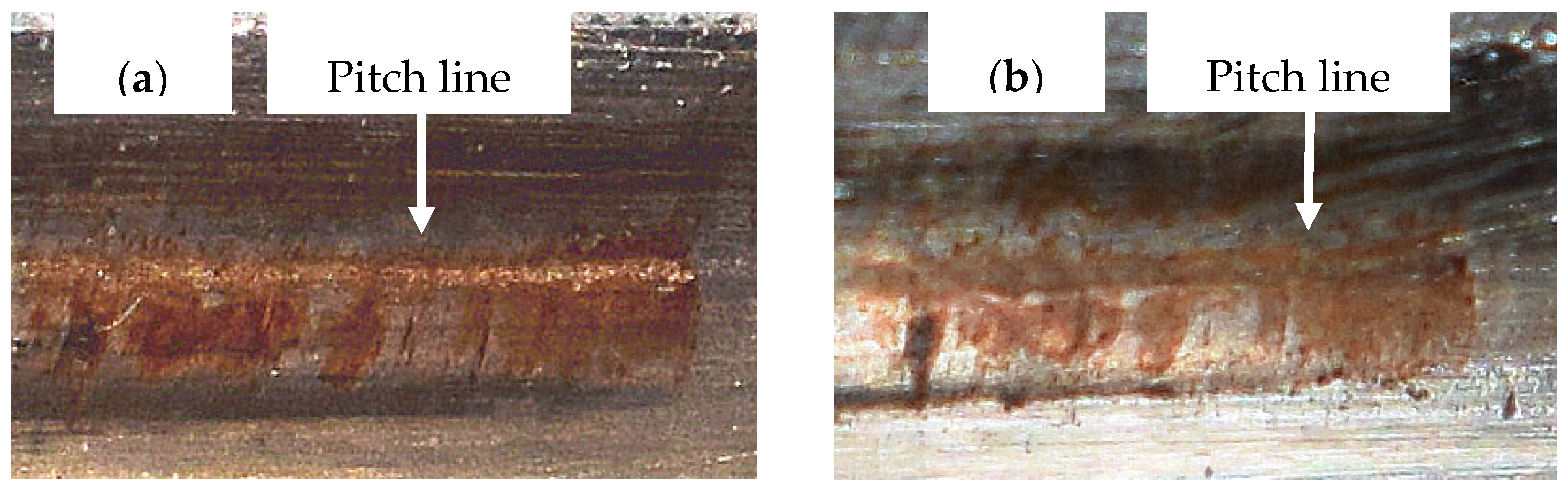

4. Results and Discussion

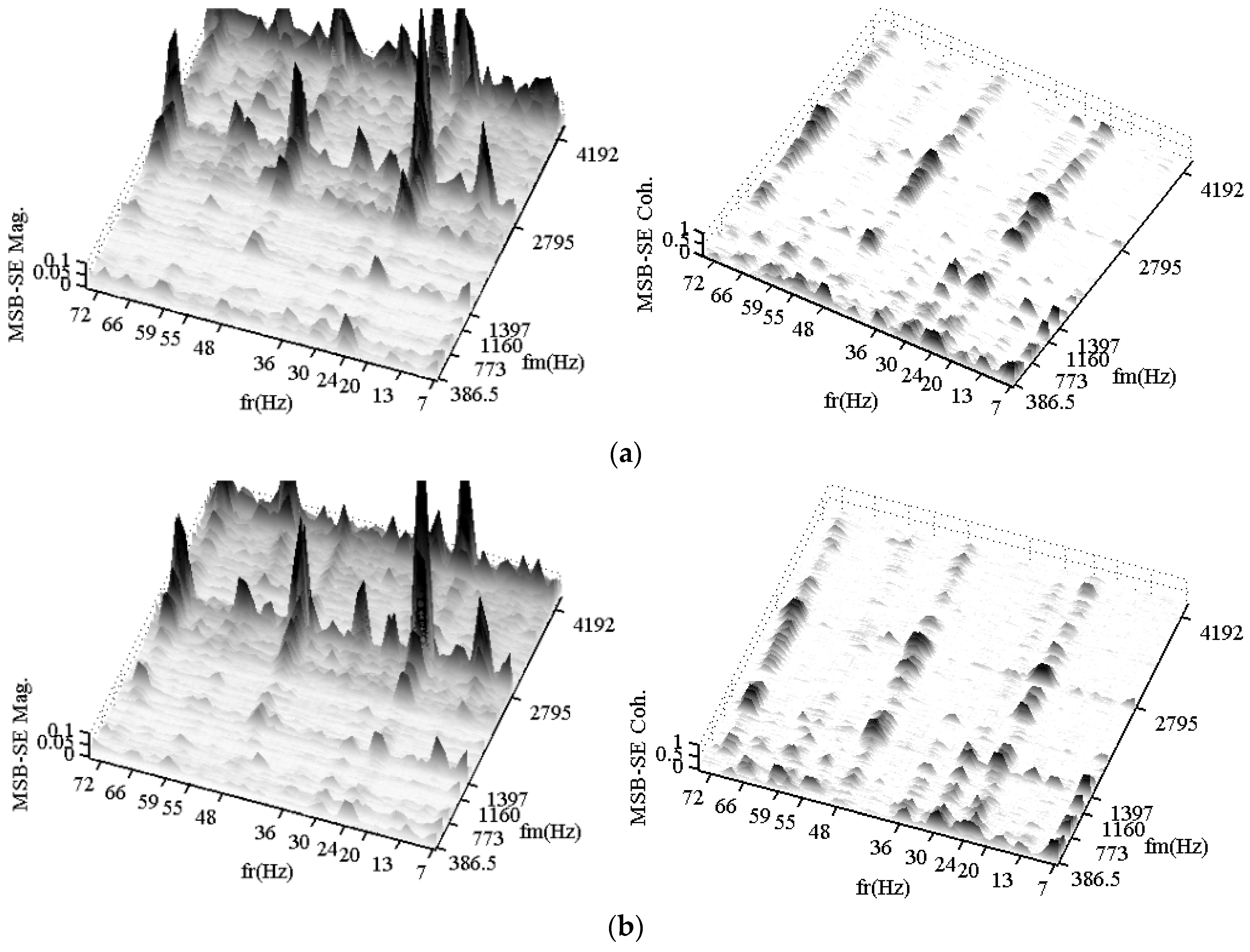

4.1. MSB-SE Characteristics of Gearbox Vibration Signals and Monitoring Indicator

4.2. Gear Wear Monitoring

5. Conclusions and Future Work

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Choy, F.K.; Polyshchuk, V.; Zakrajsek, J.J. Analysis of the effects of surface pitting and wear on the vibration of a gear transmission system. Tribol. Int. 1996, 29, 77–83. [Google Scholar] [CrossRef]

- Hu, C.; Smith, W.A.; Randall, R.B. Development of a gear vibration indicator and its application in gear wear monitoring. Mech. Syst. Signal Process. 2016, 76, 319–336. [Google Scholar] [CrossRef]

- Anwar, A.; Zhen, D.; Gu, F.; Ball, A.D. Gear wear process monitoring using acoustic signals. In Proceedings of the 21st International Congress on Sound and Vibration, Beijing, China, 13–17 July 2014.

- Gu, F.; Li, W.; Ball, A.D.; Leung, A.Y.T. The Condition Monitoring of Diesel Engines Using Acoustic Measurements Part 1: Acoustic Characteristics of the Engine and Representation of the Acoustic Signals; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2000. [Google Scholar]

- Ding, H.; Kahraman, A. Interactions between nonlinear spur gear dynamics and surface wear. J. Sound Vib. 2007, 307, 662–679. [Google Scholar] [CrossRef]

- Liu, X.; Yang, Y.; Zhang, J. Investigation on coupling effects between surface wear and dynamics in a spur gear system. Tribol. Int. 2016, 101, 383–394. [Google Scholar] [CrossRef]

- Ziaran, S.; Darula, R. Determination of the state of wear of high contact ratio gear sets by means of spectrum and cepstrum analysis. J. Vib. Acoust. 2013, 135, 021008. [Google Scholar] [CrossRef]

- Baydar, N.; Ball, A.D. A comparative study of acoustic and vibration signals in detection of gear failures using Wigner–Ville distribution. Mech. Syst. Signal Process. 2001, 15, 1091–1107. [Google Scholar] [CrossRef]

- Sawalhi, N.; Randall, R.B.; Forrester, D. Separation and enhancement of gear and bearing signals for the diagnosis of wind turbine transmission systems. Wind Energy 2013, 17, 729–743. [Google Scholar] [CrossRef]

- Zimroz, R.; Bartelmus, W. Gearbox condition estimation using cyclostationary properties of vibration signal. Key Eng. Mater. 2009, 413, 471–478. [Google Scholar] [CrossRef]

- Liu, B.; Riemenschneider, S.; Xu, Y. Gearbox fault diagnosis using empirical mode decomposition and Hilbert spectrum. Mech. Syst. Signal Process. 2006, 20, 718–734. [Google Scholar] [CrossRef]

- Amarnath, M.; Krishna, I.R.P. Detection and diagnosis of surface wear failure in a spur geared system using EEMD based vibration signal analysis. Tribol. Int. 2013, 61, 224–234. [Google Scholar] [CrossRef]

- Rafiee, J.; Rafiee, M.A.; Tse, P.W. Application of mother wavelet functions for automatic gear and bearing fault diagnosis. Expert Syst. Appl. 2010, 37, 4568–4579. [Google Scholar] [CrossRef]

- Jiang, L.; Liu, Y.; Li, X. Using bispectral distribution as a feature for rotating machinery fault diagnosis. Measurement 2011, 44, 1284–1292. [Google Scholar] [CrossRef]

- Cai, J.; Li, X. Gear Fault Diagnosis Based on Empirical Mode Decomposition and 1.5 Dimension Spectrum. Shock Vib. 2016, 1–10. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, T.; Gu, F. Gear Transmission Fault Diagnosis Based on the Bispectrum Analysis of Induction Motor Current Signatures. J. Mech. Eng. 2012, 48, 84–90. [Google Scholar] [CrossRef]

- Tian, X.; Abdallaa, G.M.; Rehab, I. Diagnosis of combination faults in a planetary gearbox using a modulation signal bispectrum based sideband estimator. In Proceedings of the 21st International Conference on Automation & Computing, University of Strathclyde, Glasgow, UK, 11–12 September 2015.

- Gu, F.; Abdalla, G.; Zhang, R.; Xu, H.; Ball, A.D. A Novel Method for the Fault Diagnosis of a Planetary Gearbox based on Residual Sidebands from Modulation Signal Bispectrum Analysis. In Proceedings of the 27th International Congress of Condition Monitoring and Diagnostic Engineering, Brisbane, Australia, 16–18 September 2014.

- Gu, F.; Shao, Y.; Hu, N.; Naid, A.; Ball, A.D. Electrical motor current signal analysis using a modified bispectrum for fault diagnosis of downstream mechanical equipment. Mech. Syst. Signal Process. 2011, 25, 360–372. [Google Scholar] [CrossRef]

- Gu, F.; Wang, T.; Alwodai, A.; Tian, X.; Shao, Y.; Ball, A.D. A new method of accurate broken rotor bar diagnosis based on modulation signal bispectrum analysis of motor current signals. Mech. Syst. Signal Process. 2015, 50, 400–413. [Google Scholar] [CrossRef]

- Howard, I.M. Higher-order spectral techniques for machine vibration condition monitoring. Proc. Inst. Mech. Eng. G 1997, 211, 211–219. [Google Scholar] [CrossRef]

- Li, Y.; Ding, K.; He, G. Vibration mechanisms of spur gear pair in healthy and fault states. Mech. Syst. Signal Process. 2016, 81, 183–201. [Google Scholar] [CrossRef]

- Feng, Z.; Zuo, M. Fault diagnosis of planetary gearboxes via torsional vibration signal analysis. Mech. Syst. Signal Process. 2013, 36, 401–421. [Google Scholar] [CrossRef]

- Shen, G.; McLaughlin, S.; Xu, Y. Theoretical and experimental analysis of bispectrum of vibration signals for fault diagnosis of gears. Mech. Syst. Signal Process. 2014, 43, 76–89. [Google Scholar]

- International Organization for Standardization. Calculation of Load Capacity of Spur and Helical Gears—Application for Industrial Gear. ISO: Geneva, Switzerland, 2002. [Google Scholar]

- Powrie, H.E.G.; Fisher, C.E.; Tasbaz, O.D.; Wood, R.J.K. Performance of an electrostatic oil monitoring system during an FZG gear scuffing test. In Proceedings of the International Conference on Condition Monitoring, University of Wales, Swansea, UK, 12–15 April 1999; pp. 145–155.

- Proctor, M.P.; Oswald, F.B.; Krants, T.L. Shuttle Rudder/Speed Brake Power Drive Unit (pdu) Gear Scuffing Tests with Flight Gears; Technical Report NASA/TM-2005-214092; Glenn Research Center: Cleveland, OH, USA, 2005.

- Castro, J.; Seabra, J. Global and local analysis of gear scuffing tests using a mixed film lubrication model. Tribol. Int. 2008, 41, 244–255. [Google Scholar] [CrossRef]

- Klein, M.A. An Experimental Investigation of Materials and Surface Treatments on Gear Contact Fatigue Life. Master’s Thesis, The Ohio State University, Columbus, OH, USA, 2009. [Google Scholar]

- Xue, J.; Li, W.; Qin, C. The scuffing load capacity of involute spur gear systems based on dynamic loads and transient thermal elastohydrodynamic lubrication. Tribol. Int. 2014, 79, 74–83. [Google Scholar] [CrossRef]

- Ganti, V.; Dewangan, Y.; Arvariya, S.; Madhavan, S. Influence of Micro-Geometry on Gear Scuffing; SAE Technical Paper 2015-26-0187; SAE International: Warrendale, PA, USA, 2015. [Google Scholar]

- Zhang, J.; Li, W.; Wang, H. A comparison of the effects of traditional shot peening and micro-shot peening on the scuffing resistance of carburized and quenched gear steel. Wear 2016, 368–369, 253–257. [Google Scholar] [CrossRef]

- Vinayak, H.; Singh, R.; Padmanabhan, C. Linear dynamic analysis of multi-mesh transmissions containing external rigid gears. J. Sound Vib. 1995, 185, 1–32. [Google Scholar] [CrossRef]

| Gear Parameters | 1st Stage | 2nd Stage |

|---|---|---|

| Number of teeth | 58/47 | 13/59 |

| Meshing frequency (Hz) | fm1 = 1421 | fm2 = 393.04 |

| Shaft frequency (Hz) | fr1 = 24.5, fr2 = 30.23, fr3 = 6.66 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, R.; Gu, X.; Gu, F.; Wang, T.; Ball, A.D. Gear Wear Process Monitoring Using a Sideband Estimator Based on Modulation Signal Bispectrum. Appl. Sci. 2017, 7, 274. https://doi.org/10.3390/app7030274

Zhang R, Gu X, Gu F, Wang T, Ball AD. Gear Wear Process Monitoring Using a Sideband Estimator Based on Modulation Signal Bispectrum. Applied Sciences. 2017; 7(3):274. https://doi.org/10.3390/app7030274

Chicago/Turabian StyleZhang, Ruiliang, Xi Gu, Fengshou Gu, Tie Wang, and Andrew D. Ball. 2017. "Gear Wear Process Monitoring Using a Sideband Estimator Based on Modulation Signal Bispectrum" Applied Sciences 7, no. 3: 274. https://doi.org/10.3390/app7030274