Influence of the Water-Cooled Heat Exchanger on the Performance of a Pulse Tube Refrigerator

Abstract

:1. Introduction

2. Experimental Apparatus and WCHXs

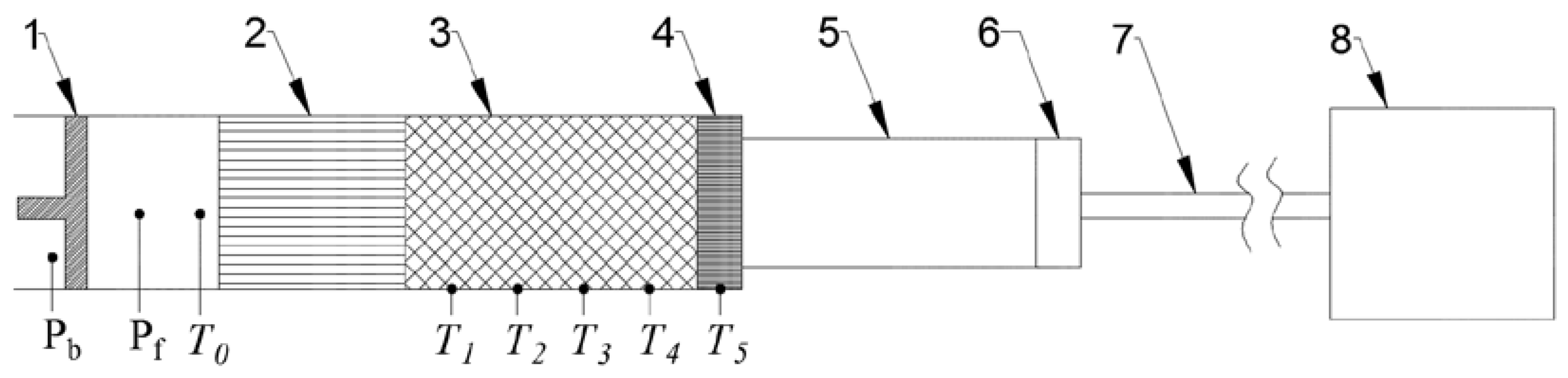

2.1. Experimental Apparatus

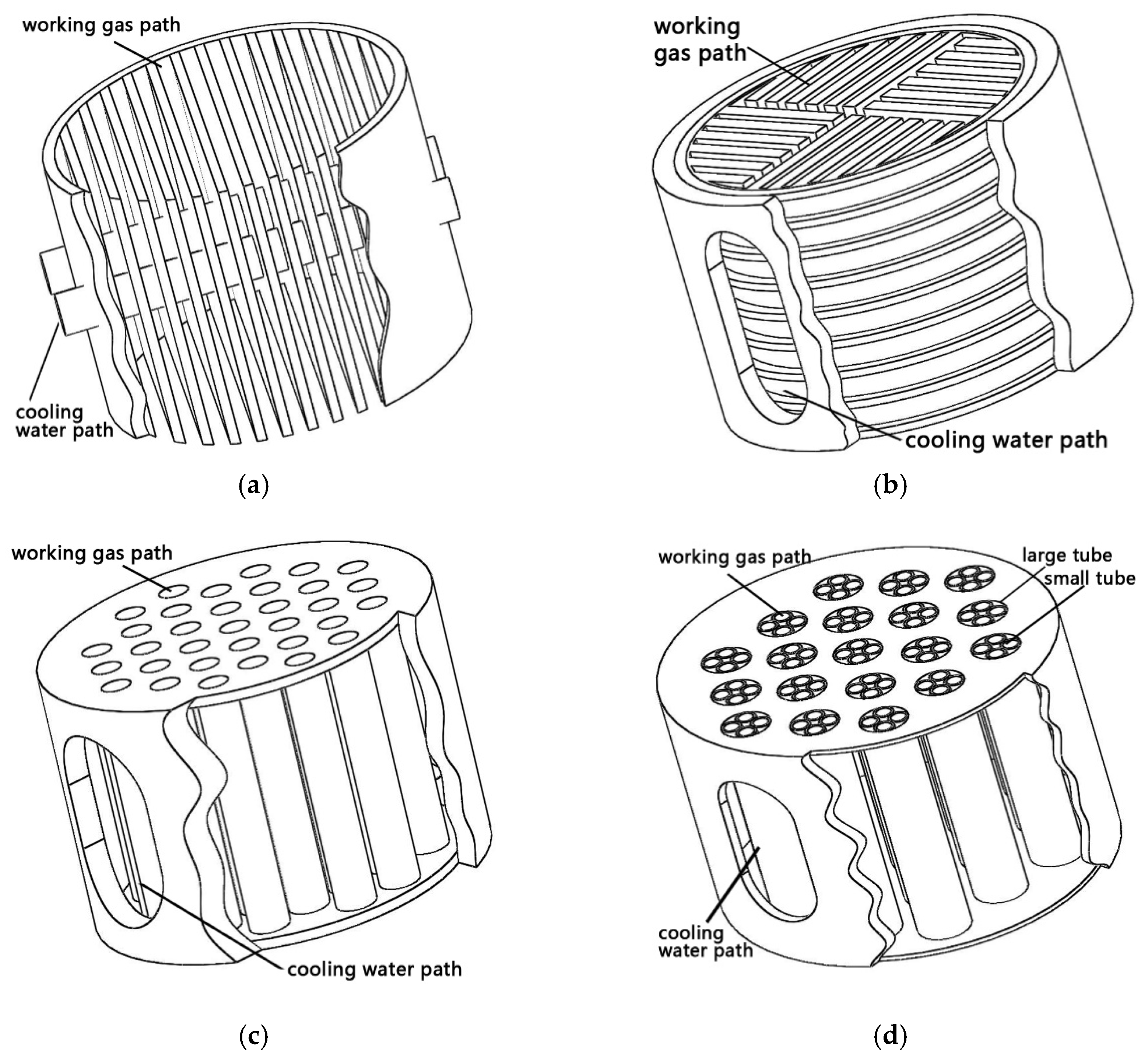

2.2. Water-Cooled Heat Exchangers

3. Experimental Results

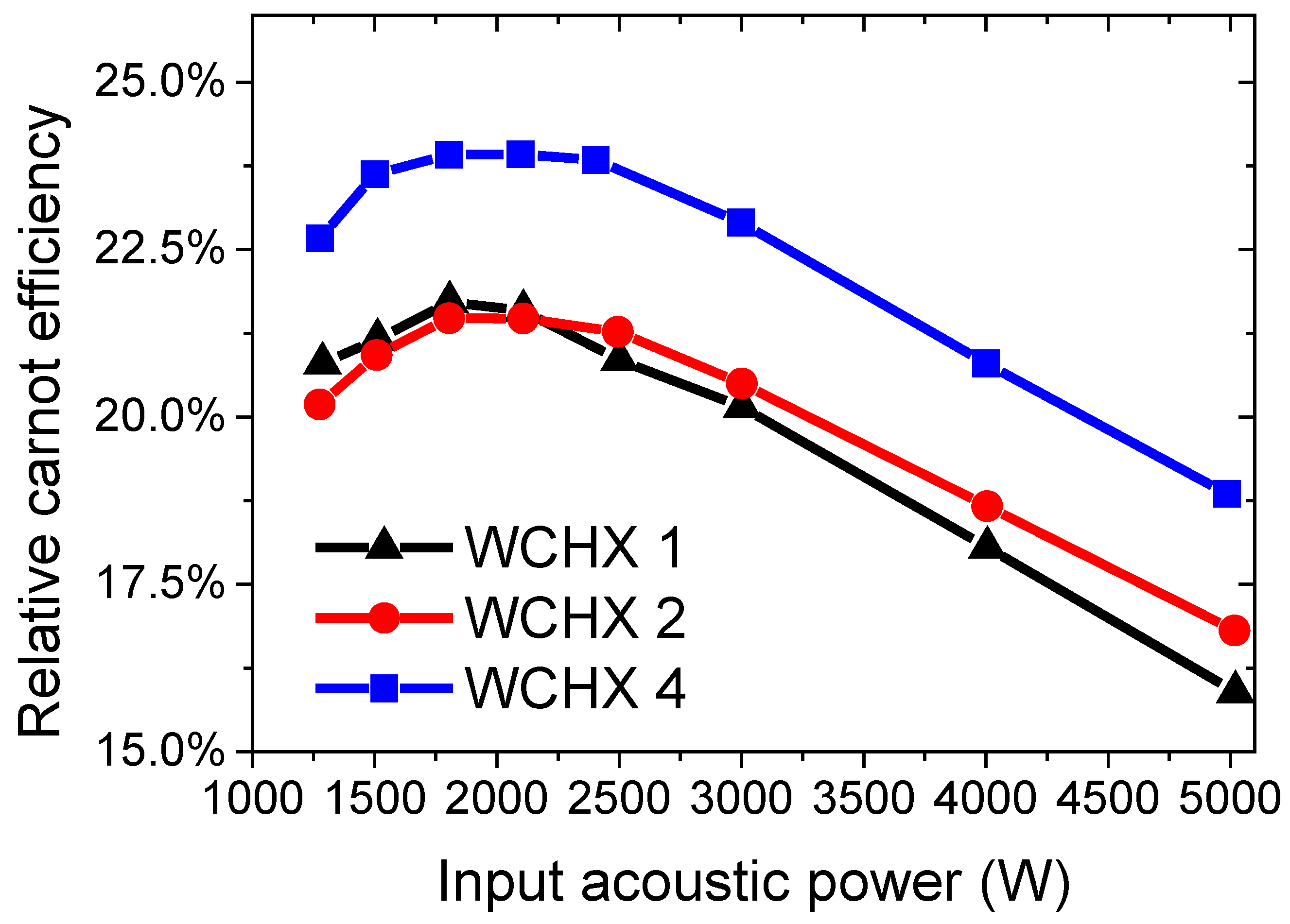

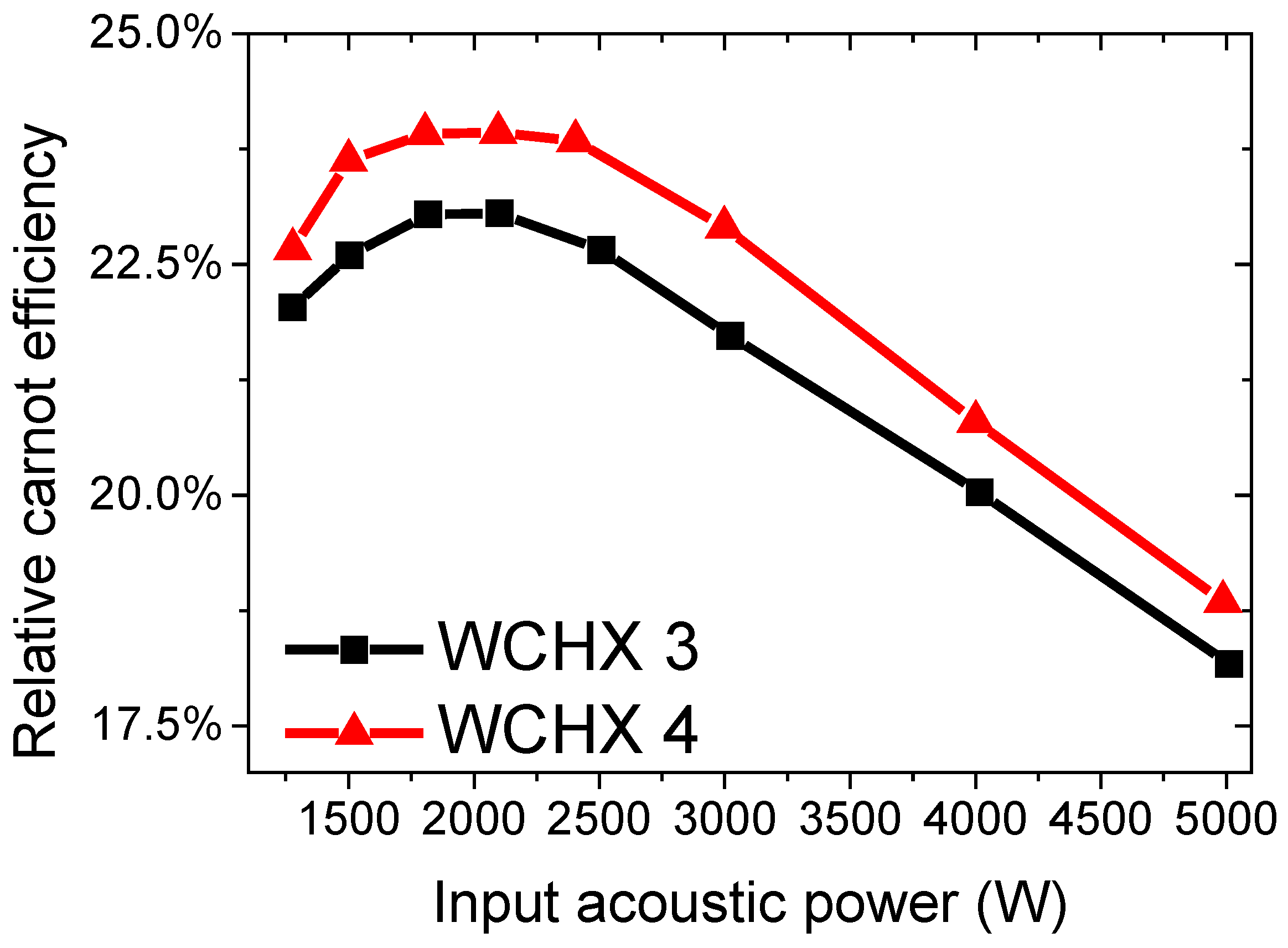

3.1. Influence of Different Configurations

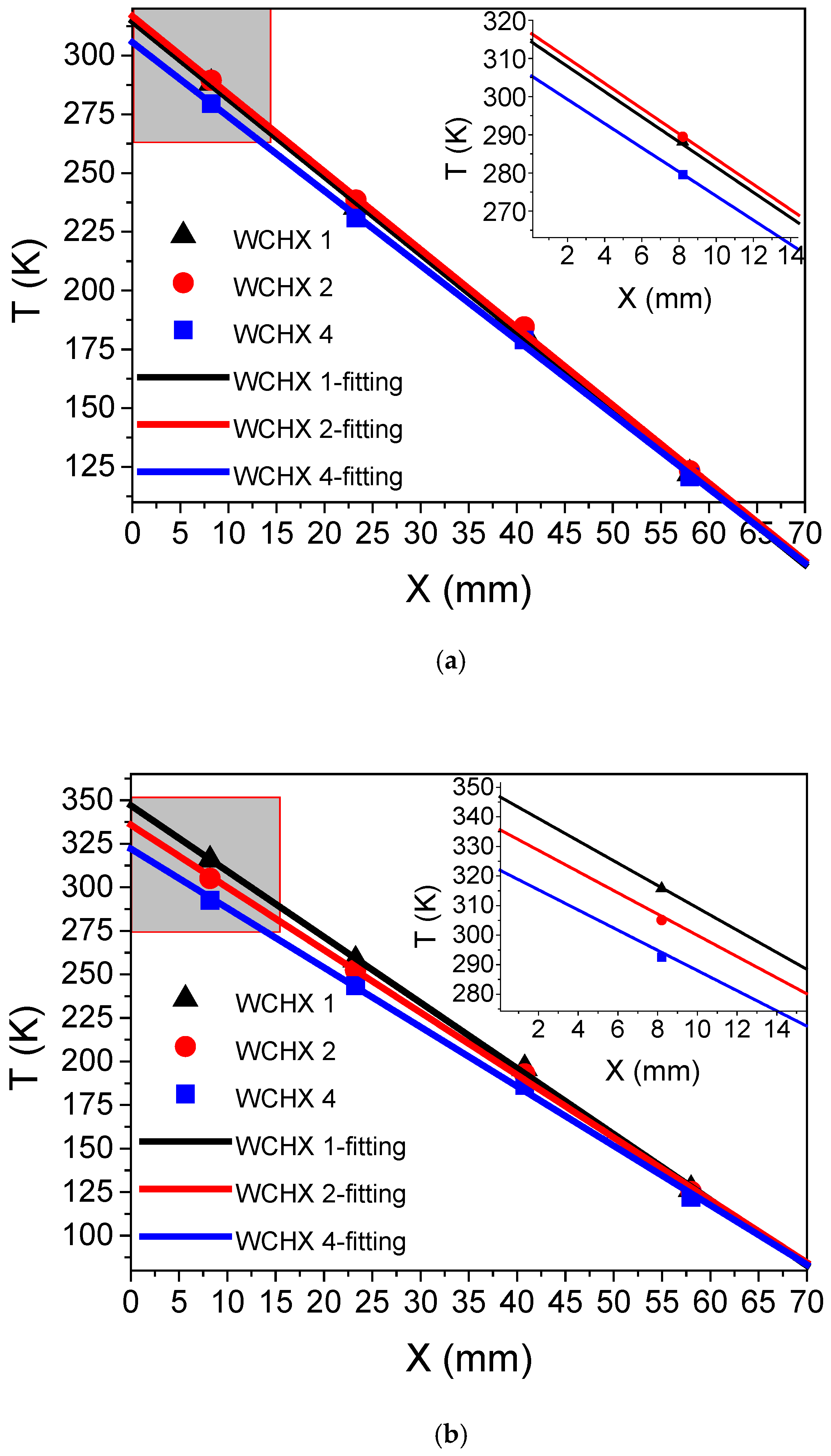

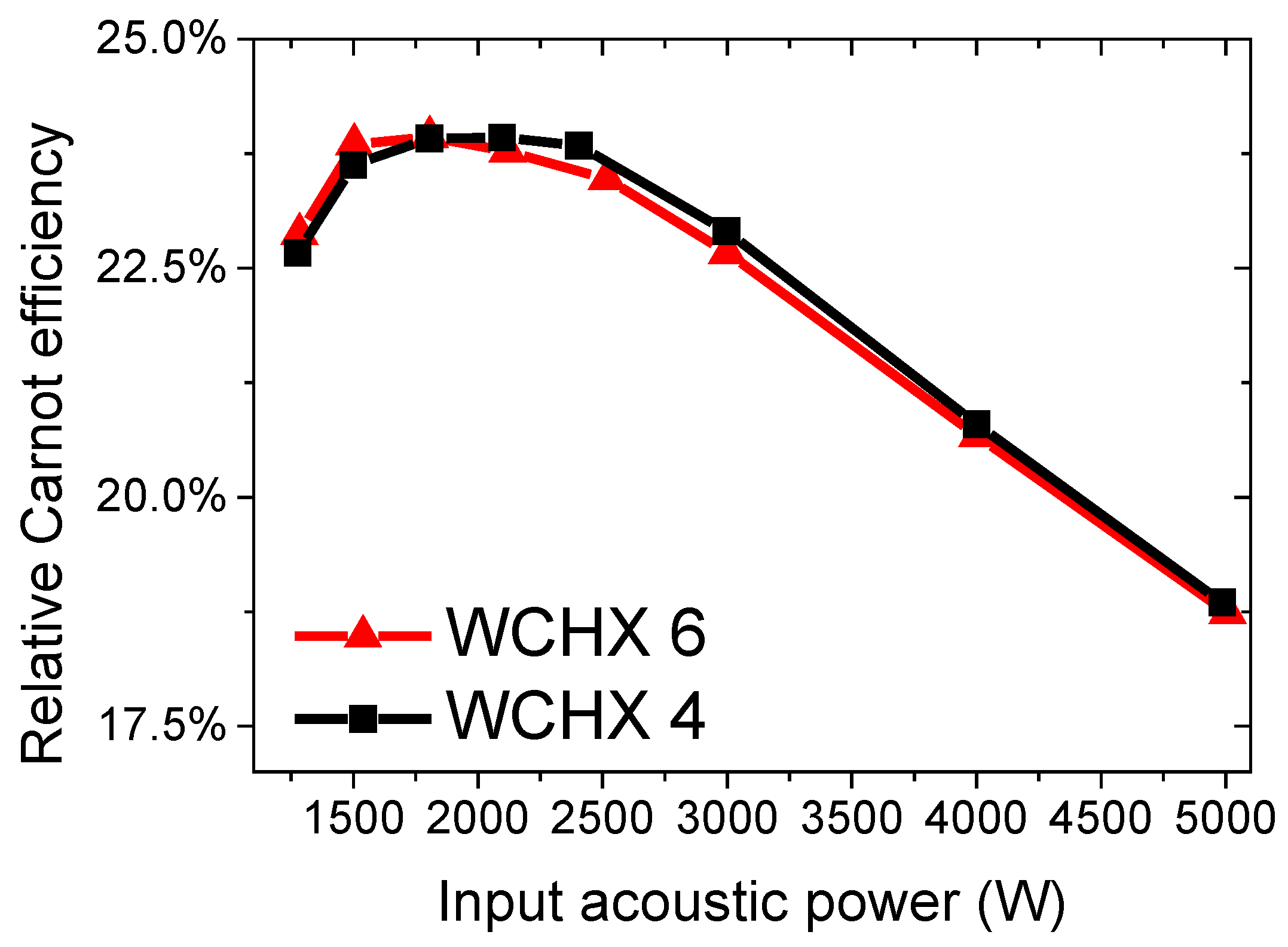

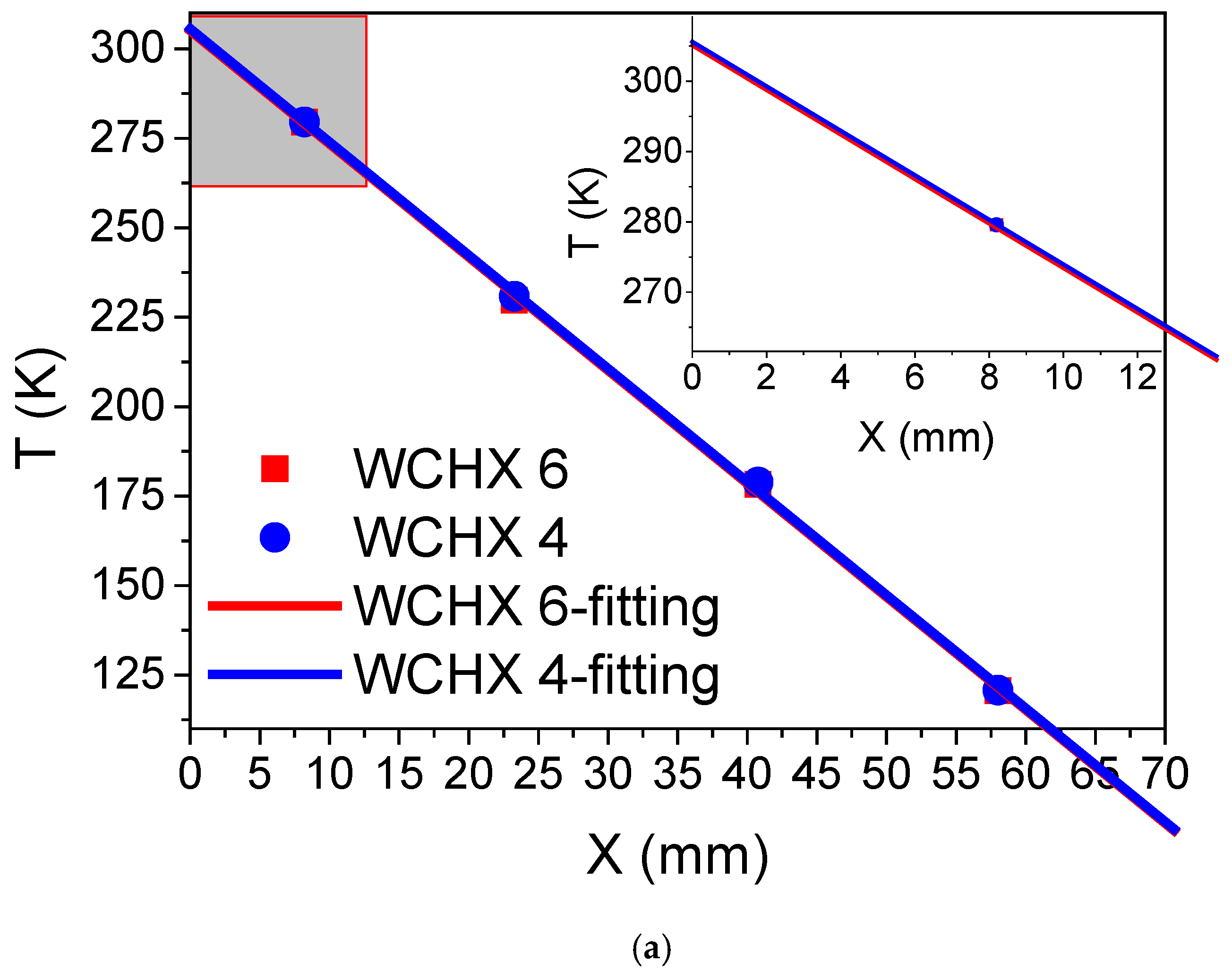

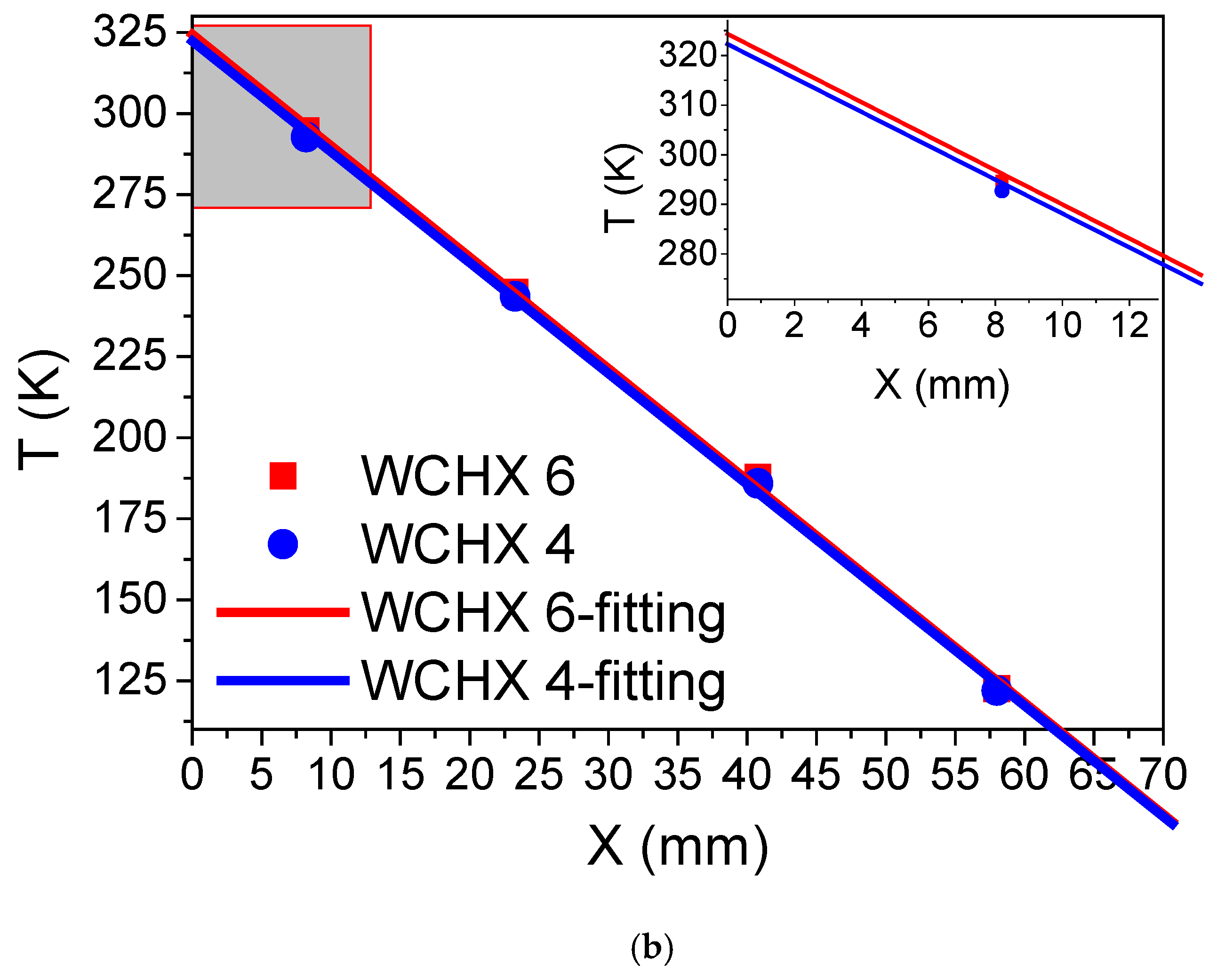

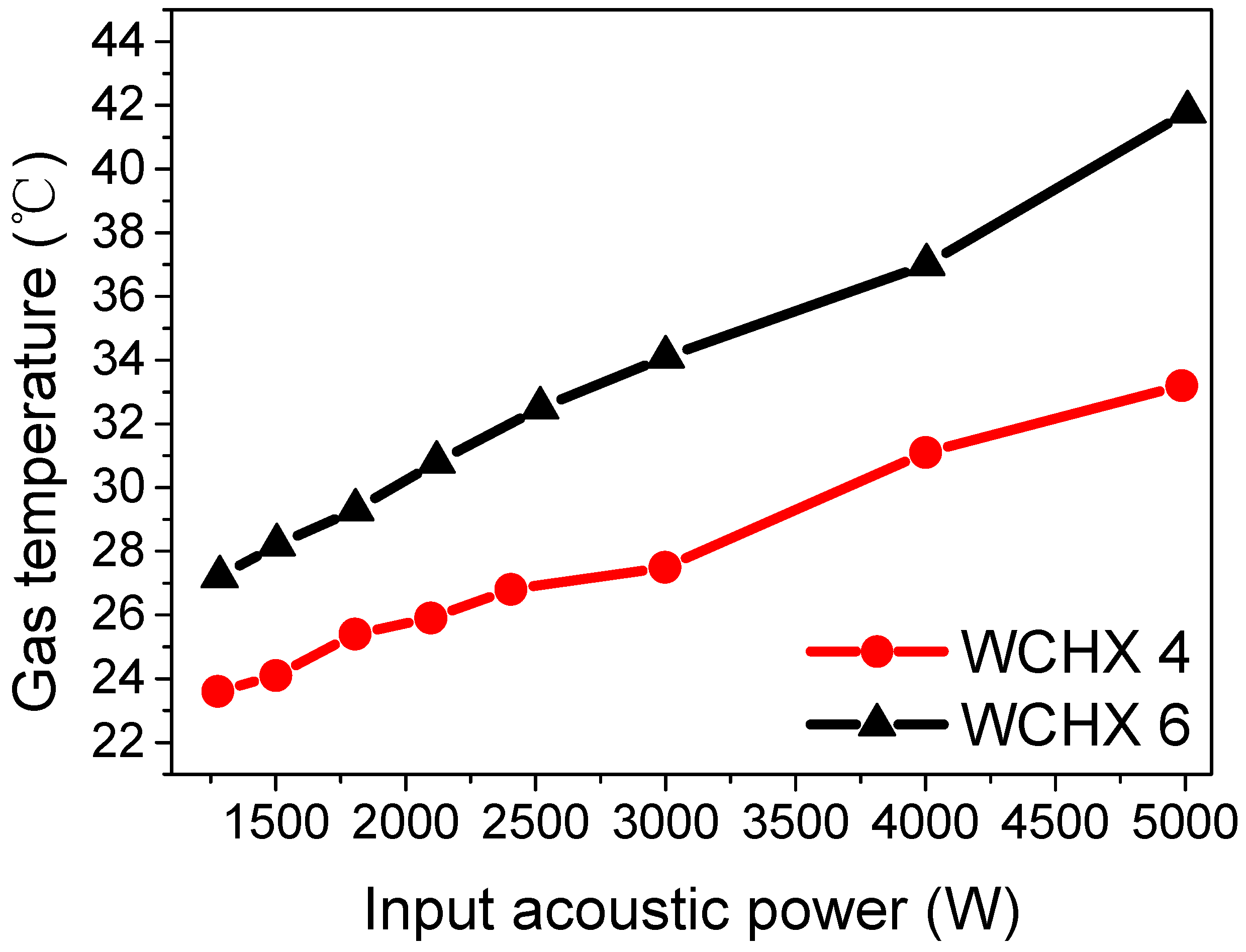

3.2. Influence of Length

3.3. Influence of Different Contact Thermal Resistance WCHXs

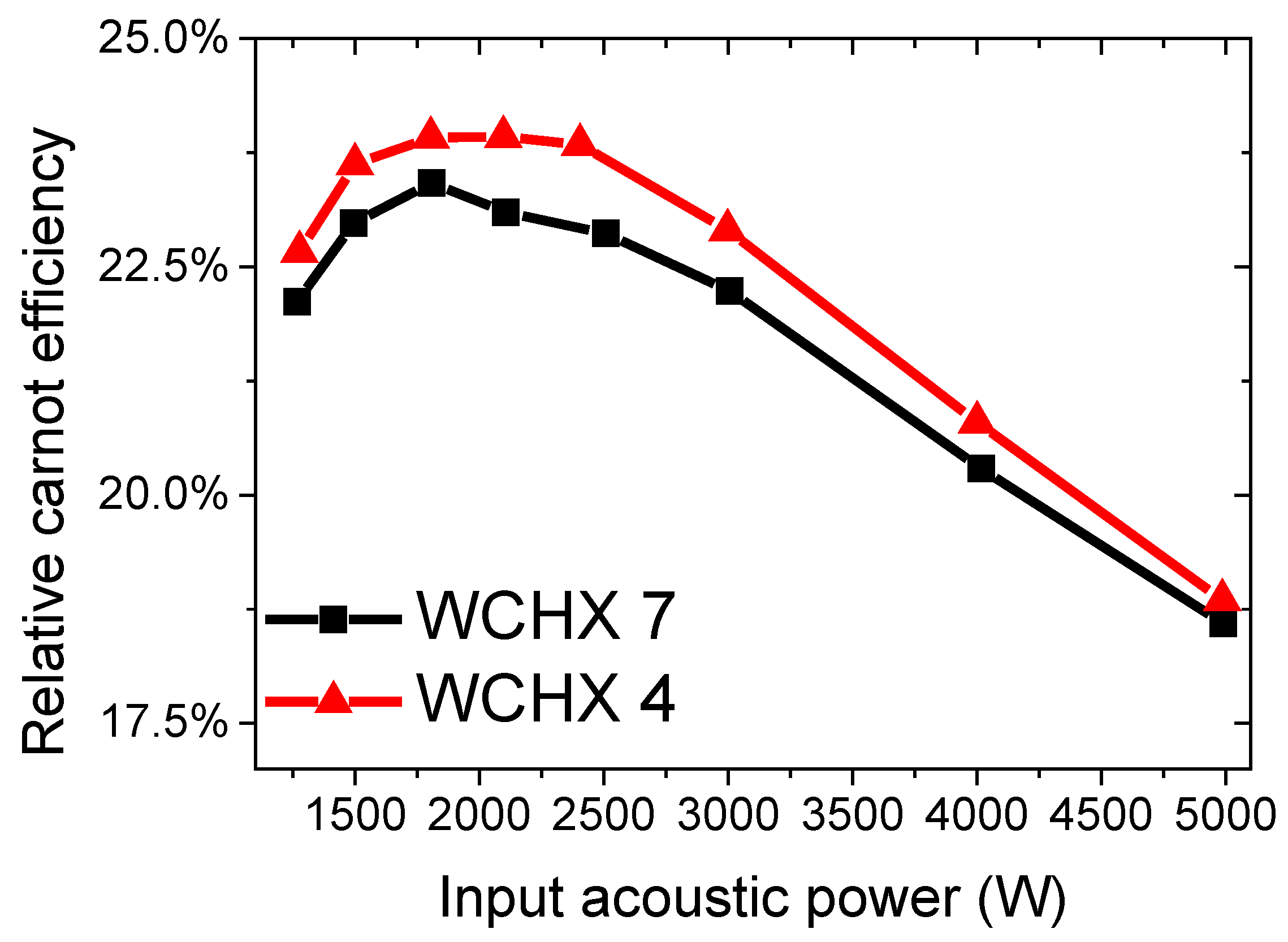

3.4. Influence of Different Hydraulic Diameter

3.5. Influence of Different Porosity

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gifford, W.E.; Longsworth, R.C. Pulse-tube refrigeration. J. Eng. Ind. 1964, 86, 264–268. [Google Scholar] [CrossRef]

- Zia, J.H. A commercial pulse tube cryocooler with 200 W refrigeration at 80 K. In Cryocoolers 13; Ross, R.G., Ed.; Springer: Boston, MA, USA, 2005; pp. 165–171. [Google Scholar]

- Zia, J.H. A pulse tube cryocooler with 300 W refrigeration at 80 K and an operating efficiency of 19% carnot. Cryocoolers 2007, 14, 141–147. [Google Scholar]

- Hu, J.Y.; Zhang, L.M.; Zhu, J.; Chen, S.; Luo, E.C.; Dai, W.; Li, H.B. A high-efficiency coaxial pulse tube cryocooler with 500 W cooling capacity at 80 K. Cryogenics 2014, 62, 7–10. [Google Scholar] [CrossRef]

- Potratz, S.A.; Nellis, G.F.; Maddocks, J.R.; Kashani, A.; Helvensteijn, B.P.M.; Rhoads, G.L.; Flake, B. Development of a large-capacity, stirling-type, pulse-tube refrigerator. AIP Conf. Proc. 2006, 823, 3–10. [Google Scholar]

- Potratz, S.A.; Abbott, T.D.; Johnson, M.C.; Albaugh, K.B. Stirling-type pulse tube cryocooler with 1 kW of refrigeration at 77 K. AIP Conf. Proc. 2008, 985, 42–48. [Google Scholar]

- Hu, J.Y.; Luo, E.; Wu, Z.; Yu, G.; Dai, W. Design of a large-capacity multi-piston pulse tube cryocooler. AIP Conf. Proc. 2012, 1434, 540–546. [Google Scholar]

- Hu, J.Y.; Chen, S.; Zhu, J.; Zhang, L.M.; Luo, E.C.; Dai, W.; Li, H.B. An efficient pulse tube cryocooler for boil-off gas reliquefaction in liquid natural gas tanks. Appl. Energy 2015, 164, 1012–1018. [Google Scholar] [CrossRef]

- Caughley, A.; Emery, N.; Nation, M.; Allpress, N.; Kimber, A.; Branje, P.; Reynolds, H.; Boyle, C.; Meier, J.; Tanchon, J. Commercial pulse tube cryocoolers producing 330 W and 1000 W at 77 K for liquefaction. IEEE Trans. Appl. Supercond. 2016, 26, 1–4. [Google Scholar] [CrossRef]

- Bretagne, E.; François, M.X.; Ishikawa, H. Investigations of acoustics and heat transfer characteristics of thermoacoustic driven pulse tube refrigerators. AIP Conf. Proc. 2004, 710, 1687–1695. [Google Scholar]

- Ki, T.; Jeong, S. Optimal design of the pulse tube refrigerator with slit-type heat exchangers. Cryogenics 2010, 50, 608–614. [Google Scholar] [CrossRef]

- Yang, K.X.; Wu, Y.N.; Zhang, A.K.; Xiong, C. Fabrication of Taper Gap Warm End Heat Exchanger in Coaxial Pulse Tube Cryocooler. Adv. Mater. Res. 2012, 591–593, 365–368. [Google Scholar] [CrossRef]

- Chen, Y.Y.; Luo, E.C.; Dai, W. Heat transfer characteristics of oscillating flow regenerator filled with circular tubes or parallel plates. Cryogenics 2007, 47, 40–48. [Google Scholar] [CrossRef]

- Gholamrezaei, M.; Ghorbanian, K. Thermal analysis of shell-and-tube thermoacoustic heat exchangers. Entropy 2016, 18, 301. [Google Scholar] [CrossRef]

- Kamsanam, W.; Mao, X.; Jaworski, A.J. Thermal performance of finned-tube thermoacoustic heat exchangers in oscillatory flow conditions. Int. J. Therm. Sci. 2016, 101, 169–180. [Google Scholar] [CrossRef]

- Jaworski, A.J.; Piccolo, A. Heat transfer processes in parallel-plate heat exchangers of thermoacoustic devices–numerical and experimental approaches. Appl. Therm. Eng. 2012, 42, 145–153. [Google Scholar] [CrossRef] [Green Version]

- Tang, K.; Yu, J.; Jin, T.; Gan, Z.H. Influence of compression-expansion effect on oscillating-flow heat transfer in a finned heat exchanger. J. Zhejiang Univ. Sci. A 2013, 14, 427–434. [Google Scholar] [CrossRef]

- Tang, K.; Yu, J.; Jin, T.; Wang, Y.P.; Tang, W.T.; Gan, Z.H. Heat transfer of laminar oscillating flow in finned heat exchanger of pulse tube refrigerator. Int. J. Heat Mass Transfer 2014, 70, 811–818. [Google Scholar] [CrossRef]

- Xu, J.Y.; Hu, J.Y.; Zhang, L.M.; Luo, E. A novel shell-tube water-cooled heat exchanger for high-capacity pulse-tube coolers. Appl. Therm. Eng. 2016, 106, 399–404. [Google Scholar] [CrossRef]

- Luo, L.A.; D’Ortona, U.; Tondeur, D. Compact heat exchangers. In Microreaction Technology: Industrial Prospects: Imret 3: Proceedings of the Third International Conference on Microreaction Technology; Ehrfeld, W., Ed.; Springer: Berlin/Heidelberg, Germany, 2000; pp. 556–565. [Google Scholar]

- Kuppan, T. Heat Exchanger Design Handbook, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2013; p. 21. [Google Scholar]

- Hu, J.Y.; Long, X.D.; Li, H.B. Heat exchanger, oscillation flow system and heat exchanger processing methods, CN104964585A [P/OL]. 2015. [Google Scholar]

- Bouvier, P.; Stouffs, P.; Bardon, J.-P. Experimental study of heat transfer in oscillating flow. Int. J. Heat Mass Transfer 2005, 48, 2473–2482. [Google Scholar] [CrossRef]

- Chen, Y.; Luo, E.; Dai, W. Heat transfer characteristics of oscillating flow regenerators in cryogenic temperature range below 20 K. Cryogenics 2009, 49, 313–319. [Google Scholar] [CrossRef]

- Hu, J.Y.; Wang, W.; Luo, E.C.; Chen, Y.Y. Acoustic field modulation in regenerators. Cryogenics 2016, 80, 1–7. [Google Scholar] [CrossRef]

| Item | Item | Value |

|---|---|---|

| Operating condition | Working gas | helium |

| Operating pressure | 3 MPa | |

| Frequency | 55 Hz | |

| Cooling temperature | 80 K | |

| Component size | Regenerator | 75 × 70 (300 mesh) |

| Pulse tube | 37 × 150 | |

| Cold head | 75 × 30 | |

| Inertance tubes | 10 × 2300 |

| WHCX | Porosity | Gas-solid Heat Transfer Area | Hydraulic Diameter | Length | Remarks |

|---|---|---|---|---|---|

| 1 | 26.2% | 0.38 m2 | 0.8 mm | 64 mm | - |

| 2 | 23.8% | 0.11 m2 | 2.44 mm | 64 mm | - |

| 3 | 25.1% | 0.261 m2 | 1.35 mm | 64 mm | - |

| 4 | 24.5% | 0.386 m2 | 0.76 mm | 64 mm | - |

| 5 | 24.5% | 0.386 m2 | 0.76 mm | 64 mm | No welding between small and big tubes |

| 6 | 24.5% | 0.193 m2 | 0.76 mm | 32 mm | - |

| 7 | 12.3% | 0.193 m2 | 0.76 mm | 64 mm | - |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Hu, J.; Xu, J.; Zhang, L.; Luo, E. Influence of the Water-Cooled Heat Exchanger on the Performance of a Pulse Tube Refrigerator. Appl. Sci. 2017, 7, 229. https://doi.org/10.3390/app7030229

Wang W, Hu J, Xu J, Zhang L, Luo E. Influence of the Water-Cooled Heat Exchanger on the Performance of a Pulse Tube Refrigerator. Applied Sciences. 2017; 7(3):229. https://doi.org/10.3390/app7030229

Chicago/Turabian StyleWang, Wei, Jianying Hu, Jingyuan Xu, Limin Zhang, and Ercang Luo. 2017. "Influence of the Water-Cooled Heat Exchanger on the Performance of a Pulse Tube Refrigerator" Applied Sciences 7, no. 3: 229. https://doi.org/10.3390/app7030229