Improving Liquid Entry Pressure of Polyvinylidene Fluoride (PVDF) Membranes by Exploiting the Role of Fabrication Parameters in Vapor-Induced Phase Separation VIPS and Non-Solvent-Induced Phase Separation (NIPS) Processes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Membrane Preparation

2.2. Membrane Characterization

2.3. Moisture Uptake Test

2.4. DCMD Experiments

3. Results and Discussion

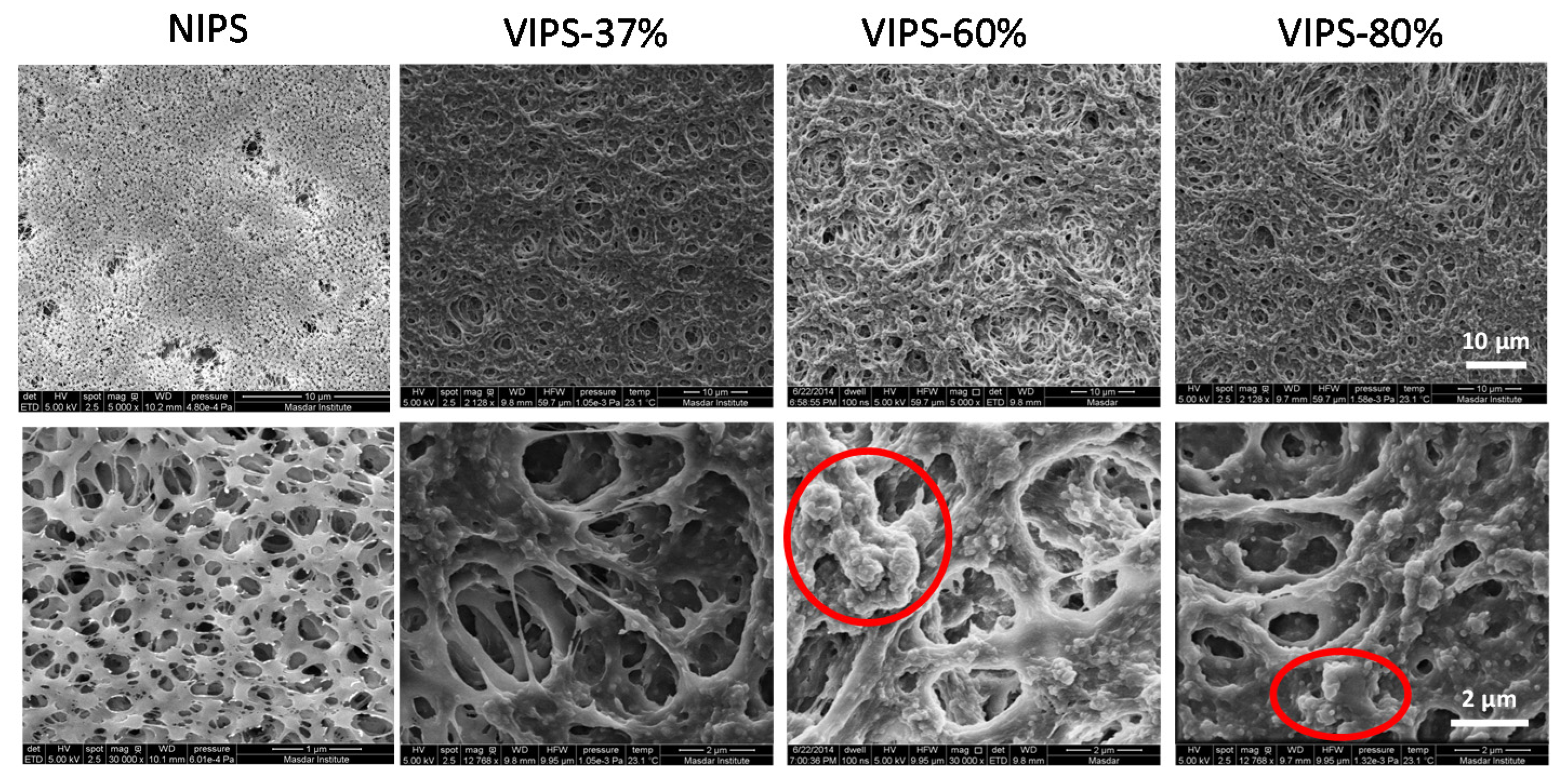

3.1. Membrane Morphologies in NIPS vs. VIPS

3.2. Going from NIPS to VIPS: A Parametric Study

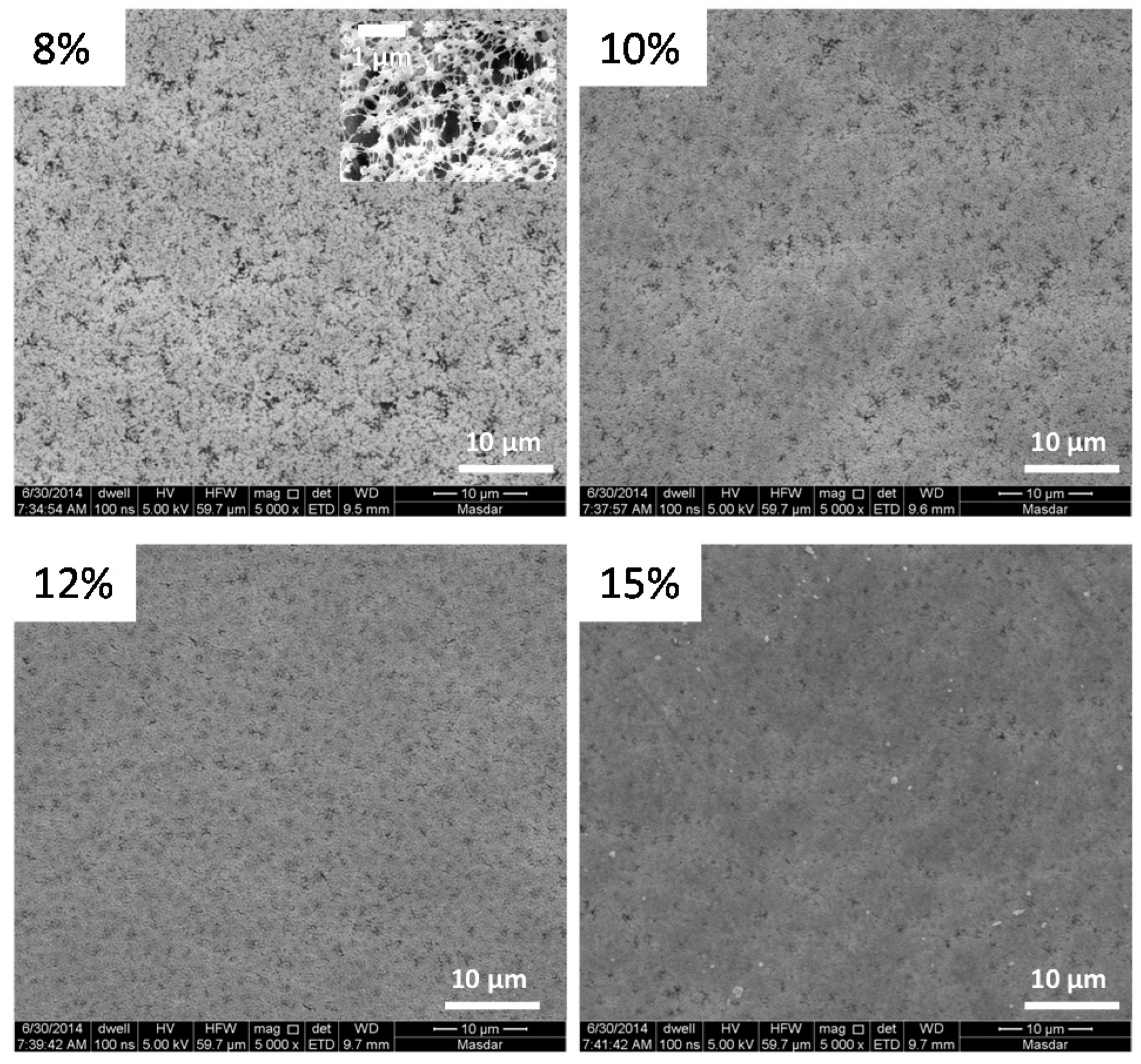

3.2.1. Effect of PVDF Concentration

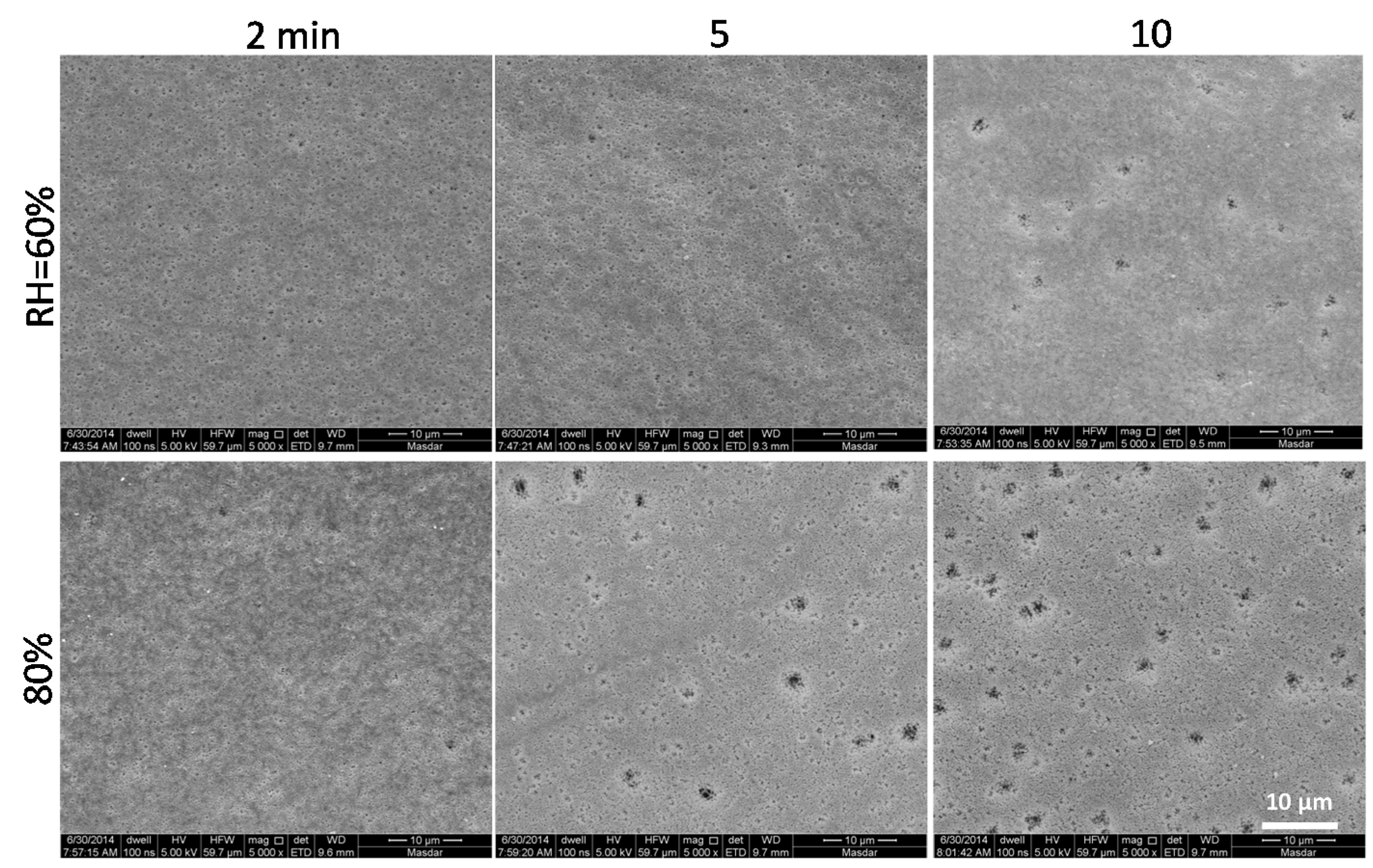

3.2.2. Effect of Humidity

3.2.3. Effect of Exposure Time

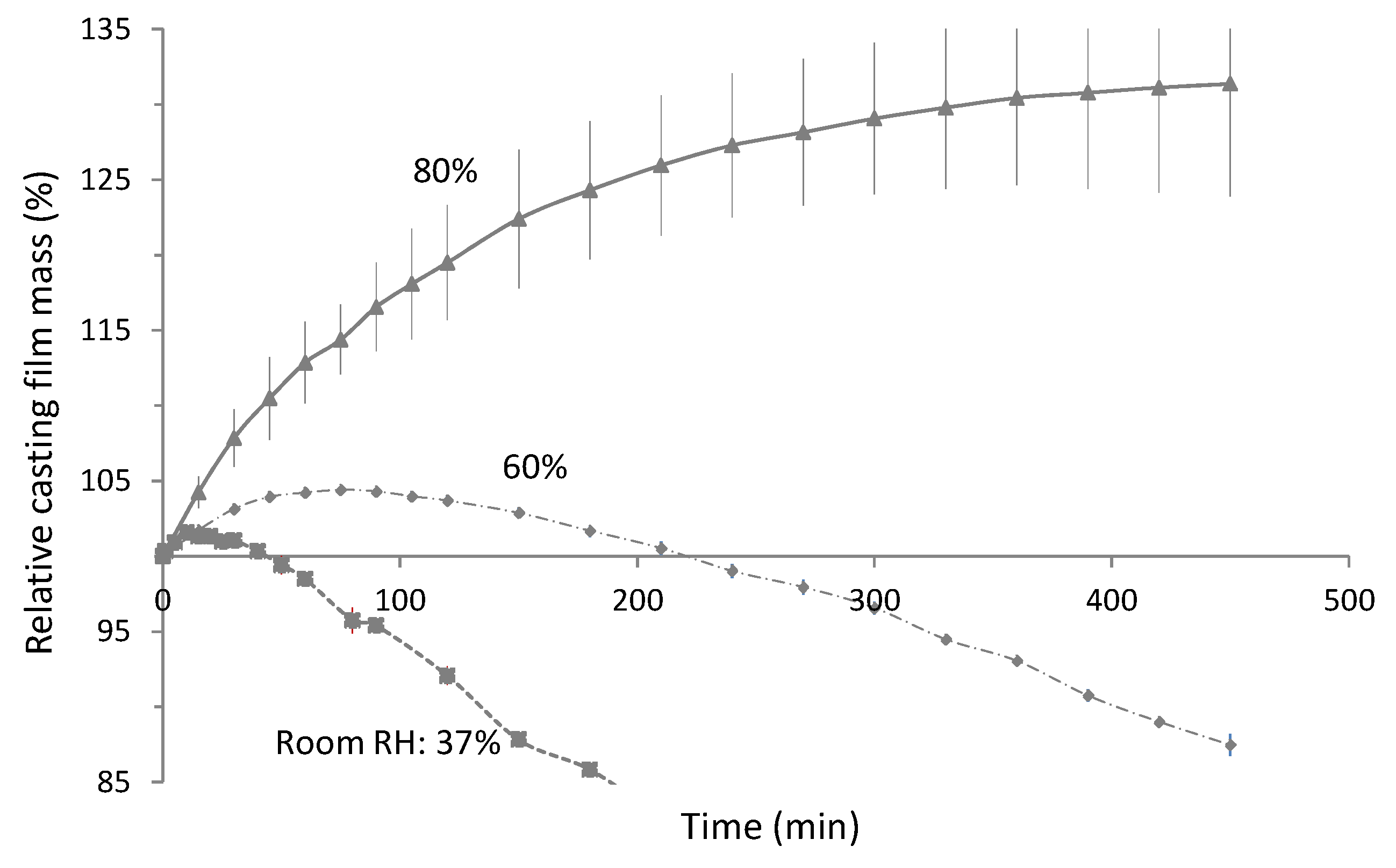

3.3. Moisture Uptake during the VIPS Process

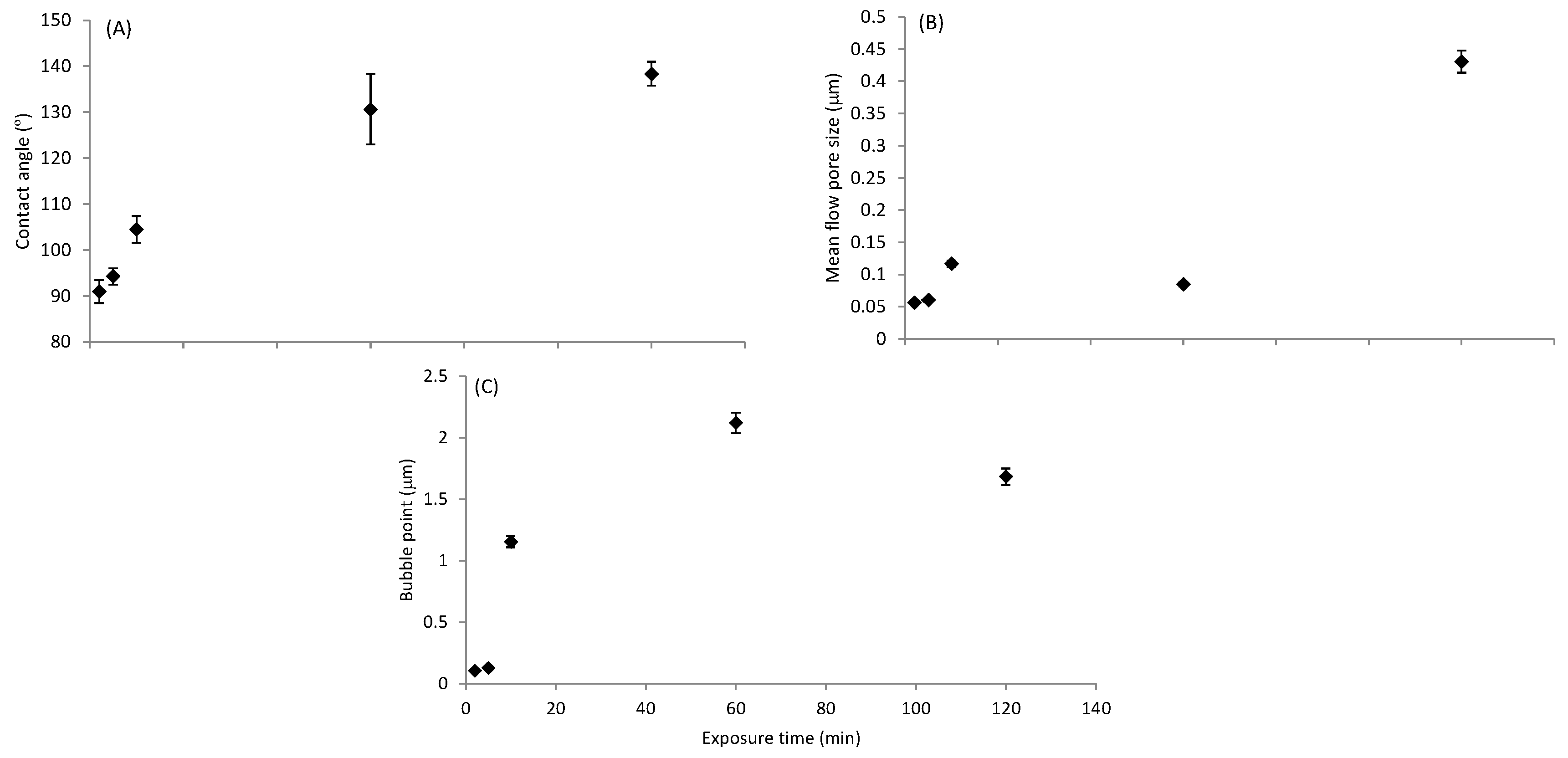

3.4. Decoupling Pore Size and Surface Properties: Effect of Casting Thickness

3.5. MD Performance

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Warsinger, D.M.; Swaminathan, J.; Guillen-Burrieza, E.; Arafat, H.A.; Lienhard, J.H., V. Scaling and fouling in membrane distillation for desalination applications: A review. Desalination 2015, 356, 294–313. [Google Scholar] [CrossRef]

- Mu, C.; Su, Y.; Sun, M.; Chen, W.; Jiang, Z. Fabrication of microporous membranes by a feasible freeze method. J. Membr. Sci. 2010, 361, 15–21. [Google Scholar] [CrossRef]

- Peng, Y.; Fan, H.; Ge, J.; Wang, S.; Chen, P.; Jiang, Q. The effects of processing conditions on the surface morphology and hydrophobicity of polyvinylidene fluoride membranes prepared via vapor-induced phase separation. Appl. Surf. Sci. 2012, 263, 737–744. [Google Scholar] [CrossRef]

- Simone, S.; Figoli, A.; Criscuoli, A.; Carnevale, M.C.; Rosselli, A.; Drioli, E. Preparation of hollow fibre membranes from PVDF/PVP blends and their application in VMD. J. Membr. Sci. 2010, 364, 219–232. [Google Scholar] [CrossRef]

- Peng, Y.; Fan, H.; Dong, Y.; Song, Y.; Han, H. Effects of exposure time on variations in the structure and hydrophobicity of polyvinylidene fluoride membranes prepared via vapor-induced phase separation. Appl. Surf. Sci. 2012, 258, 7872–7881. [Google Scholar] [CrossRef]

- Devi, S.; Ray, P.; Singh, K.; Singh, P.S. Preparation and characterization of highly micro-porous PVDF membranes for desalination of saline water through vacuum membrane distillation. Desalination 2014, 346, 9–18. [Google Scholar] [CrossRef]

- Peng, M.; Li, H.; Wu, L.; Zheng, Q.; Chen, Y.; Gu, W. Porous poly(vinylidene fluoride) membrane with highly hydrophobic surface. J. Appl. Polym. Sci. 2005, 98, 1358–1363. [Google Scholar] [CrossRef]

- Kuo, C.-Y.; Lin, H.-N.; Tsai, H.-A.; Wang, D.-M.; Lai, J.-Y. Fabrication of a high hydrophobic PVDF membrane via nonsolvent induced phase separation. Desalination 2008, 233, 40–47. [Google Scholar] [CrossRef]

- Fan, H.; Peng, Y.; Li, Z.; Chen, P.; Jiang, Q.; Wang, S. Preparation and characterization of hydrophobic PVDF membranes by vapor-induced phase separation and application in vacuum membrane distillation. J. Polym. Res. 2013, 20, 134. [Google Scholar] [CrossRef]

- Matsuyama, H.; Teramoto, M.; Nakatani, R.; Maki, T. Membrane formation via phase separation induced by penetration of nonsolvent from vapor phase. I. Phase diagram and mass transfer process. J. Appl. Polym. Sci. 1999, 74, 159–170. [Google Scholar] [CrossRef]

- Felder, R.M.; Rousseau, R.W. Elementry Principles of Chemical Processes, (with CD); John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Gopal, R.; Rizvi, S. Vapour pressures of some mono-and di-alkyl substituted aliphatic amides at different temperatures. J. Indian Chem. Soc. 1968, 45, 13–16. [Google Scholar]

- Guillen-Burrieza, E.; Thomas, R.; Mansoor, B.; Johnson, D.; Hilal, N.; Arafat, H. Effect of dry-out on the fouling of PVDF and PTFE membranes under conditions simulating intermittent seawater membrane distillation (SWMD). J. Membr.Sci. 2013, 438, 126–139. [Google Scholar] [CrossRef]

- Li, C.-L.; Wang, D.-M.; Deratani, A.; Quémener, D.; Bouyer, D.; Lai, J.-Y. Insight into the preparation of poly(vinylidene fluoride) membranes by vapor-induced phase separation. J. Membr. Sci. 2010, 361, 154–166. [Google Scholar] [CrossRef]

- Dorrer, C.; Rühe, J. Some thoughts on superhydrophobic wetting. Soft Matter 2009, 5, 51–61. [Google Scholar] [CrossRef]

- Feng, X.J.; Jiang, L. Design and Creation of Superwetting/Antiwetting Surfaces. Adv. Mater. 2006, 18, 3063–3078. [Google Scholar] [CrossRef]

- Zuo, J.; Chung, T.-S. Metal–Organic Framework-Functionalized Alumina Membranes for Vacuum Membrane Distillation. Water 2016, 8, 586. [Google Scholar] [CrossRef]

- Hilal, N.; Ismail, A.F.; Wright, C.J. PVDF Membranes for Membrane Distillation. In Membrane Fabrication; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Khayet, M.; Matsuura, T. Membrane Distillation: Principles and Applications; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Strathmann, H.; Kock, K. The formation mechanism of phase inversion membranes. Desalination 1977, 21, 241–255. [Google Scholar] [CrossRef]

- Li, M.; Katsouras, I.; Piliego, C.; Glasser, G.; Lieberwirth, I.; Blom, P.W.; de Leeuw, D.M. Controlling the microstructure of poly(vinylidene-fluoride)(PVDF) thin films for microelectronics. J. Mater. Chem. C 2013, 1, 7695–7702. [Google Scholar] [CrossRef]

- Matsuyama, H.; Teramoto, M.; Nakatani, R.; Maki, T. Membrane formation via phase separation induced by penetration of nonsolvent from vapor phase. II. Membrane morphology. J. Appl. Polym. Sci. 1999, 74, 171–178. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, L.; Sun, D.; An, Q.; Chen, H. Formation mechanism and crystallization of poly(vinylidene fluoride) membrane via immersion precipitation method. Desalination 2009, 236, 170–178. [Google Scholar] [CrossRef]

- Van de Witte, P.; Dijkstra, P.J.; Van den Berg, J.W.A.; Feijen, J. Phase separation processes in polymer solutions in relation to membrane formation. J. Membr. Sci. 1996, 117, 1–31. [Google Scholar] [CrossRef]

- Caquineau, H.; Menut, P.; Deratani, A.; Dupuy, C. Influence of the relative humidity on film formation by vapor induced phase separation. Polym. Eng. Sci. 2003, 43, 798–808. [Google Scholar] [CrossRef]

- Menut, P.; Su, Y.S.; Chinpa, W.; Pochat-Bohatier, C.; Deratani, A.; Wang, D.M.; Huguet, P.; Kuo, C.Y.; Lai, J.Y.; Dupuy, C. A top surface liquid layer during membrane formation using vapor-induced phase separation (VIPS)—Evidence and mechanism of formation. J. Membr. Sci. 2008, 310, 278–288. [Google Scholar] [CrossRef]

- Alkhudhiri, A.; Darwish, N.; Hilal, N. Membrane distillation: A comprehensive review. Desalination 2012, 287, 2–18. [Google Scholar] [CrossRef]

- Kang, G.; Cao, Y. Application and modification of poly(vinylidene fluoride) (PVDF) membranes—A review. J. Membr. Sci. 2014, 463, 145–165. [Google Scholar] [CrossRef]

- Park, Y.-S.; Lee, C.-K.; Kim, S.-K.; Oh, H.-J.; Lee, S.-H.; Choi, J.-S. Effect of temperature difference on performance of membrane crystallization-based membrane distillation system. Desalin. Water Treat. 2013, 51, 1362–1365. [Google Scholar] [CrossRef]

is initial polymer solution composition and

is initial polymer solution composition and  is composition of final membrane. DMAC: dimethylacetamide.

is composition of final membrane. DMAC: dimethylacetamide.

is initial polymer solution composition and

is initial polymer solution composition and  is composition of final membrane. DMAC: dimethylacetamide.

is composition of final membrane. DMAC: dimethylacetamide.

| Parameter | Range |

|---|---|

| Polyvinylidene fluoride (PVDF) concentration | 8%, 10%, 12% and 15% (w/w) |

| Relative humidity | N/A *, 37% (room relative humidity), 60% and 80% |

| Exposure time | 0 *, 2, 5, 10, 30, 60 and 120 min |

| Casting thickness | 250, 500, 750 and 1000 μm |

| Membrane | MPS (μm) | BP (μm) | CA | LEP (kPa) * |

|---|---|---|---|---|

| NIPS | 0.08 | 0.38 | 90.7 | 103.91 |

| VIPS (37% RH) | 7.80 | 12.25 | 136.3 | 106.79 |

| (60% RH) | 5.85 | 21.19 | 130.9 | 103.56 |

| (80% RH) | 6.07 | 10.63 | 127.2 | 106.55 |

| PVDF Concentration (w/w) | MPS (μm) | BP (μm) | CA (°) | LEP (kPa) | Volume Porosity |

|---|---|---|---|---|---|

| 8% | 0.2076 | 7.5956 | 123.2 | 108.30 | 48% |

| 10% | 0.1196 | 4.0325 | 113.1 | 111.21 | 70% |

| 12% | 0.089 | 0.210 | 94.6 | 143.93 | 88% |

| 15% | 0.064 | 0.652 | 88.9 | 96.64 | 67% |

| RH (%) | Exposure Time (min) | MPS (μm) | BP (μm) | CA (°) | LEP (kPa) |

|---|---|---|---|---|---|

| - | 2 | 0.057 | 0.10 | 91.0 | 118.34 |

| 60% | 5 | 0.060 | 0.13 | 94.3 | 167.66 |

| - | 10 | 0.137 | 0.78 | 104.5 | 137.18 |

| - | 2 | 0.073 | 0.17 | 93.6 | 141.17 |

| 80% | 5 | 0.126 | 0.85 | 97.7 | 108.86 |

| - | 10 | 0.140 | 2.90 | 98.2 | 105.66 |

| Casting Thickness (μm) | Exposure Time (min) | Average Flux (L/m2·h) | Average Salt Rejection (SR) (%) | Porosity (%) | MPS (µm) | Net Thickness (µm) |

|---|---|---|---|---|---|---|

| 500 | 5 | 8.7 ± 3.2 | 99.95 | 71 | 0.0863 | 246 |

| 10 | 13.8 ± 7.0 | 99.75 | 87 | 0.2347 | 265 | |

| 15 | 22.2 ± 6.9 | 99.91 | 76 | 0.1649 | 294 | |

| 1000 | 5 | 27.8 ± 1.9 | 99.81 | 65 | 0.0693 | 307 |

| 10 | 31.8 ± 2.9 | 99.91 | 68 | 0.0641 | 327 | |

| 15 | 11.0 ± 7.5 | 99.99 | 66 | 0.068 | 381 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdulla AlMarzooqi, F.; Roil Bilad, M.; Ali Arafat, H. Improving Liquid Entry Pressure of Polyvinylidene Fluoride (PVDF) Membranes by Exploiting the Role of Fabrication Parameters in Vapor-Induced Phase Separation VIPS and Non-Solvent-Induced Phase Separation (NIPS) Processes. Appl. Sci. 2017, 7, 181. https://doi.org/10.3390/app7020181

Abdulla AlMarzooqi F, Roil Bilad M, Ali Arafat H. Improving Liquid Entry Pressure of Polyvinylidene Fluoride (PVDF) Membranes by Exploiting the Role of Fabrication Parameters in Vapor-Induced Phase Separation VIPS and Non-Solvent-Induced Phase Separation (NIPS) Processes. Applied Sciences. 2017; 7(2):181. https://doi.org/10.3390/app7020181

Chicago/Turabian StyleAbdulla AlMarzooqi, Faisal, Muhammad Roil Bilad, and Hassan Ali Arafat. 2017. "Improving Liquid Entry Pressure of Polyvinylidene Fluoride (PVDF) Membranes by Exploiting the Role of Fabrication Parameters in Vapor-Induced Phase Separation VIPS and Non-Solvent-Induced Phase Separation (NIPS) Processes" Applied Sciences 7, no. 2: 181. https://doi.org/10.3390/app7020181