Optimization Design of Coupling Beam Metal Damper in Shear Wall Structures

Abstract

:1. Introduction

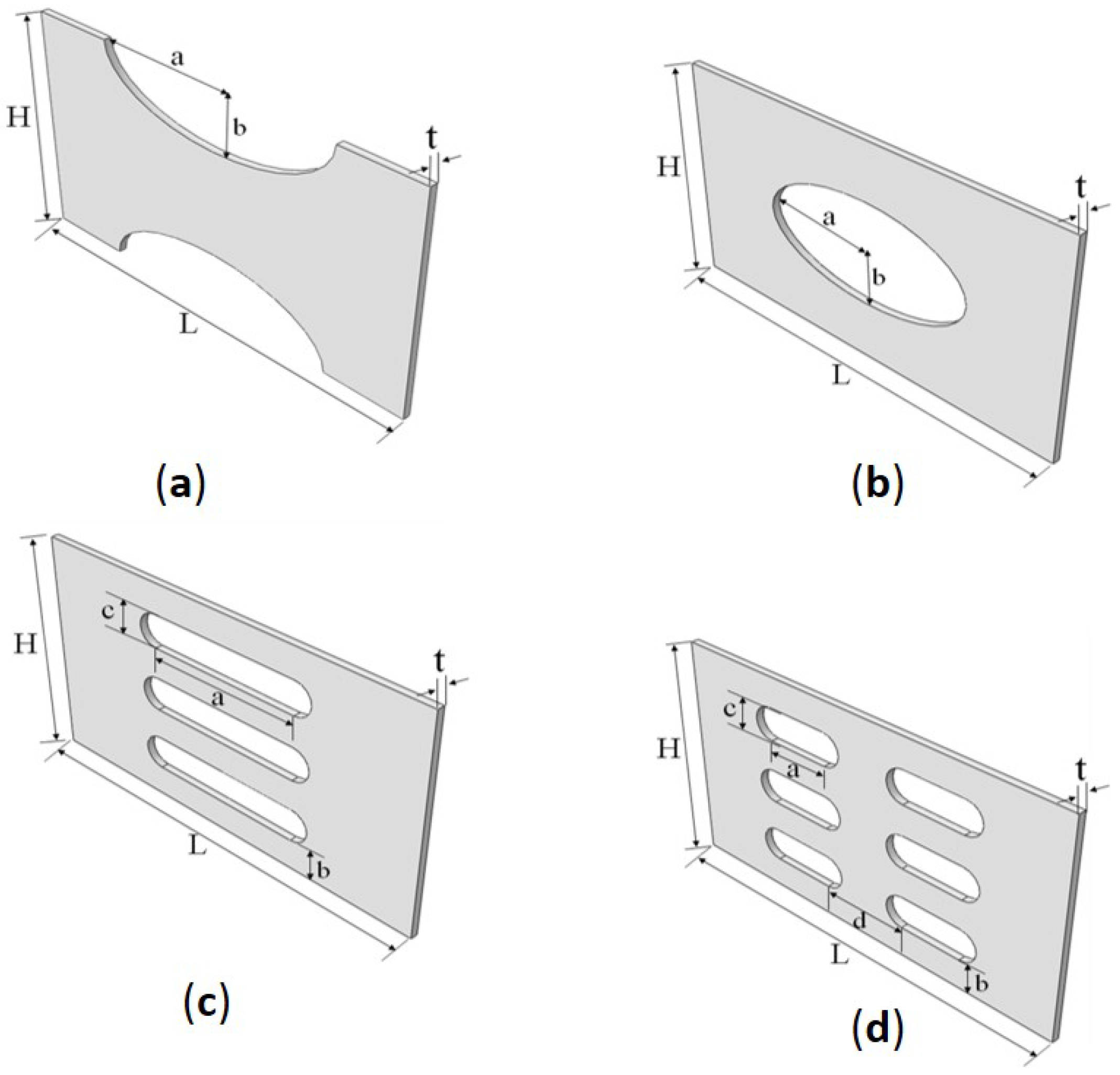

2. Coupling Beam Metal Dampers

2.1. Typical Pores in Coupling Beam Metal Dampers

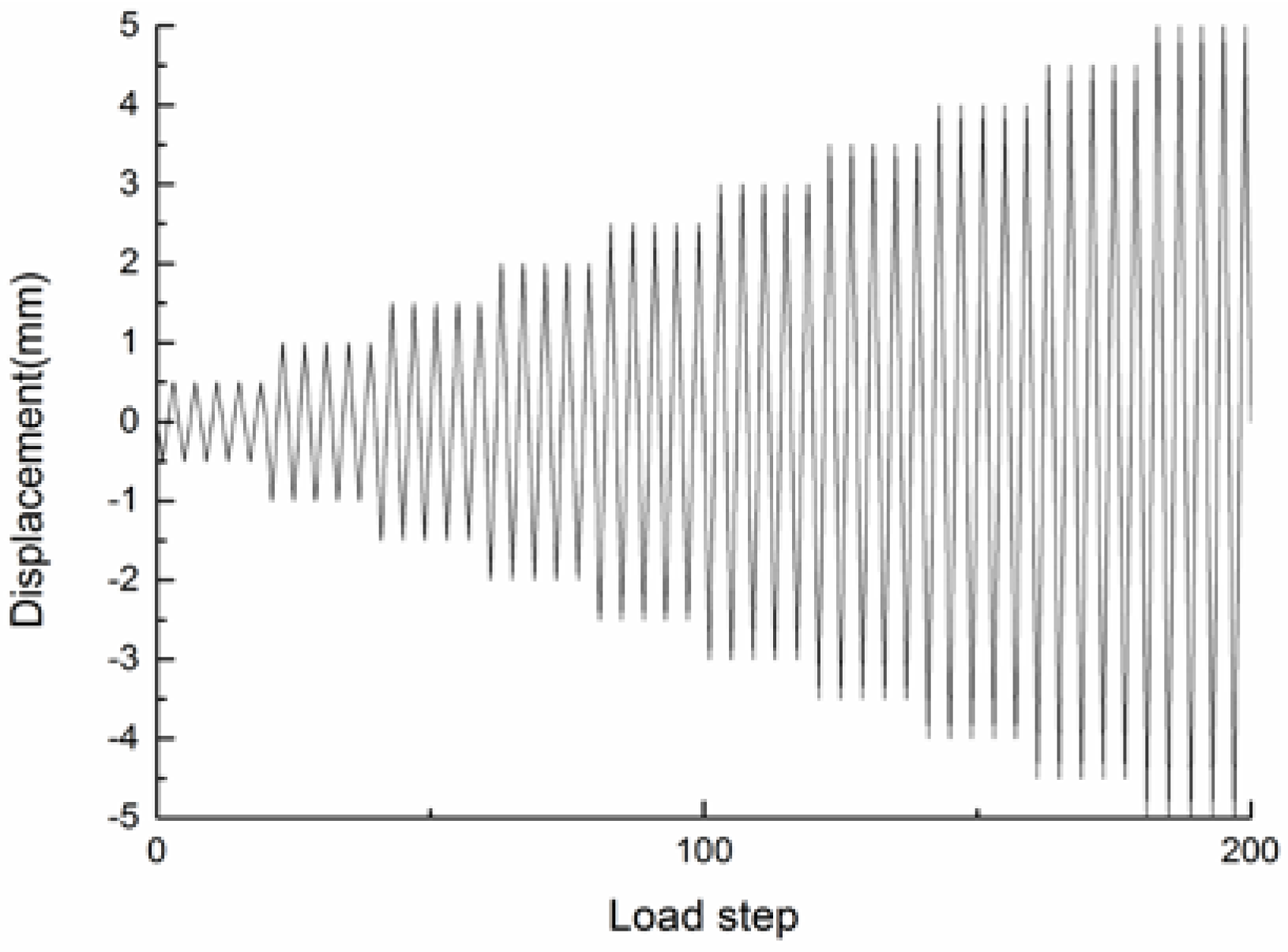

2.2. Hysteresis Energy Calculation

3. The Relationship between Pore Geometrical Parameters and Hysteresis Energy

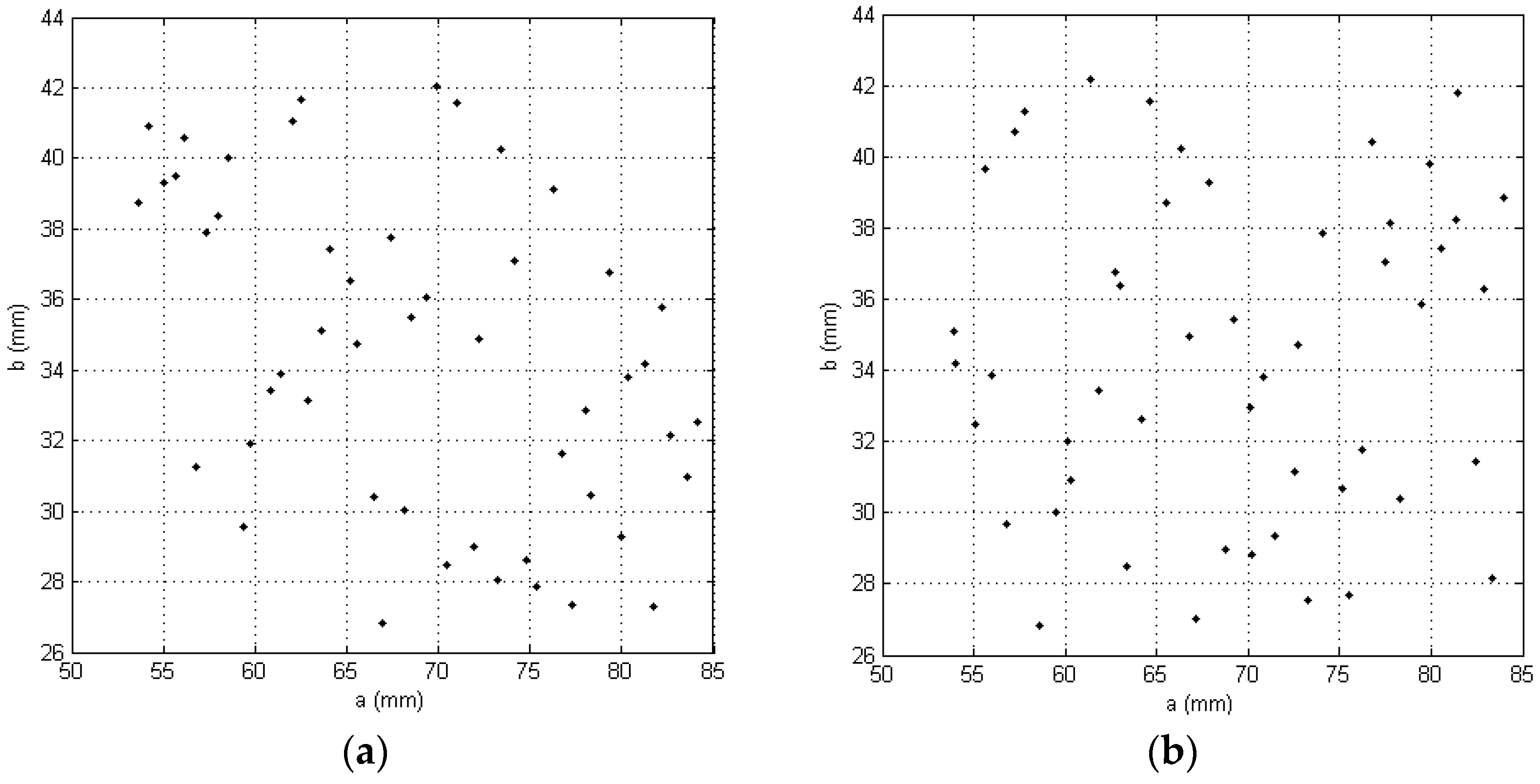

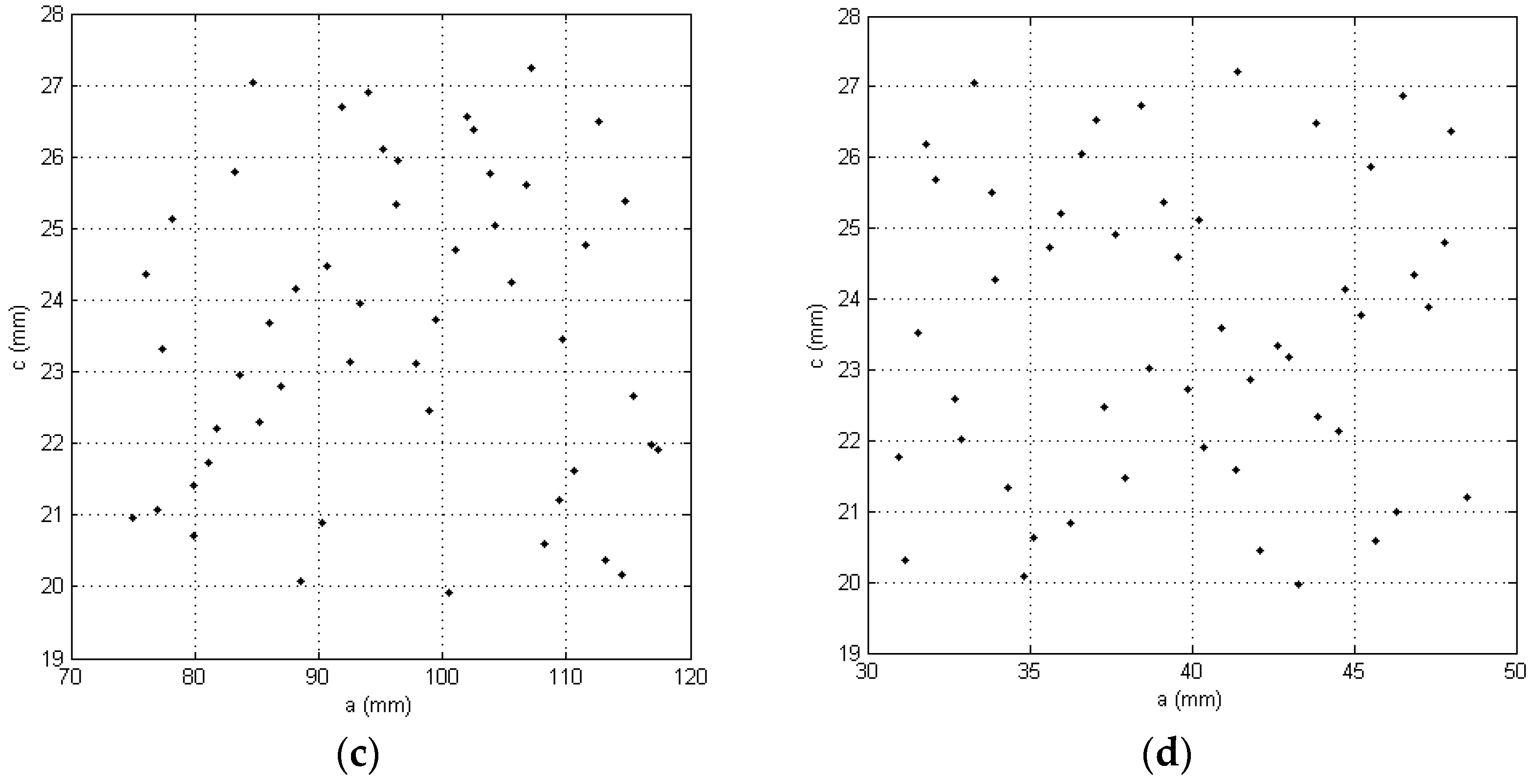

3.1. Sampling Selection

3.2. Construction of the Kriging Surrogate Model

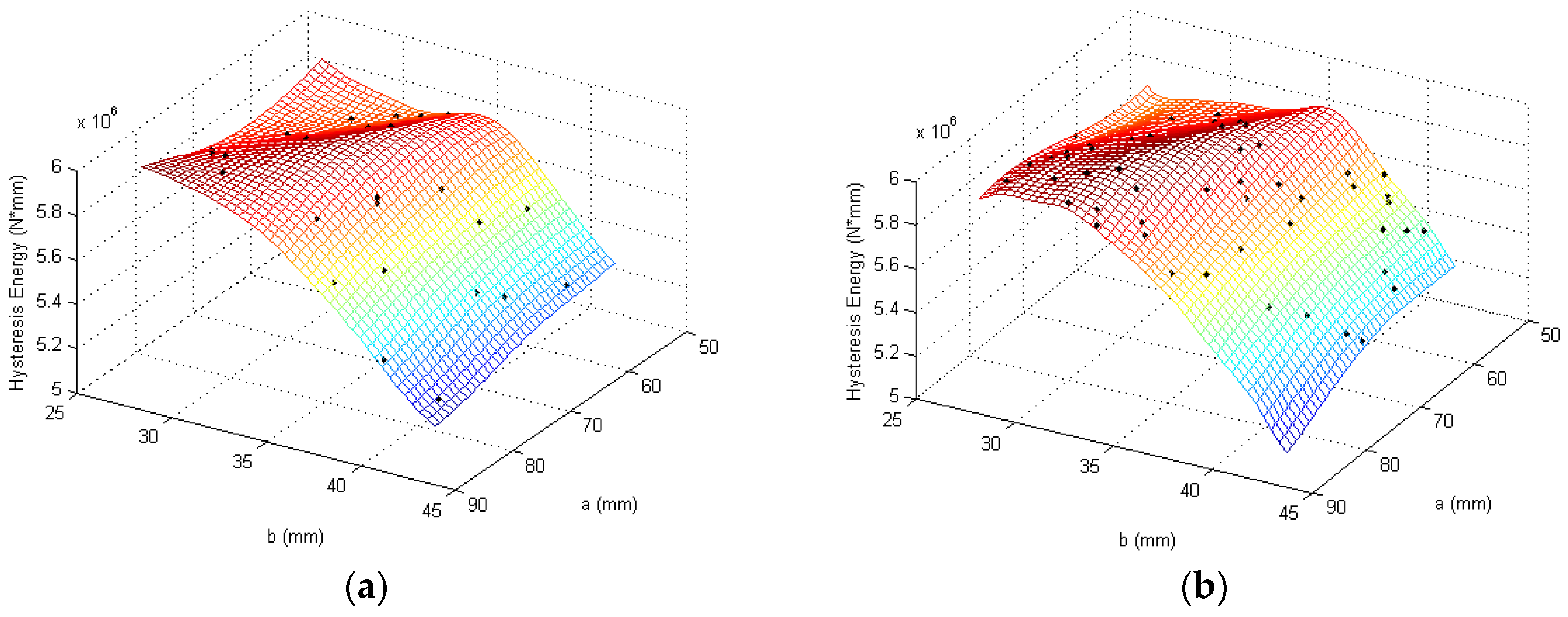

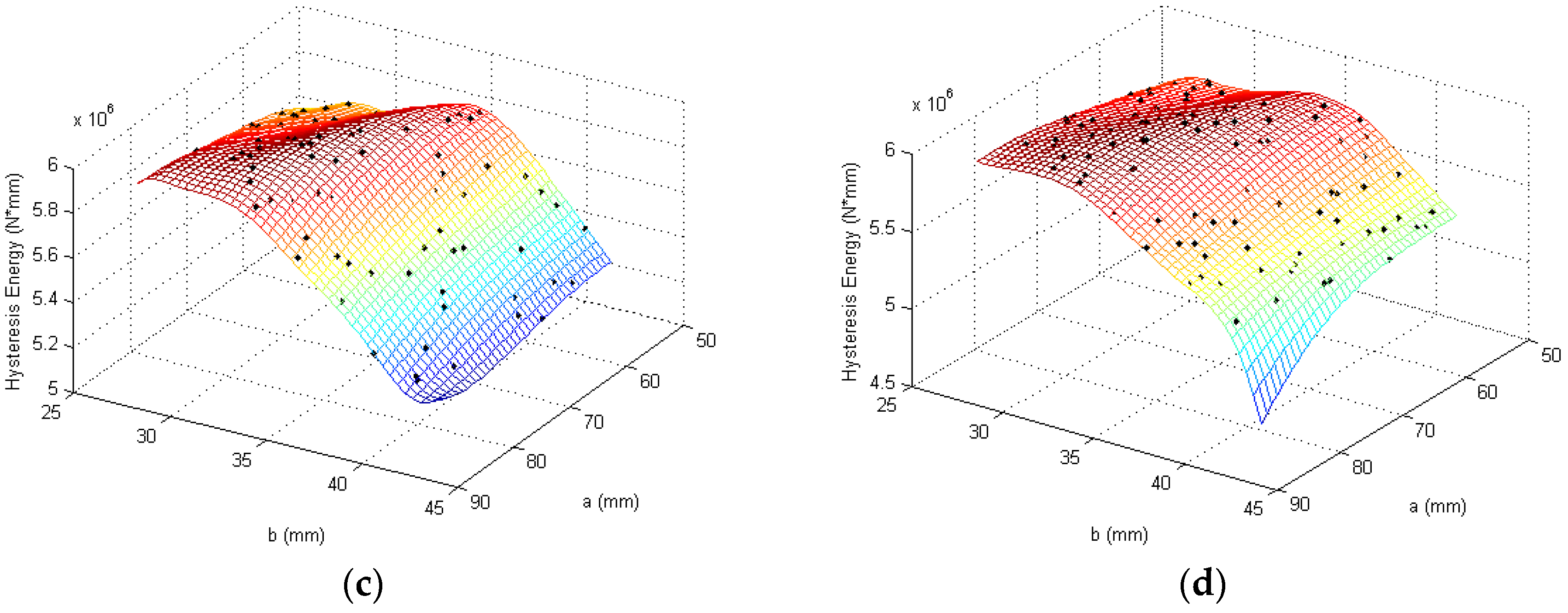

3.3. Design Parameters and Hysteretic Energy Dissipation Relationship

4. Optimization of Pore Parameters Based on the Kriging Surrogate Model

4.1. Optimization Problem

4.2. Process of Pore Parameter Optimization Based on the Kriging Model

4.3. Maximizing the Expected Increasing (EI) Add Criteria

4.4. Optimization Process

- Based on the initial sample points X and the response values Y, build agents for the Kriging model;

- Use the SCE optimization algorithm to obtain the EI maximum;

- Calculate the current optimal solution and its corresponding hysteresis energy, and set k = 1;

- Run the convergence criterion test; if the convergence criteria meet the requirements, then the object problem optimal solution is acquired. If it is not satisfied, the value will be added to the sample of the current optimal design for the next optimization modeling until the convergence criteria is met.

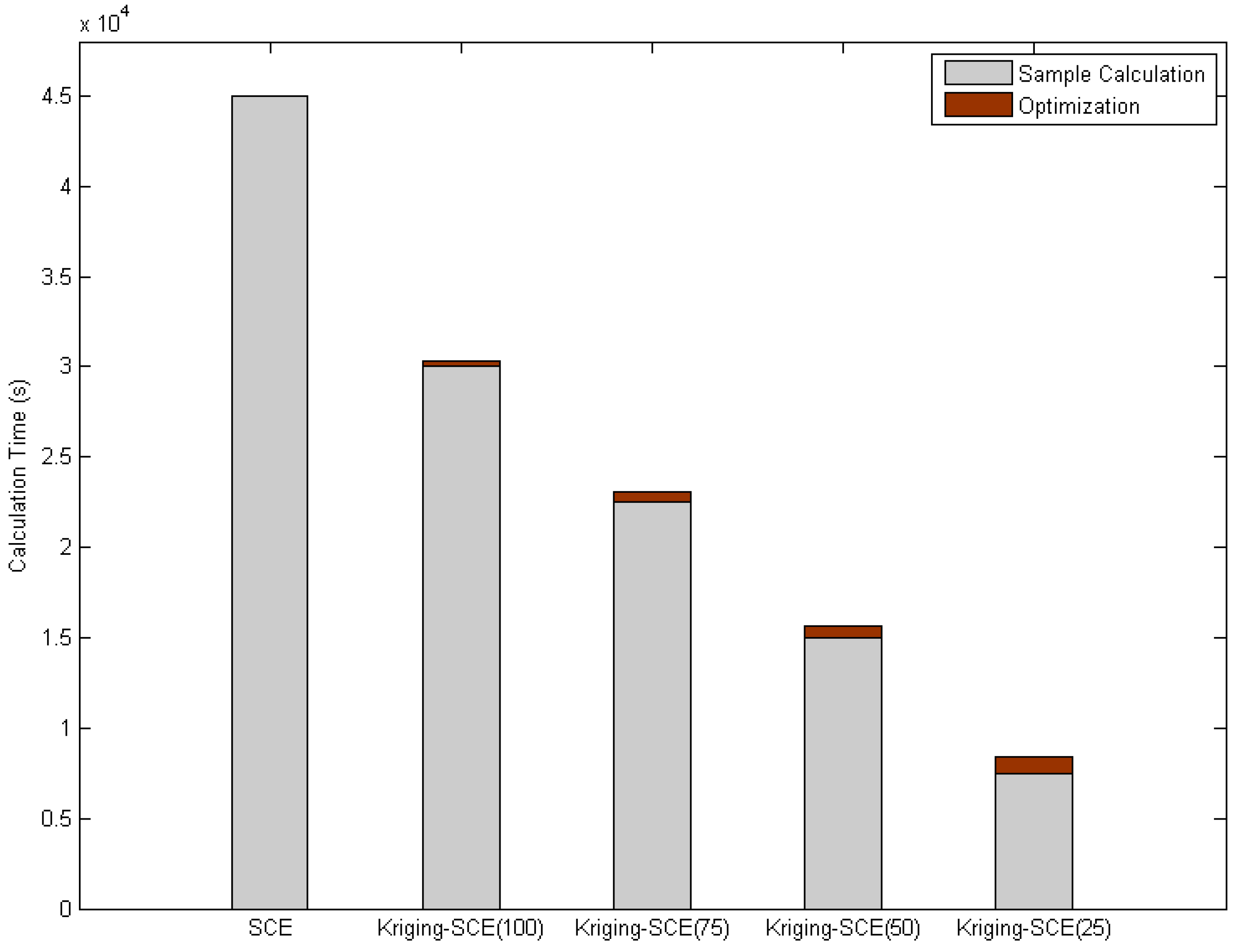

4.5. Optimal Design Results and Discussion

5. Conclusions

- (1)

- The maximum hysteresis energy exists in the feasible region for the plate with split elliptic pores, SP1, while the hysteresis energy is a monotone function in the feasible region. This suggests that the maximum hysteresis energy lies at the boundary of the feasible region for the plate with one central elliptic pore, and the ones with uniform row pores and uniform column-row pores.

- (2)

- The parameter of the optimum design method, based on the combination of the Kriging surrogate model with an intelligence algorithm, could significantly reduce the calculation time. Additionally, the initial sample conditions do influence the speed of the iterations.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Paulay, T. Simulated Seismic Loading of Spandrel Beams. J. Struct. Div. ASCE 1971, 97, 2047–2419. [Google Scholar]

- Choo, B.S.; Coull, A. Stiffening of Laterally Loaded Coupled shear Walls on Elastic Foundations. Build. Environ. 1984, 4, 251–256. [Google Scholar] [CrossRef]

- Kelly, J.M.; Skinner, R.I.; Heine, A.J. Mechanisms of Energy Absorption in Special Devices for Use in Earthquake Resistant Structures. Bull. Environ. Contam. Toxicol. 1972, 5, 63–73. [Google Scholar]

- Skinner, R.I.; Tyler, R.G.; Heine, A.J. Hysteretic Dampers for Earthquake-Resistant Structures. Earthq. Eng. Struct. Dyn. 1975, 3, 287–296. [Google Scholar] [CrossRef]

- Fortney, P.J.; Shahrooz, B.M.; Rassati, G.A. Large-Scale Testing of a Replaceable “Fuse” Steel Coupling Beam. J. Struct. Eng. 2007, 133, 1801–1807. [Google Scholar] [CrossRef]

- Rassati, G.A.; Fortney, P.J.; Shahrooz, B.M.; Johnson, P.W., III. Performance Evaluation of Innovative Hybrid Coupled Core Wall Systems. In Composite Construction in Steel and Concrete VI; American Society of Civil Engineers: Reston, VA, USA, 2011; pp. 479–492. [Google Scholar]

- Fortney, P.J.; Shahrooz, B.M.; Rassati, G.A. The Next Generation of Coupling Beams. In Proceedings of the Fifth International Conference on Composite Construction in Steel and Concrete, Mpumalanga, South Africa, 18–23 July 2004; pp. 619–630.

- Chung, H.S.; Moon, B.W.; Lee, S.K.; Park, J.H.; Min, K.W. Seismic performance of friction dampers using flexure of RC shear wall system. Struct. Des. Tall Spec. Build. 2009, 18, 807–822. [Google Scholar] [CrossRef]

- Kim, H.J.; Choi, K.S.; Oh, S.H.; Kang, C.H. Comparative study on seismic performance of conventional RC coupling beams and hybrid energy dissipative coupling beams used for RC shear walls. In Proceedings of the 15th World Conference on Earthquake Engineering, Lisbon, Portugal, 24–28 September 2012.

- Choi, K.Y.; Kim, H.J.; Kang, C.H. Experimental validation on dynamic response of RC shear wall systems coupled with hybrid energy dissipative devices. In Proceedings of the 15th World Conference on Earthquake Engineering, Lisbon, Portugal, 24–28 September 2012.

- Lyons, R.M.; Montgomery, M.S. Enhancing the seismic performance of RC coupled wall high-rise buildings with visco elastic coupling dampers. In Proceedings of the 15th World Conference on Earthquake Engineering, Lisbon, Portugal, 24–28 September 2012.

- Mao, C.; Dong, J.; Li, H.; Ou, J. Seismic performance of RC shear wall structure with novel shape memory alloy dampers in coupling beams. In Proceedings of the Society of Photo-Optical Instrumentation Engineers (SPIE) Conference Series, San Diego, CA, USA, 11 March 2012; pp. 304–320.

- Simpson, T. W.; Lin, D.K.; Wei, C. Sampling Strategies for Computer Experiments: Design and Analysis. Int. J. Reliab. Saf. 2001, 2, 209–240. [Google Scholar]

- Lee, K.H.; Park, G.J. A global robust optimization using the Kriging based Approximation model. JSME Int. J. 2006, 49, 779–788. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, X. Surrogate-based process optimization for reducing warpage in injection molding. J. Mater. Process. Technol. 2009, 209, 1302–1309. [Google Scholar] [CrossRef]

- Zhang, Z.; Ou, J.; He, Z. Optimization Design for Coupling Beam Dampers of Shear Walls. Appl. Mech. Mater. 2013, 444, 115–121. [Google Scholar] [CrossRef]

- Duan, Q.; Sorooshian, S.; Gupta, V. Effective and efficient global optimization for conceptual rainfall-runoff models. Water Resour. Res. 1992, 28, 1015–1031. [Google Scholar] [CrossRef]

- Sakata, S.; Ashida, F.; Zako, M. An efficient algorithm for Kriging approximation and optimization with large-scale sampling data. Comput. Methods Appl. Mech. Eng. 2004, 193, 385–404. [Google Scholar] [CrossRef]

- Song, X.M.; Xia, J. Integration of a statistical emulator approach with the SCE-UA method for parameter optimization of a hydrological model. Chin. Sci. Bull. 2012, 57, 3397–3403. [Google Scholar] [CrossRef]

| Opening Shapes | Design Variables | x1 (mm) | x2 (mm) | Hysteresis Energy (N*mm) | Hysteresis Energy Improvement |

|---|---|---|---|---|---|

| SP1 | SOS | 76, 72 | 31, 64 | 5,940,777 | 0.064% |

| OMS | 74, 74 | 31, 78 | 5,944,571 | ||

| SP2 | SOS | 58, 60 | 26, 83 | 4,252,911 | 5.3% |

| OMS | 53, 42 | 26, 71 | 4,477,092 | ||

| SP3 | SOS | 84, 66 | 27, 03 | 2,141,277 | 13.7% |

| OMS | 74, 67 | 27, 27 | 2,436,392 | ||

| SP4 | SOS | 32, 04 | 26, 9 | 3,950,700 | 6% |

| OMS | 30, 68 | 27, 27 | 4,084,100 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Ou, J.; Li, D.; Zhang, S. Optimization Design of Coupling Beam Metal Damper in Shear Wall Structures. Appl. Sci. 2017, 7, 137. https://doi.org/10.3390/app7020137

Zhang Z, Ou J, Li D, Zhang S. Optimization Design of Coupling Beam Metal Damper in Shear Wall Structures. Applied Sciences. 2017; 7(2):137. https://doi.org/10.3390/app7020137

Chicago/Turabian StyleZhang, Zhe, Jinping Ou, Dongsheng Li, and Shuaifang Zhang. 2017. "Optimization Design of Coupling Beam Metal Damper in Shear Wall Structures" Applied Sciences 7, no. 2: 137. https://doi.org/10.3390/app7020137