Postharvest Quality Monitoring and Variance Analysis of Peach and Nectarine Cold Chain with Multi-Sensors Technology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plant Material

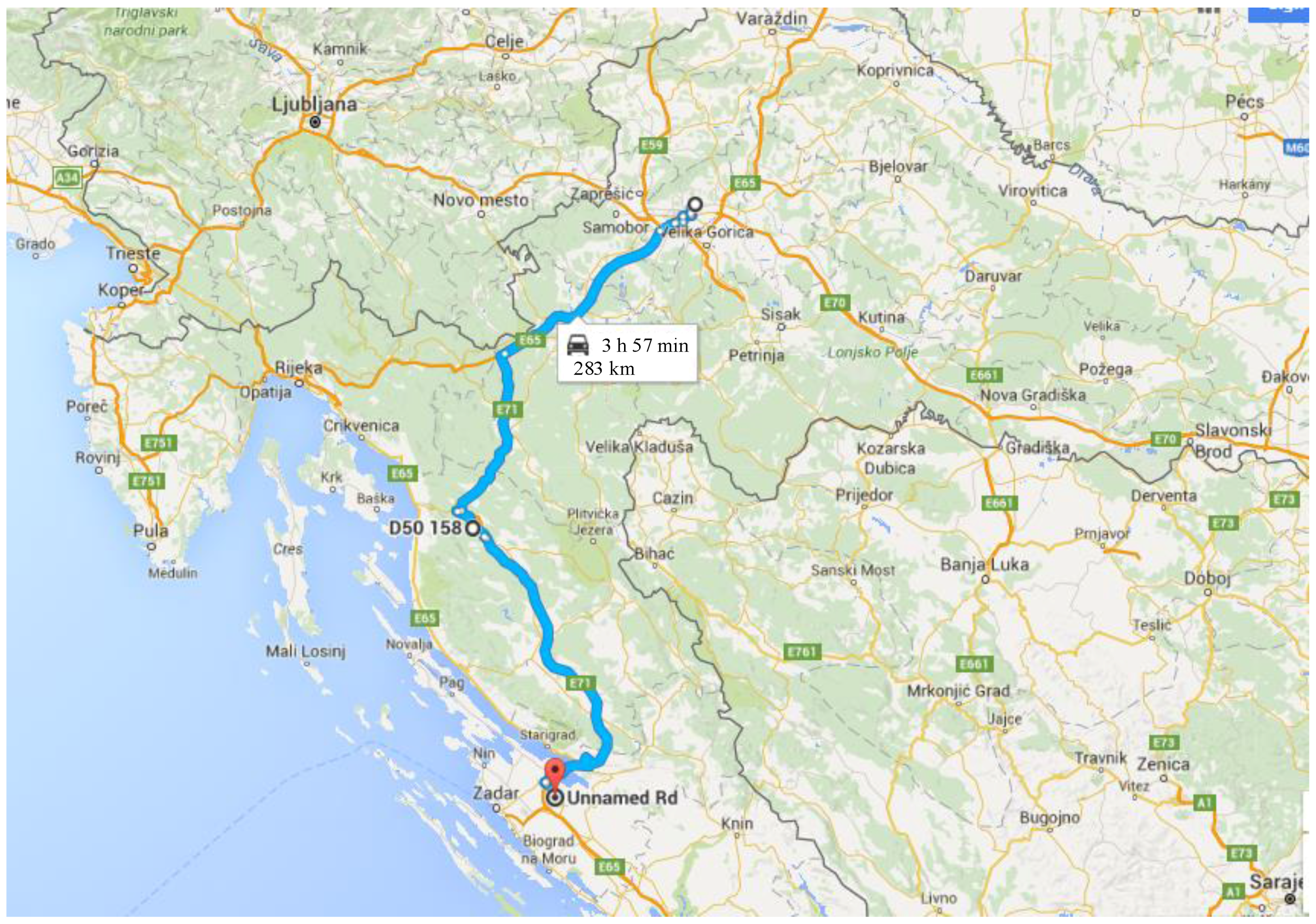

2.2. Experimental Scheme

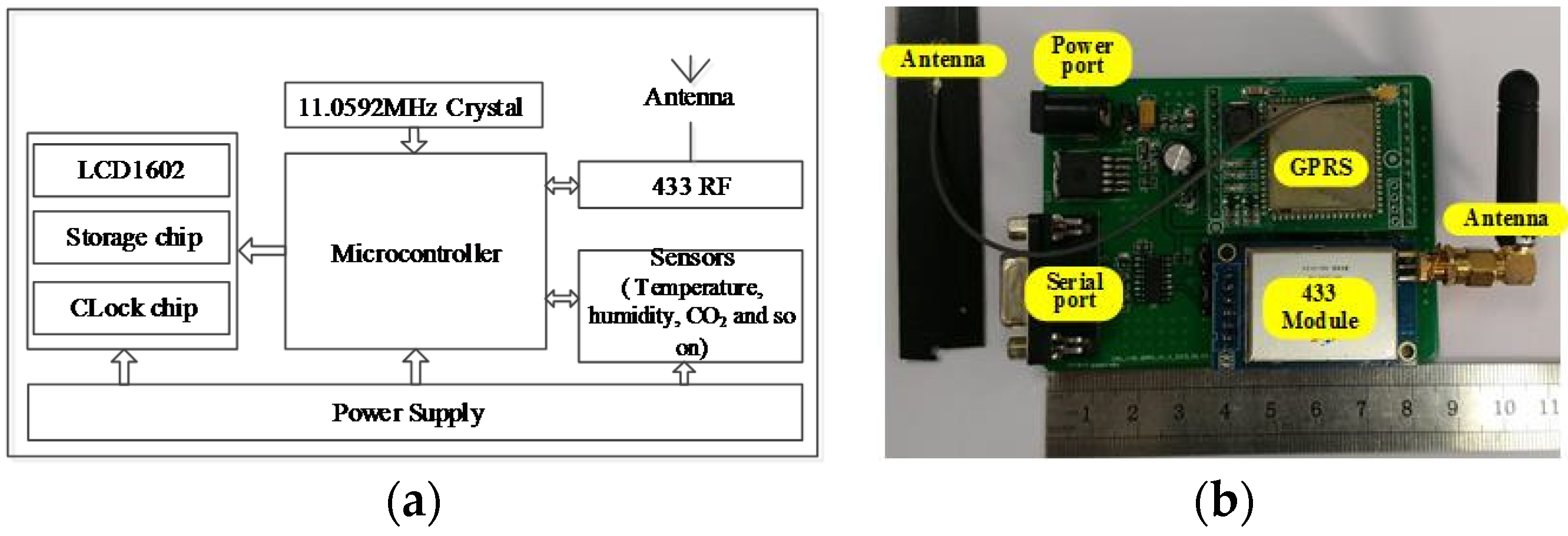

2.3. WSN Nodes

2.4. Data Analysis

3. Results and Discussion

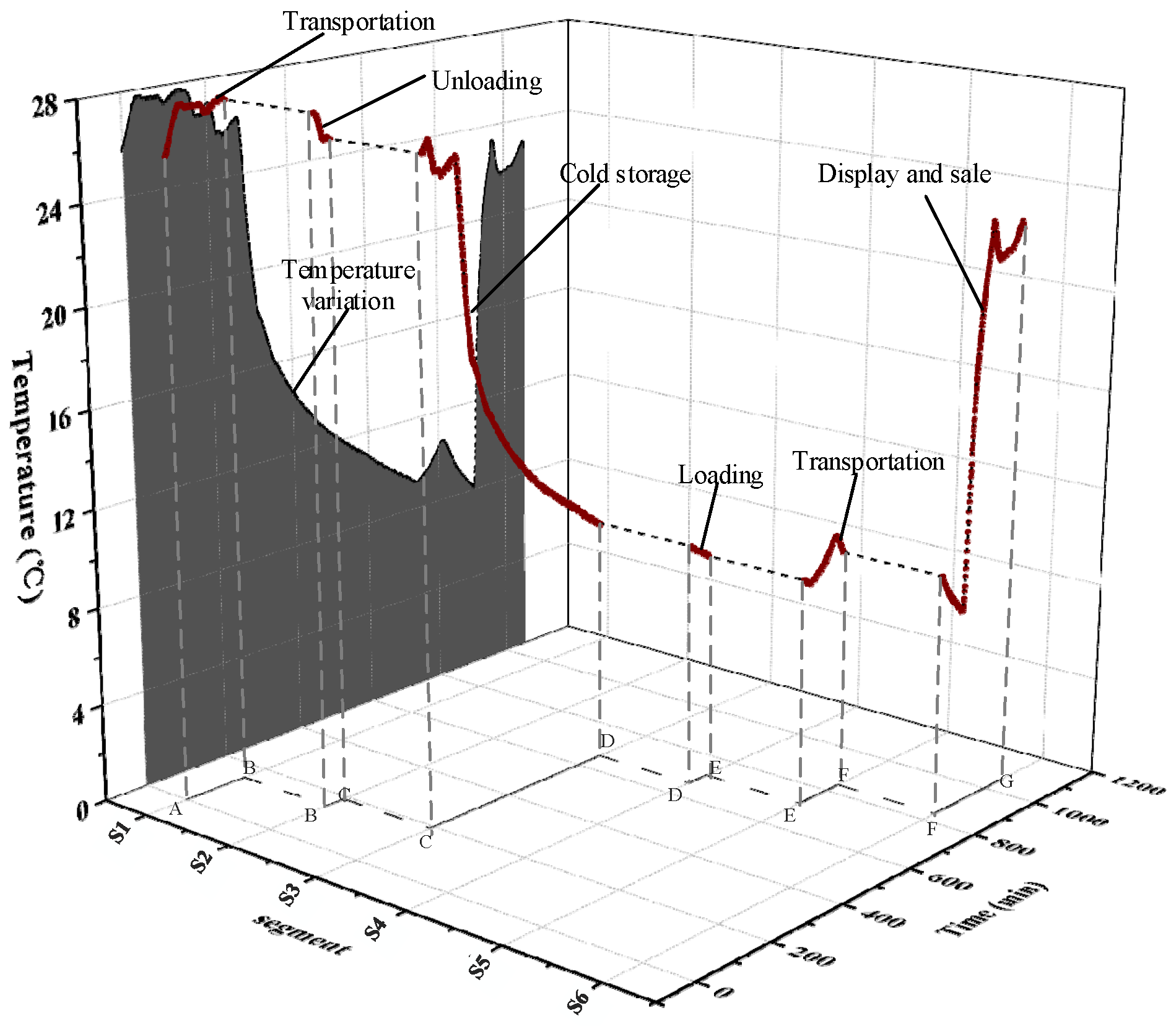

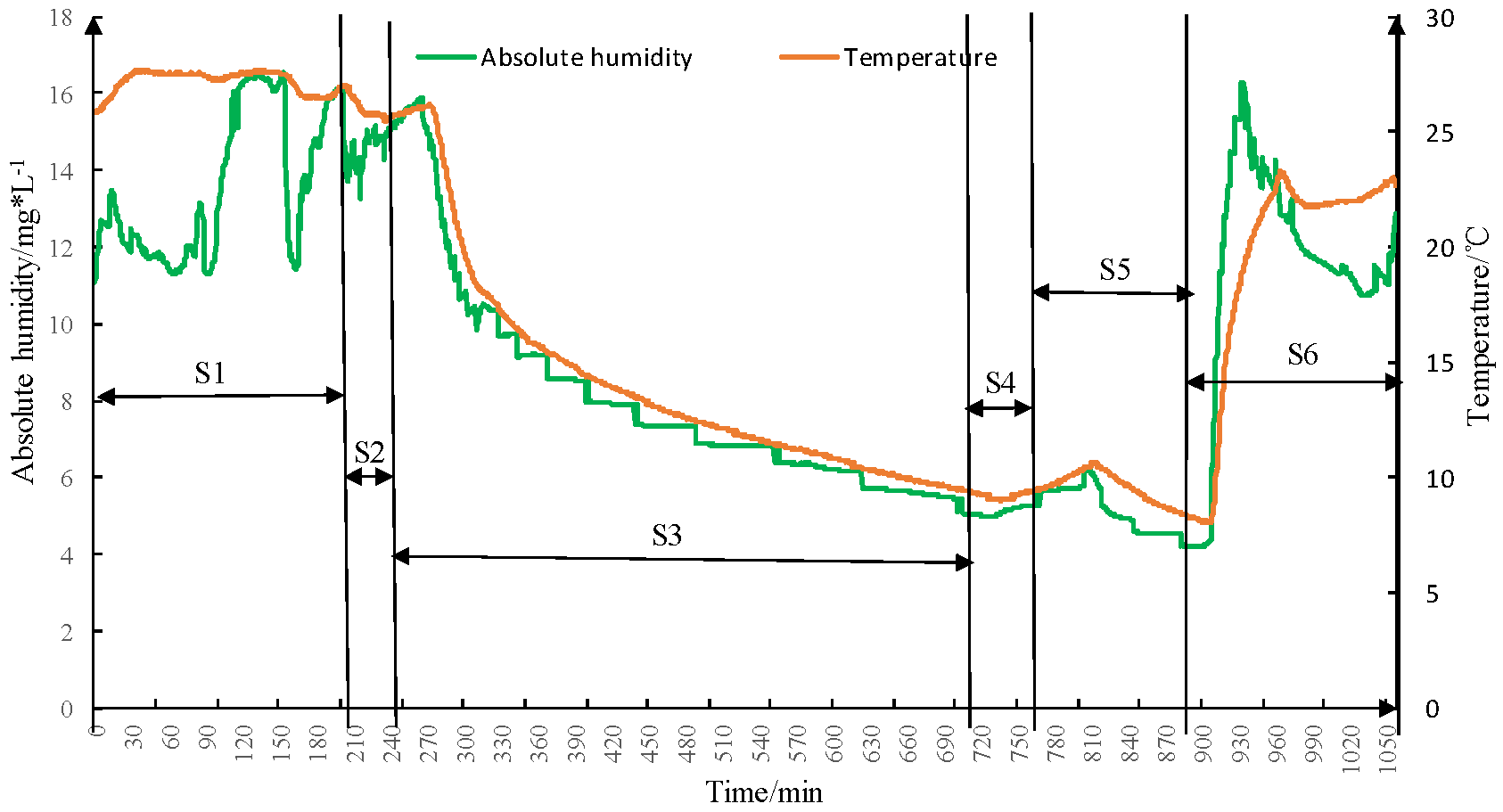

3.1. Business Flow Analysis for Cold Chain

- ✔

- S1: Normal transportation (about 4 h). Four boxes of fruit were harvested during non-rainy cooler times of the day (<25 °C) and transported from Kašić (near Zadar), Croatia to overnight cold storage in Zagreb. The peaches should be picked when they are fully ripe during dry weather and packed into boxes. The temperature, relative humidity, and CO2 level varied with the ambient air and respiration heat released by fruit. The fruit quality deteriorates and senesces quickly at ambient temperature after harvest.

- ✔

- S2: Unloading cargo. This process involved the unloading of the fruit from the car to the refrigerator, which lasted about 40 min. The temperature and relative humidity varied with the ambient temperature. This process should be performed fast and carefully to reduce the handling damage.

- ✔

- S3: Fresh fruit cold storage (about 11 h). The fruit was stored in the refrigerator overnight. The temperature decreased rapidly and the relative humidity rose quickly in this process, resulting in the complex change of CO2 levels.

- ✔

- S4: Loading cargo (40 min). The fruit was loaded from the refrigerator to the car the next morning. The temperature rose, and relative humidity and CO2 level decreased because of the influence of ambient air in the process.

- ✔

- S5: Short normal transportation (30 min). Fruit were transported to the market. The temperature was continuously rising to the ambient temperature level, and the relative humidity and CO2 level were falling continuously.

- ✔

- S6: Display and sale (several days). The fruit were simulated as being displayed and sold by wholesalers or retailers. The temperature, relative humidity, and CO2 level varied with the ambient temperature.

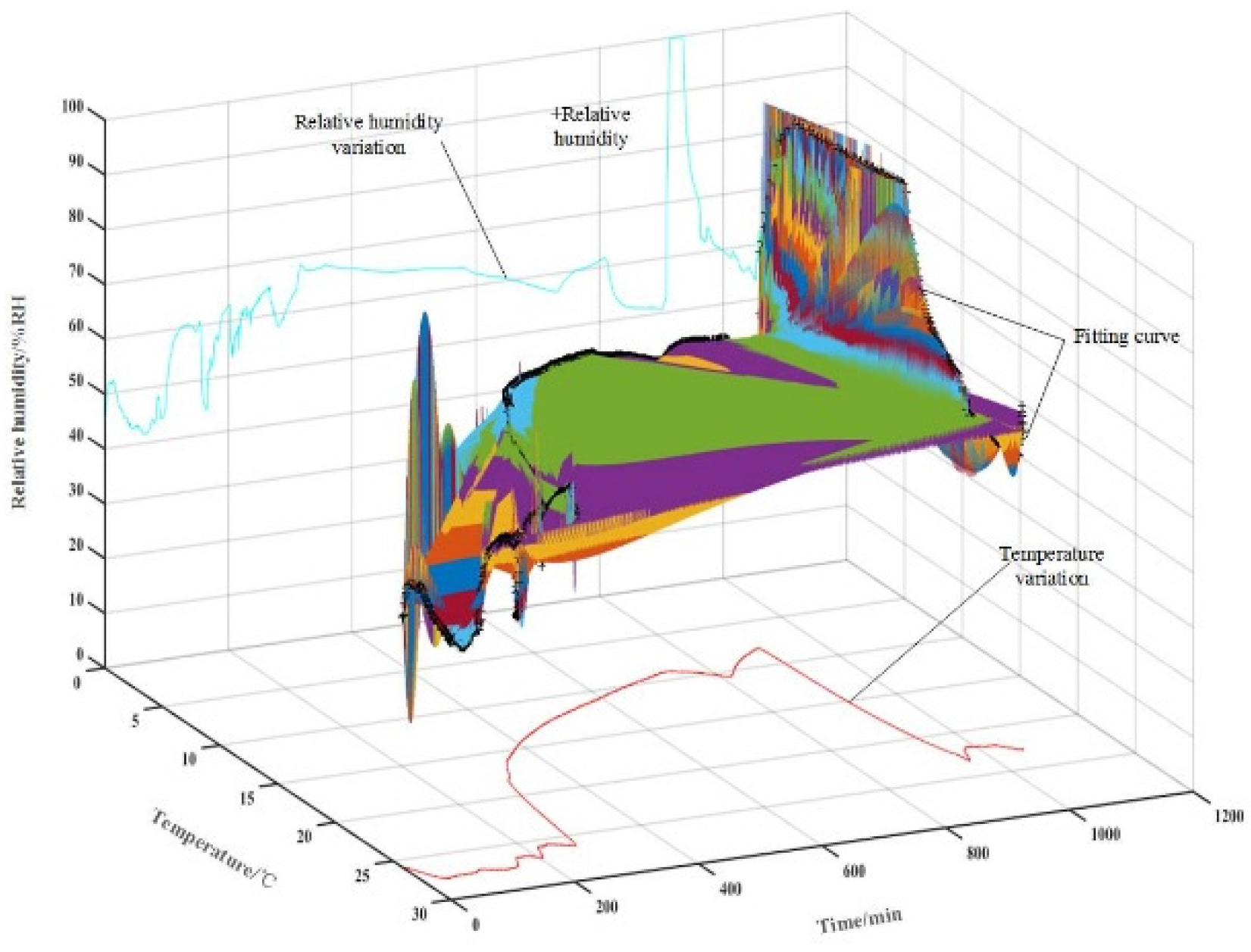

3.2. Environmental Fluctuation Analysis for Cold Chain

3.2.1. Temperature Change along with Time

3.2.2. Relative Humidity Change over Time

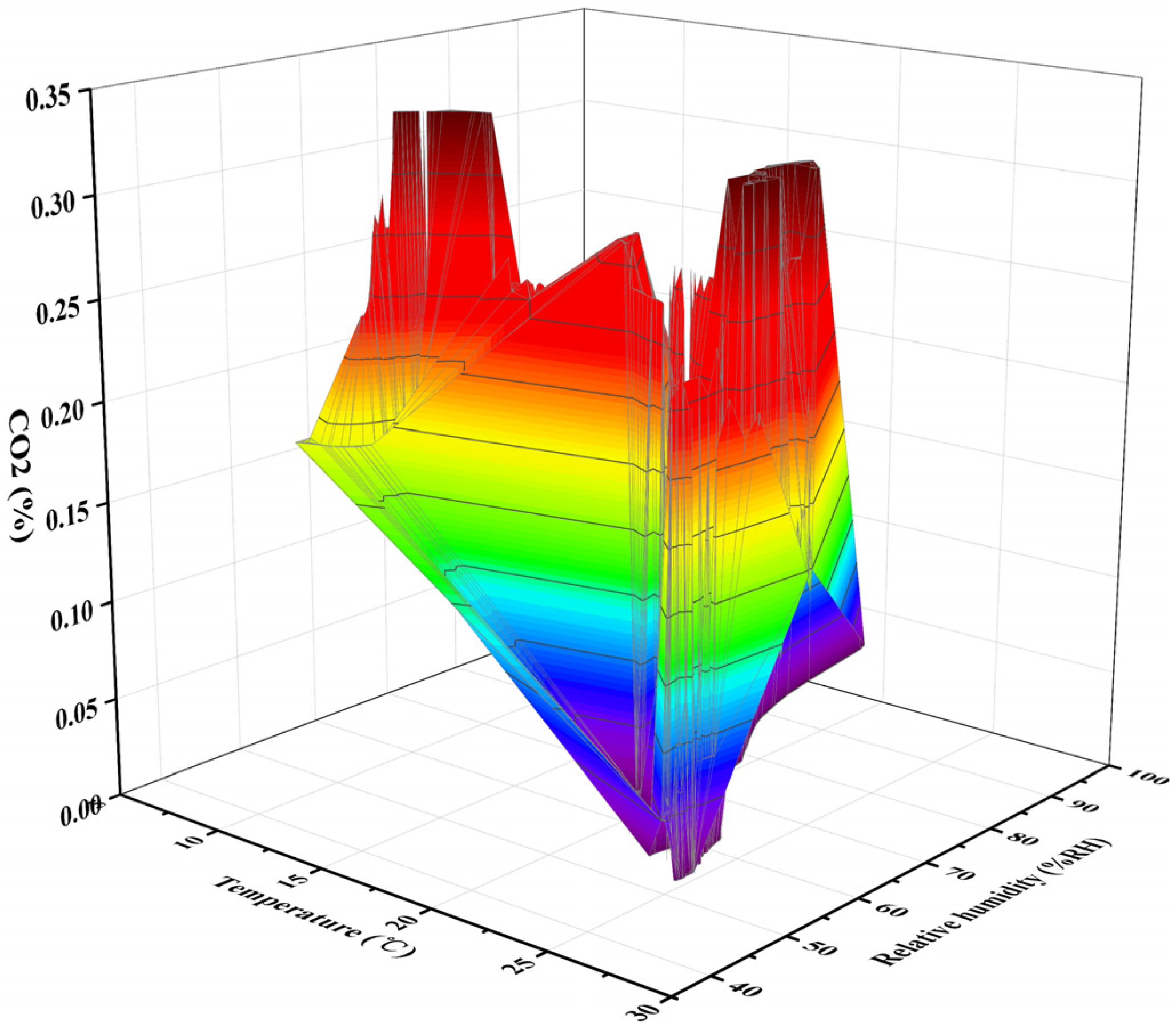

3.2.3. CO2 Level Change with Temperature and Relative Humidity Fluctuation

3.2.4. Accuracy Evaluation of Sensor Nodes

3.3. Fruit Quality Parameter Analysis

3.3.1. The Weight Change of Peaches and Nectarines

3.3.2. The Firmness Change of Peaches and Nectarines

3.3.3. The SSC Change of Peaches and Nectarines

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Practical Applications

References

- Gang, C.; Li, J.; Chen, Y.; Wang, Y.; Li, H.; Pan, B.; Odeh, I. Synergistic Effect of Chemical Treatments on Storage Quality and Chilling Injury of Honey Peaches. J. Food Process. Preserv. 2015, 39, 1108–1117. [Google Scholar] [CrossRef]

- Rizzolo, A.; Bianchi, G.; Vanoli, M.; Lurie, S.; Spinelli, L.; Torricelli, A. Electronic nose to detect volatile compound profile and quality changes in ‘Spring Belle’ peach (Prunus persica L.) during cold storage in relation to fruit optical properties measured by time-resolved reflectance spectroscopy. J. Agric. Food Chem. 2013, 61, 1671–1685. [Google Scholar] [CrossRef] [PubMed]

- Shinya, P.; Contador, L.; Predieri, S.; Rubio, P.; Infante, R. Peach ripening: Segregation at harvest and postharvest flesh softening. Postharvest Biol. Technol. 2013, 86, 472–478. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, F.; Yang, H.; Sun, X.; Liu, H.; Gong, X.; Jiang, C.; Ding, C. Changes in firmness, pectin content and nanostructure of two crisp peach cultivars after storage. LWT-Food Sci. Technol. 2010, 43, 26–32. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, F.; Yang, H.; Ye, X.; Sun, X.; Liu, D.; Yang, B.; An, H.; Deng, Y. Effects of temperature and cultivar on nanostructural changes of water-soluble pectin and chelate-soluble pectin in peaches. Carbohydr. Polym. 2012, 87, 816–821. [Google Scholar] [CrossRef]

- Raffo, A.; Nardo, N.; Tabilio, M.R.; Paoletti, F. Effects of cold storage on aroma compounds of white- and yellow-fleshed peaches. Eur. Food Res. Technol. 2008, 226, 1503–1512. [Google Scholar] [CrossRef]

- Laguerre, O.; Hoang, H.M.; Flick, D. Experimental investigation and modelling in the food cold chain: Thermal and quality evolution. Trends Food Sci. Technol. 2013, 29, 87–97. [Google Scholar] [CrossRef]

- Aung, M.M.; Chang, Y.S. Temperature management for the quality assurance of a perishable food supply chain. Food Control 2014, 40, 198–207. [Google Scholar] [CrossRef]

- Lim, T.-P.; Chye, F.Y.; Sulaiman, M.R.; Suki, N.M.; Lee, J.-S. A structural modeling on food safety knowledge, attitude, and behaviour among Bum Bum Island community of Semporna, Sabah. Food Control 2016, 60, 241–246. [Google Scholar] [CrossRef]

- Hertog, M.L.A.T.M.; Uysal, I.; McCarthy, U.; Verlinden, B.M.; Nicolaï, B.M. Shelf life modelling for first-expired-first-out warehouse management. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20130306. [Google Scholar] [CrossRef] [PubMed]

- Sciortino, R.; Micale, R.; Enea, M.; La Scalia, G. A webGIS-based system for real time shelf life prediction. Comput. Electron. Agric. 2016, 127, 451–459. [Google Scholar] [CrossRef]

- Li, Y.X.; Wang, G.X.; Liang, L.S. Effect of cold acclimation treatment and exogenous ethylene treatment on woolliness related enzymes on ‘Okubo’ peach fruits during low temperature storage. Acta Hortic. 2012, 934, 1103–1109. [Google Scholar] [CrossRef]

- Infante, R.; Aros, D.; Contador, L.; Rubio, P. Does the maturity at harvest affect quality and sensory attributes of peaches and nectarines? N. Z. J. Crop Hortic. Sci. 2012, 40, 103–113. [Google Scholar] [CrossRef]

- Yang, H.; Chen, F.; An, H.; Lai, S. Comparative studies on nanostructures of three kinds of pectins in two peach cultivars using atomic force microscopy. Postharvest Biol. Technol. 2009, 51, 391–398. [Google Scholar] [CrossRef]

- Girardi, C.L.; Corrent, A.R.; Lucchetta, L.; Zanuzo, M.R.; Da Costa, T.S.; Brackmann, A.; Twyman, R.M.; Nora, F.R.; Nora, L.; Silva, J.A.; et al. Effect of ethylene, intermittent warming and controlled atmosphere on postharvest quality and the occurrence of woolliness in peach (Prunus persica cv. Chiripá) during cold storage. Postharvest Biol. Technol. 2005, 38, 25–33. [Google Scholar] [CrossRef]

- Akbudak, B.; Eris, A. Physical and chemical changes in peaches and nectarines during the modified atmosphere storage. Food Control 2004, 15, 307–313. [Google Scholar] [CrossRef]

- Lurie, S.; Crisosto, C.H. Chilling injury in peach and nectarine. Postharvest Biol. Technol. 2005, 37, 195–208. [Google Scholar] [CrossRef]

- Ortiz, A.; Echeverría, G.; Graell, J.; Lara, I. Overall quality of ‘Rich Lady’ peach fruit after air- or CA storage. The importance of volatile emission. LWT-Food Sci. Technol. 2009, 42, 1520–1529. [Google Scholar] [CrossRef]

- Ahmed, M.J.; Singh, Z.; Khan, A.S. Postharvest Aloe vera gel-coating modulates fruit ripening and quality of ‘Arctic Snow’ nectarine kept in ambient and cold storage. Int. J. Food Sci. Technol. 2009, 44, 1024–1033. [Google Scholar] [CrossRef]

- Jin, P.; Wang, K.; Shang, H.; Tong, J.; Zheng, Y. Low-temperature conditioning combined with methyl jasmonate treatment reduces chilling injury of peach fruit. J. Sci. Food Agric. 2009, 89, 1690–1696. [Google Scholar] [CrossRef]

- Zhang, B.; Xi, W.; Wei, W.; Shen, J.; Ferguson, I.; Chen, K. Changes in aroma-related volatiles and gene expression during low temperature storage and subsequent shelf-life of peach fruit. Postharvest Biol. Technol. 2011, 60, 7–16. [Google Scholar] [CrossRef]

- Zhu, S.; Liu, M.; Zhou, J. Inhibition by nitric oxide of ethylene biosynthesis and lipoxygenase activity in peach fruit during storage. Postharvest Biol. Technol. 2006, 42, 41–48. [Google Scholar] [CrossRef]

- Casals, C.; Teixidó, N.; Viñas, I.; Llauradó, S.; Usall, J. Control of Monilinia spp. on stone fruit by curing treatments: Part I. The effect of temperature, exposure time and relative humidity on curing efficacy. Postharvest Biol. Technol. 2010, 56, 19–25. [Google Scholar] [CrossRef]

- Ziosi, V.; Noferini, M.; Fiori, G.; Tadiello, A.; Trainotti, L.; Casadoro, G.; Costa, G. A new index based on vis spectroscopy to characterize the progression of ripening in peach fruit. Postharvest Biol. Technol. 2008, 49, 319–329. [Google Scholar] [CrossRef]

- Ortiz, A.; Seymour, G.B.; Tucker, G.A.; Lara, I. Cell wall disassembly during the melting phase of softening in ‘Snow Queen’ nectarines. Postharvest Biol. Technol. 2010, 58, 88–92. [Google Scholar] [CrossRef]

- La Scalia, G.; Nasca, A.; Corona, O.; Settanni, L.; Micale, R. An innovative shelf life model based on smart logistic unit for an efficient management of the perishable food supply chain. J. Food Process Eng. 2015, 40. [Google Scholar] [CrossRef]

- Xiao, X.; Wang, X.; Zhang, X.; Chen, E.; Li, J. Effect of the Quality Property of Table Grapes in Cold Chain Logistics-Integrated WSN and AOW. Appl. Sci. 2015, 5, 747–760. [Google Scholar] [CrossRef]

- Xiao, X.; He, Q.; Fu, Z.; Xu, M.; Zhang, X. Applying CS and WSN methods for improving efficiency of frozen and chilled aquatic products monitoring system in cold chain logistics. Food Control 2016, 60, 656–666. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Wang, H.; He, J.; Li, L.; Shen, M.; Tan, X.; Min, H.; Zheng, L. Wireless sensor network for real-time perishable food supply chain management. Comput. Electron. Agric. 2015, 110, 196–207. [Google Scholar] [CrossRef]

- Qi, L.; Xu, M.; Fu, Z.; Mira, T.; Zhang, X. C2SLDS: A WSN-based perishable food shelf-life prediction and LSFO strategy decision support system in cold chain logistics. Food Control 2014, 38, 19–29. [Google Scholar] [CrossRef] [Green Version]

- Ruiz-Garcia, L.; Barreiro, P.; Robla, J.I. Performance of ZigBee-Based wireless sensor nodes for real-time monitoring of fruit logistics. J. Food Eng. 2008, 87, 405–415. [Google Scholar] [CrossRef] [Green Version]

- Mahajan, P.V.; Caleb, O.J.; Singh, Z.; Watkins, C.B.; Geyer, M. Postharvest treatments of fresh produce. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20130309. [Google Scholar] [CrossRef] [PubMed]

- Lee, T.-C.; Zhong, P.-J.; Chang, P.-T. The effects of preharvest shading and postharvest storage temperatures on the quality of ‘Ponkan’ (Citrus reticulata Blanco) mandarin fruits. Sci. Hortic. 2015, 188, 57–65. [Google Scholar] [CrossRef]

- Shahak, Y. Photoselective netting: An overview of the concept, R&D and practical implementation in agriculture. Acta Hortic. 2014, 1015, 155–162. [Google Scholar]

- Shahak, Y.; Kong, Y.; Ratner, K. The wonders of yellow netting. Acta Hortic. 2016, 1134, 327–334. [Google Scholar] [CrossRef]

- Cano-Salazar, J.; Echeverría, G.; Crisosto, C.H.; Lopez, L. Cold-Storage Potential of Four Yellow-Fleshed Peach Cultivars Defined by Their Volatile Compounds Emissions, Standard Quality Parameters, and Consumer Acceptance. J. Agric. Food Chem. 2012, 60, 1266–1282. [Google Scholar] [CrossRef] [PubMed]

- Cano-Salazar, J.; López, M.L.; Echeverría, G. Relationships between the instrumental and sensory characteristics of four peach and nectarine cultivars stored under air and CA atmospheres. Postharvest Biol. Technol. 2013, 75, 58–67. [Google Scholar] [CrossRef]

- Ma, C.; Fu, Z.; Xu, M.; Trebar, M.; Zhang, X. Evaluation on home storage performance of table grape based on sensory quality and consumers’ satisfaction. J. Food Sci. Technol. 2016, 53, 1363–1370. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aiello, G.; La Scalia, G.; Micale, R. Simulation analysis of cold chain performance based on time–temperature data. Prod. Plan. Control 2012, 23, 468–476. [Google Scholar] [CrossRef]

- Tareen, M.J.; Abbasi, N.A.; Hafiz, I.A. Postharvest application of salicylic acid enhanced antioxidant enzyme activity and maintained quality of peach cv. ‘Flordaking’ fruit during storage. Sci. Hortic. 2012, 142, 221–228. [Google Scholar] [CrossRef]

- Giné-Bordonaba, J.; Cantín, C.M.; Echeverría, G.; Ubach, D.; Larrigaudière, C. The effect of chilling injury-inducing storage conditions on quality and consumer acceptance of different Prunus persica cultivars. Postharvest Biol. Technol. 2016, 115, 38–47. [Google Scholar] [CrossRef]

- Giaccone, M.; Forlani, M.; Basile, B. Tree vigor, fruit yield and quality of nectarine trees grown under red photoselective anti-hail nets in southern Italy. Acta Hortic. 2012, 287–293. [Google Scholar] [CrossRef]

- Nanos, G.D.; Mitchell, F.G. Carbon dioxide injury and flesh softening following high-temperature conditioning in peaches. Hortscience 1991, 26, 562–563. [Google Scholar]

| Parameter | Temperature Range | Humidity Range | Volume of CO2 | GPS Module |

|---|---|---|---|---|

| Theoretical range | −2 °C–36 °C | 50%–95% | 0%–5% | Maximum height: 50,000 m |

| Sensor module | AM2322 | AM2322 | ATI | U-BLOX M8030 |

| Sensor range | −40 °C–80 °C | 0%–99.9% | 0%–5% | WGS-84 |

| Sensor accuracy | <±0.3 °C | ±2% | ±0.1% | Speed error < 0.1 m/s, direction error < 0.5 degrees |

| Response time | 5 s | 5 s | <30 s | Time accuracy: 30 ns |

| Power consumption | <0.1 mW | <0.1 mW | <25 mW | <35 mW |

| Species | Packet Losses Rate | Accuracy Error | Battery Charge Status |

|---|---|---|---|

| Kašić-Zagreb cold chain | <0.2% (2100) a | Temperature: <0.75% | 80%–90% (1 day) |

| humidity: <2% | |||

| CO2: <2% | |||

| Distance error of GPS: <30 m |

| Sample | Average Weight Loss (%) | Initial Firmness | Final Firmness | Firmness Decline Rate (%) x | Initial SSC | Final SSC | SSC Decline Rate (%) x |

|---|---|---|---|---|---|---|---|

| nectarine control | 1.86 b | 3.59 ab | 2.47 ab | 31.20 | 9.23 a | 8.21 a | 11.06 |

| nectarine red net | 2.18 ab | 3.85 a | 2.21 b | 42.60 | 9.20 a | 8.45 a | 8.15 |

| peach control | 2.43 ab | 2.99 bc | 2.61 a | 12.71 | 8.50 ab | 8.3 a | 2.35 |

| peach red net | 2.89 a | 2.94 c | 2.29 ab | 22.07 | 8.27 b | 8.1 a | 2.06 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Matetić, M.; Zhou, H.; Zhang, X.; Jemrić, T. Postharvest Quality Monitoring and Variance Analysis of Peach and Nectarine Cold Chain with Multi-Sensors Technology. Appl. Sci. 2017, 7, 133. https://doi.org/10.3390/app7020133

Wang X, Matetić M, Zhou H, Zhang X, Jemrić T. Postharvest Quality Monitoring and Variance Analysis of Peach and Nectarine Cold Chain with Multi-Sensors Technology. Applied Sciences. 2017; 7(2):133. https://doi.org/10.3390/app7020133

Chicago/Turabian StyleWang, Xiang, Maja Matetić, Huijuan Zhou, Xiaoshuan Zhang, and Tomislav Jemrić. 2017. "Postharvest Quality Monitoring and Variance Analysis of Peach and Nectarine Cold Chain with Multi-Sensors Technology" Applied Sciences 7, no. 2: 133. https://doi.org/10.3390/app7020133

APA StyleWang, X., Matetić, M., Zhou, H., Zhang, X., & Jemrić, T. (2017). Postharvest Quality Monitoring and Variance Analysis of Peach and Nectarine Cold Chain with Multi-Sensors Technology. Applied Sciences, 7(2), 133. https://doi.org/10.3390/app7020133