Performance Assessment and Scooter Verification of Nano-Alumina Engine Oil

Abstract

:1. Introduction

2. Basic Properties and Wear Test

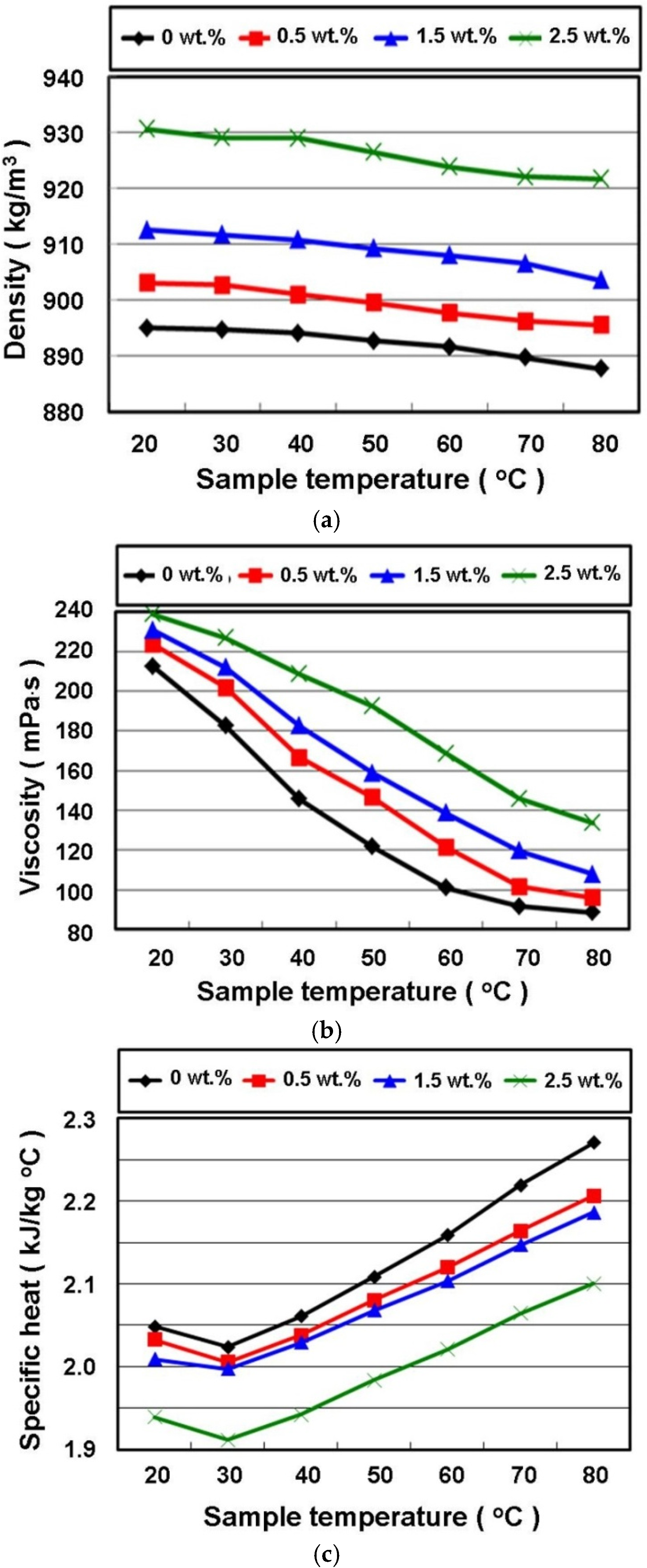

2.1. Basic Properties

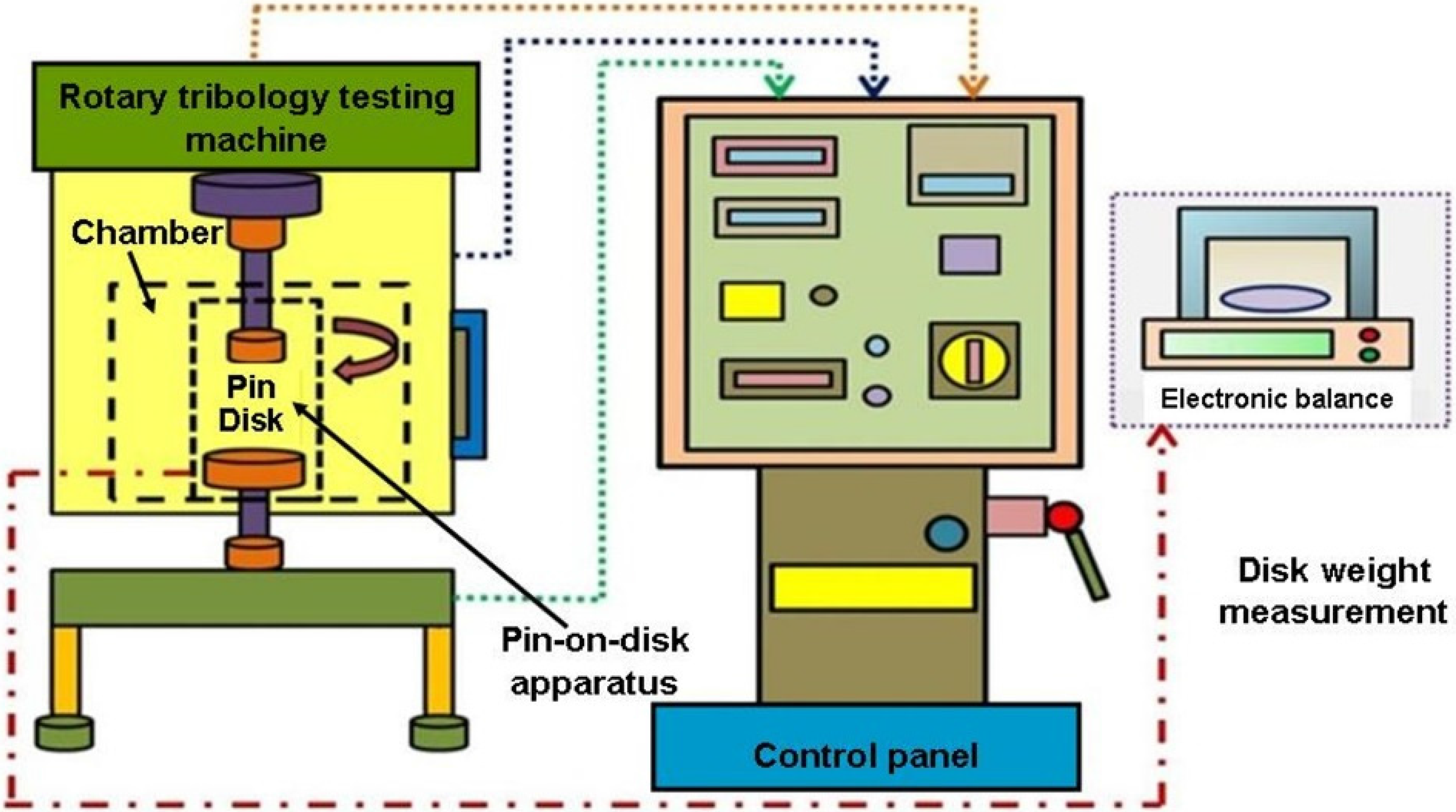

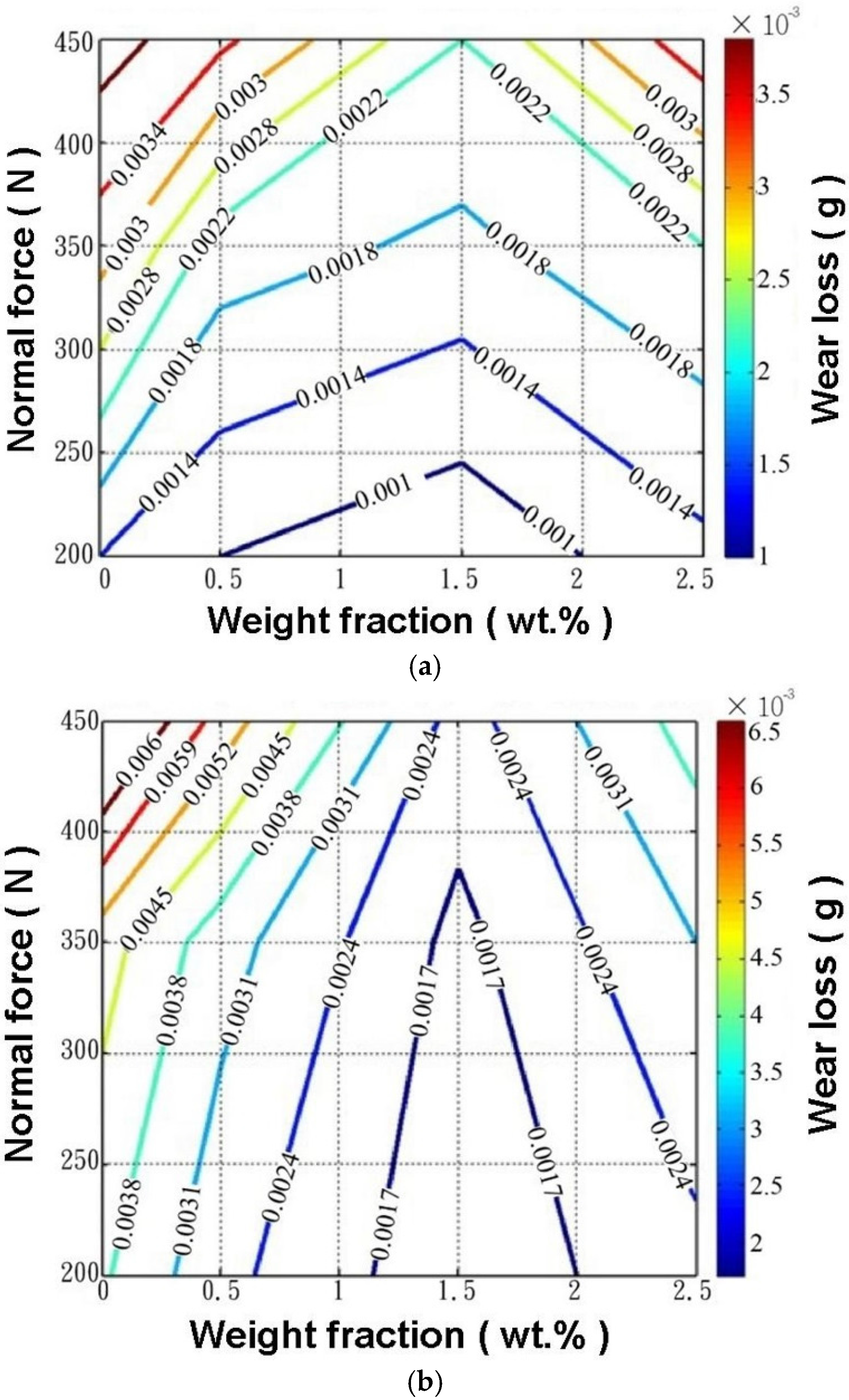

2.2. Wear Test

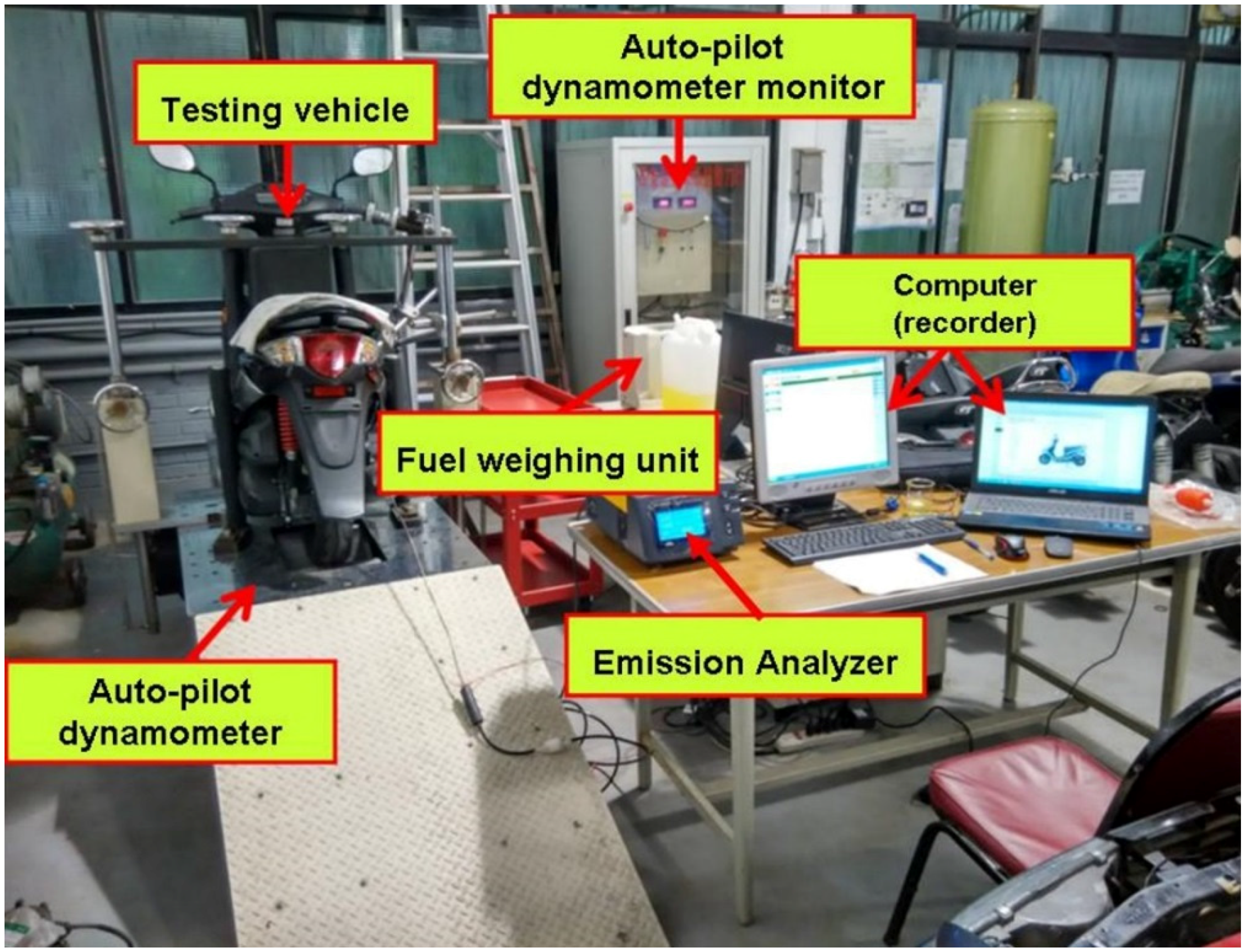

3. Real Scooter Test

4. Results and Discussion

5. Conclusions

- (1)

- Basic properties of NAEO: four test samples with weight fractions were set at 0 (non-additive), 0.5 wt. %, 1.5 wt. %, and 2.5 wt. %. The experimental evaluation of density and viscosity at various sample temperatures (20–80 °C) was conducted.

- (2)

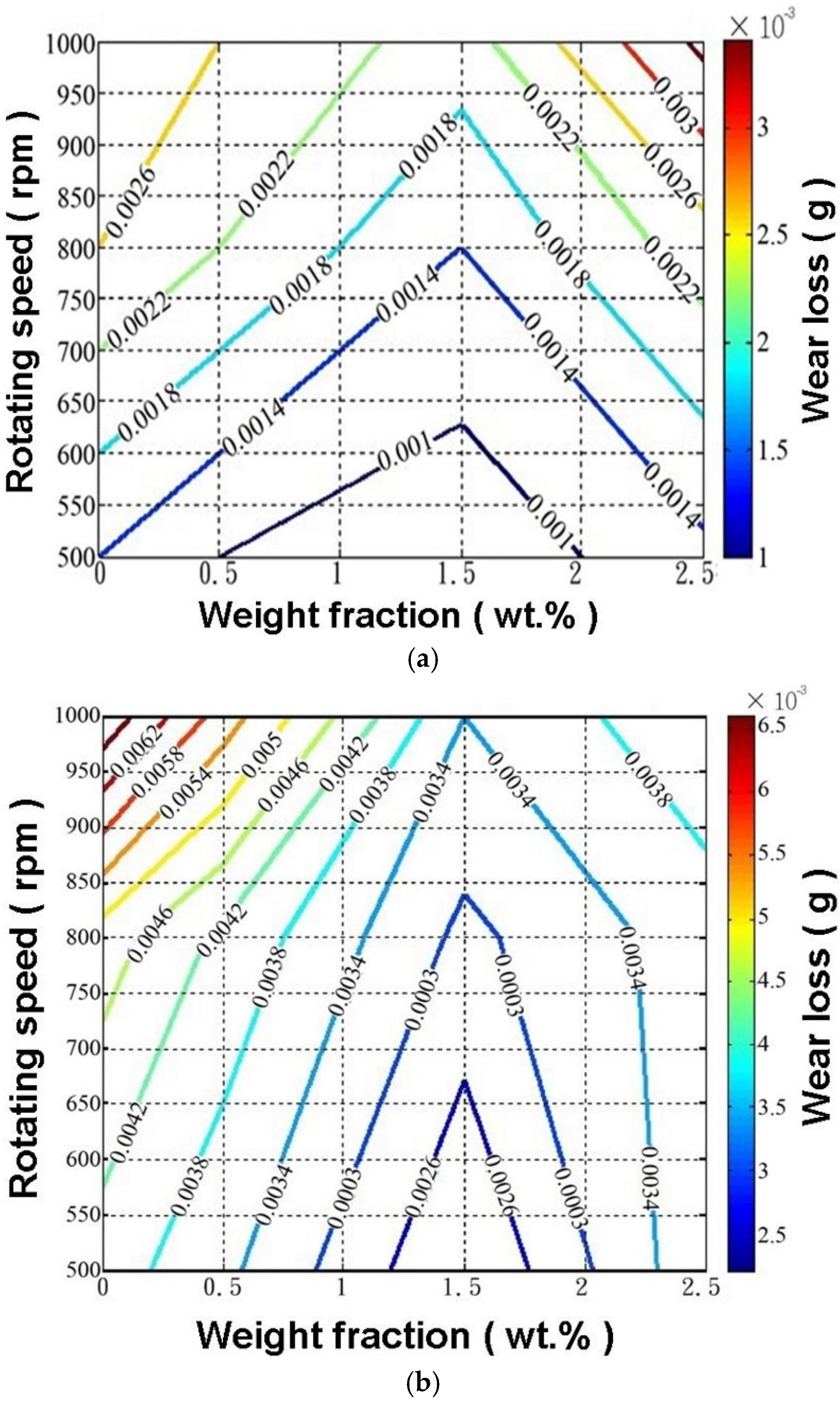

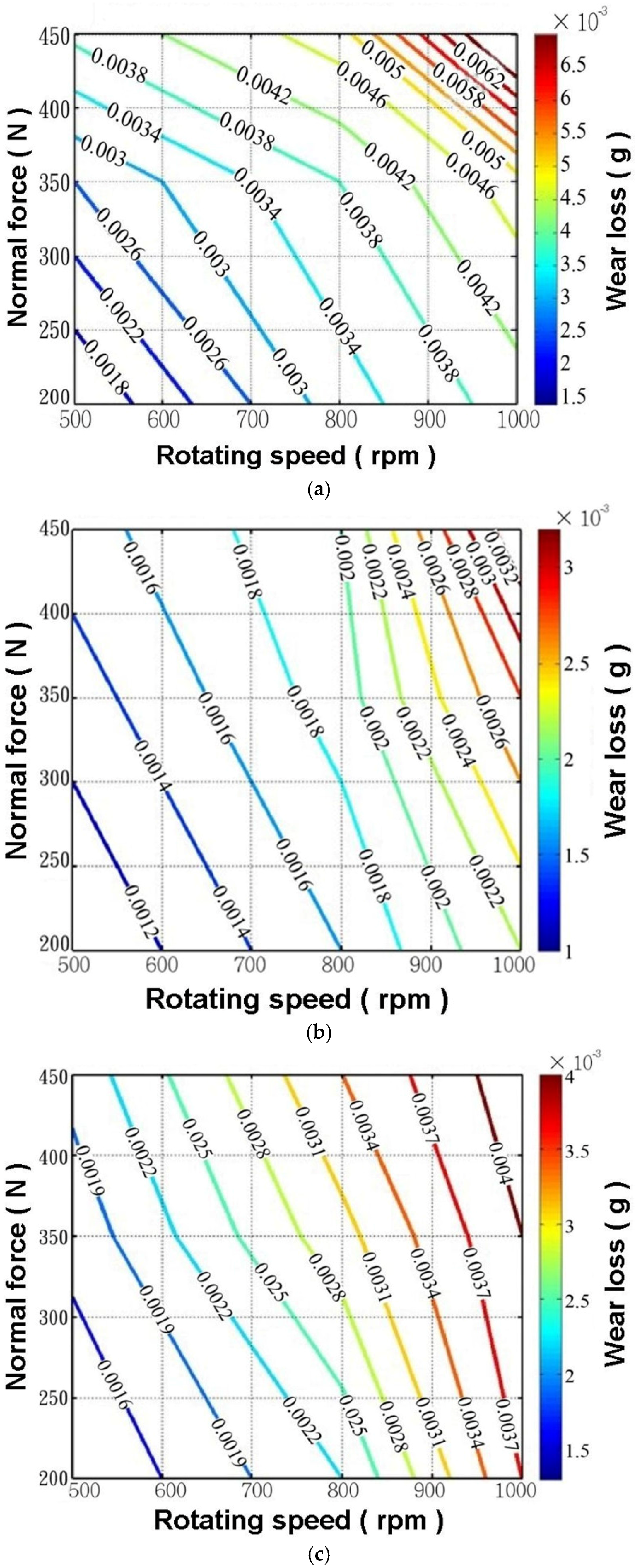

- Wear test on the platform of NAEO: A tribology testing machine with a pin-on-disk apparatus was established for the wear test. Results prove that NAEO with 1.5 wt. % Al2O3 nanoparticles (1.5 wt. % NAEO) demonstrated the best wear performance.

- (3)

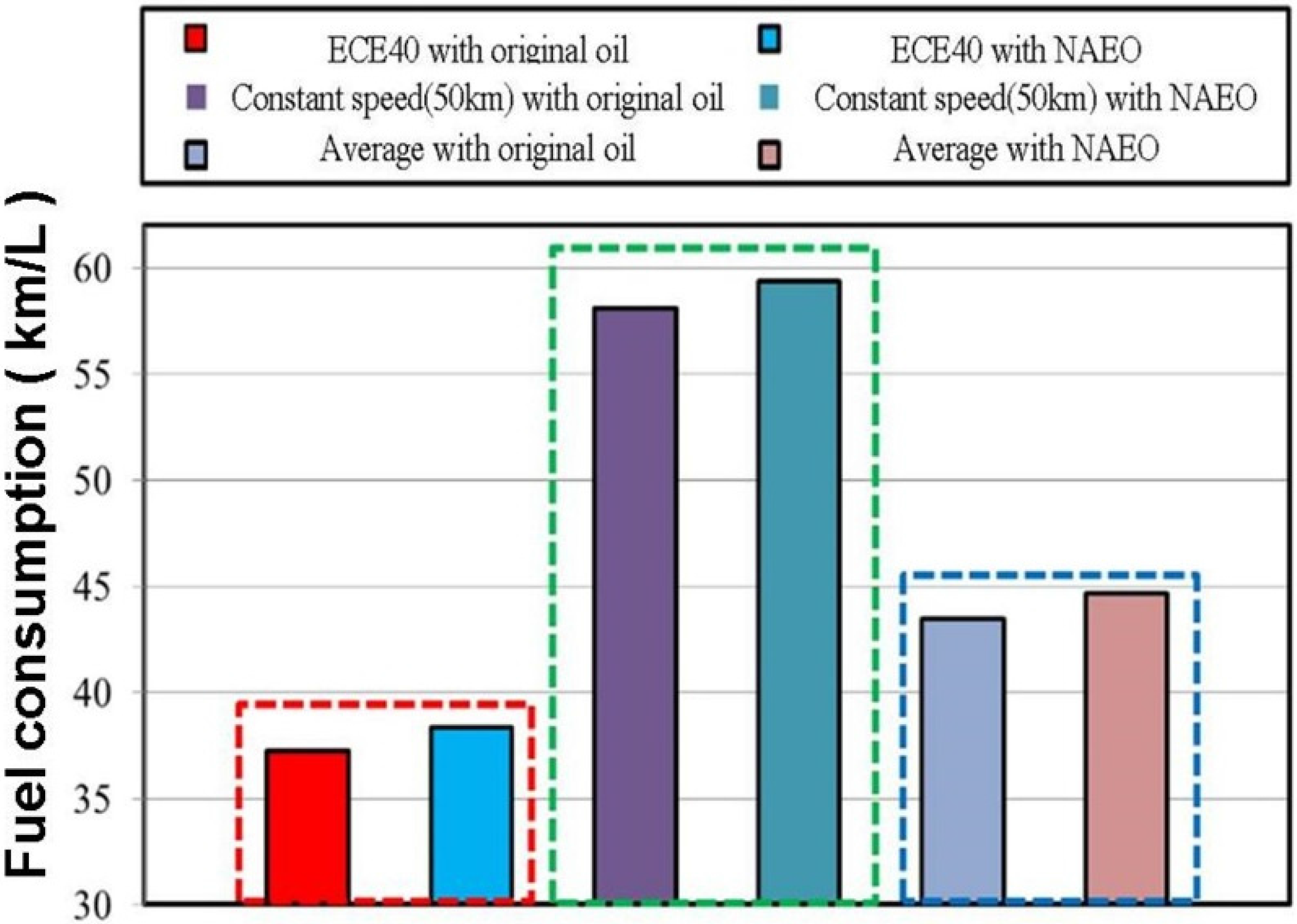

- Real scooter implementation: the 1.5 wt. % NAEO was added to the SI engine of a scooter. A dynamometer test emulated the road load to evaluate the performance. The ECE40 driving cycle, the constant speed case, and four cases of constant throttle position were conducted. Results proved that the fuel consumption for ECE40 and constant speed was decreased on average by 2.75%, while a reduction of 3.87% was seen for the constant throttle position cases.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hung, Y.H.; Teng, T.P.; Teng, T.C.; Chen, J.H. Assessment of Heat Dissipation Performance for Nanofluid. Appl. Therm. Eng. 2012, 32, 132–140. [Google Scholar] [CrossRef]

- Lomascolo, M.; Colangelo, G.; Milanese, M.; de Risi, A. Review of heat transfer in nanofluids: Conductive, convective and radiative experimental results. Renew. Sustain. Energy Rev. 2015, 43, 1182–1198. [Google Scholar] [CrossRef]

- Sarkar, J.; Ghosh, P.; Adil, A. A review on hybrid nanofluids: Recent research, development and applications. Renew. Sustain. Energy Rev. 2015, 43, 164–177. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Hou, X. Improving the tribological behavior of internal combustion engines via the addition of nanoparticles to engine oils. Nanotechnol. Rev. 2015, 4, 347–358. [Google Scholar] [CrossRef]

- Dai, W.; Kheireddin, B.; Gao, H.; Liang, H. Roles of nanoparticles in oil lubrication. Tribol. Int. 2016, 102, 88–98. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Hou, X.; Turkson, R.F.; Peng, Z.; Chen, X. Enhancing the thermophysical properties and tribological behaviour of engine oils using nano-lubricant additives. RSC Adv. 2016, 6, 77913–77924. [Google Scholar]

- Ettefaghi, E.; Ahmadi, H.; Rashidi, A.; Mohtasebi, S.S.; Alaei, M. Experimental evaluation of engine oil properties containing copper oxide nanoparticles as a nanoadditive. Int. J. Ind. Chem. 2013, 4, 28. [Google Scholar] [CrossRef]

- Babu, K.S.; Nair, K.P.; Rajendrakumar, P.K. Computational analysis of journal bearing operating under lubricant containing Al2O3 and ZnO nanoparticles. Int. J. Eng. Sci. Technol. 2014, 6, 34–42. [Google Scholar] [CrossRef]

- Dinesh, R.; Prasad, M.J.G.; Kumar, R.R.; Jerome Santharaj, N.; Santhip, J.; Raaj, A.S.A. Investigation of tribological and thermophysical properties of engine oil containing nano additives. Mater. Today Proc. 2016, 3, 45–53. [Google Scholar] [CrossRef]

- Laad, M.; Jatti, V.K.S. Titanium oxide nanoparticles as additives in engine Oil. J. King Saud Univ. Eng. Sci. 2016. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Hou, X.; Liqiang, M.; Cai, Q.; Turkson, R.F.; Chen, B. Improving the tribological characteristics of piston ring assembly in automotive engines using Al2O3 and TiO2 nanomaterials as nano-lubricant additives. Tribiol. Int. 2016, 103, 540–554. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, X.; Liu, W.; Fu, X. Performance and antiwear mechanism of Cu nano-particles as lubricating additives. Ind. Lubr. Tribol. 2009, 61, 311–318. [Google Scholar] [CrossRef]

- Choi, C.; Jung, M.; Choi, Y.; Lee, J.; Oh, J. Tribological properties of lubricating oil-based nanofluids with metal/carbon nanoparticles. J. Nanosci. Nanotechnol. 2011, 11, 368–371. [Google Scholar] [CrossRef] [PubMed]

- Vadiraj, A.; Manivasagam, G.; Kamani, K.; Sreenivasan, V.S. Effect of nano oil additive proportions on friction and wear performance of automotive materials. Tribol. Ind. 2012, 34, 3–10. [Google Scholar]

- Zin, V.; Agresti, F.; Barison, S.; Colla, L.; Gondolini, A.; Fabrizio, M. The synthesis and effect of copper nanoparticles on the tribological properties of lubricant oils. IEEE Trans. Nanotechnol. 2013, 12, 751–759. [Google Scholar] [CrossRef]

- Chu, H.Y.; Hsu, W.C.; Lin, J.F. The anti-scuffing performance of diamond nano-particles as an oil additive. Wear 2010, 268, 960–967. [Google Scholar] [CrossRef]

- Wang, B.; Wang, X.; Lou, W.; Hao, J. Rheological and tribological properties of ionic liquid-based nanofluids containing functionalized multi-walled carbon nanotubes. J. Phys. Chem. C 2010, 114, 8749–8754. [Google Scholar] [CrossRef]

- Hsin, Y.L.; Chu, H.; Jeng, Y.; Huang, Y.; Wang, M.H.; Chang, C.K. In situ de-agglomeration and surface functionalization of detonation nano-diamond, with the polymer used as an additive in lubricant oil. J. Mater. Chem. 2011, 21, 13213–13222. [Google Scholar] [CrossRef]

- Asadi, M.; Asadi, A. Dynamic viscosity of MWCNT/ZnO-engine oil hybrid nanofluid: An experimental investigation and new correlation in different temperatures and solid concentrations. Int. Commun. Heat Mass Transf. 2016, 76, 41–45. [Google Scholar] [CrossRef]

- Afrand, M.; Najafabadi, K.N.; Akbari, M. Effects of temperature and solid volume fraction on viscosity of SiO2-MWCNTs/SAE40 hybrid nanofluid as a coolant and lubricant in heat engines. Appl. Therm. Eng. 2016, 102, 45–54. [Google Scholar] [CrossRef]

- Rasheed, A.K.; Khalid, M.; Javeed, A.; Rashmi, W.; Gupta, T.C.S.M.; Chan, A. Heat transfer and tribological performance of graphene nanolubricant in an internal combustion engine. Tribol. Int. 2016, 103, 504–515. [Google Scholar] [CrossRef]

- Esfe, M.H.; Afrand, M.; Yan, W.M.; Yarmand, H.; Toghraie, D.; Dahari, M. Effects of temperature and concentration on rheological behavior of MWCNTs/SiO2(20–80)-SAE40 hybrid nano-lubricant. Int. Commun. Heat Mass Transf. 2016, 76, 133–138. [Google Scholar] [CrossRef]

- Lee, K.; Hwang, Y.; Cheong, S.; Kwon, L.; Kim, S.; Lee, J. Performance evaluation nano-lubricants of fullerene nanoparticles in refrigeration mineral oil. Curr. Appl. Phys. 2009, 9, e128–e131. [Google Scholar] [CrossRef]

- Jwo, C.S.; Jeng, L.Y.; Chang, H.; Chen, S.L. Research of vacuum pump with nano-lubricant. Key Eng. Mat. 2008, 364–366, 867–872. [Google Scholar] [CrossRef]

- Binu, K.G.; Shenoy, B.S.; Rao, D.S.; Pai, R. A variable viscosity approach for the evaluation of load carrying capacity of oil lubricated journal bearing with TiO2 nanoparticles as lubricant additives. Proc. Mater. Sci. 2014, 6, 1051–1067. [Google Scholar] [CrossRef]

- Rapoport, L.; Leshchinsky, V.; Lvovsky, M.; Nepomnyashchy, O.; Volovik, Y.; Tenne, R. Mechanism of friction of fullerenes. Ind. Lubr. Tribol. 2002, 54, 171–176. [Google Scholar] [CrossRef]

- Chiñas-Castillo, F.; Spikes, H.A. Mechanism of action of colloidal solid dispersions. J. Tribol. 2003, 125, 552–557. [Google Scholar] [CrossRef]

- Wu, Y.Y.; Tsui, W.C.; Liu, T.C. Experimental analysis of tribological properties of lubricating oils with nanoparticle additives. Wear 2007, 262, 819–825. [Google Scholar] [CrossRef]

- Hu, Z.S.; Lai, R.; Lou, F.; Wang, L.G.; Chen, Z.L.; Chen, G.X.; Dong, J.X. Preparation and tribological properties of nanometer magnesium borate as lubricating oil additive. Wear 2002, 252, 370–374. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, J.; Zhang, Z.; Liu, W.; Xue, Q. Study on the structure and tribological properties of surface-modified Cu nanoparticles. Mater. Res. Bull. 1999, 34, 1361–1367. [Google Scholar] [CrossRef]

- Zhou, X.; Fu, X.; Shi, H.; Hu, Z. Lubricating properties of Cyanex 302-modified MoS2 microspheres in base oil 500SN. Lubr. Sci. 2007, 19, 71–79. [Google Scholar]

- Rapoport, L.; Leshchinsky, V.; Lapsker, I.; Volovik, Y.; Nepomnyashchy, O.; Lvovsky, M.; Popovitz-Biro, R.; Feldman, Y.; Tenne, R. Tribological properties of WS2 nanoparticles under mixed lubrication. Wear 2003, 255, 785–793. [Google Scholar] [CrossRef]

- Liu, G.; Li, X.; Qin, B.; Xing, D.; Guo, Y.; Fan, R. Investigation of the mending effect and mechanism of copper nano-particles on a tribologically stressed surface. Tribol. Lett. 2004, 17, 961–966. [Google Scholar]

- Wan, Q.; Jin, Y.; Sun, P.; Ding, Y. Tribological behaviour of a lubricant oil containing boron nitride, nanoparticles. Proc. Eng. 2015, 102, 1038–1045. [Google Scholar] [CrossRef]

- Peng, D.X.; Chen, C.H.; Kang, Y.; Chang, Y.P.; Chang, S.Y. Size effects of SiO2 nanoparticles as oil additives on tribology of lubricant. Ind. Lubr. Tribol. 2010, 62, 111–120. [Google Scholar] [CrossRef]

- Nunn, N.; Mahbooba, Z.; Ivanov, M.G.; Ivanov, D.M.; Brenner, D.W.; Shenderova, O. Tribological properties of polyalphaolefin oil modified with nanocarbon additives. Diam. Relat. Mater. 2015, 54, 97–102. [Google Scholar] [CrossRef]

- Choi, Y.; Lee, C.; Hwang, Y.; Park, M.; Lee, J.; Choi, C.; Jung, M. Tribological behavior of copper nanoparticles as additives in oil. Curr. Appl. Phys. 2009, 9, e124–e127. [Google Scholar] [CrossRef]

- Mansot, J.L.; Bercion, Y.; Romana, L.; Martin, J.M. Nanolubrication. Braz. J. Phys. 2009, 39, 186–197. [Google Scholar] [CrossRef]

- Alawi, O.A.; Sidik, N.A.C.; Beriache, M. Applications of nanorefrigerant and nanolubricants in refrigeration, air-conditioning and heat pump systems: A review. Int. Commun. Heat Mass Transf. 2015, 68, 91–97. [Google Scholar] [CrossRef]

- Khalil, A.N.M.; Alib, M.A.M.; Azmi, A.I. Effect of Al2O3 nanolubricant with SDBS on tool wear during turning process of AISI 1050 with minimal quantity lubricant. Procedia Manuf. 2015, 2, 130–134. [Google Scholar] [CrossRef]

- Padmini, R.; Krishna, P.V.; Rao, G.K.M. Effectiveness of vegetable oil based nanofluids as potential cutting fluids in turning AISI 1040 steel. Tribol. Int. 2016, 94, 490–501. [Google Scholar] [CrossRef]

- TA Instruments. Sapphire Specific Heat Capacity Literature Values, Thermal Applications Note (TN-8A). Available online: http://www.tainstruments.co.jp/application/pdf/Thermal_Library/Applications_Notes/TN008.PDF (accessed on 9 August 2016).

- ASTM. G99–95a, Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus; ASTM International: West Conshohocken, PA, USA, 2000. [Google Scholar]

- Lue, Y.F.; Li, F.S.; Teng, T.P.; Hsu, Y.C.; Hung, Y.H. Basic properties and wearing performance of mineral oil with adding nano particles. In Proceedings of the 31th CSME Conference, Taichung, Taiwan, 6–7 December 2014. (In Chinese)

- Lue, Y.F.; Hsu, Y.C.; Teng, T.P. Performance evaluation on vacuum pumps using nanolubricants. J. Mech. Sci. Technol. 2016, in press. [Google Scholar]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lue, Y.-F.; Hung, Y.-H.; Li, F.-S.; Teng, T.-P.; Chen, S.-Y.; Wu, C.-H.; Ou, Y.-C. Performance Assessment and Scooter Verification of Nano-Alumina Engine Oil. Appl. Sci. 2016, 6, 258. https://doi.org/10.3390/app6090258

Lue Y-F, Hung Y-H, Li F-S, Teng T-P, Chen S-Y, Wu C-H, Ou Y-C. Performance Assessment and Scooter Verification of Nano-Alumina Engine Oil. Applied Sciences. 2016; 6(9):258. https://doi.org/10.3390/app6090258

Chicago/Turabian StyleLue, Yu-Feng, Yi-Hsuan Hung, Fang-Sheng Li, Tun-Ping Teng, Syuan-Yi Chen, Chien-Hsun Wu, and Yu-Chang Ou. 2016. "Performance Assessment and Scooter Verification of Nano-Alumina Engine Oil" Applied Sciences 6, no. 9: 258. https://doi.org/10.3390/app6090258