Study of the Tool Geometry Influence in Indentation for the Analysis and Validation of the New Modular Upper Bound Technique

Abstract

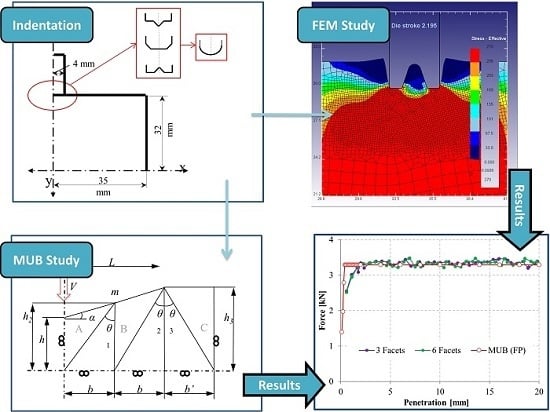

:1. Introduction

- Ti: Workpiece external strengths;

- vi: Real velocities field;

- Sv: Surface where external load are applied;

- k: Shear yield stress;

- SD*: Discontinuity surface;

- vi*: Kinematically Admissible Velocity Field (KAVF);

2. Materials and Methods

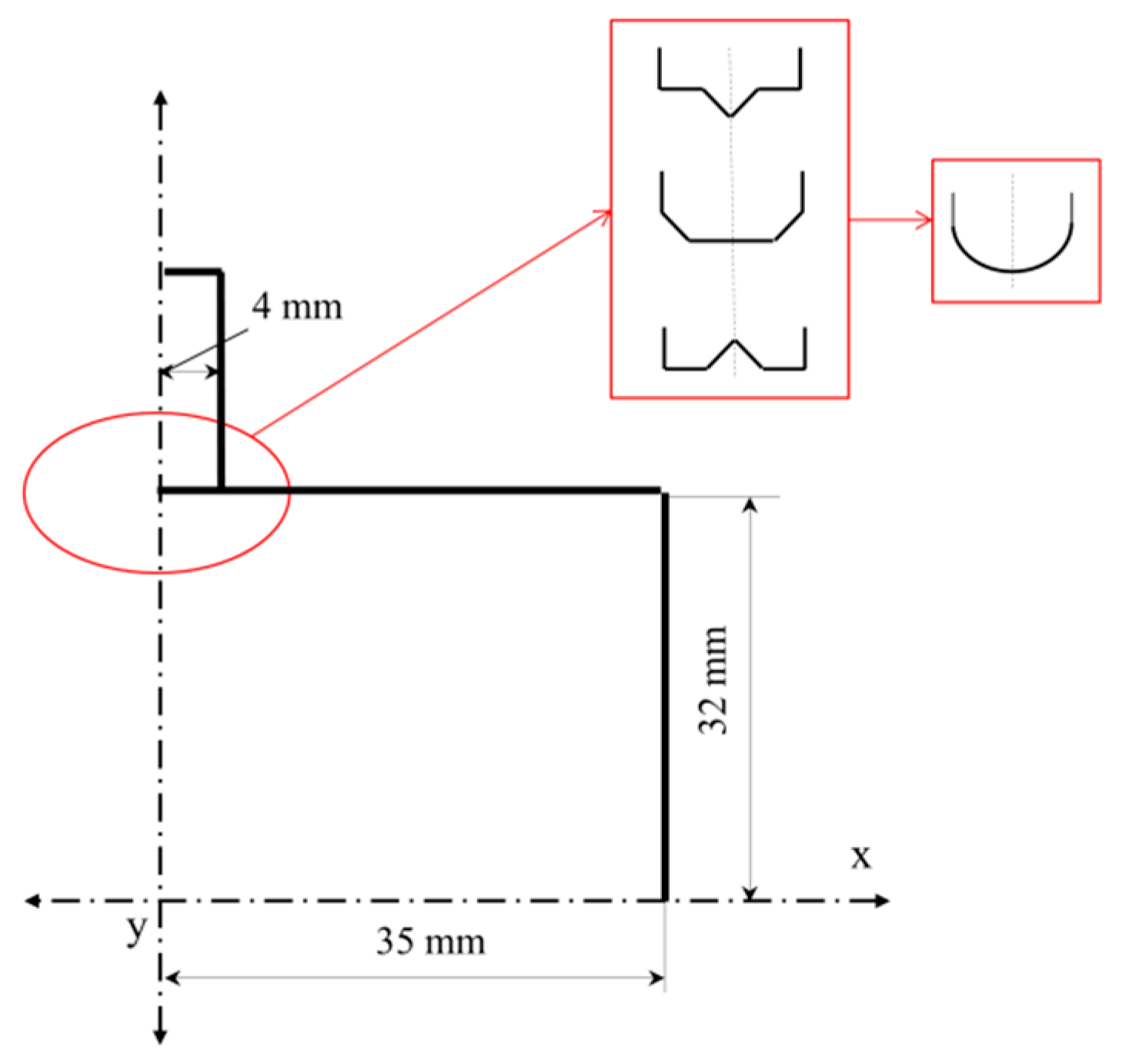

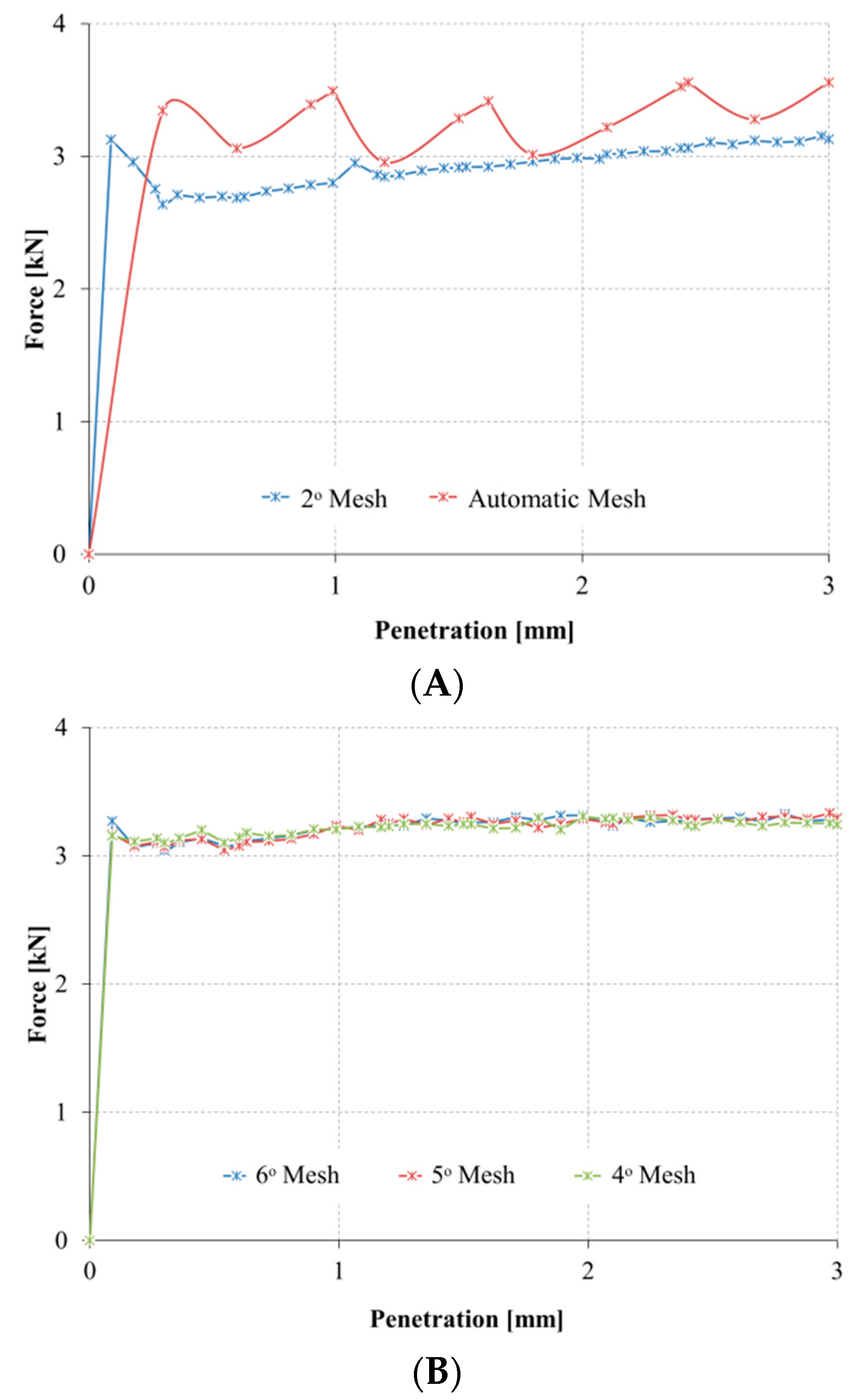

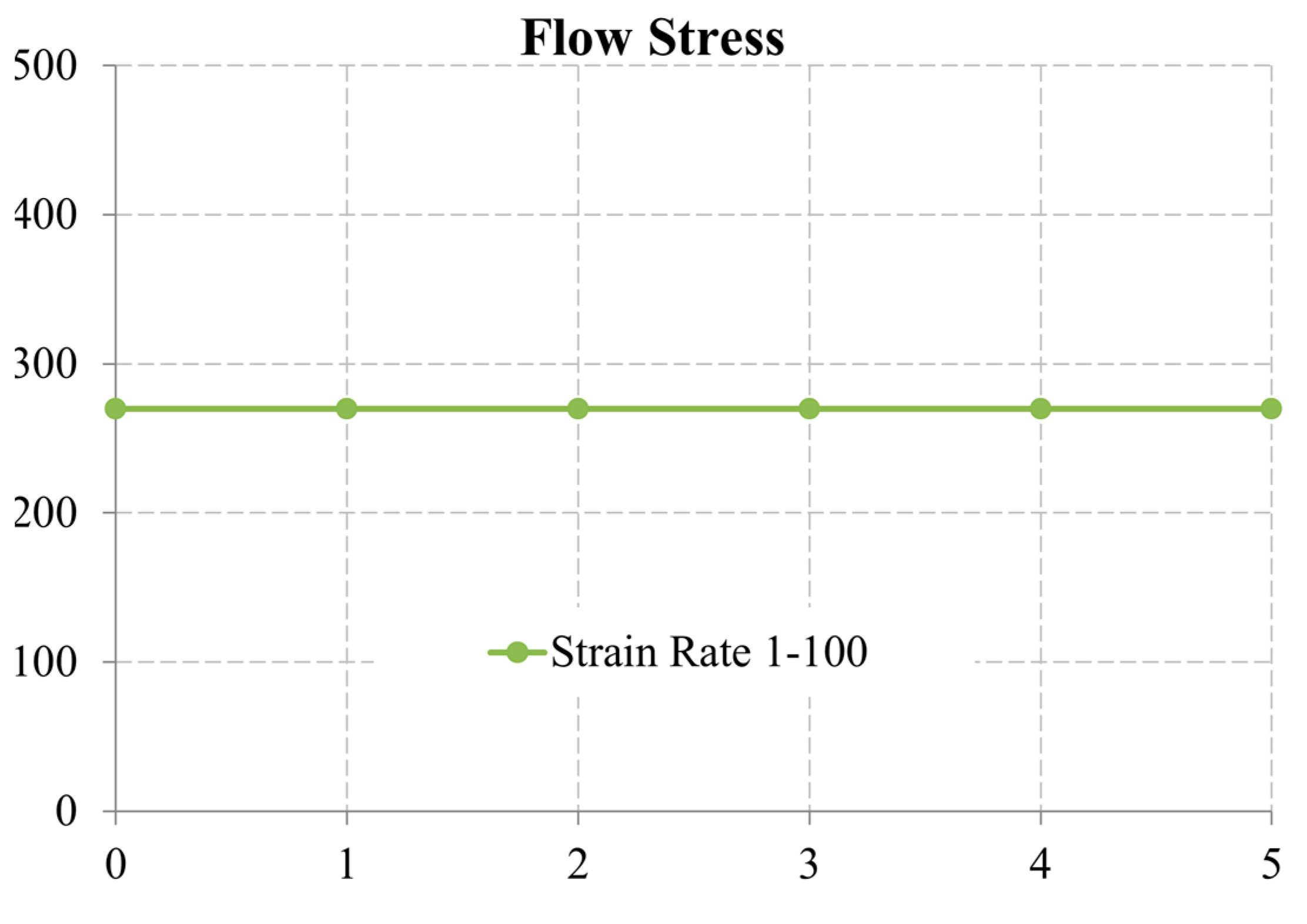

2.1. Numerical Analysis: Finite Element Method (FEM)

- = Flow stress;

- = Effective plastic strain;

- = Effective strain rate;

- T = Temperature.

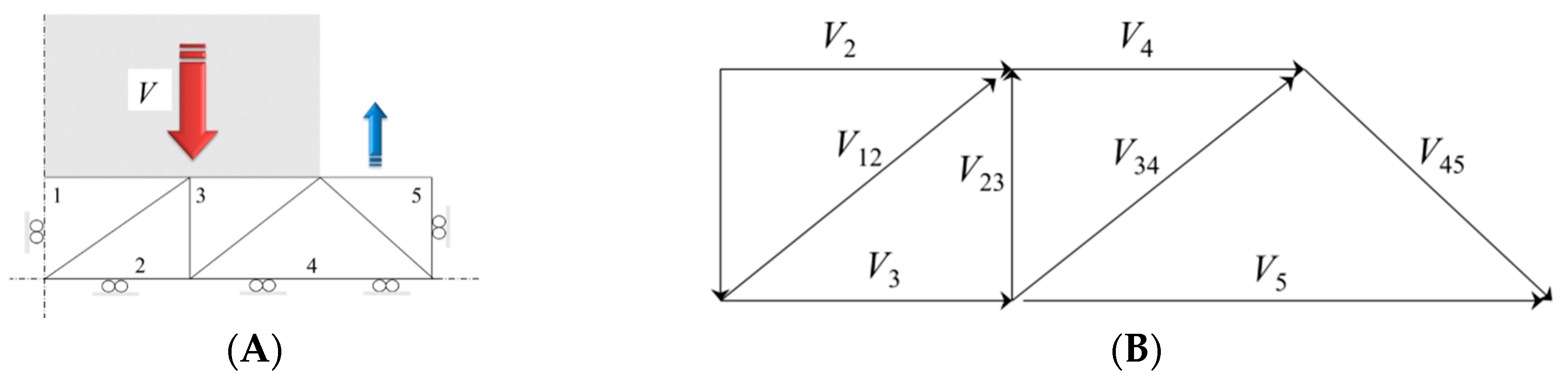

2.2. Analytical Analysis: Modular Upper Bound (MUB)

3. Results and Discussion

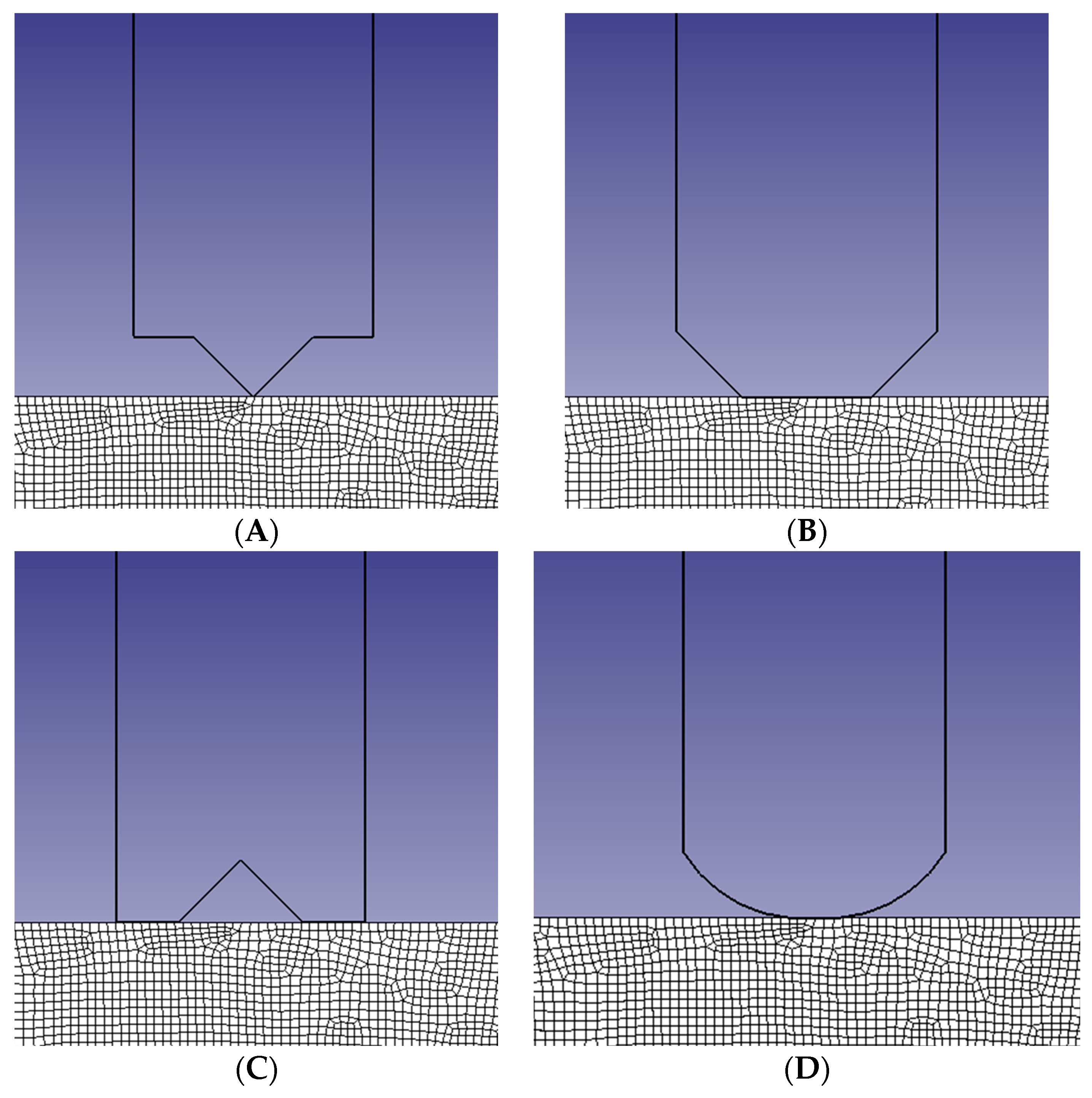

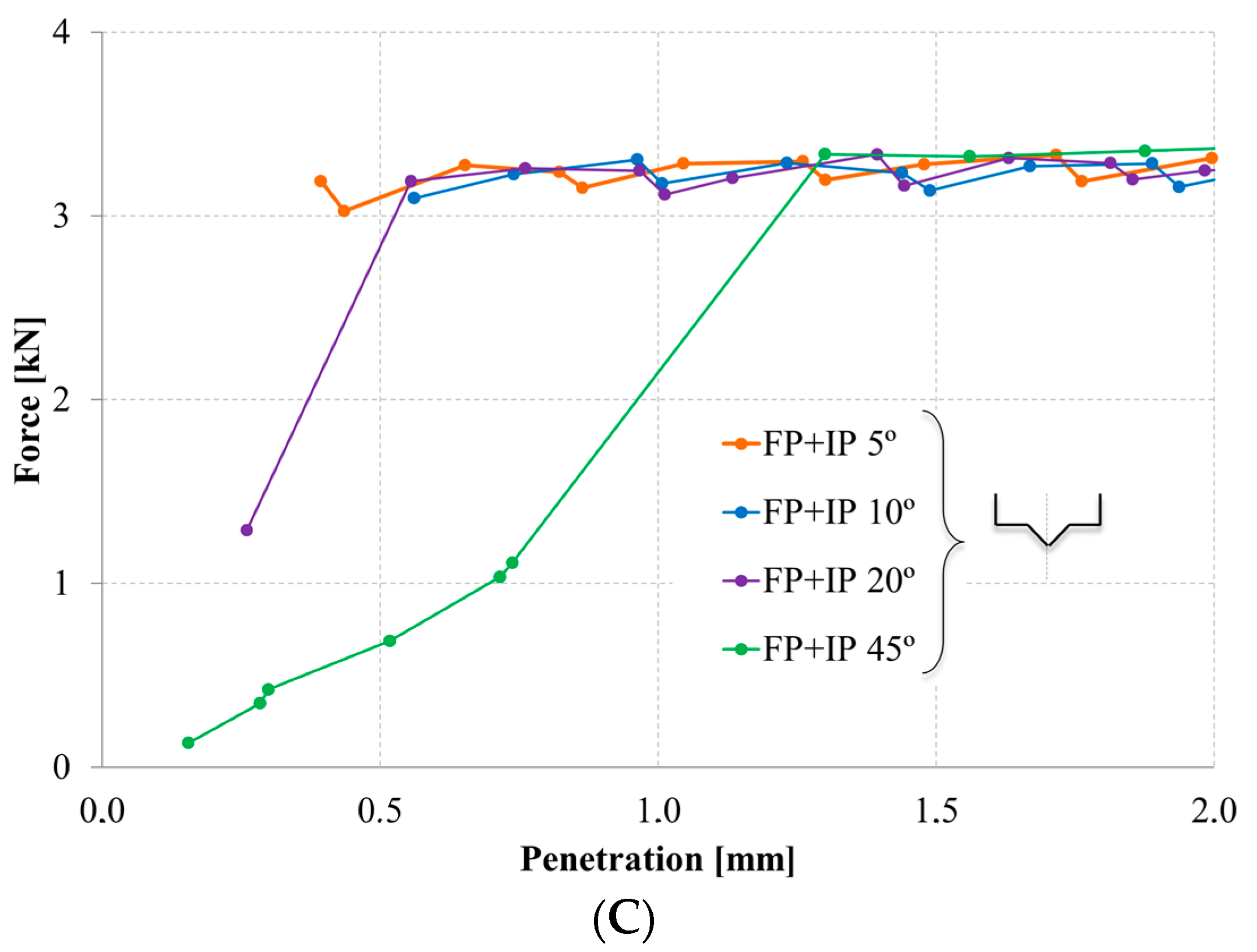

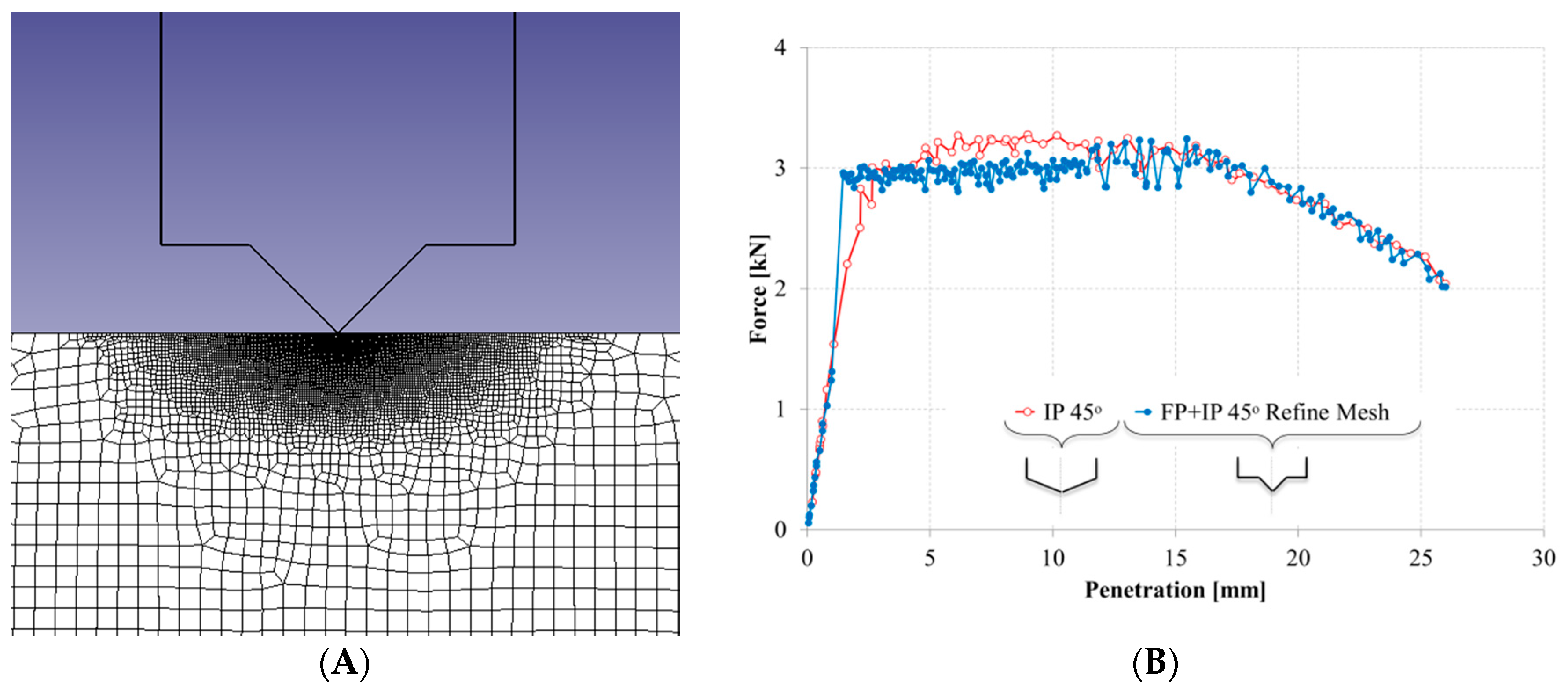

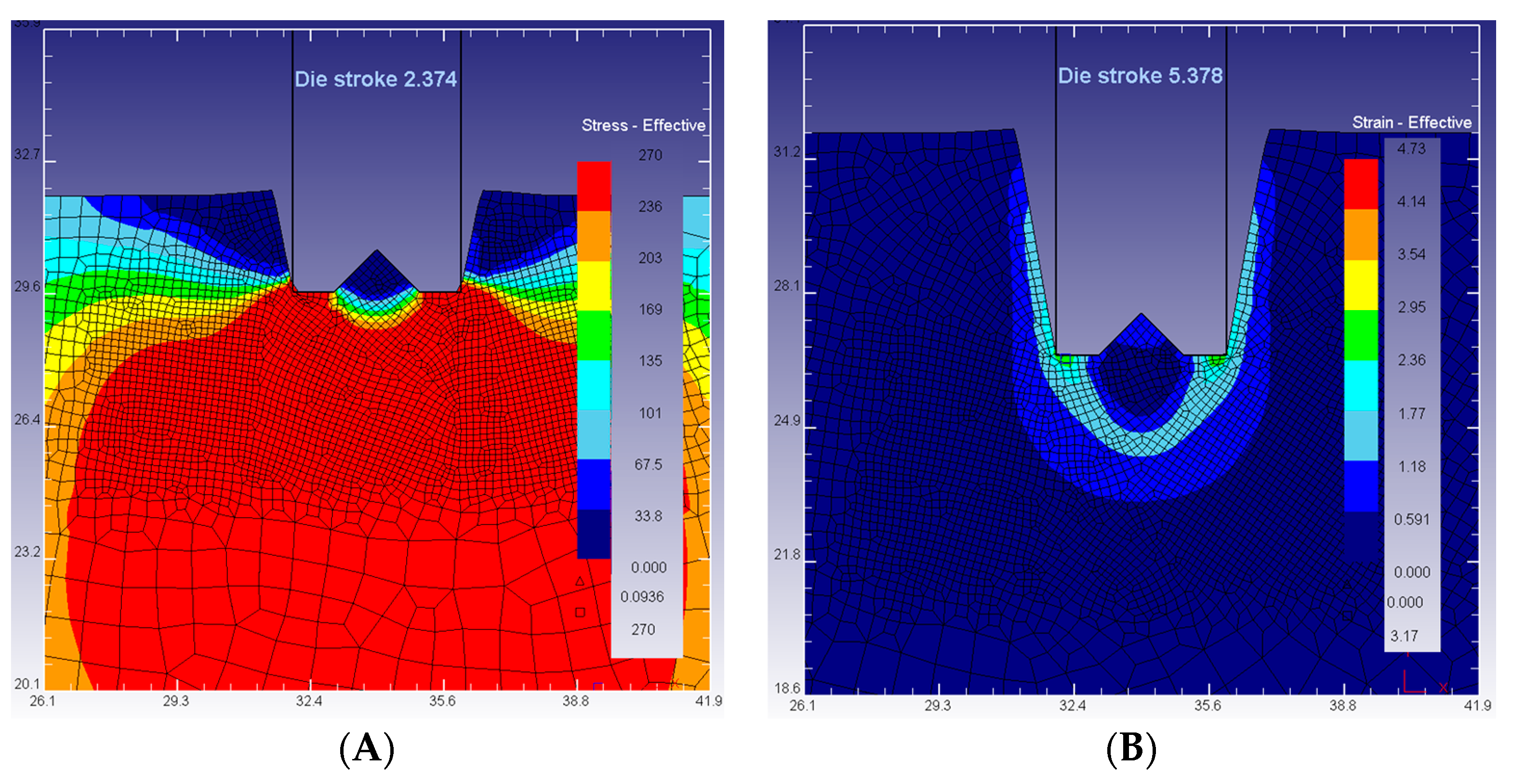

3.1. Geometry 1: Flat Punch (FP) + Inclined Punch (IP)

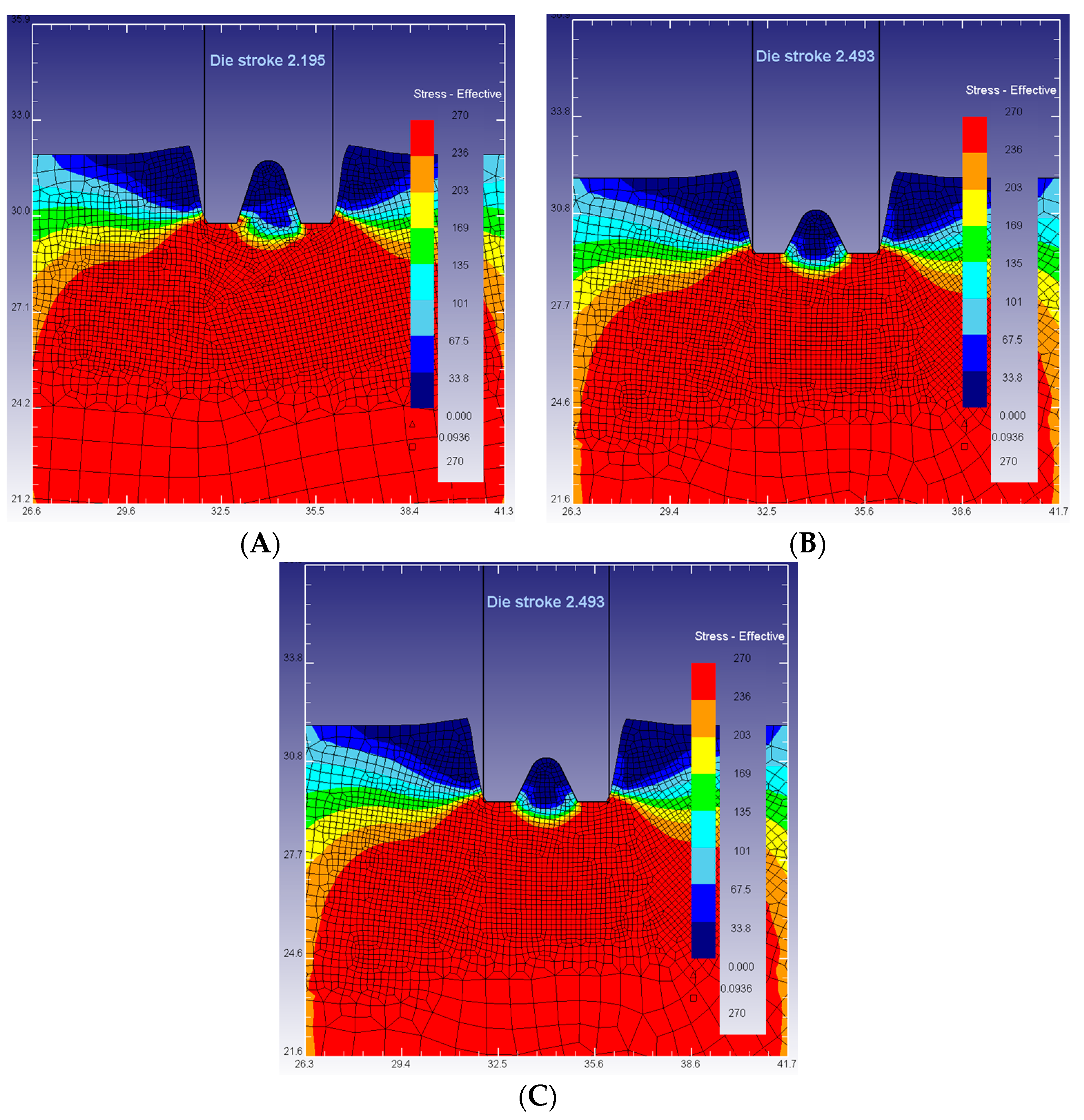

3.2. Geometry 2: IP + FP

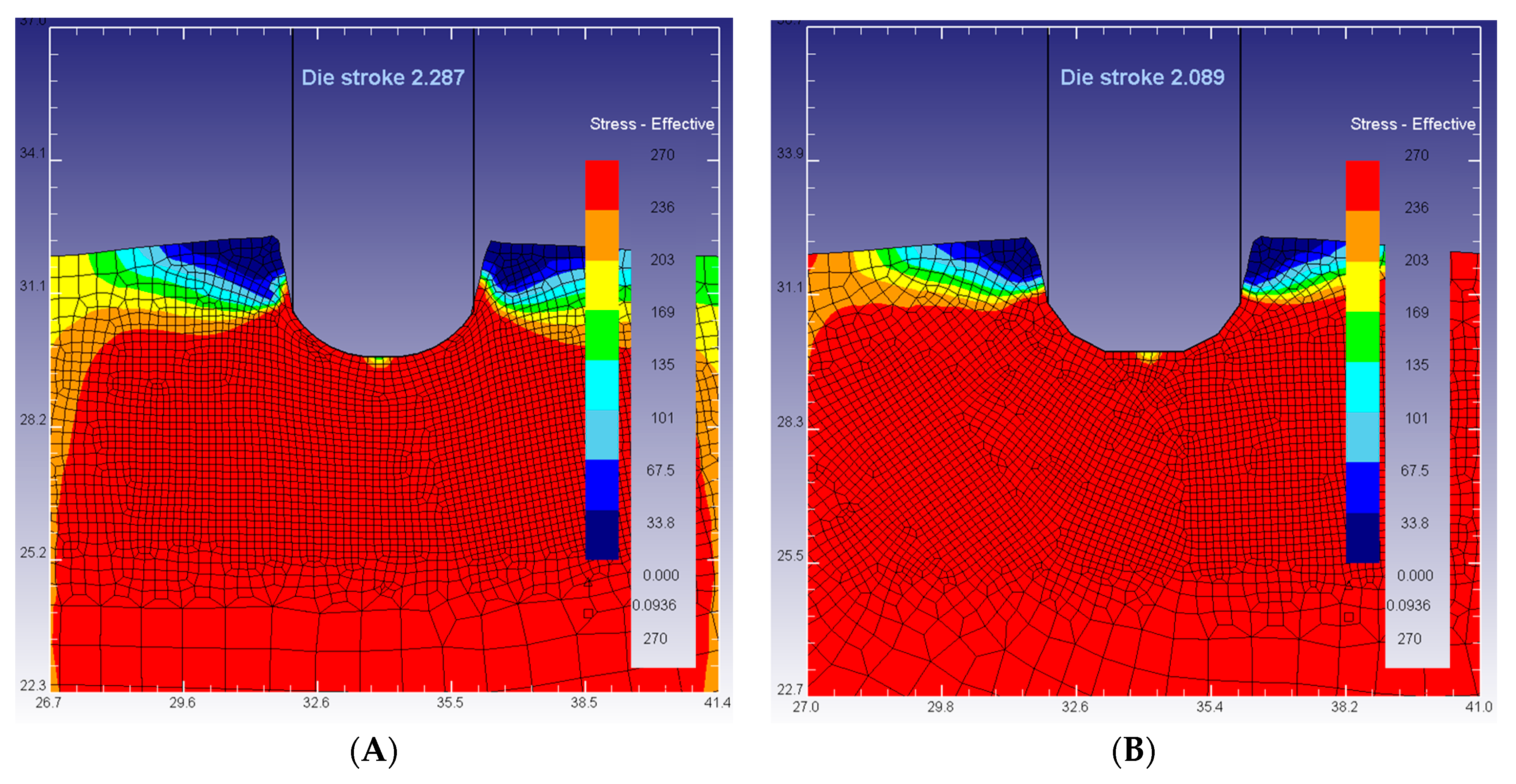

3.3. Geometry 3: Inverted Punch

3.4. Geometry 4: Curved Punch

4. Conclusions

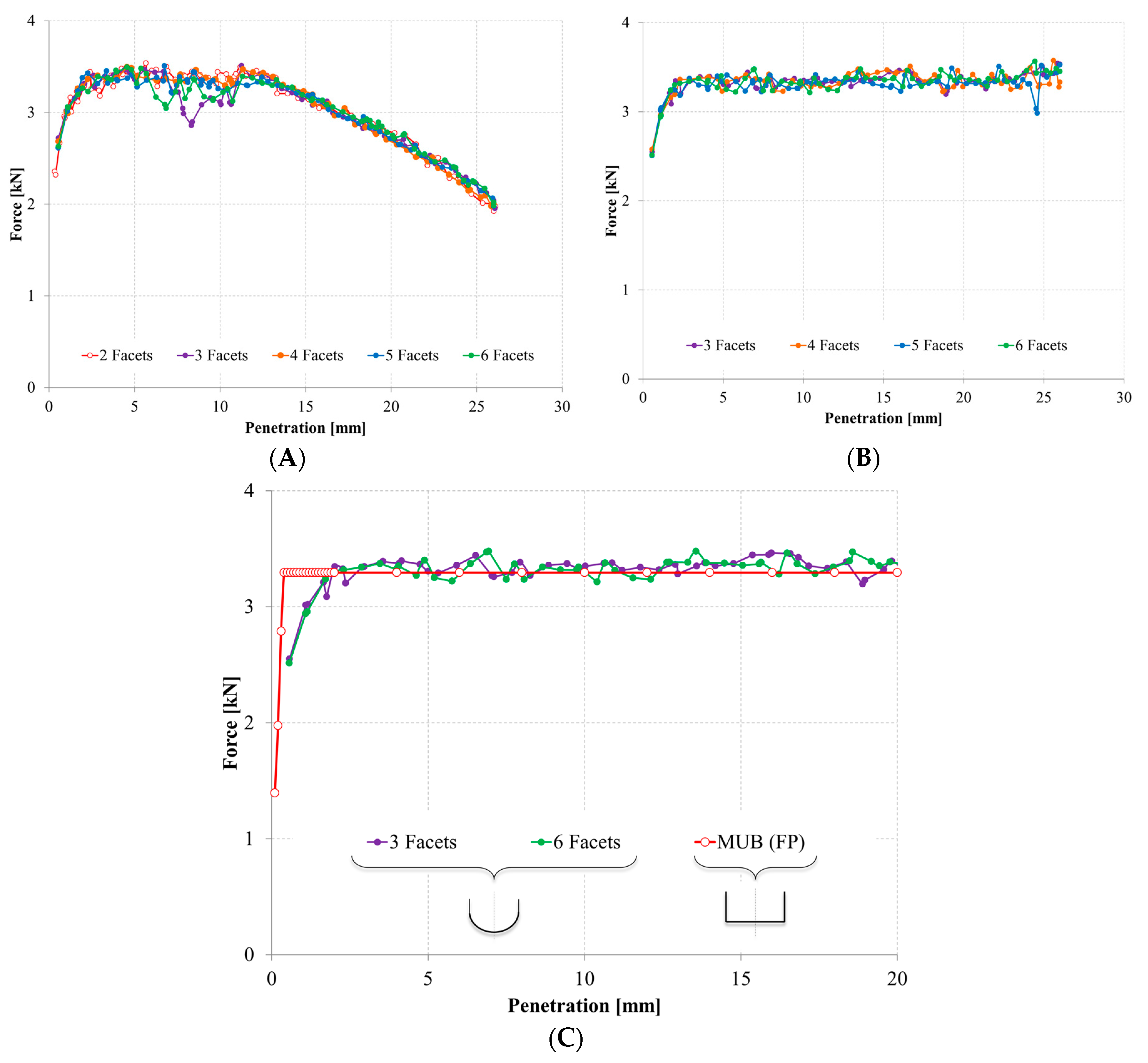

- A general trend was observed. Working with deep indentations, punch geometries present low influence, always reaching a maximum force value when the punch surface has total contact with the workpiece indented, as demonstrated with FEM analysis and MUB.

- By comparing results, it could be stated that the MUB developed method shows a good correlation with FEM results. The FEM and MUB solutions agree well with each other, being results in the same range.

- On the one hand, to obtain a maximum effort value when a total contact of the punch surface is needed, the analysis of different punch geometries can be reduced to the application of the FP MUB model. On the other hand, in case a closer analysis of the deformations’ initial stages is wanted, the application of the IP MUB model provides a more accurate solution.

- The evaluation of a curve punch was achieved by approximating the IP + FP geometry. The facets were increased until a curve geometry was obtained with six facets. The results obtained show similarities with the IP geometry and they also reach the same maximum force value.

- Unlike the conventional UBT method and FEM analysis, MUB presents much simpler constitutive equations and relations. In addition, its modular configurations confer versatility, being able to better adapt to different shapes with less resolution time.

Acknowledgment

Author Contributions

Conflicts of Interest

References

- Zhuang, W.; Hua, L.; Han, X.; Dong, L. Distribution of microstructure and Vickers hardness in spur bevel gear formed by cold rotary forging. Adv. Mech. Eng. 2014, 6, 1–13. [Google Scholar] [CrossRef]

- Nowak, J.; Madej, L.; Grosman, F.; Pietrzyk, M. Material flow analysis in the incremetal forging technology. Int. J. Mater. Form. 2010, 3, 931–934. [Google Scholar] [CrossRef]

- Tkocz, M.; Grosman, F. Application of incremental metal forming for production of aircraft integral panels. Solid State Phenom. 2014, 212, 243–246. [Google Scholar] [CrossRef]

- Grosman, F.; Madej, Ł.; Ziółkiewicz, S.; Nowak, J. Experimental and numerical investigation on development of new incremental forming process. J. Mater. Process. Technol. 2012, 212, 2200–2209. [Google Scholar] [CrossRef]

- Choi, S.; Na, K.H.; Kim, J.H. Upper-bound analysis of the rotary forging of a cylindrical billet. J. Mater. Process. Technol. 1997, 67, 78–82. [Google Scholar] [CrossRef]

- Gisbert, C.; Bernal, C.; Camacho, A.M. Improved analytical model for the calculation of forging forces during compression of bimetallic axial assemblies. Procedia Eng. 2015, 132, 298–305. [Google Scholar] [CrossRef]

- Bouffioux, C.; Eyckens, P.; Henrard, C.; Aerens, R.; Bael, A.; Sol, H.; Duflou, J.R.; Habraken, A.M. Identification of material parameters to predict single point incremental forming forces. Int. J. Mater. Form. 2008, 1, 1147–1150. [Google Scholar] [CrossRef]

- Camacho, A.M.; Marín, M.M.; Rubio, E.M.; Sebastián, M.A. Modeling strategies for efficient FE simulation of localised-incremental forging processes. AIP Conf. Proc. 2012, 1431, 725–732. [Google Scholar]

- Bernal, C.; Camacho, A.M.; Marín, M.; de Agustina, B. Methodology for the evaluation of 3D surface topography in multiple indentation processes. Int. J. Adv. Manuf. Technol. 2013, 69, 2091–2098. [Google Scholar] [CrossRef]

- Liu, Z.B.; Li, Y.L.; Daniel, W.J.T.B.; Meehan, P. Taguchi optimization of process parameters for forming time in incremental sheet forming process. Mater. Sci. Forum 2014, 773–774, 137–143. [Google Scholar] [CrossRef]

- Sieczkarek, P.; Isik, K.; Ben Khalifa, N.; Martins, P.A.F.; Tekkaya, A.E. Mechanics of sheet-bulk indentation. J. Mater. Process. Technol. 2014, 214, 2387–2394. [Google Scholar] [CrossRef]

- Song, Z.; Komvopoulos, K. Elastic-plastic spherical indentation: Deformation regimes, evolution of plasticity, and hardening effect. Mech. Mater. 2013, 61, 91–100. [Google Scholar] [CrossRef]

- Kukureka, S.N.; Craggs, G.; Ward, I.M. Analysis and modelling of the die drawing of polymers. J. Mater. Sci. 1992, 27, 3379–3388. [Google Scholar] [CrossRef]

- Moon, Y.H.; van Tyne, C.J.; Gordon, W.A. An upper bound analysis of a process-induced side-surface defect in forgings: Part 1: The velocity fields and power terms. J. Mater. Process. Technol. 2000, 99, 169–178. [Google Scholar] [CrossRef]

- Medeiros, N.; Moreira, L.P.; Bressan, J.D.; Lins, J.F.C.; Gouvêa, J.P. Upper-bound sensitivity analysis of the ECAE process. Mater. Sci. Eng. A 2010, 527, 2831–2844. [Google Scholar] [CrossRef]

- Parvizi, A.; Abrinia, K. A Two dimensional upper bound analysis of the ring rolling process with experimental and FEM verifications. Int. J. Mech. Sci. 2014, 79, 176–181. [Google Scholar] [CrossRef]

- Johnson, W.; Mellor, P.P.B. Engineering Plasticity; Ellis Horwood Limited: Chichester, UK, 1983. [Google Scholar]

- Kudo, H. An upper-bound approach to plane-strain forging and extrusion-I. Int. J. Mech. Sci. 1960, 1, 57–83. [Google Scholar] [CrossRef]

- Bermudo, C.; Martín, F.; Sevilla, L.; Martín, M.J. Experimental validation of the new modular application of the upper bound theorem in indentation. PLoS ONE 2015, 10, e0122790. [Google Scholar] [CrossRef] [PubMed]

- Bermudo, C.; Martín, F.; Sevilla, L. Application of the upper bound theorem to indentation processes with tilted punch by means of modular model. Procedia Eng. 2015, 132, 274–281. [Google Scholar] [CrossRef]

- Martín, F.; Camacho, A.M.; Domingo, R.; Sevilla, L. Modular procedure to improve the application of the upper-bound theorem in forging. Mater. Manuf. Process. 2013, 28, 282–286. [Google Scholar] [CrossRef]

- Fereshteh-Saniee, F.; Pillinger, I.; Hartley, P. Friction modelling for the physical simulation of the bulk metal forming processes. J. Mater. Process. Technol. 2004, 153–154, 151–156. [Google Scholar] [CrossRef]

- Kačmarčik, I.; Movrin, D.; Ivanišević, A. One contribution to the friction investigation in bulk metal forming. J. Technol. Plast. 2011, 36, 35–48. [Google Scholar] [CrossRef]

- Hill, R. The Mathematical Theory of Plasticity; Oxford Classic Texts in the Physical Sciences: Oxford, UK, 1998. [Google Scholar]

- Backofen, W.A. Deformation Processing; Addison-Wesley Educational Publishers Inc.: Boston, MA, USA, 1972. [Google Scholar]

| Simulation Settings | Value |

|---|---|

| Number of Simulation Steps | 100 |

| Step Increment to save | 5 |

| With equal die displacement | 0.26 (mm) |

| Remesh maximum step increment | 3 |

| Mesh Settings | Value |

|---|---|

| Number of Elements | 10,000 |

| Mesh Windows | 4 |

| Mesh Windows Relation | 0.2/2/4/20 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bermudo, C.; Sevilla, L.; Martín, F.; Trujillo, F.J. Study of the Tool Geometry Influence in Indentation for the Analysis and Validation of the New Modular Upper Bound Technique. Appl. Sci. 2016, 6, 203. https://doi.org/10.3390/app6070203

Bermudo C, Sevilla L, Martín F, Trujillo FJ. Study of the Tool Geometry Influence in Indentation for the Analysis and Validation of the New Modular Upper Bound Technique. Applied Sciences. 2016; 6(7):203. https://doi.org/10.3390/app6070203

Chicago/Turabian StyleBermudo, Carolina, Lorenzo Sevilla, Francisco Martín, and Francisco J. Trujillo. 2016. "Study of the Tool Geometry Influence in Indentation for the Analysis and Validation of the New Modular Upper Bound Technique" Applied Sciences 6, no. 7: 203. https://doi.org/10.3390/app6070203

APA StyleBermudo, C., Sevilla, L., Martín, F., & Trujillo, F. J. (2016). Study of the Tool Geometry Influence in Indentation for the Analysis and Validation of the New Modular Upper Bound Technique. Applied Sciences, 6(7), 203. https://doi.org/10.3390/app6070203