Artificial Neural Network Model to Estimate the Viscosity of Polymer Solutions for Enhanced Oil Recovery †

Abstract

:1. Introduction

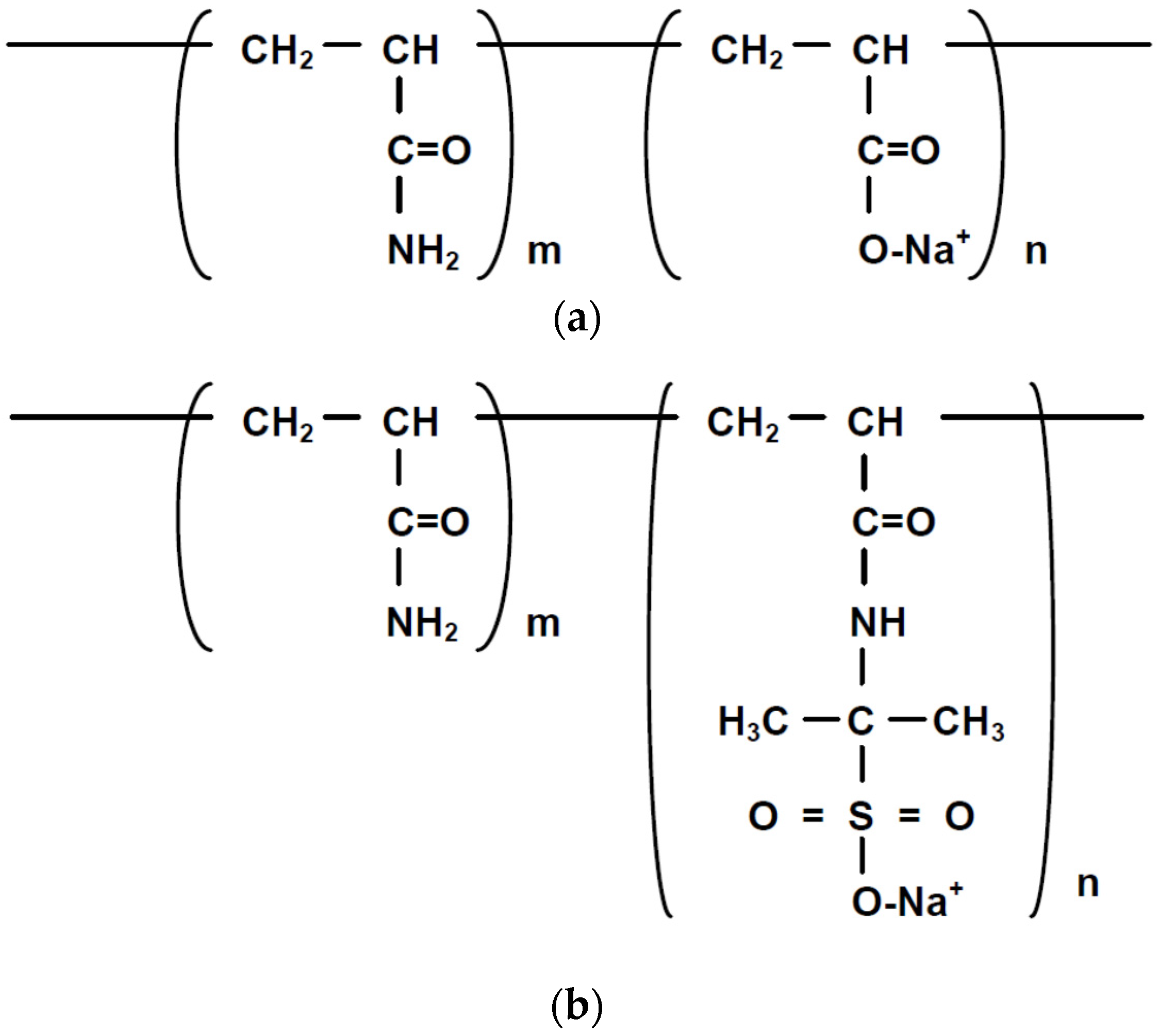

2. Types of EOR Polymers

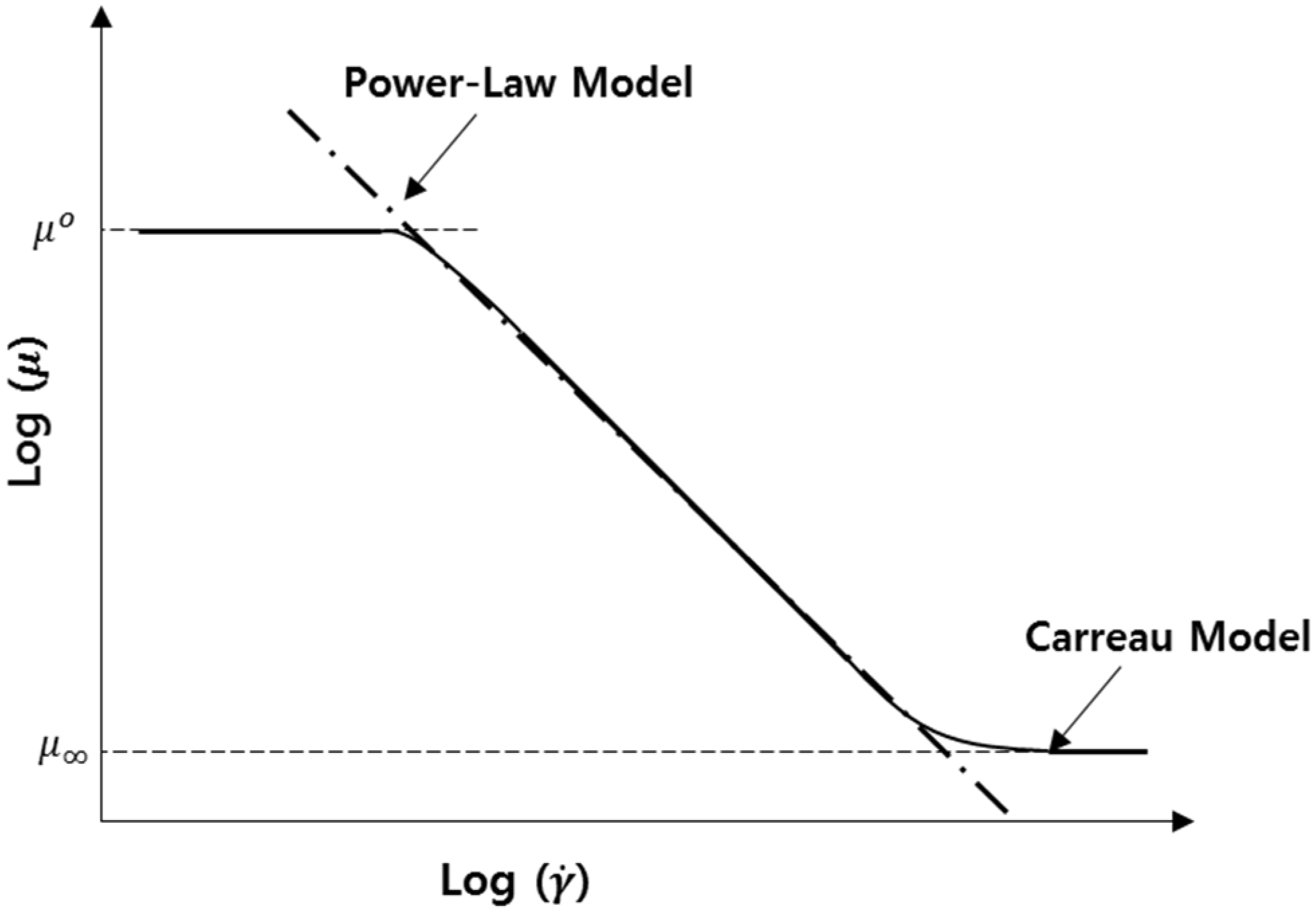

3. Rheological Characteristics of EOR Polymers

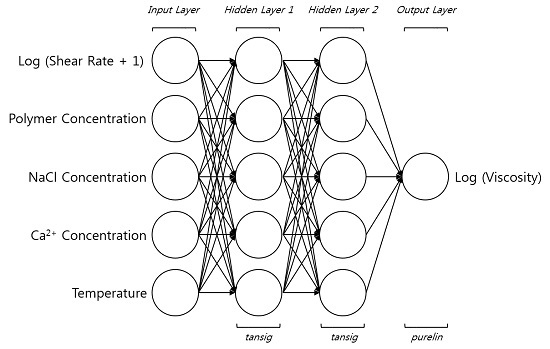

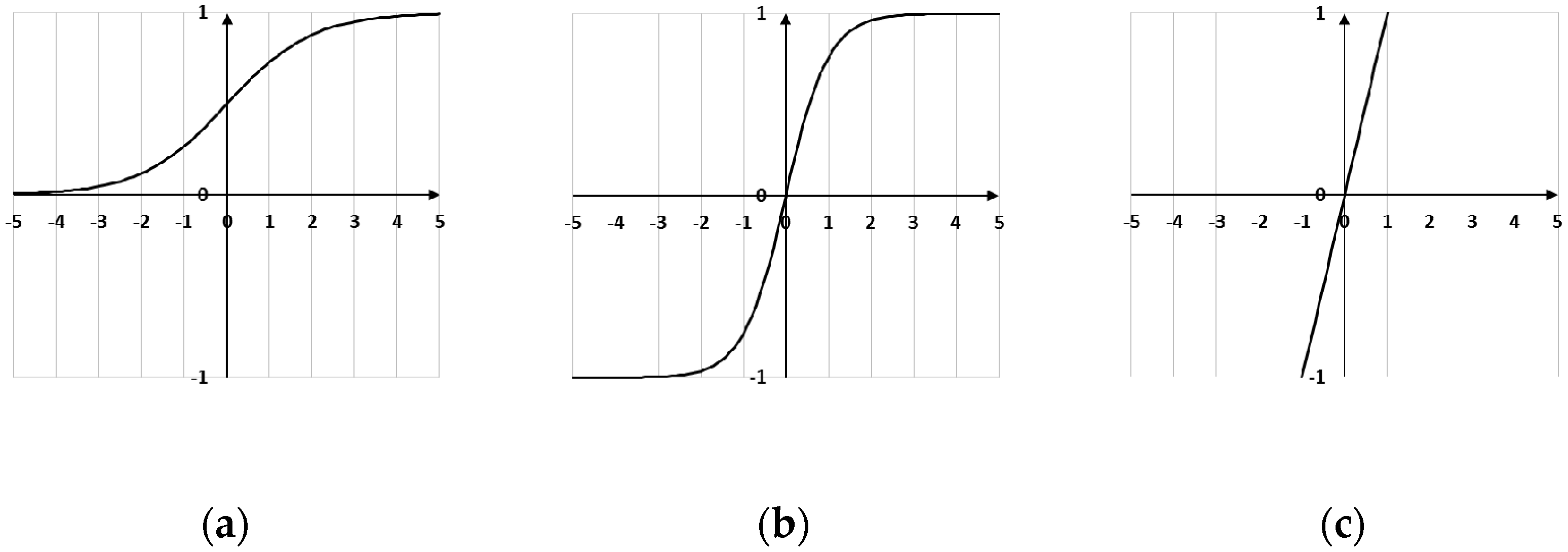

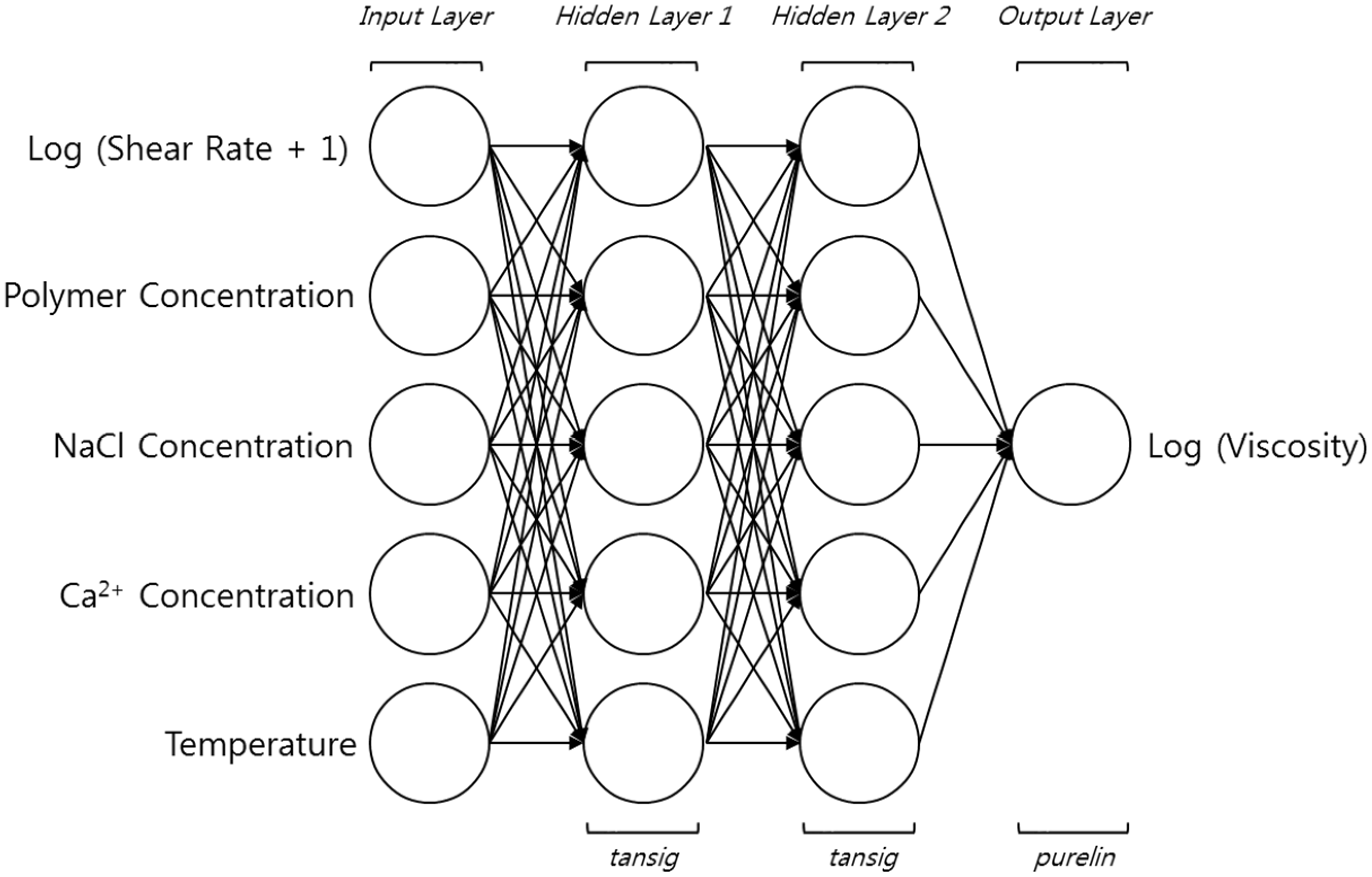

4. Development of ANN Models

5. Results of Viscosity Estimation Using ANN Models

6. Conclusions and Discussions

- In this study, ANN was applied to estimate the viscosity of various bulk solutions of the most widely-used EOR polymers (FlopaamTM 3330S, FlopaamTM 3630S and AN-125) based on shear rate, polymer concentration, NaCl concentration, Ca2+ concentration and temperature. As a result, three ANN models, one for each of the EOR polymers, were presented.

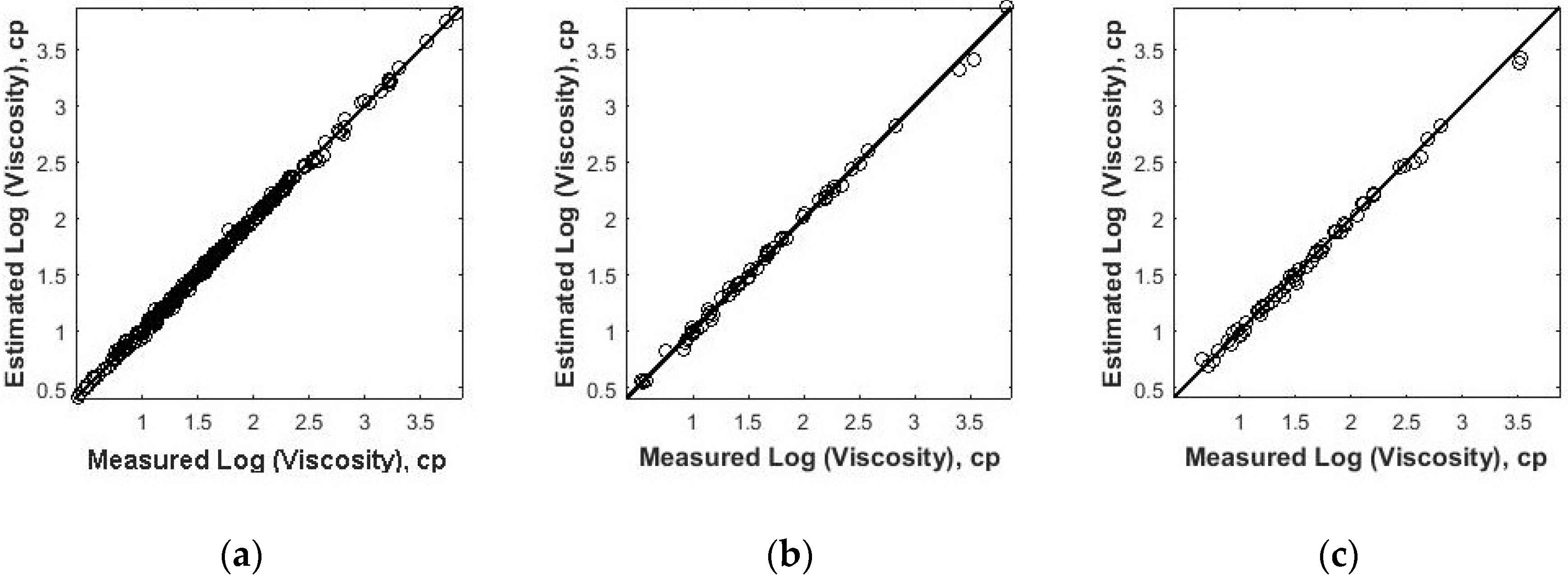

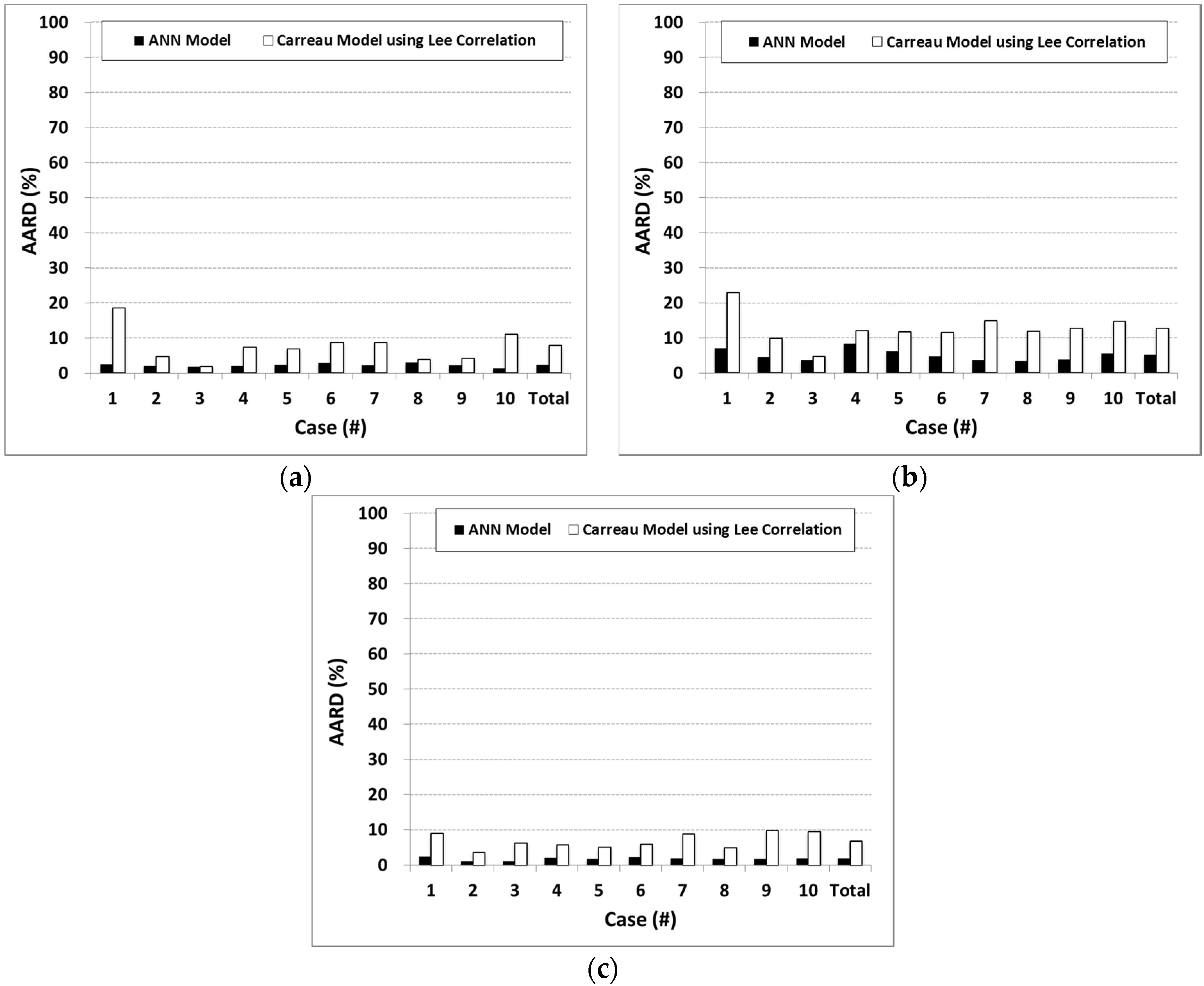

- The viscosity estimated using the ANN models is in good agreement with the measured viscosity. Based on the AARD calculations, the ANN models show higher accuracy than the Carreau model using Lee’s correlation, which is the only method to estimate the unmeasured viscosity of a polymer solution for enhanced oil recovery.

- In some conditions (low salinity or FlopaamTM 3630S), the viscosity estimation by the Carreau model using Lee’s correlation is not accurate. It is possible that the relationship between the influential parameters and viscosity can change under certain conditions, such as low salinity (0.1 wt % NaCl) or high molecular weight polymers (20 million). The ANN models proposed in this study are less affected by this effect than the Carreau model using Lee’s correlation considering the higher accuracy for all conditions of polymer solutions.

- It is concluded that the ANN models proposed in this study can be utilized for quick estimation of the viscosity of the bulk polymer solution prior to experimental measurement, which is a time-consuming process.

- One interesting finding is that the same structure of the ANN model can provide accurate estimation despite the different polymer structures of HPAM and poly(AM-co-AMPS). Considering that ANN can easily be expanded to include other factors, such as polymer characteristics (polymer structure and degree of hydrolysis, among others), it would be possible to develop an ANN model to estimate the viscosity of other EOR polymers if a method for the quantification of polymer structures can be established.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| empirical constant, generally two | |

| empirical constants | |

| empirical constants | |

| Na+ concentration | |

| empirical constant | |

| Ca2+ concentration | |

| polymer concentration | |

| empirical constants | |

| flow consistency index | |

| empirical constant | |

| power-law index | |

| total number of viscosity data | |

| temperature | |

| temperature at reference condition | |

| measured viscosity | |

| estimated viscosity | |

| shear rate | |

| viscosity | |

| intrinsic viscosity | |

| Newtonian viscosity at a high shear rate, generally solvent (water) viscosity | |

| Newtonian viscosity at a low shear rate | |

| empirical constant |

Appendix

References

- Kang, P.S.; Lim, J.S.; Huh, C. Screening Criteria and Considerations of Offshore Enhanced Oil Recovery. Energies 2016, 9, 44. [Google Scholar] [CrossRef]

- Sheng, J.J. Modern Chemical Enhanced Oil Recovery: Theory and Practice, 1st ed.; Gulf Professional Publishing: Burlington, MA, USA, 2011. [Google Scholar]

- Lake, L.W. Enhanced Oil Recovery, 1st ed.; Prentice-Hall: Eaglewood Cliffs, NJ, USA, 1989. [Google Scholar]

- Wang, D.; Xia, H.; Liu, Z.; Yang, Q. Study of the Mechanism of Polymer Solution with Visco-Elastic Behavior Increasing Microscopic Oil Displacement Efficiency and Forming of Steady ‘Oil Thread’ Flow Channel. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Jakarta, Indonesia, 17–19 April 2011.

- Mungan, N. Rheology and Adsorption of Aqueous Polymer Solutions. J. Can. Pet. Technol. 1969, 8, 45–50. [Google Scholar] [CrossRef]

- Mungan, N. Shear Viscosities of Ionic Polyacrylamide Solutions. Soc. Pet. Eng. J. 1972, 12, 469–473. [Google Scholar] [CrossRef]

- Nouri, H.H.; Root, P.J. A Study of Polymer Solution Rheology, Flow Behavior, and Oil Displacement Processes. In Proceedings of the SPE-AIME 46th Annual Fall Meeting, New Orleans, LA, USA, 3–6 October 1971.

- Ferrer, J. Some Mechanistic Features of Flow of Polymers through Porous Media. In Proceedings of the SPE-AIME 47th Annual Fall Meeting, San Antonio, TX, USA, 8–11 October 1972.

- Martin, F.D.; Sherwood, N.S. The Effect of Hydrolysis of Polyacrylamide on Solution Viscosity, Polymer Retention and Flow Resistance Properties. In Proceedings of the SPE Rocky Mountain Regional Meeting, Denver, CO, USA, 7–9 April 1975.

- Szabo, M.T. An Evaluation of Water-Soluble Polymers For Secondary Oil Recovery—Part 1 and 2. J. Pet. Technol. 1979, 31, 553–570. [Google Scholar] [CrossRef]

- Ward, J.S.; Martin, F.D. Prediction of Viscosity for Partially Hydrolyzed Polyacrylamide Solutions in the Presence of Calcium and Magnesium Ions. Soc. Pet. Eng. J. 1981, 21, 623–631. [Google Scholar] [CrossRef]

- Zaitoun, A.; Potie, B. Limiting Conditions for the Use of Hydrolyzed Polyacrylamides in Brines Containing Divalent Ions. In Proceedings of the SPE Oilfield and Geothermal Chemistry Symposium, Denver, CO, USA, 1–3 June 1983.

- Tam, K.C.; Tiu, C. Role of Ionic Species and Valency on the Steady Shear Behavior of Partially Hydrolyzed Polyacrylamide Solutions. Colloid. Polym. Sci. 1990, 268, 911–920. [Google Scholar] [CrossRef]

- Sorbie, K.S. Polymer-Improved Oil Recovery, 1st ed.; CRC Press: Boca Raton, FL, USA, 1991. [Google Scholar]

- Laboratory Investigation of the Effect of Brine Composition on Plymer Solutions-Part 1: Partially Hydrolyzed Polyacrylamide (HPAM) Case. Available online: https://www.onepetro.org/general/SPE-23533-MS (accessed on 11 May 2016).

- Moradi-Araghi, A.; Cleveland, D.H.; Westerman, I.J. Development and Evaluation of EOR Polymers Suitable for Hostile Environments: II-Copolymers of Acrylamide and Sodium AMPS. In Proceedings of the SPE International Symposium on Oilfield Chemistry, San Antonio, TX, USA, 4–6 February 1995.

- Nasr-El-Din, H.A.; Taylor, K.C. Rheology of Water-Soluble Polymers Used for Improved Oil Recovery, Multiphase Reactor and Polymerization System Hydrodynamics, 1st ed.; Gulf Publishing Company: Burlington, MA, USA, 1996. [Google Scholar]

- Choi, S.K. A Study of a pH-sensitive Polymer for Novel Conformance Control Applications. Master Thesis, The University of Texas at Austin, Austin, TX, USA, December 2005. [Google Scholar]

- Levitt, D.B.; Pope, G.A. Selection and Screening of Polymers for Enhanced-Oil Recovery. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 19–23 April 2008.

- Dupuis, G.; Rousseau, D. How to Get the Best Out of Hydrophobically Associative Polymers for IOR? New Experimental Insights. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 24–28 April 2010.

- Reichenbach-Klinke, R.; Langlotz, B.; Wenzke, B.; Spindler, C.; Brodt, G. Associative Copolymer with Favorable Properties for the Application in Polymer Flooding. In Proceedings of the SPE International Symposium on Oilfield, Woodlands, TX, USA, 11–13 April 2011.

- Duchesne, M.A.; Macchi, A.; Lu, D.Y.; Hughes, R.W.; McCalden, D.; Anthony, E.J. Artificial Neural Network Model to Predict Slag Viscosity Over a Broad Range of Temperatures and Slag Compositions. Fuel Process. Technol. 2009, 91, 831–836. [Google Scholar] [CrossRef]

- Torabi, F.; Abedini, A.; Abedini, R. The Development of an Artificial Neural Network Model for Prediction of Crude Oil Viscosities. Pet. Sci. Tech. 2011, 29, 1532–2459. [Google Scholar] [CrossRef]

- Jahirul, M.I.; Senadeera, W.; Brooks, P.; Brown, R.J.; Situ, R.; Pham, P.X.; Masri, A.R. An Artificial Neural Network (ANN) Model for Predicting Biodiesel Kinetic Viscosity as a Function of Temperature and Chemical Compositions. In Proceedings of the International Congress on Modelling and Simulation, Adelaide, Australia, 1–6 December 2013.

- Gheshlaghi, B.K.; Dehgani, M.; Parhizgar, H. Prediction of Kinetic Viscosity of Petroleum Fractions Using Artificial Neural Network. Iran. J. Oil Gas Sci. Technol. 2014, 3, 51–65. [Google Scholar]

- Prediction of Viscosities of Aqueous Two Phase Systems Containing Protein by Artificial Neural Network. Available online: http://www.omicsonline.org/open-access/prediction-of-viscosities-of-aqueous-two-phase-systems-containing-protein-by-artificial-neural-network-2157-7048.1000192.php?aid=26480 (accessed on 11 May 2016).

- Kang, P.S.; Lim, J.S. Development of Artificial Neural Network Viscosity Model of pH-Sensitive Polymer for Enhanced Oil Recovery. J. Korean Soc. Mineral Energy Resour. Eng. 2011, 48, 190–198. [Google Scholar]

- Kang, P.S.; Lim, J.S.; Huh, C. A Novel Approach in Estimating Shear-Thinning Rheology of HPAM and AMPS Polymers for Enhanced Oil Recovery Using Artificial Neural Network. In Proceedings of the 23rd International Offshore and Polar Engineering Conference, Anchorage, AK, USA, 5–30 July 2013.

- Manrique, E.J.; Muci, V.E.; Gurfinkel, M.E. EOR Field Experiences in Carbonate Reservoirs in the United States. Soc Pet. Eng. J. 2007, 10, 667–686. [Google Scholar] [CrossRef]

- Standnes, D.C.; Skjevrak, I. Literature Review of Implemented Polymer Field Projects. J. Pet. Sci. Eng. 2014, 122, 761–775. [Google Scholar] [CrossRef]

- Choi, S.K. pH Sensitive Polymers for Novel Conformance Control and Polymer Flooding Applications. PhD Thesis, The University of Texas at Austin, Austin, TX, USA, August 2008. [Google Scholar]

- Gaillard, N.; Sanders, D.; Favéro, C. Improved Oil Recovery using Thermally and Chemically Protected Compositions based on Co-and Ter-polymers Containing Acrylamide. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 24–28 April 2010.

- Gaillard, N.; Giovannetti, B.; Favéro, C.; Caritey, J.P.; Dupuis, G.; Zaitoun, A. New Water Soluble Anionic NVP Acrylamide Ter-polymers for Use in Harsh EOR Conditions. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 12–16 April 2014.

- Vermolen, E.; Haasterecht, M.; Masalmeh, S.K.; Faber, M.J.; Boersma, D.M.; Gruenenfelder, M. Pushing the Envelope for Polymer Flooding Towards High-temperature and High-salinity Reservoirs with Polyacrylamide Based Ter-Polymers. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 25–28 September 2011.

- Seright, R.S.; Fan, T.; Wavrik, K.; Wan, H.; Gaillard, N.; Favéro, C. Rheology of a New Sulfonic Associative Polymer in Porous Media. SPE Reservoir Eval. Eng. 2011, 14, 726–734. [Google Scholar] [CrossRef]

- Kulawardana, E.U.; Koh, H.; Kim, D.H.; Liyanage, P.J.; Upamali, K.; Huh, C.; Weerasooriya, U.; Pope, G.A. Rheology and Transport of Improved EOR Polymers under Harsh Reservoir Conditions. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 14–18 April 2012.

- Wu, Y.; Mahmoudkhani, A.; Watson, P.; Fenderson, T.; Nair, M. Development of New Polymers with Better Performance under Conditions of High Temperature and High Salinity. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 16–18 April 2012.

- Parker, W.O., Jr.; Lezzi, A. Hydrolysis of Sodium-2-acrylamido-2-methyl Propane Sulfonate Copolymers at Elevated Temperature in Aqueous Solution via 13C NMR Spectroscopy. Polymer 1993, 34, 4913–4918. [Google Scholar] [CrossRef]

- Zhao, T.H.; Pan, G.F.; Guo, S.F.; Hu, X.Q. Synthesis and Evaluation of AMPS/AM. J. Southwest Pet. Inst. 2006, 28, 82–84. [Google Scholar]

- Kim, D.H.; Lee, S.J.; Ahn, C.H.; Huh, C.; Pope, G.A. Development of a Viscoelastic Property Database for EOR Polymers. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 24–28 April 2010.

- Bird, R.B.; Stewart, W.E.; Lightfoot, E.N. Transport Phenomena, 1st ed.; Wiley: New York, NY, USA, 1960. [Google Scholar]

- Carreau, P.J. Rheological Equation from Molecular Network Theories. J. Rheol. 1972, 16, 99–127. [Google Scholar] [CrossRef]

- Cannella, W.J.; Huh, C.; Seright, R.S. Prediction of Xanthan Rheology in Porous Media. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 2–5 October 1988.

- Lee, S.J.; Kim, D.H.; Huh, C.; Pope, G.A. Development of a Comprehensive Rheological Property Database for EOR Polymers. In Proceedings of the SPE 124798 presented at SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 4–7 October 2009.

- Bird, R.B.; Armstrong, R.C.; Hassanger, R. Dynamics of Polymeric Liquid, 1st ed.; Wiley: New York, NY, USA, 1987. [Google Scholar]

- Lee, S.J. Development of a Comprehensive Rheological Property Database for EOR Polymers. Master Thesis, The University of Texas at Austin, Austin, TX, USA, December 2009. [Google Scholar]

- Braspenning, P.J.; Thuijsman, F.; Weijters, A.J.M.M. Artificial Neural Networks: An Introduction to ANN Theory and Practices, 1st ed.; Springer-Verlag: Berlin, Germany, 1995. [Google Scholar]

- Yegnanarayana, B. Artificial Neural Network, 1st ed.; Prentice-Hall of India: New Delhi, India, 2006. [Google Scholar]

- Priddy, K.L.; Keller, P.E. Artificial Neural Networks: An Introduction, 1st ed.; SPIE Publications: Bellingham, WA, USA, 2005. [Google Scholar]

- Levenberg, K. A Method for the Solution of Certain Problems in Least Squares. Q. Appl. Math. 1994, 2, 164–168. [Google Scholar]

- Marquardt, D.W. An Algorithm for Least-Squares Estimation of Nonlinear Parameters. J. Soc. Ind. Appl. Math. 1963, 11, 431–441. [Google Scholar] [CrossRef]

| Polymer | Type | Molecular weight (million) | Degree of hydrolysis (%) | Manufacturer |

|---|---|---|---|---|

| FlopaamTM 3330S | HPAM | 8 | 25–30 | SNF Floerger® |

| FlopaamTM 3630S | HPAM | 20 | 25–30 | |

| AN-125 | Poly(AM-co-AMPS) | 8 | 25–30 * |

| FlopaamTM 3330S, FlopaamTM 3630S, AN-125 | |||||

|---|---|---|---|---|---|

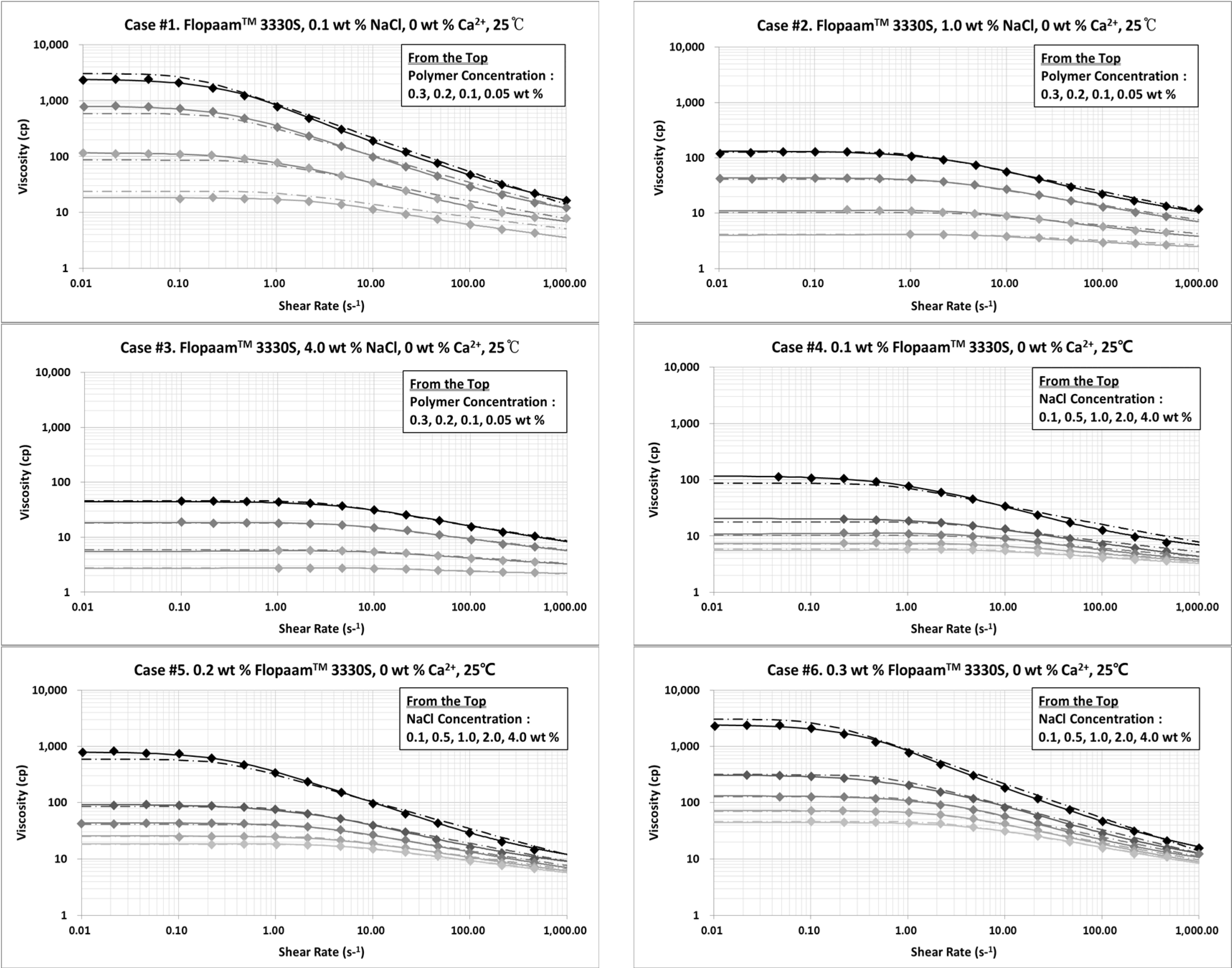

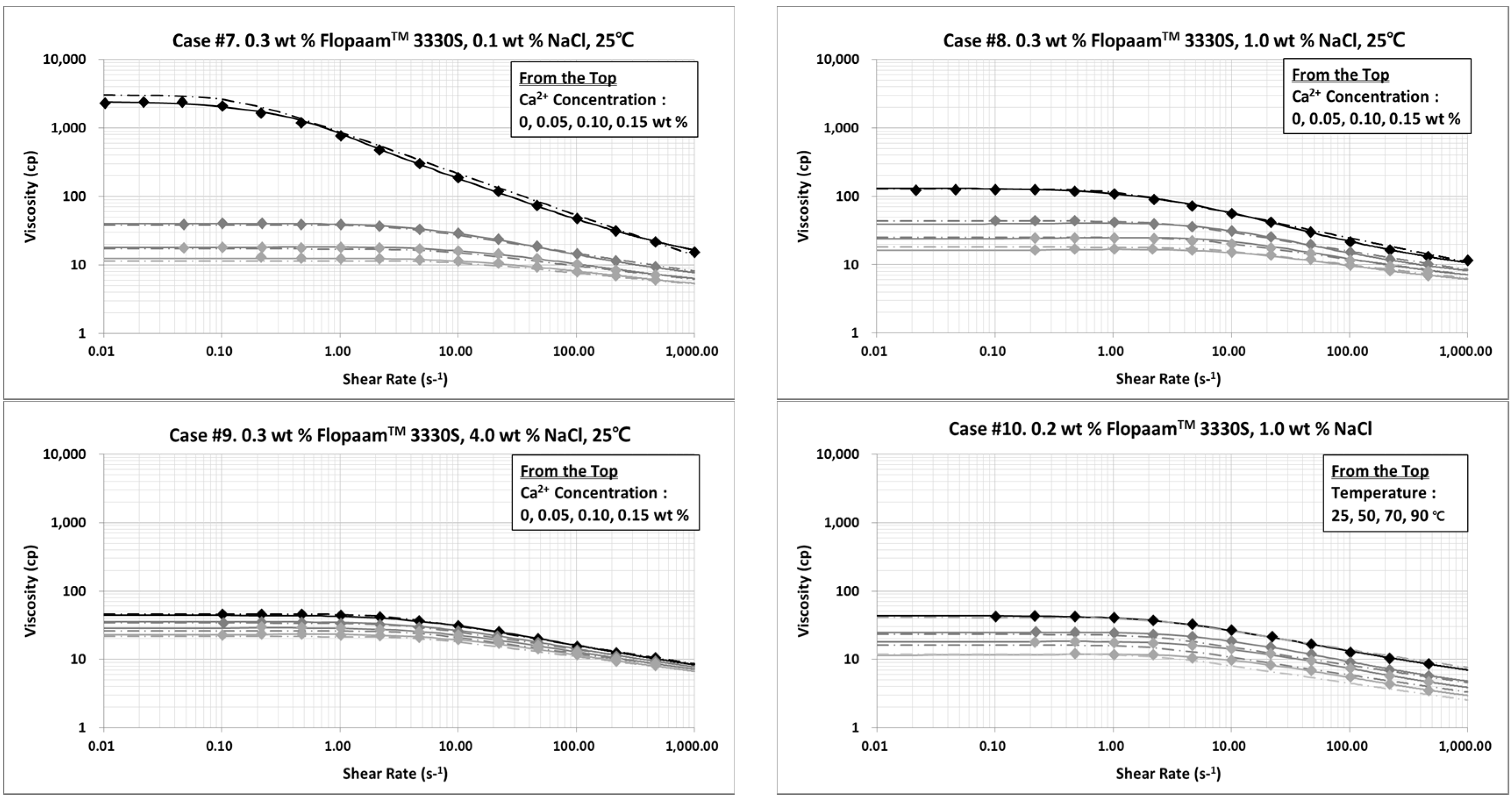

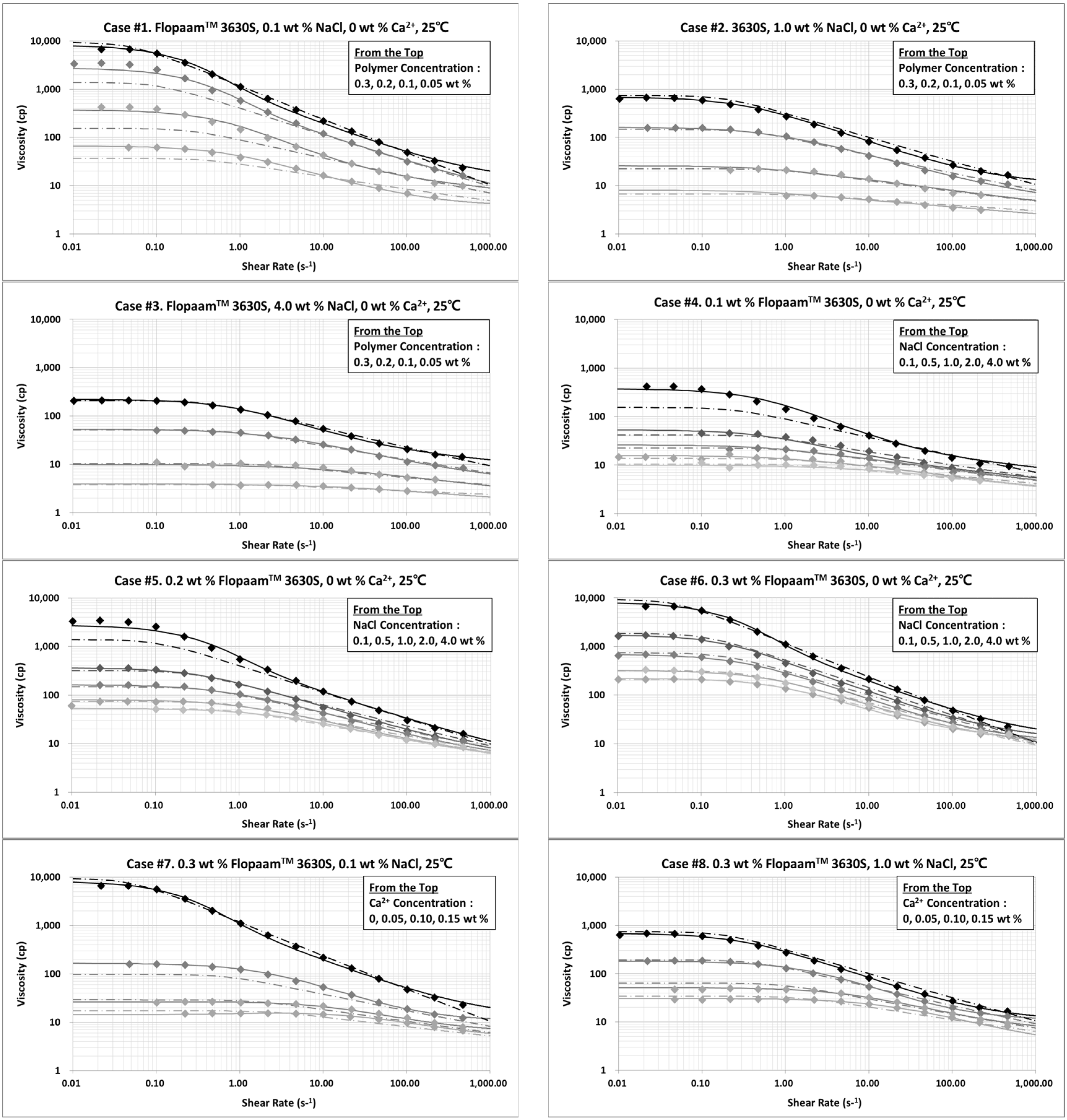

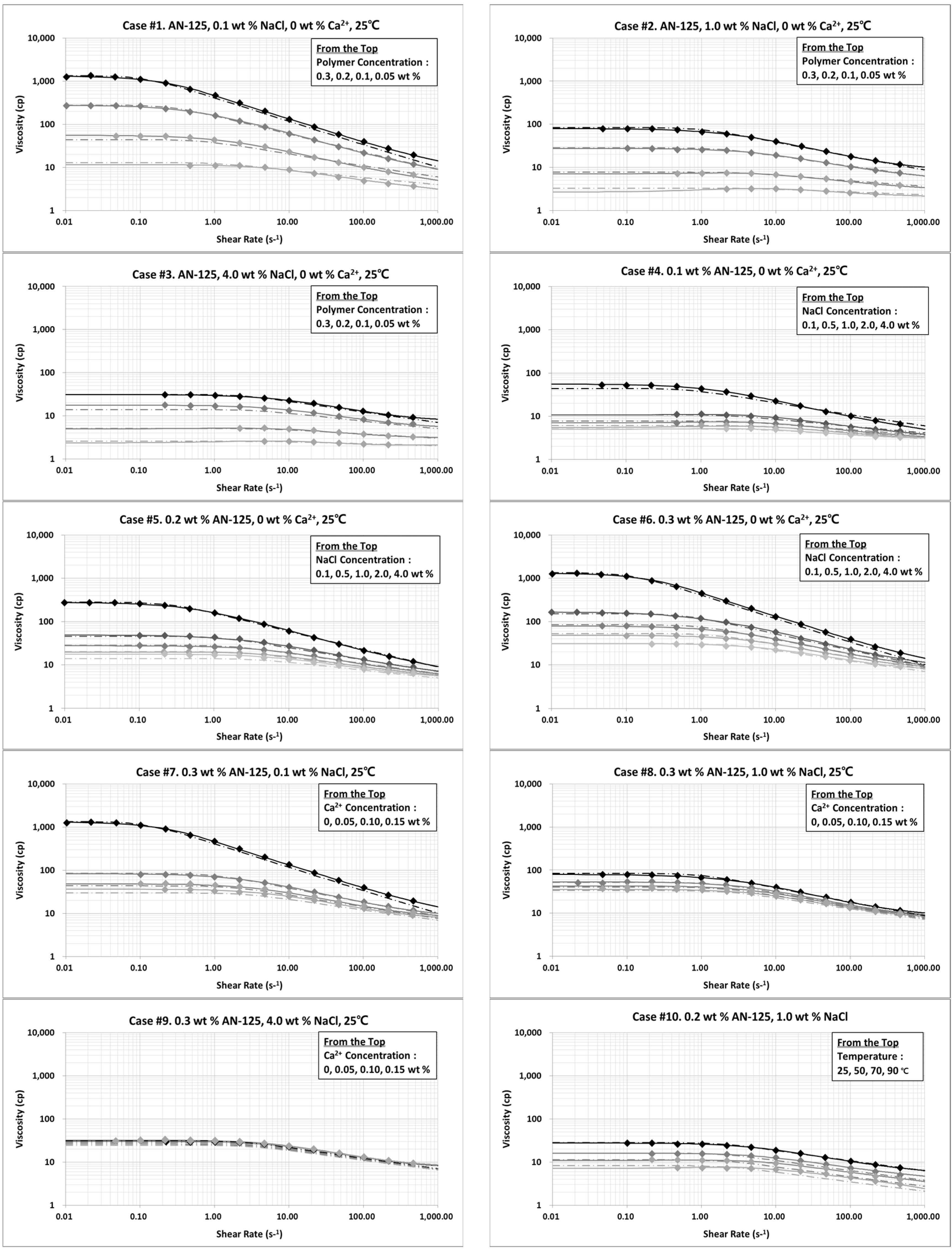

| Case (#) | Shear rate (s−1) | Polymer concentration (wt %) | NaCl concentration (wt %) | Ca2+ concentration (wt %) | Temperature (°C) |

| 1 | 0.01–1000 | 0.05, 0.1, 0.2, 0.3 | 0.1 | 0 | 25 |

| 2 | 1 | 0 | 25 | ||

| 3 | 4 | 0 | 25 | ||

| 4 | 0.1 | 0.1, 0.5, 1, 2, 4 | 0 | 25 | |

| 5 | 0.2 | 0 | 25 | ||

| 6 | 0.3 | 0 | 25 | ||

| 7 | 0.3 | 0.1 | 0, 0.05, 0.1, 0.15 | 25 | |

| 8 | 0.3 | 1 | 25 | ||

| 9 | 0.3 | 4 | 25 | ||

| 10 | 0.2 | 1 | 0 | 25, 50, 70, 90 | |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, P.-S.; Lim, J.-S.; Huh, C. Artificial Neural Network Model to Estimate the Viscosity of Polymer Solutions for Enhanced Oil Recovery. Appl. Sci. 2016, 6, 188. https://doi.org/10.3390/app6070188

Kang P-S, Lim J-S, Huh C. Artificial Neural Network Model to Estimate the Viscosity of Polymer Solutions for Enhanced Oil Recovery. Applied Sciences. 2016; 6(7):188. https://doi.org/10.3390/app6070188

Chicago/Turabian StyleKang, Pan-Sang, Jong-Se Lim, and Chun Huh. 2016. "Artificial Neural Network Model to Estimate the Viscosity of Polymer Solutions for Enhanced Oil Recovery" Applied Sciences 6, no. 7: 188. https://doi.org/10.3390/app6070188