Probabilistic Fatigue Life Prediction of Bridge Cables Based on Multiscaling and Mesoscopic Fracture Mechanics

Abstract

:1. Introduction

2. Trans-Scale Formulation for Fatigue Crack Growth of Steel Wire and Cable

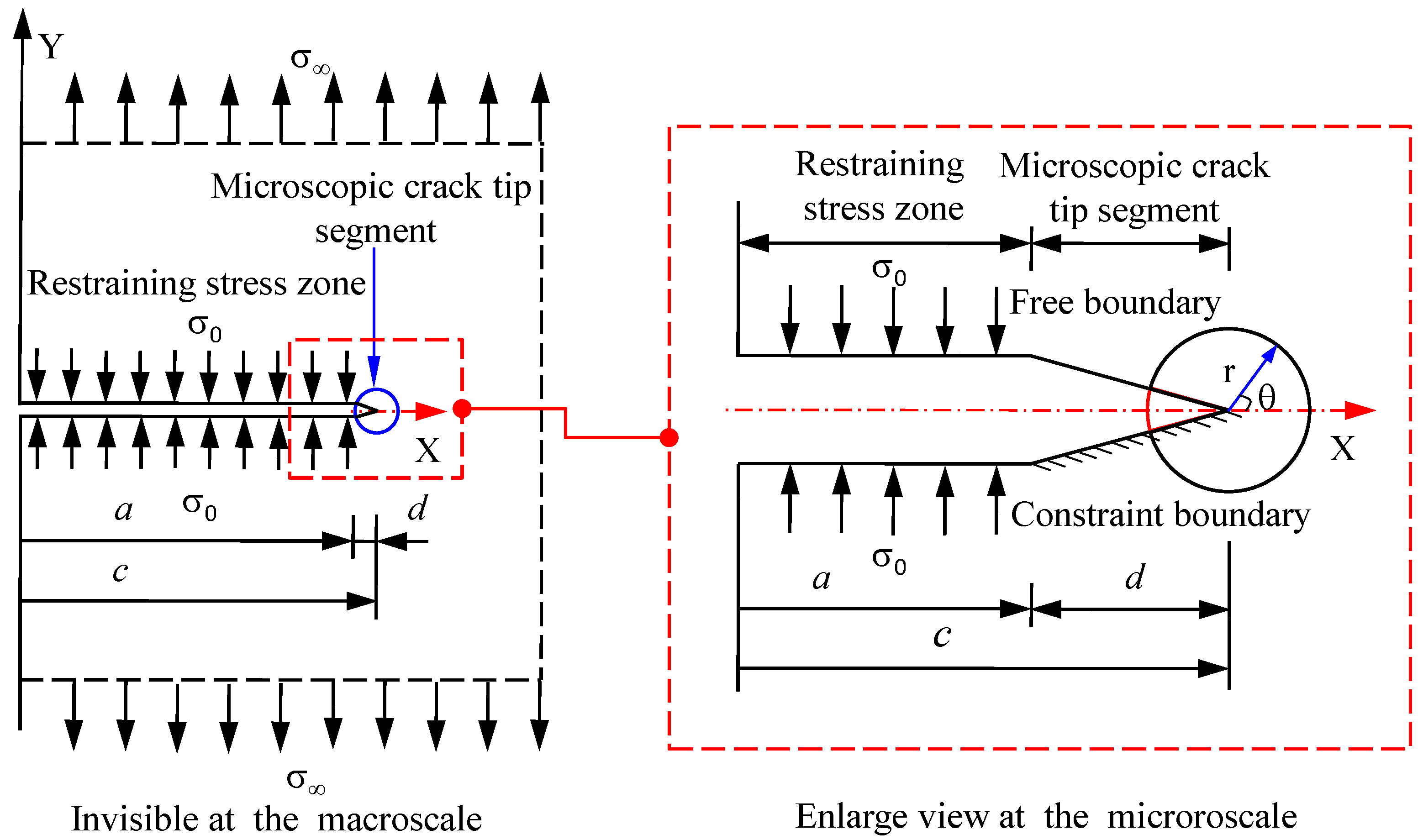

2.1. Macro/Micro Dual Scale Crack Model

2.2. Trans-Scale Formulation for Fatigue Crack Growth of Steel Wire

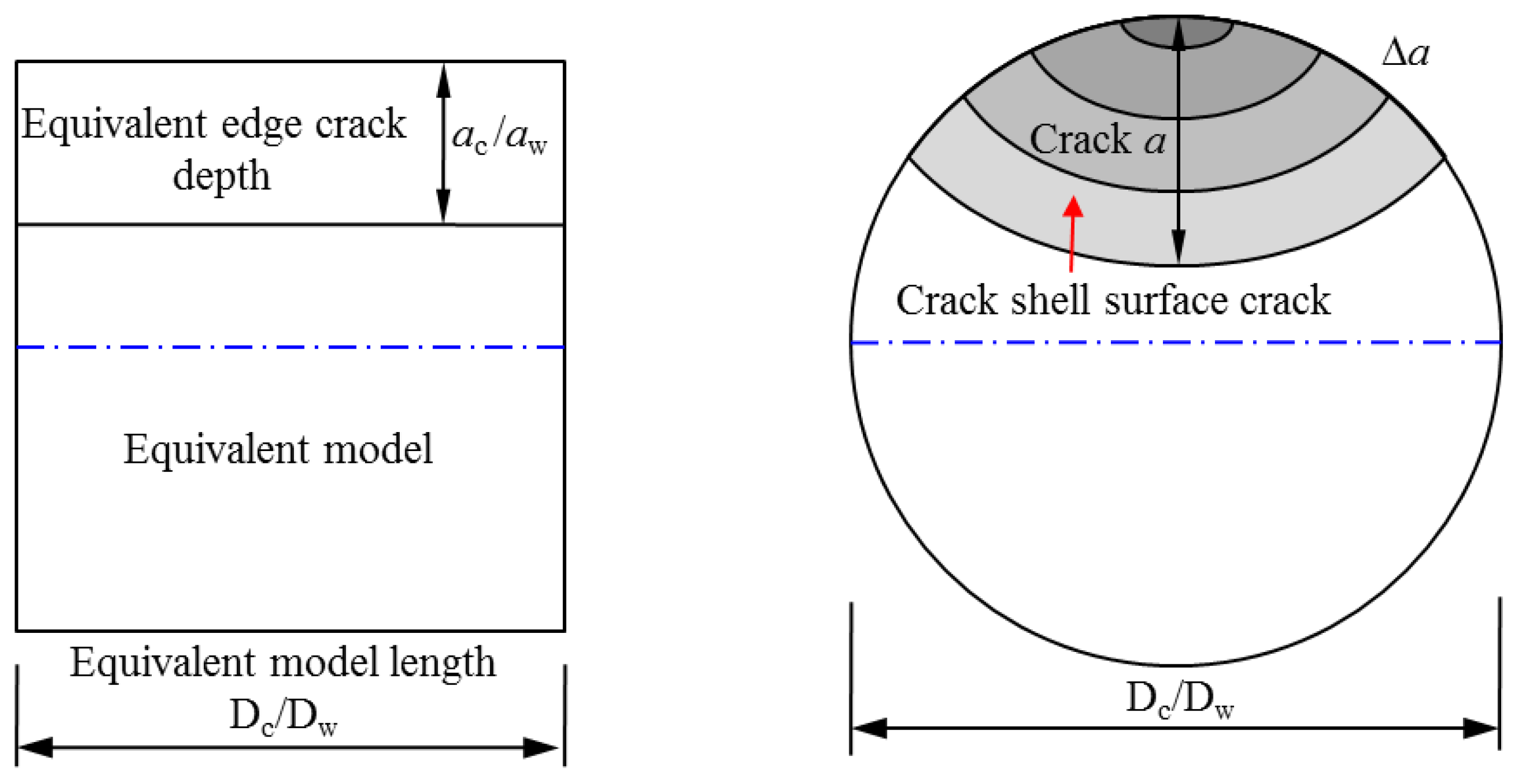

2.3. Fatigue Crack Growth of Cable

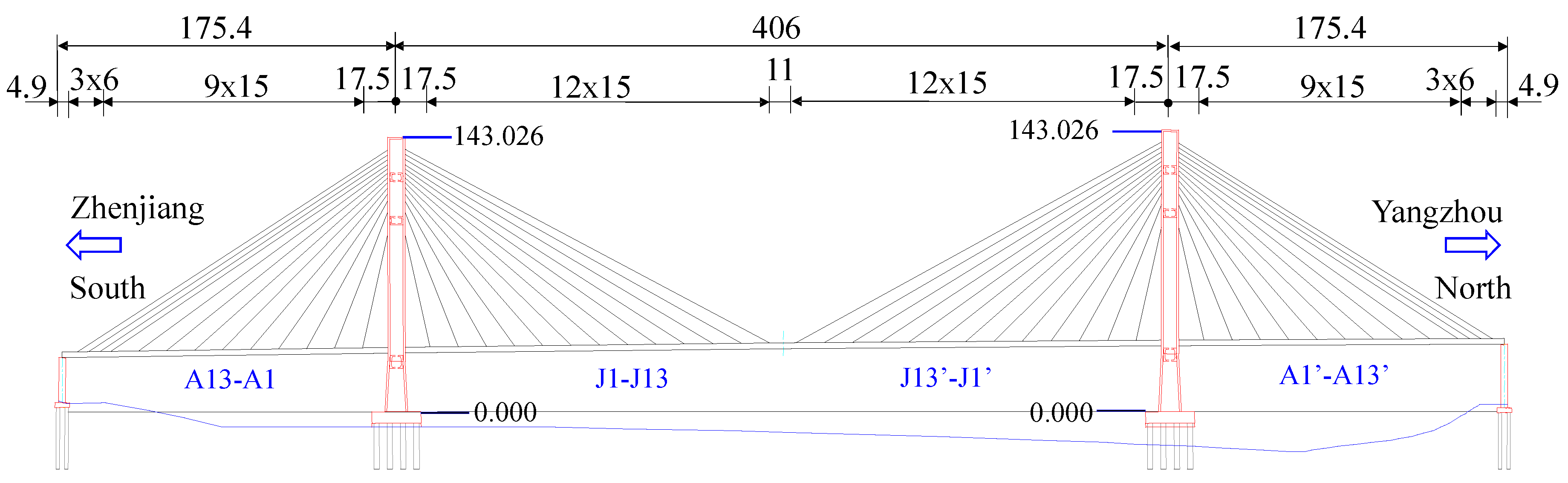

3. FE Modeling of the Runyang Cable-Stayed Bridge

3.1. Bridge Description

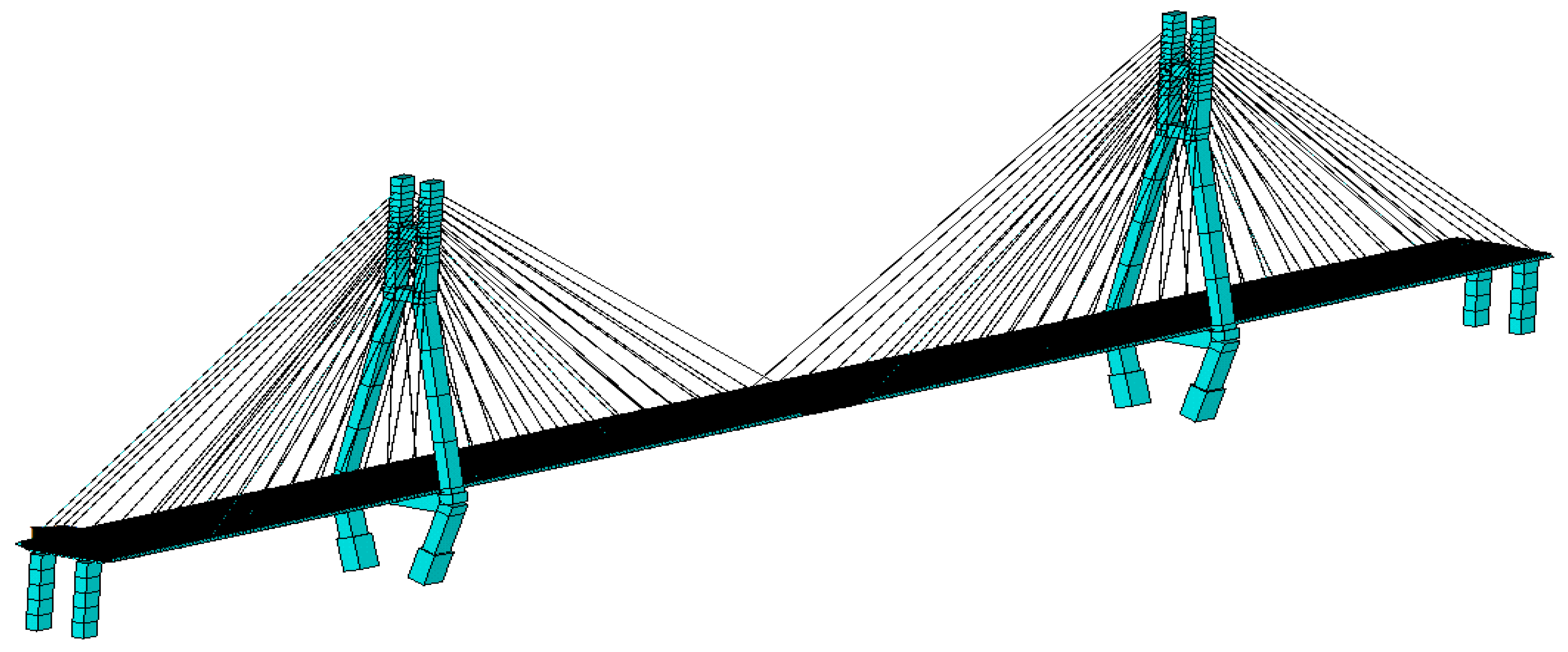

3.2. FE Modeling

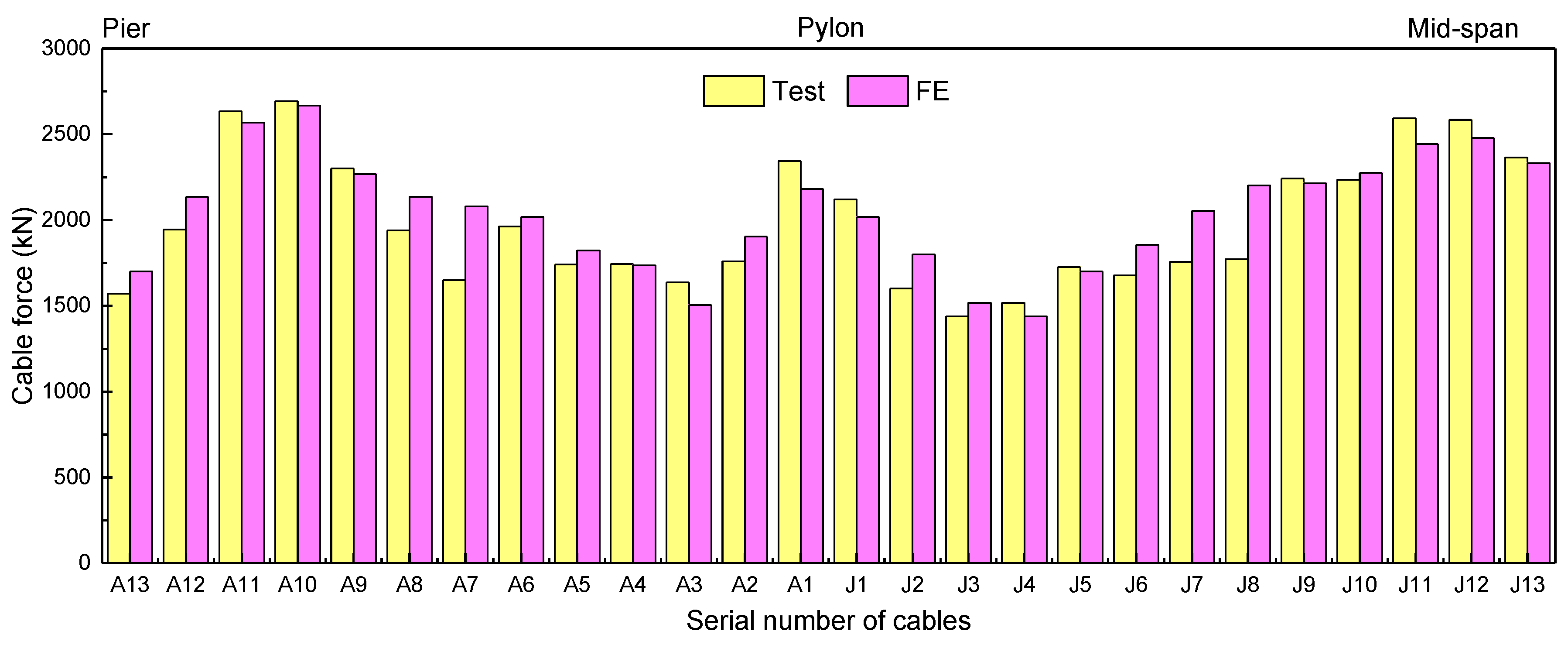

3.3. Validation of FE Model

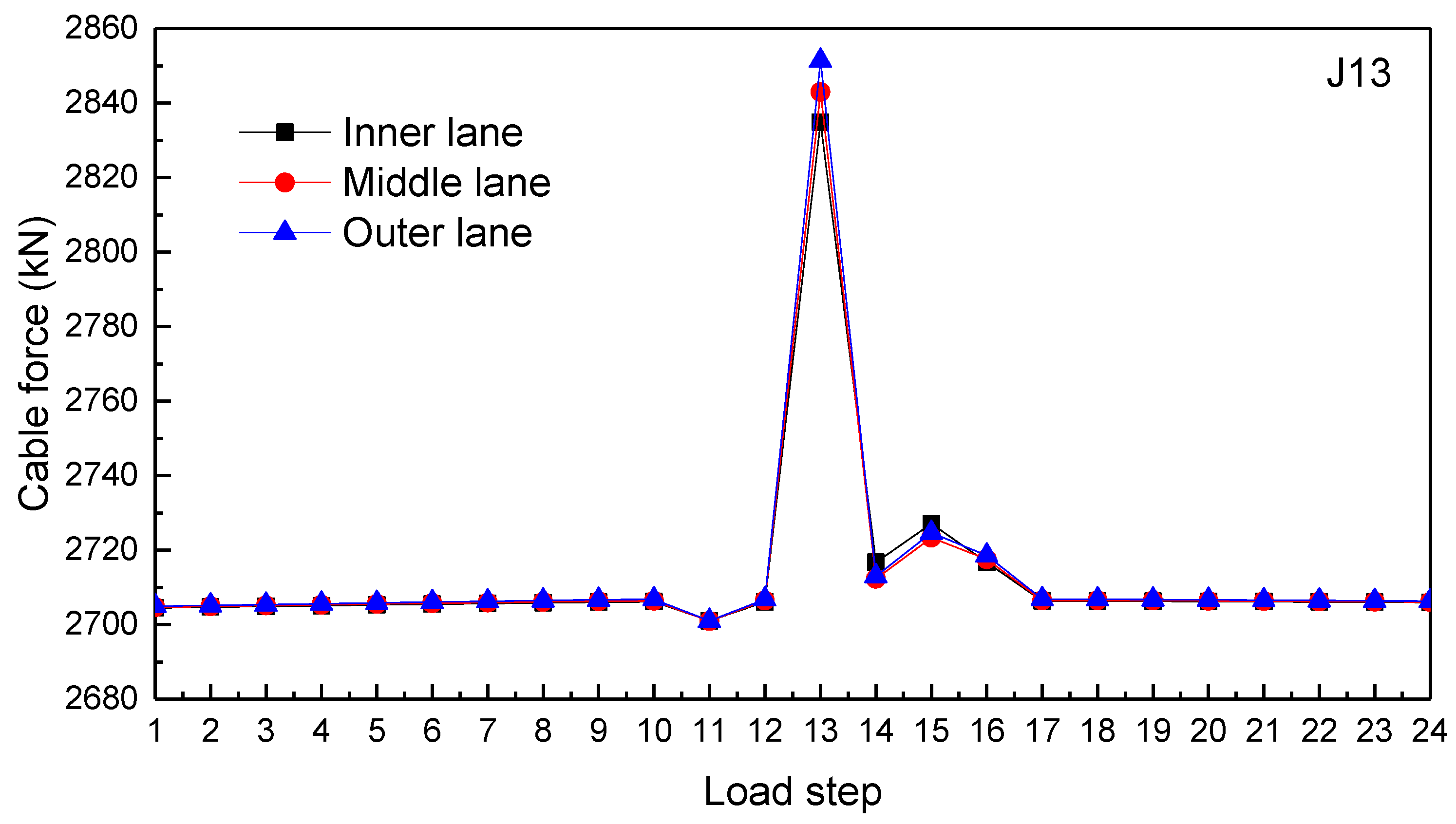

3.4. Force Analysis in Cables

4. Fatigue Life Prediction of Bridge Cables

4.1. Vehicle Load Model

4.2. Fatigue Analysis Approach

- (1)

- (2)

- According to the vehicle parameters determined in the above step, loads of a given vehicle are applied on the FE model in ANSYS. Each load step corresponds to a static FE analysis, and after each load step, the loads move forward to simulate the movement of the vehicle. Thereafter, the stress time-histories of a particular vehicle can be obtained.

- (3)

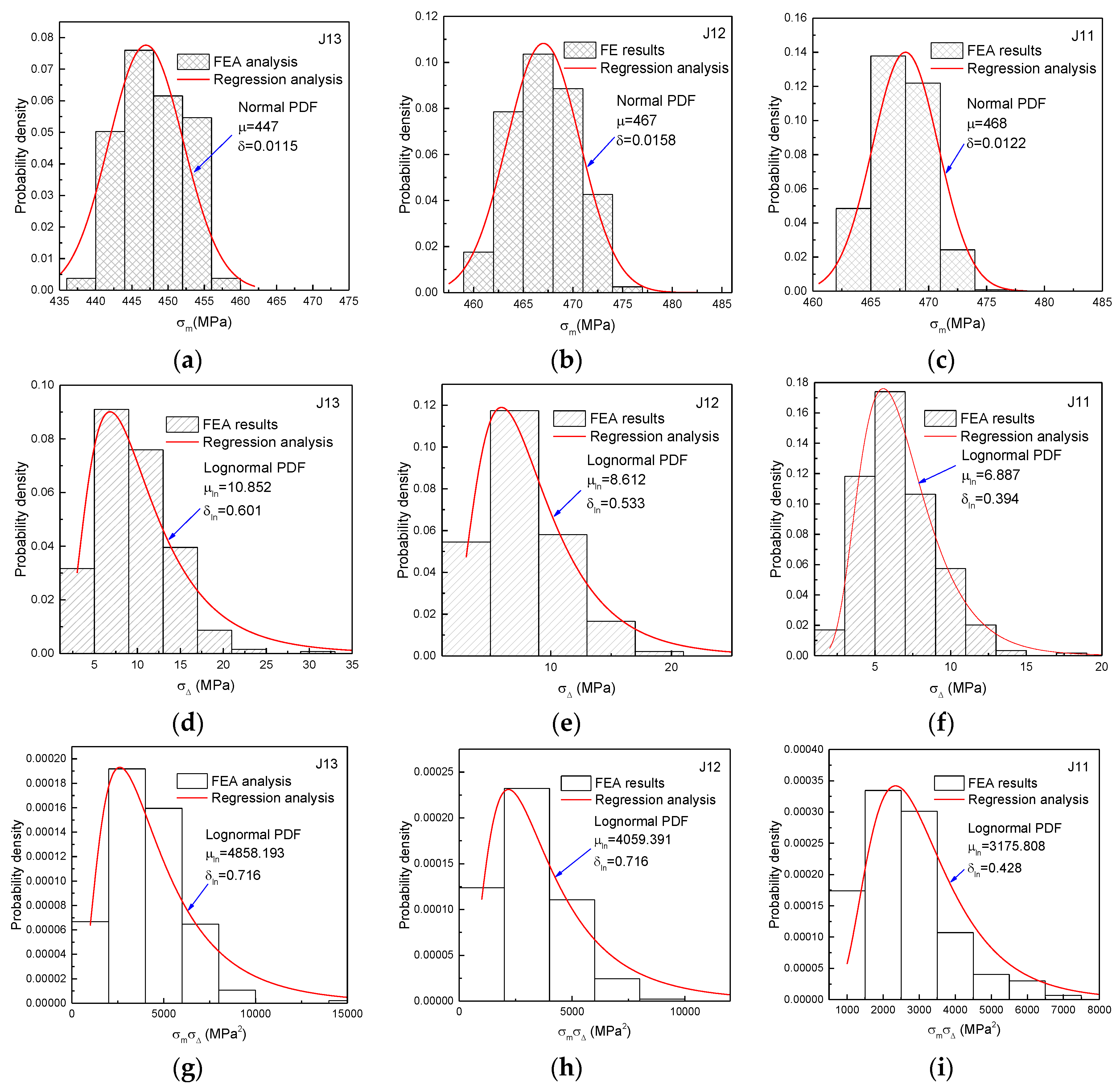

- Rain-flow counting [31] is conducted to obtain the mean stresses, the stress ranges and the corresponding number of cycles; after that, regression analysis is performed to obtain the PDFs of σmσ∆.

- (4)

- According to Equations (9) and (10), the fatigue life can be calculated as follows:where T is the fatigue life (in year) and ADV represents the number of average daily vehicles. DLA is the coefficient of dynamic load amplification, which has a mean value of 0.057 and the COV of 0.8 [39]. The critical depth of crack, acr, is calculated according to the critical wire broken rate of a cable, which follows a normal distribution with the mean value of 4mm in this study [40]. Considering the high level of uncertainty of material properties, B and E are treated as random variables, with their probabilistic properties listed in Table 4.

4.3. Results and Discussion

5. Conclusions

- Fatigue crack growth in stay cables is a multiscale process, influenced not only by the initial defects, material properties, and also by some global parameters, such as cable length, mean stress, longitudinal position and vehicle loads, etc. According to the FE analysis, long cables near bridge piers, pylons and mid-span may be more prone to fatigue than the others, and transversal positions of vehicles may influence the cable force, which calls for a more comprehensive vehicle load model including lane occupation.

- The fatigue crack growth, on the other hand, abounds with uncertainties, so that a probabilistic analysis approach is proposed, which is based on a probabilistic vehicle load model, finite element analysis and multiscaling and mesoscopic fracture mechanics. The proposed uncertain parameters, with their probabilistic properties, are defined and a demonstration study is made.

- According to the probabilistic FE analyses, the mean lives of the three cables are ranging from 29.11 to 44.54 years; however, the standard deviation of fatigue lives of the three cables are considerable, indicating that there are high possibilities for the cables to have a shorter life than designed.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ren, W.X. Ultimate behavior of long-span cable-stayed bridges. J. Bridge Eng. 1999, 4, 30–37. [Google Scholar] [CrossRef]

- Xie, X.; Li, X.Z.; Shen, Y.G. Static and dynamic characteristics of a long-span cable-stayed bridge with CFRP cables. Materials 2014, 7, 4854–4877. [Google Scholar] [CrossRef]

- Li, S.L.; Xu, Y.; Zhu, S.Y.; Guan, X.C.; Bao, Y.Q. Probabilistic deterioration model of high-strength steel wires and its application to bridge cables. Struct. Infrastruct. Eng. 2015, 11, 1240–1249. [Google Scholar] [CrossRef]

- Pipinato, A.; Pellegrino, C.; Fregno, G.; Modena, C. Influence of fatigue on cable arrangement in cable-stayed bridges. Int. J. Steel Struct. 2012, 12, 107–123. [Google Scholar] [CrossRef]

- Li, H.; Lan, C.M.; Ju, Y.; Li, D.S. Experimental and numerical study of the fatigue properties of corroded parallel wire cables. J. Bridge Eng. 2011, 17, 211–220. [Google Scholar] [CrossRef]

- Stallings, J.M.; Frank, K.H. Stay-cable fatigue behavior. J. Struct. Eng. 1991, 117, 936–950. [Google Scholar] [CrossRef]

- Mehrabi, A.B.; Ligozio, C.A.; Ciolko, A.T.; Scott, T.W. Evaluation, rehabilitation planning, and stay-cable replacement design for the hale Boggs Bridge in Luling, Louisiana. J. Bridge Eng. 2010, 15, 364–372. [Google Scholar] [CrossRef]

- Nowak, A.S.; Hong, Y.K. Bridge live-load models. J. Struct. Eng. 1991, 117, 2757–2767. [Google Scholar] [CrossRef]

- Guo, T.; Frangopol, D.M.; Chen, Y.W. Fatigue reliability assessment of steel bridge details integrating weigh-in-motion data and probabilistic finite element analysis. Comput. Struct. 2012, 112, 245–257. [Google Scholar] [CrossRef]

- Basso, P.; Casciati, S.; Faravelli, L. Fatigue reliability assessment of a historic railway bridge designed by Gustave Eiffel. Struct. Infrastruct. Eng. 2015, 11, 27–37. [Google Scholar] [CrossRef]

- Kwon, K.; Frangopol, D.M. Bridge fatigue reliability assessment using probability density functions of equivalent stress range based on field monitoring data. Int. J. Fatigue 2010, 32, 1221–1232. [Google Scholar] [CrossRef]

- Maljaars, J.; Vrouwenvelder, T. Fatigue failure analysis of stay cables with initial defects: Ewijk bridge case study. Struct. Saf. 2014, 51, 47–56. [Google Scholar] [CrossRef]

- Guo, T.; Liu, Z.X.; Zhu, J.S. Fatigue reliability assessment of orthotropic steel bridge decks based on probabilistic multi-scale finite element analysis. Adv. Steel Constr. 2015, 11, 334–346. [Google Scholar]

- Gu, M.; Xu, Y.L.; Chen, L.Z.; Xianga, H.F. Fatigue life estimation of steel girder of Yangpu cable-stayed bridge due to buffeting. J. Wind Eng. Ind. Aerodyn. 1999, 80, 383–400. [Google Scholar] [CrossRef]

- Llorca, J.; Sánchez-Gálvez, V. Fatigue limit and fatigue life prediction in high strength cold drawn eutectoid steel wires. Fatigue Fract. Eng. Mater. Struct. 1989, 12, 31–45. [Google Scholar] [CrossRef]

- Razmi, J. Fracture mechanics-based and continuum damage modeling approach for prediction of crack initiation and propagation in integral abutment bridges. J. Comput. Civ. Eng. 2015. [Google Scholar] [CrossRef]

- Ladani, L.J. Successive softening and cyclic damage in viscoplastic material. J. Electron. Packag. 2010, 132. [Google Scholar] [CrossRef]

- Chookah, M.; Nuhi, M.; Modarres, M. A probabilistic physics-of-failure model for prognostic health management of structures subject to pitting and corrosion-fatigue. Reliab. Eng. Syst. Saf. 2011, 96, 1601–1610. [Google Scholar] [CrossRef]

- Zhu, S.P.; Huang, H.Z.; Ontiveros, V.; He, L.P.; Modarres, M. Probabilistic low cycle fatigue life prediction using an energy-based damage parameter and accounting for model uncertainty. Int. J. Damage Mech. 2011. [Google Scholar] [CrossRef]

- Elachachi, S.M.; Breysse, D.; Yotte, S.; Cremona, C. A probabilistic multi-scale time dependent model for corroded structural suspension cables. Probab. Eng. Mech. 2006, 21, 235–245. [Google Scholar] [CrossRef]

- Li, C.X.; Tang, X.S.; Xiang, G.B. Fatigue crack growth of cable steel wires in a suspension bridge: Multiscaling and mesoscopic fracture mechanics. Theor. Appl. Fract. Mech. 2010, 53, 113–126. [Google Scholar] [CrossRef]

- Sih, G.C.; Tang, X.S. Asymptotic micro-stress field dependency on mixed boundary conditions dictated by micro-structural asymmetry: Mode I macro-stress loading. Theor. Appl. Fract. Mech. 2006, 46, 1–14. [Google Scholar] [CrossRef]

- Toribio, J.; Matos, J.C.; González, B. Micro-and macro-approach to the fatigue crack growth in progressively drawn pearlitic steels at different R-ratios. Int. J. Fatigue 2009, 31, 2014–2021. [Google Scholar] [CrossRef]

- Sih, G.C.; Tang, X.S. Micro/macro-crack growth due to creep-fatigue dependency on time-temperature material behavior. Theor. Appl. Fract. Mech. 2008, 50, 9–22. [Google Scholar] [CrossRef]

- Tang, X.S.; Wei, T.T. Microscopic inhomogeneity coupled with macroscopic homogeneity: A localized zone of energy density for fatigue crack growth. Int. J. Fatigue 2015, 70, 270–277. [Google Scholar] [CrossRef]

- Tang, K.K. Reliability of micro/macro-fatigue crack growth behavior in the wires of cable-stayed bridge. In Proceedings of the 13th International Conference on Fracture, Beijing, China, 16–21 June 2013.

- Tang, X.S.; Peng, X.L. An energy density zone model for fatigue life prediction accounting for non-equilibrium and non-homogeneity effects. Theor. Appl. Fract. Mech. 2015, 79, 105–112. [Google Scholar] [CrossRef]

- Kachanov, M.; Sevostianov, I. On quantitative characterization of microstructures and effective properties. Int. J. Solids Struct. 2005, 42, 309–336. [Google Scholar] [CrossRef]

- Mahmoud, K.M. Fracture strength for a high strength steel bridge cable wire with a surface crack. Theor. Appl. Fract. Mech. 2007, 48, 152–160. [Google Scholar] [CrossRef]

- Sih, G.C. Multiscale Fatigue Crack Initiation and Propagation of Engineering Materials: Structural Integrity and Microstructural Worthiness: Fatigue Crack Growth Behaviour of Small and Large Bodies; Springer: New York, NY, USA, 2008. [Google Scholar]

- Wirsching, P.H.; Shehata, A.M. Fatigue under wide band random stresses using the rain-flow method. J. Eng. Mater. Technol. 1977, 99, 205–211. [Google Scholar] [CrossRef]

- Sih, G.C.; Tang, X.S.; Li, Z.X.; Li, A.Q.; Tang, K.K. Fatigue crack growth behavior of cables and steel wires for the cable-stayed portion of Runyang bridge: Disproportionate loosening and/or tightening of cables. Theor. Appl. Fract. Mech. 2008, 49, 1–25. [Google Scholar] [CrossRef]

- Polák, J.; Zezulka, P. Short crack growth and fatigue life in austenitic-ferritic duplex stainless steel. Fatigue Fract. Eng. Mater. Struct. 2005, 28, 923–935. [Google Scholar] [CrossRef]

- Molent, L.; Barter, S.A. A comparison of crack growth behaviorin several full-scale airframe fatigue tests. Int. J. Fatigue 2007, 29, 1090–1099. [Google Scholar] [CrossRef]

- Sih, G.C. Invariant form of micro-/macro-cracking in fatigue. In Structural Integrity and Microstructural Worthiness; Springer: Dordrecht, The Netherlands, 2008; pp. 181–208. [Google Scholar]

- Sih, G.C.; Tang, X.S. Fatigue crack growth rate of cable-stayed portion of Runyang bridge: Part I—Cable crack growth due to disproportionate cable tightening/loosening and traffic loading. In Multiscale Fatigue Crack Initiation and Propagation of Engineering Materials: Structural Integrity and Microstructural Worthiness; Springer: Dordrecht The Netherlands, 2008; pp. 209–247. [Google Scholar]

- Fontanari, V.; Benedetti, M.; Monelli, B.D.; Degasperi, F. Fire behavior of steel wire ropes: Experimental investigation and numerical analysis. Eng. Struct. 2015, 84, 340–349. [Google Scholar] [CrossRef]

- Stein, M. Large sample properties of simulations using Latin hypercube sampling. Technometrics 1987, 29, 143–151. [Google Scholar] [CrossRef]

- American Association of State Highway and Transportation Officials. Subcommittee on Systems Operations and Management–2008 Strategic Plan; Association of State Highway and Transportation Officials: Washington, DC, USA, 2012. [Google Scholar]

- MCCHSRI (Ministry of Communications Chongqing Highway Science Research Institute). Technical Conditions for Hot-Extruding PE Protection High Strength Wire Cable of Cable-Stayed Bridge; GB/T 18365–2001; Ministry of Communications Chongqing Highway Science Research Institute: Beijing, China, 2001. [Google Scholar]

- Fisher, J.W. Fatigue and Fracture in Steel Bridges; Wiley: New York, NY, USA, 1984. [Google Scholar]

- NCHRP (National Cooperative Highway Research Program). Updating the Calibration Report for AASHTO LRFD Code, 20-07/186; Transportation Research Board, National Research Council: Washington, DC, USA, 2007. [Google Scholar]

- Faber, M.H.; Engelund, S.; Rackwitz, R. Aspects of parallel wire cable reliability. Struct. Saf. 2003, 25, 201–225. [Google Scholar] [CrossRef]

| Load Test | Truck Positions | Illustration | Truck Configuration |

|---|---|---|---|

| Case 1 | Sixteen trucks, symmetrically loaded at the mid-span in 4 lines and 4 rows |  |  |

|

| Vehicle Type | Graphic Illustration | Variable Designation | Distribution Type | Mean Value | Standard Deviation |

|---|---|---|---|---|---|

| 1 |  | AW11 | Lognormal | 10.54 | 3.12 |

| AW12 | Lognormal | 8.55 | 3.27 | ||

| 2 |  | AW21 | Normal | 48.29 | 14.22 |

| AW22 = AW23 | Normal | 78.54 | 36.48 | ||

| 3 |  | AW31 | Normal | 38.16 | 10.39 |

| AW32 | Normal | 35.66 | 12.87 | ||

| AW33 | Lognormal | 115.10 | 65.54 | ||

| 4 |  | AW41 | Normal | 46.26 | 10.03 |

| AW42 | Lognormal | 52.40 | 15.50 | ||

| AW43 = AW44 | Normal (0.18) | 33.83 | 5.70 | ||

| Normal (0.82) | 82.30 | 29.84 | |||

| 5 |  | AW51 | Lognormal | 48.46 | 6.33 |

| AW52 | Normal (0.23) | 43.56 | 3.29 | ||

| Normal (0.37) | 74.01 | 24.03 | |||

| Normal (0.4) | 132.12 | 18.12 | |||

| AW53 = AW54 = AW55 | Normal (0.27) | 22.96 | 1.71 | ||

| Normal (0.30) | 52.23 | 13.92 | |||

| Normal (0.43) | 83.35 | 9.51 | |||

| 6 |  | AW61 | Lognormal | 53.86 | 5.95 |

| AW62 = AW63 | Normal (0.13) | 35.35 | 4.79 | ||

| Normal (0.87) | 82.17 | 15.62 | |||

| AW64 = AW65 = AW66 | Normal (0.07) | 22.68 | 3.20 | ||

| Normal (0.16) | 38.11 | 13.95 | |||

| Normal (0.77) | 80.94 | 13.11 |

| Vehicle Type | Percentage in Traffic Volume (%) | Percentage in Each Lane (%) | ||

|---|---|---|---|---|

| Outer Lane | Middle Lane | Inner Lane | ||

| 1 | 76.66 | 9.70 | 25.74 | 41.23 |

| 2 | 0.65 | 0.36 | 0.26 | 0.03 |

| 3 | 1.57 | 0.60 | 0.87 | 0.10 |

| 4 | 1.64 | 0.92 | 0.67 | 0.04 |

| 5 | 2.54 | 1.31 | 1.17 | 0.06 |

| 6 | 16.94 | 8.43 | 7.94 | 0.57 |

| Variable Designation | Meaning of Variable | Distribution Type | Mean Value | COV | Source |

|---|---|---|---|---|---|

| B | Fracture parameter | Lognormal | 1.06 × 10−6 | 0.63 | Fisher [41] |

| E | Young’s modulus | Lognormal | 2.0 × 105 MPa | 0.05 | Elachachi et al. [20] |

| a0 | Initial crack depth | Normal | 0.01 mm | 1.2 | Mahmoud [29]; Molent [34] |

| ac | Critical crack depth | Normal | 4 mm | 0.2 | MCCHSRI [40] |

| DLA | Dynamic load amplification factor | Normal | 0.057 | 0.8 | AASHTO [39]; NCHRP [42] |

| Serial Number of Cables | σmσ∆ (MPa2) | T (year) | ||

|---|---|---|---|---|

| μln | δln | μ | σ | |

| J13 | 4858.193 | 0.716 | 29.11 | 10.32 |

| J12 | 4059.391 | 0.716 | 34.85 | 13.15 |

| J11 | 3175.808 | 0.428 | 44.54 | 17.47 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Guo, T.; Chai, S. Probabilistic Fatigue Life Prediction of Bridge Cables Based on Multiscaling and Mesoscopic Fracture Mechanics. Appl. Sci. 2016, 6, 99. https://doi.org/10.3390/app6040099

Liu Z, Guo T, Chai S. Probabilistic Fatigue Life Prediction of Bridge Cables Based on Multiscaling and Mesoscopic Fracture Mechanics. Applied Sciences. 2016; 6(4):99. https://doi.org/10.3390/app6040099

Chicago/Turabian StyleLiu, Zhongxiang, Tong Guo, and Shun Chai. 2016. "Probabilistic Fatigue Life Prediction of Bridge Cables Based on Multiscaling and Mesoscopic Fracture Mechanics" Applied Sciences 6, no. 4: 99. https://doi.org/10.3390/app6040099