Investigating the Influence of Plasma-Treated SiO2 Nanofillers on the Electrical Treeing Performance of Silicone-Rubber

Abstract

:1. Introduction

2. Sample Preparation

2.1. Base Material and Nanofiller

2.2. Silicone-Rubber Nanocomposites

2.3. Nanocomposite Treatment

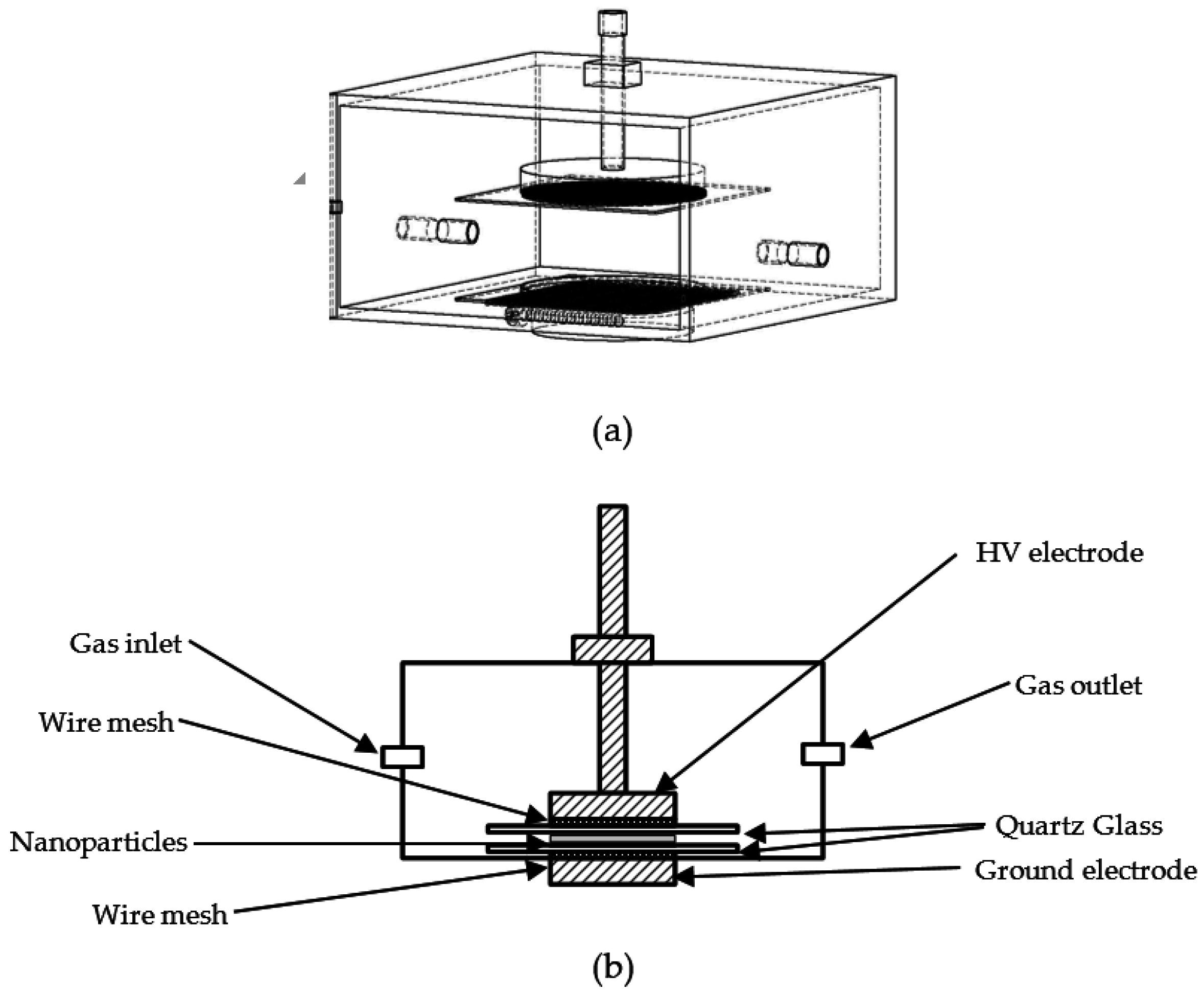

2.3.1. Atmospheric-Pressure Plasma Treatment

2.3.2. Silane Treatment

3. Experimental Set-up

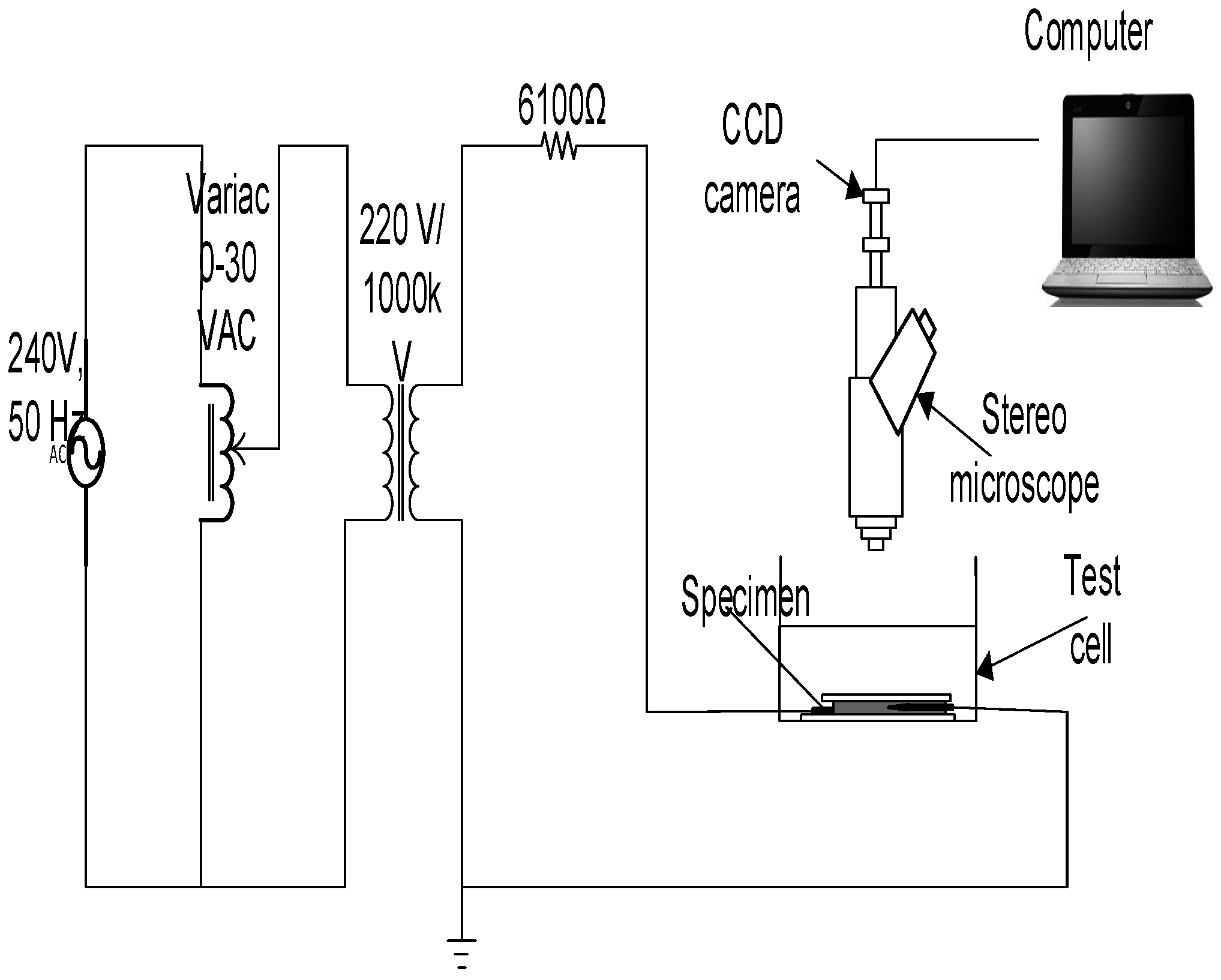

Electrical Treeing Test

4. Results and Discussion

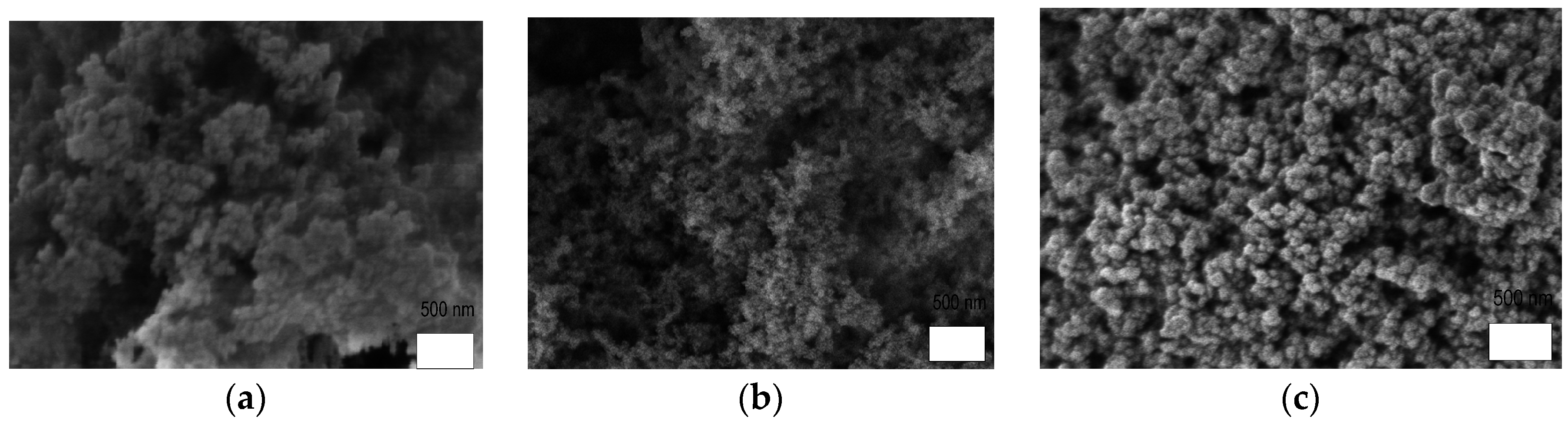

4.1. Morphological Analyses of the Plasma-Treated SiO2 Nanofillers

4.2. Influence of Plasma-Treated SiO2 Nanofillers on Silicone-Rubber Nanocomposite

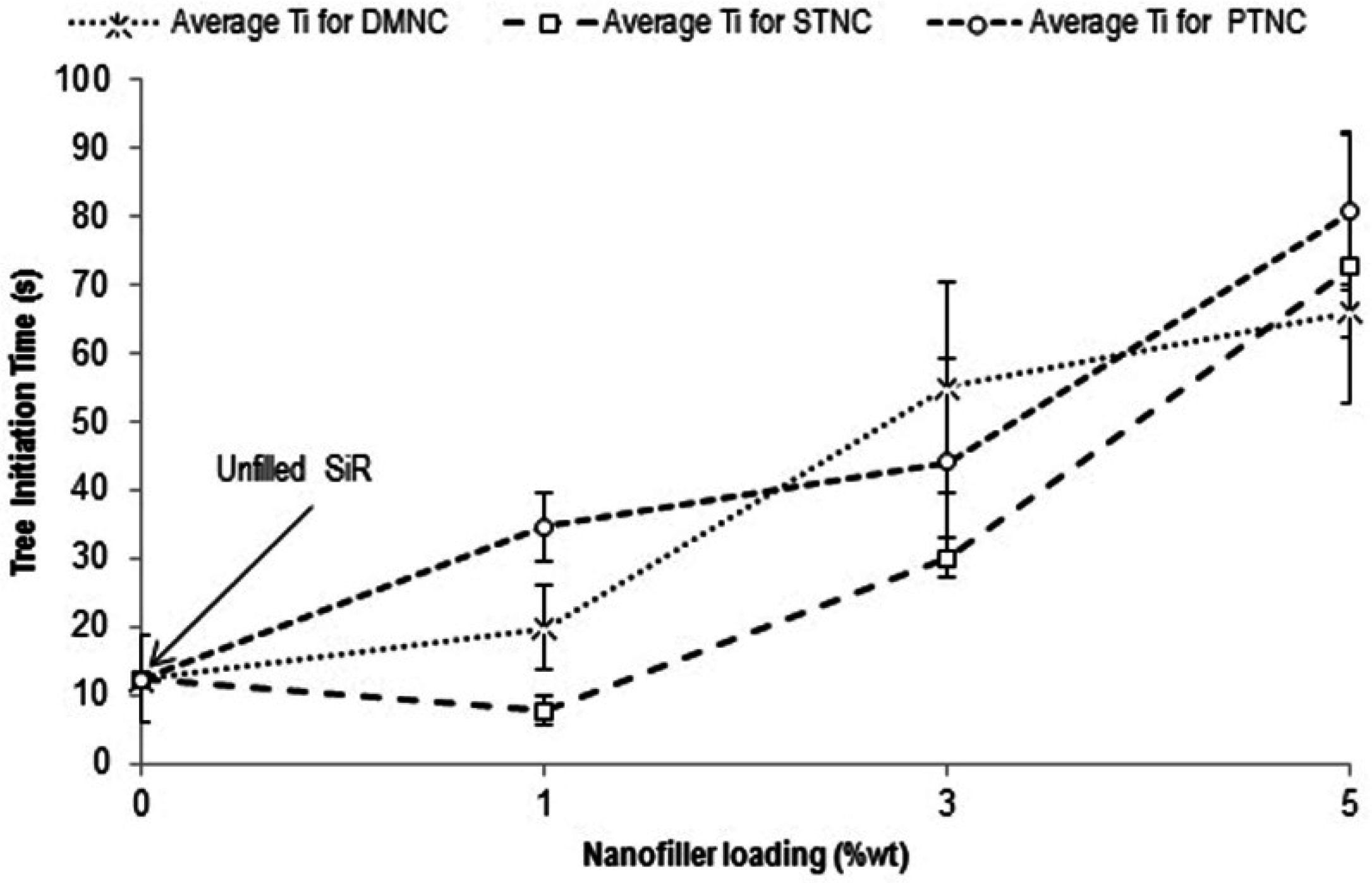

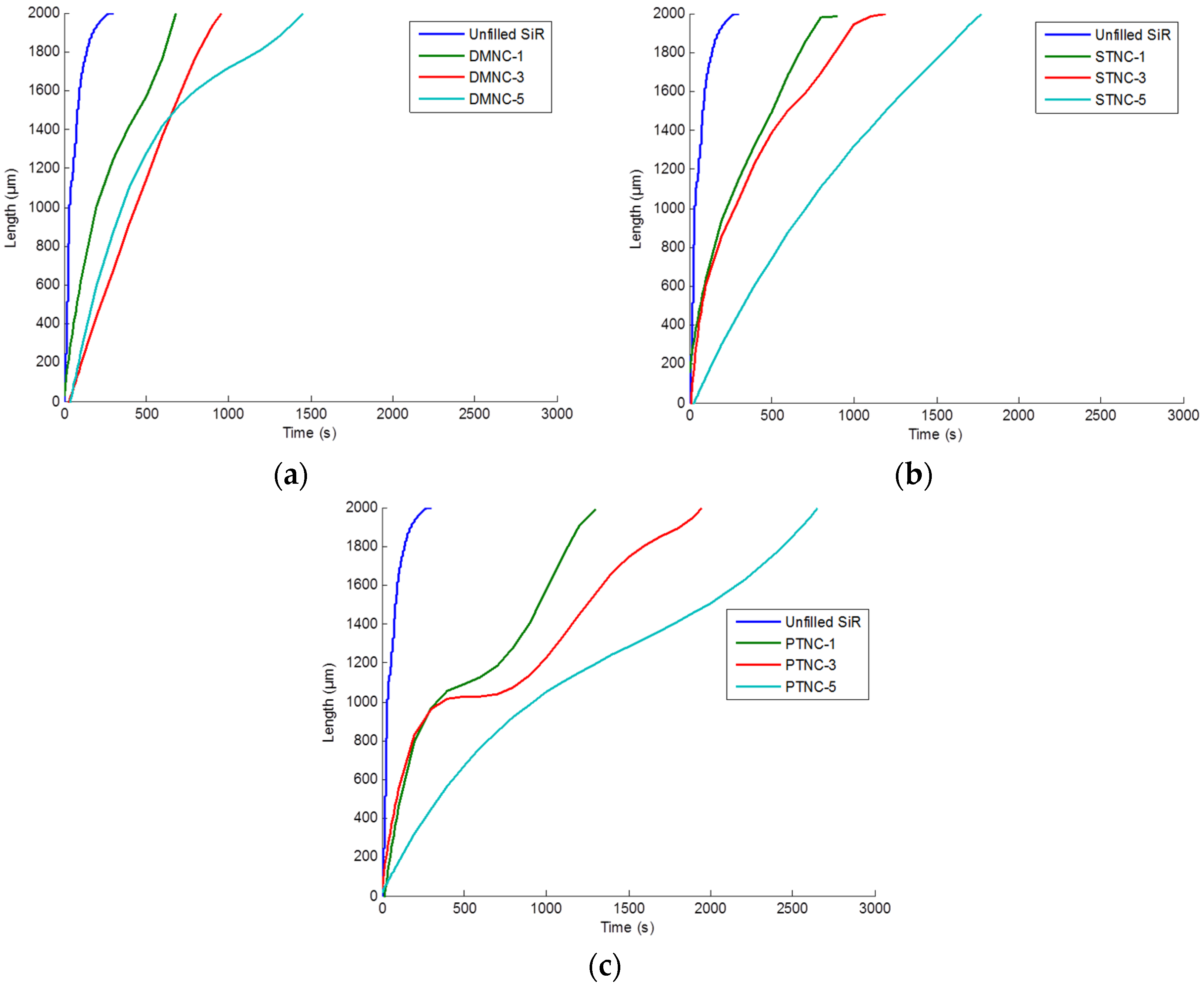

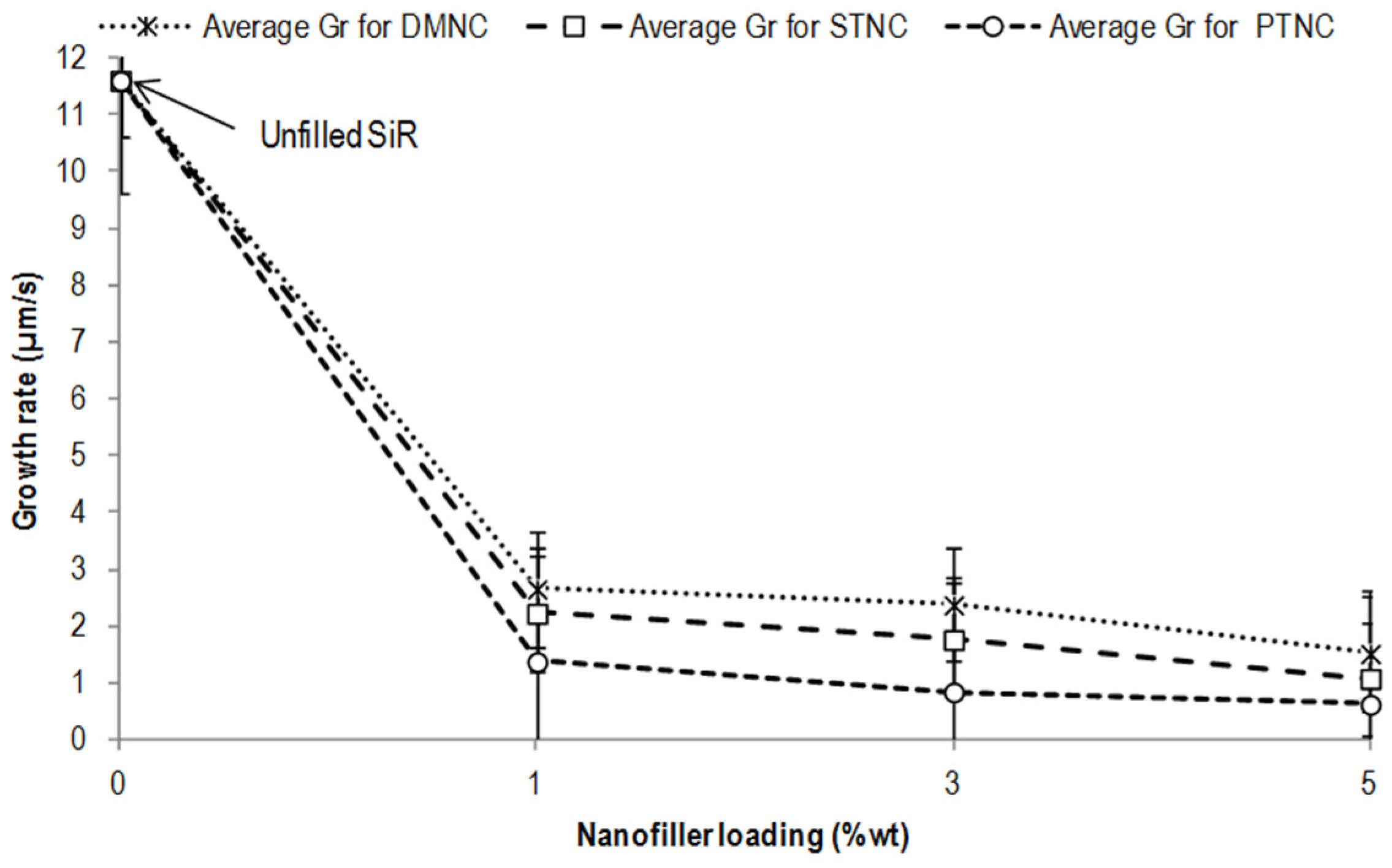

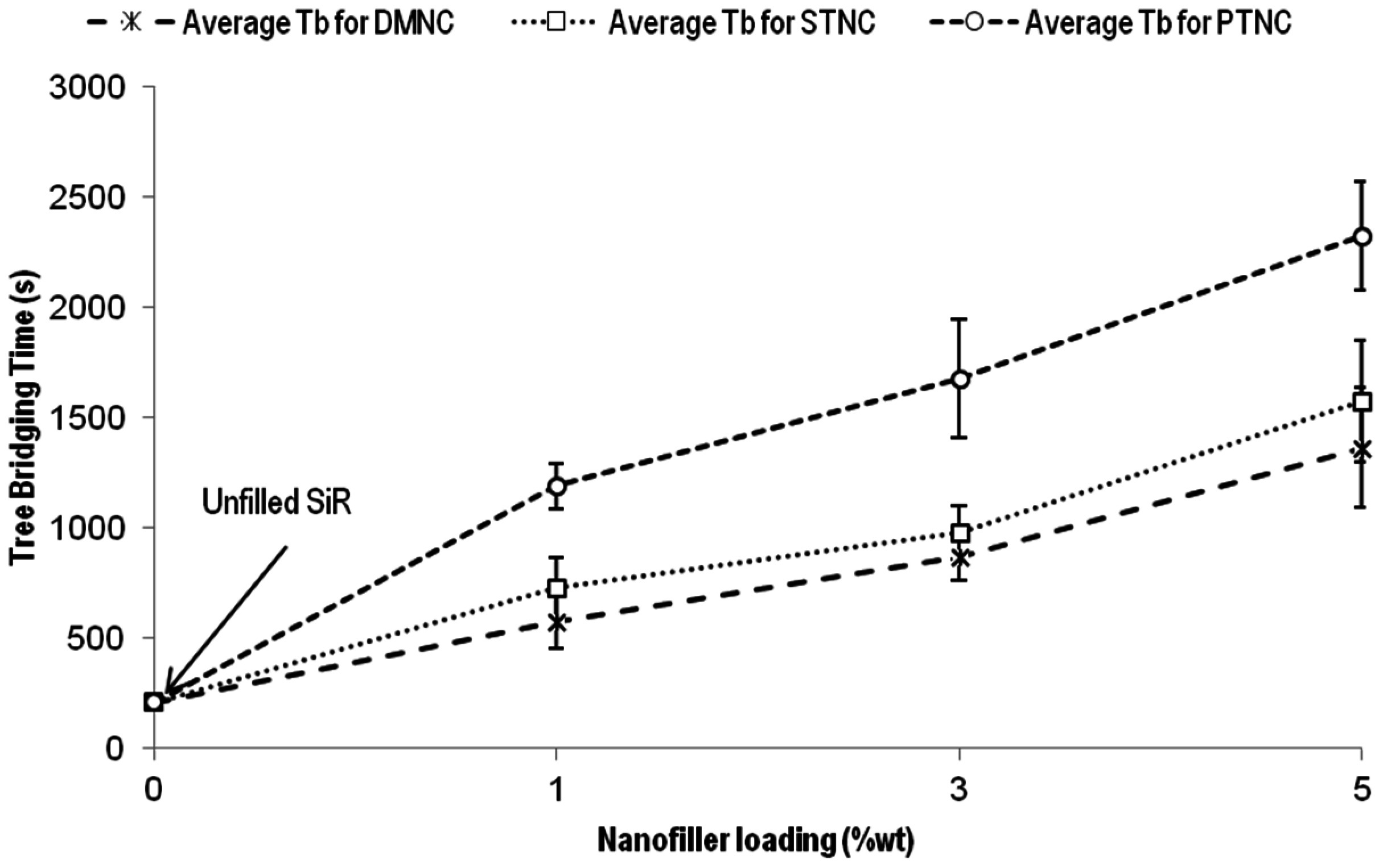

4.2.1. Electrical Tree Parameters

4.2.2. FESEM Analysis of the Silicone-Rubber Nanocomposites Filled with Plasma-Treated SiO2 Nanoparticles

5. Conclusions

- The plasma-treated SiO2 nanofillers showed smoother and smaller amounts of agglomeration nanofillers with an increase in oxygen content after treatment among the three different treatment methods of the nanocomposites.

- The plasma treatment improved the electrical tree initiation time, tree propagation time, and tree growth rates. In addition, based on the bridging times of the electrical trees, ANOVA analysis results showed a signifcant difference between the plasma-treated nanocomposites and silane-treated as well as direct-mixed nanocomposites. In addition, the plasma-treated nanocomposites exhibited the longest tree bridging times, implying that the plasma treatment of the SiO2 nanofiller improved the electrical tree performance of the silicone rubber nanocomposite. The increase in filler concentration also resulted in better electrical treeing performance.

- The plasma-treated nanocomposites possessed the least agglomeration among the three different treatment methods of the nanocomposites due to the well dispersed SiO2 nanofillers.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Du, B.X.; Gao, Y. Grow characteristics of electrical tree in silicone rubber. In Proceedings of the 16th International Symposium on High Voltage Engineering, Cape town, South Africa, 24–28 August 2009; pp. 102–106.

- Danikas, M.G.; Tanaka, T. Nanocomposites—A review of electrical treeing and breakdown. IEEE Electr. Insul. Mag. 2009, 25, 19–25. [Google Scholar] [CrossRef]

- Ding, H.-Z.; Varlow, B. Effect of nano-fillers on electrical treeing in epoxy resin subjected to ac voltage. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena, Boulder, CO, USA, 20–20 October 2004; pp. 332–335.

- Imai, T.; Sawa, F.; Nakano, T.; Ozaki, T.; Shimizu, T.; Kozako, M.; Tanaka, T. Effects of nano-and micro-filler mixture on electrical insulation properties of epoxy based composites. IEEE Trans. Dielectr. Electr. Insul. 2006, 13, 319–326. [Google Scholar] [CrossRef]

- Iizuka, T.; Ohki, Y.; Tanaka, T. Effects of coupling agent and filler dispersion on V-t characteristics of epoxy/silica nanocomposites. In Proceedings of the International Symposium on Electrical Insulating Materials, Yokkaichi, Japan, 7–11 September 2008; pp. 60–63.

- Zhou, W.; Yu, D. Effect of coupling agents on the dielectric properties of aluminum particles reinforced epoxy resin composites. J. Compos. Mater. 2011, 45, 1981–1989. [Google Scholar] [CrossRef]

- Kurnianto, R.; Murakami, Y.; Nagao, M.; Hozumi, N. Investigation of filler effect on treeing phenomenon in epoxy resin under ac voltage. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 1112–1119. [Google Scholar] [CrossRef]

- Nagao, M.; Oda, K.; Nishioka, K.; Muramoto, Y.; Hozumi, N. Effect of filler on treeing phenomenon in epoxy resin under ac voltage. In Proceedings of the International Symposium on Electrical Insulating Materials, Himeji, Japan, 19–22 November 2001; pp. 611–614.

- Yan, W.; Han, Z.J.; Phung, B.T.; Ostrikov, K. Silica nanoparticles treated by cold atmospheric-pressure plasmas improve the dielectric performance of organic–inorganic nanocomposites. ACS Appl. Mater. Interfaces 2012, 4, 2637–2642. [Google Scholar] [CrossRef] [PubMed]

- Yan, W. Nanocomposite Dielectric Materials for Power System Equipment. Ph.D. Thesis, University of New South Wales, Sydney, Australia, 2013. [Google Scholar]

- Du, B.; Ma, Z.; Gao, Y.; Han, T. Effect of ambient temperature on electrical treeing characteristics in silicone rubber. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 401–407. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, R.; Hou, F.; Zhang, X.; Xue, W. Morphology of electrical trees in silicon rubber. J. Electrost. 2013, 71, 440–448. [Google Scholar] [CrossRef]

- Ahmad, M.H.; Bashir, N.; buntat, Z.; Arief, Y.Z.; Jamil, A.A.A.; Piah, M.A.M.; Suleiman, A.A.; Dodd, S.; CHalashkanov, N. Temperature effect on electrical treeing and partial discharge characteristics of silicone rubber-based nanocomposites. J. Nanomater. 2015, 2015. [Google Scholar] [CrossRef]

- Jamil, A.A.A.; Bashir, N.; Ahmad, M.H.; Arief, Y.Z.; Kamarol, M.; Mariatti, M. Electrical treeing initiation and propagation in silicone rubber nanocomposites. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena, Shenzhen, China, 20–23 October 2013; pp. 502–505.

- Ahmad, M.; Piah, M.; Arief, Y.; Bashir, N.; Chalashkanov, N.; Dodd, S. Temperature dependance of pd from electrical trees grown in silicone rubber based nanocomposites. In Proceedings of the 2013 IEEE International Conference on Solid Dielectrics (ICSD), Bologna, Italy, 30 June–4 July 2013; pp. 816–819.

- Fang, Z.; Xie, X.; Li, J.; Yang, H.; Qiu, Y.; Kuffel, E. Comparison of surface modification of polypropylene film by filamentary dbd at atmospheric pressure and homogeneous dbd at medium pressure in air. J. Phys. D Appl. Phys. 2009, 42, 085204. [Google Scholar] [CrossRef]

- Chan, C.-M.; Ko, T.-M.; Hiraoka, H. Polymer surface modification by plasmas and photons. Surf. Sci. Rep. 1996, 24, 1–54. [Google Scholar] [CrossRef]

- Alapati, S.; Thomas, M.J. Influence of nano-fillers on electrical treeing in epoxy insulation. IET Sci. Meas. Technol. 2012, 6, 21–28. [Google Scholar] [CrossRef]

- Kurnianto, R.; Murakami, Y.; Hozumi, N.; Nagao, M.; Murata, Y. Some fundamentals on treeing breakdown in inorganic-filler/LDPE nano-composite material. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena, Kansas City, MO, USA, 15–18 October 2006; pp. 373–376.

- Musa, M.; Arief, Y.Z.; Abdul-Malek, Z.; Ahmad, M.H.; Jamil, A.A.A. Influence of nano-titanium dioxide (TiO2) on electrical tree characteristics in silicone rubber based nanocomposite. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena, Shenzhen, China, 20–23 October 2013; pp. 498–501.

- Yan, W.; Phung, B.T.; Han, Z.J.; Ostrikov, K. Plasma polymer-coated on nanoparticles to improve dielectric and electrical insulation properties of nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 548–555. [Google Scholar]

| Untreated | Silane-Treated | Plasma-Treated | |||

|---|---|---|---|---|---|

| BE (eV) | Intensity | BE (eV) | Concentration (%) | BE (eV) | Concentration (%) |

| 101.79 | 2500 | 101.70 | 2230 | 101.70 | 3040 |

| 104.79 | 655 | 103.80 | 551 | 104.68 | 545 |

| Samples | Atomic Content (%) | ||

|---|---|---|---|

| C | O | Si | |

| Untreated | 7.50 | 44.80 | 47.70 |

| Silane-treated | 25.00 | 48.08 | 26.93 |

| Plasma-treated | 9.40 | 47.60 | 43.00 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Musa, F.N.; Bashir, N.; Ahmad, M.H.; Buntat, Z.; Piah, M.A.M. Investigating the Influence of Plasma-Treated SiO2 Nanofillers on the Electrical Treeing Performance of Silicone-Rubber. Appl. Sci. 2016, 6, 348. https://doi.org/10.3390/app6110348

Musa FN, Bashir N, Ahmad MH, Buntat Z, Piah MAM. Investigating the Influence of Plasma-Treated SiO2 Nanofillers on the Electrical Treeing Performance of Silicone-Rubber. Applied Sciences. 2016; 6(11):348. https://doi.org/10.3390/app6110348

Chicago/Turabian StyleMusa, Fatin Nabilah, Nouruddeen Bashir, Mohd Hafizi Ahmad, Zolkafle Buntat, and Mohamed Afendi Mohamed Piah. 2016. "Investigating the Influence of Plasma-Treated SiO2 Nanofillers on the Electrical Treeing Performance of Silicone-Rubber" Applied Sciences 6, no. 11: 348. https://doi.org/10.3390/app6110348