Effects of Process Parameters on the Extraction of Quercetin and Rutin from the Stalks of Euonymus Alatus (Thumb.) Sieb and Predictive Model Based on Least Squares Support Vector Machine Optimized by an Improved Fruit Fly Optimization Algorithm

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental

2.1.1. Materials and Chemicals

2.1.2. Instrumentation and Analytical Conditions

2.1.3. Ultrasound-Assisted Extraction

2.1.4. Statistical Analysis

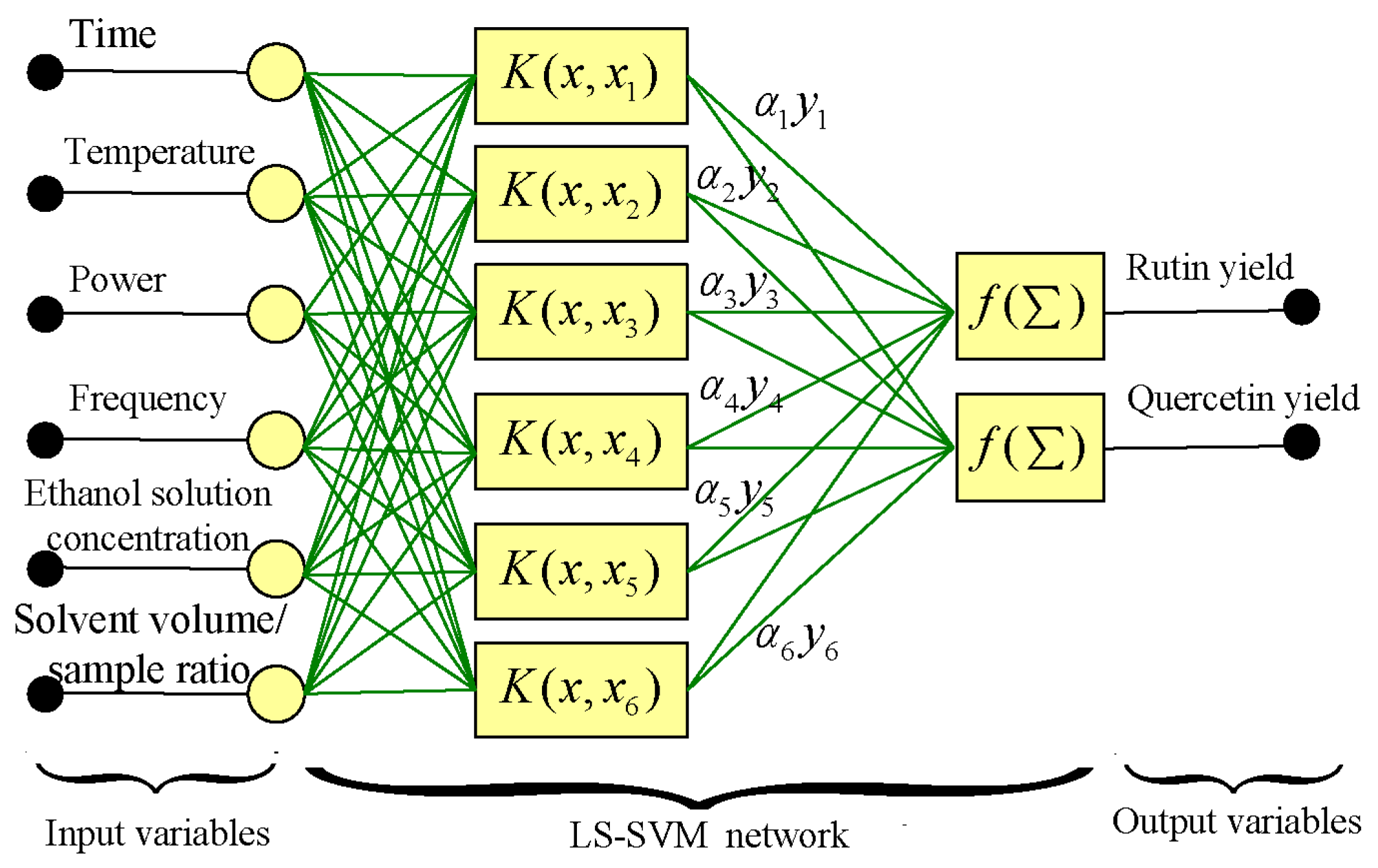

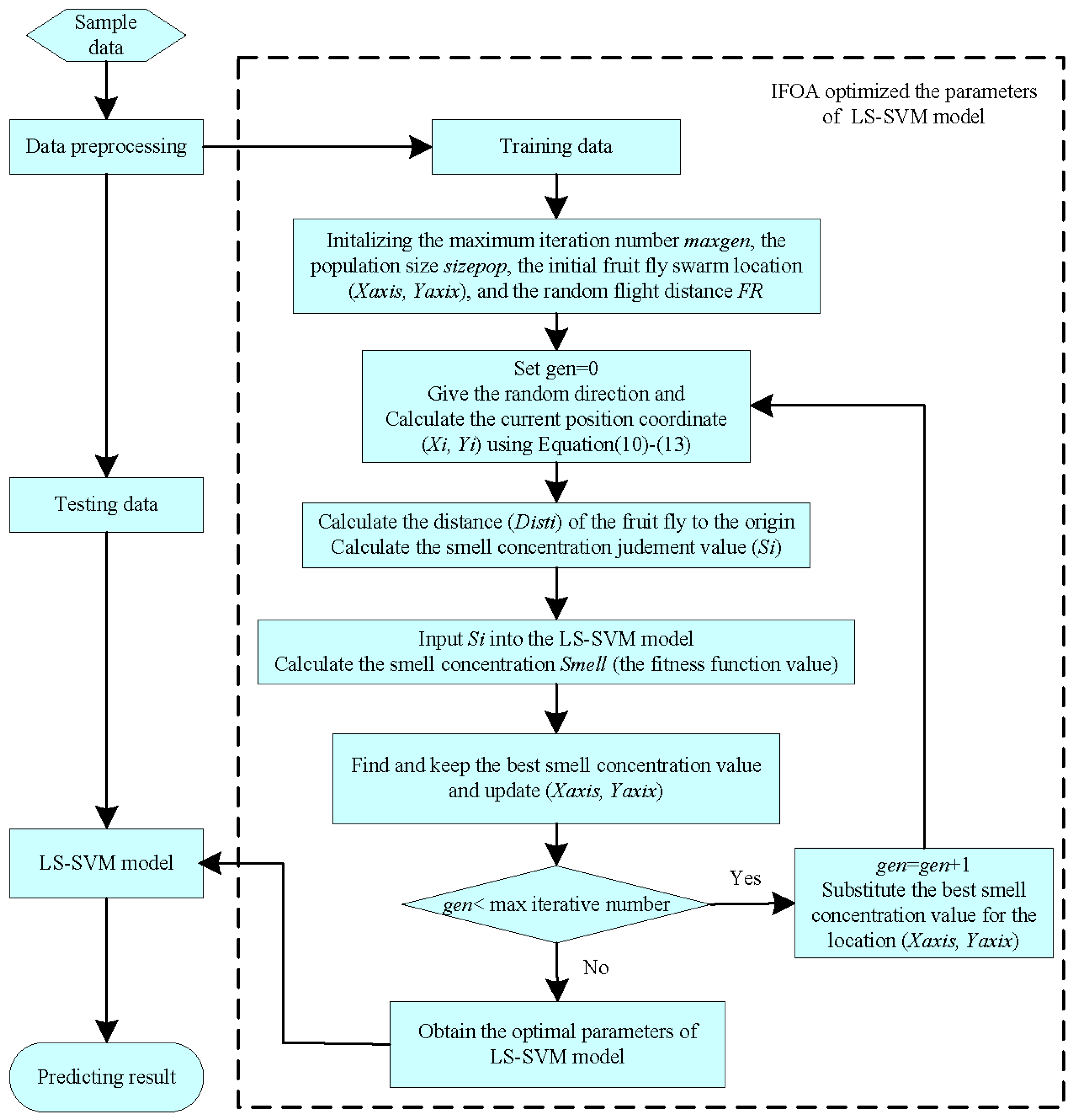

2.2. Methodology of FOA-LS-SVM Model

2.2.1. Support Vector Machine (SVM)

2.2.2. Least Squares Support Vector Machine (LS-SVM)

2.2.3. Basic Fruit Fly Optimization Algorithm (FOA)

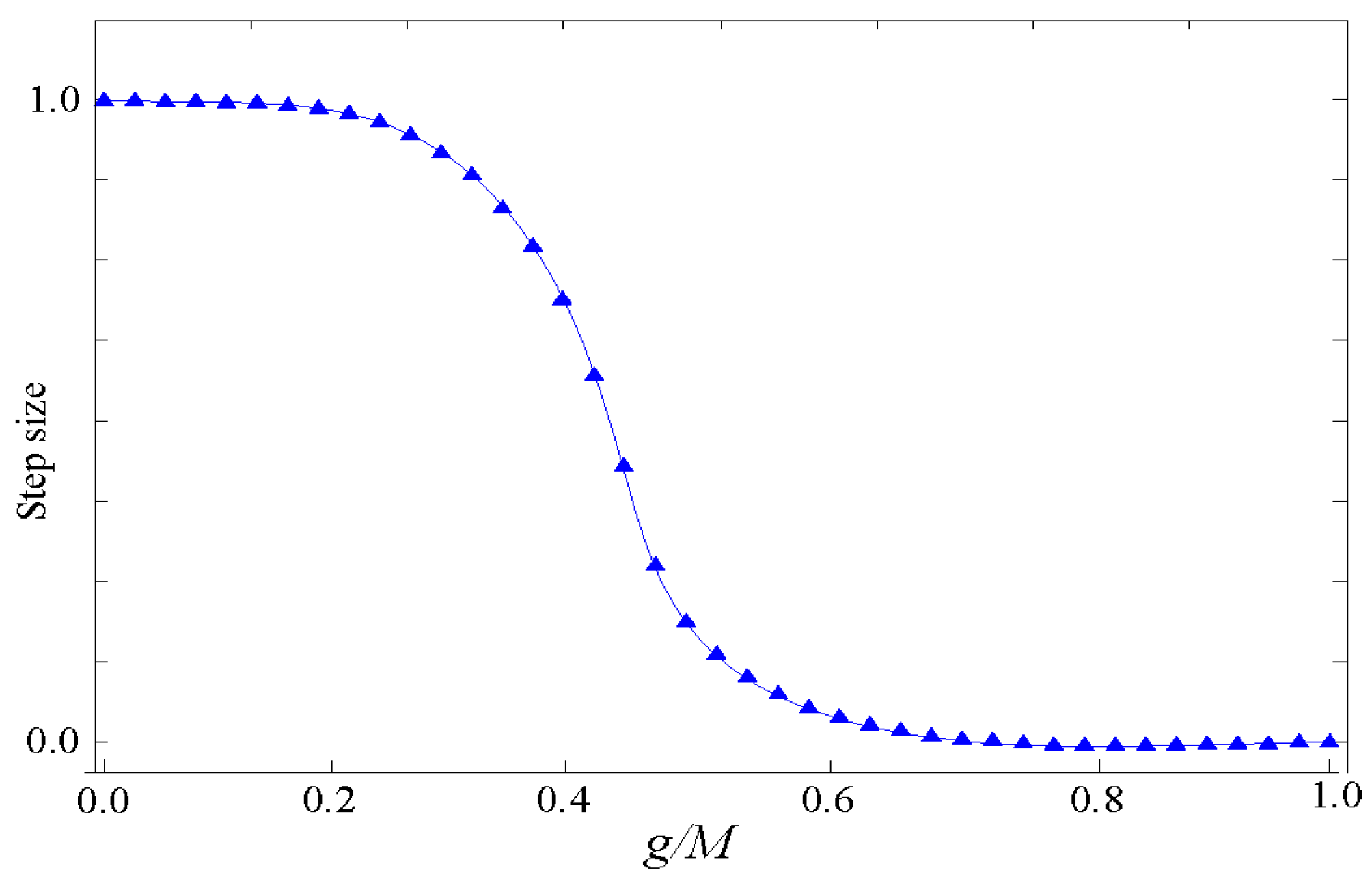

2.2.4. Improved Fruit Fly Optimization Algorithm (IFOA)

3. Results and Discussion

3.1. Effect of Process Parameters

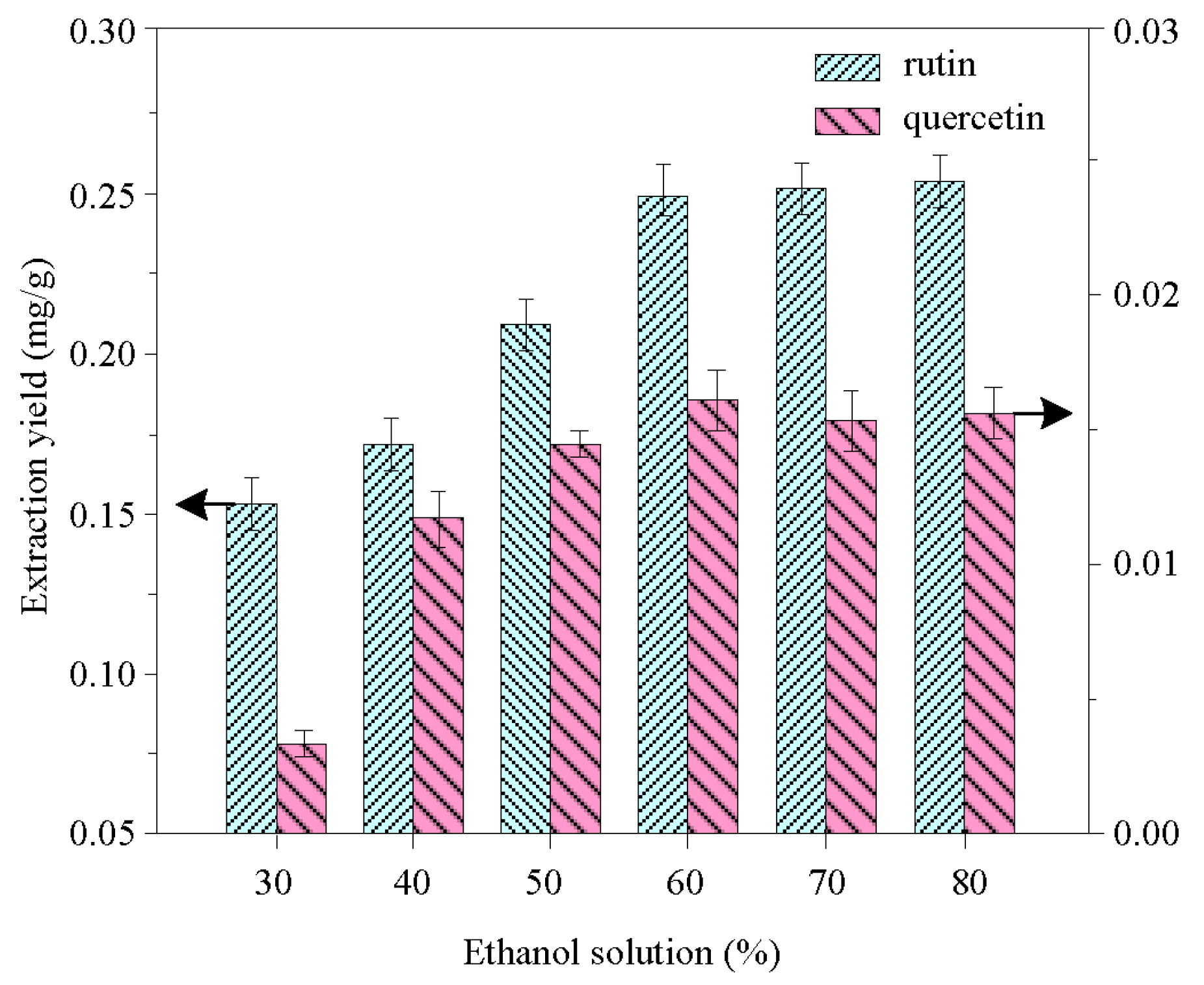

3.1.1. Effect of Concentration of Ethanol Solution

3.1.2. Effect of Solvent Volume/Sample Ratio

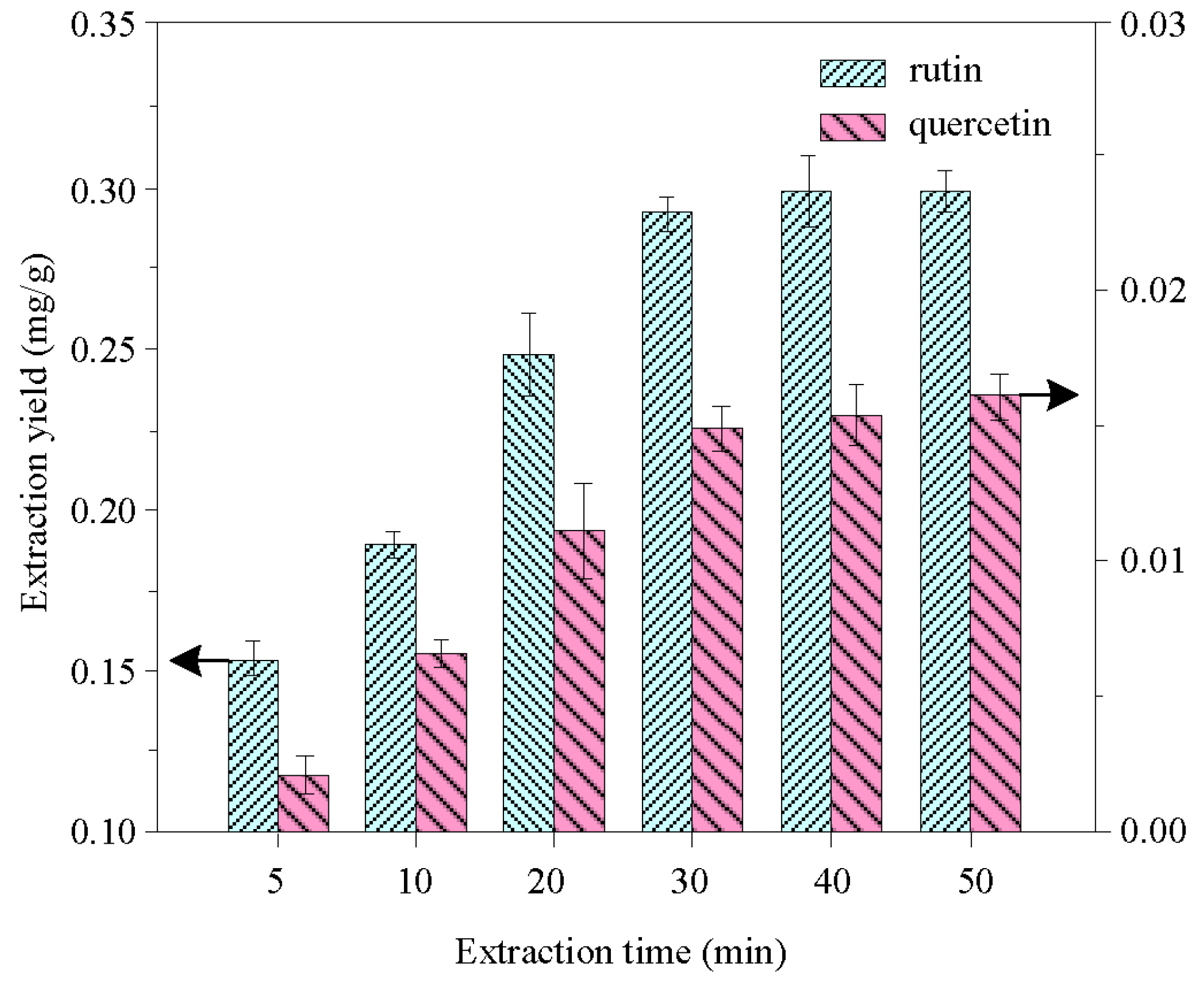

3.1.3. Effect of Extraction Time

3.1.4. Effect of Ultrasonic Power

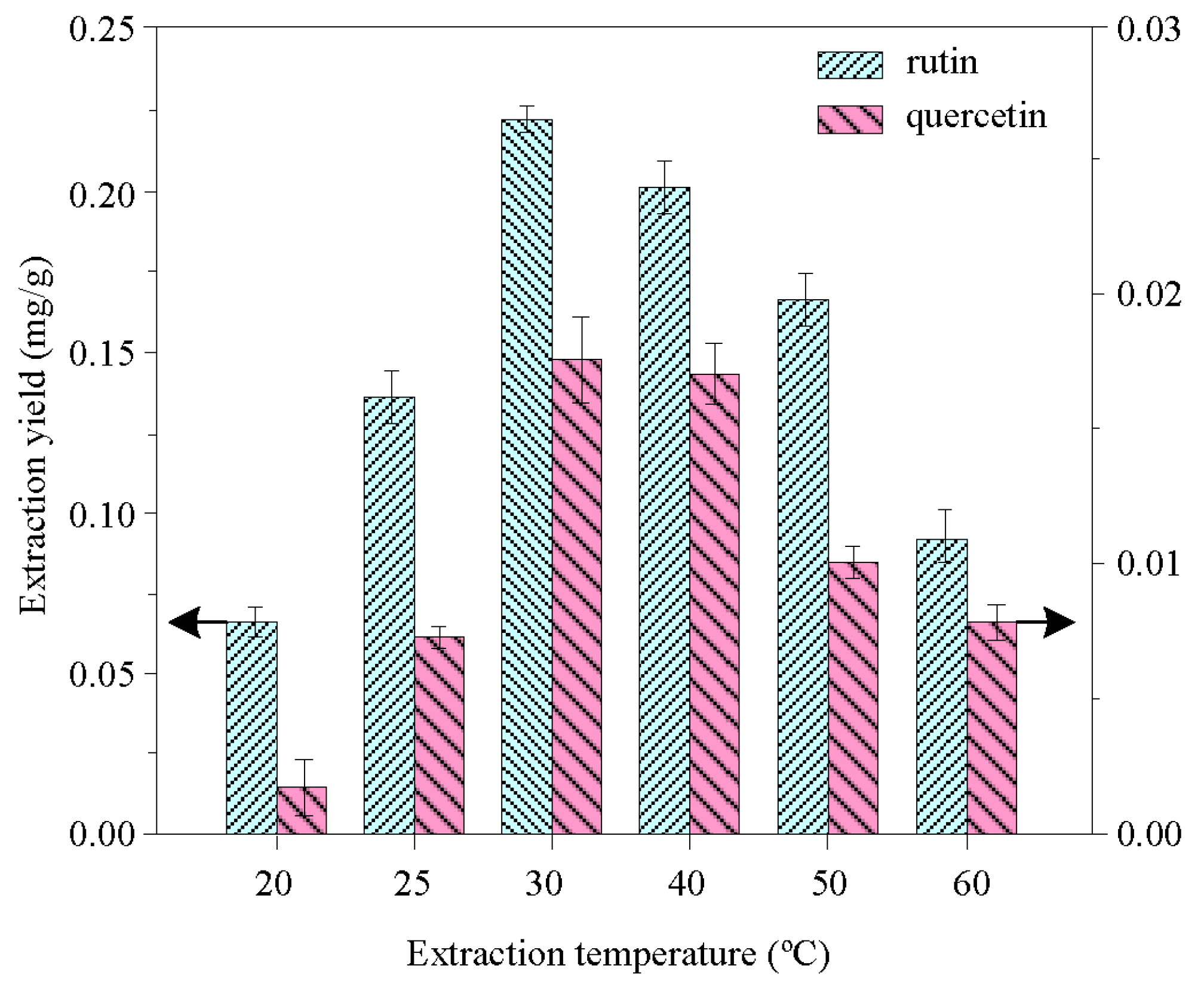

3.1.5. Effect of Extraction Temperature

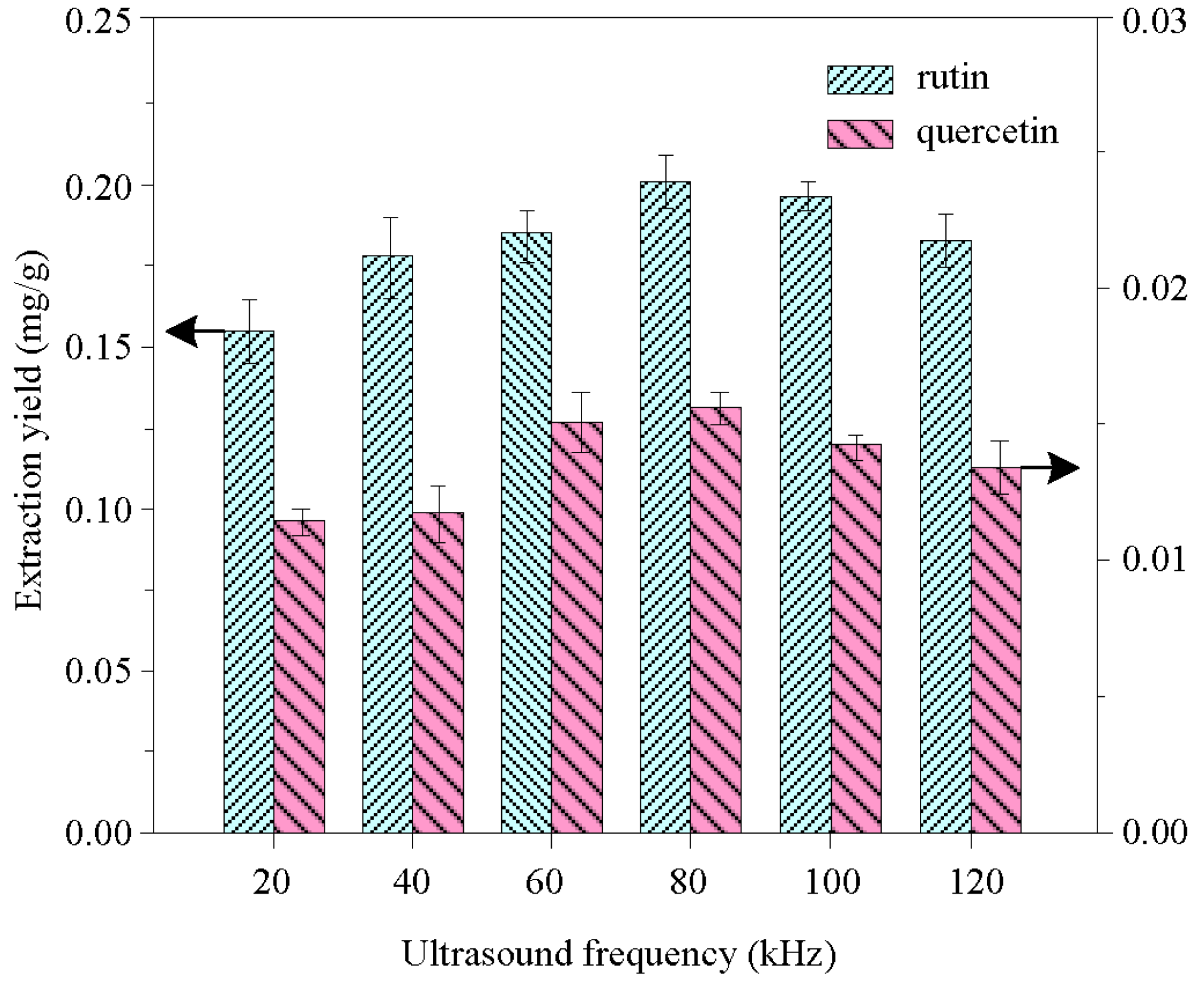

3.1.6. Effect of Ultrasonic Frequency

3.2. Modeling of UAE Using IFOA-LS-SVM

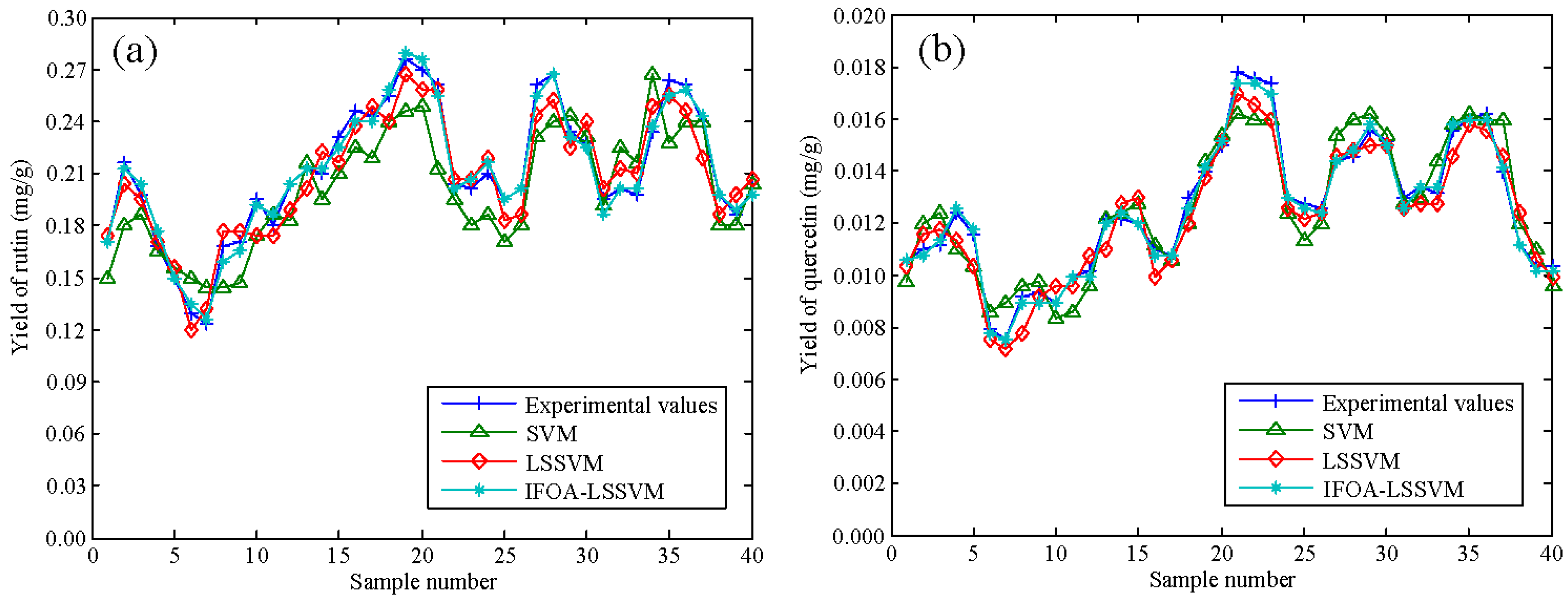

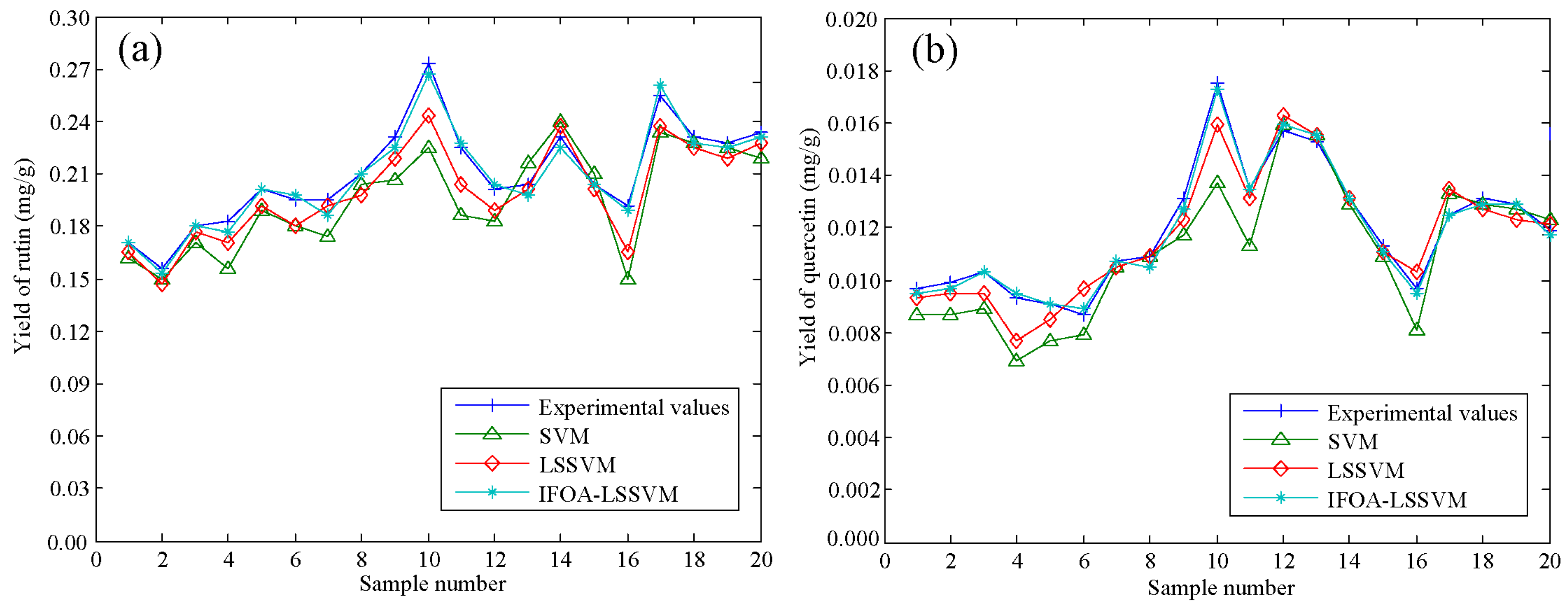

3.3. Prediction and Comparstion of between SVM, LS-SVM and IFOA-LS-SVM Models

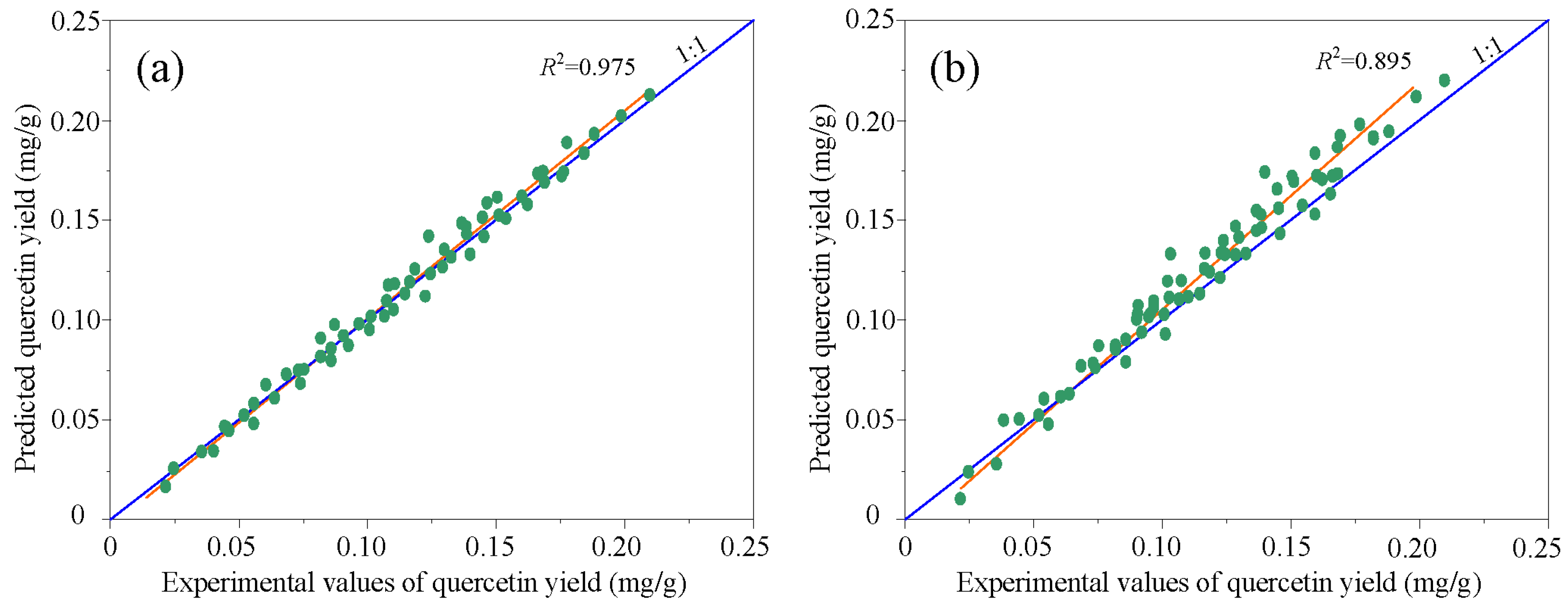

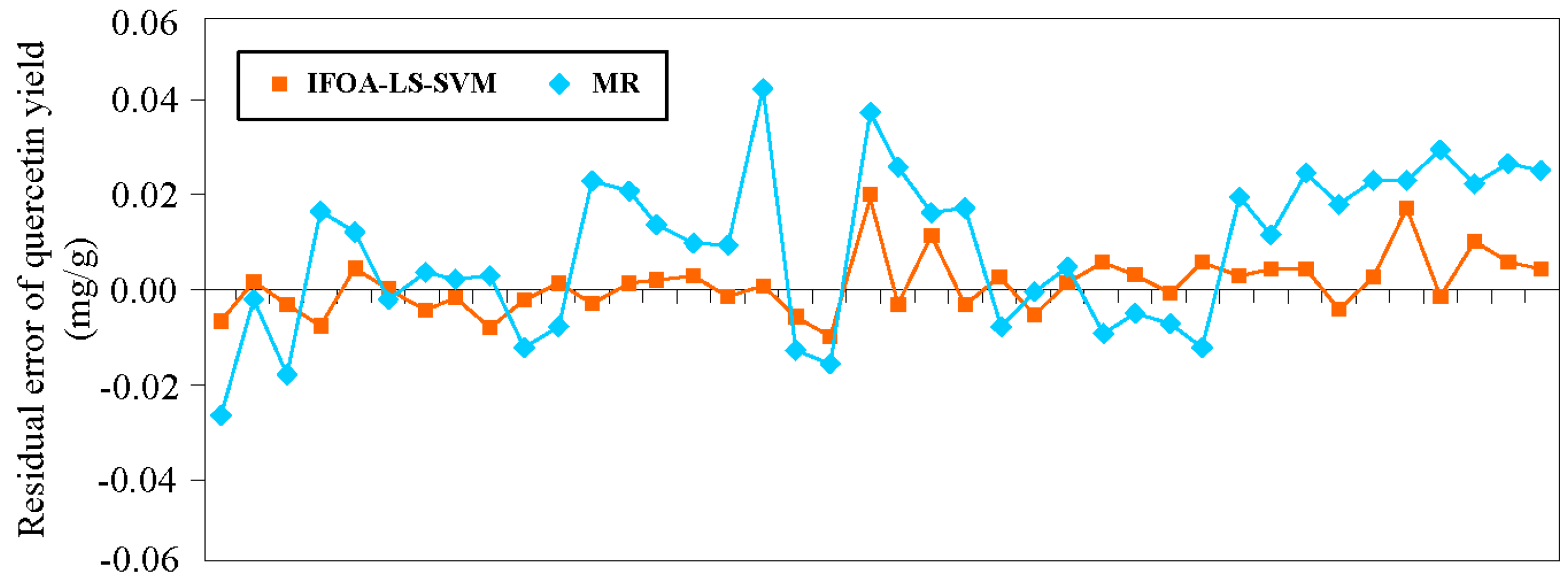

3.4. Comparison between IFOA-LS-SVM Model and MR Model

3.4.1. MR Model

3.4.2. Performance Comparison of IFOA-LS-SVM Model and Multiple Regression Model

3.5. Comparison of Training-Time between IFOA-LS-SVM Model and MR, SVM, LS-SVM Models

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chaudhuri, S.; Banerjee, A.; Basu, K.; Sengupta, B.; Sengupta, P.K. Internation of flavonoids with red blood cell membrane lipids and proteins: Antioxidant and antihemolytic effect. Int. J. Biol. Macromol. 2007, 41, 42–48. [Google Scholar] [CrossRef] [PubMed]

- Jiang, P.; Burczynski, F.; Campbell, C.; Pierce, G.; Austria, J.A.; Briggs, C.J. Rutin and flavonoid contents in three buckwheat species Fagopyrum esculentum, F. tataricum, and F. homotropicum and their protective effects against lipid perocidation. Food Res. Int. 2007, 40, 356–364. [Google Scholar] [CrossRef]

- Kado, Y.; Atobe, M.; Nonaka, T. Ultrasonic effects on electroorganic processes–Part 20. Photocatalytic oxidation of aliphatic alcohols in aqueous suspension of TiO2 powder. Ultrason. Sonochem. 2001, 8, 69–74. [Google Scholar] [CrossRef]

- Morgan, A.B.; Harris, J.D. Effects of organoclay Soxhlet extraction on mechanical properties, flammability properties and organoclay dispersion of polypropylene nanocomposites. Polymer 2003, 44, 2313–2320. [Google Scholar] [CrossRef]

- Hawthorne, S.B.; Grabanski, C.B.; Martin, E.; Miller, D.J. Comparisons of Soxhlet extraction, pressurized liquid extraction, supercritical fluid extraction and subcritical water extraction for environmental solids: Recovery, selectivity and effects on sample matrix. J. Chromatogr. A 2002, 892, 421–433. [Google Scholar] [CrossRef]

- Paganga, G.; Miller, N.; Rice-Evans, C.A. The polyphenolic content of fruit and vegetables and their antioxidant activities. What does a serving constitute. Free Radic. Res. 1999, 30, 153–162. [Google Scholar] [CrossRef] [PubMed]

- Gao, M.; Song, B.Z.; Liu, C.Z. Dynamic microwave-assisted extraction of flavonoids from Saussurea medusa Maxim cultured cells. Biochem. Eng. J. 2006, 32, 79–83. [Google Scholar] [CrossRef]

- Chen, G.; Zhang, H.; Ye, J. Determination of rutin and quercetin in plants by capillary electrophoresis with electrochemical detection. Anal. Chim. Acta 2000, 423, 69–76. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, F. Ultrasound-assisted extraction of rutin and quercetin from Euonymus alatus (Thunb.) Sieb. Ultrason. Sonochem. 2008, 15, 308–313. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Yang, Y.; Su, P.; Guo, Z. Microwave-assisted extraction of rutin and quercetin from the stalks of Euonymus alatus (Thunb.) Sieb. Phytochem. Analysis 2009, 20, 33–37. [Google Scholar]

- Kopyscinski, J.; Schildhauer, T.J.; Vogel, F.; Biollaz, S.M.A.; Wokaun, A. Applying spatially resolved concentration and temperature measurements in a catalytic plate reactor for the kinetic study of CO methanation. J. Catal. 2010, 271, 262–279. [Google Scholar] [CrossRef]

- Sicaire, A.G.; Vian, M.; Fine, F.; Joffre, F.; Carré, P.; Tostain, S.; Chemat, F. Alternative Bio-Based Solvents for Extraction of Fat and Oils: Solubility Prediction, Global Yield, Extraction Kinetics, Chemical Composition and Cost of Manufacturing. Int. J. Mol. Sci. 2015, 16, 8430–8453. [Google Scholar] [CrossRef] [PubMed]

- Cheung, Y.C.; Siu, K.C.; Wu, J.Y. Kinetic models for ultrasound-assisted extraction of water-soluble components and polysaccharides from medicinal fungi. Food Bioprocess Technol. 2013, 6, 2659–2665. [Google Scholar] [CrossRef]

- Gao, S.; Lewis, G.D.; Ashokkumar, M.; Hemar, Y. Inactivation of microorganisms by low-frequency high-power ultrasound: 2. A simple model for the inactivation mechanism. Ultrason. Sonochem. 2014, 21, 454–460. [Google Scholar] [CrossRef] [PubMed]

- Dai, L.; Yue, L.; Ouyang, W.; Wang, Z. A Kinetic Model for Ultrasound-Assisted Extraction of Geniposide from Gardenia jasminoides. Separ. Sci. Technol. 2015, 50, 1518–1522. [Google Scholar] [CrossRef]

- Vong, C.M.; Wong, P.K.; Li, Y.P. Prediction of automotive engine power and torque using least squares support vector machines and Bayesian inference. Appl. Artif. Intell. 2006, 19, 277–287. [Google Scholar] [CrossRef]

- Li, H.; Tang, X.; Wang, R.; Lin, F.; Liu, Z.; Cheng, K. Comparative Study on Theoretical and Machine Learning Methods for Acquiring Compressed Liquid Densities of 1, 1, 1, 2, 3, 3, 3-Heptafluoropropane (R227ea) via Song and Mason Equation, Support Vector Machine, and Artificial Neural Networks. Appl. Sci. 2016, 6, 25. [Google Scholar] [CrossRef]

- Wang, X.; Chen, J.; Liu, C.; Pan, F. Hybrid modeling of penicillin fermentation process based on least square support vector machine. Chem. Eng. Res. Des. 2010, 88, 415–420. [Google Scholar] [CrossRef]

- Zhao, M.; Li, Z.; He, W. Classifying Four Carbon Fiber Fabrics via Machine Learning: A Comparative Study Using ANNs and SVM. Appl. Sci. 2016, 6, 209. [Google Scholar] [CrossRef]

- Meybodi, M.K.; Shokrollahi, A.; Safari, H.; Lee, M.; Bahadori, A. A computational intelligence scheme for prediction of interfacial tension between pure hydrocarbons and water. Chem. Eng. Res. Des. 2015, 95, 79–92. [Google Scholar] [CrossRef]

- Wang, W.; Liu, X. Melt index prediction by least squares support vector machines with an adaptive mutation fruit fly optimization algorithm. Chemometr. Intell. Lab. 2015, 141, 79–87. [Google Scholar] [CrossRef]

- Chamkalani, A.; Zendehboudi, S.; Chamkalani, R.; Lohi, A.; Elkamel, A.; Chatzis, I. Utilization of support vectormachine to calculate gas compressibility factor. Fluid Phase Equilibr. 2013, 358, 189–202. [Google Scholar] [CrossRef]

- Shuai, H.; Yijun, H.; Huanjun, Y.; Dezhao, C. Progress in ant colony algorithm and its application in chemistry and chemical engineering. Comput. Appl. Chem. 2008, 25, 1. [Google Scholar]

- Wu, Q. Hybrid model based on wavelet support vector machine and modified genetic algorithm penalizing Gaussian noises for power load forecasts. Expert Syst. Appl. 2011, 38, 379–385. [Google Scholar] [CrossRef]

- Dos Santosa, G.S.; Justi Luvizottob, L.G.; Marianib, V.C.; Dos Santos, L.C. Least squares support vector machines with tuning based on chaotic differential evolution approach applied to the identification of a thermal process. Expert Syst. Appl. 2012, 39, 4805–4812. [Google Scholar] [CrossRef]

- Jiang, H.; Yan, Z.; Liu, X. Melt index prediction using optimized least squares support vector machines based on hybrid particle swarm optimization algorithm. Neurocomputing 2013, 119, 469–477. [Google Scholar] [CrossRef]

- Liao, R.J.; Zheng, H.B.; Grzybowski, S.; Yang, L.J. Particle swarm optimization-least squares support vector regression based forecasting model on dissolved gases in oil-filled power transformers. Electr. Power Syst. Res. 2011, 81, 2074–2080. [Google Scholar] [CrossRef]

- Pan, W.T. A new Fruit Fly Optimization Algorithm: Taking the financial distress model as an example. Knowl. Based Syst. 2012, 26, 69–74. [Google Scholar] [CrossRef]

- Kulkarni, V.M.; Rathod, V.K. Mapping of an ultrasonic bath for ultrasound assisted extraction of mangiferin from Mangifera indica leaves. Ultrason. Sonochem. 2014, 21, 606–611. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Chen, M.; Fan, Y.; Elsebaei, F.; Zhu, Y. Determination of rutin and quercetin in Chinese herbal medicine by ionic liquid-based pressurized liquid extraction-liquid chromatography-chemiluminescence detection. Talanta 2012, 88, 222–229. [Google Scholar] [CrossRef] [PubMed]

- Cortes, C.; Vapnik, V. Support-vector networks. Mach. Learn. 1995, 20, 273–297. [Google Scholar] [CrossRef]

- Vapnik, V.; Golowich, S.; Smola, A. Support vector machine for function approximation, regression estimation, and signal processing. In Neural Information Processing Systems; Mozer, M., Petsche, T., Eds.; MIT Press: Cambridge, MA, USA, 1997; Volume 9, pp. 265–278. [Google Scholar]

- Suykens, J.A.K.; Vandewalle, J. Least squares support vector machine classifiers. Neural Process. Lett. 1999, 9, 293–300. [Google Scholar] [CrossRef]

- Fletcher, R. Practical Methods of Optimization; John Wiley and Sons: Chichester, UK; New York, NY, USA, 1987; pp. 366–389. [Google Scholar]

- Keerthi, S.S.; Lin, C.J. Asymptotic behaviors of support vector machineswith Gaussian kernel. Neural Comput. 2003, 15, 1667–1689. [Google Scholar] [CrossRef] [PubMed]

- Chemat, F.; Fabiano-Tixier, A.S.; Vian, M.A.; Allaf, T.; Vorobiev, E. Solvent-free extraction of food and natural products. TrAC Trends Anal. Chem. 2015, 71, 157–168. [Google Scholar] [CrossRef]

- Chemat, S.; Esveld, E.D. Contribution of microwaves or ultrasonics on carvone and limonene recovery from dill fruits (Anethum graveolens L.). Innov. Food Sci. Emerg. 2013, 17, 114–119. [Google Scholar] [CrossRef]

- Park, J.E.; Atobe, M.; Fuchigami, T. Synthesis of multiple shapes of gold nanoparticles with controlled sizes in aqueous solution using ultrasound. Ultrason. Sonochem. 2006, 13, 237–241. [Google Scholar] [CrossRef] [PubMed]

- Carail, M.; Fabiano-Tixier, A.S.; Meullemiestre, A.; Chemat, F.; Caris-Veyrat, C. Effects of high power ultrasound on all-E-carotene, newly formed compounds analysis by ultra-high-performance liquid chromatography-tandem mass spectrometry. Ultrason. Sonochem. 2015, 26, 200–209. [Google Scholar] [CrossRef] [PubMed]

- Assami, K.; Chemat, S.; Meklati, B.Y.; Chemat, F. Ultrasound-Assisted Aromatisation with Condiments as an Enabling Technique for Olive Oil Flavouring and Shelf Life Enhancement. Food Anal. Methods 2015, 9, 982–990. [Google Scholar] [CrossRef]

- Liao, J.; Qu, B.; Liu, D.; Zheng, N. New method to enhance the extraction yield of rutin from Sophora japonica using a novel ultrasonic extraction system by determining optimum ultrasonic frequency. Ultrason. Sonochem. 2015, 27, 110–116. [Google Scholar] [CrossRef] [PubMed]

- Liao, J.Q.; Zheng, N.; Shun, S.G. Optimization of ultrasonic frequency for the improvement of extraction yields of bufadienolides from the Chinese medicine ChanSu by using a novel ultrasonic system. RSC Adv. 2015, 5, 49480–49486. [Google Scholar] [CrossRef]

- Liao, J.; Zheng, N.; Qu, B. An Improved Ultrasonic-Assisted Extraction Method by Optimizing the Ultrasonic Frequency for Enhancing the Extraction Efficiency of Lycopene from Tomatoes. Food Anal. Methods 2016, 9, 2288–2298. [Google Scholar] [CrossRef]

- Yilmaz, I.K.; Kaynar, O. Multiple regression, ANN (RBF, mLP) and ANFIS models for prediction of swell potential of clayey soils. Expert Syst. Appl. 2011, 38, 5958–5966. [Google Scholar] [CrossRef]

- Efroymson, M.A. Multiple regression analysis. Math. Method Digit. Comput. 1960, 1, 191–203. [Google Scholar]

- Krackhardt, D. Predicting with networks: Nonparametric multiple regression analysis of dyadic data. Soc. Netw. 1988, 10, 359–381. [Google Scholar] [CrossRef]

| Parameters | γ | σ2 |

|---|---|---|

| Rutin yield | 9913.65 | 11.08 |

| Quercetin yield | 9896.80 | 10.55 |

| Analytes | Models | RMSE | MRE (%) | MAE | TIC |

|---|---|---|---|---|---|

| Rutin | SVM | 0.1268 | 3.87 | 0.0998 | 0.0082 |

| LS-SVM | 0.1035 | 1.88 | 0.0566 | 0.0028 | |

| IFOA-LS-SVM | 0.0540 | 1.05 | 0.0189 | 0.0014 | |

| Quercetin | SVM | 0.1204 | 3.99 | 0.0965 | 0.0080 |

| LS-SVM | 0.0997 | 2.05 | 0.0557 | 0.0030 | |

| IFOA-LS-SVM | 0.0536 | 0.97 | 0.0183 | 0.0013 |

| Analytes | Models | RMSE | MRE (%) | MAE | TIC |

|---|---|---|---|---|---|

| Rutin | SVM | 0.1192 | 3.81 | 0.0798 | 0.0049 |

| LS-SVM | 0.0903 | 2.05 | 0.0466 | 0.0023 | |

| IFOA-LS-SVM | 0.0596 | 0.97 | 0.0224 | 0.0011 | |

| Quercetin | SVM | 0.1008 | 3.86 | 0.0776 | 0.0045 |

| LS-SVM | 0.0889 | 2.78 | 0.0425 | 0.0020 | |

| IFOA-LS-SVM | 0.0612 | 0.99 | 0.0231 | 0.0014 |

| Independent Variables | X1 | X2 | X3 | X4 | X5 | X6 | Constant |

|---|---|---|---|---|---|---|---|

| Coefficient | 0.236 | −0.685 | −0.198 | 0.702 | 0.225 | −0.663 | −12.146 |

| Std. error | 0.088 | 0.133 | 0.665 | 0.054 | 0.036 | 0.147 | 0.456 |

| Sig. level | 0.280 | 0.011 | 0.002 | 0.421 | 0.126 | 0.008 | 0.102 |

| Models | MR | SVM | LS-SVM | IFOA-LS-SVM |

|---|---|---|---|---|

| Training-time (s) | 16.863 | 27.652 | 3.247 | 2.298 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, J.; Qu, B.; Zheng, N. Effects of Process Parameters on the Extraction of Quercetin and Rutin from the Stalks of Euonymus Alatus (Thumb.) Sieb and Predictive Model Based on Least Squares Support Vector Machine Optimized by an Improved Fruit Fly Optimization Algorithm. Appl. Sci. 2016, 6, 340. https://doi.org/10.3390/app6110340

Liao J, Qu B, Zheng N. Effects of Process Parameters on the Extraction of Quercetin and Rutin from the Stalks of Euonymus Alatus (Thumb.) Sieb and Predictive Model Based on Least Squares Support Vector Machine Optimized by an Improved Fruit Fly Optimization Algorithm. Applied Sciences. 2016; 6(11):340. https://doi.org/10.3390/app6110340

Chicago/Turabian StyleLiao, Jiangqing, Baida Qu, and Nan Zheng. 2016. "Effects of Process Parameters on the Extraction of Quercetin and Rutin from the Stalks of Euonymus Alatus (Thumb.) Sieb and Predictive Model Based on Least Squares Support Vector Machine Optimized by an Improved Fruit Fly Optimization Algorithm" Applied Sciences 6, no. 11: 340. https://doi.org/10.3390/app6110340