4.2. Stiffness Calculation for the FSMRL Wall Structure

- (1)

For MRL walls, the elastic stiffness in the lateral force resistance (or

K) can be calculated using Equations (2)–(5) (shown in section 6) [

27]

Based on previous wall-related experiments, the equations incorporate bending deformation and structural destruction and take into account the influence of concerned variables, such as the axial compressive ratio, minor cracks, and the construction procedure.

For MRL walls with holes, the calculation of the elastic stiffness in the lateral force resistance can be conducted using Equation (6) (see

Figure 9).

Figure 9.

Sketch of the stiffness calculation for MRL walls with holes.

Figure 9.

Sketch of the stiffness calculation for MRL walls with holes.

Note: KI, KII and KIII stand for the piece-by-piece calculation results of the specimen stiffness in lateral force resistance, whereas the layer height H represents the height of the embrasure or windowsill.

- (2)

Stiffness calculation for reinforced concrete frame and seismic wall

The authors introduced the D-value method which can be expressed by Equation (7).

- (3)

Calculation of layer stiffness

The calculated value for the layer stiffness is derived from the linear superposition of the frame stiffness and the MRL wall stiffness (see Equation (8)).

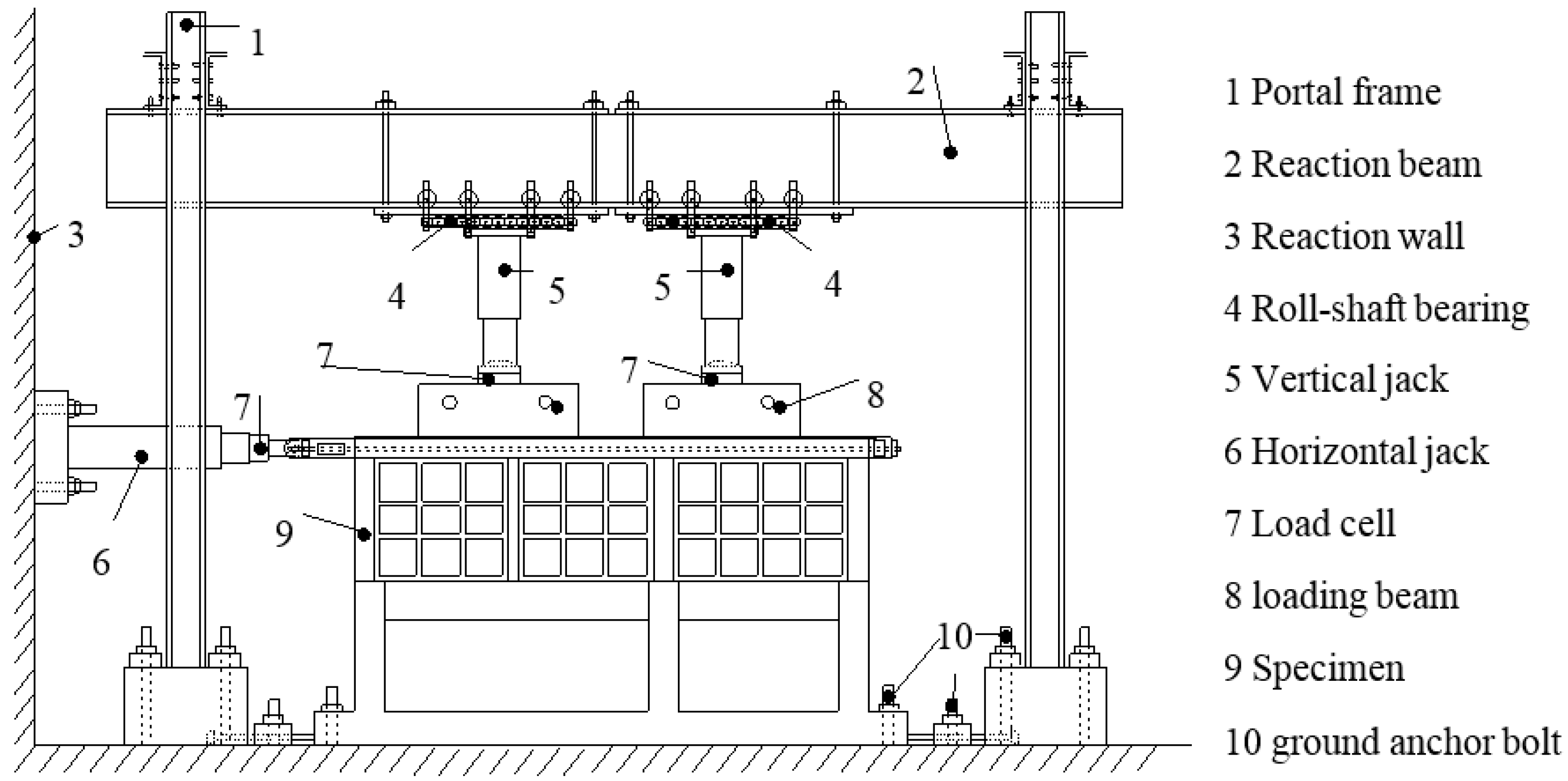

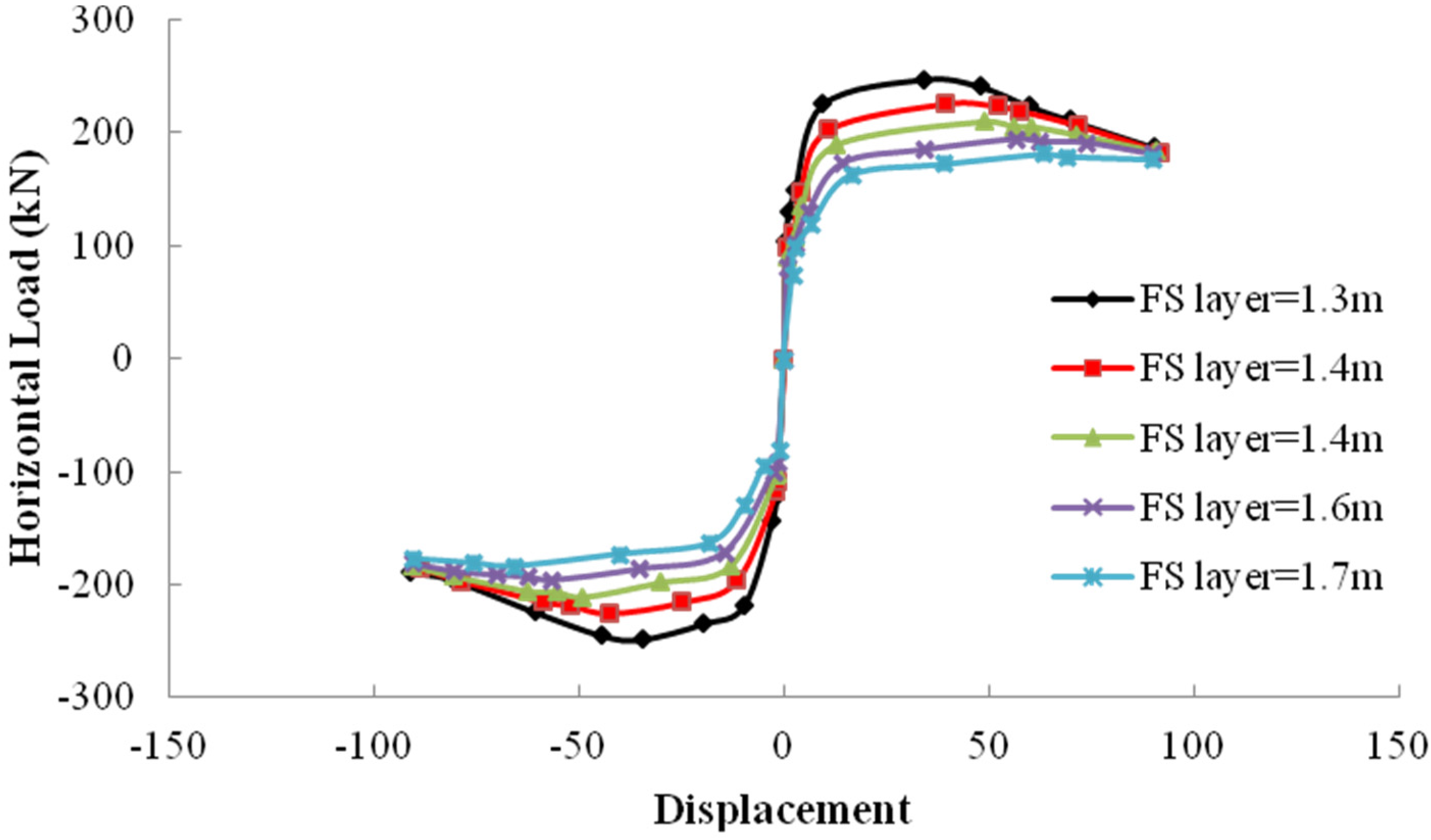

Engineering practice normally reserves a large space in the lower layer of the FSMRL wall structure. However, to avoid the early occurrence of FS column failure, this paper shortens the columns and introduces reinforcement measures. The height cut is conducted proportionally; the layer height—which is 2.6 m in practice—is 1.3 m in this paper. The paper makes use of the finite-element software OpenSees ([

16]) to simulate the influence of height changes in the FS layer on the load-bearing performance of the overall structure. The height of the FS layer is set at 1.3 m, 1.4 m, 1.5 m, 1.6 m, or 1.7 m to simulate an actual structure with a layer height of 2.6 m, 2.8 m, 3.0 m, 3.2 m, or 3.4 m respectively. The model provides a comparative diagram for skeleton curves, which are displayed as follows (see

Figure 10).

Figure 10.

Comparative diagram for the skeleton curves of the models.

Figure 10.

Comparative diagram for the skeleton curves of the models.

Using Equation (2) to Equation (8), the stiffness ratio (at the interim layer) can be determined for specimens with different frame heights.

Table 4 shows the relation between the stiffness ratio and the structure’s crack, yield, and peak loading (see

Figure 11).

Table 4.

Stiffness ratio at the interim layer with different frame supported (FS) layer heights.

Table 4.

Stiffness ratio at the interim layer with different frame supported (FS) layer heights.

| Height of FS Layer (mm) | 1300 | 1400 | 1500 | 1600 | 1700 |

|---|

| Stiffness ratio at the interim layer | 1.66 | 2.02 | 2.42 | 2.88 | 3.39 |

Figure 11.

Relation between the interim stiffness ratio and load-bearing performance.

Figure 11.

Relation between the interim stiffness ratio and load-bearing performance.

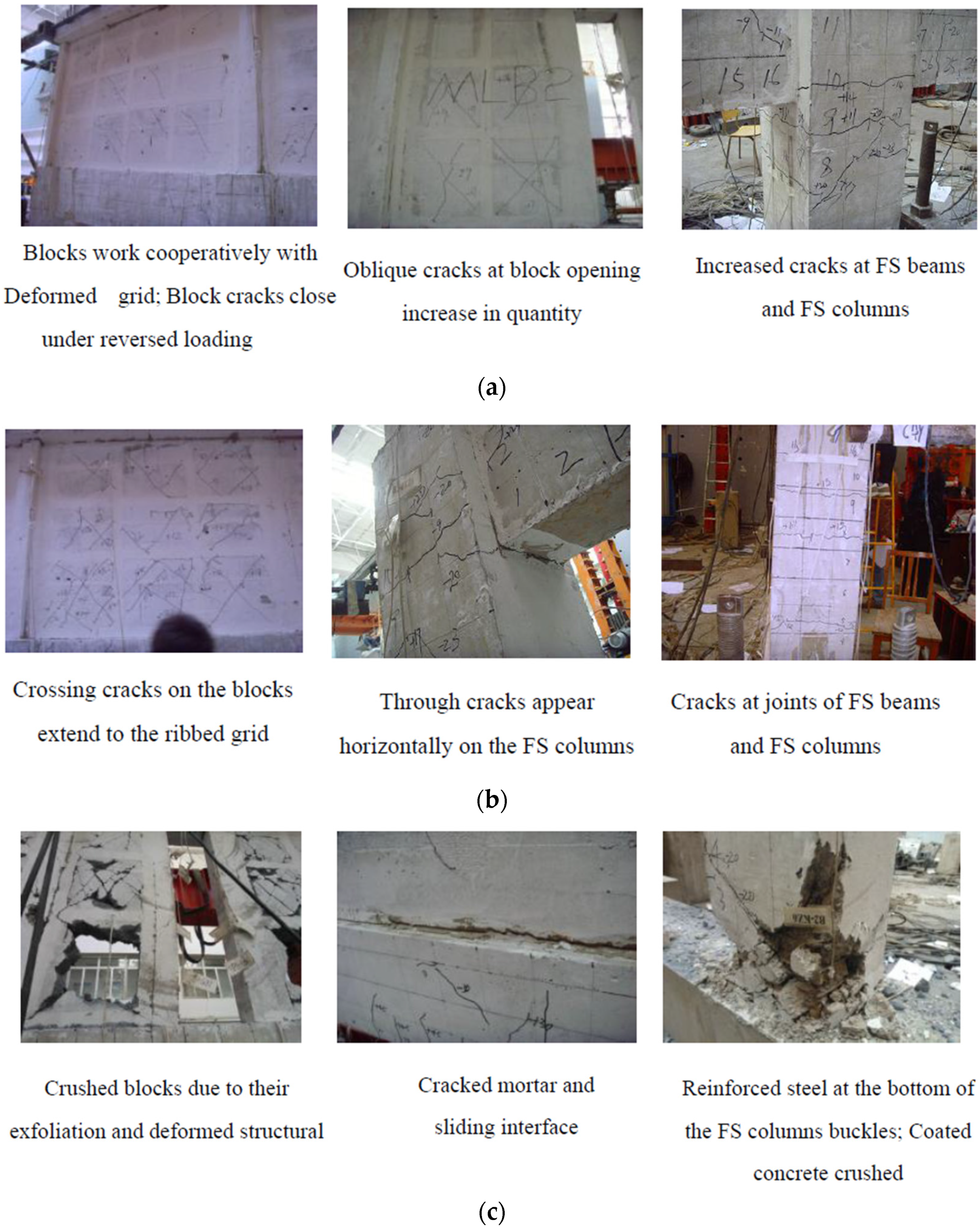

Figure 11 shows that the overall curves for the crack, yield, and peak loading decrease with increasing stiffness ratio. A closer look shows that, comparatively, the crack-loading curve follows a more steady variation pattern, whereas the decrease of the other two variables is steeper, which indicates that the stiffness ratio has a stronger influence on the structural strength at the yielding stage and under peak loading.

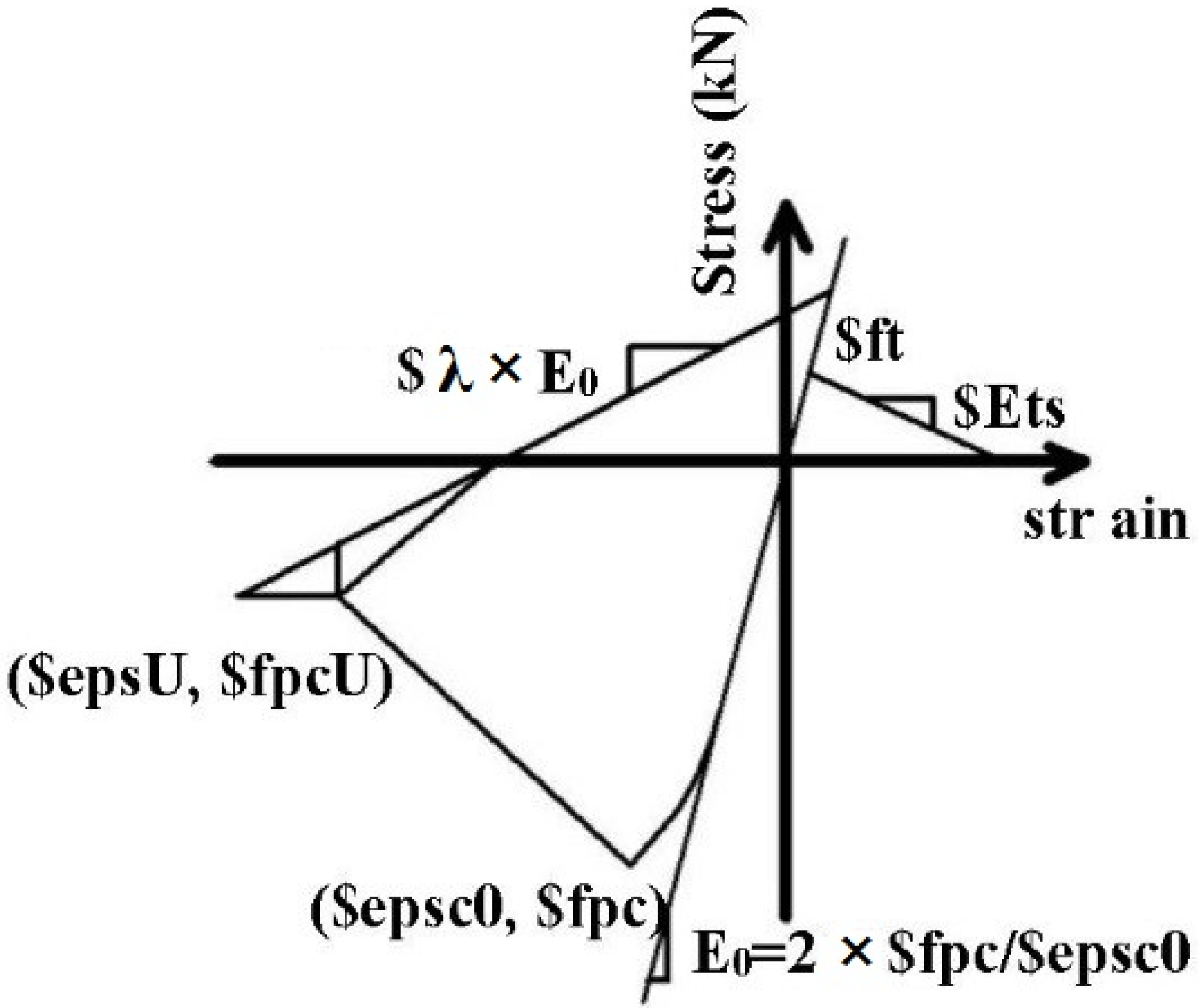

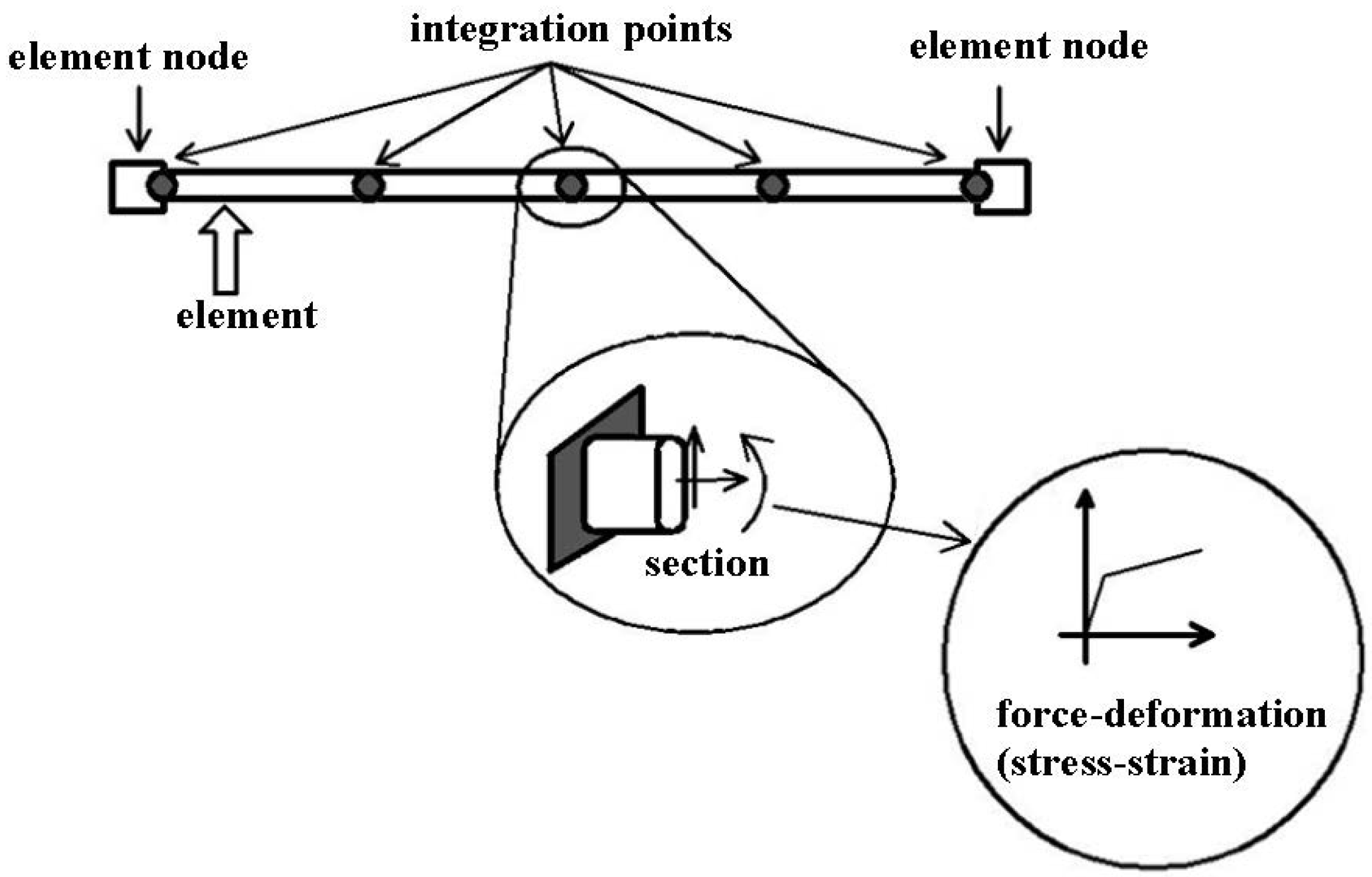

Stiffness adjustment of the FS layer and hole opening of the MRL wall are performed in an effort to obtain different stiffness ratios, either greater than or smaller than 1. The authors again use OpenSees to simulate the load bearing process to identify the preferable stiffness ratio for the interim layer of the FSMRL wall structure [

16,

28]. In the simulation of the specimen’s physical performance, the material-specialized model Concrete02 (provided by OpenSees [

16])—which takes into account the concrete’s strength and linear tensile emollescence—is applied in the study of the constitutive relation of the concrete (see

Figure 12). The uniaxial material model (Hysteretic Material) is chosen for the simulation of rebar, because the model does not eliminate the stiffness degradation upon the removal of the external force, and it is fully able to reflect the pinching effect, (see

Figure 13). The beam-column unit makes use of the non-linear fiber model that OpenSees provides in its simulation (see

Figure 14). In accordance with the equivalent principle of compressive stiffness and bending stiffness, the MRL wall is analyzed as a reinforced concrete plate, where the ShellMITC4 unit (model provided by OpenSees) is defined by a multi-layered shell element [

29,

30].

Figure 12.

Stress-strain relation of concrete.

Figure 12.

Stress-strain relation of concrete.

Figure 13.

Skeleton curve of the hysteretic material.

Figure 13.

Skeleton curve of the hysteretic material.

Figure 14.

The composite of beam and column element.

Figure 14.

The composite of beam and column element.

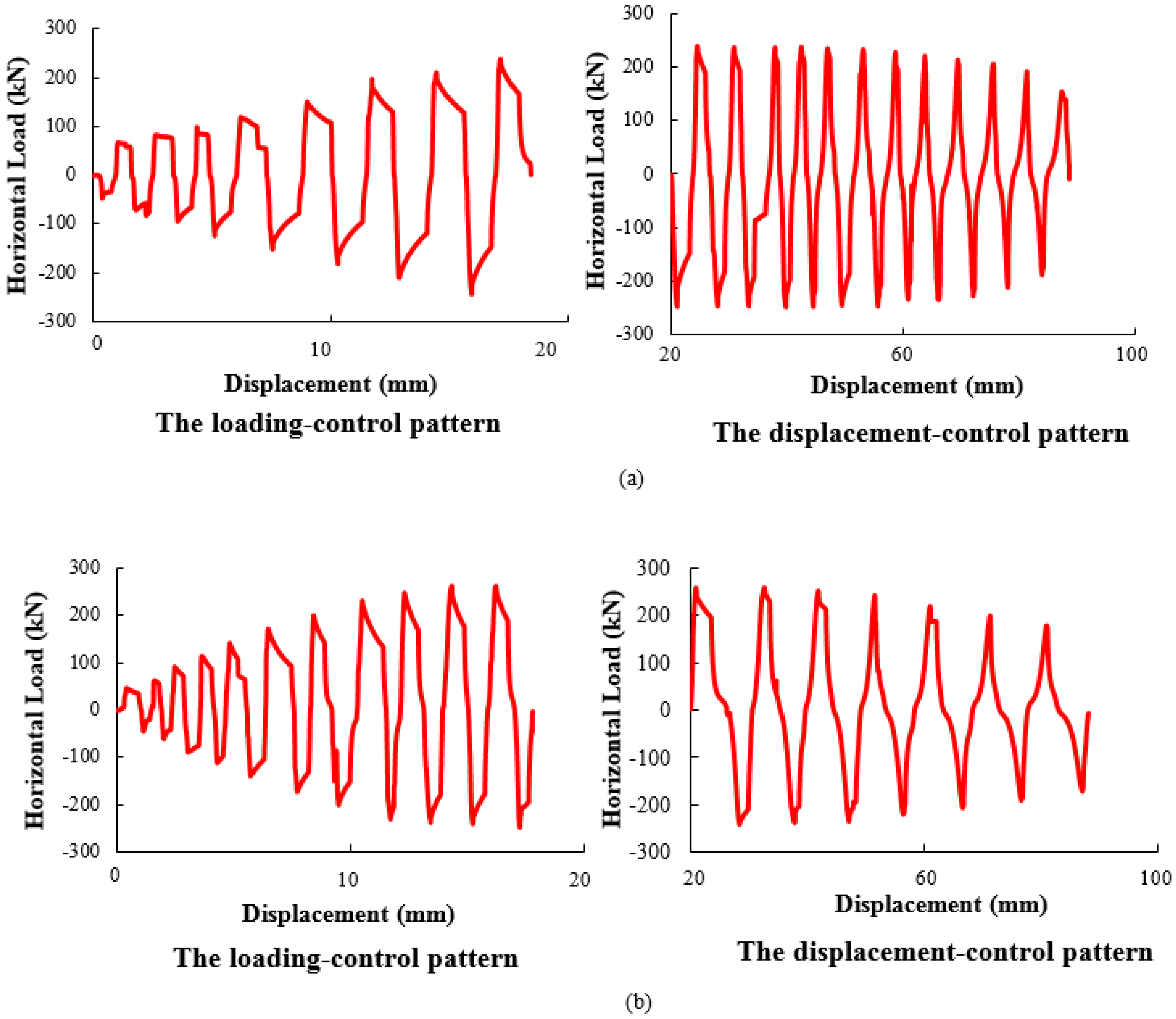

The test data collected were compared with the calculation results of the hysteretic curve and the skeleton curve to verify the model, refer to

Figure 15 for comparison of hysteretic curves and skeleton curves of the calculated values and the test data for FSMRL-2.

Figure 15.

Comparative diagrams for hysteretic and skeleton curves (calculated values and test data). (a) hysteretic curve; (b) skeleton curve.

Figure 15.

Comparative diagrams for hysteretic and skeleton curves (calculated values and test data). (a) hysteretic curve; (b) skeleton curve.

From

Figure 15, it can be concluded that the calculated values of both hysteretic curves and skeleton curves are consistent with the corresponding data collected from the test. The hysteretic loops tend to expand horizontally, which indicates a fairly good capacity for energy dissipation. Due to block and concrete exfoliation and the yielding of the reinforced steel, the hysteretic loops starts to “pinch” in the middle in the later stages of loading, whereas sliding occurs between the upper and the lower layers. The skeleton curves are consistent in terms of the trends, and the loading simulation was proven accurate from the cracking, yielding, and peaking of the damage to the specimens.

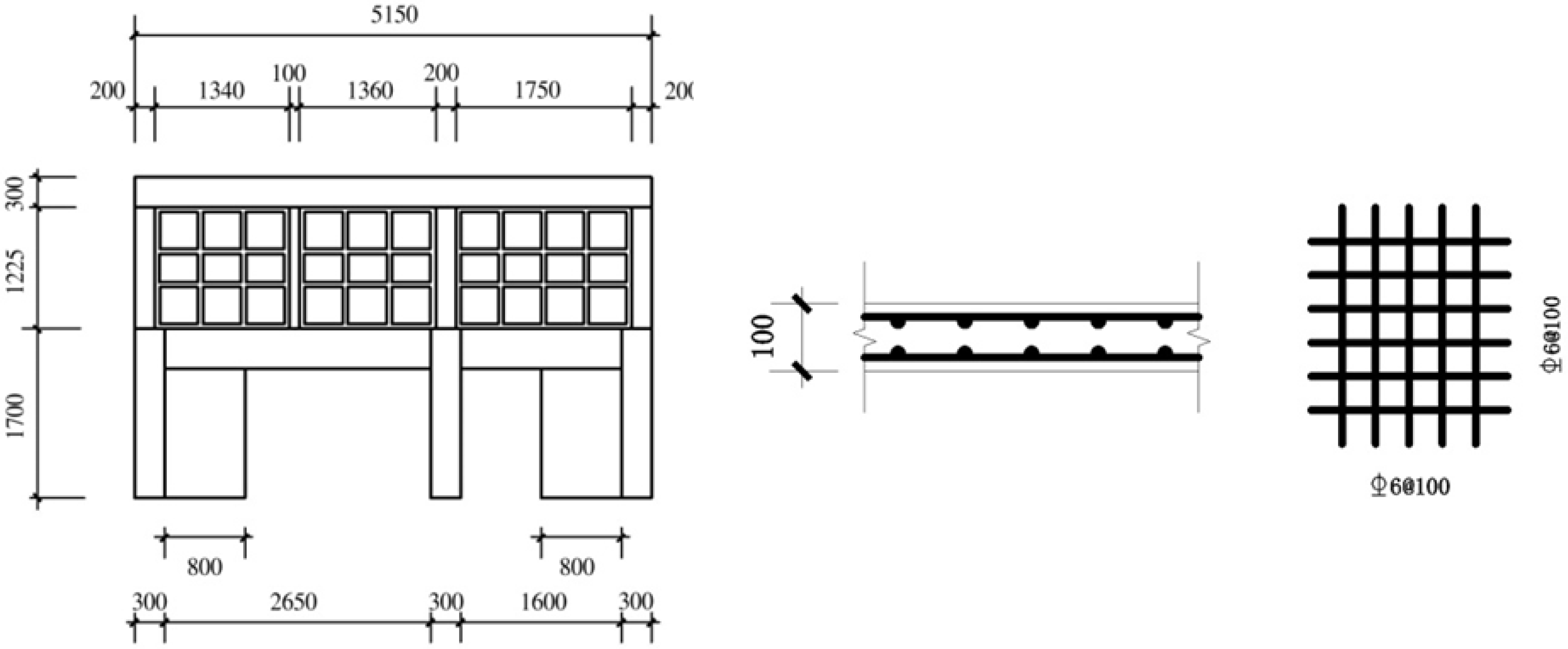

4.3. Analysis of the Load-Bearing Performance when the Stiffness Ratio Exceeds 1

As

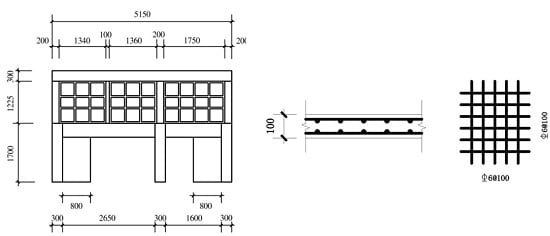

Table 1 shows, the height increase of the FS layer results in a stiffness decrease, indicating the deterioration of the load-bearing performance of the overall structure. In practice, because a large space is generally reserved for the lower layer, the layer height tends to be considerable. In this regard, shear wall structures can be introduced—when necessary—to lower the stiffness ratio at the interim layer, which helps to improve the load-bearing performance of the structure at large. Here, the paper takes the FSMRL wall structures with an FS layer height of 1700 mm as the study object, both sides of which are enhanced by shear walls of different widths, namely 0 mm for MX-1, 200 mm for MX-2, 300 mm for MX-3, 400 mm for MX-4, 500 mm for MX-5, 600 mm for MX-6, 700 mm for MX-7, and 800 mm for MX-8. With a uniformed thickness of 100 mm, the shear walls applied for this experiment—both horizontal and vertical—use φ6 reinforcement with an interval of 100 mm (See

Figure 16). The detailed reinforcement is shown in

Figure 4. The calculated results of stiffness ratio are summarized in

Table 5.

Figure 16.

The study model.

Figure 16.

The study model.

Table 5.

Stiffness ratio at the interim layer (with shear wall width as variable).

Table 5.

Stiffness ratio at the interim layer (with shear wall width as variable).

| Model | MX-1 | MX-2 | MX-3 | MX-4 | MX-5 | MX-6 | MX-7 | MX-8 |

|---|

| Stiffness ratio at the interim layer | 3.39 | 3.26 | 3.00 | 2.62 | 2.19 | 1.78 | 1.42 | 1.13 |

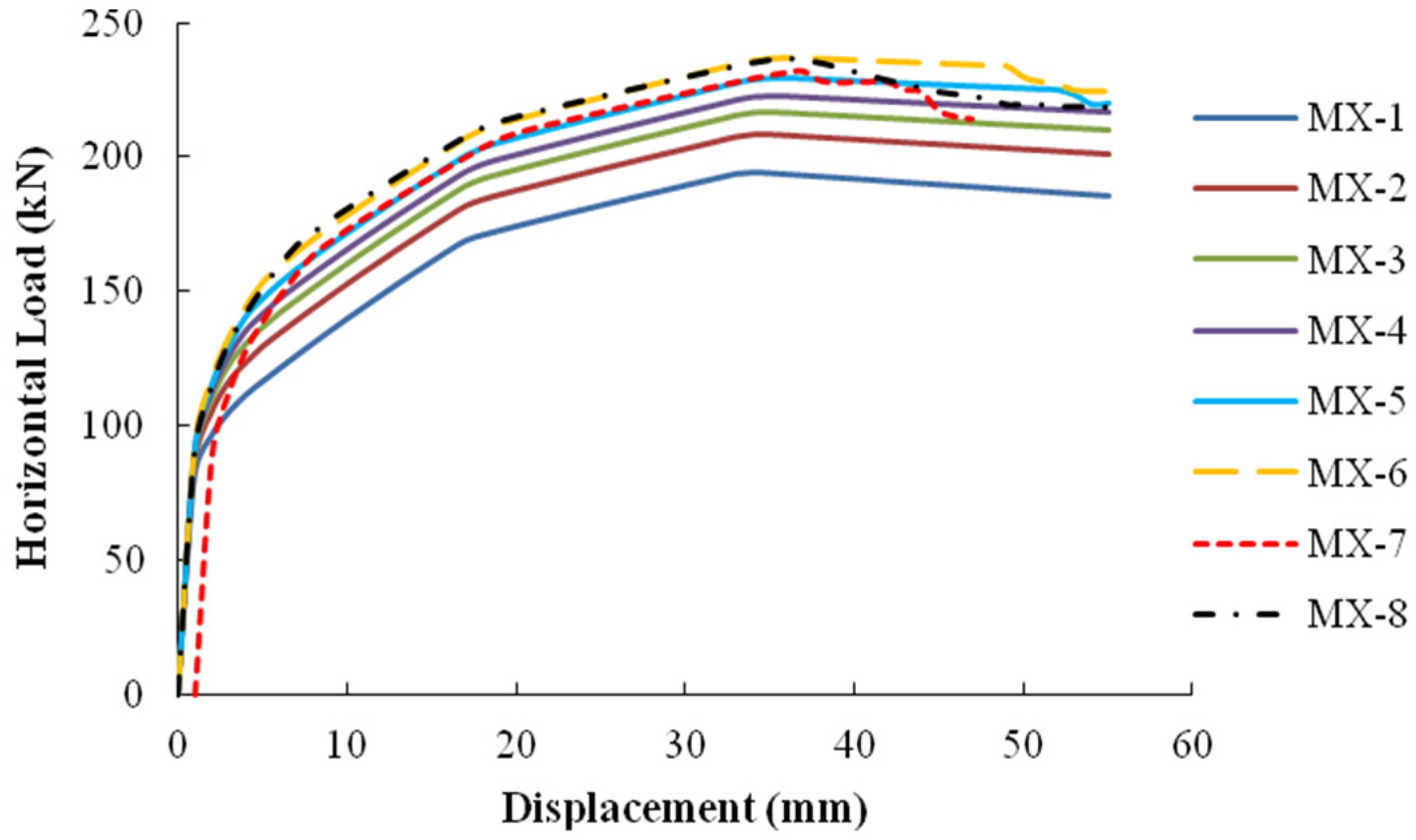

Figure 17.

Force exerted on the FSMRL wall structures (with shear wall width as variable).

Figure 17.

Force exerted on the FSMRL wall structures (with shear wall width as variable).

The simulation of the load-bearing performance is conducted using OpenSees. To streamline the calculation process, the authors conduct monotone loading to obtain loading-displacement curves, which are displayed in

Figure 17.

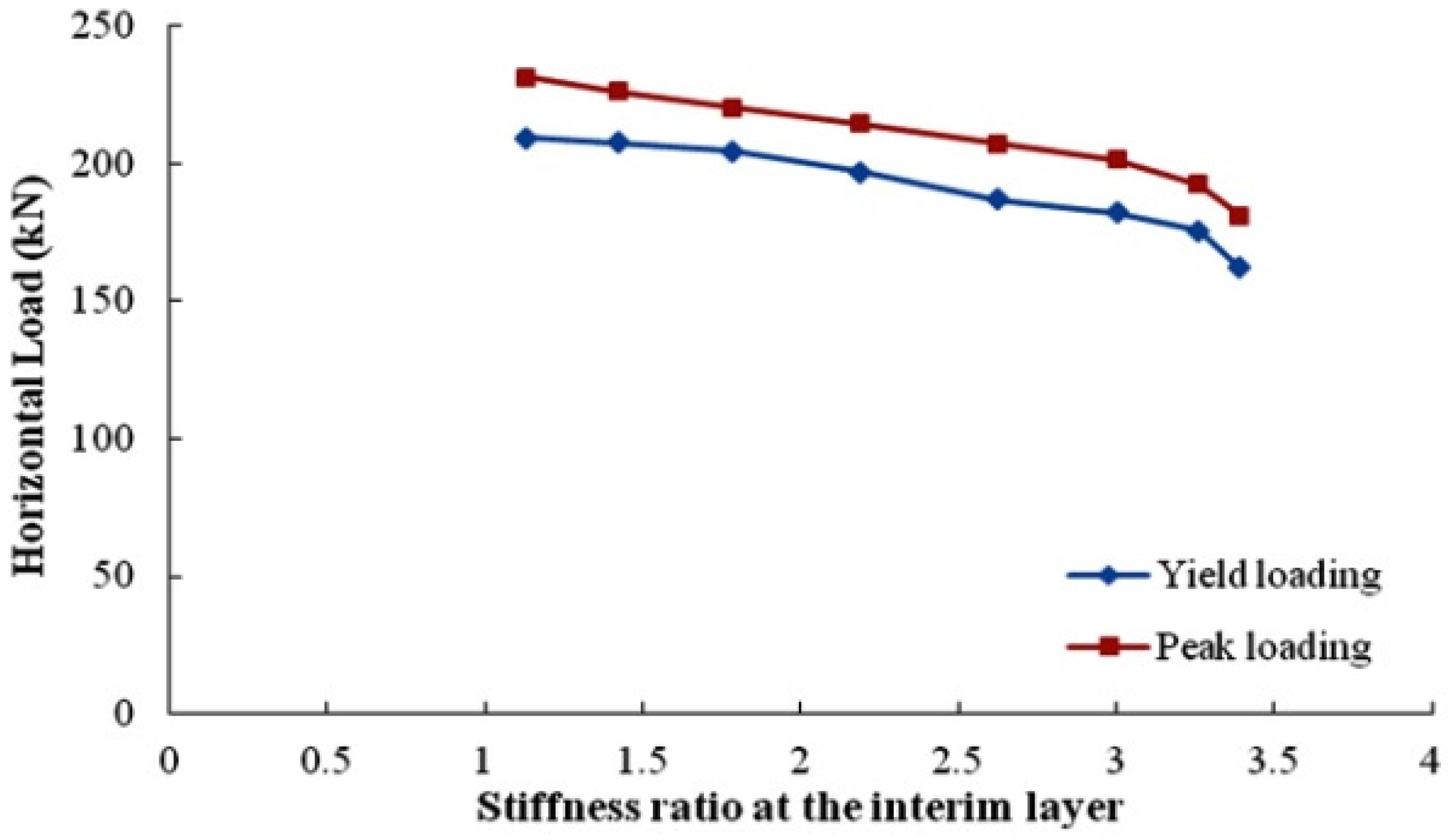

Based on the force-displacement curves, the relation between the yield loading and peak loading exerted and the stiffness ratio at the interim layer were identified (See

Figure 18).

It can be concluded from

Figure 18 that the increase in the interim stiffness ratio triggers a decline in the yield and peak loading. When the stiffness ratio exceeds 2.5, the decrease of the peak loading increases in speed, whereas the loading exerted at the yield of the specimen drops dramatically after the ratio exceeds 3. The paper recommends a not-less-than 2.5 interim stiffness ratio for the FSMRL wall structure, because the yield strength needs to be maintained at a certain level without compromising the overall structural reliability (The higher the interim stiffness ratio grows, the faster the frame-supported-layer stiffness decreases. In the meantime, the drop of the yield loading influences the overall structural reliability).

Figure 18.

Relation between the interim stiffness ratio and load-bearing performance.

Figure 18.

Relation between the interim stiffness ratio and load-bearing performance.

4.4. Analysis of the Load-Bearing Performance when the Stiffness Ratio Falls Below 1

Due to the shear wall added for this experiment and the hole opening of a large amount at the upper structure (for functional purposes), the stiffness ratio falls below 1. Therefore, it is possible that the upper structure may encounter premature failure caused by the extremely low stiffness in the lateral force resistance. To this end, the paper adjusts the location and the dimensions of the hole opening in an attempt to obtain a host of stiffness ratios below 1. The simulation is performed using OpenSees, which provides the variation pattern for the influence of the stiffness ratio on the overall structure.

The FSMRL wall structures with 100 mm thick and 800 mm wide shear walls at both sides (whose reinforcement is displayed in

Figure 16) use a 1700 mm FS layer height, and the upper structure varies in MX-9 to MX-16 from a frame with no blocks embedded to MRL walls of different widths (see

Figure 19 and

Table 6). The detailed reinforcement and dimensions for the opening are shown in

Figure 4. The interim stiffness ratios for the different structural layouts are calculated, and the results are listed in

Table 7.

Table 6.

FSMRL wall structure with different hole opening.

Table 6.

FSMRL wall structure with different hole opening.

| | Model Number | MX-9 | MX-10 | MX-11 | MX-12 | MX-13 | MX-14 | MX-15 | MX-16 |

|---|

| The Opening Rate | |

|---|

| Slab 1 | 1 | 2/3 | 2/3 | 2/3 | 1/3 | 1/3 | 1/3 | 1/3 |

| Slab 2 | 1 | 1 | 2/3 | 2/3 | 2/3 | 1/3 | 1/3 | 1/3 |

| Slab 3 | 1 | 1 | 1 | 3/4 | 3/4 | 3/4 | 1/2 | 1/4 |

Figure 19.

Partial FSMRL wall structure with different hole opening. (a) MX-9 (a frame with no blocks at the upper structure) (b) MX-16 (blocks embedded to slab 1, 2, and 3 with different opening rates at the upper structure).

Figure 19.

Partial FSMRL wall structure with different hole opening. (a) MX-9 (a frame with no blocks at the upper structure) (b) MX-16 (blocks embedded to slab 1, 2, and 3 with different opening rates at the upper structure).

Table 7.

Stiffness ratio at the interim layer (with hole as variable).

Table 7.

Stiffness ratio at the interim layer (with hole as variable).

| Model Number | MX-9 | MX-10 | MX-11 | MX-12 | MX-13 | MX-14 | MX-15 | MX-16 |

|---|

| Interim stiffness ratio | 0.11 | 0.21 | 0.32 | 0.42 | 0.52 | 0.62 | 0.72 | 0.82 |

Figure 20 depicts the load-bearing performances of the specimens.

Figure 20.

Force exerted on the FSMRL wall structures (with hole as variable).

Figure 20.

Force exerted on the FSMRL wall structures (with hole as variable).

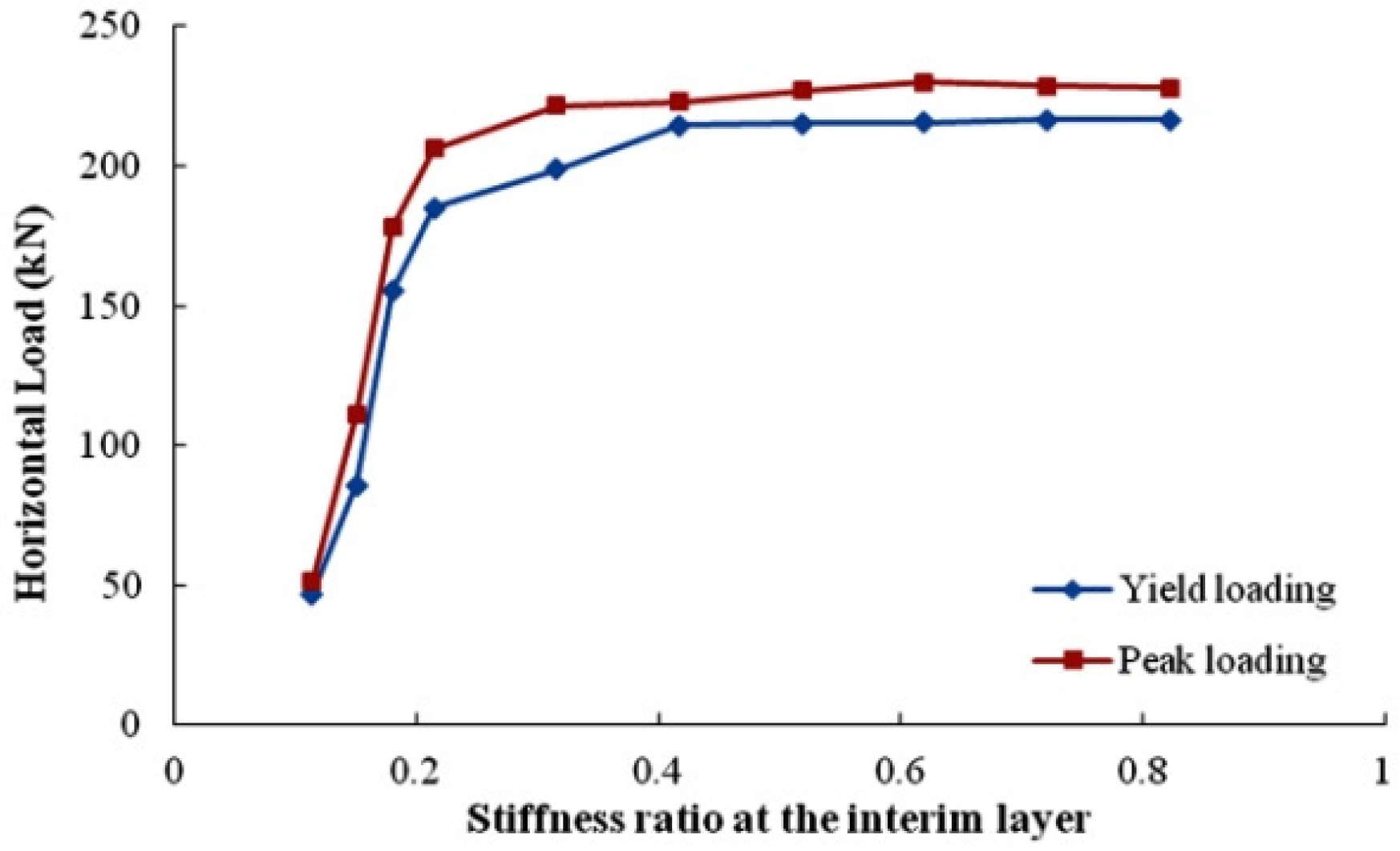

Based on the force-displacement curves listed above, the relation between the yield and peak loading and the interim stiffness ratio are identified for each specimen (see

Figure 21).

Figure 21.

Relation between interim stiffness ratio and load bearing performance.

Figure 21.

Relation between interim stiffness ratio and load bearing performance.

Figure 21 shows that when the stiffness ratio falls below 0.4, the yield and peak loading limit drop at an alarming rate due to the MRL wall’s relatively low stiffness level in lateral force resistance. The premature failure undermines the overall bearing capacity; therefore, an interim stiffness ratio of at least 0.4 must be guaranteed for the structure.