Optimisation of Synchronous Grouting Mix Ratio for Shield Tunnels

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Single Factor Test

2.3. Uniform Test

2.4. Performance Testing

- (1)

- Fluidity, bleeding, and segregation rates

- (2)

- Rheological properties test

2.5. Mix Proportion Optimisation and Verification

3. Results and Discussion

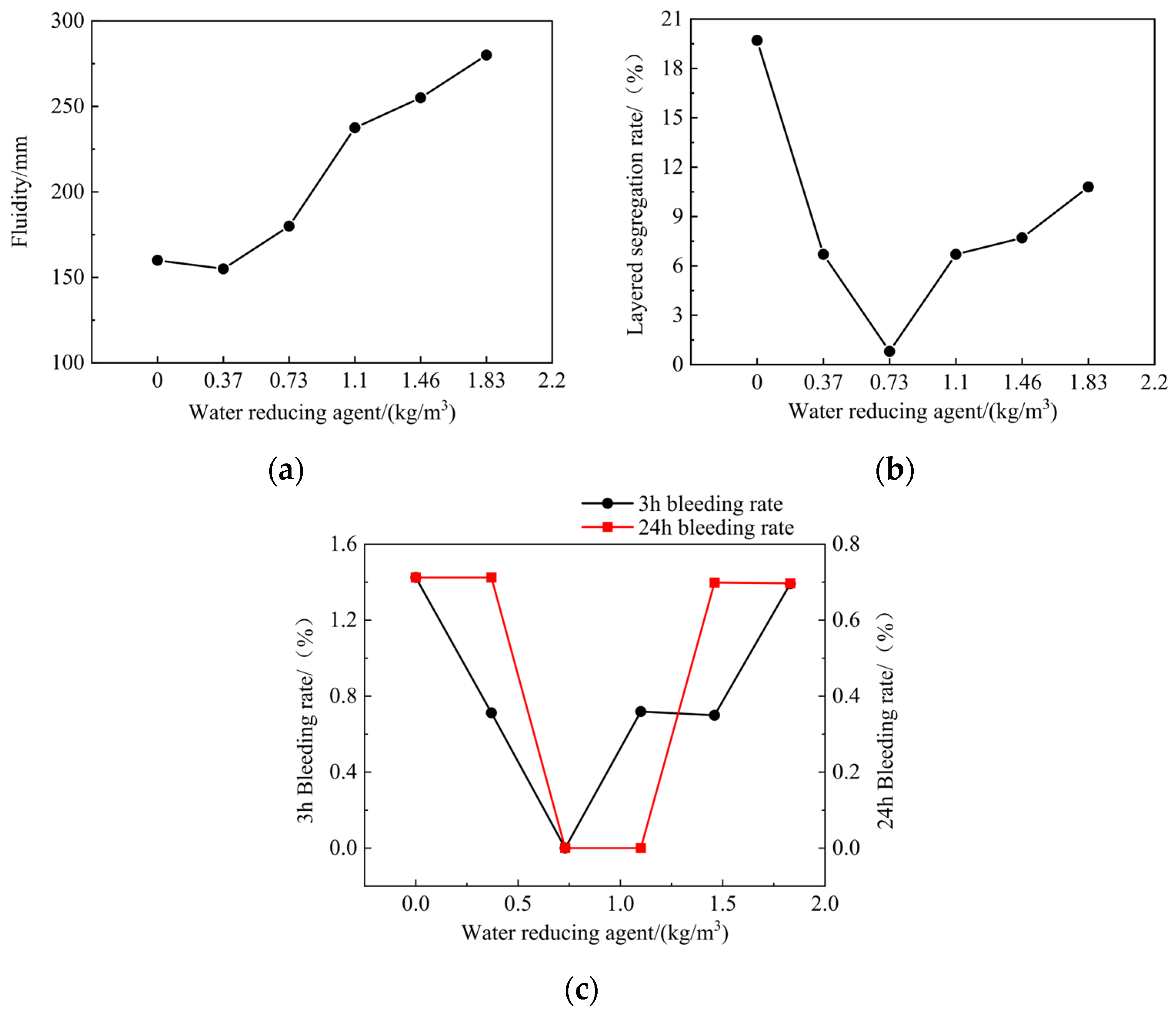

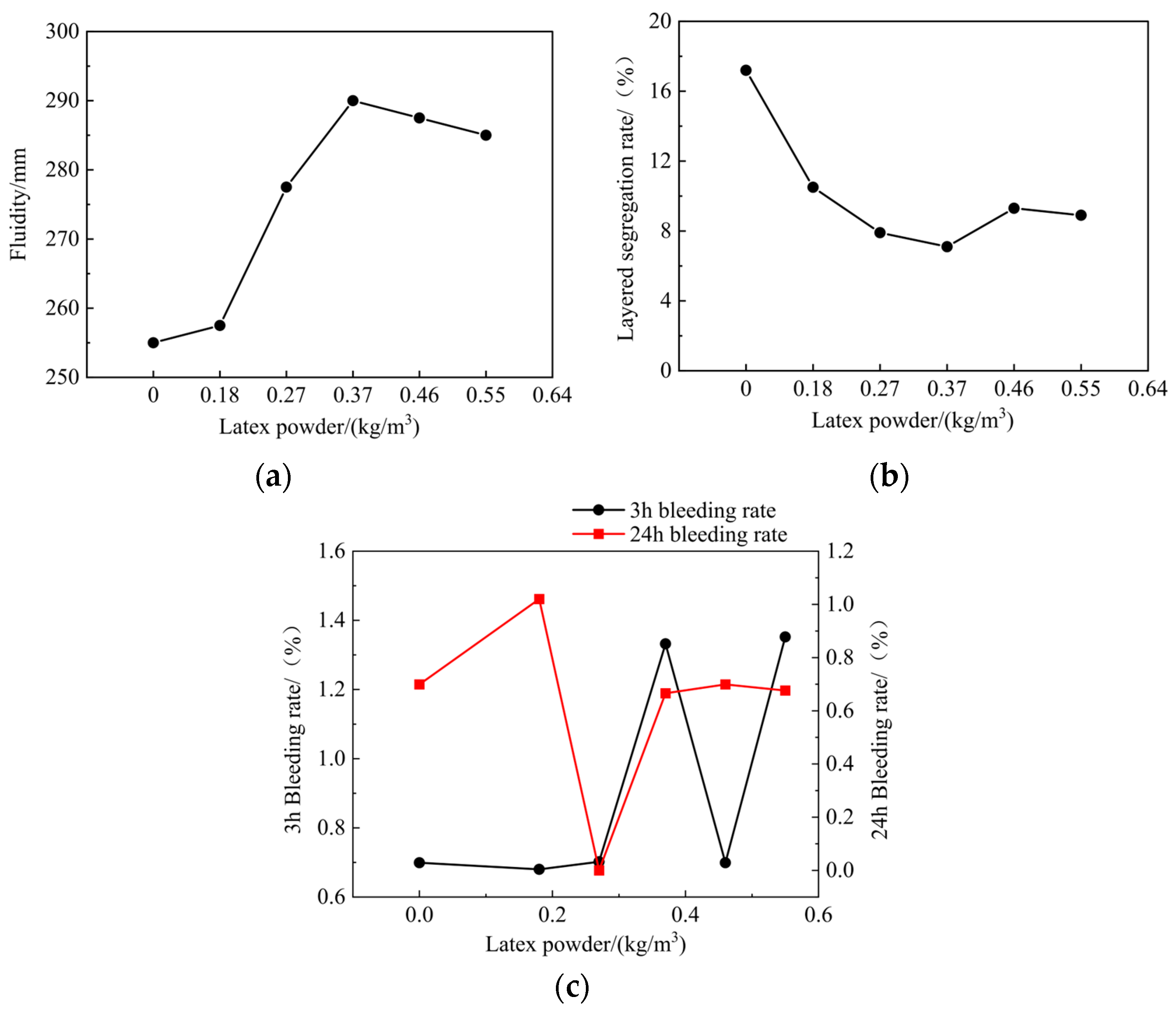

3.1. Single Factor Test

3.2. Uniform Test

3.2.1. Effects of Water–Cement, Bentonite–Water, Cement–Sand, Water Reducer–Cement, and Latex Powder–Cement Ratios on Fluidity, Segregation Rate, and Bleeding Rate

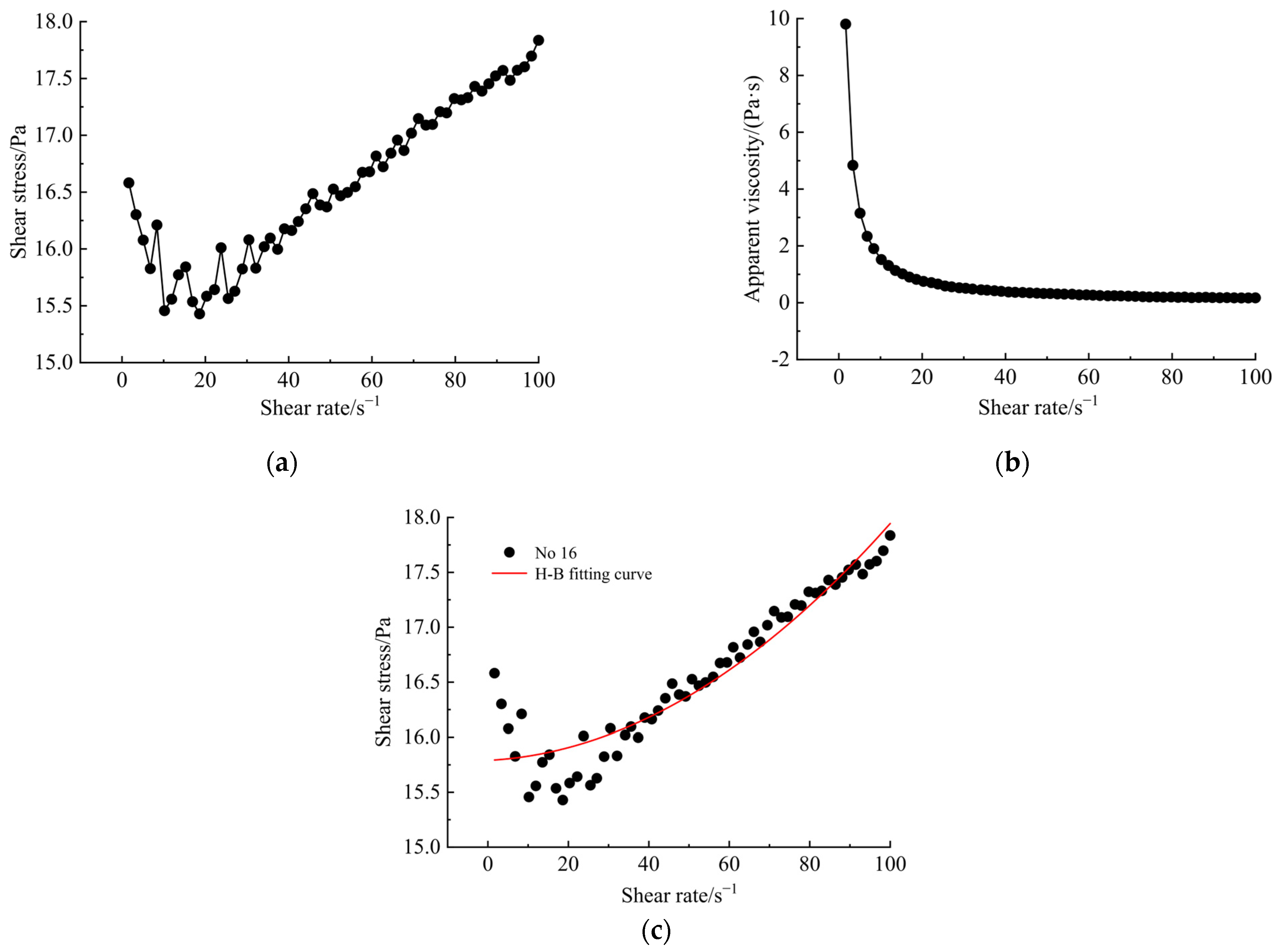

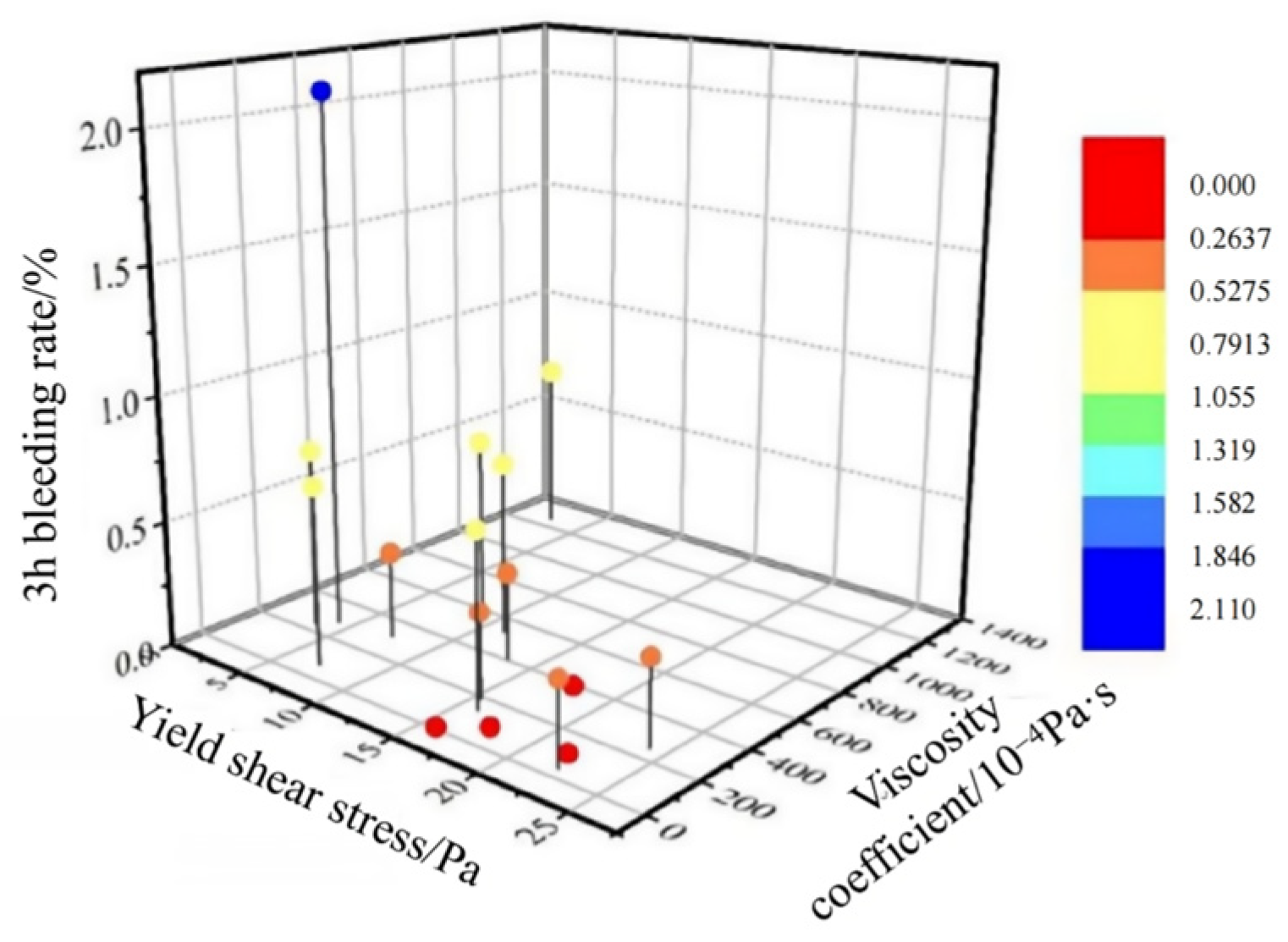

3.2.2. Effect of Slurry Rheology on Bleeding and Segregation Rates

4. Mix Ratio Optimisation

5. Conclusions

- (1)

- As the water-reducing agent dosage increased, the fluidity of the synchronous grouting slurry increased, and the segregation rate first decreased and then increased. When the water-reducing agent dosage was 0.73, the slurry segregation rate was the lowest, and as the latex powder dosage increased, the slurry fluidity first increased and then decreased. The slurry segregation rate was lowest when the latex powder dosage was 0.37.

- (2)

- The rheological behaviour of the synchronous grouting slurry conformed to the H–B model. When the shear rate was lower than 10 s−1, the yield shear stress of the slurry decreased, and the viscosity decreased rapidly as the shear rate increased. When the shear rate was 10 s−1, the shear stress increased linearly as the shear rate increased, and the viscosity was stable. The fitting results indicate that the regression model is highly accurate.

- (3)

- After conducting a multiple linear regression analysis, it was found that the bentonite–water ratio has the greatest impact on the rheological properties of the grouting slurry.

- (4)

- Slurries with a high a yield shear stress and viscosity coefficient were unlikely to bleed, and slurries with a high yield shear stress and low viscosity coefficient were unlikely to segregate. When the yield shear stress τ0 of the slurry was 15 Pa ≤ τ0 < 20 Pa and the viscosity coefficient K was 0 Pa·s ≤ K < 400 × 10−4 Pa·s, the slurry bleeding rate was zero and no bleeding occurred. When the yield shear stress τ0 was 5 Pa ≤ τ0 < 20 Pa and the viscosity coefficient K was 0 Pa·s ≤ K < 200 × 10−4 Pa·s, the segregation rate was less than 0.075% and no segregation occurred.

- (5)

- Through the multi-objective programming optimisation method and MATLAB optimisation toolbox, a mix ratio that meets the required specifications was obtained. The optimised slurry fluidity, 3 h bleeding rate, 24 h bleeding rate, segregation rate, setting time, and 28 d compressive strength were 257.5 mm, 0.71%, 0.36%, 3.1%, 6.7 h, and 2.61 MPa, respectively, which meet the requirements of synchronous grouting slurry for shield tunnels.

- (6)

- The optimised grouting slurry meets the requirements for the synchronous grouting slurry in shield tunnels, effectively preventing soil disturbance and deformation in the surrounding areas of underground construction sites. However, in addition to optimising the slurry properties, improving construction techniques can also enhance the quality of shield tunnel construction. It is recommended to further investigate and establish a more standardised method for synchronous grouting in shield tunnelling.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Z.; Jin, D.; Shi, C. Spatial Variability of Grouting Layer of Shield Tunnel and Its Effect on Ground Settlement. Appl. Sci. 2020, 10, 5002. [Google Scholar] [CrossRef]

- Zhou, Z.; Hu, J.; Liu, Z.; Lu, S. Influence Mechanism of Grout Time-Dependent Behavior for Backfill Grouting of Shield Tunnel on Surrounding Rock Stress and Deformation. China Railw. Sci. 2022, 43, 86–93. [Google Scholar] [CrossRef]

- Xu, Z.; Pan, D.; Li, S.; Zhang, Y.; Bu, Z.; Liu, J. A grouting simulation method for quick-setting slurry in karst conduit: The sequential flow and solidification method. J. Rock Mech. Geotech. Eng. 2022, 14, 423–435. [Google Scholar] [CrossRef]

- Ma, J.; Sun, A.; Jiang, A.; Guo, N.; Liu, X.; Song, J.; Liu, T. Pressure Model Study on Synchronous Grouting in Shield Tunnels Considering the Temporal Variation in Grout Viscosity. Appl. Sci. 2023, 13, 10437. [Google Scholar] [CrossRef]

- Tan, Y.; Qian, Y.; Tan, M. Printability region for 3D concrete printing using slump and slump flow test. Compos. Part B Eng. 2019, 174, 106968. [Google Scholar] [CrossRef]

- Souza, M.T.; Ferreira, I.M.; de Guzi, M.; Senff, L.; de Novaes, O. 3D printed concrete for large-scale buildings: An overview of rheology, printing parameters, chemical admixtures, reinforcements, and economic and environmental prospects. J. Build. Eng. 2020, 32, 101833. [Google Scholar] [CrossRef]

- Kostrzanowska-Siedlarz, A.; Golaszewski, J. Rheological properties and the air content in fresh concrete for self compacting high performance concrete. Constr. Build. Mater. 2015, 94, 555–564. [Google Scholar] [CrossRef]

- Liang, J. Study on the Proportion of Backfill-grouting Materials and Grout Deformation Propertiesof Shield Tunnel. Master’s Thesis, Hohai University, Nanjing, China, 2006. [Google Scholar] [CrossRef]

- Xu, J.; Lin, W.; Xu, K.; Lin, J.; Wang, B.; Miao, Q.; Ding, Q. Study on Rapid-hardening High-performance Simultaneous Grouting Material for Shield-bored Tunnels. Tunn. Constr. 2014, 34, 95–100. [Google Scholar] [CrossRef]

- Li, X.; Yang, Z.; Wang, Y.; Liu, L.; Li, R. Experimental study on the material proportioning and performance of pre-mixed shield mortar. Fly Ash Compr. Util. 2017, 3, 41–44. [Google Scholar] [CrossRef]

- da Motta, C.A.O.; de Souza, J.; Martins, V.; Shaeffer, L.; Rossini, E.G.; Biehl, L.V.; de Jesus Pacheco, D.A.; Martins, C.O.D.; Medeiros, J.L.B. Enhancing composite materials through fly ash reinforcement through powder metallurgy. Mater. Chem. Phys. 2023, 307, 128124. [Google Scholar] [CrossRef]

- Huang, D.; Wang, X.; Xia, Z.; Ruan, L.; Lu, Q.; Wang, S. Experimental Study on the Effects of Fly Ash Content on the Properties of Synchronous Grouting Slurry in Shield Tunneling. Compr. Util. 2019, 8, 74–77. [Google Scholar] [CrossRef]

- Yang, Z.; He, Z.; Liu, Y.; Chen, P.; Li, D. Recycle Application of the Shield Waste Slurry in Backfill Grouting Material: A Case Study of a Slurry Shield Tunnelling in the River-crossing Fuzhou Metro. Mod. Tunn. Technol. 2019, 56, 192–199+205. [Google Scholar] [CrossRef]

- Wang, J.; Song, P.; Tang, J.; Wang, Y.; Ma, Y.; Wang, Q. Study on basic properties of the cementitious simultaneous grouting material in shield engineering. New Build. Mater. 2018, 45, 22–25. [Google Scholar] [CrossRef]

- Wang, S.; Lin, Z.; Peng, X.; Wang, X.; Tu, G.; Song, Z. Research and evaluation on Water-dispersion resistance of synchronous grouting slurry in shield tunnel. Tunn. Undergr. Space Technol. 2022, 129, 104679. [Google Scholar] [CrossRef]

- Duan, P.; Li, S.; Wang, P. Effect of Rice Husk Ash Content on Rheological and Mechanical Properties of Repaired Mortar and Its Mechanism Analysis. Mater. Rep. 2023, 37, 247–253. [Google Scholar]

- Liu, J.; Zhao, W.; Sun, B.; Jiang, T.; Wang, Q. Time-dependent Characteristics of Rheological Properties and Yield Stress Evolution of Grouting Materials. China Civ. Eng. J. 2024, 5, 1–15. [Google Scholar] [CrossRef]

- Zhang, C.; Yu, J.; Kong, X.; Cai, Y. Effect of Chemical Admixtures on Rheological Properties of Mortars. J. Chin. Ceram. Soc. 2020, 48, 622–631. [Google Scholar] [CrossRef]

- Gu, J. Quality Control for Shearing Day Powder Mortar Grouting in Shielding Construction. Constr. Technol. 2018, 2, 13–14+19. [Google Scholar] [CrossRef]

- Abramian, A.; Staron, L.; Lagree, P.-Y. The slumping of a cohesive granular column: Continuum and discrete modeling. J. Rheol. 2020, 64, 1227. [Google Scholar] [CrossRef]

- Liu, Y.; Balmforth, N.J.; Hormozi, S. Axisymmetric viscoplastic dambreaks and the slump test. J. Non-Newton. Fluid Mech. 2018, 258, 45–57. [Google Scholar] [CrossRef]

- Cui, W.; Meng, M.; Song, H. CFD Numerical Simulation of Movement and Static Segregation of Self-compacting Concrete Aggregate. J. Build. Mater. 2021, 24, 39–44. [Google Scholar] [CrossRef]

- Wang, G.; Qu, J.; Wang, B.; Jia, R.; Qu, T. Durability analysis and inspection of Portland cement materials. Guangdong Chem. Ind. 2021, 48, 231–232. [Google Scholar] [CrossRef]

- Shao, Y. Study on the Effect of Different Fe/Al Ratios of Iron Phase on the Sulfate Resistance of Portland Cement. Master’s Thesis, University of Jinan, Jinan, China, 2024. [Google Scholar] [CrossRef]

- Cheng, B.C.; Liu, R.; Li, X.H. Effects of fly and coal bottom ash ratio on backfill material performance. Constr. Build. Mater. 2022, 319, 125831. [Google Scholar] [CrossRef]

- Xue, Y. Study on the performance of fly ash geopolymers made from different grades of fly ash as raw materials. Eng. Constr. 2022, 36, 1147–1149. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, Z.; Meng, E.; Li, Q. Impermeability and Crack Resistance of Bentonite and Basalt Fiber Modified Cement Mortar. Bull. Chin. Ceram. Soc. 2023, 42, 439–447. [Google Scholar] [CrossRef]

- Zhang, Z.; Pang, X. Application of Uniform Design Method in Determination of Silt Stiffness Parameters. Railw. Eng. 2022, 62, 126–130. [Google Scholar] [CrossRef]

- JC/T 986-2018; Cementitious Grout. China Building Materials Industry Press: Beijing, China, 2018.

- JT/T 946-2022; Grouting Material for Prestressed Structure in Highway Engineering. China Communication Press: Beijing, China, 2022.

- JGJ/T 283-2012; Echnical Specification for Application of Self-Compacting Concrete. China Architecture & Building Press: Beijing, China, 2012.

- Kashani, A.; Provis, J.L.; Qiao, G.G.; van Deventer, J.S.J. The interrelationship between surface chemistry and rheology in alkali activated slag paste. Constr. Build. Mater. 2014, 65, 583–591. [Google Scholar] [CrossRef]

- Li, Y.; Du, Q.; Zhang, M. Application of MATLAB Optimization Toolbox in Mechanical Design Optimization. Electron. Technol. Softw. Eng. 2019, 11, 58. [Google Scholar] [CrossRef]

- Wang, S.; Zhu, H.; Wang, B.; Kou, L. Review of the Packing Theory for Optimization Design of Concrete Mix Proportion. Mater. Rep. 2021, 35, 3085–3091. [Google Scholar] [CrossRef]

- Wang, X. Analysis of Energy in RO/PRO Water Desalination Using Constrained Nonlinear Optimization. Master’s Thesis, China University of Petroleum, Qingdao, China, 2019. [Google Scholar] [CrossRef]

- Pang, M.; Ma, H.; Jiang, S.; Li, J. Integrating Frontier Research Achievements into the Innovative Experimental Program Teaching of Undergraduates. Shanxi Datong Univ. J. 2024, 40, 1–6. [Google Scholar]

- Zhang, K.; Pan, L.; LI, J.; Lin, C.; Cao, Y.; Xu, N.; Pang, S. How does adsorption behavior of polycarboxylate superplasticizer effect rheology and flowability of cement paste with polypropylene fiber. Cem. Concr. Compos. 2019, 95, 228. [Google Scholar] [CrossRef]

- Liu, F. Research on Prediction Performance of Self-Compacting Concrete Based on Uitra-Fine Mortar of Work. Master’s Thesis, Wuhan University of Science and Technology, Wuhan, China, 2021. [Google Scholar] [CrossRef]

- Kandemir, G. Effects of Antiwashout Admixtures on Fresh Concrete Properties. Aci Mater. J. 2015, 92, 164–171. [Google Scholar] [CrossRef] [PubMed]

- Cai, Y.; Liu, Q. Research progress on the stability of concrete mixtures and its influence on the durability of engineering structures. J. Xi’an Univ. Archit. Technol. (Nat. Sci. Ed.) 2023, 55, 492–503. [Google Scholar] [CrossRef]

- Q/ZTJHN1-2019; Gelatin Type Dry-Mixed Mortar for Shield-Driving Grouting. China Railway Construction South China Construction Co., Ltd.: Guangzhou, China, 2019.

- Xu, G. Study on Effect of Water-Cement Ratio and Mineral Admixtures, Rubber Powder Addition on Mortar Rheology Performance. Master’s Thesis, Henan University, Kaifeng, China, 2008. [Google Scholar] [CrossRef]

- Zhou, M.; Zhang, W. Effect of additives on perforance of dry-mixed mortar. Comcrete 2007, 6, 71–73. [Google Scholar] [CrossRef]

- Yang, Q.; Jiang, C. Effect of Polymer on Performance of Cement Based Building Sealing Mortar. J. Tongji Univ. (Nat. Sci.) 2016, 44, 107–112. [Google Scholar] [CrossRef]

- Hong, L. The Research on the Mechanisms and Applications of the Redispersible Emulsion Powder Used in the Dry—mixed Mortar. Fujian Archit. Constr. 2013, 24–25, 63. [Google Scholar]

- Chen, Y.; Zhu, Q.; Liu, N.; Yu, J. Preparation and properties of an underwater dispersion resistant repair mortar modified by EVA. New Build. Mater. 2018, 45, 118–121. [Google Scholar] [CrossRef]

- Li, D. Effect of functional materials on the properties of polymer modified waterproof mortar. New Build. Mater. 2023, 50, 107–109+127. [Google Scholar] [CrossRef]

- Zhang, C. Study on Preparation and Properties of Modified Repair Materials for Anticorrosive Formwork—Concrete Interface. Master’s Thesis, Anhui Jianzhu University, Hefei, China, 2023. [Google Scholar] [CrossRef]

- Yang, H.; Wu, W.; Ye, X.; Gui, H.; Zhou, Z. Research on performance of high flowability and ultra-high early strength polymer repairing mortar. New Build. Mater. 2020, 47, 42–45. [Google Scholar] [CrossRef]

- Qi, L.; Li, X.; Jiang, S. Influence of parameters of mix proportion on the properties of high strength repair mortar. Low Temp. Archit. Technol. 2018, 40, 9–10+26. [Google Scholar] [CrossRef]

- Wang, X. Effect of redispersible latex powder on the performance of low-temperature cementing cement slurry. Drill. Fluid Complet. Fluid 2015, 32, 65–67+71+107–108. [Google Scholar] [CrossRef]

- Tan, Z.; Bernal, S.A.; Provis, J.L. Reproducible mini-slump test procedure for measuring the yield stress of cementitious pastes. Mater. Struct. 2017, 50, 235. [Google Scholar] [CrossRef]

- Dai, X.; Aydin, S.; Yardimic, M.Y.; Lesage, K.; de Schutter, G. Influence of water to binder ratio on the rheology and structural Build-up of Alkali-Activated Slag/Fly ash mixtures. Constr. Build. Mater. 2020, 264, 120253. [Google Scholar] [CrossRef]

- Rifaai, Y.; Yahia, A.; Mostafa, A.; Aggoun, S.; Kadri, E.H. Rheology of fly ash-based geopolymer: Effect of NaOH concentration. Constr. Build. Mater. 2019, 223, 583–594. [Google Scholar] [CrossRef]

- Palacios, M.; Alonso, M.M.; Varga, C.; Puertas, F. Influence of the alkaline solution and temperature on the rheology and reactivity of alkali-activated fly ash pastes. Cem. Concr. Compos. 2019, 95, 277–284. [Google Scholar] [CrossRef]

- Liu, P. Study on the Influence of Solid Properties on the Fluidity of Coal mine Filling Slurry. Ph.D. Thesis, China Coal Research Institute, Beijing, China, 2021. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, J.; Li, N.; Meng, J.; Lv, X.; Zhou, S.; Ma, Q.; Wang, C. Formation and viscosity characteristics of cyclopentane hydrate slurry with wax and surfactant. Low-Carbon Chem. Chem. Eng. 2024, 49, 113–123. [Google Scholar] [CrossRef]

- Zhou, C.; Qin, X.; Xu, C. Experimental Study on the Influencing Factors of Working Performance of Gangue-based Slurry. J. Munic. Technol. 2023, 41, 202–206+212. [Google Scholar] [CrossRef]

- Beris, A.N.; Tsamopoulos, J.A.; Armstrong, R.C.; Brown, R.A. Creeping motion of a sphere through a Bingham plastic. J. Fluid Mech. 1985, 158, 219–244. [Google Scholar] [CrossRef]

- Dhonde, H.B. Fresh and Hardened Properties of Self-Consolidating Fiber-Reinforced Concrete. ACI Mater. J. 2007, 104, 491–500. [Google Scholar] [CrossRef]

| Title | SiO2 | Al2O3 | CaO | MgO | SO3 | Fe2O3 | Na2O | K2O | Loss |

|---|---|---|---|---|---|---|---|---|---|

| [%] | [%] | [%] | [%] | [%] | [%] | [%] | [%] | [%] | |

| Cement | 21.44 | 5.85 | 61.28 | 1.25 | 2.01 | 2.75 | — | — | 5.42 |

| Fly ash | 58.12 | 27.93 | 2.72 | 0.64 | 0.83 | 4.85 | 0.13 | 1.31 | 3.47 |

| Bentonite | 72.15 | 13.42 | 2.69 | 2.36 | — | 1.59 | 0.55 | 0.36 | 6.88 |

| No. Test | Cement | Fly Ash | Sand | Bentonite | Water Reducing Agent |

|---|---|---|---|---|---|

| [kg/m3] | [kg/m3] | [kg/m3] | [kg/m3] | [kg/m3] | |

| A1 | 95 | 270 | 570 | 65 | 0.00 |

| A2 | 95 | 270 | 570 | 65 | 0.37 |

| A3 | 95 | 270 | 570 | 65 | 0.73 |

| A4 | 95 | 270 | 570 | 65 | 1.10 |

| A5 | 95 | 270 | 570 | 65 | 1.46 |

| A6 | 95 | 270 | 570 | 65 | 1.83 |

| No. Test | Cement | Fly Ash | Sand | Bentonite | Water Reducing Agent | Latex Powder |

|---|---|---|---|---|---|---|

| [kg/m3] | [kg/m3] | [kg/m3] | [kg/m3] | [kg/m3] | [kg/m3] | |

| B1 | 95 | 270 | 570 | 65 | 1.46 | 0.00 |

| B2 | 95 | 270 | 570 | 65 | 1.46 | 0.18 |

| B3 | 95 | 270 | 570 | 65 | 1.46 | 0.27 |

| B4 | 95 | 270 | 570 | 65 | 1.46 | 0.37 |

| B5 | 95 | 270 | 570 | 65 | 1.46 | 0.46 |

| B6 | 95 | 270 | 570 | 65 | 1.46 | 0.55 |

| No. Test | Ratio of Water to Cementitious Material Content | Ratio of Bentonite to Water Content | Ratio of Cementitious Material to Sand Content | Ratio of Water Reducer to Cementitious Material Content | Ratio of Latex Powder to Cementitious Material Content |

|---|---|---|---|---|---|

| [%] | [%] | [%] | [%] | [%] | |

| 1 | 88 | 20 | 64 | 0.30 | 0.100 |

| 2 | 73 | 20 | 69 | 0.20 | 0.075 |

| 3 | 73 | 25 | 64 | 0.10 | 0.125 |

| 4 | 73 | 30 | 74 | 0.30 | 0.050 |

| 5 | 88 | 35 | 74 | 0.10 | 0.075 |

| 6 | 78 | 35 | 64 | 0.20 | 0.050 |

| 7 | 73 | 35 | 69 | 0.40 | 0.100 |

| 8 | 88 | 25 | 79 | 0.40 | 0.050 |

| 9 | 83 | 25 | 74 | 0.20 | 0.100 |

| 10 | 83 | 30 | 64 | 0.40 | 0.075 |

| 11 | 78 | 25 | 69 | 0.30 | 0.075 |

| 12 | 78 | 30 | 79 | 0.10 | 0.100 |

| 13 | 78 | 20 | 74 | 0.40 | 0.125 |

| 14 | 83 | 20 | 69 | 0.10 | 0.050 |

| 15 | 83 | 35 | 79 | 0.30 | 0.125 |

| 16 | 88 | 30 | 69 | 0.20 | 0.125 |

| No. Test | Diffusion Diameter | Vertical Diffusion Diameter | Fluidity |

|---|---|---|---|

| [mm] | [mm] | [mm] | |

| 1 | 230 | 235 | 232.5 |

| 2 | 100 | 100 | 100.0 |

| 3 | 95 | 95 | 95.0 |

| 4 | 170 | 170 | 170.0 |

| 5 | 95 | 95 | 95.0 |

| 6 | 90 | 90 | 90.0 |

| 7 | 95 | 100 | 97.5 |

| 8 | 255 | 260 | 257.5 |

| 9 | 235 | 235 | 235 |

| 10 | 105 | 110 | 107.5 |

| 11 | 110 | 120 | 115.0 |

| 12 | 105 | 110 | 107.5 |

| 13 | 190 | 195 | 192.5 |

| 14 | 165 | 165 | 165.0 |

| 15 | 100 | 100 | 100.0 |

| 16 | 115 | 115 | 115.0 |

| No. Test | Dry Weight of Upper Aggregate | Dry Weight of Middle Aggregate | Dry Weight of Lower Aggregate | Layered Segregation Rate |

|---|---|---|---|---|

| [g] | [g] | [g] | [%] | |

| 1 | 840.6 | 850.4 | 886.3 | 1.1 |

| 2 | 848.7 | 912.6 | 920.7 | 7.1 |

| 3 | 834.0 | 945.6 | 941.7 | 12.3 |

| 4 | 786.3 | 853.7 | 854.4 | 8.1 |

| 5 | 763.4 | 769.1 | 779.9 | 0.7 |

| 6 | 849.1 | 901.0 | 893.4 | 5.9 |

| 7 | 853.4 | 868.0 | 879.9 | 1.7 |

| 8 | 730.5 | 749.6 | 749.5 | 2.6 |

| 9 | 804.2 | 811.9 | 819.2 | 0.9 |

| 10 | 884.0 | 886.6 | 875.4 | 0.3 |

| 11 | 865.1 | 861.4 | 888.1 | −0.4 |

| 12 | 799.6 | 798.6 | 802.9 | −0.1 |

| 13 | 815.1 | 822.4 | 845.9 | 0.9 |

| 14 | 864.3 | 848.0 | 858.1 | −1.9 |

| 15 | 702.7 | 807.5 | 759.7 | 13.9 |

| 16 | 817.5 | 813.0 | 795.3 | −0.6 |

| No. Test | Initial Pulp Surface | 3 h Bleeding Surface | 3 h Expansion Surface | 24 h Bleeding Surface | 24 h Expansion Surface | 3 h Bleeding Rate | 24 h Bleeding Rate |

|---|---|---|---|---|---|---|---|

| [mm] | [mm] | [mm] | [mm] | [mm] | [%] | [%] | |

| 1 | 284 | 286 | 282 | 286 | 276 | 280 | 278 |

| 2 | 282 | 296 | 284 | 296 | 282 | 294 | 282 |

| 3 | 296 | 298 | 298 | 298 | 296 | 298 | 296 |

| 4 | 284 | 292 | 284 | 292 | 284 | 292 | 284 |

| 5 | 290 | 292 | 288 | 294 | 286 | 292 | 288 |

| 6 | 280 | 280 | 280 | 280 | 280 | 280 | 280 |

| 7 | 294 | 332 | 294 | 332 | 292 | 332 | 294 |

| 8 | 276 | 282 | 276 | 280 | 274 | 278 | 276 |

| 9 | 280 | 290 | 280 | 290 | 280 | 288 | 280 |

| 10 | 288 | 304 | 290 | 304 | 288 | 304 | 288 |

| 11 | 282 | 296 | 282 | 296 | 280 | 294 | 280 |

| 12 | 296 | 300 | 296 | 300 | 296 | 300 | 296 |

| 13 | 284 | 290 | 286 | 292 | 284 | 290 | 284 |

| 14 | 282 | 282 | 282 | 282 | 280 | 280 | 280 |

| 15 | 292 | 302 | 292 | 302 | 292 | 300 | 292 |

| 16 | 286 | 302 | 286 | 302 | 286 | 302 | 286 |

| No. Test | Bingham | M–B | H–B | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| τ0 | η0 | R2 | τ0 | η0 | c | R2 | τ0 | K | n | R2 | |

| [Pa] | [×10−4 Pa·s] | [Pa] | [×10−4 Pa·s] | [×10−5] | [Pa] | [×10−4 Pa·s] | |||||

| 1 | 4.18 | 155.30 | 0.97163 | 4.11 | 197.40 | −4.14 | 0.97589 | 4.11 | 287.10 | 0.87 | 0.97331 |

| 2 | 8.20 | 388.50 | 0.97377 | 8.07 | 464.40 | −7.36 | 0.97557 | 8.10 | 622.40 | 0.90 | 0.97450 |

| 3 | 15.07 | 475.40 | 0.96384 | 15.21 | 394.00 | 8.00 | 0.96508 | 15.32 | 190.50 | 1.19 | 0.96751 |

| 4 | 17.58 | 530.30 | 0.98770 | 17.61 | 510.90 | 1.91 | 0.98757 | 17.67 | 393.30 | 1.06 | 0.98812 |

| 5 | 15.81 | 337.60 | 0.95364 | 15.91 | 281.50 | 5.52 | 0.95457 | 16.00 | 139.10 | 1.19 | 0.95679 |

| 6 | 21.16 | 604.20 | 0.92924 | 21.56 | 368.70 | 23.16 | 0.93740 | 21.71 | 110.00 | 1.36 | 0.94267 |

| 7 | 23.50 | 838.10 | 0.97218 | 23.86 | 628.60 | 20.60 | 0.97574 | 24.08 | 257.00 | 1.25 | 0.97767 |

| 8 | 3.31 | 210.30 | 0.96393 | 3.28 | 230.60 | −2.00 | 0.96388 | 3.41 | 239.80 | 0.93 | 0.96366 |

| 9 | 8.29 | 204.30 | 0.98397 | 8.26 | 221.10 | −1.66 | 0.98413 | 7.34 | 315.40 | 0.98 | 0.98382 |

| 10 | 13.25 | 553.10 | 0.98300 | 13.27 | 542.60 | 1.03 | 0.98272 | 13.36 | 408.80 | 1.06 | 0.98318 |

| 11 | 11.18 | 442.70 | 0.98103 | 11.08 | 504.20 | −6.05 | 0.98195 | 11.13 | 530.10 | 0.95 | 0.98094 |

| 12 | 18.28 | 258.20 | 0.97408 | 18.41 | 182.10 | 7.48 | 0.97926 | 17.54 | 92.40 | 1.28 | 0.98196 |

| 13 | 3.02 | 229.30 | 0.97944 | 2.84 | 334.40 | −10.34 | 0.99281 | 2.59 | 1264.80 | 0.66 | 0.99424 |

| 14 | 6.97 | 188.60 | 0.97535 | 7.04 | 145.50 | 4.24 | 0.97831 | 7.09 | 67.10 | 1.22 | 0.98006 |

| 15 | 21.96 | 347.80 | 0.88915 | 22.29 | 157.20 | 18.75 | 0.90503 | 22.34 | 38.70 | 1.47 | 0.91153 |

| 16 | 15.45 | 218.70 | 0.85224 | 15.79 | 18.70 | 19.67 | 0.89730 | 15.76 | 7.47 | 1.73 | 0.90098 |

| Ratio of Water to Cementitious Material Content | Ratio of Bentonite to Water Content | Ratio of Cementitious Material to Sand Content | Ratio of Water Reducer to Cementitious Material Content | Ratio of Latex Powder to Cementitious Material Content |

|---|---|---|---|---|

| [%] | [%] | [%] | [%] | [%] |

| 75 | 18 | 63 | 0.30 | 0.05 |

| Cement | FLY ASH | Sand | Bentonite | Water | Water Reducing Agent | Latex Powder |

|---|---|---|---|---|---|---|

| [kg/m3] | [kg/m3] | [kg/m3] | [kg/m3] | [kg/m3] | [kg/m3] | [kg/m3] |

| 143.490 | 407.510 | 874.610 | 74.390 | 413.250 | 1.653 | 0.276 |

| Fluidity | 3 h Bleeding Rate | 24 h Bleeding Rate | Segregation Rate | Setting Time | 28 d Strength |

|---|---|---|---|---|---|

| [mm] | [%] | [%] | [%] | [h] | [MPa] |

| 257.50 | 0.71 | 0.36 | 3.1 | 6.70 | 2.61 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, H.; Zhang, Y.; Zhu, W.; Zhong, Q.; Huang, X. Optimisation of Synchronous Grouting Mix Ratio for Shield Tunnels. Appl. Sci. 2024, 14, 4098. https://doi.org/10.3390/app14104098

Zhou H, Zhang Y, Zhu W, Zhong Q, Huang X. Optimisation of Synchronous Grouting Mix Ratio for Shield Tunnels. Applied Sciences. 2024; 14(10):4098. https://doi.org/10.3390/app14104098

Chicago/Turabian StyleZhou, Hongmei, Yixiang Zhang, Wanxu Zhu, Qingyu Zhong, and Xinyu Huang. 2024. "Optimisation of Synchronous Grouting Mix Ratio for Shield Tunnels" Applied Sciences 14, no. 10: 4098. https://doi.org/10.3390/app14104098