Theoretical Exposure Dose Modeling and Phase Modulation to Pattern a VLS Plane Grating with Variable-Period Scanning Beam Interference Lithography

Abstract

:1. Introduction

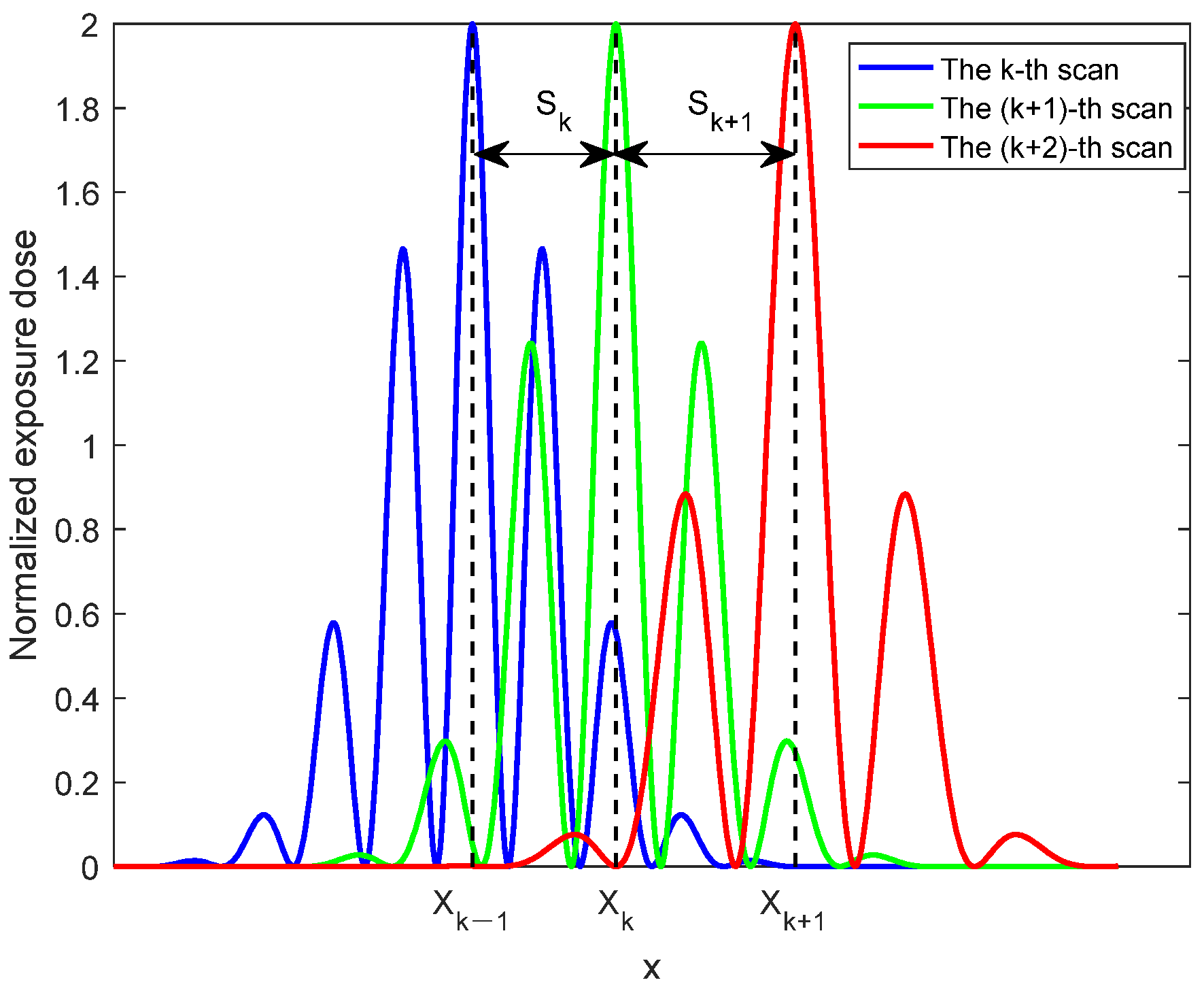

2. Model of the Total Exposure Dose for VLS Grating Patterning

3. Phase Modulation Effects of the Parameters and Parameter Selection

3.1. General Parameters and Numerical Calculation

3.2. Phase Modulation Effects of the Parameters

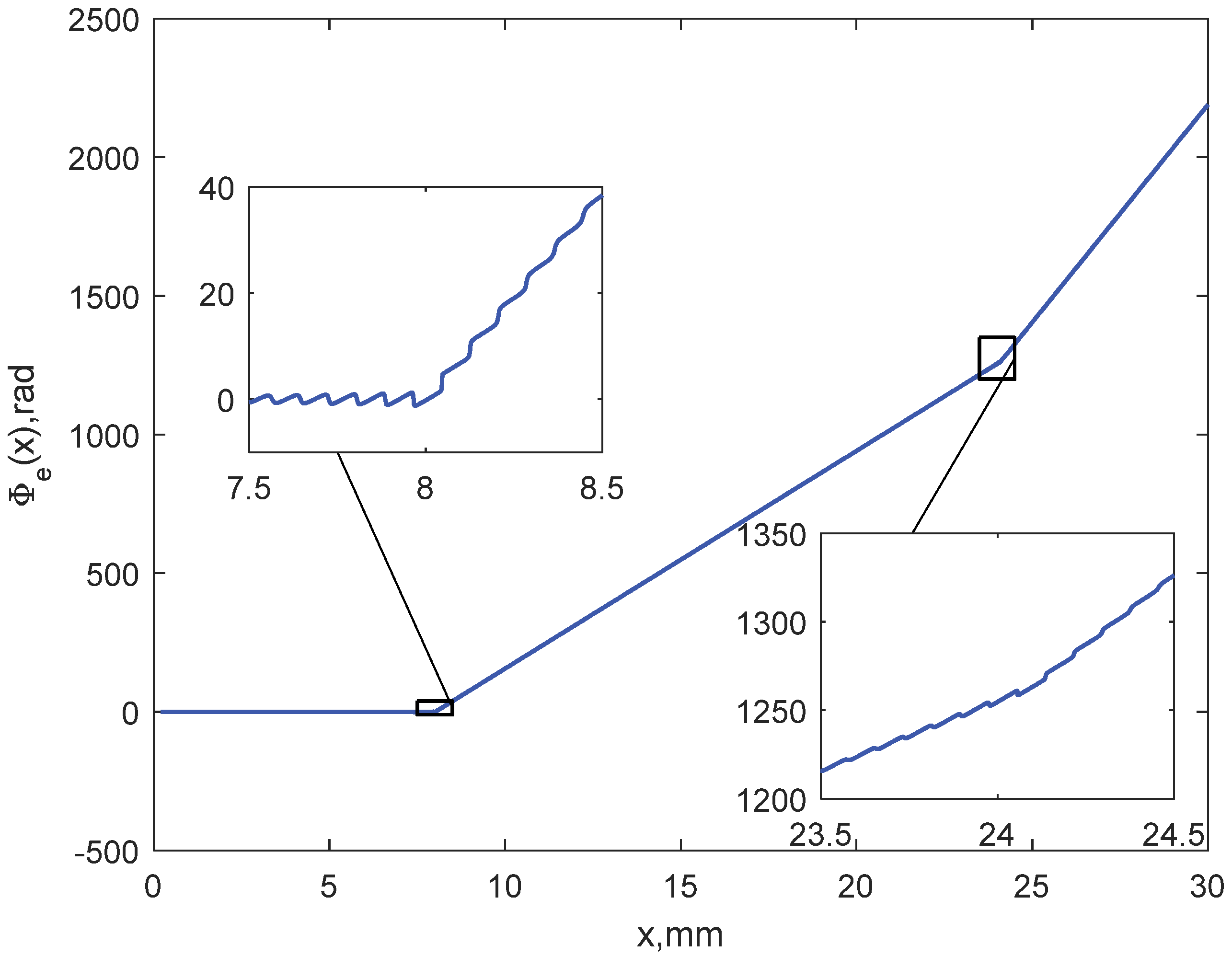

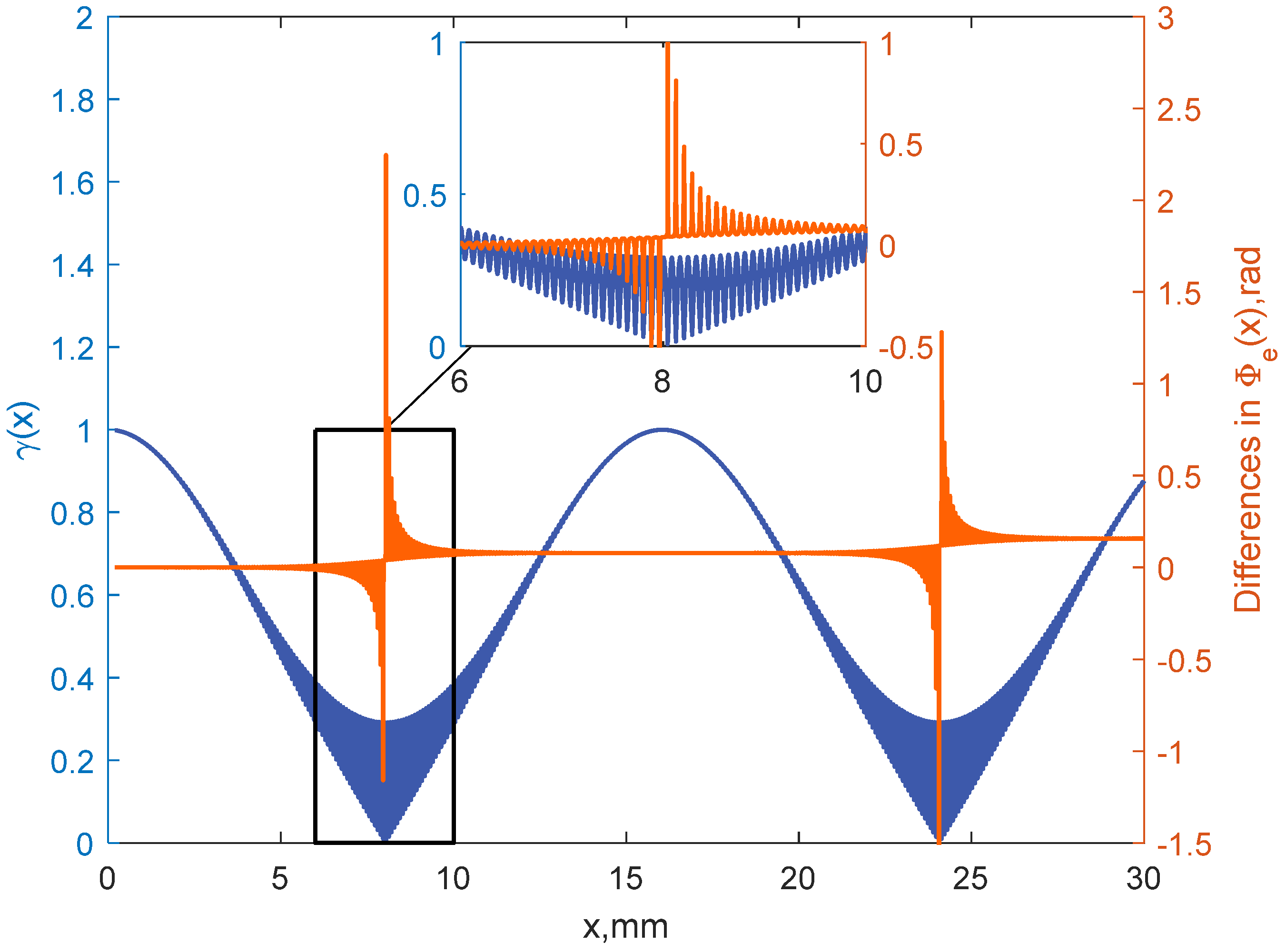

3.2.1. Phase Modulation by Varying Only δk

- Intuitively varying δk according to Фg(x)

- 2.

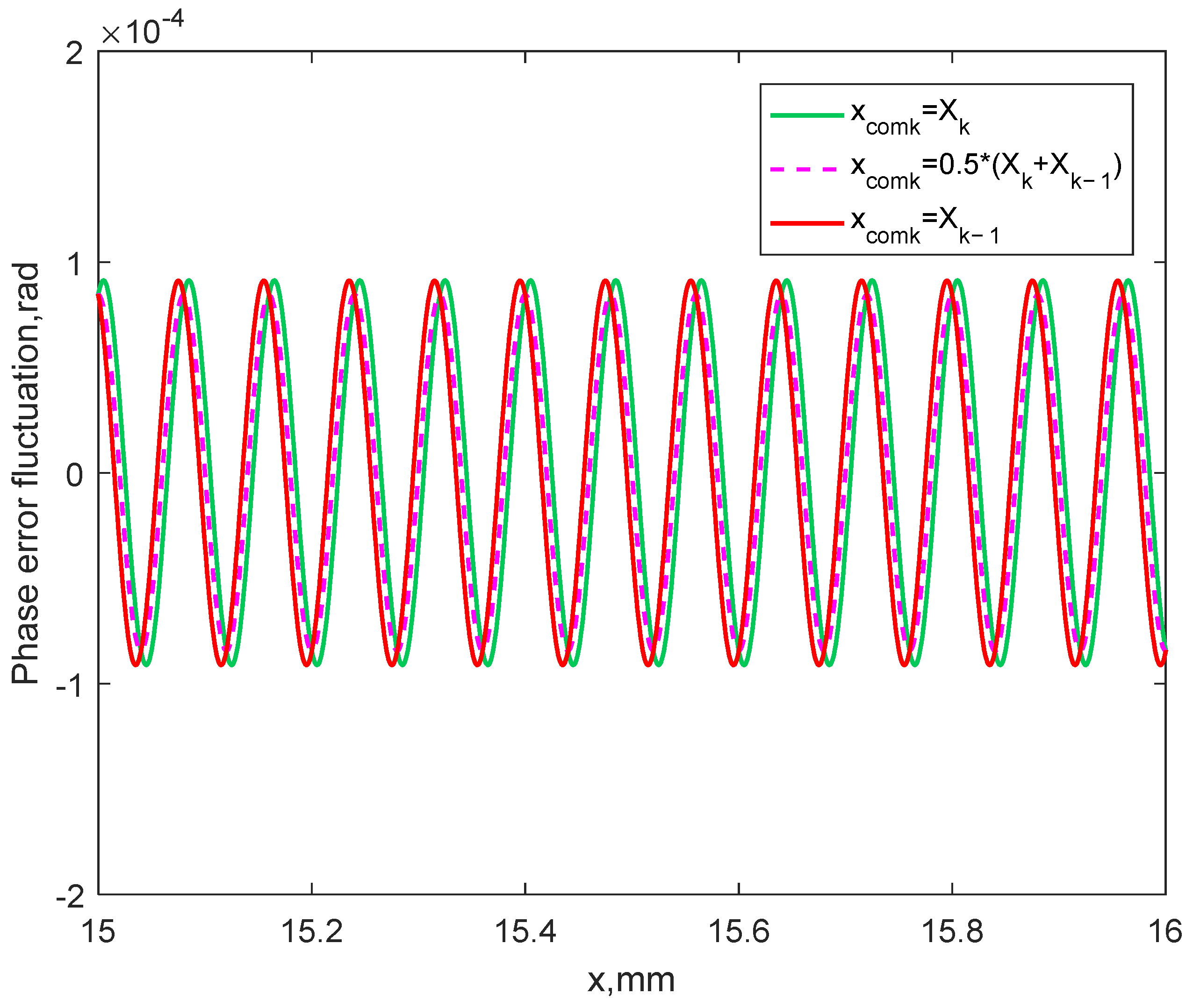

- Phase modulation effect by only varying δk according to Xk

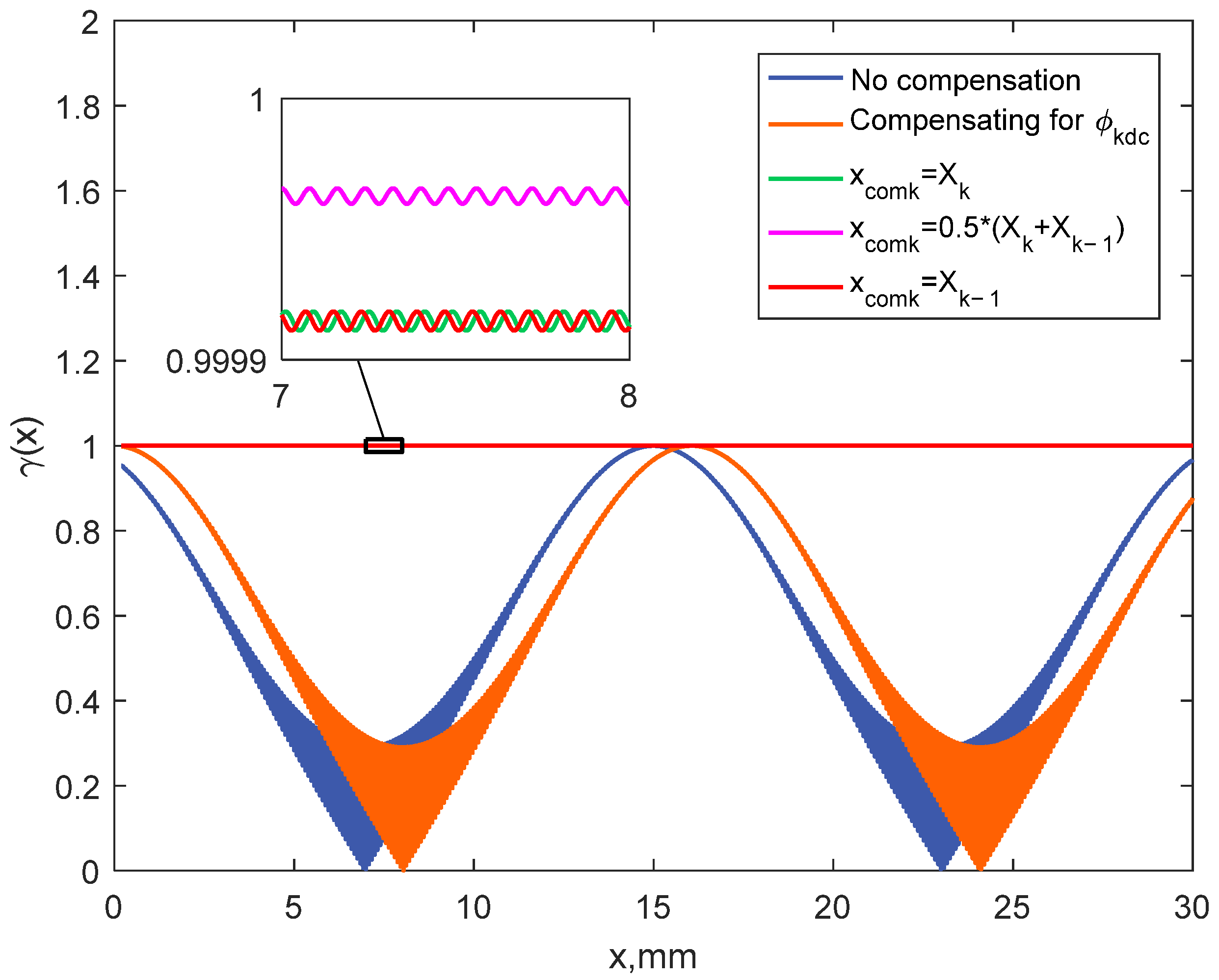

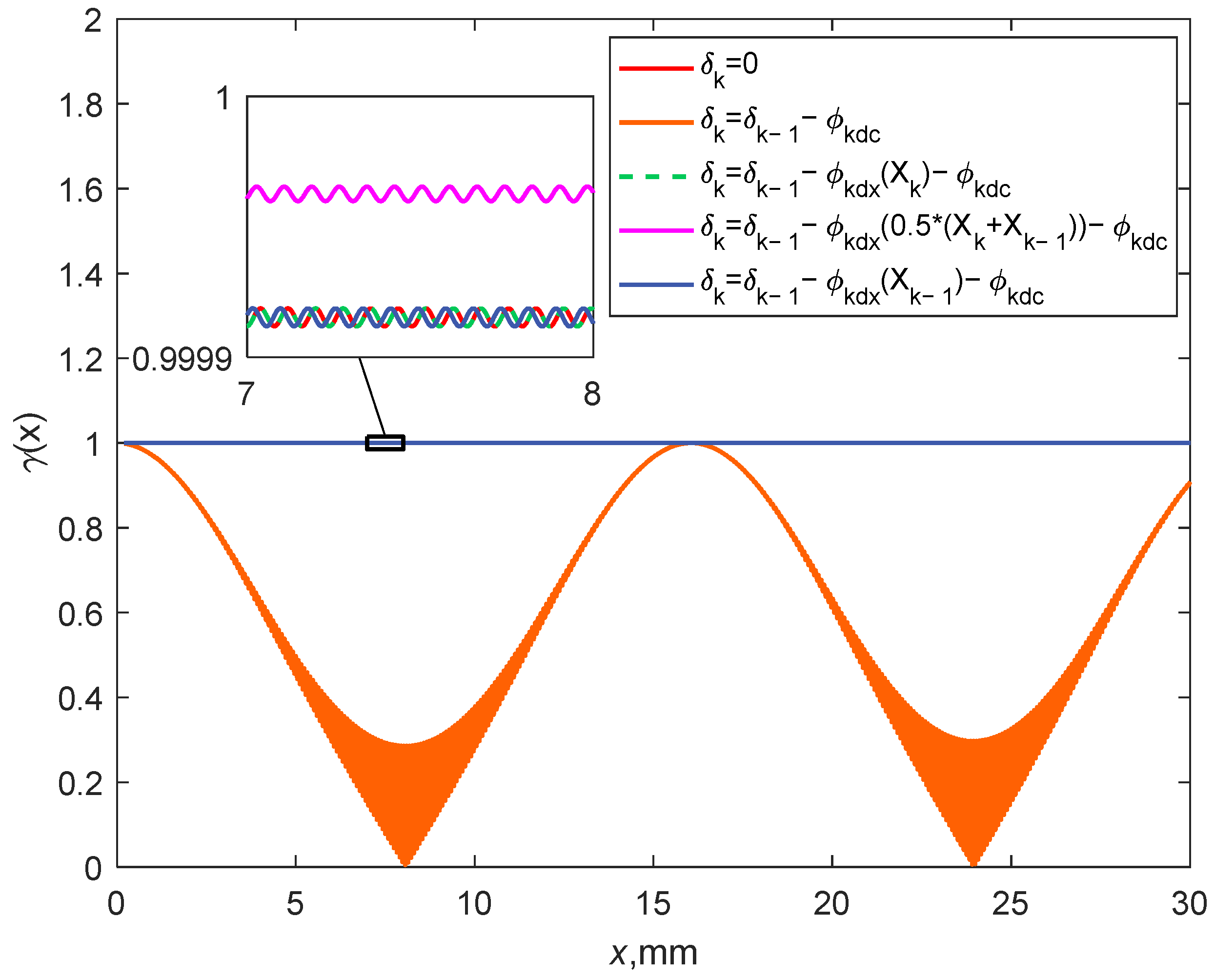

3.2.2. Phase Modulation by Varying fk and δk

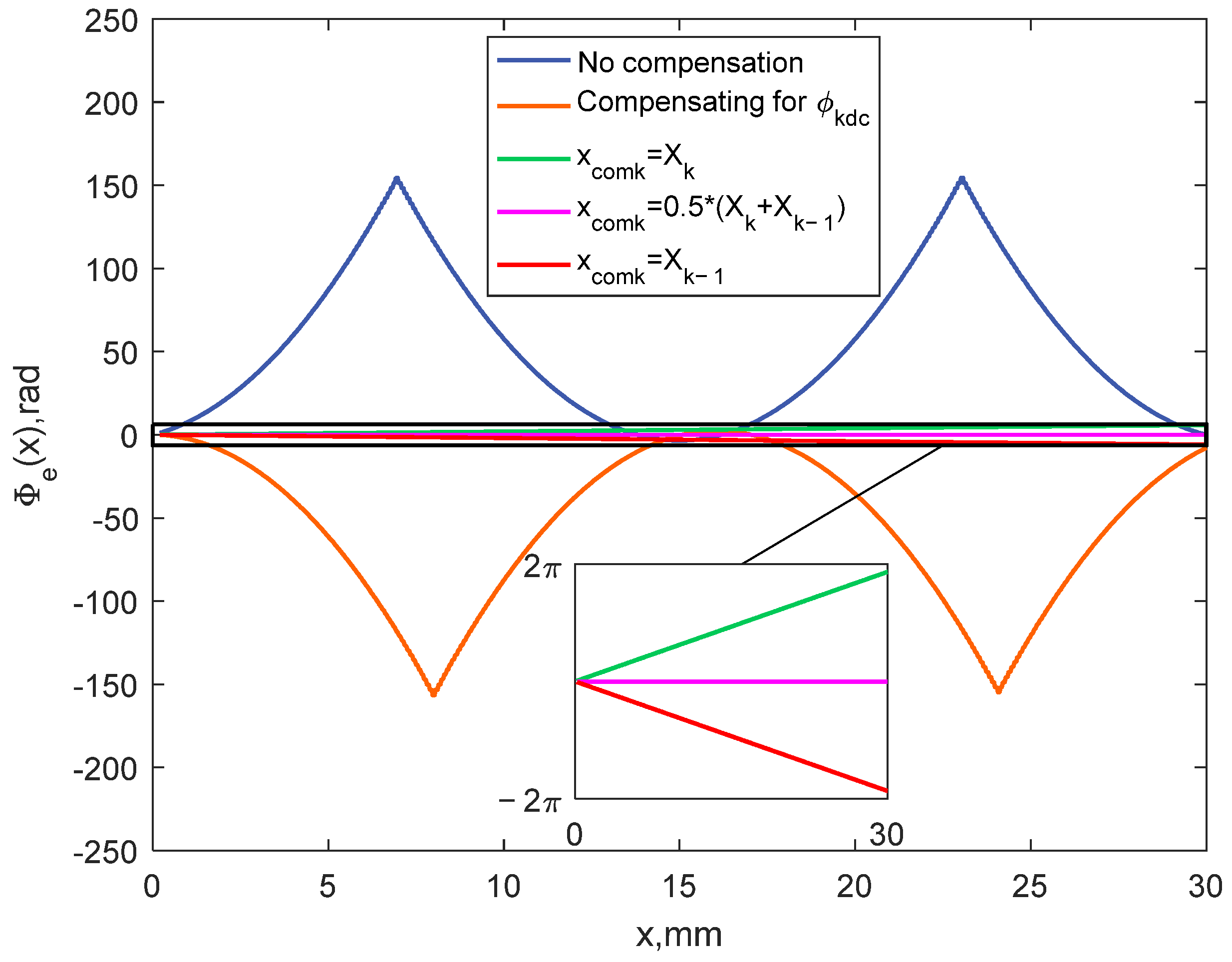

3.2.3. Phase Modulation by Varying fk, Sk and δk

3.3. Parameter Selection for Phase Modulation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- He, W.; Zhang, W.; Meng, F.; Zhu, L. Electron beam lithography inscribed varied-line-spacing and uniform integrated reflective plane grating fabricated through line-by-line method. Opt. Laser Eng. 2021, 138, 106456. [Google Scholar] [CrossRef]

- Voronov, D.L.; Warwick, T.; Gullikson, E.M.; Salmassi, F.; Naulleau, P.; Artemiev, N.A.; Lum, P.; Padmore, H.A. Variable line spacing diffraction grating fabricated by direct write lithography for synchrotron beamline applications. Proc. SPIE 2014, 9207, 920706. [Google Scholar]

- Reininger, R.; de Castro, A.R.B. High resolution, large spectral range, in variable-included-angle soft X-ray monochromators using a plane VLS grating. Nucl. Instrum. Methods Phys. Res. A 2005, 538, 760–770. [Google Scholar] [CrossRef]

- Pu, T.; Cao, F.; Liu, Z.; Xie, C. Deep learning for the design and characterization of high efficiency self-focusing grating. Opt. Commun. 2022, 510, 127951. [Google Scholar] [CrossRef]

- Vannoni, M.; Martin, I.F. Absolute, high-accuracy characterization of a variable line spacing grating for the European XFEL soft X-ray monochromator. Opt. Express 2017, 25, 26519. [Google Scholar] [CrossRef] [PubMed]

- Shimizu, Y.; Ishizuka, R.; Mano, K.; Kanda, Y.; Matsukuma, H.; Gao, W. An absolute surface encoder with a planar scale of variable periods. Precis. Eng. 2021, 67, 36–47. [Google Scholar] [CrossRef]

- Koike, M.; Namioka, T. Plane grating for high-resolution grazing-incidence monochromators: Holographic grating versus mechanically ruled varied-line-spacing grating. Appl. Opt. 1997, 36, 6308–6318. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y. The Research on Design Methods and Fabricating Technology of Varied Line-Space Holographic Plane Grating. Ph.D. Thesis, Chinese Academy of Sciences, Beijing China, 2015. [Google Scholar]

- Wang, K.; Zheng, J.; Liu, Y.; Gao, H.; Zhuang, S. Electrically tunable two-dimensional holographic polymer-dispersed liquid crystal grating with variable period. Opt. Commun. 2017, 392, 128–134. [Google Scholar] [CrossRef]

- Schattenburg, M.L.; Chang, C.H.; Heilmann, R.K.; Montoya, J.; Zhao, Y. Advanced interference lithography for Nanomanufacturing. Int. Soc. Nanomanufacturing 2006, 44, 441–445. [Google Scholar]

- Schattenburg, M.L.; Chen, C.G.; Heilmann, R.K.; Konkola, P.T.; Pati, G.S. Progress towards a general grating patterning technology using phase-locked scanning beams. Proc. SPIE 2002, 4485, 378–384. [Google Scholar]

- Pati, G.S.; Heilmann, R.K.; Konkola, P.T.; Joo, C.; Chen, C.G.; Murphy, E.; Schattenburg, M.L. Generalized scanning beam interference lithography system for patterning gratings with variable period progressions. J. Vac. Sci. Technol. B 2002, 20, 2617–2621. [Google Scholar] [CrossRef] [Green Version]

- Song, Y.; Liu, Y.; Jiang, S.; Zhu, Y.; Zhang, L.; Liu, Z. Method for exposure dose monitoring and control in scanning beam interference lithography. Appl. Opt. 2021, 60, 2767–2774. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Yang, H.; Li, Y.; Jiang, S.; Wang, W.; Song, Y.; Bayanheshig; Li, W. Active control technology of a diffraction grating wavefront by scanning beam interference lithography. Opt. Express 2021, 29, 37066. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.; Lü, B.; Song, Y.; Liu, Z.; Wang, W.; Li, S.; Bayanheshig. Heterodyne period measurement in a scanning beam interference lithography system. Appl. Opt. 2020, 59, 5830–5836. [Google Scholar] [CrossRef] [PubMed]

- Heilmann, R.K.; Konkola, P.T.; Chen, C.G.; Pati, G.S.; Schattenburg, M.L. Digital heterodyne interference fringe control system. J. Vac. Sci. Technol. B. 2001, 19, 2342–2346. [Google Scholar] [CrossRef] [Green Version]

- Montoya, J. Toward Nano-Accuracy in Scanning Beam Interference Lithography. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2006. [Google Scholar]

- Chen, C.G. Beam Alignment and Image Metrology for Scanning Beam Interference Lithography: Fabricating Gratings with Nanometer Phase Accuracy. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2003. [Google Scholar]

- Konkola, P.T. Design and Analysis of a Scanning Beam Interference Lithography System for Patterning Gratings with Nanometer-Level Distortions. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2003. [Google Scholar]

- Li, C. Variable-Line-Spacing Grating Monochromators Design and Key Techniques. Ph.D. Thesis, University of Science and Technology of China, Hefei, China, 2014. [Google Scholar]

- Jiang, S.; Bayanheshig; Li, W.; Song, Y.; Pan, M. Effect of period setting value on printed phase in scanning beam interference lithography system. Acta Opt. Sin. 2014, 34, 0905003. [Google Scholar] [CrossRef]

- Dill, F.H.; Hornberger, W.P.; Hauge, P.S.; Shaw, J.M. Characterization of positive photoresist. IEEE Trans. Electron Devices 1975, 22, 445–452. [Google Scholar] [CrossRef]

- Han, J.; Bayanheshig; Li, W.; Kong, P. Profile evolution of grating masks according to exposure dose and interference fringe contrast in the fabrication of holographic grating. Acta Opt. Sin. 2012, 32, 0305001. [Google Scholar] [CrossRef]

- Jiang, Y.; Bayanheshig; Yang, S.; Zhao, X.; Wu, N.; Li, W. Study on the effects and compensation effect of recording parameters error on imaging performance of holographic grating in on-line spectral diagnose. Spectrosc. Spectr. Anal. 2016, 36, 857–863. [Google Scholar]

| xcomk | gp(x) Coefficients | Relative Errors of gp(x) Coefficients | ||

|---|---|---|---|---|

| ngp0, L/mm | ngp1, L/mm2 | ε(ng0) = |ngp0 − ng0|/ng0 | ε(ng1) = |ngp1 − ng1|/ng1 | |

| Xk | 1200.0311 | −0.7783 | 2.5943 × 10−5 | <1 × 10−8 |

| (Xk + Xk−1)/2 | 1200.0000 | −0.7783 | <1 × 10−8 | <1 × 10−8 |

| Xk−1 | 1199.9689 | −0.7783 | −2.5943 × 10−5 | <1 × 10−8 |

| xcomk | gp(x) Coefficients | Relative Errors of gp(x) Coefficients | ||

|---|---|---|---|---|

| ngp0, L/mm | ngp1, L/mm2 | ε(ng0) | ε(ng1) | |

| Xk | 1200.0311 | −0.7783 | 2.5943 × 10−5 | −2.5946 × 10−5 |

| (Xk + Xk−1)/2 | 1200.0000 | −0.7783 | <1 × 10−8 | <1 × 10−8 |

| Xk−1 | 1199.9689 | −0.7783 | −2.5943 × 10−5 | 2.5946 × 10−5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Y.; Zhang, N.; Liu, Y.; Zhang, L.; Liu, Z. Theoretical Exposure Dose Modeling and Phase Modulation to Pattern a VLS Plane Grating with Variable-Period Scanning Beam Interference Lithography. Appl. Sci. 2022, 12, 7946. https://doi.org/10.3390/app12157946

Song Y, Zhang N, Liu Y, Zhang L, Liu Z. Theoretical Exposure Dose Modeling and Phase Modulation to Pattern a VLS Plane Grating with Variable-Period Scanning Beam Interference Lithography. Applied Sciences. 2022; 12(15):7946. https://doi.org/10.3390/app12157946

Chicago/Turabian StyleSong, Ying, Ning Zhang, Yujuan Liu, Liu Zhang, and Zhaowu Liu. 2022. "Theoretical Exposure Dose Modeling and Phase Modulation to Pattern a VLS Plane Grating with Variable-Period Scanning Beam Interference Lithography" Applied Sciences 12, no. 15: 7946. https://doi.org/10.3390/app12157946