Experimental Study on Electrical Resistivity Characteristics of Saturated Sand Mixes with Bentonite Slurry

Abstract

:1. Introduction

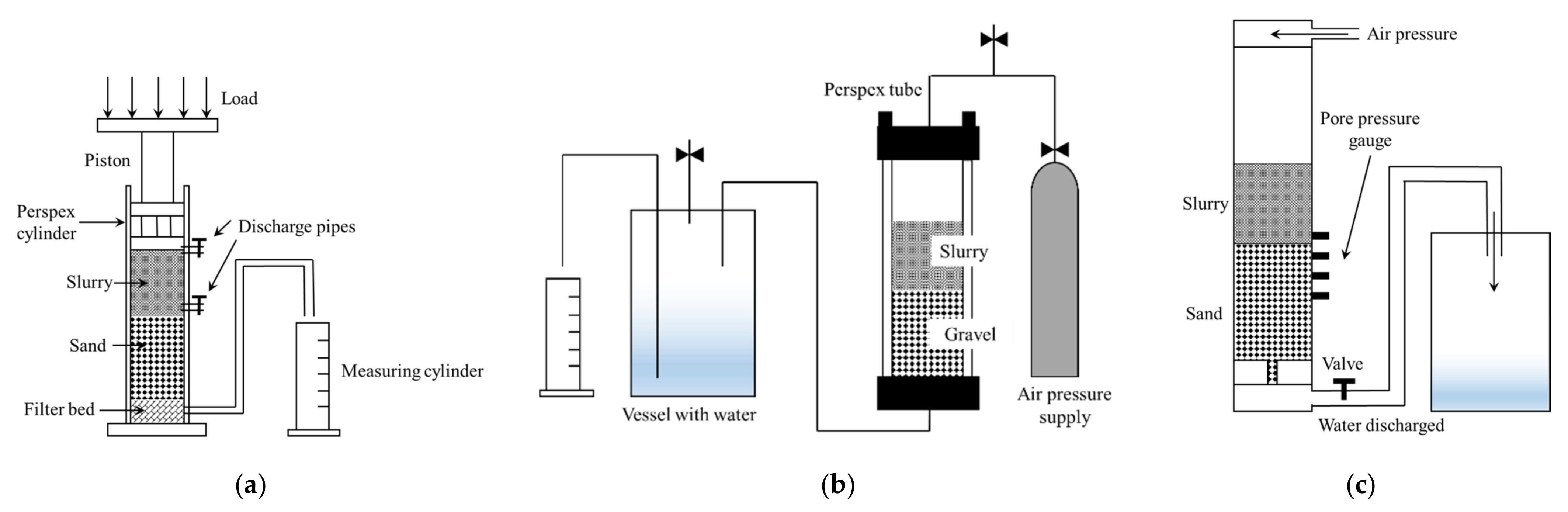

2. Slurry Penetration Mechanism and Test

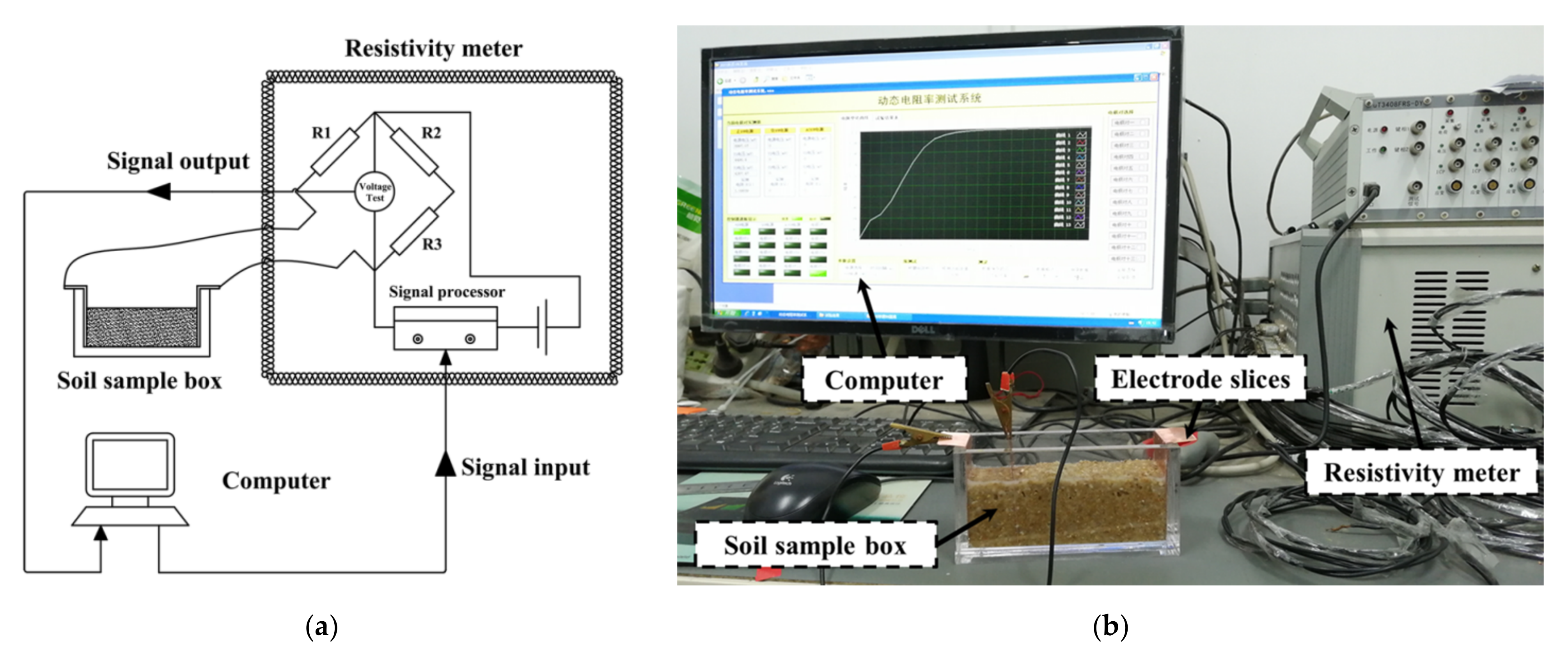

3. Experimental Principle and Apparatus

4. Materials and Method

4.1. Raw Materials

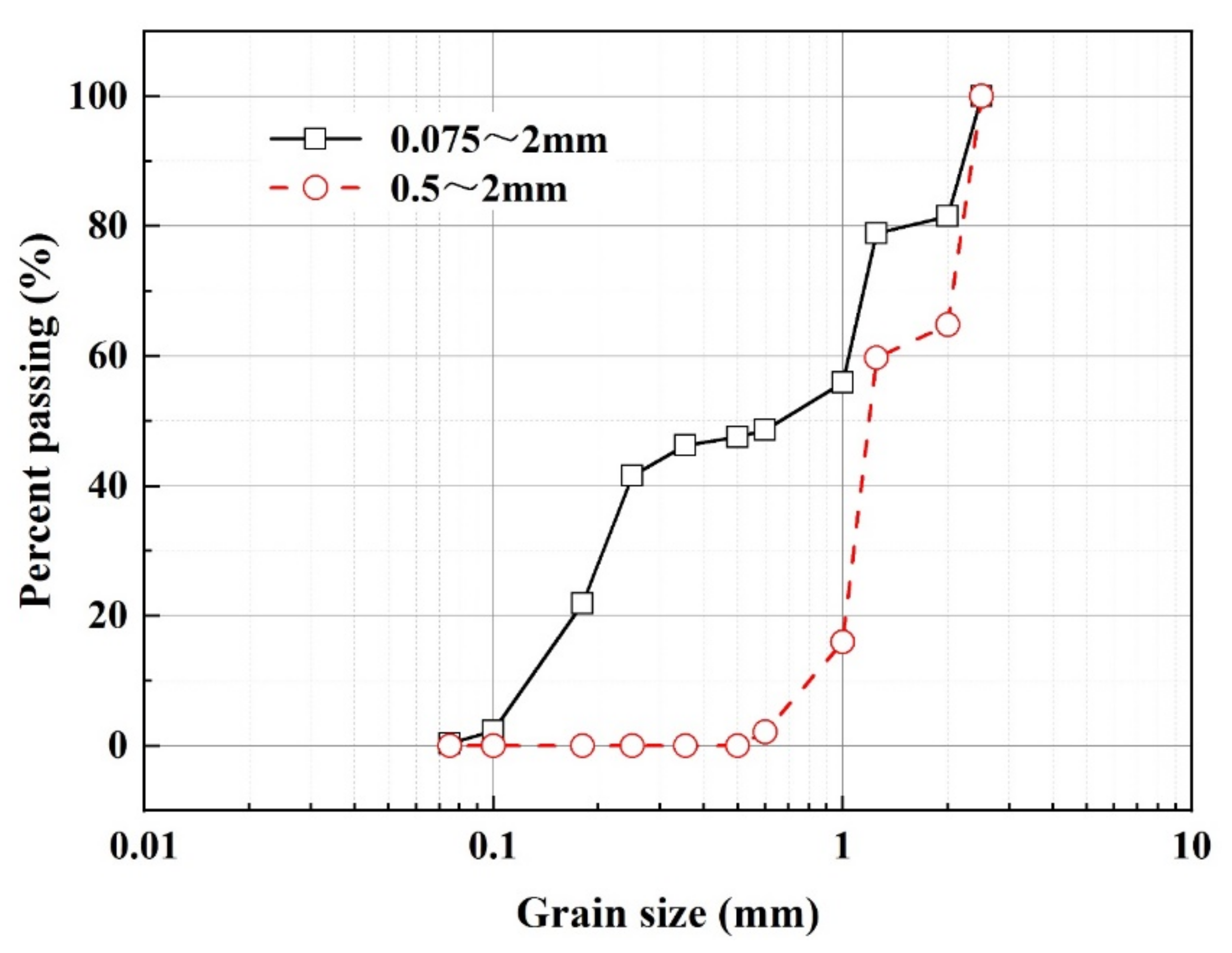

4.1.1. Soil Samples and Water Environment

4.1.2. Bentonite Slurry

4.2. Test Procedure

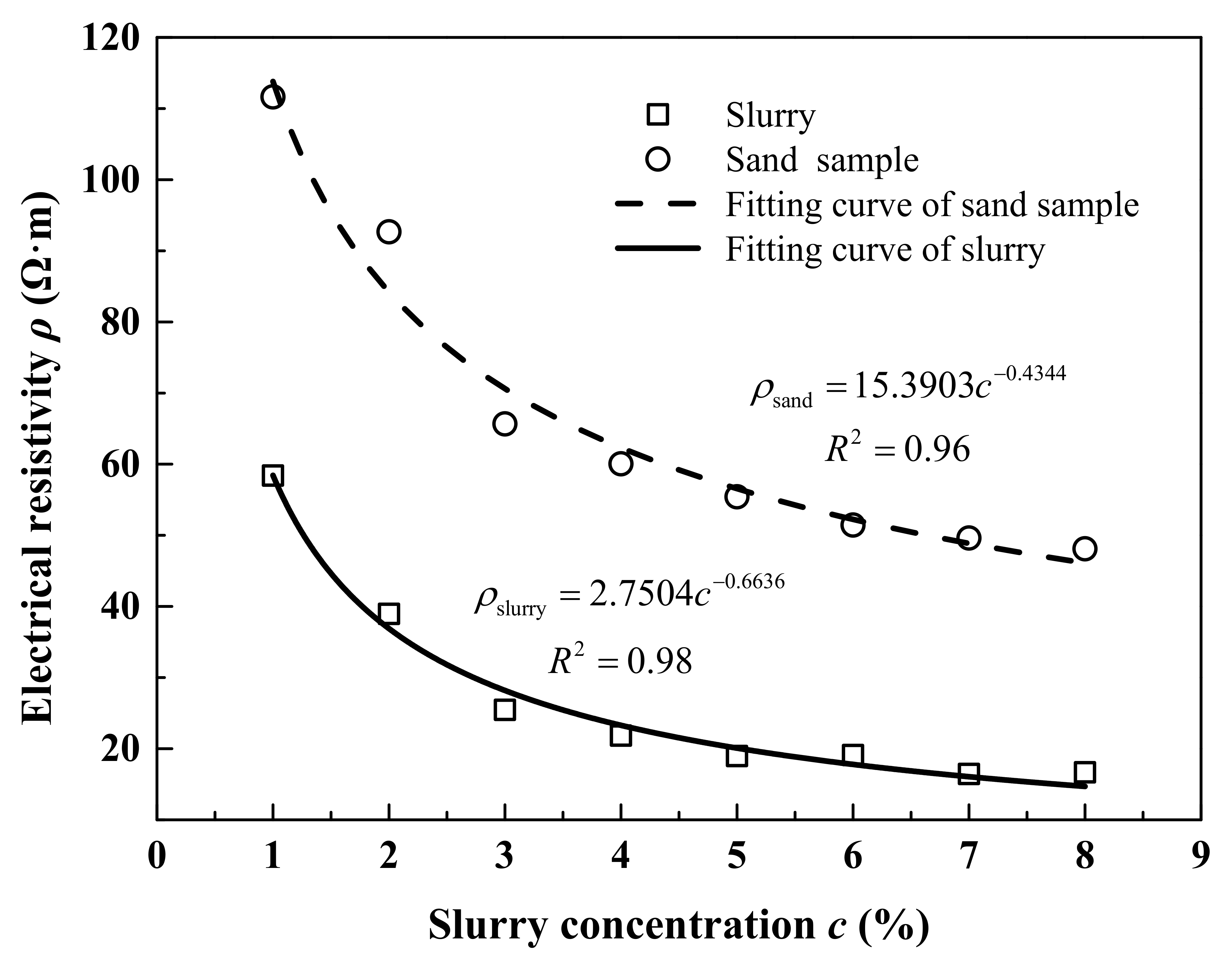

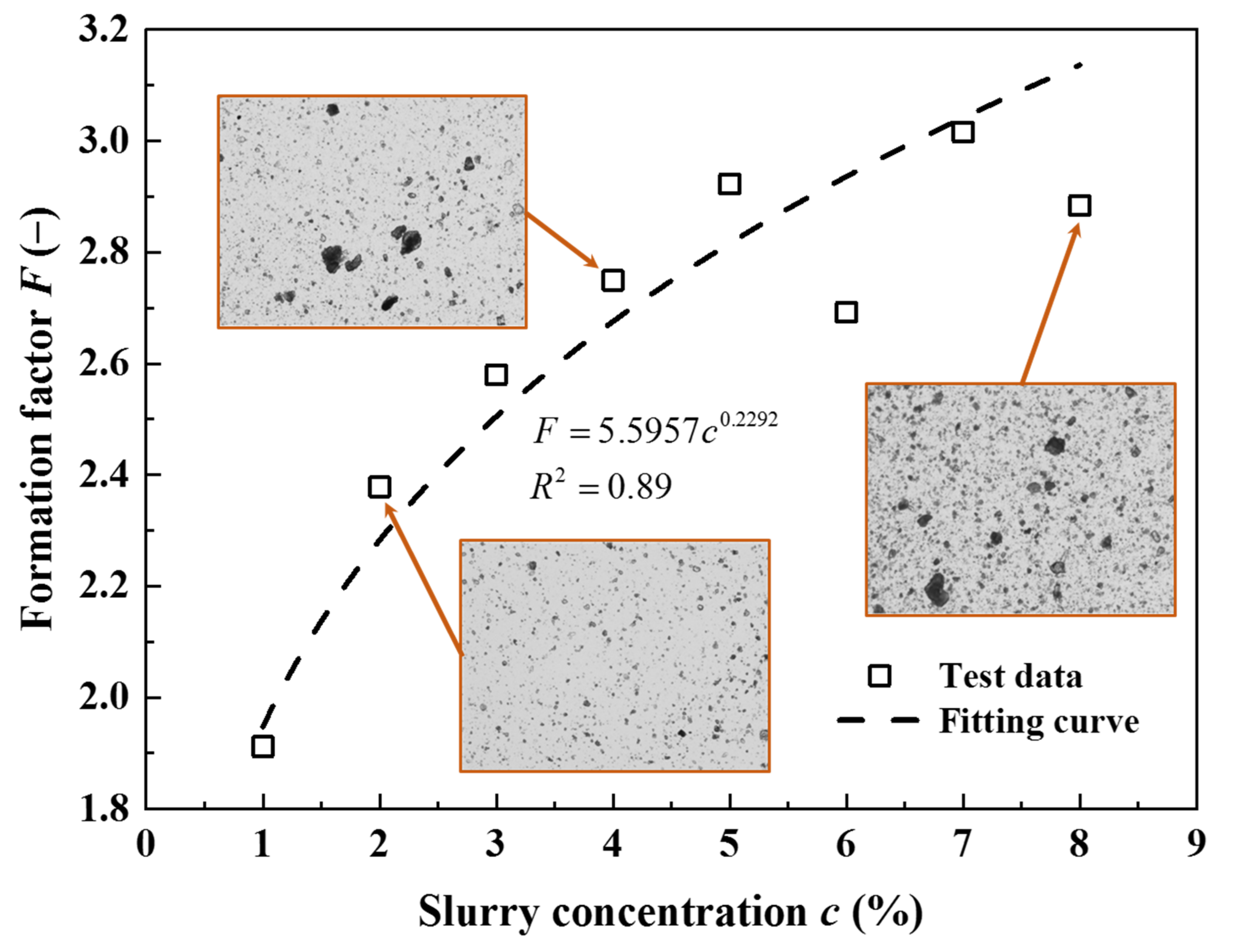

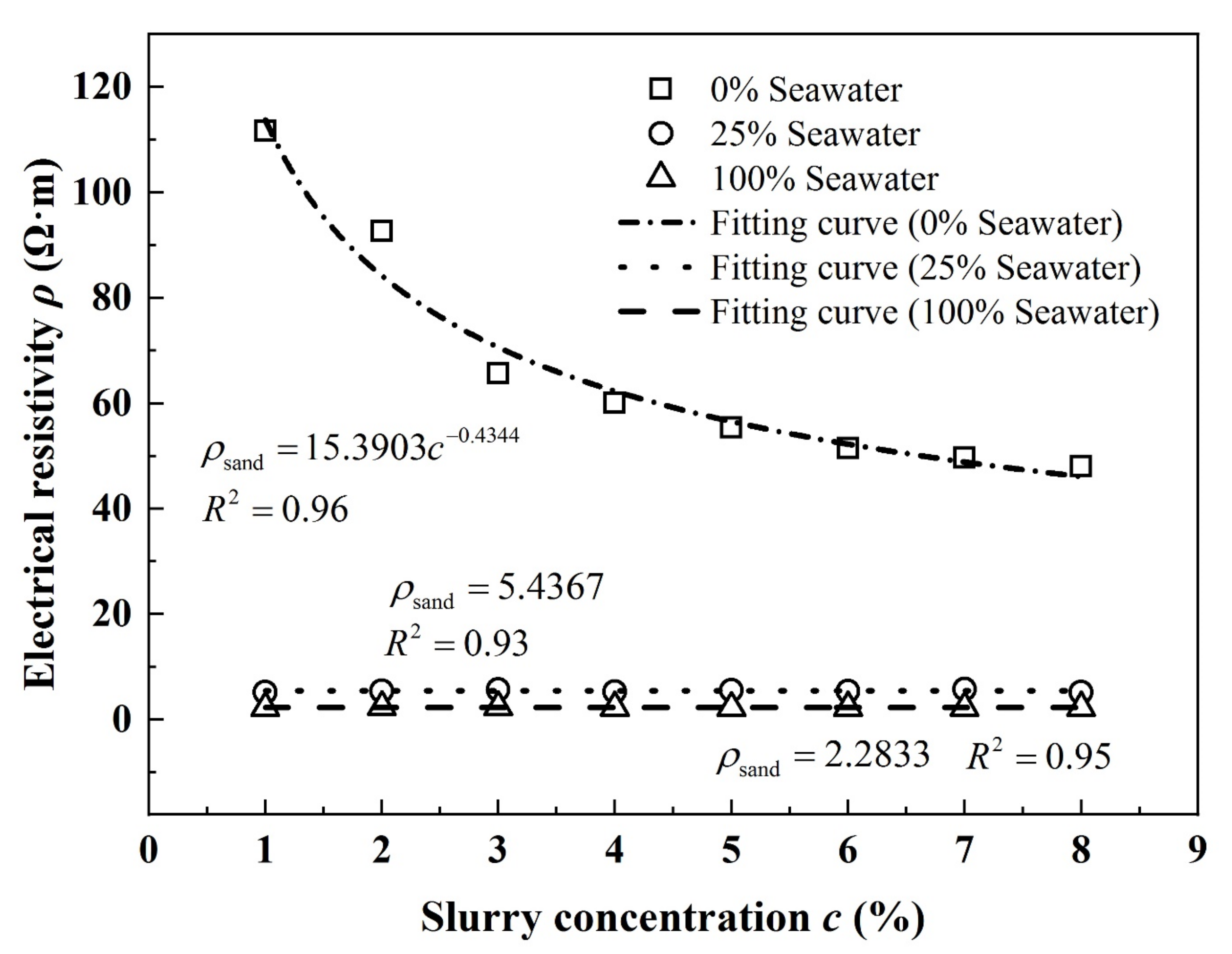

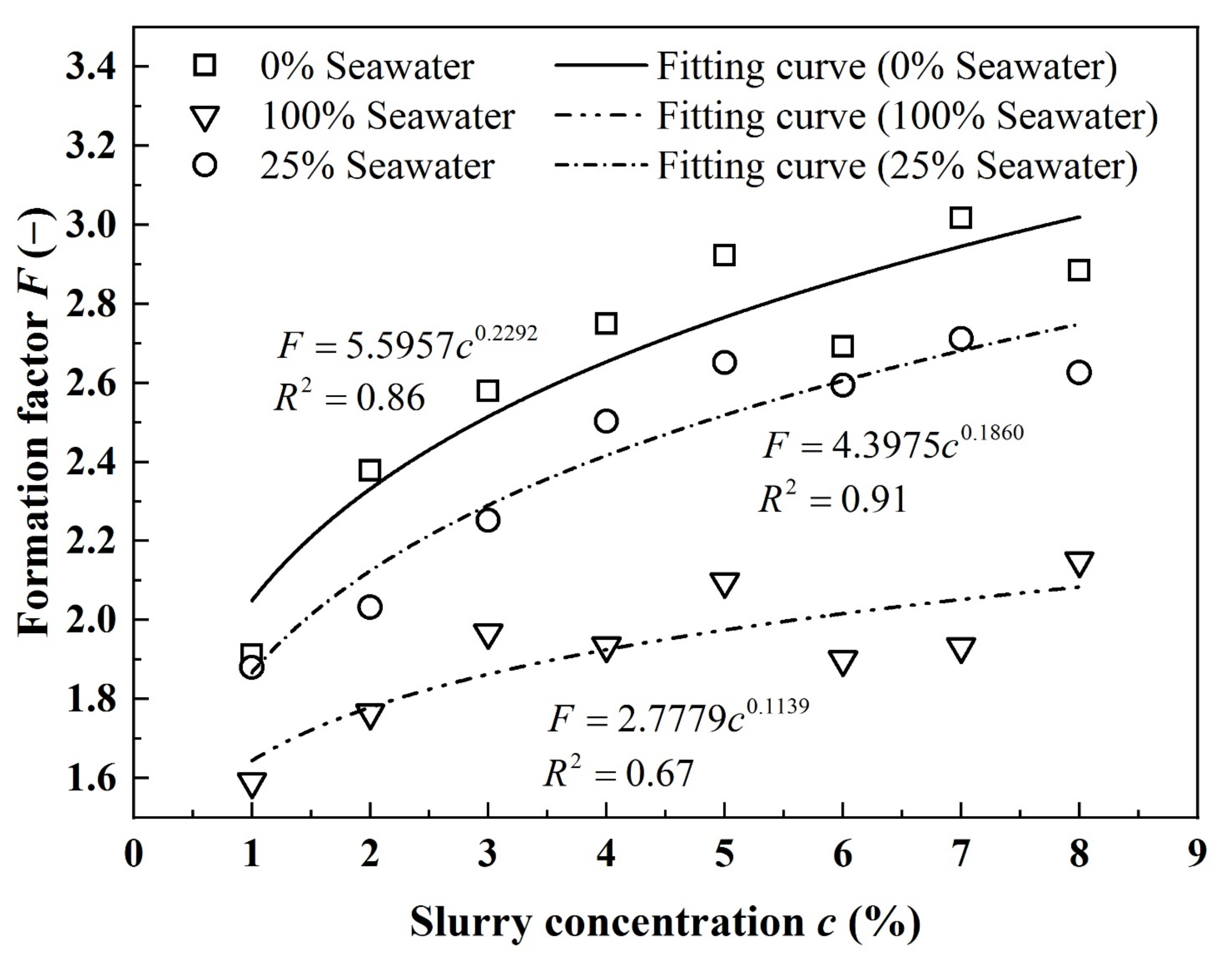

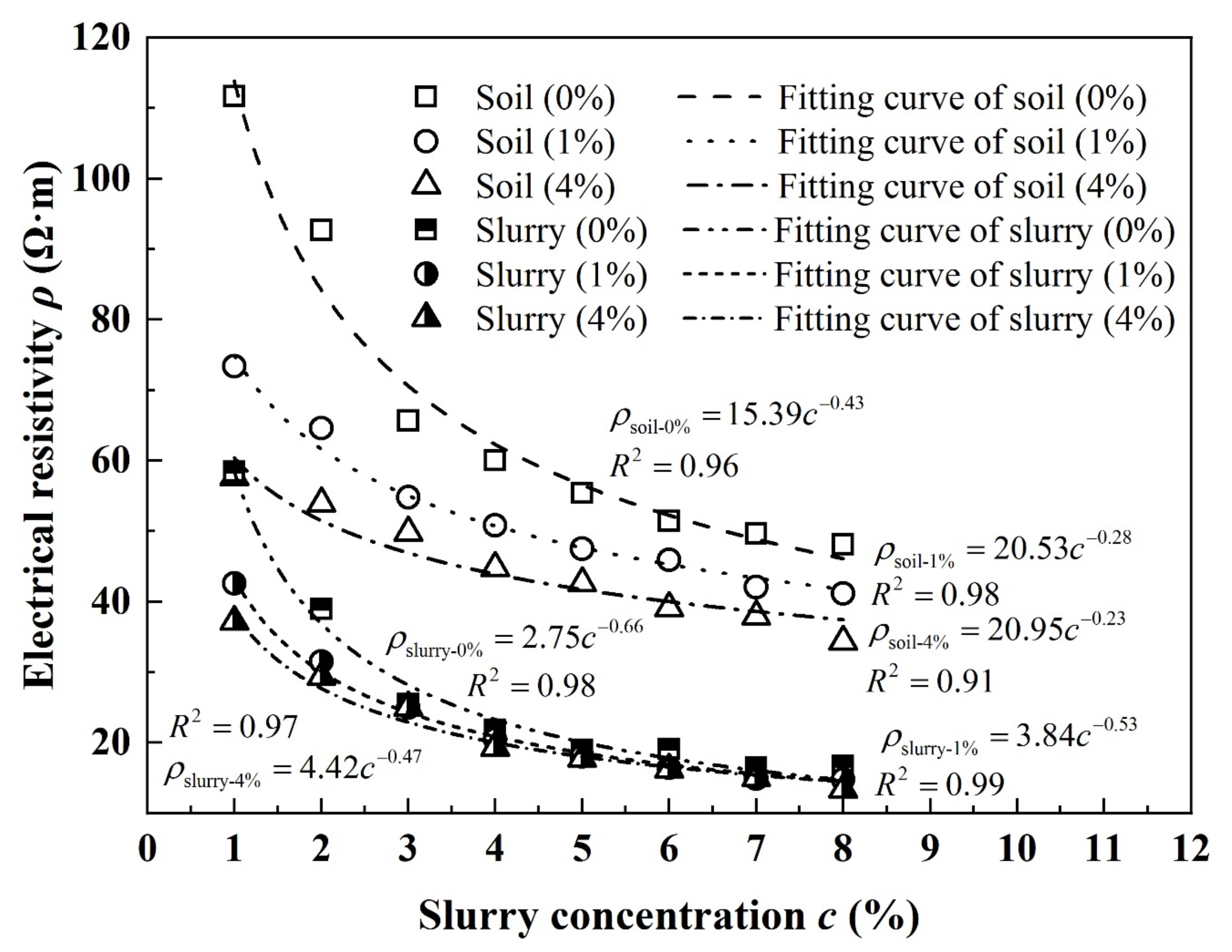

5. Results and Discussion

5.1. Water Environment

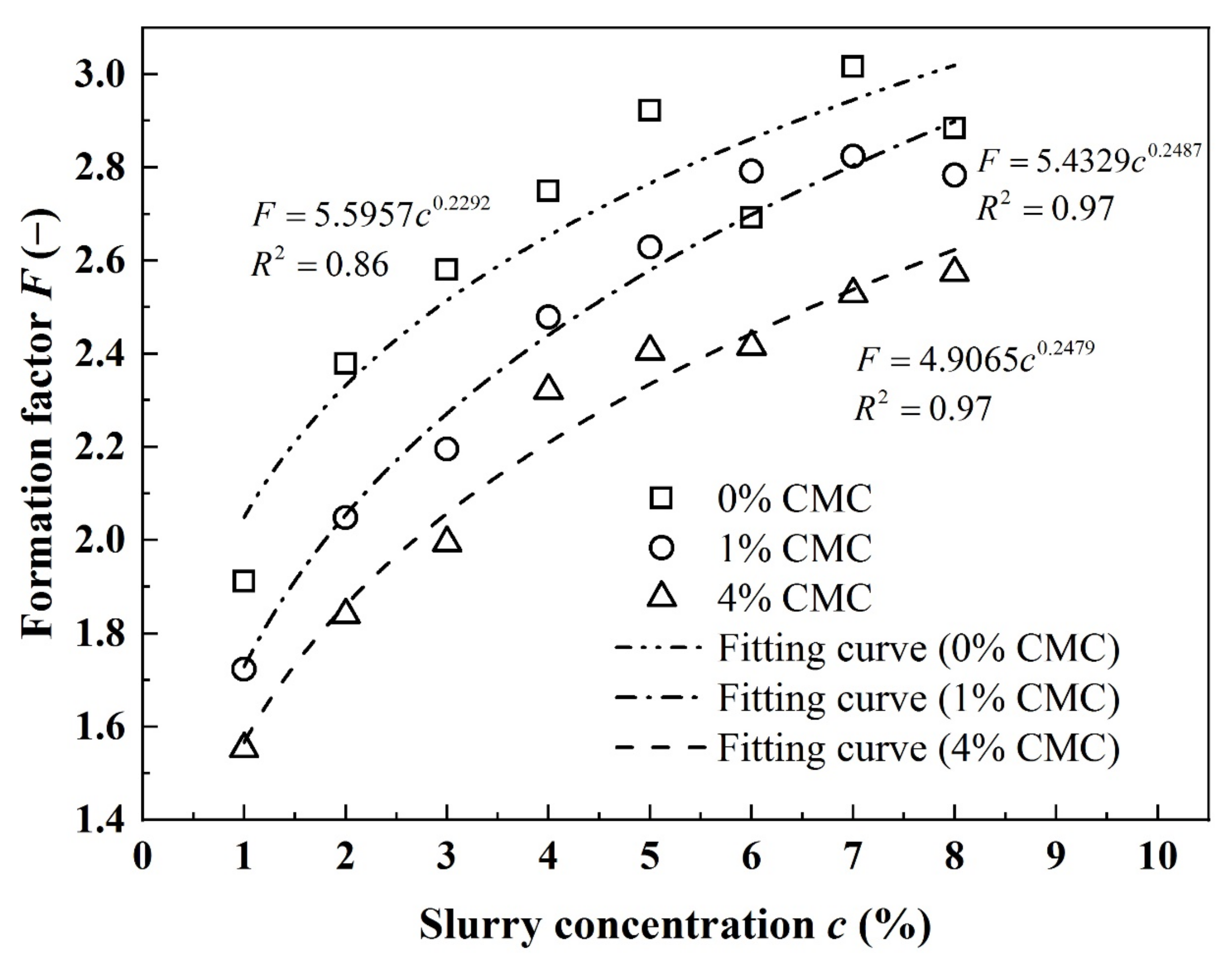

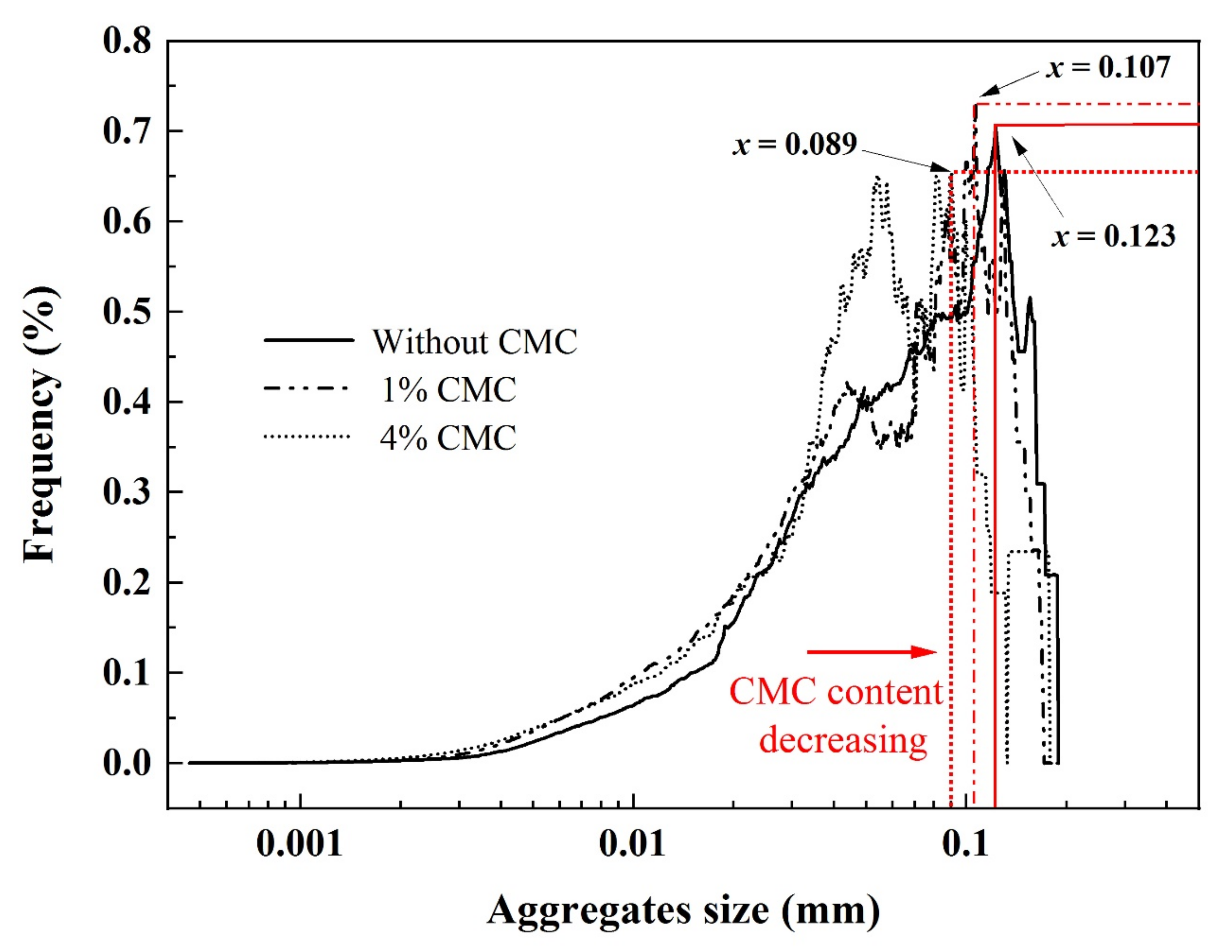

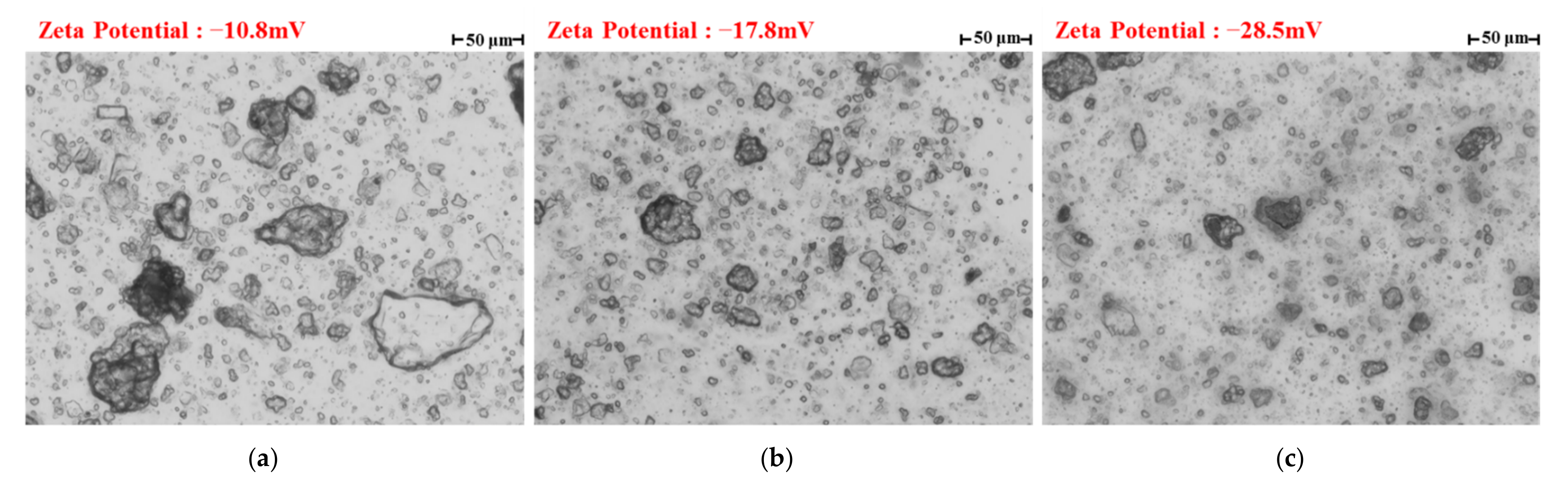

5.2. CMC Contents

5.3. Particle Gradation of Soil Samples

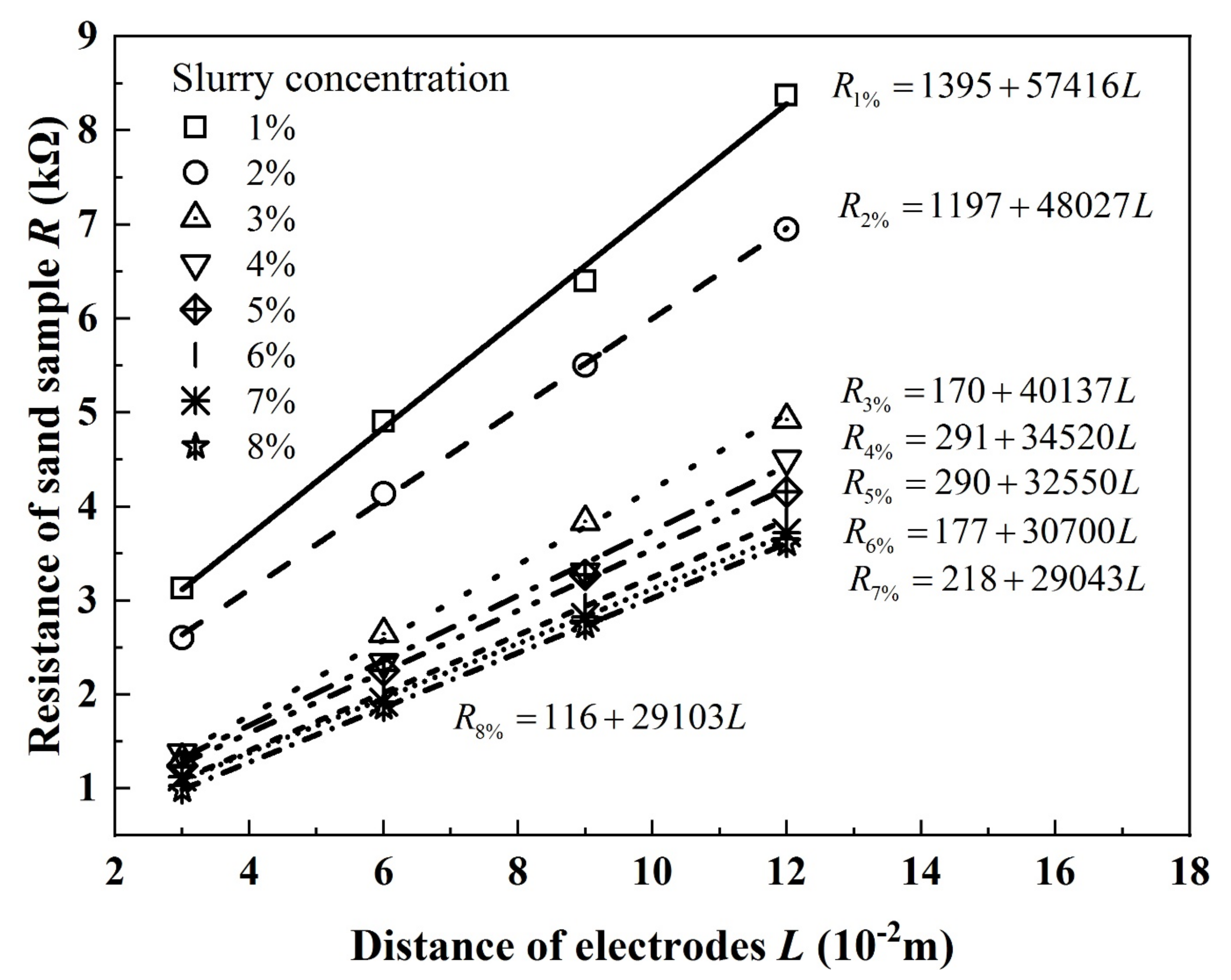

5.4. Electrode Distance

6. Conclusions

- (1)

- The slurry penetration observably increased the number of ions in saturated soil and decreased the electrical resistivity of soil. The relation between soil electrical resistivity and amount of slurry penetration can be expressed by the power function of slurry concentration. Additionally, the soil porosity and particle gradation also exerts influences on the soil electrical resistivity.

- (2)

- Seawater and CMC decreased the electrical resistivity of bentonite slurry and slurry-soil mixture. Since the amount of free ions in seawater is much greater than that in slurry, the effect of bentonite slurry on the soil electrical resistivity can be ignored. Besides, the bentonite particles flocculate into aggregates rapidly in a seawater environment, which further promotes the decrease in soil resistivity. Therefore, the method of electrical resistivity measurement in this paper is not applicable in the offshore engineering.

- (3)

- The magnitude of soil resistivity is a result of competition between the soil formation factor and electrolytes. Engineers cannot ignore the slurry-induced changes of soil structure when assessing the slurry penetration in practical engineering, otherwise the magnitude as well as the migration distance of the slurry will be overestimated.

- (4)

- Contact resistance between electrode slices and soil samples decreased with the increase in slurry penetration. The variance of the contact resistances may bring about a strong deviation in the soil electrical resistivity. In order to obtain a stable and reliable value of soil electrical resistivity, multiple tests with different distances are recommended and the soil electrical resistivity can be determined by calculating the slope of fitting curves.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Anagnostou, G.; Kovári, K. Face stability in slurry and EPB shield tunneling. Geotech. Asp. Undergr. Constr. Soft Ground 1996, 28, 453–458. [Google Scholar]

- Nasiri, A.; Ghaffarkhah, A.; Moraveji, M.K.; Gharbanian, A.; Valizadeh, M. Experimental and field test analysis of different loss control materials for combating lost circulation in bentonite mud. J. Nat. Gas Sci. Eng. 2017, 44, 1–8. [Google Scholar] [CrossRef]

- Lei, M.F.; Yao, L.; Cao, C.Y. Design method of slurry volume–weight in trenching construction of underground diaphragm wall in soft stratum. Geotech. Geol. Eng. 2017, 35, 2697–2704. [Google Scholar]

- Horizon Directional Drilling. Available online: https://v.qq.com/x/page/u066245aulf.html (accessed on 1 November 2021).

- Cast-in-Place Pile. Available online: http://cn.trustexporter.com/cp-jgejic/o6495620.htm (accessed on 1 November 2021).

- Zhang, Z.; Yin, T.; Huang, X.; Dias, D. Slurry filtration process and filter cake formation during shield tunnelling: Insight from coupled CFD-DEM simulations of slurry filtration column test. Tunn. Undergr. Space Technol. 2019, 87, 64–77. [Google Scholar] [CrossRef]

- Mao, J.H.; Yuan, D.J.; Jin, D.L.; Liu, S.N. Influence of Cutting Tools on Filter Cake Formation during Slurry Shield Tunnelling. KSCE J. Civ. Eng. 2021, 25, 2261–2274. [Google Scholar] [CrossRef]

- Nie, Y.X.; Hu, L.; Wen, Q. The quantitative relationship of soil resistivity and saturation degree. Chin. J. Rock Mech. Eng. 2016, 35, 3441–3448. [Google Scholar]

- Wang, B.H.; Wang, Z.H.; Jiang, P.P.; Zhou, A.Z. Electrical resistivity characteristics of saturated sand with varied porosities. Chin. J. Geotech. Eng. 2017, 9, 1739–1745. [Google Scholar]

- Depountis, N.; Harris, C.; Davies, M. An assessment of miniaturised electrical imaging equipment to monitor pollution plume evolution in scaled centrifuge modelling. Eng. Geol. 2001, 60, 83–94. [Google Scholar] [CrossRef]

- Fukue, M.; Minato, T.; Matsumoto, M.; Horibe, H.; Taya, N. Use of a resistivity cone for detecting contaminated soil layers. Eng. Geol. 2001, 60, 361–369. [Google Scholar] [CrossRef]

- Jinguuji, M.; Toprak, S.; Kunimatsu, S. Visualization technique for liquefaction process in chamber experiments by using electrical resistivity monitoring. Soil Dyn. Earthq. Eng. 2007, 27, 191–199. [Google Scholar] [CrossRef]

- Shea, P.F.; Luthin, J.N. An Investigation of the Use of The Four-Electrode Probe for Measuring Soil Salinity In Situ. Soil Sci. 1961, 92, 331–339. [Google Scholar] [CrossRef]

- Pincus, H.; Kalinski, R.; Kelly, W. Estimating Water Content of Soils from Electrical Resistivity. Geotech. Test. J. 1993, 16, 323. [Google Scholar] [CrossRef]

- Nowroozi, A.A.; Horrocks, S.B.; Henderson, P. Saltwater intrusion into the freshwater aquifer in the eastern shore of Virginia: A reconnaissance electrical resistivity survey. J. Appl. Geophys. 1999, 42, 1–22. [Google Scholar] [CrossRef]

- Acworth, R.I. Investigation of dryland salinity using the electrical image method. Soil Res. 1999, 37, 623–636. [Google Scholar] [CrossRef]

- Yaramanci, U. Geoelectric exploration and monitoring in rock salt for the safety assessment of underground waste disposal sites. J. Appl. Geophys. 2000, 44, 181–196. [Google Scholar] [CrossRef]

- Zhu, W.; Min, F.L.; Zhong, X.C. Slurry and Filter Cake in Slurry Shield; Science Press: Beijing, China, 2016; pp. 10–11. [Google Scholar]

- Müller, K.H. Stability of slurry trenches. In Proceedings of the 5th European Conference on Soil Mechanics and Foundation Engineering, Madrid, Spain, 10–19 April 1972; pp. 543–553. [Google Scholar]

- Min, F.; Zhu, W.; Han, X. Filter cake formation for slurry shield tunneling in highly permeable sand. Tunn. Undergr. Space Technol. 2013, 38, 423–430. [Google Scholar] [CrossRef]

- Min, F.L.; Zhu, W.; Wei, D.W.; Xia, S.Q. Change of pore water pressure in soil as filter cakes formed on excavation face in slurry shield. Chin. J. Geotech. Eng. 2013, 35, 722–727. [Google Scholar]

- Talmon, A.M.; Mastbergen, D.R.; Huisman, M. Invasion of Pressurized Clay Suspensions into Granular Soil. J. Porous Media 2013, 16, 351–365. [Google Scholar] [CrossRef]

- Xu, T.; Bezuijen, A.; Dias, T. Slurry infiltration ahead of slurry TBM’s in saturated sand: Laboratory tests and consequences for practice. In Proceedings of the 9th International Symposium on Geotechnical Aspects of Underground Construction in Soft Ground, Sao Paulo, Brazil, 3–6 April 2017; pp. 121–126. [Google Scholar] [CrossRef]

- Zied, S.; Jean, C.; Luc, D.; Dupla, J.C. Evaluation of elementary filtration properties of a cement grout injected in a sand. Can. Geotech. J. 2006, 43, 1273–1289. [Google Scholar]

- Fritz, P. Additives for Slurry Shields in Highly Permeable Ground. Rock Mech. Rock Eng. 2006, 40, 81–95. [Google Scholar] [CrossRef]

- Xu, T.; Bezuijen, A. Pressure infiltration characteristics of bentonite slurry. Géotechnique 2019, 69, 364–368. [Google Scholar] [CrossRef]

- Yin, X.S.; Chen, R.P.; Li, Y.C.; Qi, S. A column system for modeling bentonite slurry infiltration in sands. J. Zhejiang Univ. Sci. A (Appl. Phys. Eng.) 2016, 17, 818–827. [Google Scholar] [CrossRef] [Green Version]

- Archie, G.E. The Electrical Resistivity Log as an Aid in Determining Some Reservoir Characteristics. Trans. AIME 1942, 146, 54–62. [Google Scholar] [CrossRef]

- Glover, P.W.J. Archie’s law—A reappraisal. Solid Earth 2016, 7, 1157–1169. [Google Scholar] [CrossRef] [Green Version]

- Glover, P. Geophysical Properties of the Near Surface Earth: Electrical Properties. In Treatise on Geophysics; Elsevier: Amsterdam, The Netherlands, 2015; Volume 11, pp. 89–137. [Google Scholar]

- ASTM D1141-98(2003): Standard Practice for the Preparation of Substitude Ocean Water; American Society for Testing and Materials: West Conshohocken, PA, USA, 2003.

- API: Recommended Practice Standard Procedure for Field Testing Water-Based Drilling Fluids, 13B-1, 3rd ed.; American Petroleum Institute: Washington, DC, USA, 2003.

- Min, F.; Du, J.; Zhang, N.; Chen, X.; Lv, H.; Liu, L.; Yu, C. Experimental study on property change of slurry and filter cake of slurry shield under seawater intrusion. Tunn. Undergr. Space Technol. 2019, 88, 290–299. [Google Scholar] [CrossRef]

- Alshawabkeh, A.N.; Gale, R.J.; Ozsu-Acar, E.; Bricka, R.M. Optimization of 2-D Electrode Configuration for Electrokinetic Remediation. Soil Sediment Contam. Int. J. 1999, 8, 617–635. [Google Scholar] [CrossRef]

- Braunovic, M.; Konchits, V.V.; Myshkin, N.K. Electrical Contacts: Fundamentals, Applications and Technology; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Zhuang, Y.-F.; Wang, Z. Interface Electric Resistance of Electroosmotic Consolidation. J. Geotech. Geoenvironmental Eng. 2007, 133, 1617–1621. [Google Scholar] [CrossRef]

- Greenwood, A.J. Constriction resistance and the real area of contact. Br. J. Appl. Phys. 1966, 17, 1621. [Google Scholar] [CrossRef]

| Salt composition | NaCl | MgCl2 | Na2SO4 | CaCl2 | KCl | NaHCO3 |

| Concentration (g/L) | 24.53 | 5.20 | 4.09 | 1.16 | 0.69 | 0.20 |

| Slurry Concentrations/(%) | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| Specific gravity/(−) | 1.01 | 1.01 | 1.02 | 1.03 | 1.03 | 1.04 | 1.05 | 1.05 |

| Viscosity/(mPa·s) | 4.61 | 5.41 | 8.14 | 12.65 | 24.72 | 74.27 | 275.58 | 428.07 |

| Soil Gradation | Water Environment | Slurry Penetration | |

|---|---|---|---|

| Contents of CMC Solution | Contents of Bentonite | ||

| I (0.5~2 mm) | 0%-Deionized water | 0% | 1~8% |

| 1% | 1~8% | ||

| 4% | 1~8% | ||

| 25%-Seawater | 0% | 1~8% | |

| 100%-Seawater | 0% | 1~8% | |

| II (0.075~2 mm) | 0%-Deionized water | 0% | 1~8% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, J.; Yuan, D.; Jin, D.; Wang, B.; Wu, S. Experimental Study on Electrical Resistivity Characteristics of Saturated Sand Mixes with Bentonite Slurry. Appl. Sci. 2021, 11, 12126. https://doi.org/10.3390/app112412126

Mao J, Yuan D, Jin D, Wang B, Wu S. Experimental Study on Electrical Resistivity Characteristics of Saturated Sand Mixes with Bentonite Slurry. Applied Sciences. 2021; 11(24):12126. https://doi.org/10.3390/app112412126

Chicago/Turabian StyleMao, Jiahua, Dajun Yuan, Dalong Jin, Binghui Wang, and Shangkun Wu. 2021. "Experimental Study on Electrical Resistivity Characteristics of Saturated Sand Mixes with Bentonite Slurry" Applied Sciences 11, no. 24: 12126. https://doi.org/10.3390/app112412126