Review of Hygroscopic Coating on Aluminum Fin Surface of Air Conditioning Heat Exchanger

Abstract

:1. Introduction

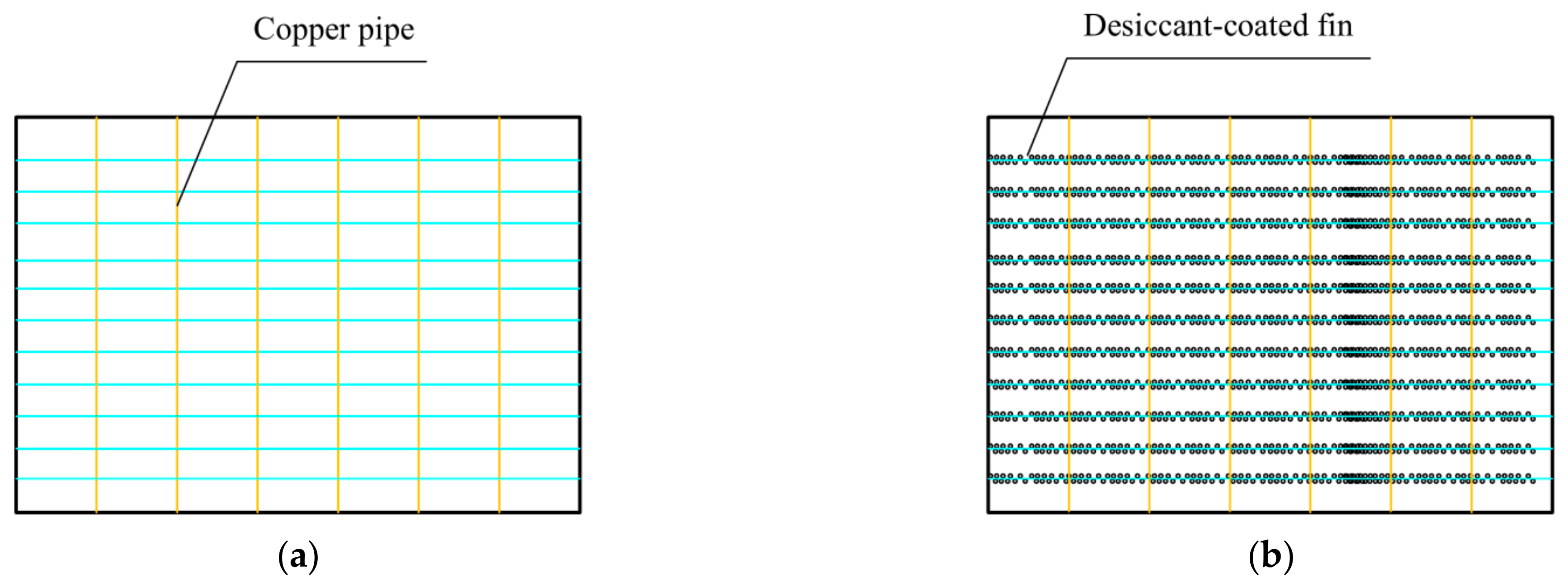

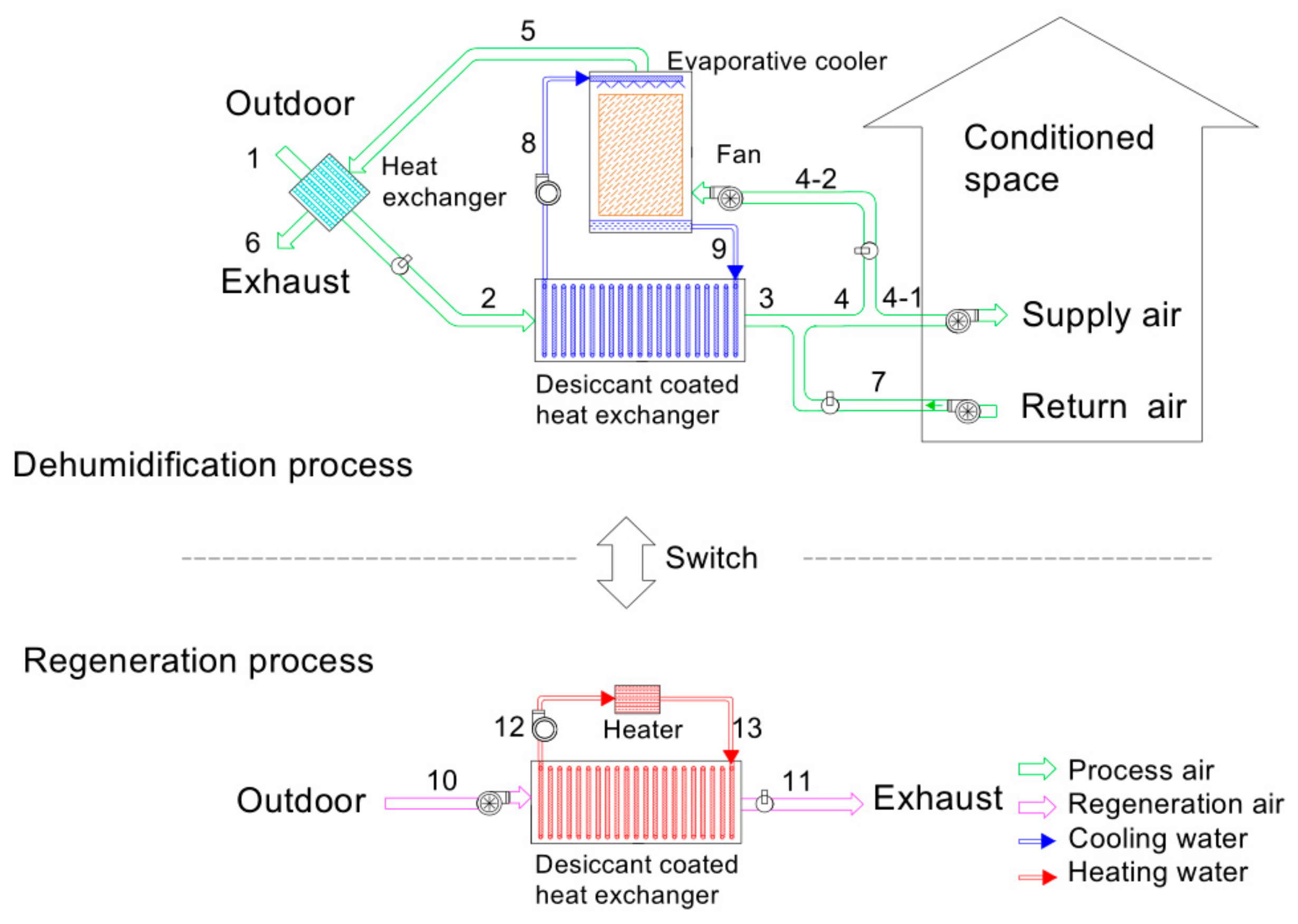

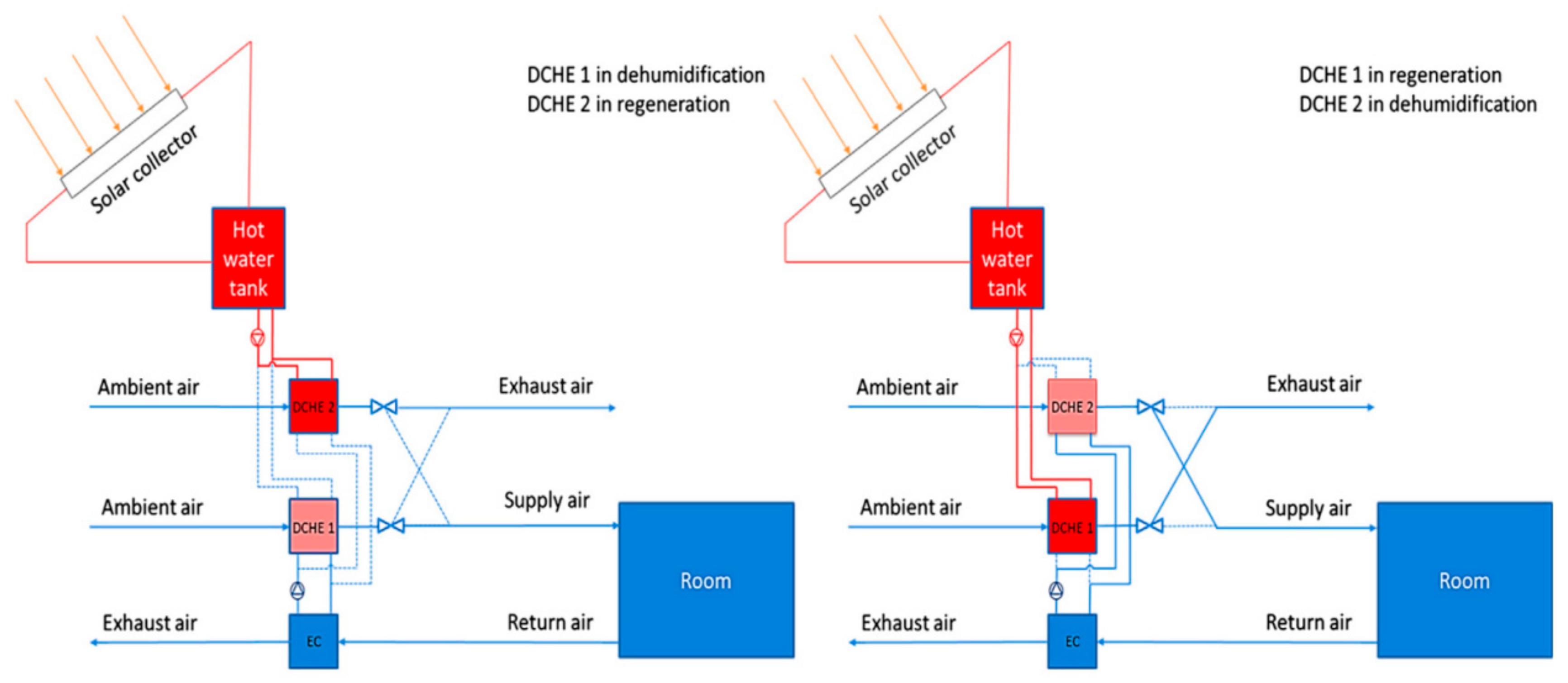

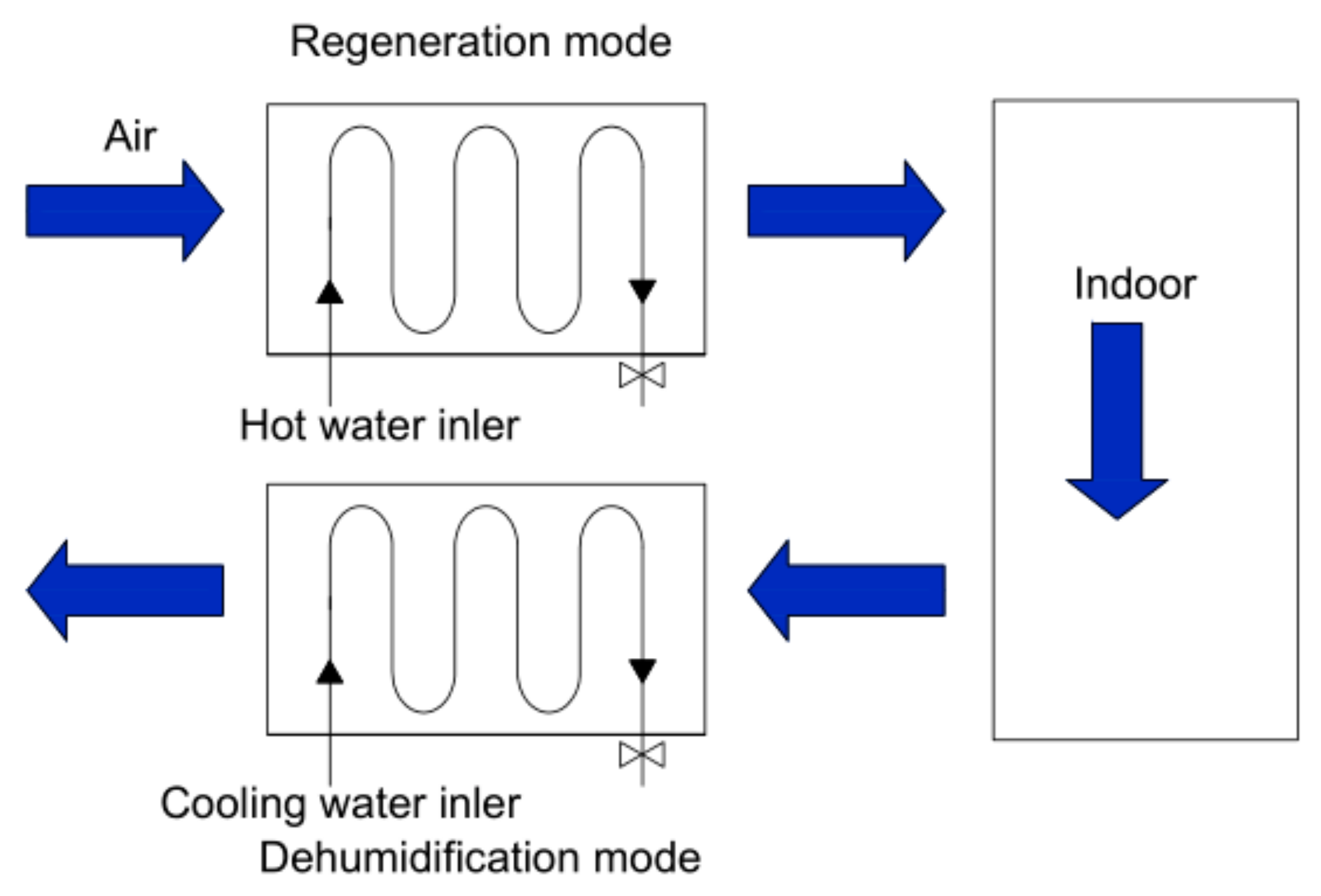

2. Desiccant-Coated Heat Exchangers

2.1. Desiccant Materials

2.2. Factors Affecting the Performance of DCHE

2.3. Applications in Air Conditioning Systems

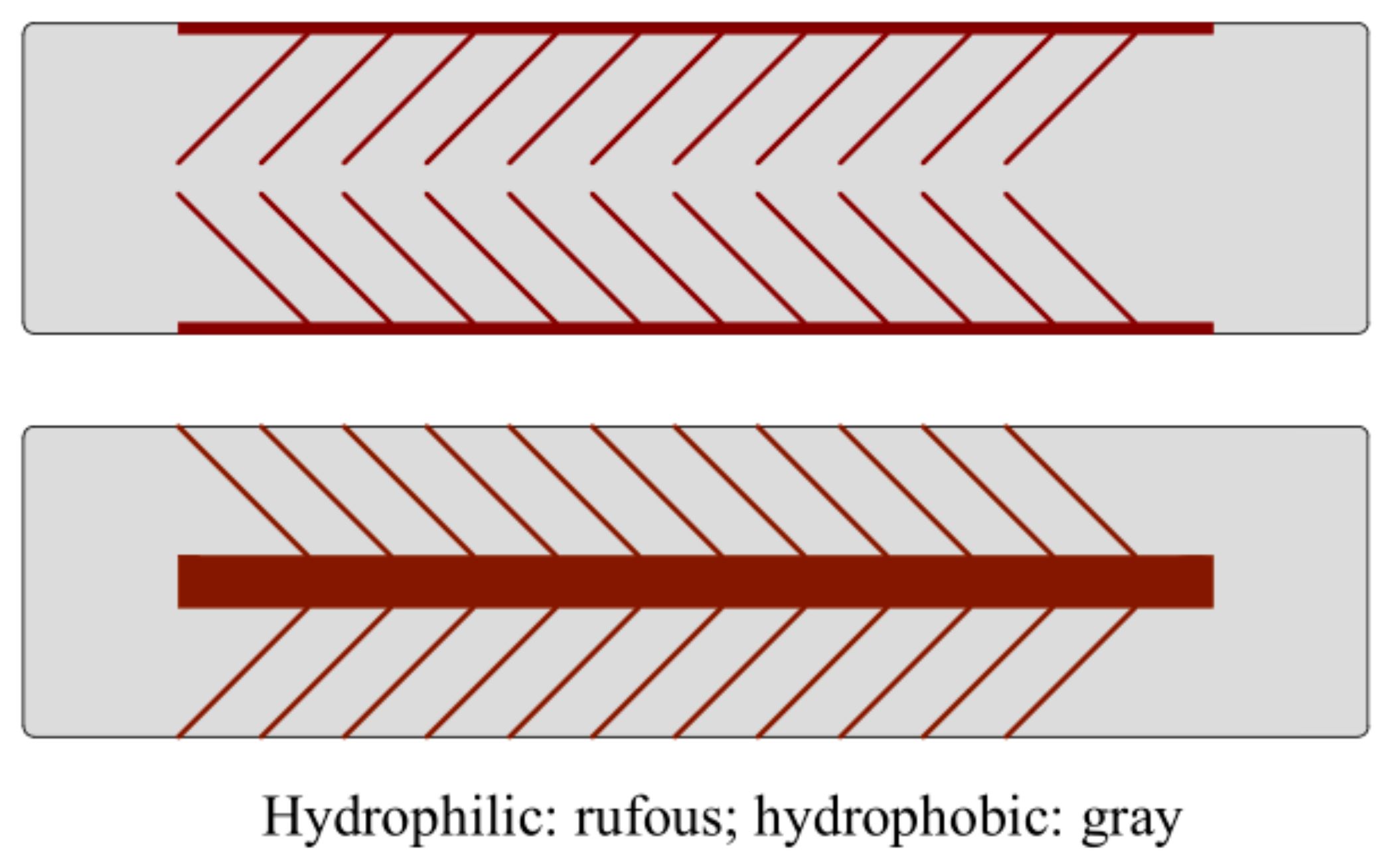

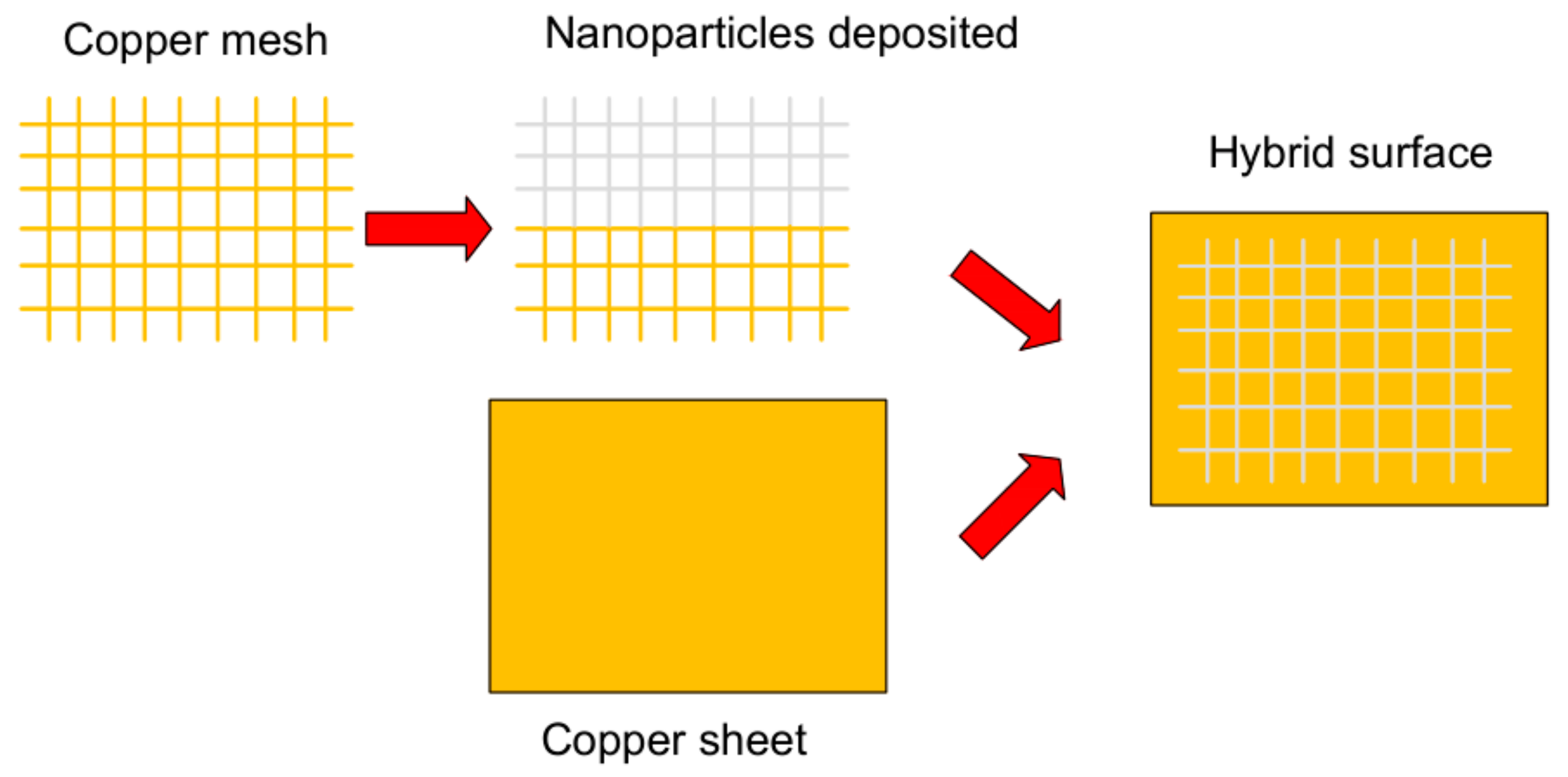

3. Hydrophobic/Hydrophilic Coated Heat Exchangers

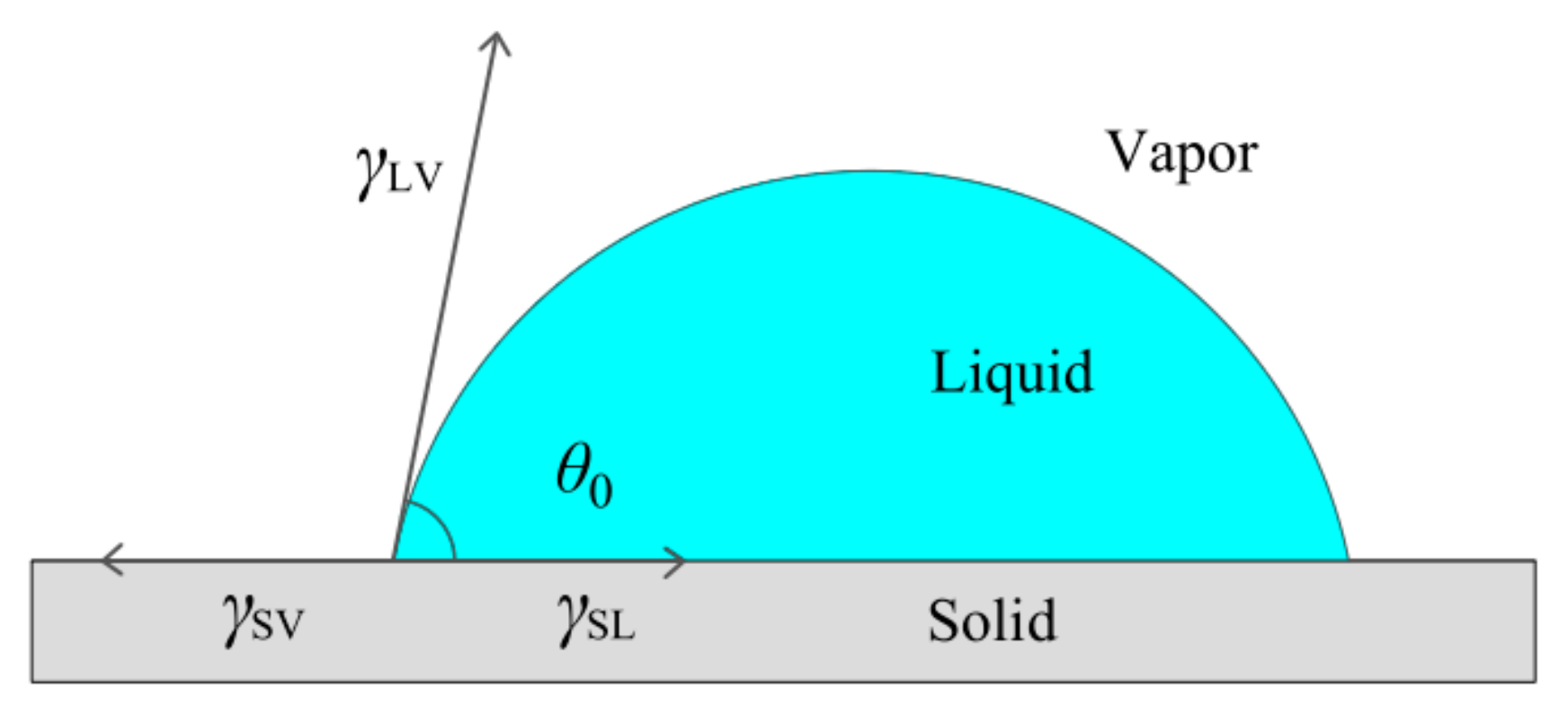

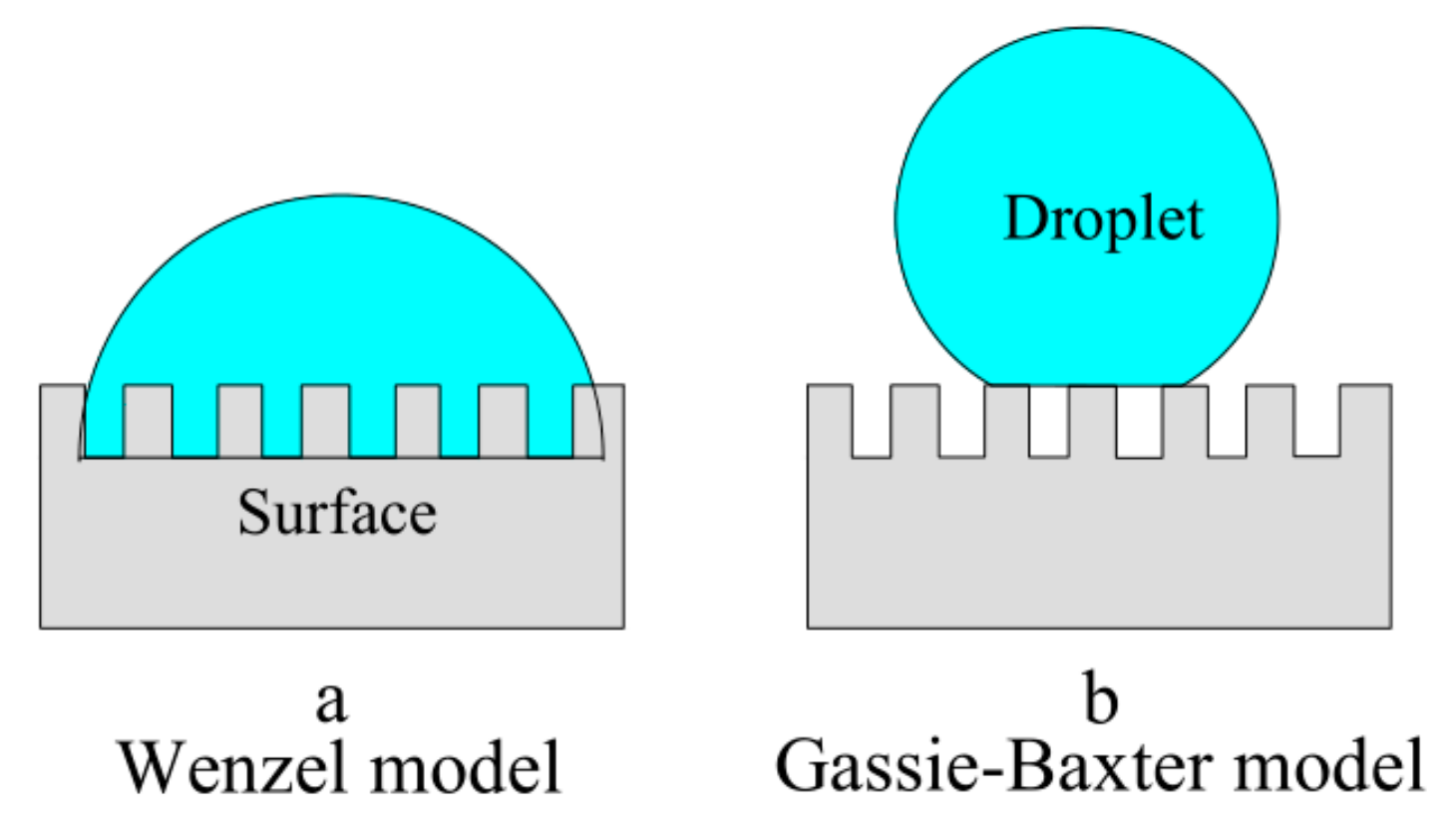

3.1. State of Surface Wettability

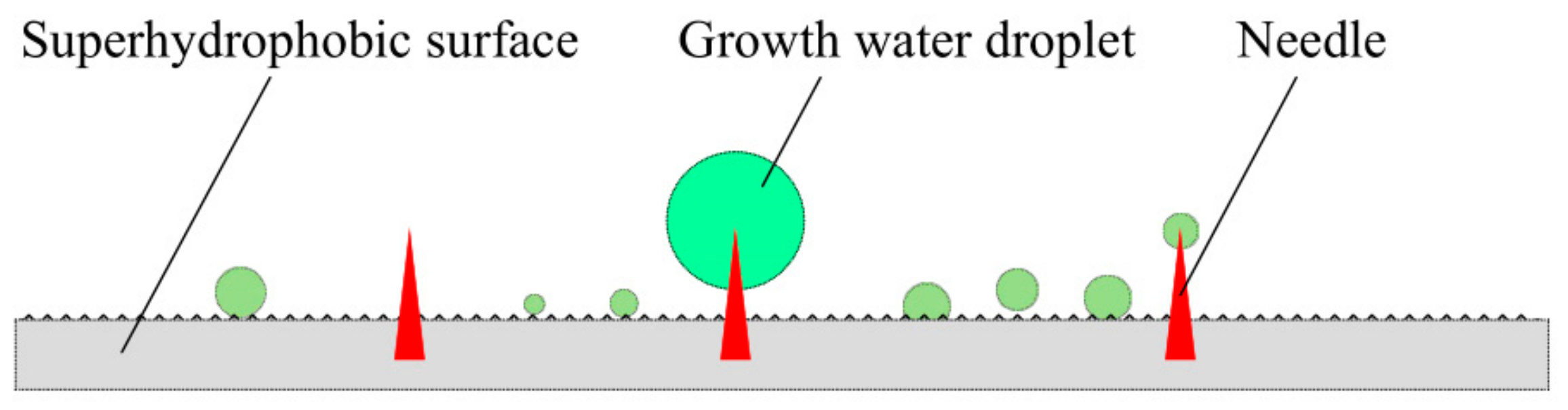

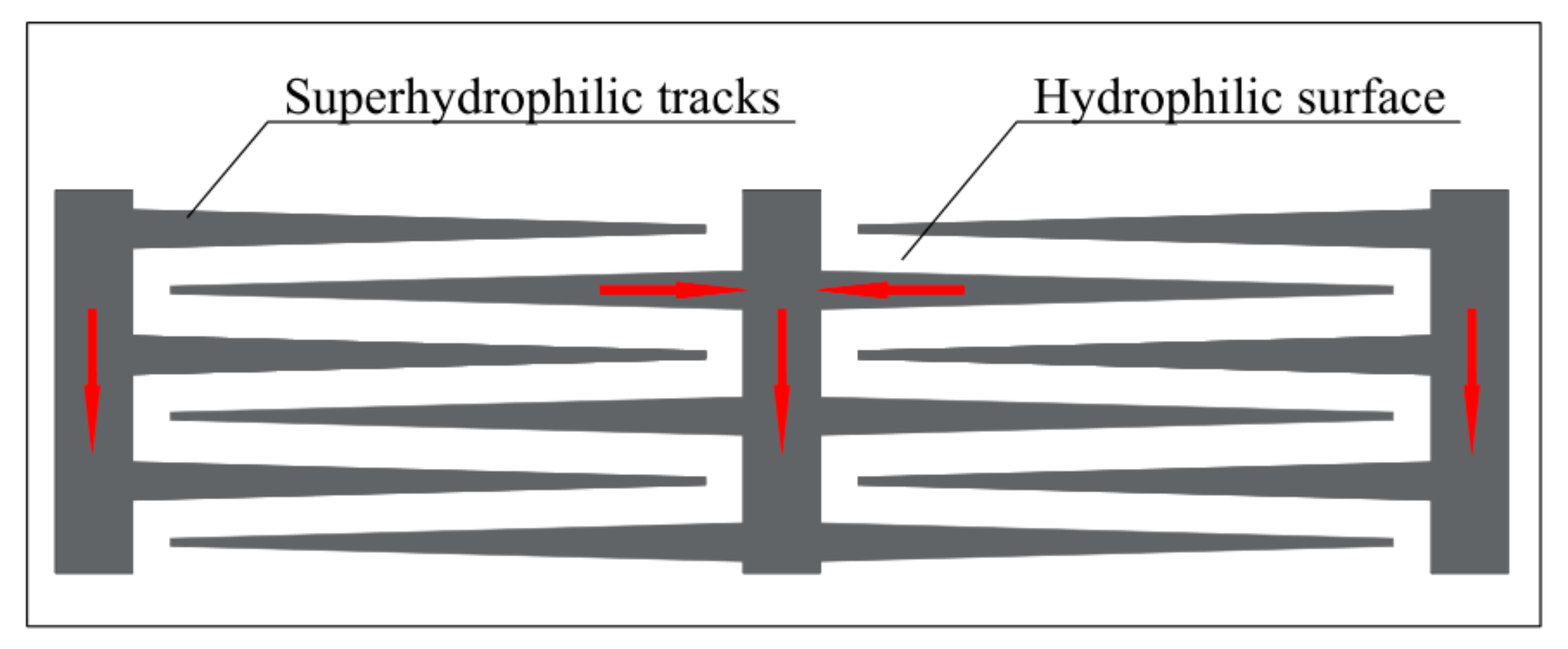

3.2. Kinds of Surface Wettability

3.3. Applications in Air Conditioning Systems

4. Challenges and Future Works

4.1. For Desiccant-Coated Heat Exchangers

- After the addition of the hygroscopic salts, the adsorption capacity of the conventional desiccants has been significantly improved. However, their negative consequences, such as corrosion and deliquescence, require further research.

- How to reduce the pressure drop and enhance the mass and heat transfer of the DCHE, and reduce the desiccants regeneration temperature need to be developed.

- In the air conditioning system, the dehumidification and regeneration system is complex, difficult to control, and large, which requires a more competitive design.

4.2. For Hydrophobic/Hydrophilic Coated Heat Exchangers

- Hybrid hydrophobic-hydrophilic coated surfaces are complex, which are difficult or expensive to fabricate; it is necessary to find a simple preparation method suitable for industrial production.

- Most of these hydrophobic/hydrophilic coating surfaces have poor mechanical durability and often fail after dust clogging and metal oxidative corrosion.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Qu, M.; Abdelaziz, O.; Gao, Z.M.; Yin, H.X. Isothermal membrane-based air dehumidification: A comprehensive review. Renew. Sustain. Energy Rev. 2018, 82, 4060–4069. [Google Scholar] [CrossRef]

- Daou, K.; Wang, R.Z.; Xia, Z.Z. Desiccant cooling air conditioning: A review. Renew. Sustain. Energy Rev. 2006, 10, 55–77. [Google Scholar] [CrossRef]

- Vakiloroaya, V.; Samali, B.; Fakhar, A.; Pishghadam, K. A review of different strategies for HVAC energy saving. Energy Convers. Manag. 2014, 77, 738–754. [Google Scholar] [CrossRef]

- Zhang, F.; Yin, Y.; Zhang, X. Performance analysis of a novel liquid desiccant evaporative cooling fresh air conditioning system with solution recirculation. Build. Environ. 2017, 117, 218–229. [Google Scholar] [CrossRef]

- Li, Z.; Michiyuki, S.; Takeshi, F. Experimental study on heat and mass transfer characteristics for a desiccant-coated fin-tube heat exchanger. Int. J. Heat Mass Transf. 2015, 89, 641–651. [Google Scholar] [CrossRef]

- Chatterjee, A.; Derby, M.M.; Peles, Y.; Jensen, M.K. Enhancement of condensation heat transfer with patterned surfaces. Int. J. Heat Mass Transf. 2014, 71, 675–681. [Google Scholar] [CrossRef] [Green Version]

- She, X.H.; Cong, L.; Nie, B.J.; Leng, G.H.; Peng, H.; Chen, Y.; Zhang, X.S.; Wen, T.; Yang, H.X.; Luo, Y.M. Energy-efficient and -economic technologies for air conditioning with vapor compression refrigeration: A comprehensive review. Appl. Energy 2018, 232, 157–186. [Google Scholar] [CrossRef]

- Maher, S. Review of humidity control technologies in buildings. J. Build. Eng. 2018, 19, 539–551. [Google Scholar]

- Mosavi, A.; Mehdizadeh, H.; Abbasian-Naghneh, S.; Kalbasi, R.; Cheraghian, G. Incorporation of horizontal fins into a pcm-based heat sink to enhance the safe operation time: Applicable in electronic device cooling. Appl. Sci. 2020, 10, 6308. [Google Scholar] [CrossRef]

- Rostami, S.; Aghakhani, S.; Pordanjani, A.H.; Afrand, M.; Shadloo, M.S. A review on the control parameters of natural convection in different shaped cavities with and without nanofluid. Processes 2020, 8, 1011. [Google Scholar] [CrossRef]

- Huang, J.; Liu, M.; Jin, T. A comprehensive empirical correlation for finned heat exchangers with parallel plates working in oscillating flow. Appl. Sci. 2017, 7, 117. [Google Scholar] [CrossRef] [Green Version]

- Liang, C.; Tong, X.; Lei, T.; Li, Z.; Wu, G. Optimal design of an air-to-air heat exchanger with cross-corrugated triangular ducts by using a particle swarm optimization algorithm. Appl. Sci. 2017, 7, 554. [Google Scholar] [CrossRef] [Green Version]

- Ganesan, P.; Vanaki, S.M.; Thoo, K.K.; Chin, W.M. Air-side heat transfer characteristics of hydrophobic and super-hydrophobic fin surfaces in heat exchangers: A review. Int. Commun. Heat Mass 2016, 74, 27–35. [Google Scholar] [CrossRef]

- Caprì, A.; Frazzica, A.; Calabrese, L. Recent developments in coating technologies for adsorption heat pumps: A review. Coatings 2020, 10, 855. [Google Scholar] [CrossRef]

- Sultan, M.; El-Sharkawy, I.I.; Miyazaki, T.; Saha, B.B.; Koyama, S. An overview of solid desiccant dehumidification and air conditioning systems. Renew. Sustain. Energy Rev. 2015, 46, 16–29. [Google Scholar] [CrossRef]

- Ling, J.; Kuwabara, O.; Hwang, Y.; Radermacher, R. Experimental evaluation and performance enhancement prediction of desiccant assisted separate sensible and latent cooling air-conditioning system. Int. J. Refrig. 2011, 34, 946–957. [Google Scholar] [CrossRef]

- Qadar, G.C.; Muzaffar, A.; Nadeem, A.S.; Syed, I.H.G.; Shahab, K. Integration of solar assisted solid desiccant cooling system with efficient evaporative cooling technique for separate load handling. Appl. Therm. Eng. 2018, 140, 696–706. [Google Scholar] [CrossRef]

- Aziz, A.A.; Sumiyoshi, D.; Akashi, Y. Low cost humidity controlled air-conditioning system for building energy savings in tropical climate. J. Build. Eng. 2017, 11, 9–16. [Google Scholar] [CrossRef]

- Vivekh, P.; Kumja, M.; Bui, D.T.; Chua, K. Recent developments in solid desiccant coated heat exchangers—A review. Appl. Energy 2018, 229, 778–803. [Google Scholar] [CrossRef]

- Tu, Y.D.; Wang, R.Z.; Hua, L.J.; Ge, T.S.; Cao, B.Y. Desiccant-coated water-sorbing heat exchanger: Weakly-coupled heat and mass transfer. Int. J. Heat Mass Transf. 2017, 113, 22–31. [Google Scholar] [CrossRef]

- Shang, Y.; Zhang, D.; Guo, L. Cucl-intermediated construction of short-range-ordered Cu2O mesoporous spheres with excellent adsorption performance. J. Mater. Chem. 2011, 22, 856–861. [Google Scholar] [CrossRef]

- Oh, S.J.; Ng, K.C.; Thu, K.; Ja, M.K.; Islam, M.R.; Chun, W.; Chua, K.J.E. Studying the performance of a dehumidifier with adsorbent coated heat exchangers for tropical climate operations. Sci. Technol. Built Energy 2017, 23, 127–135. [Google Scholar] [CrossRef]

- Dhar, P.L.; Singh, S.K. Studies on solid desiccant based hybrid air-conditioning systems. Appl. Therm. Eng. 2001, 21, 119–134. [Google Scholar] [CrossRef]

- Erta, H.; Orhan, B.; Lmaz, T.; Hepba, A. Experimental investigation of a novel desiccant cooling system. Energy Build. 2010, 42, 2049–2060. [Google Scholar]

- Saeed, A.; Al-Alili, A. A review on desiccant coated heat exchangers. Sci. Technol. Built Energy 2016, 23, 136–150. [Google Scholar] [CrossRef]

- Akram, E.; Ge, T.S.; Wang, R.Z. Water adsorption on the coated aluminum sheets by composite materials (LiCl + LiBr)/silica gel. Energy 2018, 160, 64–71. [Google Scholar]

- Zhao, Y.; Ge, T.S.; Dai, Y.J.; Wang, R.Z. Experimental investigation on a desiccant dehumidification unit using fin-tube heat exchanger with silica gel coating. Appl. Therm. Eng. 2014, 63, 52–58. [Google Scholar] [CrossRef]

- La, D.; Dai, Y.J.; Li, Y.; Wang, R.Z.; Ge, T.S. Technical development of rotary desiccant dehumidification and air conditioning: A review. Renew. Sustain. Energy Rev. 2010, 14, 130–147. [Google Scholar] [CrossRef]

- Zheng, X.; Ge, T.S.; Jiang, Y.; Wang, R.Z. Experimental study on silica gel-licl composite desiccants for desiccant coated heat exchanger. Int. J. Refrig. 2015, 51, 24–32. [Google Scholar] [CrossRef]

- Oh, S.J.; Ng, K.C.; Chun, W.; Chua, K. Evaluation of a dehumidifier with adsorbent coated heat exchangers for tropical climate operations. Energy 2017, 137, 441–448. [Google Scholar] [CrossRef]

- Bongs, C.; Morgenstern, A.; Lukito, Y.; Henning, H.M. Advanced performance of an open desiccant cycle with internal evaporative cooling. Sol. Energy 2014, 104, 103–114. [Google Scholar] [CrossRef]

- Ge, T.S.; Dai, Y.J.; Wang, R.Z.; Peng, Z.Z. Experimental comparison and analysis on silica gel and polymer coated fin-tube heat exchangers. Energy 2010, 35, 2893–2900. [Google Scholar] [CrossRef]

- Tu, Y.D.; Wang, R.Z.; Ge, T.S. Moisture uptake dynamics on desiccant-coated, water-sorbing heat exchanger. Int. J. Therm. Sci. 2018, 126, 13–22. [Google Scholar] [CrossRef]

- Zheng, X.; Wang, R.Z.; Ge, T.S.; Hu, L.M. Performance study of sapo-34 and fapo-34 desiccants for desiccant coated heat exchanger systems. Energy 2015, 93, 88–94. [Google Scholar] [CrossRef]

- Aristov, Y.I. Challenging offers of material science for adsorption heat transformation: A review. Appl. Therm. Eng. 2013, 50, 1610–1618. [Google Scholar] [CrossRef]

- Bidyut, B.S.; Anutosh, C.; Shigeru, K.; Yu, I.A. A new generation cooling device employing CaCl2-in-silica gel-water system. Int. J. Heat Mass Transf. 2009, 52, 516–524. [Google Scholar]

- Aristov, Y.I.; Restuccia, G.; Tokarev, M.M.; Buerger, H.D.; Freni, A. Selective water sorbents for multiple applications. 11. CaCl2 confined to expanded vermiculite. React. Kinet. Catal. Lett. 2000, 71, 377–384. [Google Scholar] [CrossRef]

- Jia, C.X.; Dai, Y.J.; Wu, J.Y.; Wang, R.Z. Experimental comparison of two honeycombed desiccant wheels fabricated with silica gel and composite desiccant material. Energy Convers. Manag. 2006, 47, 2523–2534. [Google Scholar] [CrossRef]

- Jia, C.X.; Dai, Y.J.; Wu, J.Y.; Wang, R.Z. Use of compound desiccant to develop high performance desiccant cooling system. Int. J. Refrig. 2007, 30, 345–353. [Google Scholar] [CrossRef]

- Ge, T.S.; Ziegler, F.; Wang, R.Z. A mathematical model for predicting the performance of a compound desiccant wheel (a model of compound desiccant wheel). Appl. Therm. Eng. 2010, 30, 1005–1015. [Google Scholar] [CrossRef]

- Zheng, X.; Ge, T.S.; Wang, R.Z. Recent progress on desiccant materials for solid desiccant cooling systems. Energy 2014, 74, 280–294. [Google Scholar] [CrossRef]

- Zheng, X.; Wang, R.Z.; Ge, T.S. Experimental study and performance predication of carbon based composite desiccants for desiccant coated heat exchangers. Int. J. Refrig. 2016, 72, 124–131. [Google Scholar] [CrossRef]

- Hu, L.M.; Ge, T.S.; Jiang, Y.; Wang, R.Z. Performance study on composite desiccant material coated fin-tube heat exchangers. Int. J. Heat Mass Transf. 2015, 90, 109–120. [Google Scholar] [CrossRef]

- Gordeeva, L.G.; Grekova, A.D.; Krieger, T.A.; Aristov, Y.I. Adsorption properties of composite materials (LiCl + LiBr)/silica. Micropor. Mesopor. Mater. 2009, 126, 262–267. [Google Scholar] [CrossRef]

- Ge, T.S.; Zhang, J.Y.; Dai, Y.J.; Wang, R.Z. Experimental study on performance of silica gel and potassium formate composite desiccant coated heat exchanger. Energy 2017, 141, 149–158. [Google Scholar] [CrossRef]

- Jagirdar, M.; Lee, P.S. Mathematical modeling and performance evaluation of a desiccant coated fin-tube heat exchanger. Appl. Energy 2018, 212, 401–415. [Google Scholar] [CrossRef]

- Andres, S.V.; Sun, X.Y.; Ge, T.S.; Dai, Y.J.; Wang, R.Z. Experimental investigation on performance of a novel composite desiccant coated heat exchanger in summer and winter seasons. Energy 2019, 166, 506–518. [Google Scholar]

- Zheng, X.; Chen, K.; Lin, Z. Synthesis and characterization of alginate-silica gel composites for adsorption dehumidification. Ind. Eng. Chem. Res. 2020, 59, 5760–5767. [Google Scholar] [CrossRef]

- Entezari, M.; Wang, R. Super atmospheric water harvesting hydrogel with alginate chains modified with binary salts. ACS Mater. Lett. 2020, 2, 471–477. [Google Scholar] [CrossRef]

- Ge, T.S.; Cao, W.; Pan, X.; Dai, Y.J.; Wang, R.Z. Experimental investigation on performance of desiccant coated heat exchanger and sensible heat exchanger operating in series. Int. J. Refrig. 2017, 83, 88–98. [Google Scholar] [CrossRef]

- Tomohiro, H.; Mao, Y.; Naoki, N.; Chaobin, D.; Eiji, H. Gravimetric method for sorption performance measurement of desiccant wheel and desiccant coated heat exchanger. Appl. Therm. Eng. 2018, 144, 639–646. [Google Scholar]

- Sun, X.Y.; Dai, Y.J.; Ge, T.S.; Zhao, Y.; Wang, R.Z. Experimental and comparison study on heat and moisture transfer characteristics of desiccant coated heat exchanger with variable structure sizes. Appl. Therm. Eng. 2018, 38, 1822–1827. [Google Scholar] [CrossRef]

- Chai, S.W.; Sun, X.Y.; Zhao, Y.; Dai, Y.J. Experimental investigation on a fresh air dehumidification system using heat pump with desiccant coated heat exchanger. Energy 2019, 171, 306–314. [Google Scholar] [CrossRef]

- Ge, T.S.; Dai, Y.J.; Wang, R.Z.; Li, Y. Feasible study of a self-cooled solid desiccant cooling system based on desiccant coated heat exchanger. Appl. Therm. Eng. 2013, 58, 281–290. [Google Scholar] [CrossRef]

- Turkan, U.E.; Ali, G.; Hannes, F.; Alexander, M.; Constanze, B. Performance evaluation of a desiccant coated heat exchanger with two different desiccant materials. Appl. Therm. Eng. 2018, 143, 701–710. [Google Scholar]

- Kumar, A.; Yadav, A. Experimental investigation of solar driven desiccant air conditioning system based on silica gel coated heat exchanger. Int. J. Refrig. 2016, 69, 51–63. [Google Scholar] [CrossRef]

- Sun, X.Y.; Dai, Y.J.; Ge, T.S.; Zhao, Y.; Wang, R.Z. Comparison of performance characteristics of desiccant coated air-water heat exchanger with conventional air-water heat exchanger-experimental and analytical investigation. Energy 2017, 137, 399–411. [Google Scholar] [CrossRef]

- Ge, T.S.; Dai, Y.J.; Wang, R.Z. Performance study of desiccant coated heat exchanger air conditioning system in winter. Energy Convers. Manag. 2016, 123, 559–568. [Google Scholar] [CrossRef]

- Ma, X.; Ding, G.; Zhang, Y.; Wang, K. Airside heat transfer and friction characteristics for enhanced fin-and-tube heat exchanger with hydrophilic coating under wet conditions. Int. J. Refrig. 2007, 30, 1153–1167. [Google Scholar] [CrossRef]

- Luo, Y.; Yang, H.; Lu, L. Dynamic and microscopic simulation of the counter-current flow in a liquid desiccant dehumidifier. Appl. Energy 2014, 136, 1018–1025. [Google Scholar] [CrossRef]

- Guo, L.; Tang, G.H. Dropwise condensation on bioinspired hydrophilic-slippery surface. RSC Adv. 2018, 8, 39341–39351. [Google Scholar] [CrossRef] [Green Version]

- Sheng, Q.; Sun, J.; Wang, Q.; Wang, W.; Wang, H.S. On the onset of surface condensation: Formation and transition mechanisms of condensation mode. Sci. Rep. 2016, 6, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Zhao, H.; Beysens, D. From droplet growth to film growth on a heterogeneous surface: Condensation associated with a wettability gradient. Langmuir 1995, 11, 627–634. [Google Scholar] [CrossRef]

- Patankar, N.A. Supernucleating surfaces for nucleate boiling and dropwise condensation heat transfer. Soft Matter 2010, 6, 1613–1620. [Google Scholar] [CrossRef]

- Ishii, D.; Yabu, H.; Shimomura, M. Novel biomimetic surface based on a self-organized metal−polymer hybrid structure. Chem. Mater. 2009, 21, 1799–1801. [Google Scholar] [CrossRef]

- Thickett, S.C.; Neto, C.; Harris, A.T. Biomimetic surface coatings for atmospheric water capture prepared by dewetting of polymer films. Adv. Mater. 2011, 23, 3718–3722. [Google Scholar] [CrossRef]

- Young, T. An essay on the cohesion of fluids. Phil. Trans. Roy. Soc. Lond. 1805, 95, 65–87. [Google Scholar]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Trans. Faraday Soc. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Cassie, A.B.D.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Suzuki, S.; Ueno, K. Apparent contact angle calculated from a water repellent model with pinning effect. Langmuir 2017, 33, 138–143. [Google Scholar] [CrossRef]

- Mondal, B.; Eain, M.M.G.; Xu, Q.F.; Egan, V.M.; Punch, J.; Lyons, A.M. Design and fabrication of a hybrid superhydrophobic-hydrophilic surface that exhibits stable dropwise condensation. ACS Appl. Mater. Interfaces 2015, 7, 23575–23588. [Google Scholar] [CrossRef]

- Ju, J.; Yao, X.; Yang, S.; Wang, L.; Jiang, L. Cactus stem inspired cone-arrayed surfaces for efficient fog collection. Adv. Funct. Mater. 2014, 24, 6933–6938. [Google Scholar] [CrossRef]

- Hu, H.W.; Tang, G.H.; Niu, D. Experimental investigation of condensation heat transfer on hybrid wettability finned tube with large amount of noncondensable gas. Int. J. Heat Mass Transf. 2015, 85, 513–523. [Google Scholar] [CrossRef]

- Mahapatra, P.S.; Ghosh, A.; Ganguly, R.; Megaridis, C.M. Key design and operating parameters for enhancing dropwise condensation through wettability patterning. Int. J. Heat Mass Transf. 2016, 92, 877–883. [Google Scholar] [CrossRef]

- Ghosh, A.; Beaini, S.; Zhang, B.J.; Ganguly, R.; Megaridis, C.M. Enhancing dropwise condensation through bioinspired wettability patterning. Langmuir 2014, 30, 13103–13115. [Google Scholar] [CrossRef]

- Derby, M.M.; Chatterjee, A.; Peles, Y.; Jensen, M.K. Flow condensation heat transfer enhancement in a mini-channel with hydrophobic and hydrophilic patterns. Int. J. Heat Mass Transf. 2014, 68, 151–160. [Google Scholar] [CrossRef] [Green Version]

- Alwazzan, M.; Egab, K.; Peng, B.; Khan, J.; Chen, L. Condensation on hybrid-patterned copper tubes (i): Characterization of condensation heat transfer. Int. J. Heat Mass Transf. 2017, 112, 991–1004. [Google Scholar] [CrossRef]

- Yin, K.; Du, H.; Dong, X.; Wang, C.; Duan, J.; He, J. A simple way to achieve bioinspired hybrid wettability surface with micro/nanopatterns for efficient fog collection. Nanoscale 2017, 9, 14620–14626. [Google Scholar] [CrossRef] [PubMed]

- Cao, M.; Xiao, J.; Yu, C.; Li, K.; Jiang, L. Hydrophobic/hydrophilic cooperative janus system for enhancement of fog collection. Small 2015, 11, 4379–4384. [Google Scholar] [CrossRef] [PubMed]

- Li, J.S.; Ueda, E.; Nallapaneni, A.; Li, L.X.; Levkin, P.A. Printable superhydrophilic-superhydrophobic micropatterns based on supported lipid layers. Langmuir ACS J. Surf. Colloids 2012, 28, 8286–8291. [Google Scholar] [CrossRef]

- Garrod, R.P.; Harris, L.G.; Schofield, W.C.E.; Mcgettrick, J.; Ward, L.J.; Teare, D.O.H. Mimicking a stenocara beetles back for microcondensation using plasmachemical patterned superhydrophobic/superhydrophilic surfaces. Langmuir 2007, 23, 689–693. [Google Scholar] [CrossRef]

- Hou, Y.; Yu, M.; Chen, X.; Wang, Z.; Yao, S. Recurrent filmwise and dropwise condensation on a beetle mimetic surface. ACS Nano 2015, 9, 71–81. [Google Scholar] [CrossRef]

- Lei, Z.; Berg, M.C.; Cebeci, F.C.; Kim, Y.; Milwid, J.M.; Rubner, M.F.; Cohen, R.E. Patterned superhydrophobic surfaces: Toward a synthetic mimic of the namibdesert beetle. Nano Lett. 2006, 6, 1213–1217. [Google Scholar]

- Zhang, L.; Wu, J.; Hedhili, M.; Yang, X.; Wang, P. Inkjet printing for direct micropatterning of a superhydrophobic surface: Toward biomimetic fog harvesting surfaces. J. Mater. Chem. A 2015, 3, 2844–2852. [Google Scholar] [CrossRef]

- Zhuang, D.; Ding, G.; Hu, H.; Fujino, H.; Inoue, S. Condensing droplet behaviors on fin surface under dehumidifyingcondition: Part I: Numerical model. Appl. Therm. Eng. 2016, 105, 336–344. [Google Scholar] [CrossRef]

- Ma, X.; Ding, G.; Zhang, Y.; Wang, K. Effects of hydrophilic coating on air side heat transfer and friction characteristics of wavy fin and tube heat exchangers under dehumidifying conditions. Energy Convers. Manag. 2007, 48, 2525–2532. [Google Scholar] [CrossRef]

- Yang, K.S.; Lin, K.H.; Tu, C.W.; He, Y.Z.; Wang, C.C. Experimental investigation of moist air condensation on hydrophilic, hydrophobic, superhydrophilic, and hybrid hydrophobic-hydrophilic surfaces. Int. J. Heat Mass Transf. 2017, 115, 1032–1041. [Google Scholar] [CrossRef]

- Wang, C.C.; Chang, C.T. Heat and mass transfer for plate fin-and-tube heat exchangers, with and without hydrophilic coating. Int. J. Heat Mass Transf. 1998, 41, 3109–3120. [Google Scholar] [CrossRef]

- Wang, C.C.; Lee, W.S.; Sheu, W.J.; Chang, Y.J. A comparison of the airside performance of the fin-and-tube heat exchangers in wet conditions; with and without hydrophilic coating. Appl. Therm. Eng. 2002, 22, 267–278. [Google Scholar] [CrossRef]

- Kim, K.; Lee, K.S. Characteristics and performance evaluation of surface-treated louvered-fin heat exchangers under frosting and wet conditions. Int. J. Heat Mass Transf. 2012, 55, 6676–6681. [Google Scholar] [CrossRef]

| Aluminum Sheet Types | Advantages | Disadvantages |

|---|---|---|

| Conventional | Simple production and low initial investment | Weak dehumidification capacity, low heat transfer coefficient |

| Desiccant-coated | Strong dehumidification capacity, recyclable low-grade energy | High initial investment and difficult system control |

| Hydrophobic coated | High heat transfer coefficient | Weak dehumidification capacity |

| Hydrophilic coated | Strong dehumidification ability | Low heat transfer coefficient |

| Hydrophobic/hydrophilic coated | High water droplet nucleation rate and surface heat transfer efficiency | Expensive to fabricate and poor mechanical durability |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, S.; Chen, W.; Yang, W.; Zhao, X. Review of Hygroscopic Coating on Aluminum Fin Surface of Air Conditioning Heat Exchanger. Appl. Sci. 2021, 11, 5193. https://doi.org/10.3390/app11115193

He S, Chen W, Yang W, Zhao X. Review of Hygroscopic Coating on Aluminum Fin Surface of Air Conditioning Heat Exchanger. Applied Sciences. 2021; 11(11):5193. https://doi.org/10.3390/app11115193

Chicago/Turabian StyleHe, Song, Wang Chen, Wansheng Yang, and Xudong Zhao. 2021. "Review of Hygroscopic Coating on Aluminum Fin Surface of Air Conditioning Heat Exchanger" Applied Sciences 11, no. 11: 5193. https://doi.org/10.3390/app11115193