Characterization of Nano-Mechanical, Surface and Thermal Properties of Hemp Fiber-Reinforced Polycaprolactone (HF/PCL) Biocomposites

Abstract

:1. Introduction

2. Experimental Procedures

2.1. Materials

2.2. Fabrication of Neat Poly(-Caprolactone) (PCL) and Hemp Fiber (HF)/PCL Biocomposite Samples

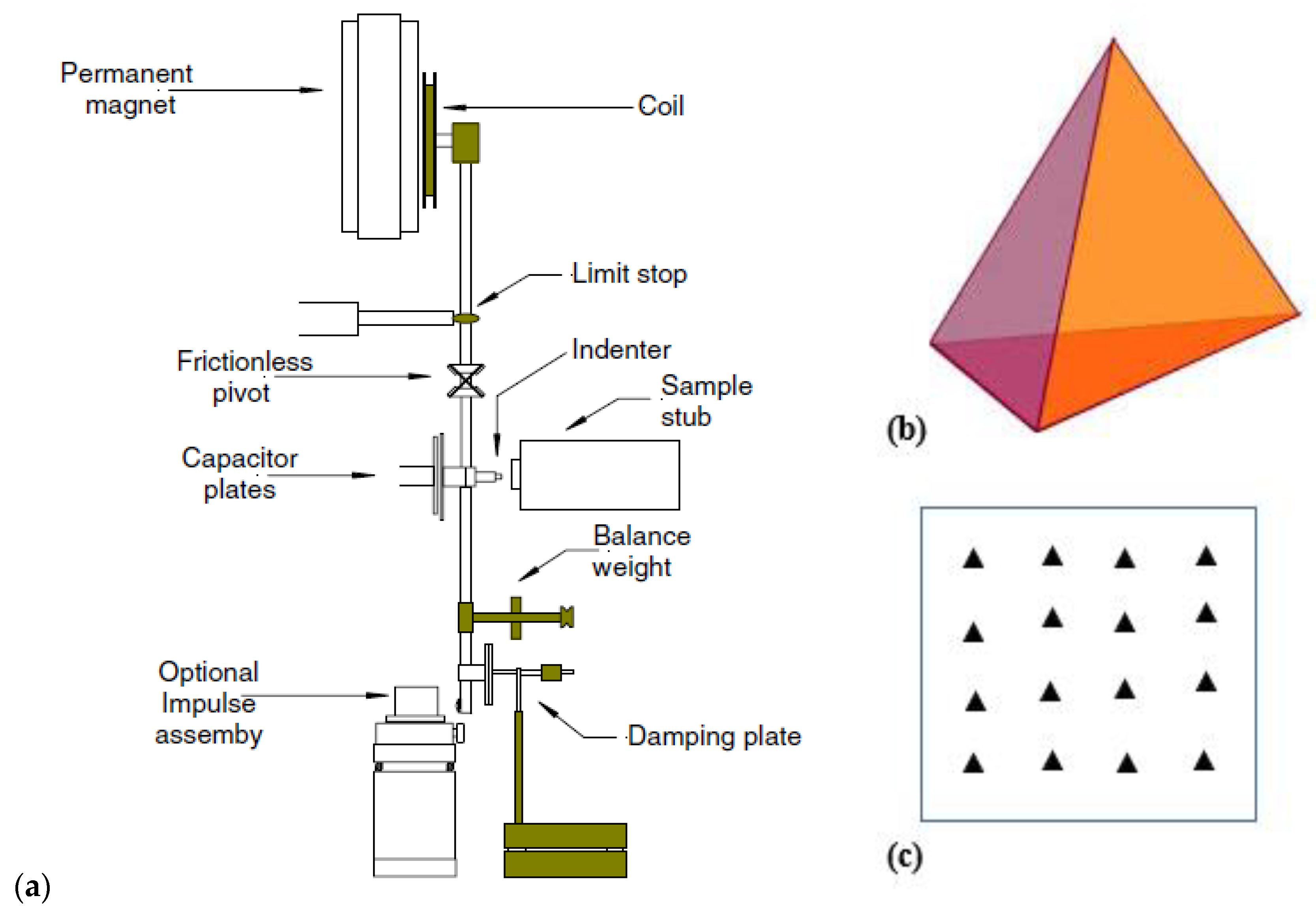

2.3. Nanoindentation Test

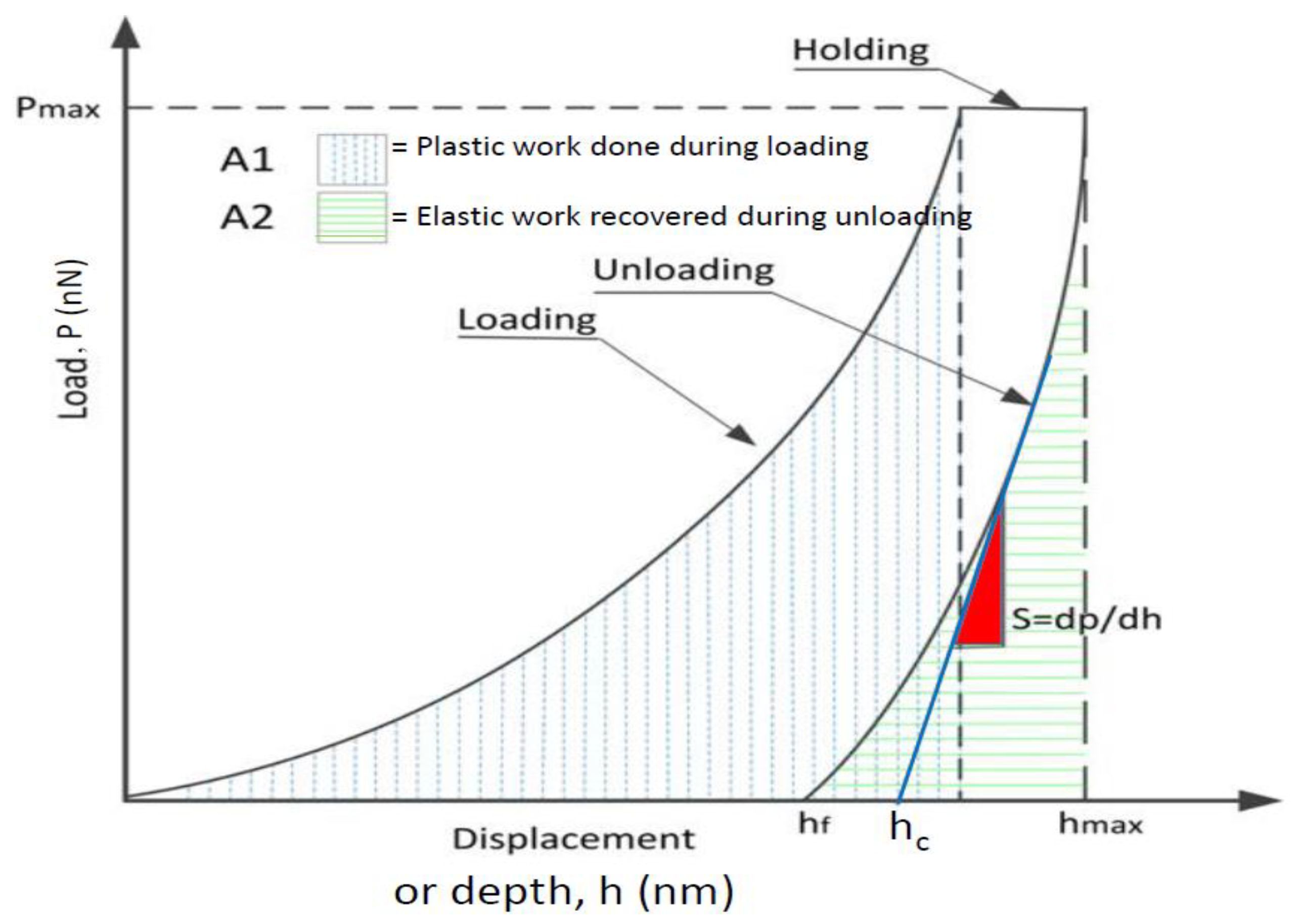

2.4. Analysis of Nanoindentation Quantities

2.5. Thermal Stability Analysis

2.5.1. Thermogravimetric Analysis (TGA)

2.5.2. Differential Scanning Calorimetry (DSC)

- Equilibrate at −15 °C

- Isothermal for 1 min

- Ramp 5.00 °C/min to 120 °C

- Cooling: Non regulated section (decrease between 10 and 15 °C/min) [41]

- Isothermal for 1 min

- Ramp 10 °C/min to 120 °C.

2.5.3. Thermal Conductivity

2.6. Contact Angle and Surface Energy Determination

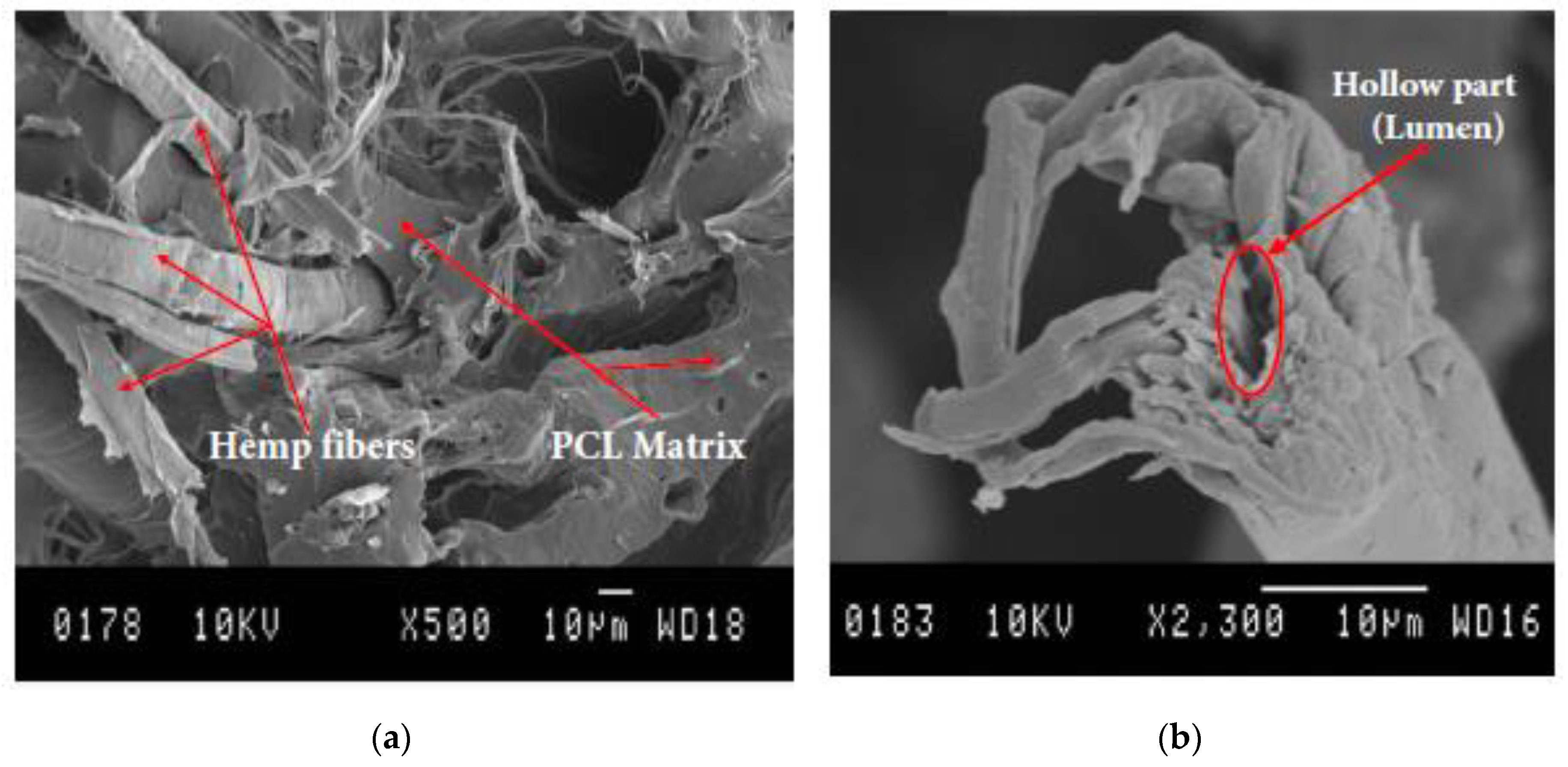

2.7. Scanning Electron Microscopy (SEM)

3. Results and Discussion

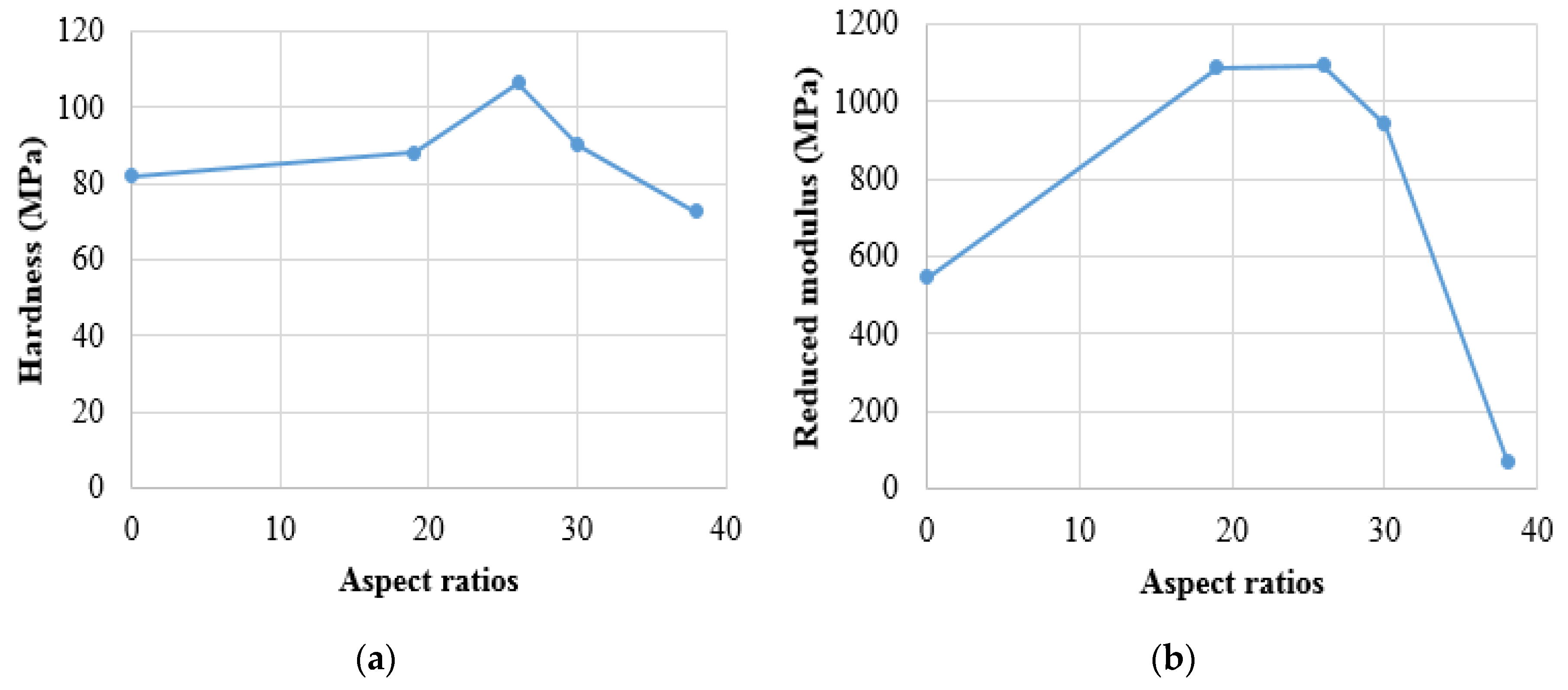

3.1. Nanoindentation Behavior

3.2. Thermal Properties: Thermogravimetric, Differential Scanning Calorimetry and Conductivity Analysis

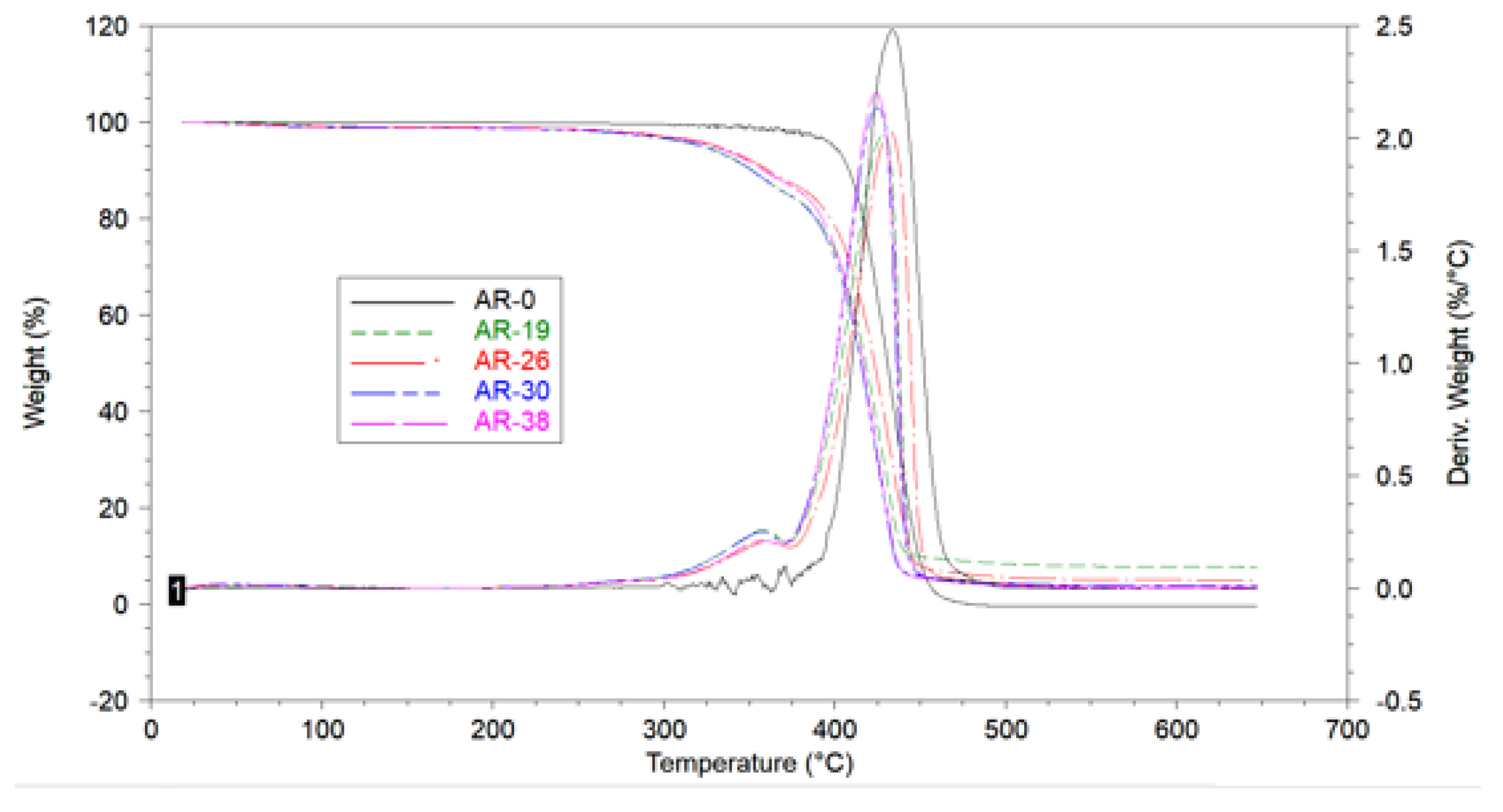

3.2.1. Thermal Stability

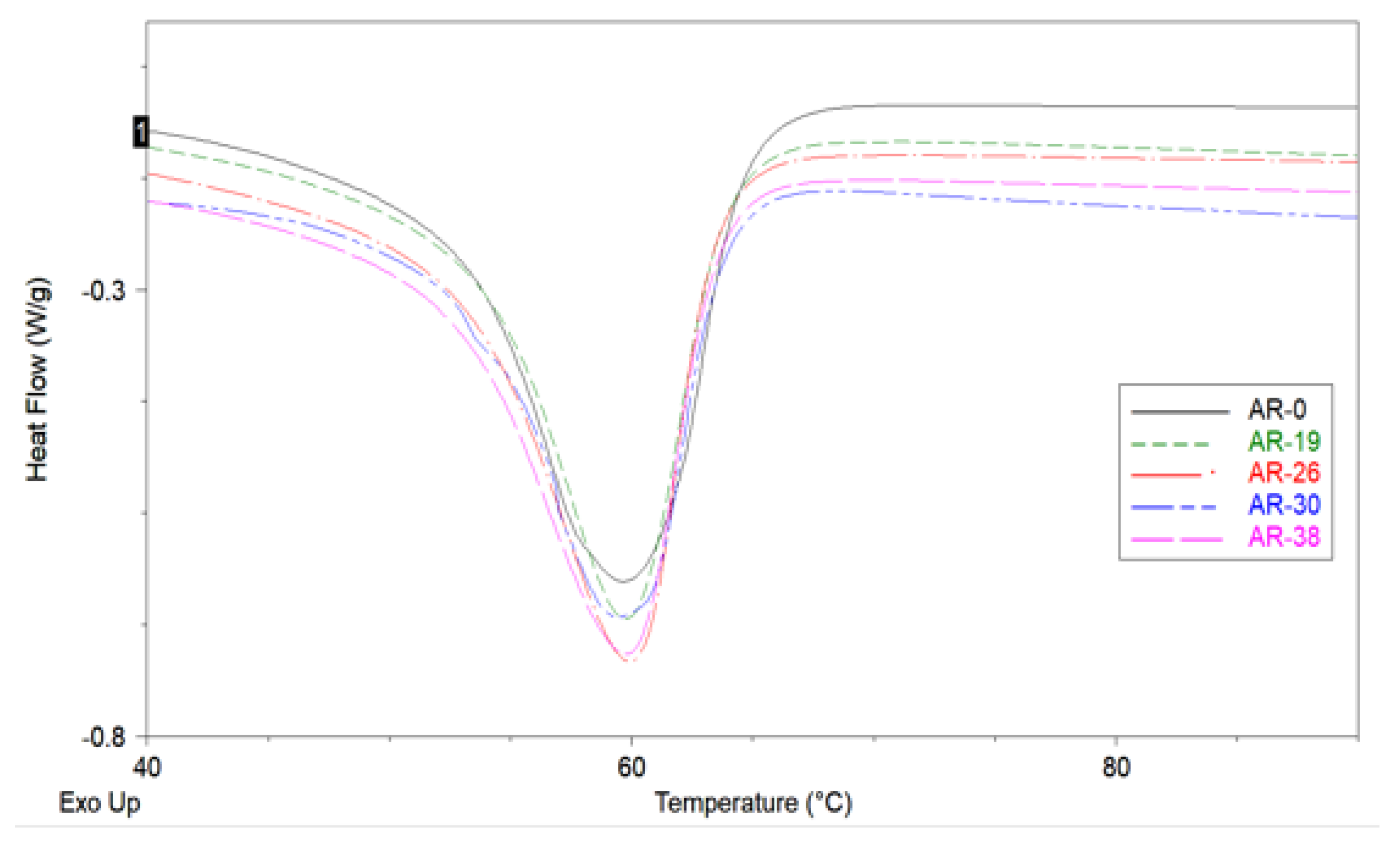

3.2.2. Crystallization Behavior

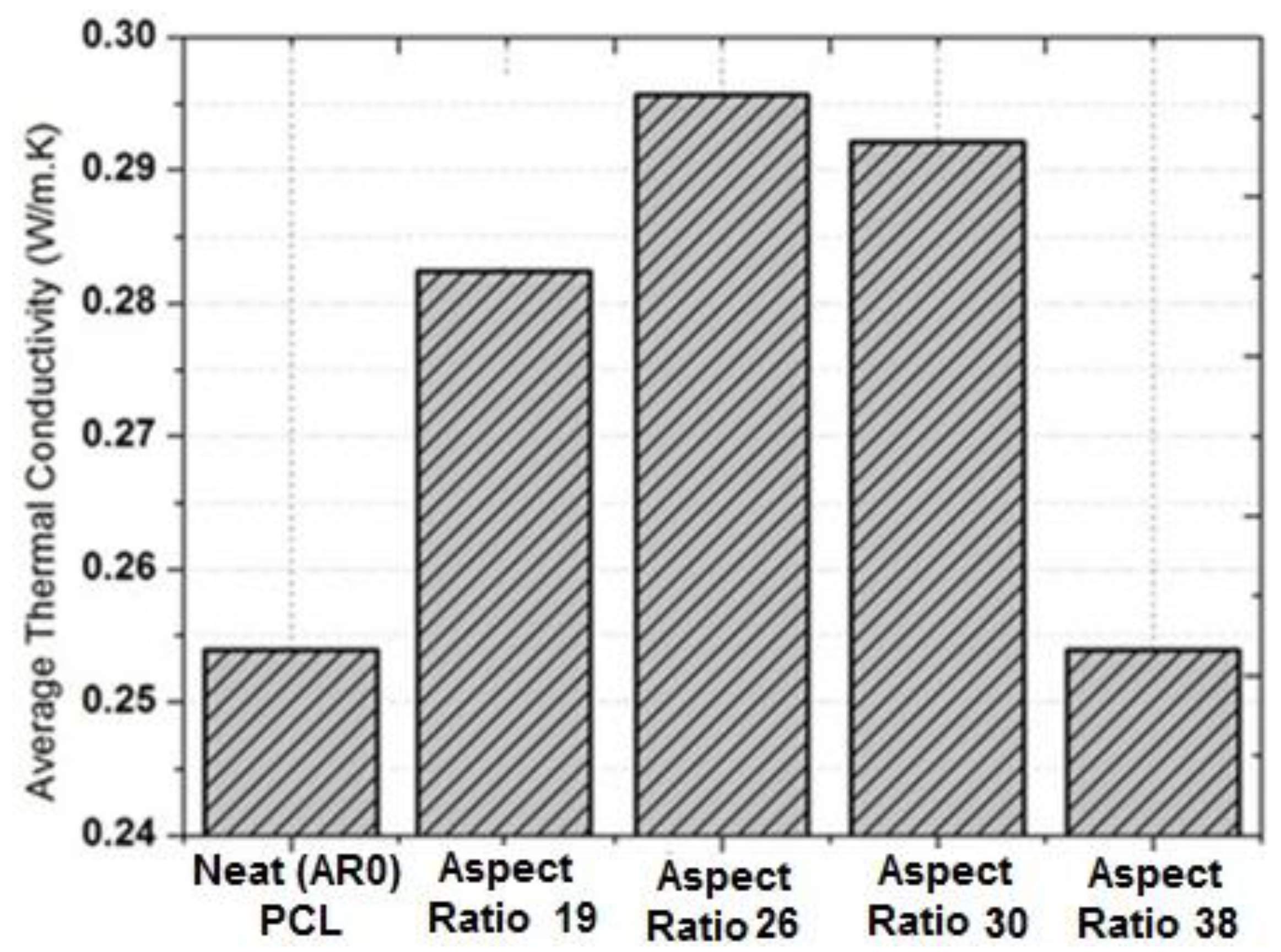

3.2.3. Thermal Conductivity

3.3. Contact Angle and Surface Energy Characterization

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bledzki, A.; Gassan, J. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.Y.; Richardson, M.O.W. Effect of Water Absorption on the Mechanical Properties of Hemp Fiber Reinforced Unsaturated Polyester Composites. Compos. Sci. Technol. 2007, 67, 1674–1683. [Google Scholar] [CrossRef]

- Mohanty, A.; Misra, M.; Drzal, L.T. Sustainable Bio-Composites from Renewable Resources: Opportunities and Challenges in the Green Materials World. J. Polym. Environ. 2002, 10, 19–26. [Google Scholar] [CrossRef]

- Bourmaud, A.; Dhakal, H.N.; Habrant, A.; Padovani, J.; Siniscalco, D.; Ramage, M.H.; Beaugrand, J.; Shah, D.U. Exploring the potential of waste leaf sheath date palm fibres for composite reinforcement through a structural and mechanical analysis. Compos. Part A Appl. Sci. Manuf. 2017, 103, 292–303. [Google Scholar] [CrossRef] [Green Version]

- Shahzad, A. Hemp fiber and its composites—A review. J. Compos. Mater. 2011, 46, 973–986. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.Y.; Bennett, N. Influence of Fiber Treatment and Glass Fiber Hybridisation on Thermal Degradation and Surface Energy Characteristics of Hemp/Unsaturated Polyester Composites. Compos. Part B Eng. 2012, 43, 2757–2761. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Hinrichsen, G. Biofibres, biodegradable polymers and biocomposites: An overview. Macromol. Mater. Eng. 2000, 276, 1–24. [Google Scholar] [CrossRef]

- Rout, J.; Tripathy, S.S.; Misra, M.; Mohanty, A.; Nayak, S.K. The influence of fiber surface modification on the mechanical properties of coir-polyester composites. Polym. Compos. 2001, 22, 468–476. [Google Scholar] [CrossRef]

- Beaugrand, J.; Berzin, F. Lignocellulosic Fibre Reinforced Composites: Influence of Compounding Conditions on Defibrization and Mechanical Properties. J. Appl. Polym. Sci. 2013, 128, 1227–1238. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Skrifvars, M.; Adekunle, K.; Zhang, Z. Falling weight impact response of jute/methacrylated soybean oil bio-composites under low velocity impact loading. Compos. Sci. Technol. 2014, 92, 134–141. [Google Scholar] [CrossRef] [Green Version]

- Berzin, F.; Vergnes, B.; Beaugrand, J. Evolution of Lignocellulosic Fiber Lengths along the Screw Profile during Twin Screw Compounding with Polycaprolactone. Compos. Part A Appl. Sci. Manuf. 2014, 59, 30–36. [Google Scholar] [CrossRef]

- Avolio, R.; Graziano, V.; Pereira, Y.; Cocca, M.; Gentile, G.; Errico, M.; Ambrogi, V.; Avella, M. Effect of cellulose structure and morphology on the properties of poly(butylene succinate-co-butylene adipate) biocomposites. Carbohydr. Polym. 2015, 133, 408–420. [Google Scholar] [CrossRef] [PubMed]

- Hull, D.; Clyne, T. An Introduction to Composite Materials; Cambridge University Press, (CUP): Cambridge, NY, USA, 1996. [Google Scholar]

- Wibowo, A.; Mohanty, A.K.; Misra, M.; Drzal, L.T. Chopped Industrial Hemp Fiber Reinforced Cellulosic Plastic Biocomposites: Thermomechanical and Morphological Properties. Ind. Eng. Chem. Res. 2004, 43, 4883–4888. [Google Scholar] [CrossRef]

- Sapuan, S.; Leenie, A.; Harimi, M.; Beng, Y.; Sapuan, S.M. Mechanical properties of woven banana fibre reinforced epoxy composites. Mater. Des. 2006, 27, 689–693. [Google Scholar] [CrossRef]

- Harish, S.; Michael, D.P.; Bensely, A.; Lal, D.M.; Rajadurai, A.; Sivasankaran, H. Mechanical property evaluation of natural fiber coir composite. Mater. Charact. 2009, 60, 44–49. [Google Scholar] [CrossRef]

- Astarita, A.; Boccarusso, L.; Durante, M.; Viscusi, A.; Sansone, R.; Carrino, L. Study of the Production of a Metallic Coating on Natural Fiber Composite Through the Cold Spray Technique. J. Mater. Eng. Perform. 2018, 27, 739–750. [Google Scholar] [CrossRef]

- Jee, A.-Y.; Lee, M. Comparative analysis on the nanoindentation of polymers using atomic force microscopy. Polym. Test. 2010, 29, 95–99. [Google Scholar] [CrossRef]

- Liao, Q.; Huang, J.; Zhu, T.; Xiong, C.; Fang, J. A hybrid model to determine mechanical properties of soft polymers by nanoindentation. Mech. Mater. 2010, 42, 1043–1047. [Google Scholar] [CrossRef]

- Ferencz, R.; Sánchez, J.; Blumich, B.; Herrmann, W. AFM nanoindentation to determine Young’s modulus for different EPDM elastomers. Polym. Test. 2012, 31, 425–432. [Google Scholar] [CrossRef]

- Shen, L.; Tjiu, W.C.; Liu, T. Nanoindentation and morphological studies on injection-molded nylon-6 nanocomposites. Polymer 2005, 46, 11969–11977. [Google Scholar] [CrossRef]

- Shen, L.; Wang, L.; Liu, T.; He, C. Nanoindentation and Morphological Studies of Epoxy Nanocomposites. Macromol. Mater. Eng. 2006, 291, 1358–1366. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.Y.; Richardson, M.O.W. Nanoindentation Behavior of Layered Silicate Reinforced Unsaturated Polyester Nanocomposites. Polym. Test. 2006, 25, 846–852. [Google Scholar] [CrossRef]

- Lam, C.K.; Lau, K.T. Localized elastic modulus distribution of nanoclay/epoxy composites by using nanoindentation. Compos. Struct. 2006, 75, 553–558. [Google Scholar] [CrossRef]

- Aldousiri, B.; Dhakal, H.N.; Onuh, S.; Zhang, Z.; Bennett, N. Nanoindentation behaviour of layered silicate filled spent polyamide-12 nanocomposites. Polym. Test. 2011, 30, 688–692. [Google Scholar] [CrossRef]

- Sánchez-Romate, X.F.; Rams, J.; Campo, M.; Jiménez-Suárez, A.; Ureña, A. Characterization of carbon nanofiber/epoxy nanocomposites by the nanoindentation technique. Compos. Part B Eng. 2011, 42, 638–644. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Hosseinkhani, M.; Naimi-Jamal, M.R.; Tourani, H. Nanoindentation and nanoscratch investigations on graphene-based nanocomposites. Polym. Test. 2013, 32, 45–51. [Google Scholar] [CrossRef]

- Zhu, R.; Yadama, V.; Liu, H.; Lin, R.J.T.; Harper, D.P. Fabrication and Characterization of Nylon 6/Cellulose Nanofibrils Melt-Spun Nanocomposite Filaments. Compos. Part A Appl. Sci. Manuf. 2017, 97, 111–119. [Google Scholar] [CrossRef] [Green Version]

- Perrier, A.; Le Bourhis, E.; Touchard, F.; Chocinski-Arnault, L. Effect of water ageing on nanoindentation response of single hemp yarn/epoxy composites. Compos. Part A Appl. Sci. Manuf. 2016, 84, 216–223. [Google Scholar] [CrossRef]

- Wei, G.; Bhushan, B.; Torgerson, P.M. Nanomechanical characterization of human hair using nanoindentation and SEM. Ultramicroscopy 2005, 105, 248–266. [Google Scholar] [CrossRef]

- Tanguy, M.; Bourmaud, A.; Baley, C. Plant cell walls to reinforce composite materials: Relationship between nanoindentation and tensile modulus. Mater. Lett. 2016, 167, 161–164. [Google Scholar] [CrossRef]

- Sair, S.; Oushabi, A.; Kammouni, A.; Tanane, O.; Abboud, Y.; El Bouari, A. Mechanical and thermal conductivity properties of hemp fiber reinforced polyurethane composites. Case Stud. Constr. Mater. 2018, 8, 203–212. [Google Scholar] [CrossRef]

- Idicula, M.; Boudenne, A.; Umadevi, L.; Ibos, L.; Candau, Y.; Thomas, S. Thermophysical properties of natural fibre reinforced polyester composites. Compos. Sci. Technol. 2006, 66, 2719–2725. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, D.-Y.; Martin, F.H.; Zhang, X.-Q.; Wang, R.; Wang, D.-Y. Influence of phenylphosphonate based flame retardant on epoxy/glass fiber reinforced composites (GRE): Flammability, mechanical and thermal stability properties. Compos. Part B Eng. 2017, 110, 511–519. [Google Scholar] [CrossRef] [Green Version]

- Guettler, B.E.; Moresoli, C.; Simon, L.C. Contact angle and surface energy analysis of soy materials subjected to potassium permanganate and autoclave treatment. Ind. Crop. Prod. 2013, 50, 219–226. [Google Scholar] [CrossRef]

- Urai, T.; Kamai, M.; Fujii, H. Estimation of Intrinsic Contact Angle of Various Liquids on PTFE by Utilizing Ultrasonic Vibration. J. Mater. Eng. Perform. 2016, 25, 3384–3389. [Google Scholar] [CrossRef]

- Chen, H.; Cheng, H.; Jiang, Z.; Qin, D.; Yu, Y.; Tian, G.; Lu, F.; Fei, B.; Wang, G. Contact Angles of Single Bamboo Fibers Measured in Different Environments and Compared with Other Plant Fibers and Bamboo Strips. Bioresources 2013, 8, 2827–2838. [Google Scholar] [CrossRef] [Green Version]

- Oliver, W.; Pharr, G. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Hardiman, M.; Vaughan, T.J.; McCarthy, C.T. A Review of Key Developments and Pertinent Issues in Nanoindentation Testing of Fiber Reinforced Plastic Microstructures. Compos. Struct. 2017, 180, 782–798. [Google Scholar] [CrossRef]

- Molazemhosseini, A.; Tourani, H.; Naimi-Jamal, M.R.; Khavandi, A. Nanoindentation and nanoscratching responses of PEEK based hybrid composites reinforced with short carbon fibers and nano-silica. Polym. Test. 2013, 32, 525–534. [Google Scholar] [CrossRef]

- Zafeiropoulos, N.; Baillie, C. A study of the effect of surface treatments on the tensile strength of flax fibres: Part II. Application of Weibull statistics. Compos. Part A Appl. Sci. Manuf. 2007, 38, 629–638. [Google Scholar] [CrossRef]

- Young, T., III. An essay on the cohesion of fluids. Philos. Trans. R. Soc. Lond. 1805, 95, 65–87. [Google Scholar]

- Bargir, S.; Dunn, S.; Jefferson, B.; Macadam, J.; Parsons, S. The use of contact angle measurements to estimate the adhesion propensity of calcium carbonate to solid substrates in water. Appl. Surf. Sci. 2009, 255, 4873–4879. [Google Scholar] [CrossRef]

- Fowkes, F.M. Determination of interfacial tensions, contact angles, and dispersion forces in surfaces by assuming additivity of intermolecular interactions in surfaces. J. Phys. Chem. 1962, 66, 382. [Google Scholar] [CrossRef]

- Singh, S.S.; Jansen, M.A.; Franz, N.M.; Chawla, N. Microstructure and Nanoindentation of the Rostrumof Curculio Longinasus Chittenden, 1927 (Coleoptera: Curculionidae). Mater. Charact. 2016, 118, 206–211. [Google Scholar] [CrossRef] [Green Version]

- Deng, X.; Cleveland, C.; Karcher, T.; Koopman, M.; Chawla, N.; Chawla, K. Nanoindentation Behavior of Nanolayered Metal-Ceramic Composites. J. Mater. Eng. Perform. 2005, 14, 417–423. [Google Scholar] [CrossRef]

- Jang, J.-I.; Lance, M.; Wen, S.; Tsui, T.Y.; Pharr, G. Indentation-induced phase transformations in silicon: Influences of load, rate and indenter angle on the transformation behavior. Acta Mater. 2005, 53, 1759–1770. [Google Scholar] [CrossRef]

- Lucca, D.A.; Herrmann, K.; Klopfstein, M.J. Nanoindentation: Measuring methods and applications. CIRP Ann. 2010, 59, 803–819. [Google Scholar] [CrossRef]

- Cocca, M.; Avolio, R.; Gentile, G.; di Pace, E.; Errico, M.E.; Avella, M. Amorphized Cellulose as Filler in Biocomposites Based on Poly(ε-Caprolactone). Carbohydr. Polym. 2015, 118, 170–182. [Google Scholar] [CrossRef]

- Oushabi, A.; Sair, S.; Abboud, Y.; Tanane, O.; El Bouari, A. An experimental investigation on morphological, mechanical and thermal properties of date palm particles reinforced polyurethane composites as new ecological insulating materials in building. Case Stud. Constr. Mater. 2017, 7, 128–137. [Google Scholar] [CrossRef]

| Samples | Hardness (GPa) | Reduced Modulus (GPa) | Elastic Recovery (mm) | Plastic Work (nJ) | Elastic Work (nJ) | Maximum Depth (nm) | Plastic Depth (nm) |

|---|---|---|---|---|---|---|---|

| AR_00 (Neat) | 0.0820 (±0.009) | 0.5457 (±0.042) | 0.3886 (±0.019) | 0.98 (±0.086) | 1.05 (±0.115) | 1855.46 (±8.12) | 1336.42 (±20.32) |

| AR_19 | 0.0882 (±0.006) | 1.0893 (±0.135) | 0.2083 (±0.017) | 1.40 (±0.145) | 0.94 (±0.050) | 1820.97 (±8.40) | 1507.39 (±24.58) |

| AR_26 | 0.1066 (±0.009) | 1.0936 (±0.127) | 0.2510 (±0.018) | 1.58 (±0.220) | 1.21 (±0.107) | 1815.58 (±6.43) | 1451.56 (±23.08) |

| AR_30 | 0.0903 (±0.013) | 0.9433 (±0.116) | 0.2448 (±0.026) | 1.43 (±0.226) | 1.08 (±0.182) | 1852.19 (±35.87) | 1488.63 (±44.00) |

| AR_38 | 0.0726 (±0.004) | 0.5403 (±0.026) | 0.3470 (±0.015) | 0.95 (±0.080) | 0.93 (±0.072) | 1841.73 (±12.70) | 1367.43 (±17.72) |

| Samples | Main Degradation Temperature (°C) |

|---|---|

| AR_00 | 433 |

| AR_19 | 428 |

| AR_26 | 432 |

| AR_30 | 424 |

| AR_38 | 424 |

| Samples | Degree of Crystallinity χ (%) |

|---|---|

| AR_00 | 50.9 |

| AR_19 | 55.7 |

| AR_26 | 60.6 |

| AR_30 | 56.5 |

| AR_38 | 58.0 |

| Specimens | Contact Angle (°) | |

|---|---|---|

| Glycerol | Distilled Water | |

| AR_00 * | 86.70 | 94.12 |

| AR_19 | 93.07 | 101.95 |

| AR_26 | 85.21 | 95.77 |

| AR_30 | 79.19 | 86.87 |

| AR_38 | 87.85 | 86.65 |

| Liquid | Total Surface Energy (mN/m) |

|---|---|

| Distilled water | 72 |

| Glycerol | 64 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dhakal, H.N.; Ismail, S.O.; Beaugrand, J.; Zhang, Z.; Zekonyte, J. Characterization of Nano-Mechanical, Surface and Thermal Properties of Hemp Fiber-Reinforced Polycaprolactone (HF/PCL) Biocomposites. Appl. Sci. 2020, 10, 2636. https://doi.org/10.3390/app10072636

Dhakal HN, Ismail SO, Beaugrand J, Zhang Z, Zekonyte J. Characterization of Nano-Mechanical, Surface and Thermal Properties of Hemp Fiber-Reinforced Polycaprolactone (HF/PCL) Biocomposites. Applied Sciences. 2020; 10(7):2636. https://doi.org/10.3390/app10072636

Chicago/Turabian StyleDhakal, Hom Nath, Sikiru Oluwarotimi Ismail, Johnny Beaugrand, Zhongyi Zhang, and Jurgita Zekonyte. 2020. "Characterization of Nano-Mechanical, Surface and Thermal Properties of Hemp Fiber-Reinforced Polycaprolactone (HF/PCL) Biocomposites" Applied Sciences 10, no. 7: 2636. https://doi.org/10.3390/app10072636