CBR Predictive Models for Granular Bases Using Physical and Structural Properties

Abstract

:1. Introduction

2. Materials and Methods

Characteristics of Tested Materials

3. Results

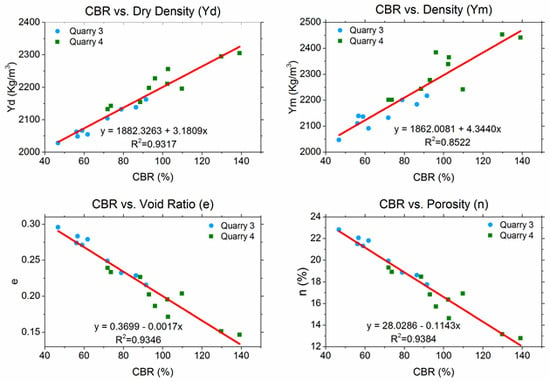

3.1. Regression Analysis

3.2. CBR Predictive Model

4. Discussion

5. Conclusions

- The predictive models for CBR tests were applied according to the classification of the considered soil. Four different CBR predictive models were obtained: for gravel and sand with some plasticity (GW-GM and SM); for sands (SP); for clean gravel (GW); and clean gravel well or poorly graded (GW or GP).

- For the development of the regression models, 14 parameters of the soil were considered.

- The more influencing parameters on the results of CBR tests were: γm, γd, e, n, and w. The last parameter presented an important influence on plastic materials.

- The precision of the models presented in this research was tested using compacted samples from different quarries to those initially employed for the development of the models. In this sense, it was observed that Equation (1) was more precise for samples compacted at the optimum level. On the other hand, Equation (4) presented important differences to experimental results, which might come from the origin of the parent rock.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gurung, N. A laboratory study on the tensile response of unbound granular base road pavement model using geosynthetics. Geotext. Geomembr. 2003, 21, 59–68. [Google Scholar] [CrossRef]

- Alawi, M.H.; Helal, M.M. A mathematical model for the distribution of heat through pavement layers in Makkah roads. J. King Saud Univ.—Eng. Sci. 2014, 26, 41–48. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Xuan, W.; Ma, X. Statistical Methods Applied to Pavement Construction Quality Assurance. In ICCTP 2010: Integred Transportation Systems-Green Intelligent Reliable; American Society of Civil Engineers: Reston, VA, USA, 2010. [Google Scholar]

- Tan, S.G.; Cheng, D. Quality Assurance of Performance Data for Pavement Management Systems. In Proceedings of the Geo-Hubei 2014 International Conference on Sustainable Civil Infrastructure, Yichang, Hubei, China, 20–22 July 2014. [Google Scholar]

- Rico, A.; Del Castillo, H. La Ingeniería de Suelos en las Vías Terrestres Vol. 2 Carreteras, Ferrocarriles y Aeropuertos, 1st ed.; Limusa Noriega Editores: Mexico City, Mexico, 1998. [Google Scholar]

- Karrech, A.; Duhamel, D.; Bonnet, G.; Roux, J.N.; Chevoir, F.; Canou, J.; Sab, K. A computational procedure for the prediction of settlement in granular materials under cyclic loading. Comput. Methods Appl. Mech. Eng. 2007, 197, 80–94. [Google Scholar] [CrossRef] [Green Version]

- Jiang, Y.; Wong, L.N.Y.; Ren, J. A numerical test method of California bearing ratio on graded crushed rocks using particle flow modeling. J. Traffic Transp. Eng. 2015, 2, 107–115. [Google Scholar] [CrossRef]

- Araya, A.; Molenaar, A.; Houben, L. Characterization of unbound granular materials using repeated load CBR and Triaxial Testing. In Proceedings of the GeoShanghai International Conference 2010, Shangai, China, 3–5 June 2010. [Google Scholar]

- Liu, Z.; Zhang, Y.; Di, J. Analysis on the Factors affecting the CBR value of silt oadbed. In Proceedings of the International Conference on Transportation Engineering, Chengdu, China, 25–27 July 2009. [Google Scholar]

- Joseph, D.; Vipulanandan, C. Characterization of Field Compacted Soils (Unsoaked) Using the California Bearing Ratio Test. In Proceedings of the Geo-Frontiers Congress 2011, Dallas, TX, USA, 13–16 March 2011. [Google Scholar]

- Patel, M.A.; Patel, H.S. Laboratory Assessment to Correlate Strength Parameter from Physical Properties of Subgrade. Procedia Eng. 2013, 51, 200–209. [Google Scholar] [CrossRef] [Green Version]

- Rollings, M.P.; Rollings, R.S. Geotechnical Materials in Construction, 1st ed.; McGraw-Hill Professional: New York, NY, USA, 1996. [Google Scholar]

- ASTM D75/D75M-09. Standard Practice for Sampling Aggregates; ASTM International: West Conshohocken, PA, USA, 2009. [Google Scholar]

- ASTM C702/C702M-11. Standard Specification for Materials for Reducing Samples of Aggregate to Testing Size; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- ASTM D4318-5. Standard Practice for Liquid Limit, Plastic Limit, and Plasticity Index of Soils; ASTM International: West Conshohocken, PA, USA, 2005. [Google Scholar]

- SCT M-MMP-1-08/03. Masas Volumétricas y Coeficientes de Variación Volumétrica; Secretaría de Comunicaciones y Transportes: Mexico City, Mexico, 2003. [Google Scholar]

- ASTM C127-12. Standard Practice for Density, Relative Density (Specific Gravity), and Absorption of Coarse Aggregate; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ASTM D1557-9. Standard Specification for Materials for Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 ft-lbf/ft3(2700 kN-m/m3); ASTM International: West Conshohocken, PA, USA, 2009. [Google Scholar]

- ASTM D1883-7. Standard Specification for Materials for CBR (California Bearing Ratio) of Laboratory-Compacted Soils; ASTM International: West Conshohocken, PA, USA, 2007. [Google Scholar]

- ASTM D2216-10. Standard Specification for Laboratory Determination of Water (Moisture) Content of Soil and Rock by Mass; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- Juarez, E.; Rico, A. Mecánica de Suelos Tomo I: Fundamentos de la Mecánica de Suelos, 1st ed.; Limusa: Mexico City, Mexico, 2012. [Google Scholar]

| Location | Quarry | Coordinates UTM (m) | Origin of Rock | Type of Material | Treatment | Classification USCS | |

|---|---|---|---|---|---|---|---|

| North | East | ||||||

| Querétaro | 1 | 2281062.80 | 363855.13 | Igneous basic extrusive | Basalt | Total crushing and sieving | GW-GM y SM |

| Mexicali | 2 | 3603070.10 | 629274.95 | Sedimentary | Clastic | Partial crushing and sieving | SP |

| 3 | 3573429.00 | 657540.00 | Sedimentary | Clastic | Partial crushing and sieving | GW | |

| 4 | 3568274.44 | 657006.26 | Sedimentary | Clastic | Partial crushing and sieving | GP | |

| Quarry | LVW (kg/m3) | SD Ss | Modified Proctor Compaction Test | CBR (%) | USCS | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LL (%) | PI (%) | Direct Values | Corrected Values | Added w (%) | CE (kN*m/m3) | |||||||

| γd (kg/m3) | wopt (%) | γd (kg/m3) | wopt (%) | |||||||||

| 1 | 27 | 12 | 1772 | 2.75 | 2240 | 8.0 | 2314 | 6.9 | 8.3 | 2692 | 111 | GW-GM |

| 2 | - | - | 1811 | 2.63 | 2230 | 5.3 | 2272 | 4.4 | 5.3 | 2642 | 86 | SP |

| 3 | - | - | 1681 | 2.63 | 2162 | 2.6 | 2294 | 1.6 | 2.6 | 2642 | 92 | GW |

| 4 | - | - | 1704 | 2.64 | 2304 | 5.9 | 2346 | 4.4 | 5.9 | 2645 | 139 | GP |

| Quarry | CE (kN-m/m3) | Sample | γd (kg/m3) | CBR (%) | Gravimetric | Volumetric | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (kg/m3) | (%) | (%) | ||||||||||||||

| γs | γd | γm | Ss | w | Cr | e | n | Gw | Ga | θ | Gc | |||||

| 1 | 2692 | 1 | 1772 | 111 | 2753 | 2208 | 2391 | 2.75 | 8.3 | 93 | 0.25 | 20 | 92 | 7 | 18.4 | 95 |

| 2676 | 2 | 1759 | 184 | 2757 | 2217 | 2327 | 2.76 | 4.9 | 83 | 0.24 | 20 | 55 | 44 | 10.9 | 97 | |

| 2690 | 3 | 1759 | 178 | 2757 | 2241 | 2394 | 2.76 | 6.8 | 91 | 0.23 | 19 | 81 | 18 | 15.2 | 98 | |

| 2673 | 4 | 1759 | 147 | 2757 | 2197 | 2349 | 2.76 | 7.9 | 82 | 0.25 | 20 | 74 | 25 | 15.2 | 108 | |

| 786 | 5 | 1616 | 98 | 2810 | 2041 | 2226 | 2.81 | 8.5 | 100 | 0.38 | 27 | 67 | 32 | 18.5 | 100 | |

| 601 | 6 | 1616 | 49 | 2815 | 1957 | 2091 | 2.81 | 6.8 | 80 | 0.44 | 30 | 43 | 56 | 13.4 | 96 | |

| 602 | 7 | 1616 | 28 | 2815 | 1986 | 1986 | 2.81 | 5.0 | 87 | 0.46 | 32 | 29 | 70 | 9.5 | 100 | |

| 2 | 2642 | 8 | 2158 | 72 | 2634 | 2158 | 2248 | 2.63 | 4.2 | 83 | 0.22 | 18 | 50 | 50 | 9.0 | 83 |

| 9 | 2230 | 86 | 2634 | 2230 | 2348 | 2.63 | 5.3 | 100 | 0.18 | 15 | 77 | 23 | 11.7 | 100 | ||

| 10 | 2192 | 72 | 2634 | 2192 | 2333 | 2.63 | 6.4 | 91 | 0.20 | 17 | 84 | 16 | 14.1 | 91 | ||

| 11 | 2144 | 43 | 2634 | 2144 | 2326 | 2.63 | 8.5 | 79 | 0.23 | 19 | 98 | 2 | 18.2 | 79 | ||

| 1179 | 12 | 2090 | 55 | 2634 | 2090 | 2198 | 2.63 | 5.2 | 83 | 0.26 | 21 | 53 | 47 | 10.9 | 83 | |

| 13 | 2118 | 53 | 2634 | 2118 | 2243 | 2.63 | 5.9 | 91 | 0.24 | 20 | 64 | 36 | 12.6 | 91 | ||

| 14 | 2146 | 64 | 2634 | 2146 | 2288 | 2.63 | 6.6 | 100 | 0.23 | 19 | 77 | 23 | 14.2 | 100 | ||

| 15 | 2122 | 56 | 2634 | 2122 | 2274 | 2.63 | 7.1 | 93 | 0.24 | 19 | 78 | 22 | 15.1 | 93 | ||

| 16 | 2076 | 41 | 2634 | 2076 | 2257 | 2.63 | 8.7 | 79 | 0.27 | 21 | 85 | 15 | 18.1 | 79 | ||

| 17 | 2084 | 26 | 2634 | 2084 | 2295 | 2.63 | 10.2 | 81 | 0.26 | 21 | 102 | −2 | 21.2 | 81 | ||

| 3 | 2642 | 18 | 2104 | 72 | 2627 | 2104 | 2132 | 2.63 | 1.4 | 88 | 0.25 | 20 | 14 | 86 | 2.8 | 88 |

| 19 | 2138 | 86 | 2627 | 2138 | 2184 | 2.63 | 2.1 | 95 | 0.23 | 19 | 25 | 75 | 4.6 | 95 | ||

| 20 | 2162 | 92 | 2627 | 2162 | 2217 | 2.63 | 2.6 | 100 | 0.22 | 18 | 32 | 68 | 5.6 | 100 | ||

| 21 | 2132 | 79 | 2627 | 2132 | 2201 | 2.63 | 3.2 | 94 | 0.23 | 19 | 37 | 63 | 6.9 | 94 | ||

| 1179 | 22 | 2028 | 47 | 2627 | 2028 | 2046 | 2.63 | 0.9 | 90 | 0.30 | 23 | 8 | 92 | 1.9 | 90 | |

| 23 | 2054 | 62 | 2627 | 2054 | 2091 | 2.63 | 1.8 | 97 | 0.28 | 22 | 17 | 83 | 3.7 | 97 | ||

| 24 | 2062 | 56 | 2627 | 2062 | 2110 | 2.63 | 2.3 | 99 | 0.27 | 22 | 22 | 78 | 4.8 | 99 | ||

| 25 | 2066 | 59 | 2627 | 2066 | 2137 | 2.63 | 3.4 | 100 | 0.27 | 21 | 33 | 67 | 7.0 | 100 | ||

| 26 | 2048 | 57 | 2627 | 2048 | 2139 | 2.63 | 4.5 | 95 | 0.28 | 22 | 42 | 58 | 9.2 | 95 | ||

| 4 | 2645 | 27 | 2196 | 110 | 2642 | 2196 | 2241 | 2.64 | 2.1 | 82 | 0.20 | 17 | 27 | 73 | 4.6 | 82 |

| 28 | 2198 | 93 | 2642 | 2198 | 2277 | 2.64 | 3.6 | 82 | 0.20 | 17 | 47 | 53 | 7.9 | 82 | ||

| 29 | 2256 | 103 | 2642 | 2256 | 2365 | 2.64 | 4.8 | 92 | 0.17 | 15 | 75 | 25 | 10.9 | 92 | ||

| 30 | 2304 | 139 | 2642 | 2304 | 2441 | 2.64 | 5.9 | 100 | 0.15 | 13 | 107 | −7 | 13.6 | 100 | ||

| 31 | 2294 | 130 | 2642 | 2294 | 2453 | 2.64 | 6.9 | 98 | 0.15 | 13 | 120 | −20 | 15.8 | 98 | ||

| 1181 | 32 | 2142 | 74 | 2642 | 2142 | 2201 | 2.64 | 2.7 | 84 | 0.23 | 19 | 31 | 69 | 5.9 | 84 | |

| 33 | 2132 | 72 | 2642 | 2132 | 2201 | 2.64 | 3.2 | 82 | 0.24 | 19 | 36 | 64 | 6.9 | 82 | ||

| 34 | 2154 | 89 | 2642 | 2154 | 2243 | 2.64 | 4.1 | 86 | 0.23 | 18 | 48 | 52 | 8.9 | 86 | ||

| 35 | 2210 | 102 | 2642 | 2210 | 2339 | 2.64 | 5.8 | 97 | 0.20 | 16 | 79 | 21 | 12.9 | 97 | ||

| 36 | 2226 | 96 | 2642 | 2226 | 2384 | 2.64 | 7.0 | 100 | 0.19 | 16 | 100 | 0 | 15.7 | 100 | ||

| Quarry | Sample | Gravimetric | Volumetric | CE | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| γs | γd | γm | Cr. | θ | ||||||||||

| 1–4 | 1–36 | 0.096 | 0.545 | 0.402 | 0.096 | 0.004 | 0.024 | 0.197 | 0.205 | 0.083 | 0.083 | 0.013 | 0.041 | 0.355 |

| USCS | Gravimetric (g/cm3) | Volumetric (%) | CE | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| γs | γd | γm | Cr | θ | |||||||||

| GW-GMSM | 0.6470 | 0.8312 | 0.7758 | 0.7291 | 0.9145 | 0.2552 | 0.8631 | 0.8540 | 0.3929 | 0.3929 | 0.0393 | 0.0159 | 0.7573 |

| SP | ---- | 0.7293 | 0.0634 | ---- | 0.7030 | 0.4540 | 0.7293 | 0.7293 | 0.2744 | 0.2744 | 0.6454 | 0.4486 | 0.3166 |

| GW | ---- | 0.9682 | 0.7999 | ---- | 0.0037 | 0.0201 | 0.9666 | 0.9675 | 0.0934 | 0.0934 | 0.0118 | 0.0201 | 0.8124 |

| GP | ---- | 0.8556 | 0.7118 | ---- | 0.3094 | 0.4461 | 0.8527 | 0.8556 | 0.5442 | 0.5442 | 0.3532 | 0.4455 | 0.4796 |

| GW and GP | 0.4612 | 0.9317 | 0.8522 | 0.4612 | 0.4315 | 0.0101 | 0.9346 | 0.9384 | 0.6336 | 0.6336 | 0.4814 | 0.0008 | 0.3571 |

| USCS | γd (x1) | γm (x2) | Constant | R2 | Error | Standard Deviation | |||

|---|---|---|---|---|---|---|---|---|---|

| GW-GM SM | −0.6231 | ---- | −9.5447 | −1319.1924 | ---- | 1924.9925 | 0.9052 | 26.3470 | 3.7380 |

| SP | 1.6064 | ---- | −5.3303 | 2462.2411 | 0 | −3913.2472 | 0.9559 | 4.4894 | 1.7746 |

| GW | 0.5979 | 0.0024 | ---- | 469.4978 | 0 | −1307.6738 | 0.9686 | 3.4216 | 2.4894 |

| GP | 13.9330 | 0.0667 | ---- | 4816.3003 | 292.0012 | −36564.5609 | 0.8938 | 9.4288 | 2.4352 |

| GW and GP | 0.1856 | −0.0551 | ---- | −346.259 | 0 | −113.4502 | 0.9256 | 6.8143 | 6.0547 |

| Quarry | Sample | USCS | Consistency Limits | Origin of Rock | Type | Model | CBR (%) | Difference | |

|---|---|---|---|---|---|---|---|---|---|

| Expl | Num | ||||||||

| 5 | 37 | GW | Plastic | Igneous extrusive basic | Crushed | Equation (1) | 160 | 164 | 4 |

| 6 | 38 | GP | Non plastic | Igneous extrusive acid | Sieved | Equation (4) | 110 | 104 | 4 |

| 7 | 39 | GW | Plastic | Igneous extrusive basic | Crushed | Equation (1) | 111 | 174 | 63 |

| 40 | GW | Plastic | Equation (1) | 175 | 180 | 5 | |||

| 41 | GW | Plastic | Equation (1) | 170 | 180 | 10 | |||

| 42 | GW | Plastic | Equation (1) | 124 | 176 | 52 | |||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Montes-Arvizu, M.E.; Chavez-Alegria, O.; Rojas-Gonzalez, E.; Gaxiola-Camacho, J.R.; Millan-Almaraz, J.R. CBR Predictive Models for Granular Bases Using Physical and Structural Properties. Appl. Sci. 2020, 10, 1414. https://doi.org/10.3390/app10041414

Montes-Arvizu ME, Chavez-Alegria O, Rojas-Gonzalez E, Gaxiola-Camacho JR, Millan-Almaraz JR. CBR Predictive Models for Granular Bases Using Physical and Structural Properties. Applied Sciences. 2020; 10(4):1414. https://doi.org/10.3390/app10041414

Chicago/Turabian StyleMontes-Arvizu, Mildred Estivaly, Omar Chavez-Alegria, Eduardo Rojas-Gonzalez, Jose Ramon Gaxiola-Camacho, and Jesus Roberto Millan-Almaraz. 2020. "CBR Predictive Models for Granular Bases Using Physical and Structural Properties" Applied Sciences 10, no. 4: 1414. https://doi.org/10.3390/app10041414