Solar Cell Cracks and Finger Failure Detection Using Statistical Parameters of Electroluminescence Images and Machine Learning

Abstract

1. Introduction

2. Methodology

2.1. Image Processing

2.2. Machine Learning Classifiers

3. Implemented Feature Vectors and Data Labelling

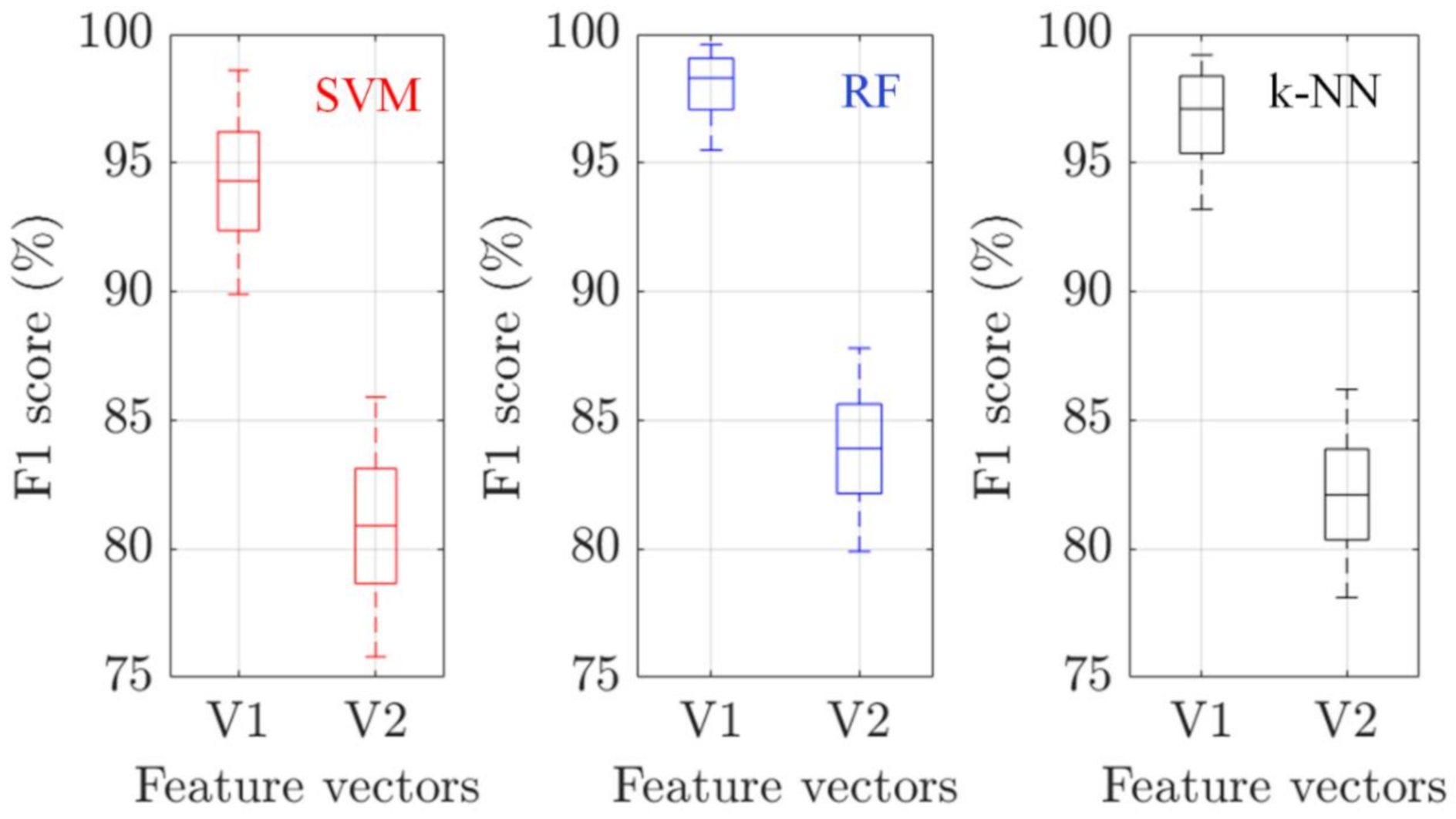

4. Results and Performance Discussion

Performance Analysis

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Statistical Parameters | Formulae |

|---|---|

| Cell level EL pixels | |

| Mean | |

| Standard deviation (SD) | |

| Skewness | |

| Kurtosis | |

| Inactive area | |

| Sensitivity peak | |

| Full-width | |

| Entropy | |

| Angular second moment | |

| Kstat | |

| Variation | |

| Median | |

| Percentiles | |

| Zscore | |

| Error of measurement |

Appendix B

References

- Haegel, N.M.; Atwater, H.; Barnes, T.; Breyer, C.; Burrell, A.; Chiang, Y.-M.; De Wolf, S.; Dimmler, B.; Feldman, D.; Glunz, S.; et al. Terawatt-scale photovoltaics: Transform global energy. Science 2019, 364, 836–838. [Google Scholar] [CrossRef] [PubMed]

- Green, M. Photovoltaic technology and visions for the future. Prog. Energy 2019, 1, 013001. [Google Scholar] [CrossRef]

- Köntges, M.; Kurtz, S.; Packard, C.; Jahn, U.; Berger, K.; Kato, K.; Kazuhilo, F.; Thomas, F.; Liu, H.; van Iseghem, M. IEA-PVPS Task 13: Review of Failures of Photovoltaic Modules; SUPSI: Manno, Switzerland, 2014. [Google Scholar]

- Spataru, S.; Hacke, P.; Sera, D. Automatic detection and evaluation of solar cell micro-cracks in electroluminescence images using matched filters. In Proceedings of the 2016 IEEE 43rd Photovoltaic Specialists Conference (PVSC); Institute of Electrical and Electronics Engineers (IEEE), Portland, OR, USA, 5–10 June 2016; pp. 1602–1607. [Google Scholar]

- Spataru, S.; Hacke, P.; Sera, D.; Glick, S.; Kerekes, T.; Teodorescu, R. Quantifying solar cell cracks in photovoltaic modules by electroluminescence imaging. In Proceedings of the 2015 IEEE 42nd Photovoltaic Specialist Conference (PVSC), Institute of Electrical and Electronics Engineers (IEEE), New Orleans, LA, USA, 14–19 June 2015; pp. 1–6. [Google Scholar]

- Dhimish, M.; Holmes, V.; Mehrdadi, B.; Dales, M. The impact of cracks on photovoltaic power performance. J. Sci. Adv. Mater. Devices 2017, 2, 199–209. [Google Scholar] [CrossRef]

- Kajari-Schršder, S.; Kunze, I.; Kšntges, M. Criticality of Cracks in PV Modules. Energy Procedia 2012, 27, 658–663. [Google Scholar] [CrossRef]

- Akram, M.W.; Li, G.; Jin, Y.; Chen, X.; Zhu, C.; Zhao, X.; Khaliq, A.; Faheem, M.; Ahmad, A. CNN based automatic detection of photovoltaic cell defects in electroluminescence images. Energy 2019, 189, 116319. [Google Scholar] [CrossRef]

- De Rose, R.; Malomo, A.; Magnone, P.; Crupi, F.; Cellere, G.; Martire, M.; Tonini, D.; Sangiorgi, E. A methodology to account for the finger interruptions in solar cell performance. Microelectron. Reliab. 2012, 52, 2500–2503. [Google Scholar] [CrossRef]

- Zafirovska, I.; Juhl, M.K.; Weber, J.W.; Wong, J.; Trupke, T. Detection of Finger Interruptions in Silicon Solar Cells Using Line Scan Photoluminescence Imaging. IEEE J. Photovolt. 2017, 7, 1496–1502. [Google Scholar] [CrossRef]

- Breitenstein, O.; Bauer, J.S.; Bothe, K.; Hinken, D.; Muller, J.; Kwapil, W.; Schubert, M.C.; Warta, W. Can luminescence imaging replace lock-in thermography on solar cells and wafers? IEEE J. Photovolt. 2011, 1, 159–167. [Google Scholar] [CrossRef]

- Fuyuki, T.; Kondo, H.; Yamazaki, T.; Takahashi, Y.; Uraoka, Y. Photographic surveying of minority carrier diffusion length in polycrystalline silicon solar cells by electroluminescence. Appl. Phys. Lett. 2005, 86, 262108. [Google Scholar] [CrossRef]

- Köntges, M.; Kunze, I.; Kajari-Schröder, S.; Breitenmoser, X.; Bjørneklett, B. The risk of power loss in crystalline silicon based photovoltaic modules due to micro-cracks. Sol. Energy Mater. Sol. Cells 2011, 95, 1131–1137. [Google Scholar] [CrossRef]

- Deitsch, S.; Christlein, V.; Berger, S.; Buerhop-Lutz, C.; Maier, A.; Gallwitz, F.; Riess, C. Automatic classification of defective photovoltaic module cells in electroluminescence images. Sol. Energy 2019, 185, 455–468. [Google Scholar] [CrossRef]

- Fada, J.S.; Hossain, M.A.; Braid, J.L.; Yang, S.; Peshek, T.J.; French, R.H. Electroluminescent Image Processing and Cell Degradation Type Classification via Computer Vision and Statistical Learning Methodologies. In Proceedings of the 2017 IEEE 44th Photovoltaic Specialist Conference (PVSC), Institute of Electrical and Electronics Engineers (IEEE), Washington, DC, USA, 25–30 June 2017; pp. 3456–3461. [Google Scholar]

- Bhoopathy, R.; Kunz, O.; Juhl, M.K.; Trupke, T.; Hameiri, Z. Outdoor photoluminescence imaging of photovoltaic modules with sunlight excitation. Prog. Photovolt. Res. Appl. 2018, 26, 69–73. [Google Scholar] [CrossRef]

- Alpaydin, E. Introduction to Machine Learning; The MIT Press: Cambridge, MA, USA, 2010. [Google Scholar]

- Bishop, C.M. Pattern Recognition and Machine Learning (Information Science and Statistics); Springer: London, UK, 2006. [Google Scholar]

- Karimi, A.M.; Fada, J.S.; Liu, J.; Braid, J.L.; Koyuturk, M.; French, R.H. Feature Extraction, Supervised and Unsupervised Machine Learning Classification of PV Cell Electroluminescence Images. In Proceedings of the 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC) (A Joint Conference of 45th IEEE PVSC, 28th PVSEC & 34th EU PVSEC), Institute of Electrical and Electronics Engineers (IEEE), Waikoloa Village, HI, USA, 10–15 June 2018; pp. 0418–0424. [Google Scholar]

- Sun, M.-J.; Lv, S.; Zhao, X.; Li, R.; Zhang, W.; Zhang, X. Defect Detection of Photovoltaic Modules Based on Convolutional Neural Network. In Proceedings of the Lecture Notes of the Institute for Computer Sciences, Social Informatics and Telecommunications Engineering; Springer Science and Business Media LLC: Cham, Switzerland, 2018; pp. 122–132. [Google Scholar]

- Tseng, D.-C.; Iu, Y.-S.; Chou, C.-M. Automatic Finger Interruption Detection in Electroluminescence Images of Multicrystalline Solar Cells. Math. Probl. Eng. 2015, 2015, 1–12. [Google Scholar] [CrossRef]

- Mantel, C.; Villebro, F.; Benatto, G.A.D.R.; Parikh, H.R.; Wendlandt, S.; Hossain, K.; Poulsen, P.B.; Spataru, S.; Sera, D.; Forchhammer, S. Machine learning prediction of defect types for electroluminescence images of photovoltaic panels. In Applications of Machine Learning; International Society for Optics and Photonics: Bellingham, WA, USA, 2019; pp. 1–9. [Google Scholar]

- Hsu, C.-C.; Lin, C.-W. CNN-Based Joint Clustering and Representation Learning with Feature Drift Compensation for Large-Scale Image Data. IEEE Trans. Multimed. 2017, 20, 421–429. [Google Scholar] [CrossRef]

- Tsai, D.-M.; Wu, S.-C.; Chiu, W.-Y. Defect Detection in Solar Modules Using ICA Basis Images. IEEE Trans. Ind. Inform. 2013, 9, 122–131. [Google Scholar] [CrossRef]

- Anwar, S.A.; Abdullah, M.Z. Micro-crack detection of multi-crystalline solar cells featuring an improved anisotropic diffusion filter and image segmentation technique. EURASIP J. Image Video Process. 2014, 2014, 15. [Google Scholar] [CrossRef]

- Li, X.; Wang, J.; Chen, Z. Intelligent fault pattern recognition of aerial photovoltaic module images based on deep learning technique. J. Syst. Cybern. Inf. 2018, 16, 67–71. [Google Scholar]

- Li, X.; Yang, Q.; Lou, Z.; Yan, W. Deep Learning Based Module Defect Analysis for Large-Scale Photovoltaic Farms. IEEE Trans. Energy Convers. 2019, 34, 520–529. [Google Scholar] [CrossRef]

- Ding, S.; Yang, Q.; Li, X.; Yan, W.; Ruan, W. Transfer learning based PV module defect diagnosis using aerial images. In Proceedings of the 2018 International Conference on Power System Technology (POWERCON), Guangzhou, China, 6–8 November 2018; pp. 4245–4250. [Google Scholar]

- Chen, H.; Pang, Y.; Hu, Q.; Liu, K. Solar cell surface defect inspection based on multi-spectral convolutional neural network. J. Intell. Manuf. 2020, 31, 453–468. [Google Scholar] [CrossRef]

- Luo, Z.; Cheng, S.Y.; Zheng, Q. GAN-Based Augmentation for Improving CNN Performance of Classification of Defective Photovoltaic Module Cells in Electroluminescence Images. IOP Conf. Ser. Earth Environ. Sci. 2019, 354, 012106. [Google Scholar] [CrossRef]

- Rousseeuw, P. Least median of squares regression. J. Am. Stat. Assoc. 1984, 79, 871–880. [Google Scholar] [CrossRef]

- Malis, E.; Vargas, M. Deeper Understanding of the Homography Decomposition for Vision-Based Control; INRIA: Paris, France, 2007. [Google Scholar]

- Szeliski, R. Computer Vision: Algorithms and Applications; Springer-Verlag: London, UK, 2010. [Google Scholar]

- Perspective Control Correction with Mathworks. Available online: https://se.mathworks.com/matlabcentral/fileexchange/35531-perspective-control-correction/ (accessed on 5 April 2020).

- Mantel, C.; Villebro, F.; Parikh, H.; Spataru, S.; Benatto, G.A.D.R.; Sera, D.; Poulsen, P.B.; Forchhammer, S. Method for Estimation and Correction of Perspective Distortion of Electroluminescence Images of Photovoltaic Panels. IEEE J. Photovolt. 2020, 10, 1797–1802. [Google Scholar] [CrossRef]

- Ali, U.; Mahmood, M.T. Analysis of Blur Measure Operators for Single Image Blur Segmentation. Appl. Sci. 2018, 8, 807. [Google Scholar] [CrossRef]

- Deitsch, S.; Buerhop-Lutz, C.; Maier, A.; Gallwitz, F.; Riess, C. Segmentation of photovoltaic module cells in electroluminescence images. Clin. Orthop. Relat. Res. 2018, 1806, 455–468. [Google Scholar]

- Hearst, M.A.; Dumais, S.T.; Osuna, E.; Platt, J.; Scholkopf, B. Support vector machines. IEEE Intell. Syst. Their Appl. 2019, 13, 18–28. [Google Scholar] [CrossRef]

- Applying Supervised Learning with Mathworks. Available online: https://se.mathworks.com/campaigns/offers/machine-learning-with-matlab.html (accessed on 21 August 2020).

- Linge, S.; Langtangen, H.P. Programming for Computations—Python: A Gentle Introduction to Numerical Simulations with Python; Springer: London, UK, 2016. [Google Scholar]

- Mckinney, W. Pandas: A foundational python library for data analysis and statistics. Python High Perform. Sci. Comput. 2011, 4, 1–9. [Google Scholar]

- Ziegler, A.; James, R.G.; Witten, D.; Hastie, T.; Tibshirani, R. An introduction to statistical learning with applications. Biometr. J. 2016, 58, 440. [Google Scholar]

- Kotsiantis, S. Supervised machine learning: A review of classification techniques. Informatica 2007, 31, 249–268. [Google Scholar]

- Breiman, L. Random forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Breiman, L.; Freidman, J.; Stone, C.J.; Olshen, R.A. Classification and Regression Trees; CRC Press: Boca Raton, FL, USA, 1984. [Google Scholar]

- VanderPlas, J. Python Data Science Handbook; O’Reilly Media Inc.: Sebastopol, CA, USA, 2016. [Google Scholar]

- Powers, D. Evaluation: From precision, recall and f-factor to ROC, informedness, markedness, and correlation. Mach. Learn. Technol. 2008, 2, 37–63. [Google Scholar]

- Buratti, Y.; Dick, J.; Le Gia, Q.; Hameiri, Z. A Machine Learning Approach to Defect Parameters Extraction: Using Random Forests to Inverse the Shockley-Read-Hall Equation. In Proceedings of the 2019 IEEE 46th Photovoltaic Specialists Conference (PVSC), Institute of Electrical and Electronics Engineers (IEEE), Chicago, IL, USA, 16–21 June 2019; pp. 3070–3073. [Google Scholar]

- Spataru, S.; Parikh, H.; Hacke, P.; Benatto, G.A.d.R.; Sera, D. Quantification of solar cell failure signatures based on statistical analysis of electroluminescence images. In Proceedings of the 33rd European Photovoltaic Solar Energy Conference and Exhibition: EU PVSEC, Amsterdam, The Netherlands, 25–29 September 2017; pp. 1466–1472. [Google Scholar]

- Statistical Functions Using Scipy.Stats. Available online: https://docs.scipy.org/doc/scipy/reference/stats.html (accessed on 9 September 2020).

| Module Images | Cell Images | ‘Class 0’ | ‘Class 1’ | ‘Class 2’ |

|---|---|---|---|---|

| 753 | 45,906 | 756 | 629 | 44,521 |

| Balanced data-set | 2185 | 756 | 629 | 800 |

| Parameter | Accuracy (%) | (%) | (%) | F1 Score (%) |

|---|---|---|---|---|

| Formulae | ) |

| Feature Vectors | Statistical Parameters (V1) | Pixel Intensity Histogram + Statistical Parameters (V2) | ||||

|---|---|---|---|---|---|---|

| ML Classifiers | SVM | RF | k-NN | SVM | RF | k-NN |

| F1 score (%) | 94.3 | 98.3 | 97.1 | 80.9 | 83.9 | 82.1 |

| Accuracy (%) | 96.7 | 99.2 | 98.4 | 76.6 | 83.1 | 83.9 |

| Recall (%) | 93.8 | 97.9 | 96.3 | 79.9 | 81.9 | 80.6 |

| Precision (%) | 92.8 | 99.2 | 97.9 | 82.9 | 86.2 | 85.5 |

| Research Article | Method (Vector) | Classifier | F1score (%) | Accuracy (%) | Detected Defects | EL Cell Images (Dataset) |

|---|---|---|---|---|---|---|

| This study | Statistical parameters (V1) | RF | 98.3 | 99.6 | Cracks B and C | |

| k-NN | 97.1 | 98.5 | micro-crack A | 2185 | ||

| SVM | 94.3 | 96.7 | finger failures | |||

| Cracked, busbar | ||||||

| [19] | Haralicks features | SVM | 98 | 98.9 | corroded, edge and busbar darkened, | 6264 |

| CNN | 97 | 98.2 | ||||

| Spectral clustering | ||||||

| [21] | ROI location | k-mean method | 92.1 | 99.1 | Interrupted finger defects | ---- |

| Stochastic gradient descent | SVM | --- | 98.7 | |||

| [15] | MLP-ANN | --- | 98.1 | Cracked, corroded | 14,200 | |

| RF | --- | 96.9 | ||||

| NAG based learning | Cracks (normal, linear, cross, flaky, broken) | |||||

| [20] | CNN | --- | 98.4 | 6120 | ||

| Isolated deep learning | ||||||

| [8] | CNN | 91.9 | 93 | Different defects | >7872 | |

| Transfer learning via t-SNE | Material defects, grid fingers, deep and microcracks, cell degradation | |||||

| [14] | CNN | 88.4 | 88.4 | 2624 | ||

| Material defects, grid fingers, deep and microcracks, cell degradation | ||||||

| [14] | Kaze/VGG | SVM | 82.5 | 82.4 | 2624 | |

| Hough region detection | Cracks B and C | |||||

| [22] | SVM | 5.1 | 99.7 | micro-crack A | 47,244 | |

| RF | 4.4 | 96.7 | finger failures | |||

| Percentile region detection | Cracks B and C | |||||

| [22] | RF | 6.6 | 96.5 | micro-crack A | 47,244 | |

| SVM | 4.1 | 99.7 | finger failures |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parikh, H.R.; Buratti, Y.; Spataru, S.; Villebro, F.; Reis Benatto, G.A.D.; Poulsen, P.B.; Wendlandt, S.; Kerekes, T.; Sera, D.; Hameiri, Z. Solar Cell Cracks and Finger Failure Detection Using Statistical Parameters of Electroluminescence Images and Machine Learning. Appl. Sci. 2020, 10, 8834. https://doi.org/10.3390/app10248834

Parikh HR, Buratti Y, Spataru S, Villebro F, Reis Benatto GAD, Poulsen PB, Wendlandt S, Kerekes T, Sera D, Hameiri Z. Solar Cell Cracks and Finger Failure Detection Using Statistical Parameters of Electroluminescence Images and Machine Learning. Applied Sciences. 2020; 10(24):8834. https://doi.org/10.3390/app10248834

Chicago/Turabian StyleParikh, Harsh Rajesh, Yoann Buratti, Sergiu Spataru, Frederik Villebro, Gisele Alves Dos Reis Benatto, Peter B. Poulsen, Stefan Wendlandt, Tamas Kerekes, Dezso Sera, and Ziv Hameiri. 2020. "Solar Cell Cracks and Finger Failure Detection Using Statistical Parameters of Electroluminescence Images and Machine Learning" Applied Sciences 10, no. 24: 8834. https://doi.org/10.3390/app10248834

APA StyleParikh, H. R., Buratti, Y., Spataru, S., Villebro, F., Reis Benatto, G. A. D., Poulsen, P. B., Wendlandt, S., Kerekes, T., Sera, D., & Hameiri, Z. (2020). Solar Cell Cracks and Finger Failure Detection Using Statistical Parameters of Electroluminescence Images and Machine Learning. Applied Sciences, 10(24), 8834. https://doi.org/10.3390/app10248834