Optical and Electrochemical Characterization of Nanoporous Alumina Structures: Pore Size, Porosity, and Structure Effect

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Chemical Surface and Morphological Characterizations

2.3. Optical Characterization

2.4. Electrochemical Characterization

3. Results and Discussion

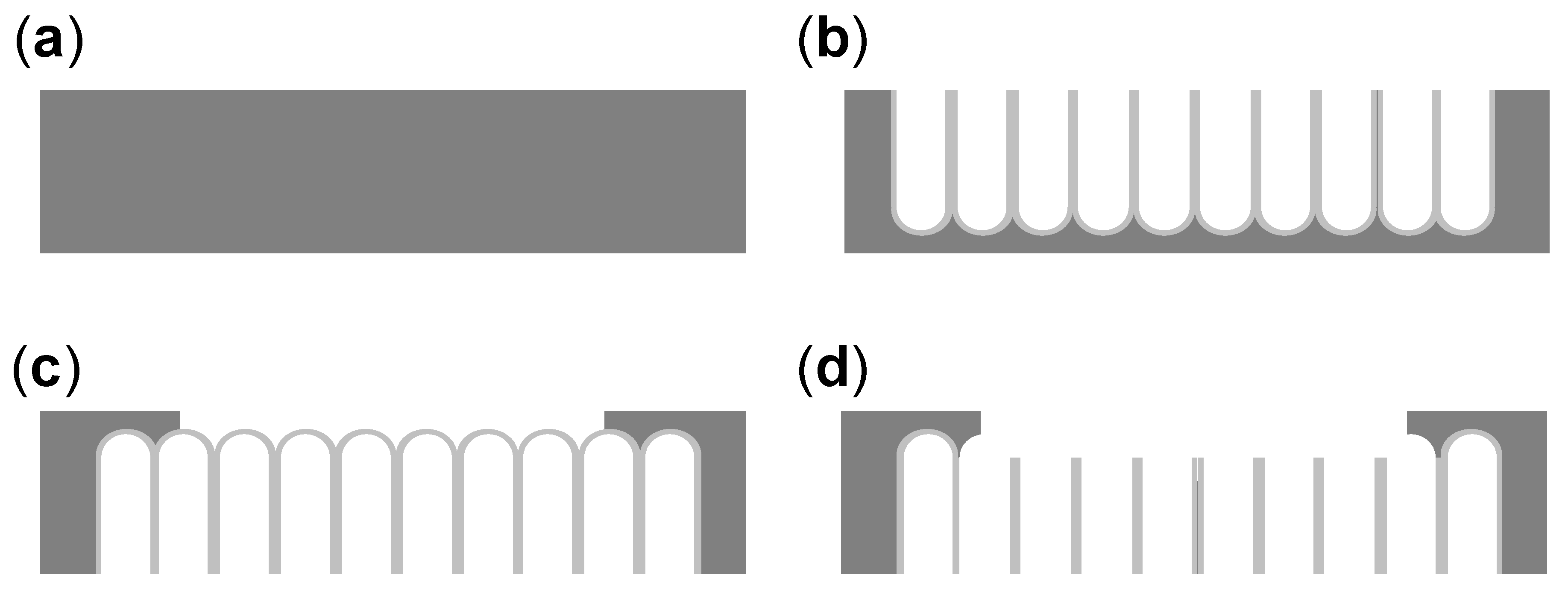

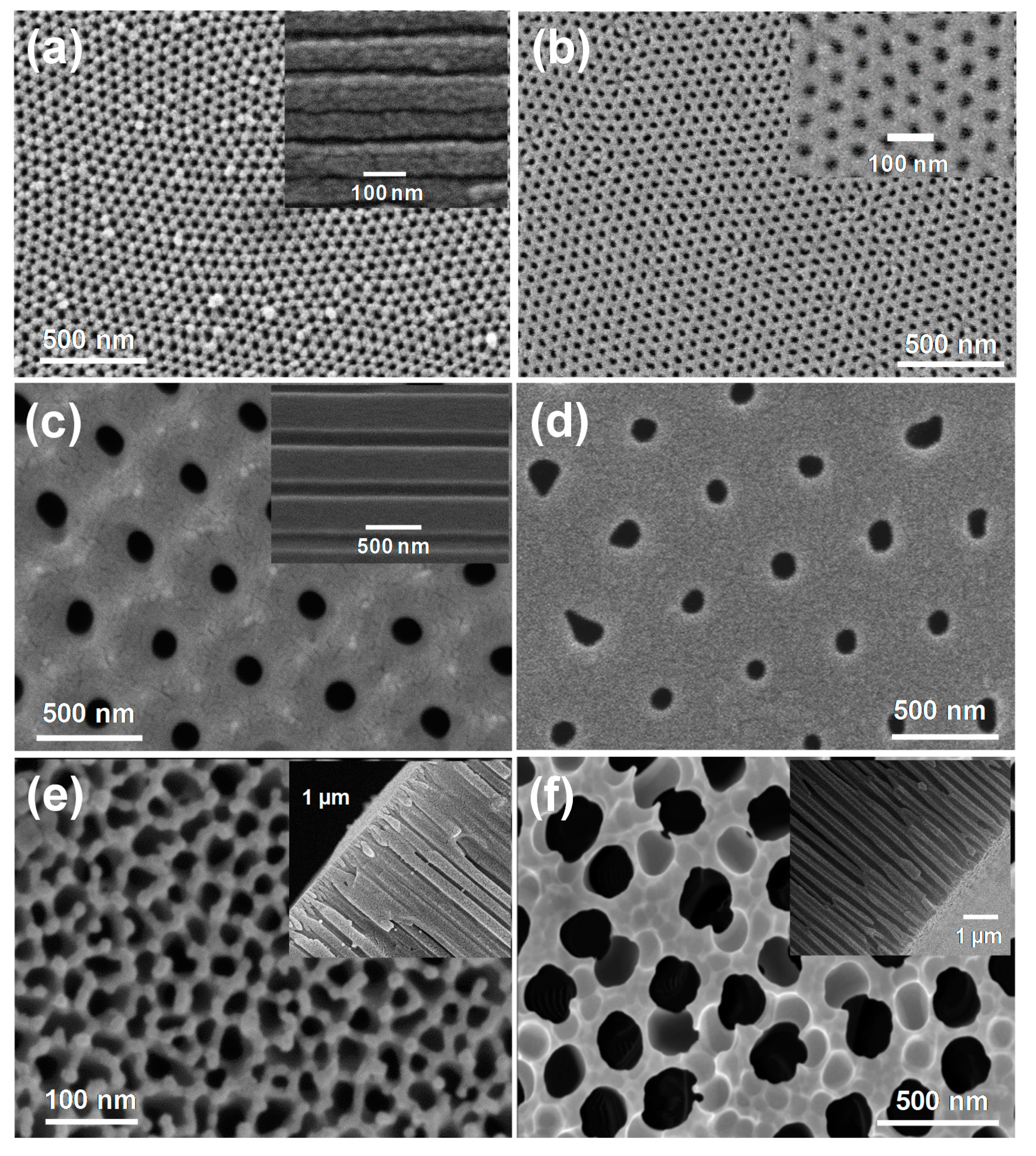

3.1. Chemical Surface and Morphological Characterizations

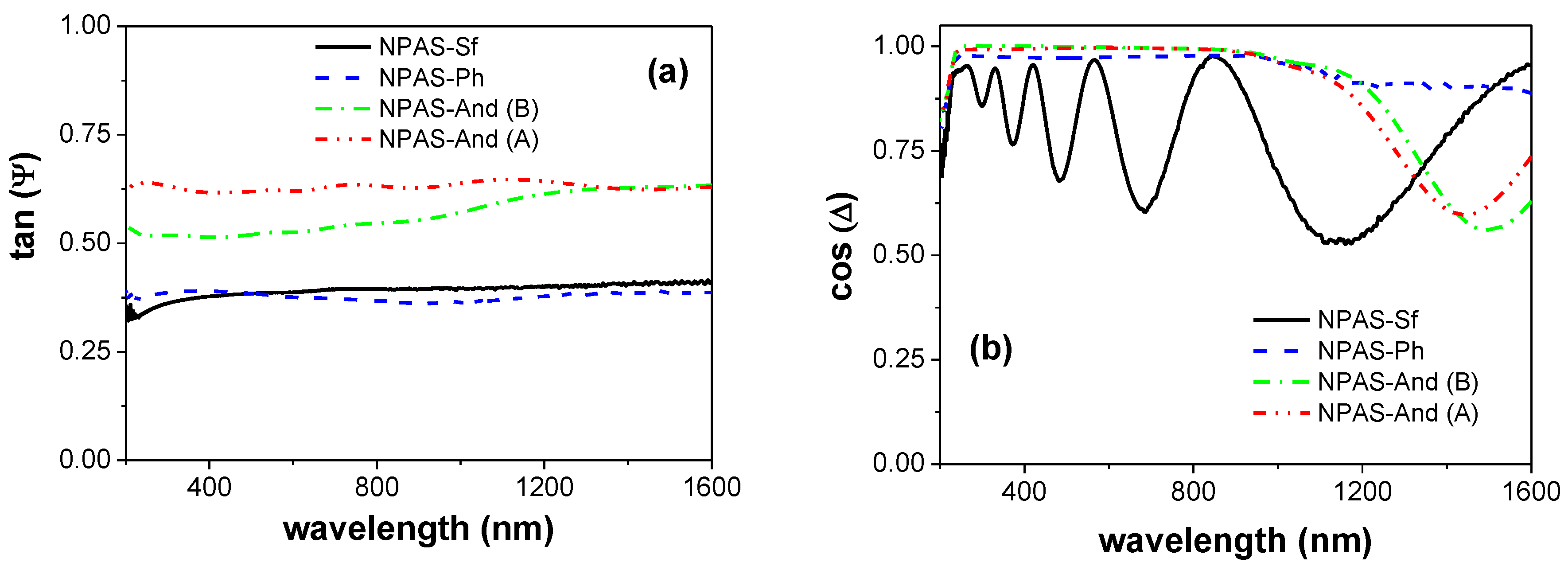

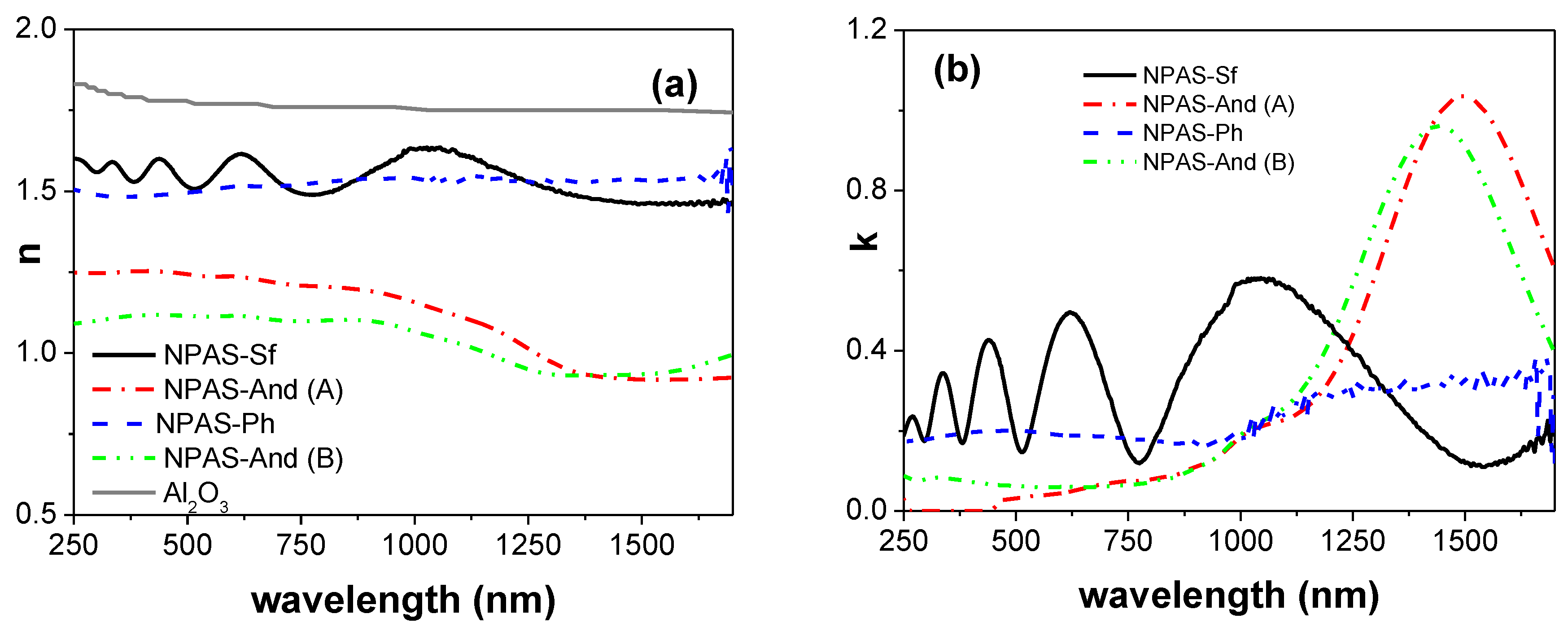

3.2. Optical Characterization

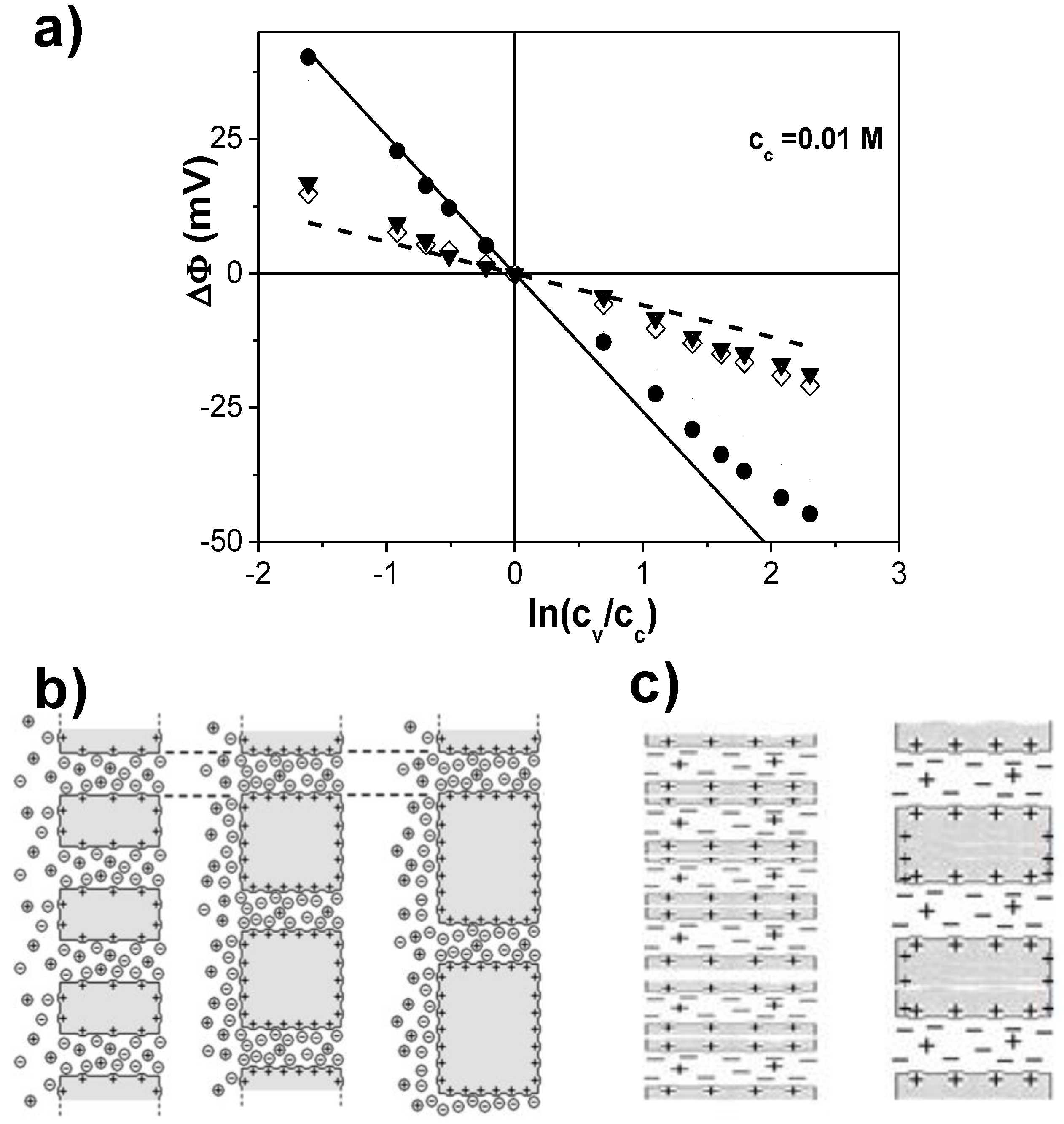

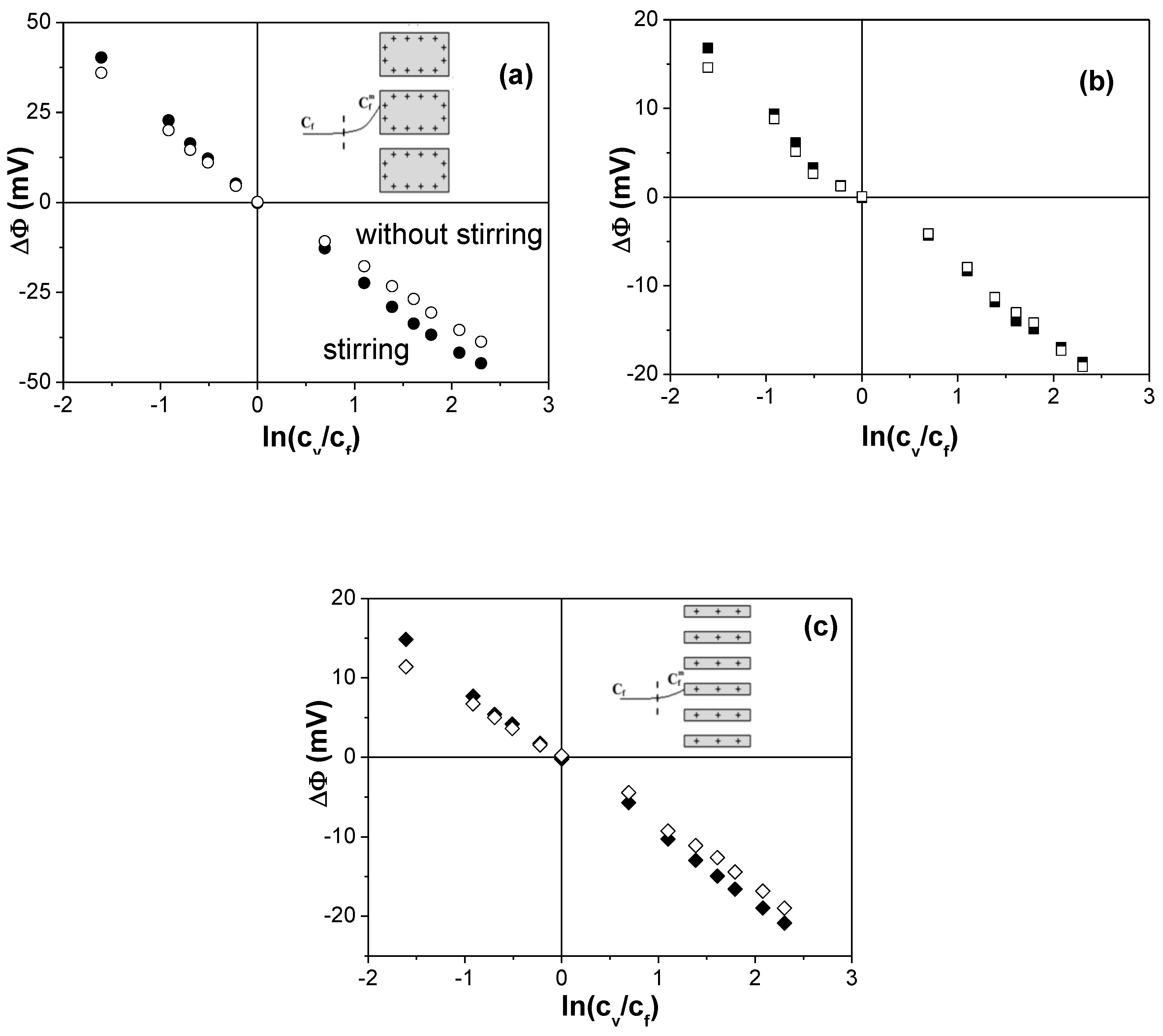

3.3. Electrochemical Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Masuda, H.; Fukuda, K. Ordered metal nanohole arrays made by a two-Step replication of honeycomb structures of anodic alumina. Science 1995, 268, 1466–1468. [Google Scholar] [CrossRef] [PubMed]

- Lee, W.; Park, S.J. Porous anodic aluminum oxide: Anodization and templated synthesis of functional nanostructures. Chem. Rev. 2014, 114, 7487–7556. [Google Scholar] [CrossRef] [PubMed]

- Badini Confalonieri, G.A.; Vega, V.; Ebbing, A.; Mishra, D.; Szary, P.; Prida, V.M.; Petracic, O.; Zabel, H. Template-assisted self-assembly of individual and clusters of magnetic nanoparticles. Nanotechnology 2011, 22, 285608. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zierold, R.; Wu, Z.; Biskupek, J.; Kaiser, U.; Bachmann, J.; Kril, C.E., III; Nielsch, K. Magnetic, Multilayered Nanotubes of Low Aspect Ratios for Liquid Suspensions. Adv. Mater. 2010, 21, 226–232. [Google Scholar] [CrossRef]

- Bae, C.; Zierold, R.; Montero-Moreno, J.M.; Kim, H.; Shin, H.; Bachmann, J.; Nielsch, K. Multisegmented nanotubes by surface-selective atomic layer deposition. J. Mater. Chem. C 2013, 1, 621–625. [Google Scholar] [CrossRef]

- Sousa, C.T.; Leitao, D.C.; Proenca, M.P.; Ventura, J.; Pereira, A.M.; Araujo, J.P. Nanoporous alumina as templates for multifunctional applications. Appl. Phys. Rev. 2014, 1, 031102. [Google Scholar] [CrossRef]

- Mendez, M.; Gonzalez, S.; Vega, V.; Teixeira, J.M.; Hernando, B.; Luna, C.; Prida, V.M. Ni-Co Alloy and Multisegmented Ni/Co Nanowire Arrays Modulated in Composition: Structural Characterization and Magnetic Properties. Crystals 2017, 7, 66. [Google Scholar] [CrossRef] [Green Version]

- Law, C.S.; Lim, S.Y.; Abell, A.D.; Voelcker, N.H.; Santos, A. Nanoporous Anodic Alumina Photonic Crystals for Optical Chemo- and Biosensing: Fundamentals, Advances, and Perspectives. Nanomaterials 2018, 8, 788. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hoess, A.; Thormann, A.; Friedmann, A.; Heilmann, A. Self-supporting nanoporous alumina membranes as substrates for hepatic cell cultures. J. Biomed. Mater. Res. Part A 2012, 100, 2230–2238. [Google Scholar] [CrossRef]

- Galdun, L.; Vega, V.; Vargová, Z.; Barriga-Castro, E.D.; Luna, C.; Varga, R.; Prida, V.M. Intermetallic Co2FeIn Heusler Alloy Nanowires for Spintronics Applications. ACS Appl. Nano Mater. 2018, 1, 7066–7074. [Google Scholar] [CrossRef] [Green Version]

- Salaheldeen, M.; Mendez, M.; Vega, V.; Fernandez, A.; Prida, V.M. Tuning nanohole sizes in Ni hexagonal antidot arrays: Large perpendicular magnetic anisotropy for spintronic applications. ACS Appl. Nano Mater. 2019, 2, 1866–1875. [Google Scholar] [CrossRef]

- Aguilera, A.; Jayaraman, V.; Sanagapalli, S.; Singh, R.S.; Singh, V.; Singh, K.; Singh, V.P. Porous alumina templates and nanostructured CdS for thin film solar cell applications. Sol. Energy Mater. Sol. Cells 2006, 90, 713–726. [Google Scholar] [CrossRef]

- Hsu, W.-L.; Cheng, C.-H.; Wu, C.-L.; Pai, Y.-H.; Lin, G.-R. Nano-porous MOSLEDs with spatially confined Si quantum dots buried in anodic aluminum oxide membrane. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 1–7. [Google Scholar] [CrossRef]

- Chen, Q.; Yang, F.; Wan, R.; Fang, D. Improving lumen maintenance by nanopore array dispersed quantum dots for on-chip light emitting diodes. Appl. Phys. Lett. 2017, 111, 243505. [Google Scholar] [CrossRef]

- Marsal, L.F.; Vojkuvka, L.; Formentin, P.; Pallarés, J.; Ferré-Borrul, J. Fabrication and optical characterization of nanoporous alumina films annealed at different temperatures. Opt. Mater. 2009, 31, 860–864. [Google Scholar] [CrossRef]

- Yang, T.; Wang, X.; Liu, W.; Shi, Y.; Yang, F. Double-layer anti-reflection coating containing a nanoporous anodic aluminium oxide layer for GaAs solar cells. Opt. Express 2013, 21, 18207–18215. [Google Scholar] [CrossRef] [Green Version]

- Li, Q.; Elimelech, M. Organic Fouling and Chemical Cleaning of Nanofiltration Membranes: Measurements and Mechanisms. Environ. Sci. Technol. 2004, 38, 4683–4693. [Google Scholar] [CrossRef] [PubMed]

- Tin, M.M.M.; Anioke, G.; Nakagoe, O.; Tanabe, S.; Kodamatani, H.; Nghiem, L.D.; Fujioka, T. Membrane fouling, chemical cleaning and separation performance assessment of a chlorine-resistant nanofiltration membrane for water recycling applications. Sep. Purif. Tech. 2017, 189, 170–175. [Google Scholar] [CrossRef] [Green Version]

- Romero, V.; Vega, V.; García, J.; Prida, V.M.; Hernando, B.; Benavente, J. Ionic transport across tailored nanoporous anodic alumina membranes. J. Colloid Interface Sci. 2012, 376, 40–46. [Google Scholar] [CrossRef] [PubMed]

- Bluhm, E.A.; Schroeder, N.C.; Bauer, E.; Fife, J.N.; Chamberlin, R.M.; Abney, K.D.; Young, J.S.; Jarvinen, G.D. Surface Effects on Metal Ion Transport across Porous Alumina Membranes. 2. Trivalent Cations: Am, Tb, Eu, and Fe. Langmuir 2000, 16, 7056–7060. [Google Scholar] [CrossRef]

- Porta-i-Batalla, M.; Xifré-Pérez, E.; Eckstein, C.; Ferré-Borrull, F.; Marsal, L.F. 3D Nanoporous Anodic Alumina Structures for Sustained Drug Release. Nanomaterials 2017, 7, 227. [Google Scholar] [CrossRef] [PubMed]

- Petukhov, D.I.; Napolskii, K.S.; Eliseev, A.A. Permeability of anodic alumina membranes with branched channels. Nanotechnology 2012, 23, 335601. [Google Scholar] [CrossRef] [PubMed]

- Seo, I.; Kwon, C.; Lee, H.H.; Kim, Y.; Kim, K.; Yoon, T. Assembly of Colloidal Nanoparticles into Anodic Aluminum Oxide Templates by Dip-Coating Process. IEEE Trans. Nanotech. 2009, 8, 707–712. [Google Scholar] [CrossRef]

- Kumeria, T.; Santos, A.; Losic, D. Nanoporous anodic alumina platforms: Engineered surface chemistry and structure for optical sensing applications. Sensors 2014, 14, 11878–11918. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fang, J.; Levchenko, I.; van der Laan, T.; Kumar, S.; Ostrikov, K. Multipurpose nanoporous alumina–carbon nanowall bi-dimensional nano-hybrid platform via catalyzed and catalyst-free plasma CVD. Carbon 2014, 78, 627–632. [Google Scholar] [CrossRef]

- Romero, V.; Vega, V.; García, J.; Zierold, R.; Nielsch, K.; Prida, V.M.; Hernando, B.; Benavente, J. Changes in Morphology and Ionic Transport Induced by ALD SiO2 Coating of Nanoporous Alumina Membranes. ACS Appl. Mater. Interfaces 2013, 5, 3556–3564. [Google Scholar] [CrossRef]

- Vázquez, M.I.; Romero, V.; Benavente, J.; Romero, R.; Hierrezuelo, J.; López-Romero, J.M.; Contreras-Cáceres, R. Characterization and stability of a bioactivated alumina nanomembrane for application in flow devices. Microporous Mesoporous Mater. 2016, 226, 88–93. [Google Scholar] [CrossRef]

- Vega, V.; Gelde, L.; González, A.S.; Prida, V.M.; Hernando, B.; Benavente, J. Diffusive transport through surface functionalized nanoporous alumina membranes by atomic layer deposition of metal oxides. J. Ind. Eng. Chem. 2017, 52, 66–72. [Google Scholar] [CrossRef]

- Gelde, L.; Cuevas, A.L.; Martínez de Yuso, M.D.V.; Benavente, J.; Vega, V.; González, A.S.; Prida, V.M.; Hernando, B. Influence of TiO2-Coating Layer on Nanoporous Alumina Membranes by ALD Technique. Coatings 2018, 8, 60. [Google Scholar] [CrossRef] [Green Version]

- Cuevas, A.L.; Martínez de Yuso, M.V.; Vega, V.; González, A.S.; Prida, V.M.; Benavente, J. Influence of ALD Coating Layers on the Optical Properties of Nanoporous Alumina-Based Structures. Coatings 2019, 9, 43. [Google Scholar] [CrossRef] [Green Version]

- Gâlcă, A.C.; Kooij, E.S.; Wormeester, H.; Salm, C. Structural and optical characterization of porous anodic aluminum oxide. J. Appl. Phys. 2003, 94, 4296–4305. [Google Scholar] [CrossRef]

- Moghadam, H.; Samimi, A.; Behzadmehr, A. Effect of nanoporous anodic aluminum oxide (AAO) characteristics on solar absorptivity. Transp. Phenom. Nano Micro Scales 2013, 1, 110–116. [Google Scholar] [CrossRef]

- Hierro-Rodriguez, A.; Rocha-Rodrigues, P.; Valdés-Bango, F.; Alameda, J.M.; Jorge, P.A.S.; Santos, J.L.; Araujo, J.P.; Teixeira, J.M.; Guerreiro, A. On the anodic aluminium oxide refractive index of nanoporous templates. J. Phys. D Appl. Phys. 2015, 48, 455105. [Google Scholar] [CrossRef] [Green Version]

- Gioti, M.; Laskarakis, A.; Logothetidis, S. IR-FUV ellipsometry studies on the optical, electronic and vibrational properties of polymeric membranes. Thin Solid Films 2004, 455, 283–287. [Google Scholar] [CrossRef]

- Ogielo, W.; Wormeester, H.; Wessling, M.; Benes, N.E. Spectroscopic ellipsometry analysis of a thin film composite membrane consisting of polysulphone on a porous α-alumina support. ACS Appl. Mater. Interfaces 2012, 4, 935–943. [Google Scholar] [CrossRef] [PubMed]

- Briggs, D.; Seah, M.P. Practical Surface Analysis. In Auger and X-Ray Photoelectron Spectroscopy, 2nd ed.; John Wiley & Sons: Chichester, UK, 1995; ISBN 9780471953401. [Google Scholar]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef] [PubMed]

- Logothetidis, S.; Gioti, M.; Gravalidis, C. Optical and electronic characterization on polymeric membranes. Synth. Met. 2003, 138, 369–374. [Google Scholar] [CrossRef]

- Romero, V.; Vázquez, M.I.; Benavente, J. Study of ionic and diffusive transport through a regenerated cellulose nanoporous membrane. J. Membr. Sci. 2013, 433, 152–159. [Google Scholar] [CrossRef]

- Lakshminarayanaiah, N. Transport Phenomena in Membranes; Academic Press Inc.: New York, NY, USA, 1970; ISBN 9780124342507. [Google Scholar]

- Benavente, J.; García, J.M.; Riley, R.; Lozano, A.E.; de Abajo, J. Sulfonated poly(ether ether sulfones): Characterization and study of dielectrical properties by impedance spectroscopy. J. Membr. Sci. 2000, 175, 43–52. [Google Scholar] [CrossRef]

- Macdonal, J.R. Impedance Spectroscopy; John Wiley: New York, NY, USA, 1987; ISBN 9780471831228. [Google Scholar]

- Benavente, J. Use of Impedance Spectroscopy for characterization of modified membranes. In Membrane Modification: Technology and Applications; Hilal, N., Kayet, M., Wright, C.J., Eds.; CRC Press: Boca Raton, FL, USA, 2012; ISBN 9781439866368. [Google Scholar]

- Fontyn, M.; van’t Riet, K.; Bijsterbosch, B.H. Surface spectroscopic studies of pristine and fouled membranes part 1. Method development and pristine membrane characterization. Colloids Surf. 1991, 54, 331–347. [Google Scholar] [CrossRef]

- Romero, V.; Vázquez, M.I.; Cañete, S.; Vega, V.; García, J.; Prida, V.M.; Hernando, B.; Benavente, J. Frictional and electrical effects involved in the diffusive transport through a nanoporous alumina membrane. J. Phys. Chem. C 2013, 117, 25513–25518. [Google Scholar] [CrossRef]

- Vázquez, M.I.; Romero, V.; Vega, V.; García, J.; Prida, V.M.; Hernando, B.; Benavente, J. Morphological, Chemical Surface, and Diffusive Transport Characterizations of a Nanoporous Alumina Membrane. Nanomaterials 2015, 5, 2192–2202. [Google Scholar] [CrossRef] [PubMed]

- Romero, V.; Vega, V.; García, J.; Prida, V.M.; Hernando, B.; Benavente, J. Effect of Porosity and Concentration Polarization on Electrolyte Diffusive Transport Parameters through Ceramic Membranes with Similar Nanopore Size. Nanomaterials 2014, 4, 700–711. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nielsch, K.; Choi, J.; Schwirn, K.; Wehrspohn, R.B.; Gösele, U. Self-ordering regimes of porous alumina: The 10% porosity rule. Nano Lett. 2002, 2, 677–680. [Google Scholar] [CrossRef]

- Palacio, L.; Prádanos, P.; Calvo, J.I.; Hernández, A. Porosity measurements by a gas penetration method and other techniques applied to membrane characterization. Thin Solid Films 1999, 348, 22–29. [Google Scholar] [CrossRef]

- Tompkins, G.; Hilfiker, J.N. Spectroscopic Ellipsometry: Practical Application to Thin Film Characterization, 1st ed.; Momentum Press: New York, NY, USA, 2016; pp. 57–70. ISBN 9781606507278. [Google Scholar]

- Fujiwara, H. Spectroscopic Ellipsometry Principles and Applications; John Wiley & Sons: Chischester, UK, 2007; ISBN 9780470016084. [Google Scholar]

- Holbein, J.; Steinhart, M.; Schiene-Fisher, C.; Benda, A.; Hof, M.; Hübner, C.G. Confined diffusion in ordered nanoporous membranes. Small 2007, 3, 380–385. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Mishra, N.; Turner, J.N.; Spencer, M.G. Diffusivity of sub-1,000 Da molecules in 40 nm silicon-based alumina pores. Microfluid. Nanofluid. 2008, 5, 695–701. [Google Scholar] [CrossRef]

- Kipke, S.; Schmid, G. Nanoporous alumina membranes as diffusion controlling systems. Adv. Funct. Mater. 2014, 14, 1184–1190. [Google Scholar] [CrossRef]

- Helfferich, F.G. Ion Exchange; McGraw-Hill: New York, NY, USA, 1962; ISBN 9780070280700. [Google Scholar]

- Meyer, K.H.; Sievers, J.F. La perméabilité des membranes I. Théorie de la perméabilité ionique. Helv. Chim. Acta 1936, 19, 649–664. [Google Scholar] [CrossRef]

- Teorell, T. Transport phenomena in membranes eighth Spiers Memorial Lecture. Discuss. Faraday Soc. 1956, 21, 9–26. [Google Scholar] [CrossRef]

- Lanteri, Y.; Szymczyk, A.; Fievet, P. Influence of Steric, Electric, and Dielectric Effects on Membrane Potential. Langmuir 2008, 24, 7955–7962. [Google Scholar] [CrossRef] [PubMed]

- Robinson, R.A.; Stokes, R.H. Electrolyte Solutions; Butterworths: London, UK, 1970; ISBN 9780408184908. [Google Scholar]

- Sarker, S.; Ahammad, A.J.S.; Seo, H.W.; Kim, D.M. Electrochemical Impedance Spectra of Dye-Sensitized Solar Cells: Fundamentals and Spreadsheet Calculation. Int. J. Photoenergy 2014, 2014, 851705. [Google Scholar] [CrossRef] [Green Version]

- Zhao, S.; Berry-Gair, J.; Li, W.; Guan, G.; Yang, M.; Li, J.; Lai, F.; Corà, F.; Holt, K.; Brett, D.J.L.; et al. The Role of Phosphate Group in Doped Cobalt Molybdate: Improved Electrocatalytic Hydrogen Evolution Performance. Adv. Sci. 2020, 7, 1903674. [Google Scholar] [CrossRef] [PubMed]

- Vázquez, M.I.; de Lara, R.; Benavente, J. Characterisation of two microporous ceramic membranes with different geometrical parameters: Effect of protein adsorption on electrochemical parameters. J. Eur. Ceram. Soc. 2007, 27, 4245–4250. [Google Scholar] [CrossRef]

- Augustin, S.; Hennige, V.; Hörpel, G.; Hying, C. Ceramic but flexible: New ceramic foils for fuel cells and batteries. Desalination 2002, 146, 23–28. [Google Scholar] [CrossRef]

- Benavente, J.; Silva, V.; Prádanos, P.; Palacio, L.; Hernández, A.; Jonson, G. Comparison of the Volume Charge Density of Nanofiltration Membranes Obtained from Retention and Conductivity Experiments. Langmuir 2010, 26, 11841–11849. [Google Scholar] [CrossRef]

| Sample | C (%) | O (%) | Al (%) | N (%) | S (%) | P (%) | O/Al |

|---|---|---|---|---|---|---|---|

| NPAS-Sf | 16.9 | 53.0 | 25.7 | 0.7 | 2.1 | 1.9 | 2.07 |

| NPAS-Ph | 19.2 | 51.7 | 27.2 | 0.6 | 0.9 | 1.90 | |

| NPAS-And | 16.6 | 50.8 | 27.8 | 0.5 | 3.1 | 1.83 |

| Sample | <rp> (nm) | <Dint> (nm) | <Θ > (%) |

|---|---|---|---|

| NPAS-Sf | 12 ± 2 | 65 ± 5 | 12 |

| NPAS-Ph | 90 ± 20 | 490 ± 30 | 12 |

| NPAS-And (A) | 10 * | 40 ± 10 | 23 |

| NPAS-And (B) | 100 * | 360 ± 80 | 30 |

| Sample | <n> | <n> | <n> |

|---|---|---|---|

| (250–1700) nm | (250–00) nm | (800–1700) nm | |

| NPAS-Sf | 1.54 ± 0.06 | 1.55 ± 0.04 | 1.53 ± 0.06 |

| NPAS-Ph | 1.52 ± 0.02 | 1.52 ± 0.02 | 1.53 ± 0.02 |

| NPAS-And (A) | 1.14 ± 0.09 | 1.24 ± 0.02 | 1.08 ± 0.09 |

| NPAS-And (B) | 1.05± 0.05 | 1.11 ± 0.02 | 1.06 ± 0.05 |

| Sample | Xef (M) | tCl− | DNa+/DCl− | PSCl− (%) |

|---|---|---|---|---|

| NPAS-Sf | +0.0122 | 0.742 | 0.348 | 33.0 |

| NPAS-Ph | +0.0013 | 0.627 | 0.595 | 3.1 |

| NPAS-And | +0.0015 | 0.652 | 0.534 | 9.6 |

| Sample | Rs/s (Ω) | Cs/s (F) |

|---|---|---|

| NPAS-Sf | 8840 | 9.4 × 10−12 |

| NPAS-Ph | 7400 | 8.3·× 10−12 |

| NPAS-And | 7800 | 7.9·× 10−12 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cuevas, A.L.; González, A.S.; Vega, V.; Prida, V.M.; Benavente, J. Optical and Electrochemical Characterization of Nanoporous Alumina Structures: Pore Size, Porosity, and Structure Effect. Appl. Sci. 2020, 10, 4864. https://doi.org/10.3390/app10144864

Cuevas AL, González AS, Vega V, Prida VM, Benavente J. Optical and Electrochemical Characterization of Nanoporous Alumina Structures: Pore Size, Porosity, and Structure Effect. Applied Sciences. 2020; 10(14):4864. https://doi.org/10.3390/app10144864

Chicago/Turabian StyleCuevas, Ana Laura, A. Silvia González, Víctor Vega, Víctor M. Prida, and Juana Benavente. 2020. "Optical and Electrochemical Characterization of Nanoporous Alumina Structures: Pore Size, Porosity, and Structure Effect" Applied Sciences 10, no. 14: 4864. https://doi.org/10.3390/app10144864