1. Introduction

Sustainability has been considered as being significant in creation of competitive advantage and as a driver of innovation for manufacturing firms (

Claudy et al. 2016;

Nidumolu et al. 2009). Companies are becoming more aware of the importance of sustainability and are increasingly incorporating the features of sustainable businesses into their corporate and operation strategies (

Paulraj et al. 2017). Driven from popular notion of triple bottom line perspective (people, planet and profit) of

Elkington (

1998), sustainability is considered as taking simultaneously responsible approaches towards society, environment, and economy (

Adams et al. 2016).

Literature in the field have identified that innovation practices among the supply chain helps companies to achieve sustainability (

Lintukangas et al. 2019). Firms with a higher level of sustainability orientation are more likely to implement sustainability-oriented innovation (

Adams et al. 2016;

Claudy et al. 2016). In this context, new product development (NPD) is a determinant for a company’s success and integrating their supplier-related sustainability practices into the early stages of NPD is key to improving both sustainability and operational performance of new products (

Gmelin and Seuring 2014;

Jabbour et al. 2015).

Nevertheless, prior evidence bridging between innovation and NPD with sustainability in operations management, has analysed the association of sustainably-oriented innovations and innovation outcomes, considering the role of mediating factors such as organisational leadership, culture, market knowledge competences, and customer focus regarding this association (

Claudy et al. 2016;

Jin et al. 2019;

Obal et al. 2020). In this context, many other studies sought to develop a systematic approach to sustainable new products (

Ahmad et al. 2018;

Tuli and Shankar 2015), suggesting tools and mechanism to link sustainability with NPD, such as environmental or eco-design, eco-innovation, recyclability, and lean thinking (

Nepal et al. 2011;

Oliveira et al. 2018;

Rossi et al. 2016). However, to our knowledge, very few empirical studies have attempted to explore any links between the adoption of sustainability practices from a broad perspective, considering both internal and external and the association between them, to explain NPD success. This confirms that sustainability orientation and NPD is still one of the least understood areas in sustainability management (

Cheng 2020;

Claudy et al. 2016), with very limited empirical evidences (

Adams et al. 2016;

Neutzling et al. 2018). Sustainability and NPD are in the core of success for manufacturing companies nowadays and therefore, advancing in the knowledge on how both things interact is on great importance (

Hallstedt et al. 2013;

Lintukangas et al. 2019).

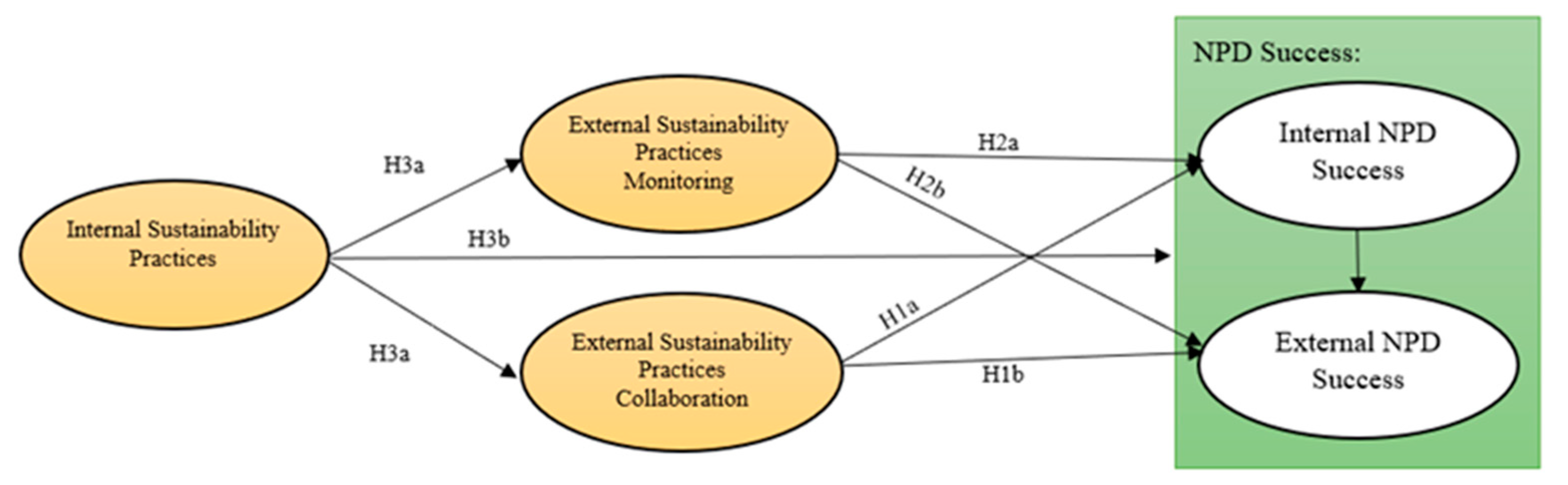

This study aims to shed new light on the abovementioned issue by analysing how and to what extent a firm’s sustainability practices affect the success of its NPD. For this purpose, sustainability practices are grouped into internal sustainability practices and external sustainability practices. Internal practices are those sustainability practices that are applied to the firm’s internal operations, while external practices are those that are implemented beyond the boundaries of the firm, particularly with suppliers (

Laari et al. 2016;

Sancha et al. 2019). These practices typically require a certain level of cooperation with, and monitoring of, close supply chain actors (

Danese et al. 2019). In addition, NPD success is classified to external and internal measures. Internal measure refers to the development process including time, quality, and other technical aspects of the product while the external success measure refers mostly to the non-technical dimensions including customer satisfaction and financial issues (

García et al. 2008). As such, the expected effects of adopting these practices on NPD success are neither immediate nor intuitive.

The objective is to advance the understanding on the topic considering the existence of trade-offs between different strategies (e.g., monitoring vs. collaboration) and the difficulties that NPD managers face in balancing sustainability targets with the demands of supply chain actors and external pressures (

Claudy et al. 2016). Hence, the theoretical part of the paper develops three sets of hypotheses that take advantage of statements of natural resource-based view (NRBV) theory, social capital theory, and transaction cost theory which help to understand the link between sustainability and NPD. The SmartPLS approach is used to test the hypothesised relationships. The data used comes from the fourth round of the High-Performance Manufacturing project and includes a total of 281 interviews across three industries in 16 countries.

This study contributes to the literature in several ways. First, it contributes to the debate on how manufacturing firms can improve the success of their new products. Our study advances these research streams by proposing how a buying firm could enhance NPD success through investing on sustainability issues in their operational process under NRBV theoretical perspective as well as extending the requirements to their supply chain through sustainability-related practices with suppliers under social capital and transactional cost theoretical frameworks. We seek to facilitate the exchange between these three perspectives by highlighting how they complement and support each other.

Second, unlike the previous studies on suppliers’ integration in NPD considering only the importance of green suppliers’ collaboration for NPD success (

Kähkönen et al. 2017;

Neutzling et al. 2018;

Wang et al. 2021), this study contributes to the field by differentiating various sustainability practices and distinguishing between different measures of NPD success.

Third, developing two separated constructs for external sustainability practices of focal firms (i.e., supplier monitoring and supplier collaboration practices) provides some additional insights on the trade-offs between these two ways to manage sustainability with suppliers and their effects on NPD success. Therefore, this study throws light on the unique impact of different sustainability practices on different measures of NPD success. The results highlight the benefits of adopting both controlling and collaborative frameworks of sustainability for the success of new products. Furthermore, the results of this study provide useful insights for both managers seeking to adopt sustainable practices and policymakers seeking to further promote a sustainable supply chain.

Fourth, while many other studies are limited to the sample data from a specific industry or only one country, this study gathers the empirical evidence using a unique database that integrated 281 manufacturing firms from across 3 industries and 16 countries located in Asia, Europe, and America. Using such a multi-country, multi-industry sample contributes significantly to the empirical investigations related to the impact of sustainability on the success of NPD.

The rest of this paper is organised as follows:

Section 2 presents a literature review. In

Section 3, development of hypotheses is explained. The empirical methodology, the statistic treatment, and empirical results are presented in

Section 4.

Section 5 closes the paper with conclusions, implications, and future research opportunities.

2. Theoretical Framework

Previous research on sustainability as well as in NPD has demonstrated that a focal firm’s actions towards the environment and innovation are not only limited to its own performance but also to the actions of close supply chain members (

Chen and Chen 2019). Firms, therefore, have no option other than integrating sustainability features into their operation and extending it to their key partners, but also should simultaneously take up some activities for behavioural/relational issues related to interaction with them. It requires to explain this phenomenon through different theoretical lenses while considering their potential trade-offs. In this context, the natural resource-based view (NRBV) theory provides a framework that emphasises the importance of environmental factors in terms of a firm’s green competences (

Hart 1995). A sustainability strategy includes the adoption of intra–inter organisational environmental practices that may permit the building of causally ambiguous resources through continuous learning and repeated practices, for example, from pollution prevention strategies as well as the creation of complex resources through environmental collaboration in product stewardship or sustainable development projects (

Shi et al. 2012).

By incorporating environmental requirements in NPD, a focal firm is able to improve environmental performance of new products in terms of energy efficiency and environmental footprint (

Gerstlberger et al. 2014;

Wang et al. 2021), resulting in enhanced performance of new products in terms of time to market, quality, and cost of R&D (

Wang et al. 2021). Collaborative teams integrated by sustainability-oriented firms are more likely to find environmentally-friendly innovations in new products and processes, achieving more efficiently the use of resources and producing less waste and environmental burdens, which ultimately drive enhanced performance and NPD success (

Claudy et al. 2016).

Close to this view, social relationships within supply chains can be formulated through different forms of inter-organisational activities (

Putnam 1995), which are particularly relevant for NPD and for sustainability (

Woo et al. 2016). For instance, through supplier involvement in NPD, the level of information processing and information transfer from one party to another is improved (

Wlazlak et al. 2018), facilitating the voluntary sharing of innovative ideas, access to technology, knowledge, R&D services, and resources required for NPD (

Du et al. 2016;

Mazzola et al. 2015). Further, the firm´s social capital obtained from buyer-supplier interaction enhances the innovation search span of the firm causing reduction in the search cost (

Du et al. 2016). To convert such relational social capital to the rent for superior performance of NPD, a specific capability is needed (

Zhang and Wu 2013). NRBV provides such capability in the sustainability-oriented buyer-supplier relationship to integrate such joint efforts in the form of NPD practices with sustainability environmental objectives. Therefore, the communication, information sharing, knowledge exchange, and the trust under the long-term buyer-supplier collaborative relationship promotes the joint innovative efforts and facilitates joint solution development to sustainability issues during NPD (

Lee 2015).

However, based on the transaction cost theory, different governing mechanisms, including supplier assessment and collaboration, have been proposed to focal firms in order to manage the relationship with their suppliers which can affect both sustainability and NPD (

Gimenez and Sierra 2013). Only sustainability-committed suppliers can design and develop new sustainable products and invest in new sustainability processes (

Chen and Chen 2019;

Jansson et al. 2017). Further, the selection of a supplier with a high level of sustainability orientation, either as a source of sustainability-related knowledge or as a source of technological and R&D services, strengthens the NPD outcome (

Cheng 2020). Accordingly, monitoring-oriented strategies are usually conducted by focal firms to select, control, evaluate, and verify suppliers with respect to their compliance with sustainability requirements (

Gualandris et al. 2015).

5. Discussion and Conclusions

The aim of this study was to analyse how and to what extent the adoption of sustainability practices can affect the success of new products. To address this issue, this study argues that each set of sustainability practices (internal, external collaborative, and external monitoring) implemented by the firm has a different effect on NPD success. Under theoretical frameworks of NRBV, social capital and transaction cost, and using a PLS-SEM approach, empirical findings confirm that various sustainability practices adopted by a focal firm have different effects for both operational dimensions (internal) and for market dimensions (external) of new products’ success. More specifically, estimations demonstrate that the adoption of external sustainability practices directly improves the success of new products in terms of operational (internal) outcomes and indirectly reinforces the markets’ (external) measure of the success of new products. This result is aligned with the knowledge, experience, resources, and technology sharing benefits obtained by establishing social capital in buyer-supplier relationships.

Despite the primary expectation for a negative link between monitoring approaches and internal NPD success in virtue of transactional cost associated with these types of practices, the evidence confirms our hypothesis and reveals that the adoption of assessment-based attitude towards regulation and standard, can assure suppliers’ compliance and their implementation of proactive strategies which, in result, foster the technical attributes of NPD. Our result is consistent with the previous notion that the compliance performance of suppliers is related to green product innovation development (

Lee and Kim 2011).

On the other hand, the results report that adopting practices aimed to reduce input consumption and emissions have an indirect effect on the success of new products through the positive effect on the adoption of external sustainability practices. One possible reason for the negative insignificant result for direct effect of internal practices with internal (operational aspect) NPD success might be that in contrary with reactive environmental strategies such as pollution control or improving the workforce environment through indoor air quality, the proactive environmental practices targeted in improvement of energy efficiency or pollution prevention do not yield immediate benefits for a firm. Further, the negative insignificant result for the association of these practices with external (market dimension) NPD success also can be explained through the requirements of initial investment in technology, training, and re-defining organizational processes which may offset the overall commercial success of the NPD at the beginning stage (

Laari et al. 2016). However, these findings indicate that a focal firm´s sustainability orientation (internally and externally) enable NPD success.

To be concluded, the distinction between internal and external dimensions contributes to significant improvement in the understanding of how NPD success works in relation with sustainability in manufacturing. While the adoption of sustainability practices explains the success of new products related to cost, quality, and ease of manufacturing by only 9.80%

1, the explanation power is 42.80% when also considering market dimension of success in line with

García et al. (

2008). Moreover, the adoption of external sustainability practices is reinforced by the adoption of internal sustainability practices. The results highlight that in the context of NPD and sustainability initiatives, the participation of internal functions and external supply chain agents is required (

Hemonnet-Goujot et al. 2019) and, therefore, actions including collaborative and monitoring sustainability practices with suppliers can positively influence the performance of products. Hence, trust and close relationships built on a basis of collaboration in sustainability among the supply chain is a determinant for NPD success. As a result, this paper sheds new light on the alignment of sustainable supply chain management and innovation performance (NPD), thus contributing to a better picture regarding the relation between sustainability in the supply chain and NPD. Moreover, these results have also several implications for theory and practice.

For practitioners, this study highlights that adopting sustainability practices has a positive external effect on firm performance. In particular, evidence shows that the use of both inter-firm monitoring and collaboration with suppliers have positive effects on new products, not only improving aspects related to the production process but also in terms of commercial success in the long term. These results are an invitation for managers to invest in sustainability, adopting a proactive approach using sustainability in a broader way. Moreover, when firms evaluate their suppliers to make their supply chains more environmentally and socially responsible, they enable their suppliers to develop new products with environmental appeal, and reap the advantages that stem from better organizational (environmental, social, and operational) performance. Firms willing to enhance their new products´ operational features may enjoy benefits investing in the adoption of sustainable approaches in their relational social networks while intending to improve their image, reputation, and overall commercial success can find benefits from complimentary internal and external sustainability strategies. Contrary to the previous studies which only consider the significance of green suppliers’ collaboration for NPD success (

Kähkönen et al. 2017;

Neutzling et al. 2018;

Wang et al. 2021), in this study, we observed that both monitoring and collaborative sustainability practices independently strengthen NPD success. Furthermore, this paper debates the nature of the sustainability-oriented relationship by illuminating the unique impact of different collaborative and monitoring practices on different measures of NPD success, and thus could bring forth useful insights for managers. For example, as for focal firms´ managers, technically and financially, it might be important to know which type of sustainability practices influence the success of NPD (and how), and which aspects of success will be affected. Having a better image of the association of sustainability and NPD helps these managers to develop their corporate strategies more appropriately.

The challenge is, therefore, twofold. First, to carry out the necessary internal investments in sustainability aligned with the environment, people, and performance (TBL), which do not always allow firms to observe short-term benefits. By doing so, the objectives of the organisation would be aligned not only with obtaining benefits but also with reinforcing the commitment to the environment and to people (

Neutzling et al. 2018). The positive significant effect of R&D_size control variables indicate that if managers develop and cheer up the spirit of commitment to sustainability in their employees then sustainable-oriented employees working in R&D can act as a motivation for sustainability-related knowledge sharing with external partners (suppliers) during a new product development process. In addition, this paper demonstrates the positive effects of adopting a more advanced approaches to sustainability, because as observed, investing in internal sustainability practices enhance the development of supply chain relationships, which are a determinant for the success of new products.

Second, managers face the challenge of managing the trade-offs between their inhouse sustainability related operations and collaboration and control with suppliers. This result supports the idea of complementarity of different sustainability practices adopted and implemented by focal firms. Within the preview of NRBV and social capital theories, such sustainability-focused relational interactions facilitate knowledge exchange, technological and resources sharing under respect and trust which are ambient for joint practices (NPD). The strong significant effect on the market dimension (external) of new product success is attained when the internal practices and collaborative approaches with suppliers are implemented (ISP->ESPc->INPD->ENPD with coefficient of 0.164 and p = 0.011). In other words, manufacturing firms in joint efforts with their suppliers by integrating environmental consideration in development of new products can improve the operational features of new products which, in turn, enhances the value for customers and strengthens the market attributes of the success.

For academia, this study shows the existence of positive externalities through adopting sustainability practices regarding the success of a new product. Understanding these effects requires an investigation of the intersection of different but related frameworks. For instance, linking social capital with NRBV perspectives, the development of new products through sustainability-oriented collaborative relationships between a focal firm and its suppliers develops a required capability to convert such interaction to more value for customers through fostering trust, mutual respect, and knowledge and capabilities sharing possibilities between parties which eventually promotes NPD success. However, while a sustainability-oriented relationship requires a certain level of commitment and behaviour towards sustainability by suppliers, the transaction cost theory prevents the existence of a cost-related monitoring mechanism implemented by a focal firm to monitor compliance performance of suppliers. This highlights that understanding the effects of sustainability on performance needs to consider a broad perspective which looks at the interlinking of different theoretical approaches which may complement each other and help to improve the understanding of a complex phenomenon. Accordingly, this paper suggests the interconnection of the NRBV, social capital, and transaction cost theories as useful theoretical lenses for differentiating the impact of sustainability-oriented supply chain management on NPD success.

Moreover, the empirical evidence also suggests new lines for future research on the sustainability–NPD link. However, a first limitation of the paper is that effective involvement of supply chain members (internal and external) is supposed to be affected by sustainability practices but is not directly measured. Involvement of supply chain members has been indicated as a determinant of NPD success, however, the link between involvement and sustainability orientation was not. Future research should consider the mediating/moderating effect of sustainability on supply involvement to explain NPD success. Another limitation is that the sustainability orientation was considered as the driver of the link between sustainability practices and NPD success, however, the effect of this factor was not examined. Future research may take into account the mediating effect of sustainability orientation in this association. Further, while this research has advanced our understanding about the relationship between sustainability and NPD success, the study is conditioned by the cross-sectional nature of the data; future research should look for conclusive results using longitudinal analysis. Finally, the link between sustainability and NPD success could be affected by contextual factors. Hence, further research in future studies should consider small versus large firms, developed versus developing countries, or manufacturing versus service companies.