Reductions of PAH and Soot by Center Air Injection

Abstract

:1. Introduction

2. Experimental Section

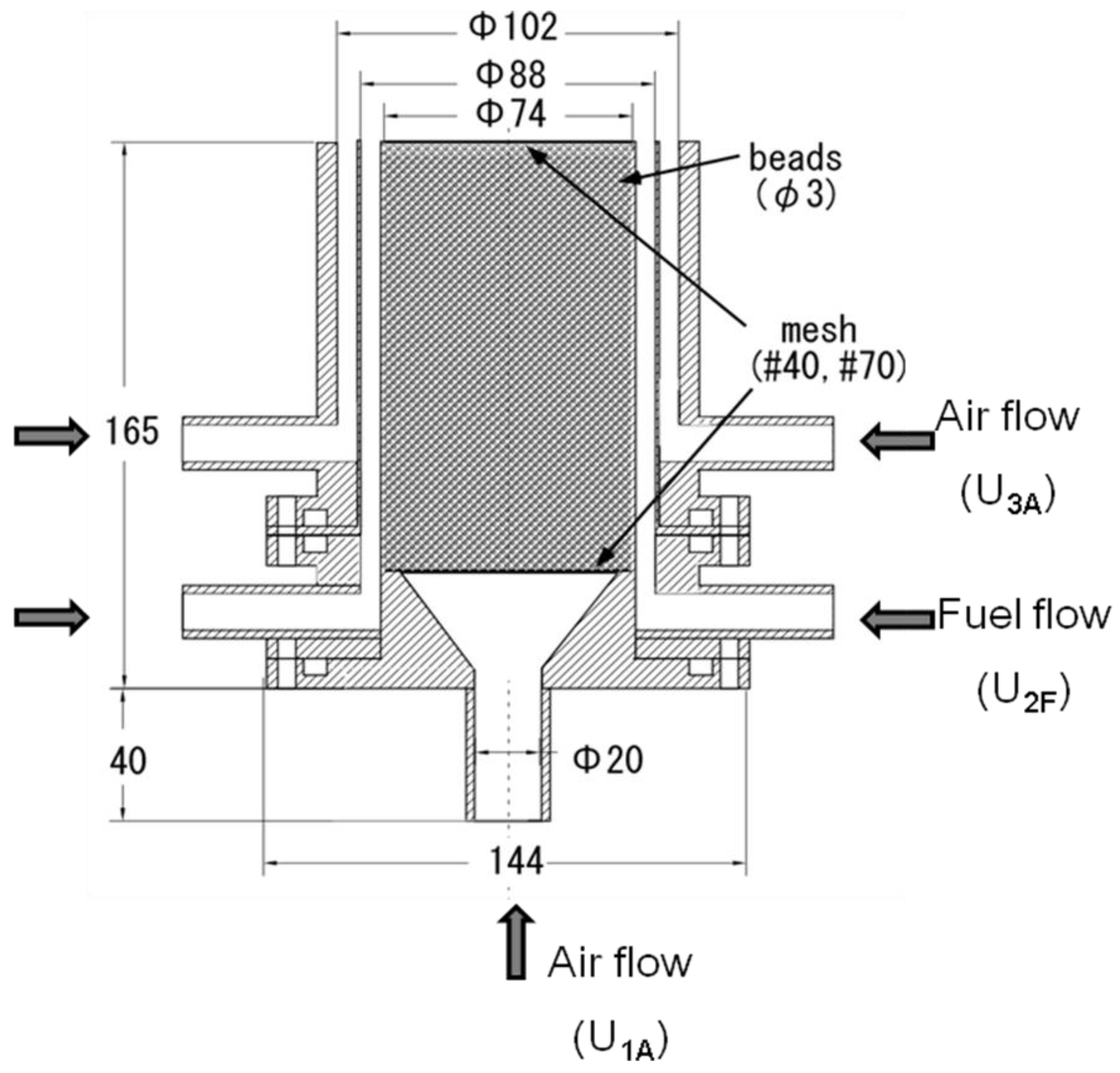

2.1. Triple Port Burner

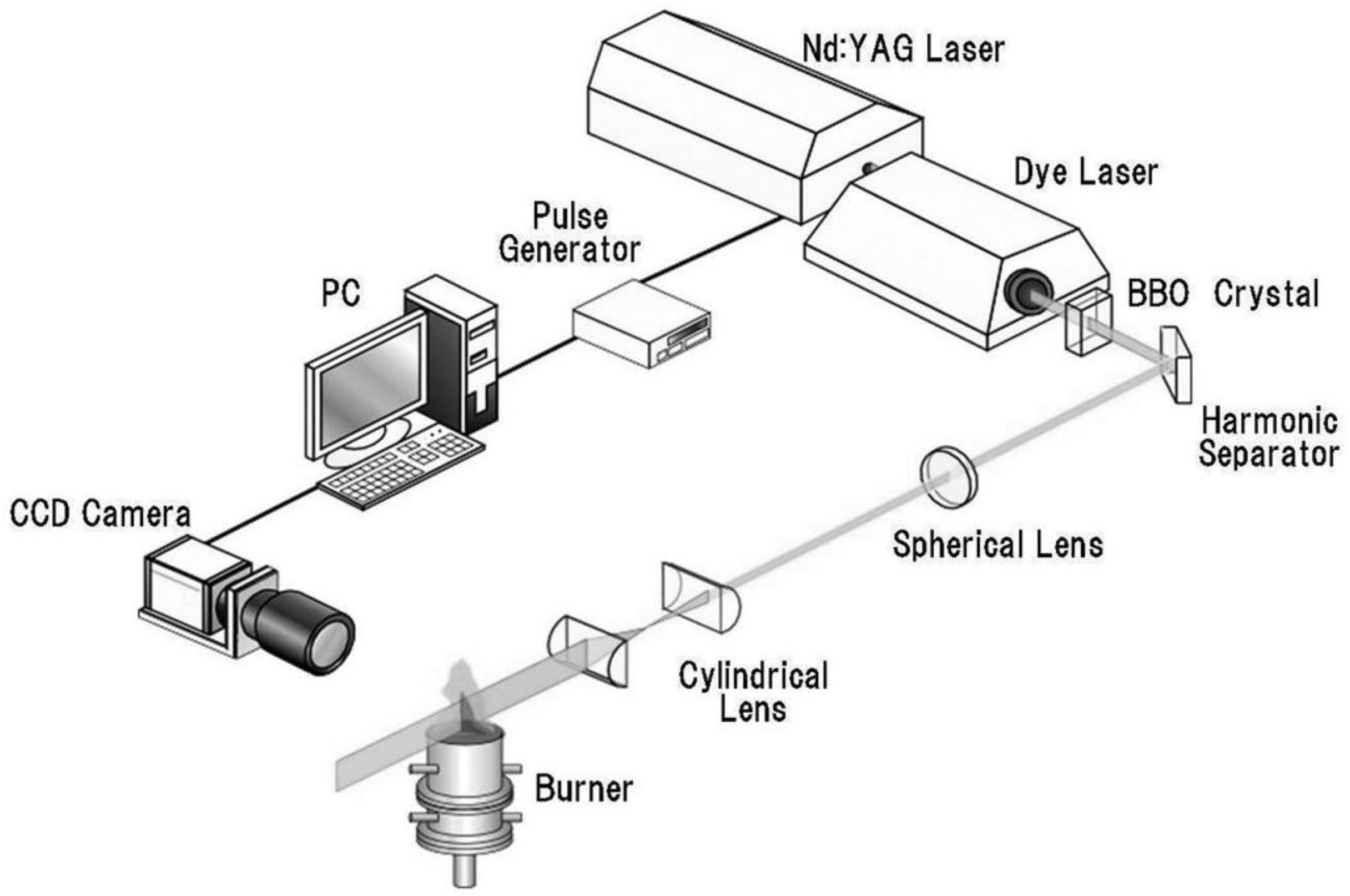

2.2. Measurement System

3. Results

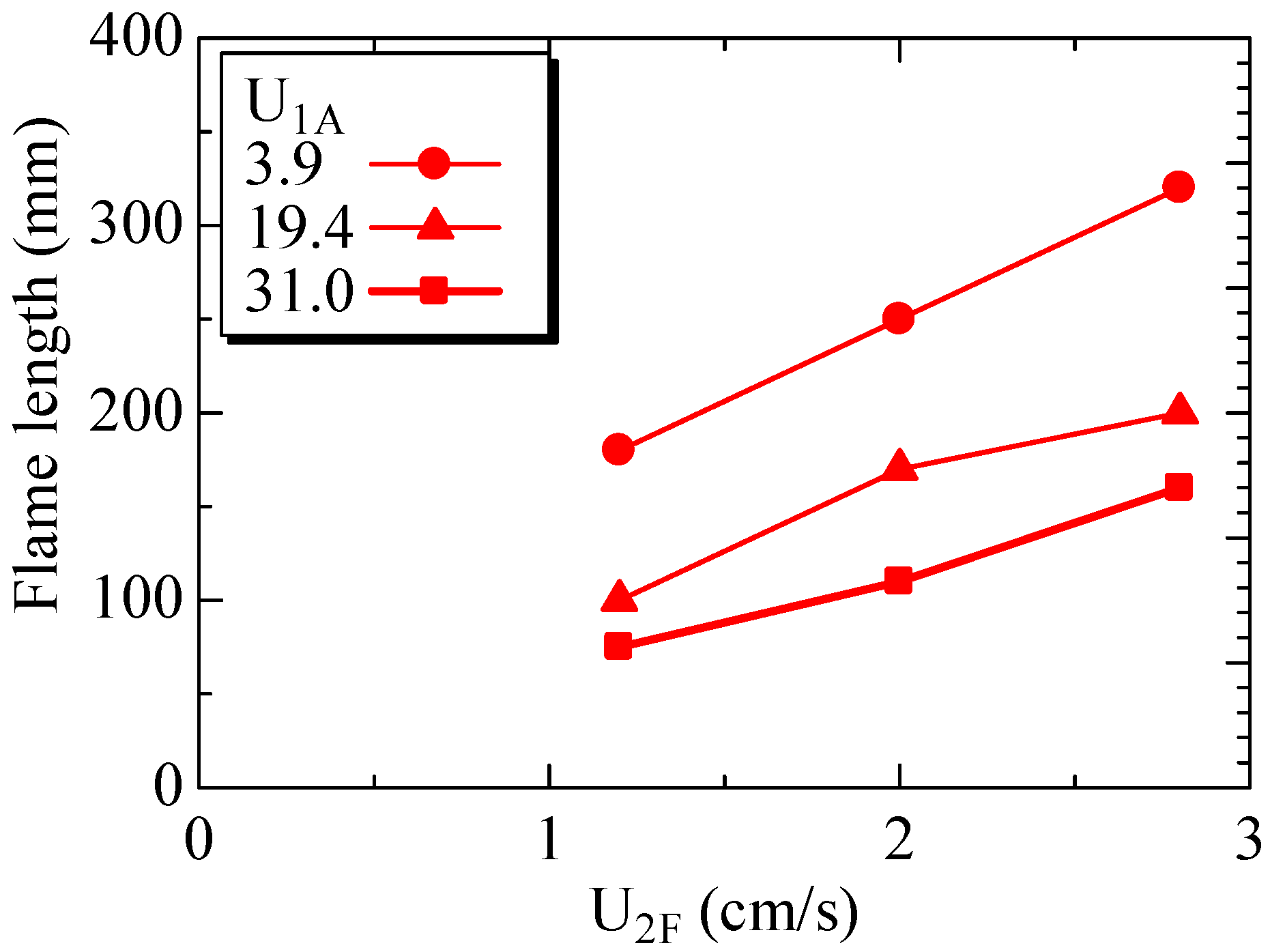

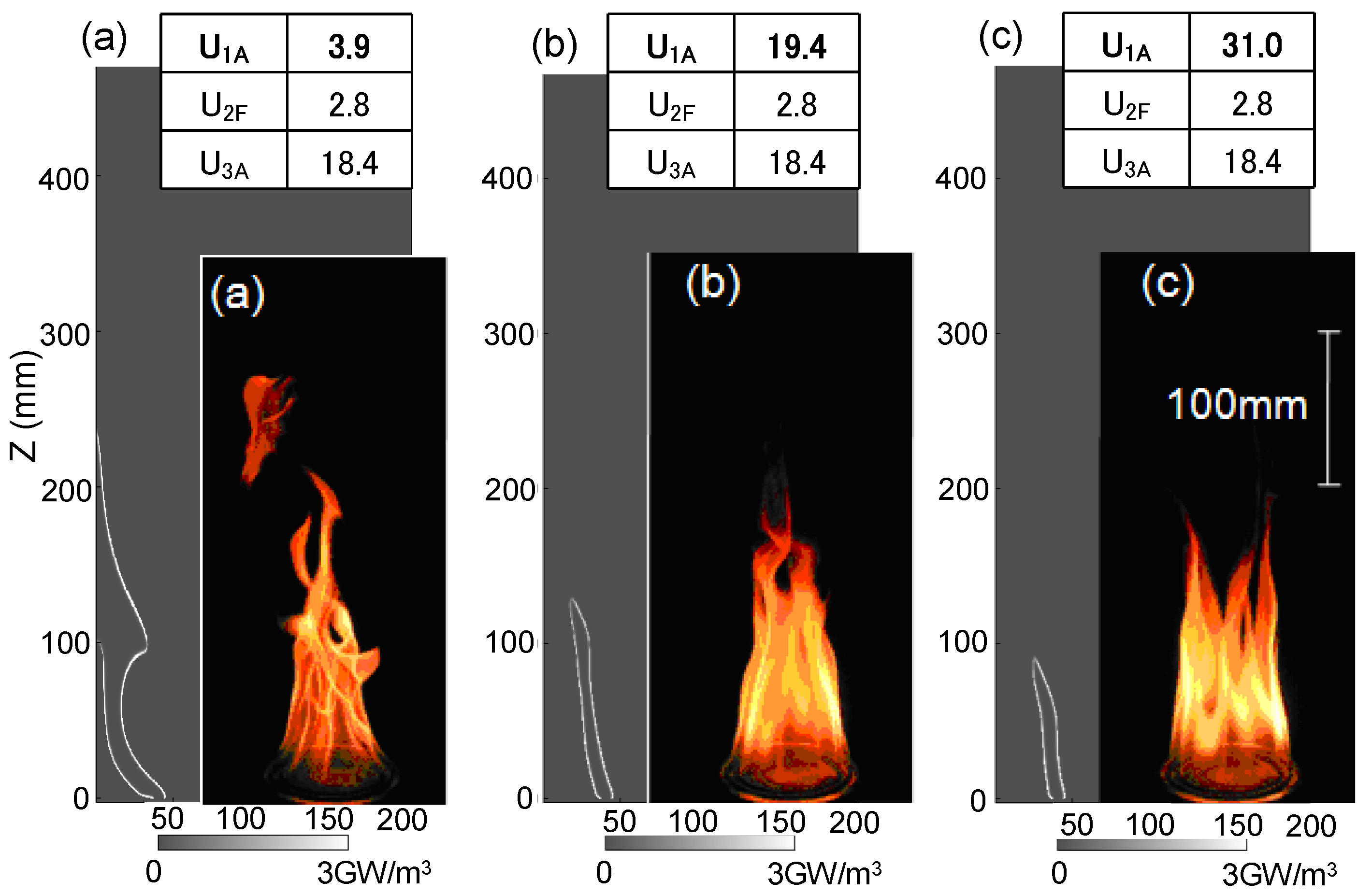

3.1. Appearance of Flame

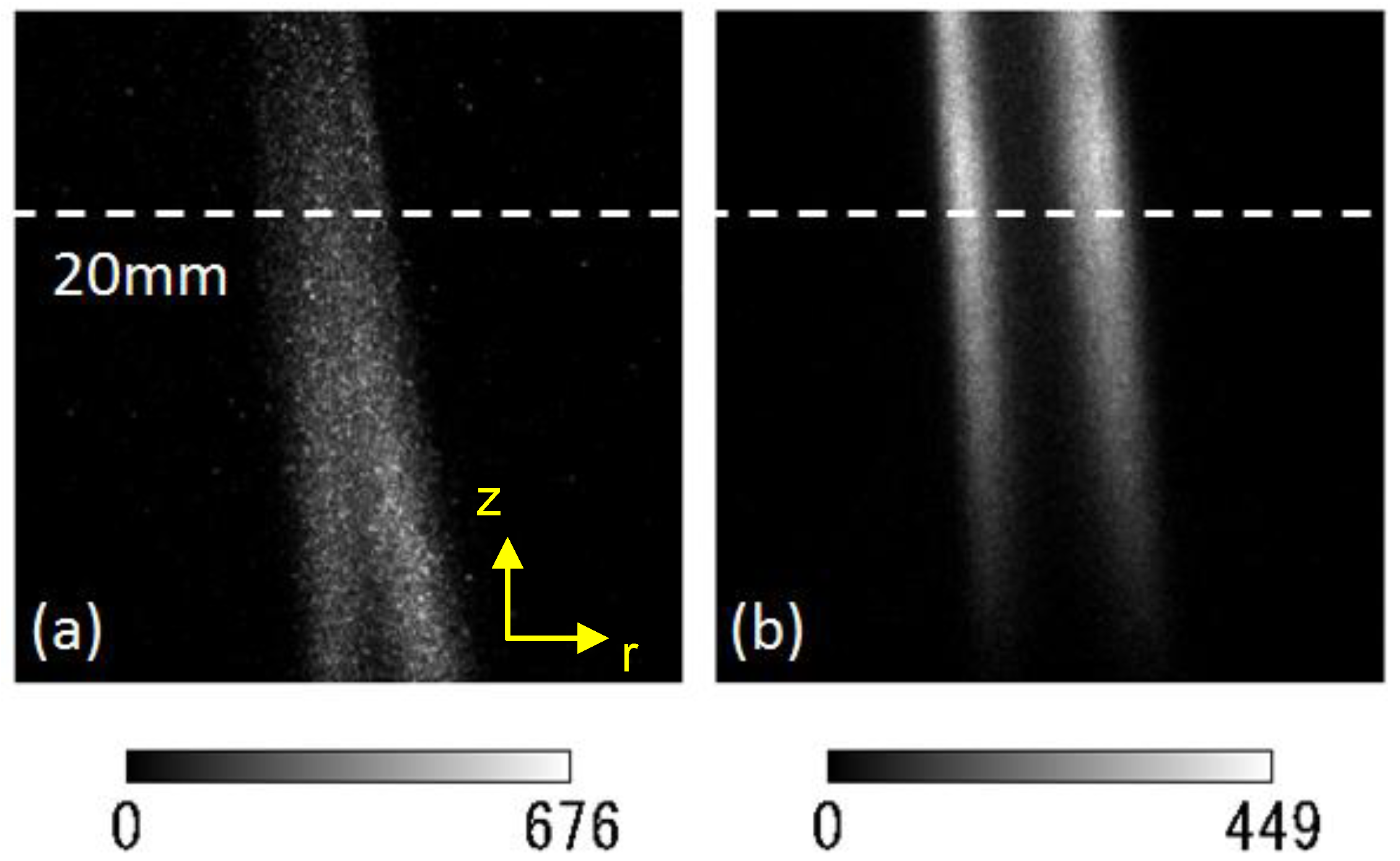

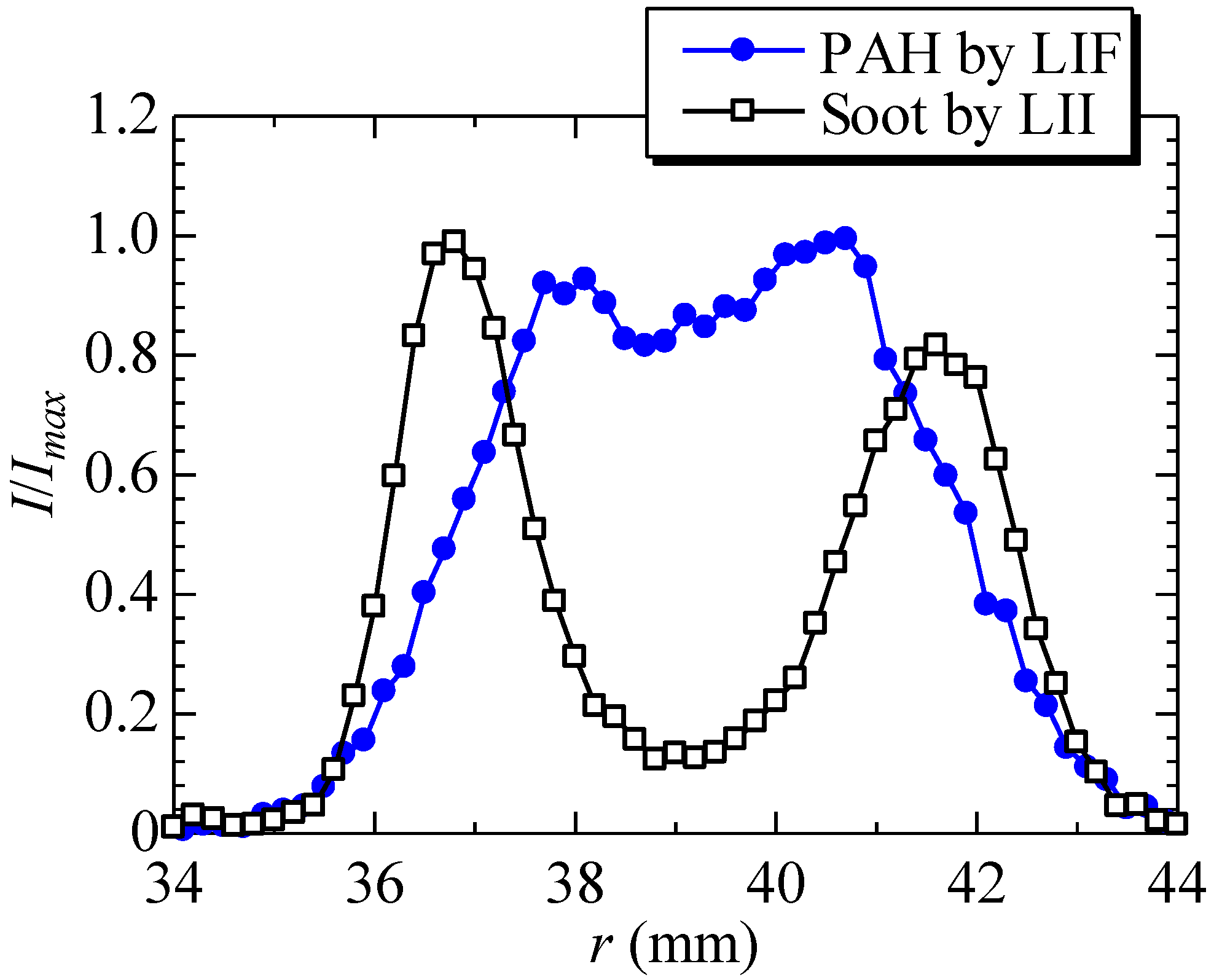

3.2. PAH and Soot Profiles

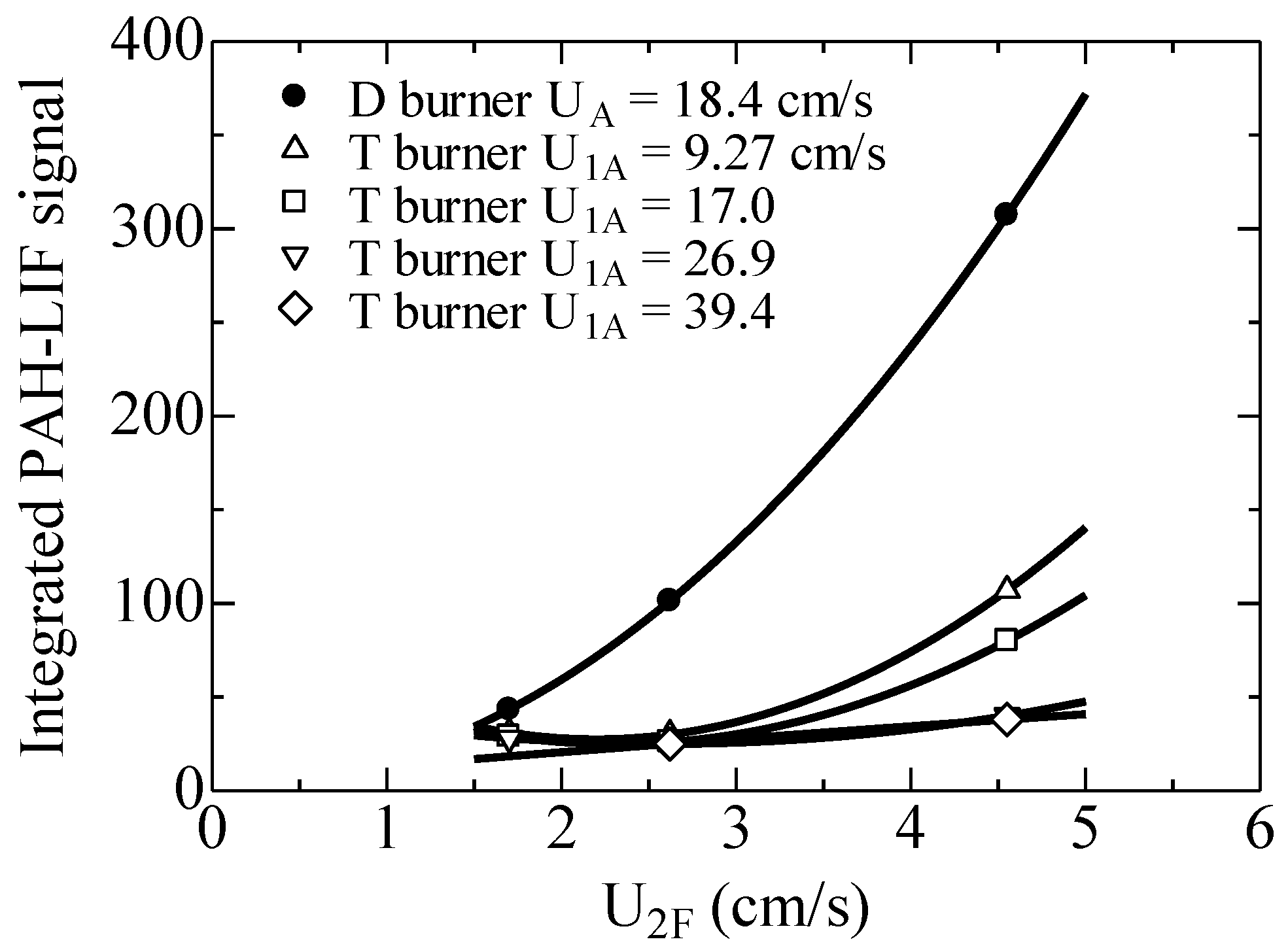

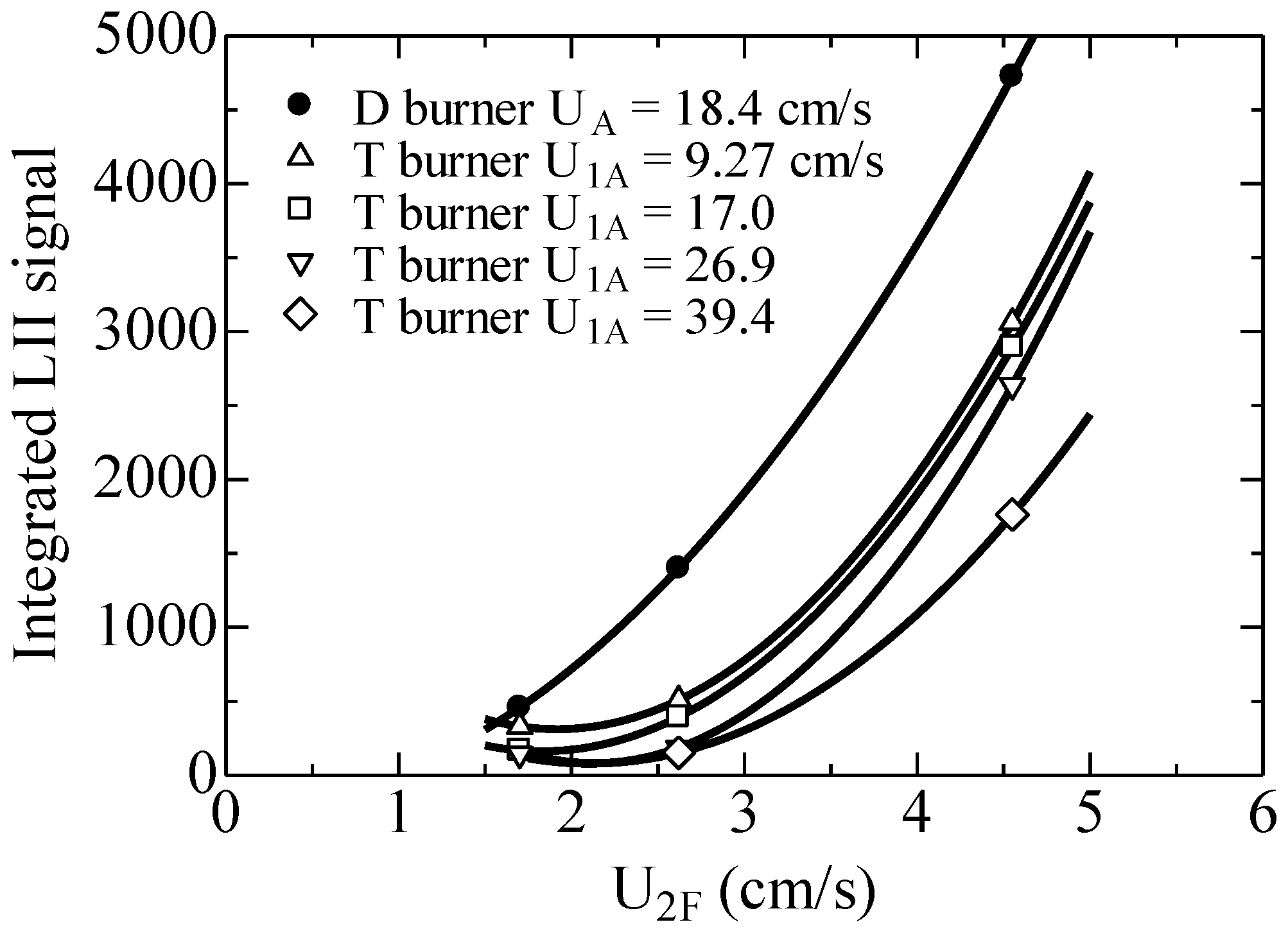

3.3. PAH and Soot Amounts

4. Discussion

5. Conclusions

- (1)

- In the triple port burner, two different blue flames are observed near the burner rim, followed by the bright luminous flames with soot. The flame length determined by the luminous flame zone is longer when the fuel flow velocity is increased. On the other hand, the flame length is decreased with an increase in the internal air flow velocity;

- (2)

- Two separate PAH and soot regions are observed. PAH exists between two soot regions, because PAH is a precursor substance of soot. Amounts of PAH and soot of the triple port burner are much smaller than those of the double port burner. Based on the correlation between PAH and soot, the exponential factor turns to be 1.6;

- (3)

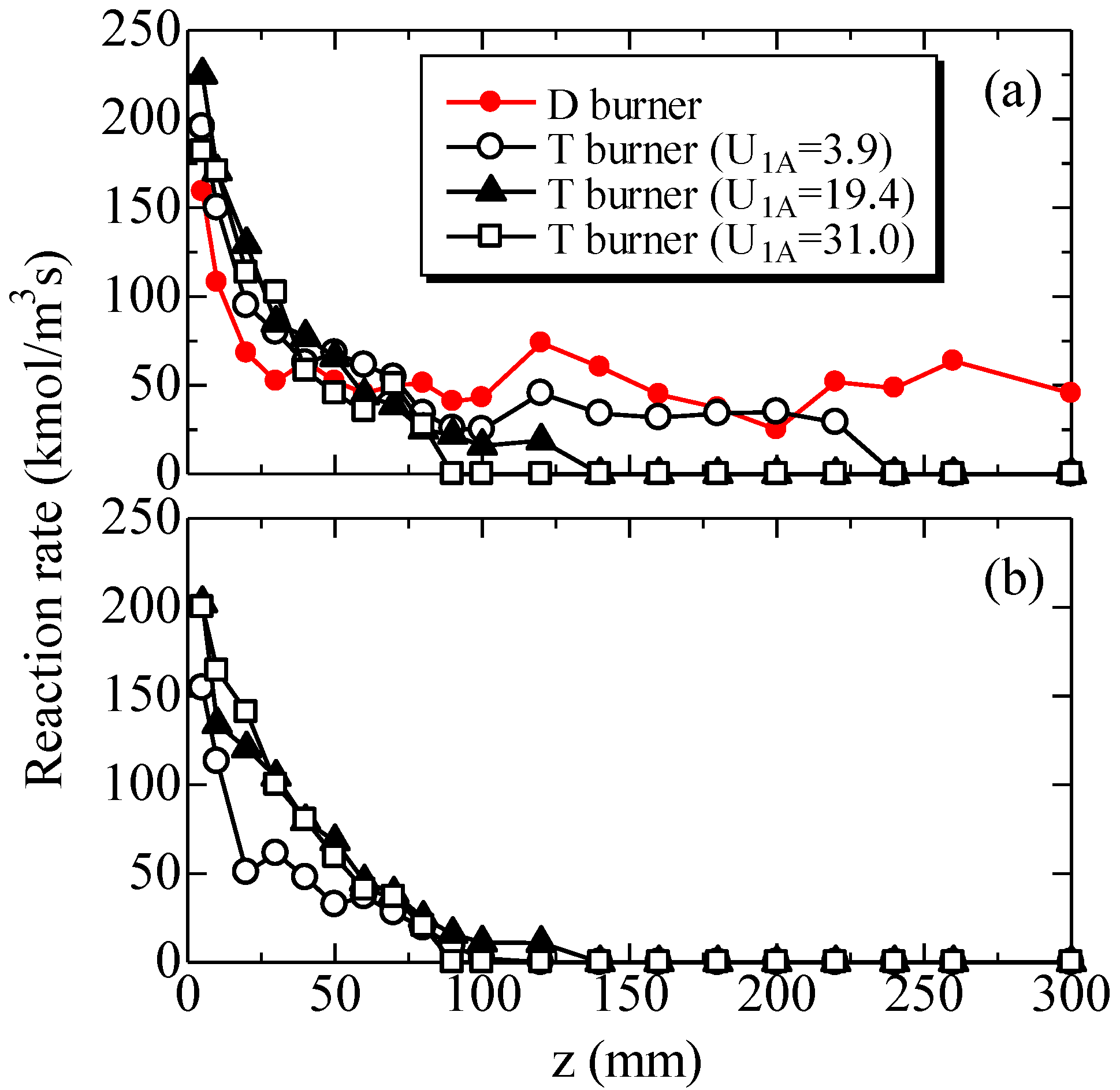

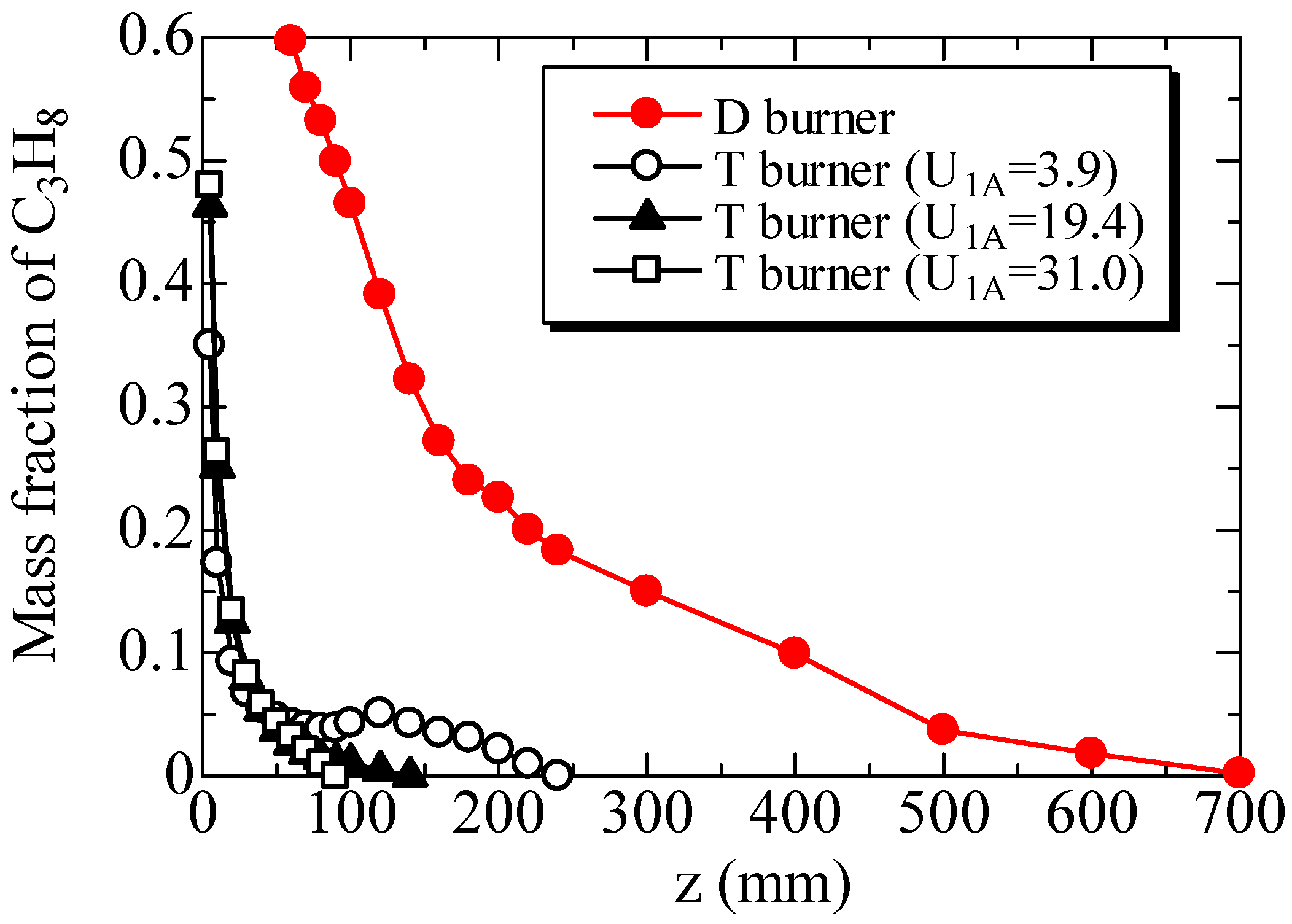

- Since the fuel is consumed only in one diffusion flame, the fuel consumption rate of the double port burner is relatively lower. On the other hand, in the case of the tripe port burner, the fuel consumption is largely promoted, because two air flows are supplied to form inner and outer flames. Moreover, even at the same external air flow velocity, the fuel consumption is promoted by increasing the internal air flow velocity, resulting in the shorter flame length. Hence, the center air jet plays an important role for the promotion of fuel consumption. As a result, in comparison with the double port burner, amounts of PAH and soot are largely reduced.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kennedy, I.M. The health effects of combustion-generated aerosols. Proc. Combust. Inst. 2007, 31, 2757–2770. [Google Scholar] [CrossRef]

- Frenklach, M.; Wang, H. Soot Formation in Combustion-Mechanisms and Models; Springer: Berlin/Heidelberg, Germany, 2004; pp. 162–164. [Google Scholar]

- Chen, D.; Zainuddin, Z.; Yapp, E.; Akroyd, J.; Mosbach, S.; Kraft, M. A fully coupled simulation of PAH and soot growth with a population balance model. Proc. Combust. Inst. 2013, 34, 1827–1835. [Google Scholar] [CrossRef]

- Vander Wal, R.L.; Jensen, K.A.; Choi, M.Y. Simultaneous laser-induced emission of soot and polycyclic aromatics hydrocarbons within a gas-jet diffusion flame. Combust. Flame 1997, 109, 399–414. [Google Scholar]

- Yamamoto, K.; Kato, S.; Isobe, Y.; Hayashi, N.; Yamashita, H. Lifted flame structure of coannular jet flames in a triple port burner. Proc. Combust. Inst. 2011, 33, 1195–1201. [Google Scholar]

- Shaddix, C.R.; Williams, T.C.; Blevins, L.G.; Schefer, R.W. Flame structure of steady and pulsed sooting inverse jet diffusion flames. Proc. Combust. Inst. 2005, 30, 1501–1508. [Google Scholar]

- Kumfer, B.M.; Skeen, S.A.; Axelbaum, R.L. Soot inception limits in laminar diffusion flames with application to oxy-fuel combustion. Combust. Flame 2008, 154, 546–556. [Google Scholar]

- Okuyama, G; Yamamoto, K.; Hayashi, N.; Yamashita, H. Combustion characteristics and flame structure in a triple port burner. In Proceedings of the 6th International Conference Computational Heat and Mass Transfer, Guangzhou, China, 18–22 May 2009; pp. 373–378.

- Yamamoto, K.; Takemoto, M. Measurement of PAH and soot of diffusion flames in a triple port burner. Fuel Process. Technol. 2013, 107, 99–106. [Google Scholar] [CrossRef]

- Yoon, S.S.; Lee, S.M.; Chung, S.H. Effect of mixing methane, ethane, propane, and propene on the synergistic effect of PAH and soot formation in ethylene-base counterflow diffusion flames. Proc. Combust. Inst. 2005, 30, 1417–1424. [Google Scholar] [CrossRef]

- D’Anna, A.; Commodo, M.; Violi, S.; Allouis, C.; Kent, J. Nano organic carbon and soot in turbulent non-premixed ethylene flames. Proc. Combust. Inst. 2007, 31, 621–629. [Google Scholar]

- Yamamoto, K.; Fujikake, F.; Matsui, K. Non-catalytic after-treatment for diesel particulates using carbon-fiber filter and experimental validation. Proc. Combust. Inst. 2011, 34, 2865–2875. [Google Scholar] [CrossRef]

- Yamamoto, K.; Ozeki, M.; Hayashi, N.; Yamashita, H. Burning velocity and OH concentration in premixed combustion. Proc. Combust. Inst. 2009, 32, 1227–1235. [Google Scholar] [CrossRef]

- Yamamoto, K.; Ishii, S.; Ohnishi, M. Local flame structure and turbulent burning velocity by joint PLIF imaging. Proc. Combust. Inst. 2011, 33, 1285–1292. [Google Scholar] [CrossRef]

- Schulz, C.; Kock, B.F.; Hofmann, M.; Michelsen, H.; Will, S.; Bougie, B.; Suntz, R.; Smallwood, G. Laser-induced incandescence: Recent trends and current questions. Appl. Phys. B 2006, 83, 333–354. [Google Scholar]

- Melton, L.A. Soot diagnostics based on laser heating. Appl. Opt. 1984, 23, 2201–2208. [Google Scholar] [CrossRef]

- Goulay, F.; Schrader, P.E.; Nemes, L.; Dansson, M.A.; Michelsen, H.A. Photochemical interferences for laser-induced incandescence of flame-generated soot. Proc. Combust. Inst. 2009, 32, 963–970. [Google Scholar] [CrossRef]

- Wang, H.; Frenklach, M. A detailed kinetic modeling study of aromatics formation in laminar premixed acetylene and ethylene flames. Combust. Flame 1997, 110, 173–221. [Google Scholar] [CrossRef]

- Marinov, N.M.; Pitz, W.J.; Westbrook, C.K.; Vincitore, A.M.; Castaldi, M.J.; Senkan, S.M.; Melius, C.F. Aromatic and polycyclic aromatic hydrocarbon formation in a laminar premixed n-butane flame. Combust. Flame 1998, 114, 192–213. [Google Scholar] [CrossRef]

- Frenklach, M. Reaction mechanism of soot formation in flames. Phys. Chem. Chem. Phys. 2002, 4, 2028–2037. [Google Scholar] [CrossRef]

- Westbrook, C.K.; Dryer, F.L. Simplified reaction mechanisms for the oxidation of hydrocarbon fuels in flames. Combust. Sci. Technol. 1981, 27, 265–280. [Google Scholar]

- Grinstein, F.F.; Kailasanath, K. Exothermicity and three-dimensional effects in unsteady propane square jets. Proc. Combust. Inst. 1996, 26, 91–96. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Yamamoto, K.; Takemoto, M. Reductions of PAH and Soot by Center Air Injection. Environments 2014, 1, 42-53. https://doi.org/10.3390/environments1010042

Yamamoto K, Takemoto M. Reductions of PAH and Soot by Center Air Injection. Environments. 2014; 1(1):42-53. https://doi.org/10.3390/environments1010042

Chicago/Turabian StyleYamamoto, Kazuhiro, and Masahiro Takemoto. 2014. "Reductions of PAH and Soot by Center Air Injection" Environments 1, no. 1: 42-53. https://doi.org/10.3390/environments1010042