Novel Nozzle Shapes for Synthetic Jet Actuators Intended to Enhance Jet Momentum Flux

Abstract

:1. Introduction

2. Problem Parameters

2.1. Basic Synthetic Jet Dimensionless Parameters

2.2. Synthetic Jet Integral Quantities

2.3. Parameters for Lumped Element Model

3. Measurement Methods

3.1. The Synthetic Jet Actuator

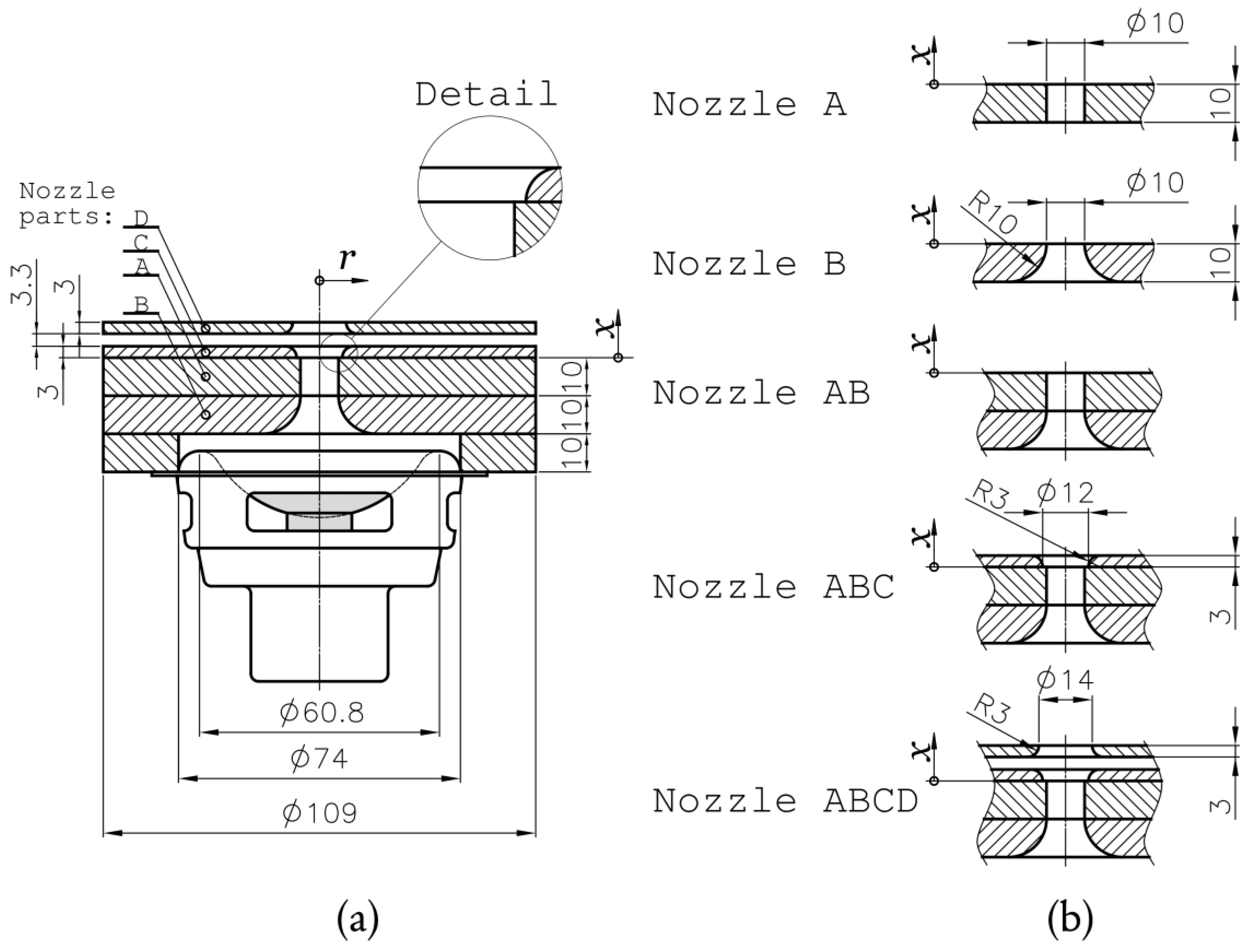

- Nozzle AB was a combination of the previous nozzles. Note that an experimental study of similar nozzle geometries was done, e.g., by Nani and Smith [32].

- The fourth nozzle was denoted as ABC (it consists of three nozzle plates A+B+C, see Figure 1a) and had a special novel design with rounded lips at both inner and outer nozzle ends. A similar shape was tested by Lee and Goldstein [36] for a slot-type nozzle. However, this study’s nozzle was circular and equipped with a small step at the end of the straight nozzle section. This step promoted flow separation and prevented flow reattachment during extrusion stroke.

- The ABCD nozzle combined the design by Rylatt and O’Donovan [37] with the ABC nozzle. The nozzle contained an auxiliary outer nozzle—denoted as part D, see Figure 1a. The auxiliary nozzle had a greater diameter (12.0 mm) than Dn = 10.0 mm and was placed 3.3 mm downstream from the exit of nozzle ABC, see Figure 1a. The rounded edge of the part D was oriented towards the actuator outlet, helping to direct the radially dispersed momentum flux along the x-axis.

3.2. Data Acquisition and Measurement Methods

3.2.1. Measurement of the Jet Thrust Using Precision Scales

- For relatively weak SJs at the dimensionless stroke length of L0/Dn from 0.5 to 5 (i.e., including the vicinity of the SJ existence threshold), the maximum deviation is within ±5.4%.

- For stronger SJs at L0/Dn ≥ 5, the maximum deviation is only ±3.4%.

3.2.2. Hot-Wire and Cavity Pressure Measurements

4. Experimental Results

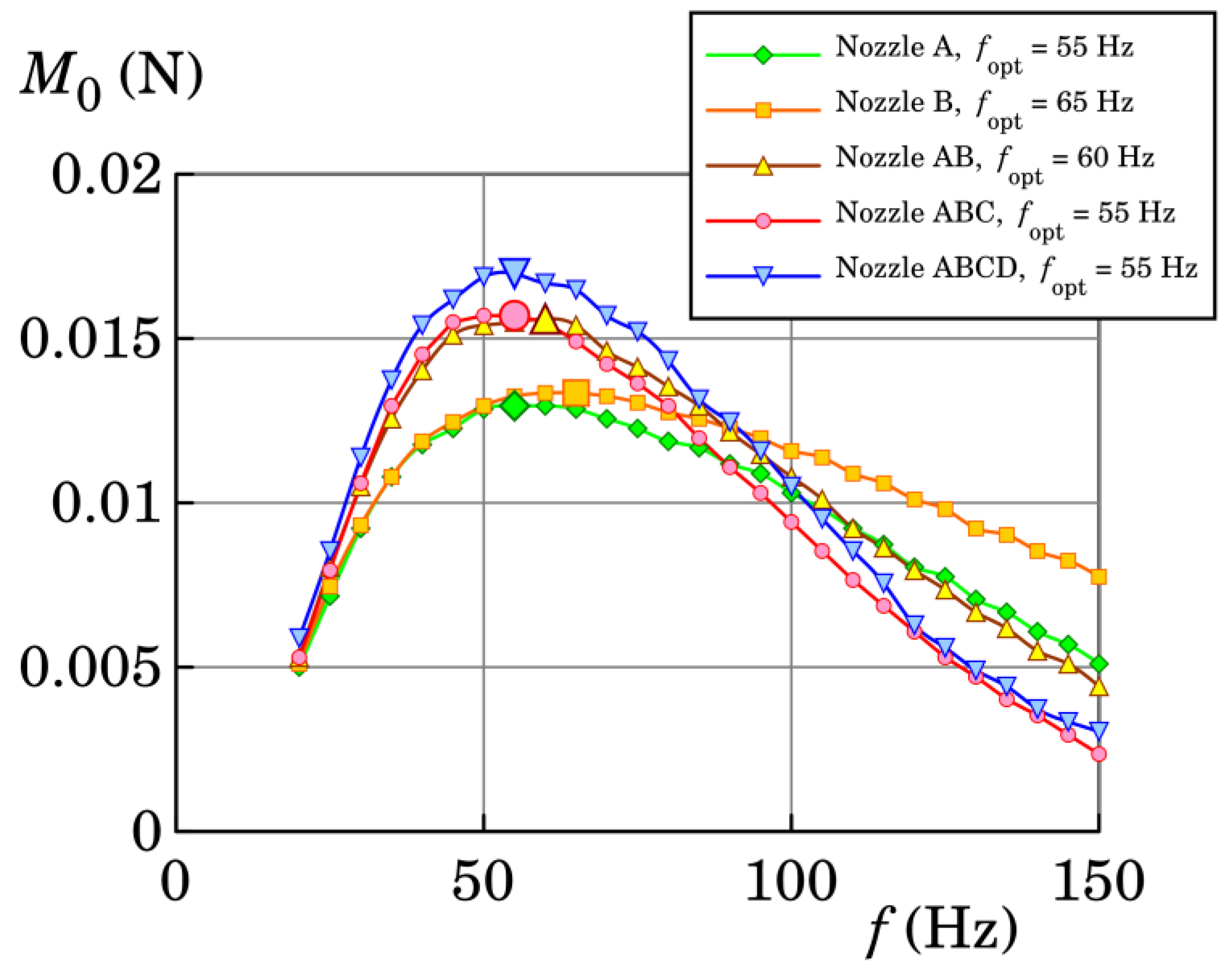

4.1. Frequency Characteristics

4.2. Synthetic Jet Thrust Measurement

4.3. Measurement of Velocity Profiles

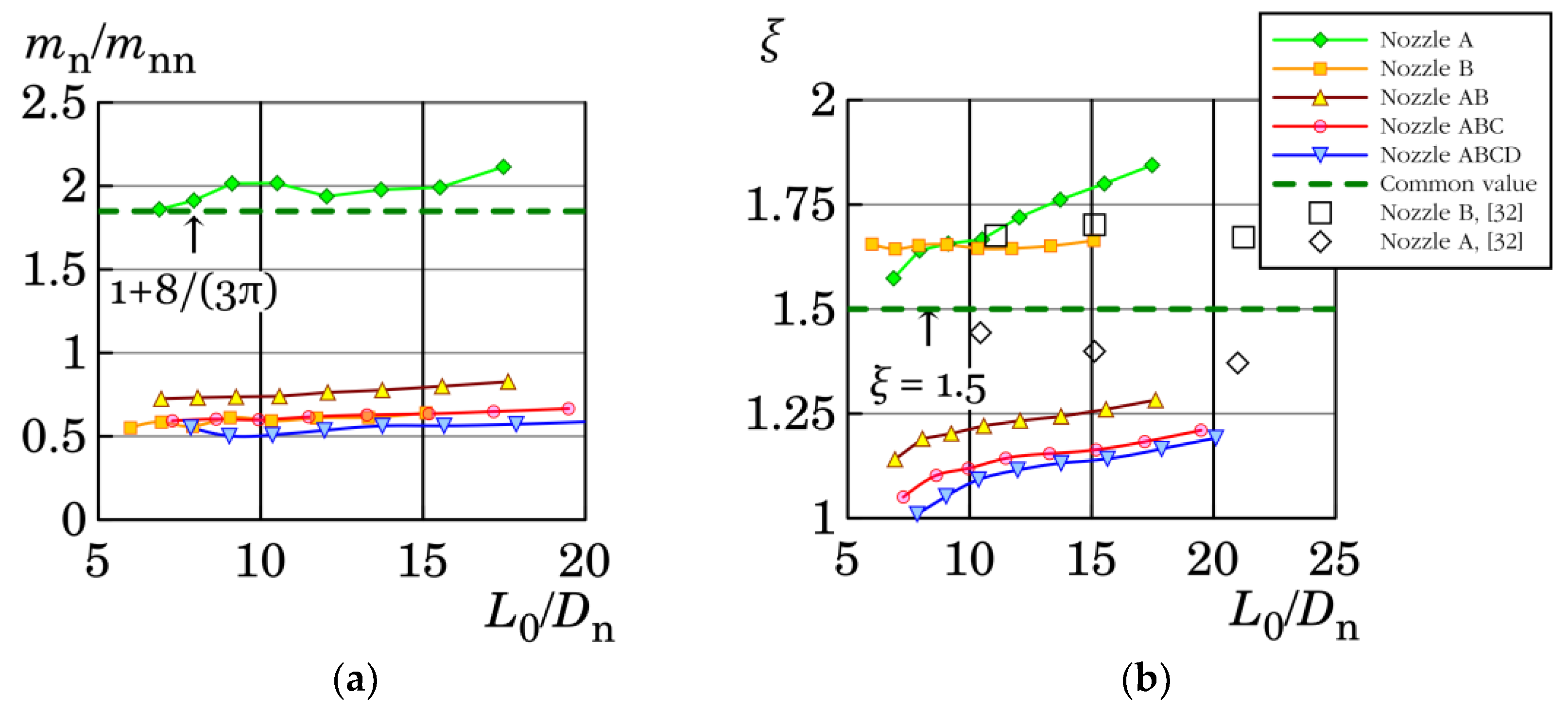

4.4. Evaluation of mn and ξ

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

Nomenclature

| D | diameter, m |

| e | electrical voltage, V |

| f | driving frequency, Hz |

| g | magnitude of the gravitational acceleration, m/s2 |

| i | electrical current, A |

| L | length, m |

| M | momentum flux, N |

| m | mass, kg |

| p | pressure, Pa |

| P | input power, W |

| r | radial coordinate, m |

| Re | Reynolds number, 1 |

| S | cross-sectional area, m2 |

| T | time period, s |

| t | time, s |

| u | velocity, m/s |

| x | axial coordinate, m |

| ρ | density, kg/m3 |

| Subscripts | |

| 0 | averaging in time and space |

| A | related to the nozzle A |

| b | barometric |

| c | cavity |

| d | diaphragm |

| e | electrical |

| E | extrusion stroke |

| n | nozzle |

| nn | related to nozzle internal |

| Superscripts | |

| * | dimensionless |

Appendix A. Estimation of mn and ξ

References

- Smith, B.L.; Glezer, A. The formation and evolution of synthetic jets. Phys. Fluids 1998, 10, 2281–2297. [Google Scholar] [CrossRef]

- Cater, J.E.; Soria, J. The evolution of round zero-net-mass-flux jets. J. Fluid Mech. 2002, 472, 167–200. [Google Scholar] [CrossRef]

- Lardeau, S.; Leschziner, M.A. The interaction of round synthetic jets with a turbulent boundary layer separating from a rounded ramp. J. Fluid Mech. 2011, 683, 172–211. [Google Scholar] [CrossRef] [Green Version]

- Bernardini, C.; Carnevale, M.; Manna, M.; Martelli, F.; Simoni, D.; Zunino, P. Turbine blade boundary layer separation suppression via synthetic jet: An experimental and numerical study. J. Therm. Sci. 2012, 21, 404–412. [Google Scholar] [CrossRef]

- Jabbal, M.; Zhong, S. Particle image velocimetry measurements of the interaction of synthetic jets with a zero-pressure gradient laminar boundary layer. Phys. Fluids 2010, 22, 063603. [Google Scholar] [CrossRef] [Green Version]

- Sahni, O.; Wood, J.; Jansen, K.E.; Amitay, M. Three-dimensional interactions between a finite-span synthetic jet, a crossflow. J. Fluid Mech. 2011, 671, 254–287. [Google Scholar] [CrossRef]

- Xia, X.; Mohseni, K. Transitional region of a round synthetic jet. Phys. Rev. Fluids 2018, 3, 011901. [Google Scholar] [CrossRef]

- Chiatto, M.; Capuano, F.; de Luca, L. Numerical and experimental characterization of a double-orifice synthetic jet actuator. Meccanica 2018, 53, 2883–2896. [Google Scholar] [CrossRef]

- Seo, J.H.; Cadieux, F.; Mittal, R.; Deem, E.; Cattafesta, L. Effect of synthetic jet modulation schemes on the reduction of a laminar separation bubble. Phys. Rev. Fluids 2018, 3, 033901. [Google Scholar] [CrossRef]

- Xia, Z.-X.; Luo, Z.-B. Physical factors of primary jet vectoring control using synthetic jet actuators. Appl. Math. Mech. 2007, 28, 907–920. [Google Scholar] [CrossRef]

- Ben Chiekh, M.; Ferchichi, M.; Béra, J.-C.C. Aerodynamic flow vectoring of a wake using asymmetric synthetic jet actuation. Exp. Fluids 2012, 53, 1797–1813. [Google Scholar] [CrossRef]

- Trávníček, Z.; Němcová, L.; Kordík, J.; Tesař, V.; Kopecký, V. Axisymmetric impinging jet excited by a synthetic jet system. Int. J. Heat Mass Transf. 2012, 55, 1279–1290. [Google Scholar] [CrossRef]

- McGuinn, A.; Farrelly, R.; Persoons, T.; Murray, D.B. Flow regime characterisation of an impinging axisymmetric synthetic jet. Exp. Therm. Fluid Sci. 2013, 47, 241–251. [Google Scholar] [CrossRef] [Green Version]

- Lee, A.; Yeoh, G.H.; Timchenko, V.; Reizes, J.A. Heat transfer enhancement in micro-channel with multiple synthetic jets. Appl. Therm. Eng. 2012, 48, 275–288. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, P.; Xie, Y. Numerical investigation of heat transfer characteristics of impinging synthetic jets with different waveforms. Int. J. Heat Mass Transf. 2018, 125, 1017–1027. [Google Scholar] [CrossRef]

- Trávníček, Z.; Vít, T.; Tesař, V. Hybrid synthetic jets as the nonzero-net-mass-flux synthetic jets. Phys. Fluids 2006, 18, 081701. [Google Scholar] [CrossRef]

- Trávníček, Z.; Tesař, V.; Kordík, J. Performance of synthetic jet actuators based on hybrid and double-acting principles. J. Vis. 2008, 11, 221–229. [Google Scholar] [CrossRef]

- Kordík, J.; Trávníček, Z. Novel fluidic diode for hybrid synthetic jet actuator. J. Fluids Eng. 2013, 135, 101101. [Google Scholar] [CrossRef]

- Kordík, J.; Broučková, Z.; Trávníček, Z. Impinging jet-based fluidic diodes for hybrid synthetic jet actuators. J. Vis. 2015, 18, 449–458. [Google Scholar] [CrossRef]

- Gallas, Q.; Holman, R.; Nishida, T.; Carroll, B.; Sheplak, M.; Cattafesta, L. Lumped element modeling of piezoelectric-driven synthetic jet actuators. AIAA J. 2003, 41, 240–247. [Google Scholar] [CrossRef]

- Kim, B.H.; Williams, D.R.; Emo, S.; Acharya, M. Modeling pulsed-blowing systems for flow control. AIAA J. 2005, 43, 314–325. [Google Scholar] [CrossRef]

- Kordík, J.; Trávníček, Z. Axisymmetric synthetic jet actuators with large streamwise dimensions. AIAA J. 2013, 51, 2862–2877. [Google Scholar] [CrossRef]

- De Luca, L.; Girfoglio, M.; Coppola, G. Modeling and experimental validation of the frequency response of synthetic jet actuators. AIAA J. 2014, 52, 1733–1748. [Google Scholar] [CrossRef]

- Sharma, R.N. Fluid-dynamic-based analytical model for synthetic jet actuation. AIAA J. 2007, 45, 1841–1847. [Google Scholar] [CrossRef]

- Chiatto, M.; Capuano, F.; Coppola, G.; de Luca, L. LEM characterization of synthetic jet actuators driven by piezoelectric element: A review. Sensors 2017, 17, 1216. [Google Scholar] [CrossRef] [PubMed]

- Broučková, Z.; Trávníček, Z. Visualization study of hybrid synthetic jets. J. Vis. 2015, 18, 581–593. [Google Scholar] [CrossRef]

- Mohseni, K.; Mittal, R. Synthetic Jets: Fundamentals and Applications; CRC Press, Taylor & Francis: Boca Raton, FL, USA, 2015. [Google Scholar]

- Persoons, T.; O’Donovan, T.S. A pressure-based estimate of synthetic jet velocity. Phys. Fluids 2007, 19, 128104. [Google Scholar] [CrossRef] [Green Version]

- Persoons, T. General reduced-order model to design and operate synthetic jet actuators. AIAA J. 2012, 50, 916–927. [Google Scholar] [CrossRef]

- Kordík, J.; Trávníček, Z. Optimal diameter of nozzles of synthetic jet actuators based on electrodynamic transducers. Exp. Therm. Fluid Sci. 2017, 86, 281–294. [Google Scholar] [CrossRef]

- Kordík, J.; Broučková, Z.; Vít, T.; Pavelka, M.; Trávníček, Z. Novel methods for evaluation of the Reynolds number of synthetic jets. Exp. Fluids 2014, 55, 1757. [Google Scholar] [CrossRef]

- Nani, D.J.; Smith, B.L. Effect of orifice inner lip radius on synthetic jet efficiency. Phys. Fluids 2012, 24, 115110. [Google Scholar] [CrossRef]

- Kordík, J.; Trávníček, Z.; Timchenko, V.; Ismail, N.A. The predominant effect of stroke length on velocity profiles at the exit of axisymmetric synthetic jet actuators. Int. J. Heat Fluid Flow 2017, 66, 197–208. [Google Scholar] [CrossRef]

- Tesař, V.; Kordík, J. Quasi-similarity model of synthetic jets. Sens. Actuators A Phys. 2009, 149, 255–265. [Google Scholar] [CrossRef]

- Tesař, V.; Kordík, J. Time-mean structure of axisymmetric synthetic jets. Sens. Actuators A Phys. 2010, 161, 217–224. [Google Scholar] [CrossRef]

- Lee, C.Y.; Goldstein, D.B. Two-dimensional synthetic jet simulation. AIAA J. 2002, 40, 510–516. [Google Scholar] [CrossRef]

- Rylatt, D.I.; O’Donovan, T.S. Heat transfer enhancement to a confined impinging synthetic air jet. Appl. Therm. Eng. 2013, 51, 468–475. [Google Scholar] [CrossRef] [Green Version]

- Kordík, J.; Trávníček, Z. Non-harmonic excitation of synthetic jet actuators based on electrodynamic transducers. Int. J. Heat Fluid Flow 2018, 73, 154–162. [Google Scholar] [CrossRef]

- Trávníček, Z.; Fedorchenko, A.I.; Wang, A.-B. Enhancement of synthetic jets by means of an integrated valve-less pump, Part I: Design of the actuator. Sens. Actuator A Phys. 2005, 120, 232–240. [Google Scholar] [CrossRef]

- Kooijman, G.; Ouweltjes, O. Finite difference time domain electroacoustic model for synthetic jet actuators including nonlinear flow resistance. J. Acoust. Soc. Am. 2009, 125, 1911–1918. [Google Scholar] [CrossRef] [PubMed]

- Trávníček, Z.; Broučková, Z. A synthetic jet issuing from a bio-inspired actuator with an oscillating nozzle lip. J. Fluids Eng. 2018, 140, 101104. [Google Scholar] [CrossRef]

- Kordík, J.; Trávníček, Z. Integral quantities of axisymmetric synthetic jets evaluated from a direct jet thrust measurement. Flow Turbul. Combust. 2018. submitted. [Google Scholar]

- Kordík, J. Theoretical and Experimental Analysis of Synthetic and Hybrid Synthetic Jet Actuators. Ph.D. Thesis, Czech Technical University, Prague, Czech Republic, 2011. [Google Scholar]

| Quantity | Symbol | Value | Unit |

|---|---|---|---|

| Synthetic jet actuator | |||

| Loudspeaker type | Aurasound NS3-193-8A | ||

| Nozzle diameter | Dn | 10.0 | (mm) |

| Diaphragm effective diameter | Dd | 60.8 | (mm) |

| Mass of air inside the nozzle volume | mnn | 0.92, 2.1, 3.0, 3.5, 4.1 | (mg) |

| Fluid: air | |||

| Ambient temperature | Ta | 24.2–26.6 | (°C) |

| Barometric pressure | pb | 98 000–98 900 | (Pa) |

| Density | ρ | 1.14–1.15 | (kg/m3) |

| Forcing | |||

| Input real power | Pe | 0.13, 0.20, 0.30, 0.45, 0.68, 1.02, 1.53, and 2.30 | (W) |

| Actuating frequency | f | 55–65 | (Hz) |

| Nozzle A | 55 Hz |

| Nozzle B | 65 Hz |

| Nozzle AB | 60 Hz |

| Nozzle ABC | 55 Hz |

| Nozzle ABCD | 55 Hz |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kordík, J.; Trávníček, Z. Novel Nozzle Shapes for Synthetic Jet Actuators Intended to Enhance Jet Momentum Flux. Actuators 2018, 7, 53. https://doi.org/10.3390/act7030053

Kordík J, Trávníček Z. Novel Nozzle Shapes for Synthetic Jet Actuators Intended to Enhance Jet Momentum Flux. Actuators. 2018; 7(3):53. https://doi.org/10.3390/act7030053

Chicago/Turabian StyleKordík, Jozef, and Zdeněk Trávníček. 2018. "Novel Nozzle Shapes for Synthetic Jet Actuators Intended to Enhance Jet Momentum Flux" Actuators 7, no. 3: 53. https://doi.org/10.3390/act7030053