1. Introduction

As a universal component of automatic transmission, torque converters have been widely used in construction vehicles owing to their unique power performance [

1,

2]. However, torque converters have low transmission efficiency and a narrow high-efficiency range, posing a difficult problem that hinders the wider application of hydrodynamic transmission [

3,

4]. Therefore, recent research has focused on developing a new transmission system suitable for construction vehicles.

In single power flow transmission systems, the hydrostatic transmission system (HST), composed of a pump and a motor, is the only transmission system with both low-speed torque increase (the low-speed torque increase characteristic is a transmission characteristic that can ensure that the power source always rotates at high speed; the system speed ratio is inversely proportional to the torque ratio; and the maximum torque can be output at a zero speed ratio) and stepless speed regulation, except for automatic transmission. Some scholars have attempted to use HST to compensate for the shortcomings of the torque converter [

5,

6]. However, large-displacement pumps and motors are expensive, and the transmission efficiency of HST is extremely low under ultra-high-pressure operating conditions [

7]. Therefore, HST has been partially used in low-horsepower, compact vehicles, but it is still not widely used in construction vehicles.

In dual power flow transmission systems, the hydro-mechanical transmission system (HMTS) is most suitable for heavy-duty vehicles. HMTS comprises hydrostatic and mechanical transmissions that transmit power in parallel [

8]. This system exhibits the stability of hydrostatic transmission and the efficiency of mechanical transmission, and it can achieve high-power, high-efficiency stepless speed change transmission, therefore constituting an ideal transmission form [

9].

In the early stages of design, the HMTS was primarily utilized for steering in military tracked vehicles, belonging to one of the dual differential transmission systems [

10]. At this point, the two transmission paths of the HMTS transmitted power in parallel and unidirectionally, and only one power split transmission mode existed within the system. However, with the development of vehicle transmission technology, the HMTS began to be applied to transmissions, and this type of transmission has been commonly referred to as the hydro-mechanical continuously variable transmission (HMCVT) [

11]. Many scholars have conducted a significant amount of research on HMCVT. Rossetti and Macor introduced the basic structural characteristics of HMCVT; established the mathematical models of mechanical, hydraulic, and control systems; and optimized the transmission efficiency and the structural dimensions of the transmission as the objective function using a multi-objective particle swarm algorithm. Their results can increase the maximum efficiency of the transmission system to 84~85.5% [

12]. Pettersson et al. used engineering vehicles as the application object and proposed a novel HMCVT based on a shared pressure rail for the transmission system and secondary controlled work hydraulics, which reduced the weight of the wheel loader work equipment by 30% [

13]. Liu et al. proposed a two-stage input coupling layout multi-stage HMCVT based on a two-phase power distribution mechanism. The proposed HMCVT presents a mean efficiency of about 83% in a wide speed range [

14]. Considering all-terrain vehicles as the research object, Wu et al. designed an HMCVT equipped with a single planetary gear, and they used an active disturbance rejection control algorithm with feedforward compensation to regulate the speed ratio, which can control the overshoot of the actual speed ratio at around 3.75% [

15].

In addition to theoretical research, many companies have launched mature HMCVT products, which have been widely used in vehicle transmission systems. As early as the 1970s, the American corporation Sundstrand developed the DMT-15 and DMT-25 HMCVTs for heavy-duty vehicles [

16]. The Vario-type HMCVT developed by the German corporation Fendt is widely used in various high-power tractors. To improve the transmission efficiency, the hydraulic motor of the Vario is set at a 45° angle to the energy storage shaft, and the hydraulic transmission system has an ultimate pressure of 55 MPa [

17,

18]. The ZF Eccom series of HMCVT from ZF Group in Germany adopted a closed-loop system of low-power pumps and motors, with four stepless speed regulation segments in both the forward and reverse directions. ZF Eccom mainly operates within a range of hydraulic power split ratios of less than 10%, and the average transmission efficiency exceeds 80% [

19]. In addition, Caterpillar (USA), Komatsu (Japan), JCB (UK), and Deutz-Fahr (Italy), among others, use HMCVT extensively on bulldozers, loaders, excavators, and other related high-horsepower vehicles [

20,

21].

HMCVT has a wide range of applications, and its structural forms are diverse. However, a thorough review of the literature reveals that, whether in theoretical research or production applications, almost all HMCVTs not only start with hydrostatic transmission, but also include two transmission modes: power split transmission mode and power reflux transmission mode. In the power reflux transmission mode, part of the power input from the power source is output externally, while the rest is stored within the system in the form of reflux power [

22]. Affected by the reflux power, the efficiency of the power reflux transmission mode is lower than that of the power split transmission mode, and it has higher strength requirements for transmission components [

23]. Therefore, the power split transmission mode has received more attention, whereas the power reflux transmission mode has rarely been mentioned. However, research has revealed that the power reflux transmission mode can accumulate the power input from the power source in the form of reflux power; thus, the HMTS in the power reflux transmission mode has similar transmission performance as the hydrodynamic transmission system, which not only ensures that the engine maintains high-speed operation at zero vehicle speed and avoids stalling, but also improves the vehicle’s ability to start and overcome obstacles. Although the efficiency of the power reflux transmission mode is lower than that of the power split transmission mode, reasonable configuration can cause the HMTS in the power reflux transmission mode to have significantly higher transmission efficiency than the torque converter.

The phenomenon of power reflux in power reflux transmission mode has received the attention of Professor Sun, who presented the following conclusions after comparing the HMTS with the torque converter: ① The hydrodynamic internal reflux phenomenon generated by the circulation of the fluid medium provides a pathway for energy accumulation, which is the fundamental reason for the torque converter being able to achieve low-speed torque increase characteristics [

24]; ② having the power reflux transmission feature is a prerequisite for the transmission system to achieve the low-speed torque increase characteristic; and ③ owing to the high efficiency of mechanical transmission, it is possible to replace the hydrodynamic internal reflux transmission system of a torque converter with a power external reflux transmission system composed of a stepless speed regulation component and a differential gear train (DGT) [

25].

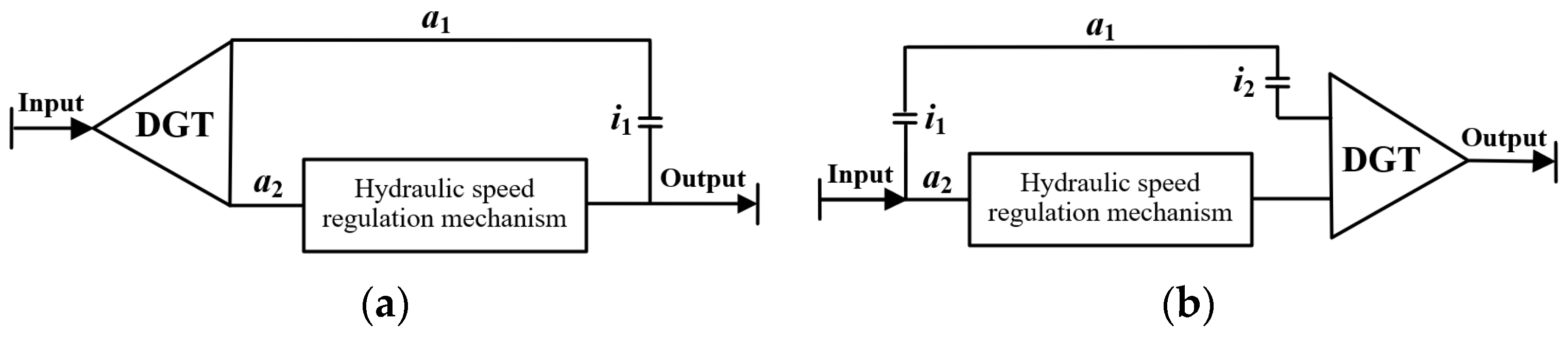

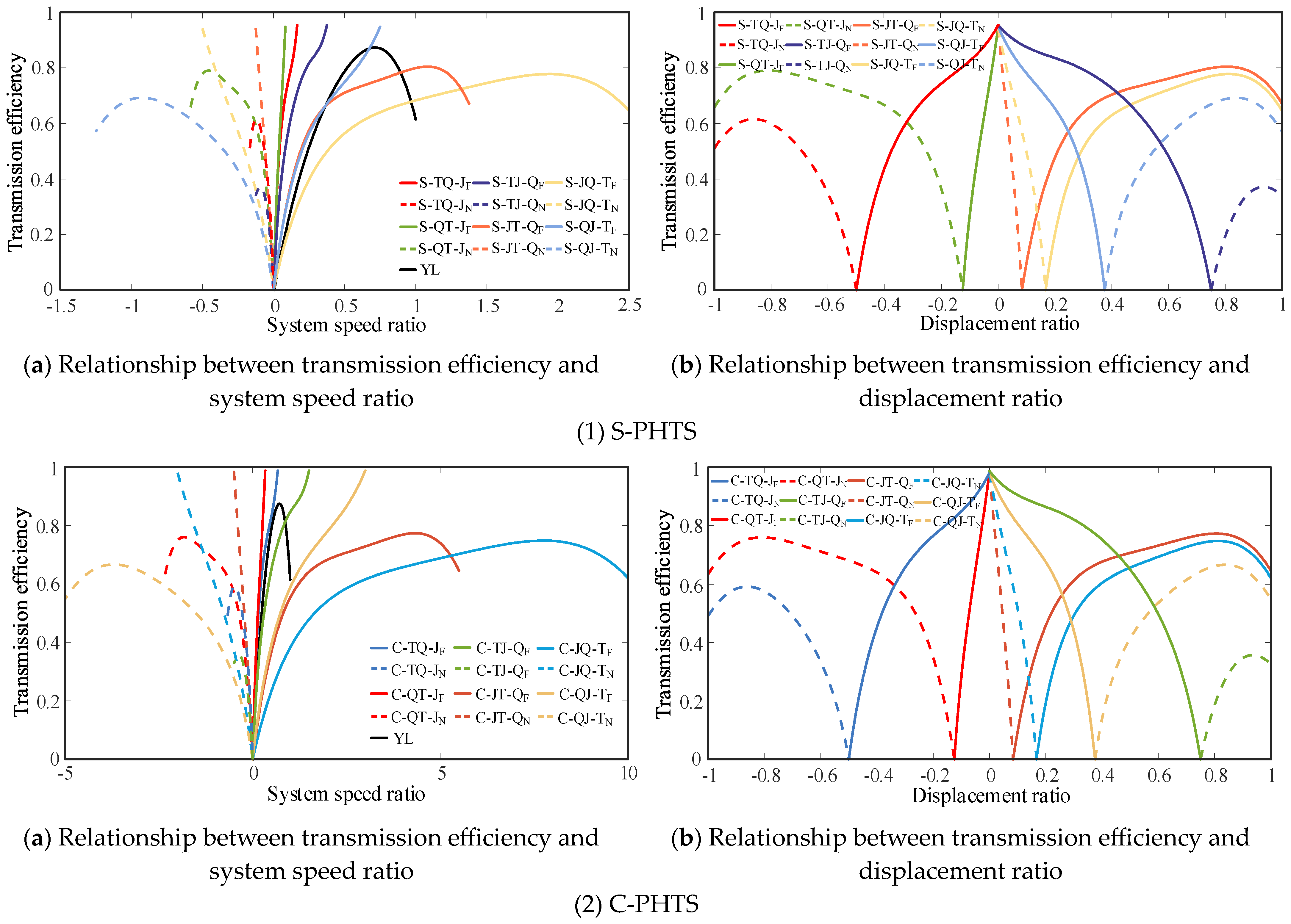

Based on the aforementioned viewpoints, this study applies the power reflux transmission mode of the HMTS to the starting of a construction vehicle, and refers to the HMTS operating only in the power reflux transmission mode as the power reflux hydro-mechanical transmission system (PHTS). Based on the power coupling forms of the HMTS, two basic configurations of PHTS, namely, the split-shaft power reflux hydro-mechanical transmission system (S-PHTS) and the combined-shaft power reflux hydro-mechanical transmission system (C-PHTS), are investigated. Based on the differences in the layout forms of the closed-loop hydraulic system (CLHS) and DGT, this paper enumerates 12 PHTS configurations in each basic configuration. By comparing and analyzing the internal relationship between the configuration and the power flow, transmission characteristics, and energy loss mechanism of the PHTS, the optimal PHTS configuration suitable for construction vehicles is explored.

The research reveals that significant differences exist between the transmission characteristics of C-PHTS and S-PHTS. Reasonable configurations can enable PHTS to significantly improve the efficiency of the construction vehicle’s transmission system, reducing energy consumption while ensuring power performance. Expanding the displacement ratio control range of the CLHS and combining the power reflux and power split transmission modes in an orderly manner can widen the high-efficiency range of the vehicle transmission system without increasing the number of vehicle gears. The research on PHTS configuration not only provides a theoretical foundation for understanding, exploring, and applying PHTS, but also conducts a detailed analysis and comparison of the configurations of PHTS. While helping to understand the PHTS, it also theoretically proves that replacing the hydrodynamic internal reflux transmission system with a hydrostatic external reflux transmission system is feasible.

This paper is organized as follows:

Section 2 introduces the basic configurations of the single planetary gear PHTS as well as the transmission characteristics and layout method of the CLHS.

Section 3 enumerates all potential configurations of the PHTS and analyzes the power flow transmission characteristics of various configurations, as well as the energy storage mechanism of the PHTS.

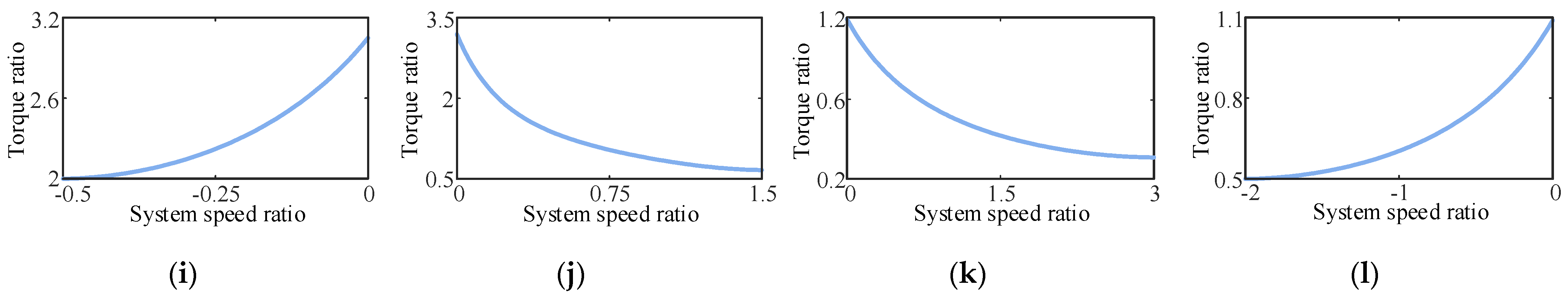

Section 4 calculates the speed regulation characteristics, transmission efficiency characteristics, low-speed torque increase characteristics, and maximum torque ratio of the PHTS. It also compares the transmission efficiency characteristics of the S-PHTS and C-PHTS, exploring the fundamental reasons for their efficiency difference.

Section 5 analyses the feasibility of the PHTS configurations and searches for the best PHTS configuration suitable for construction vehicles by comparing it with the transmission efficiency of the torque converter. Conclusions are presented in

Section 6.

3. Power-Flow Transmission Characteristics of PHTS

Affected by the reflux power, the power transmission mechanism of the PHTS is considerably different from those of most transmission systems. To conduct in-depth research on the PHTS, the study of the power-flow transmission characteristics of the PHTS must be prioritized.

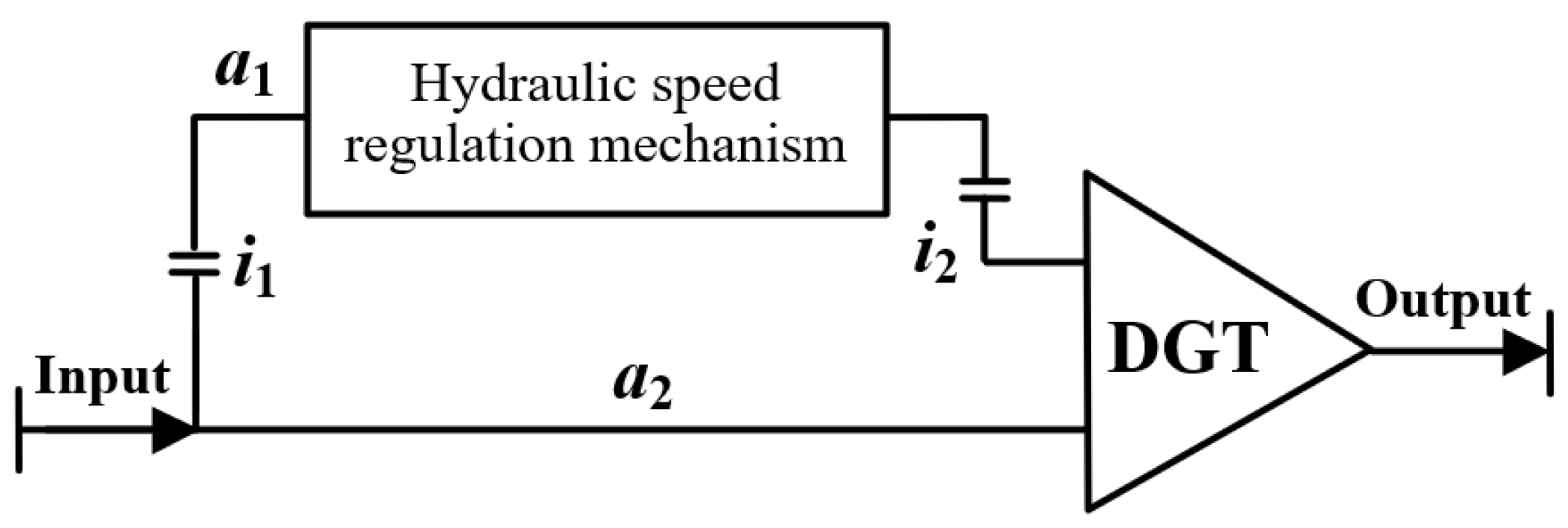

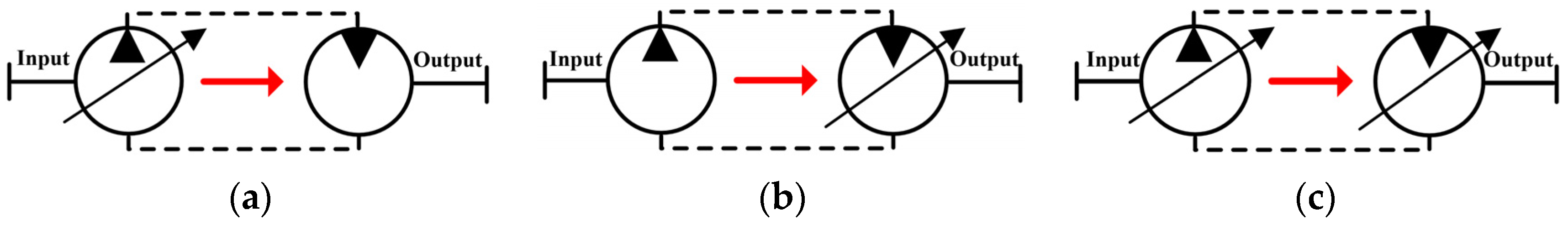

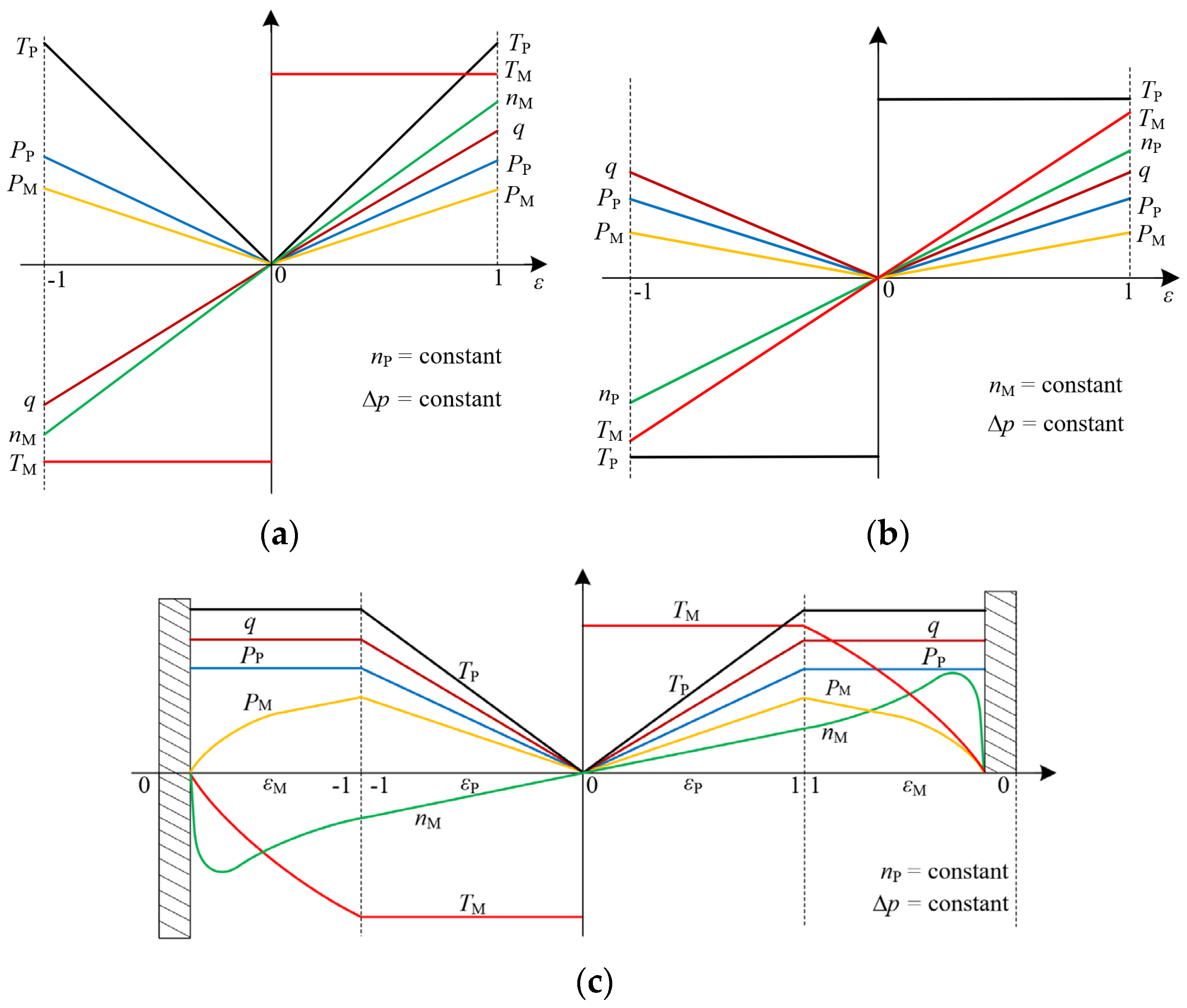

The structure of an internal–external meshing single-row planetary gear (IMSPG) is simple and compact, and it has high transmission efficiency. It is widely used in vehicle transmission systems [

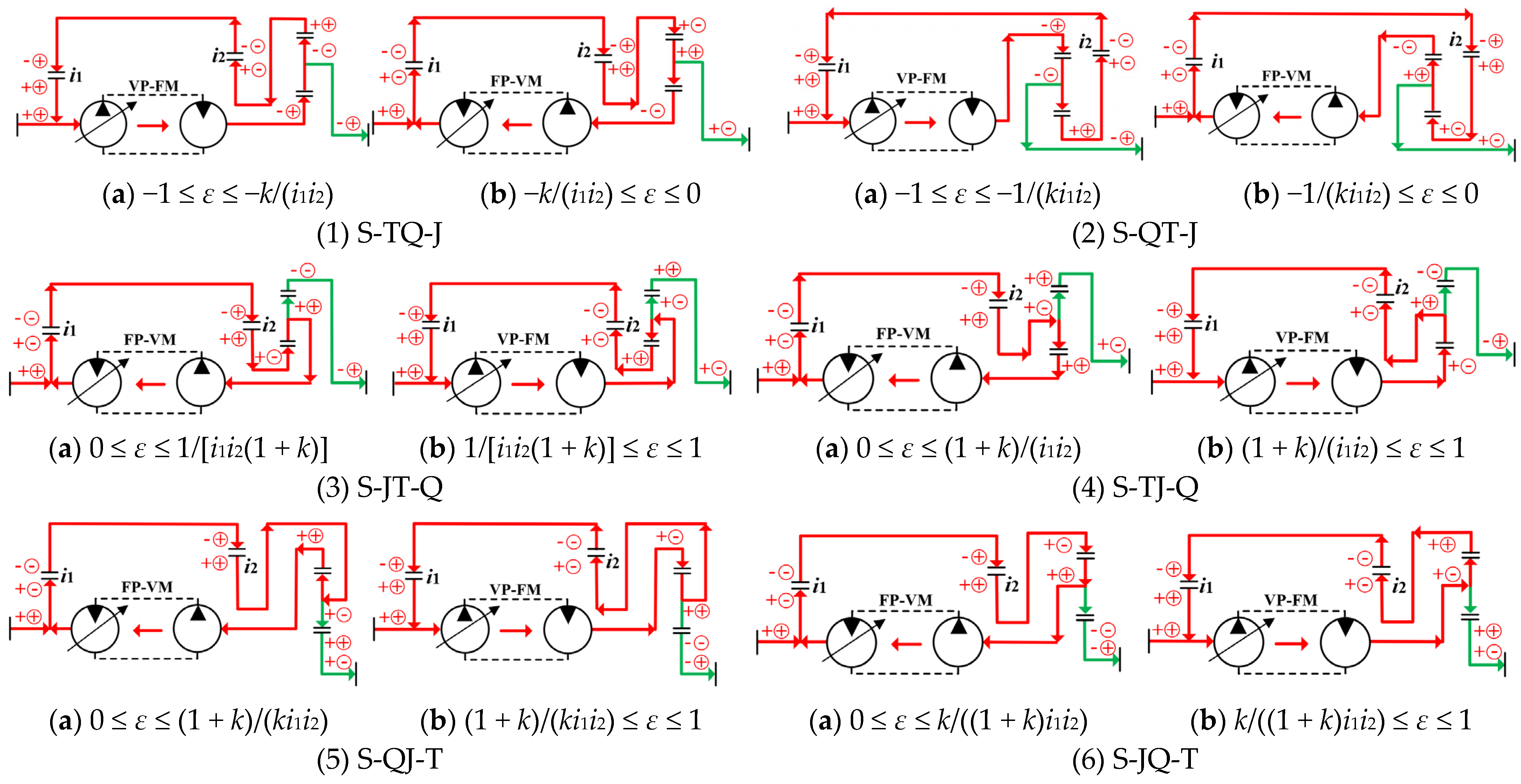

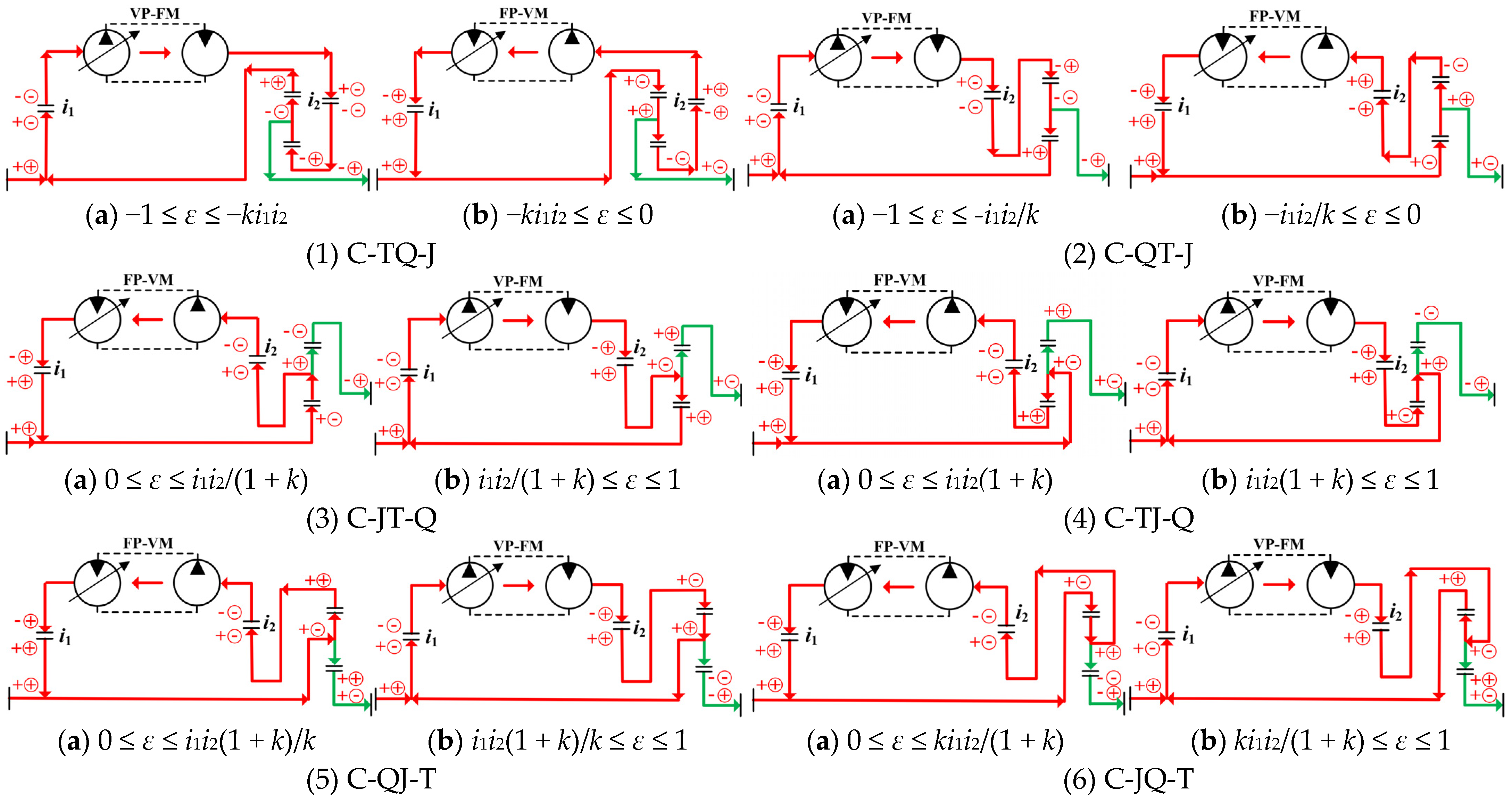

29]. When the PHTS uses an IMSPG as the DGT, all possible configurations and power-flow transmission states of the PHTS are as shown in

Figure 5 and

Figure 6.

As shown in

Figure 5 and

Figure 6, 12 power-flow transmission states exist for each of the S-PHTS and C-PHTS. To ensure that power can be transmitted in the desired manner, the structure form, layout method, and regulation method of the CLHS should be significantly different, even in different power-flow transmission states of the same DGT connection form. Therefore,

Figure 5 and

Figure 6 not only analyze the power-flow, but also, accordingly, provide 24 PHTS configurations. In the PHTS, the selection of the DGT input and output elements and the displacement ratio of the CLHS collectively determine the direction of the power flow in the system. Each configuration of the CLHS must be controlled within the specified displacement ratio range; otherwise, the configuration may be ineffective.

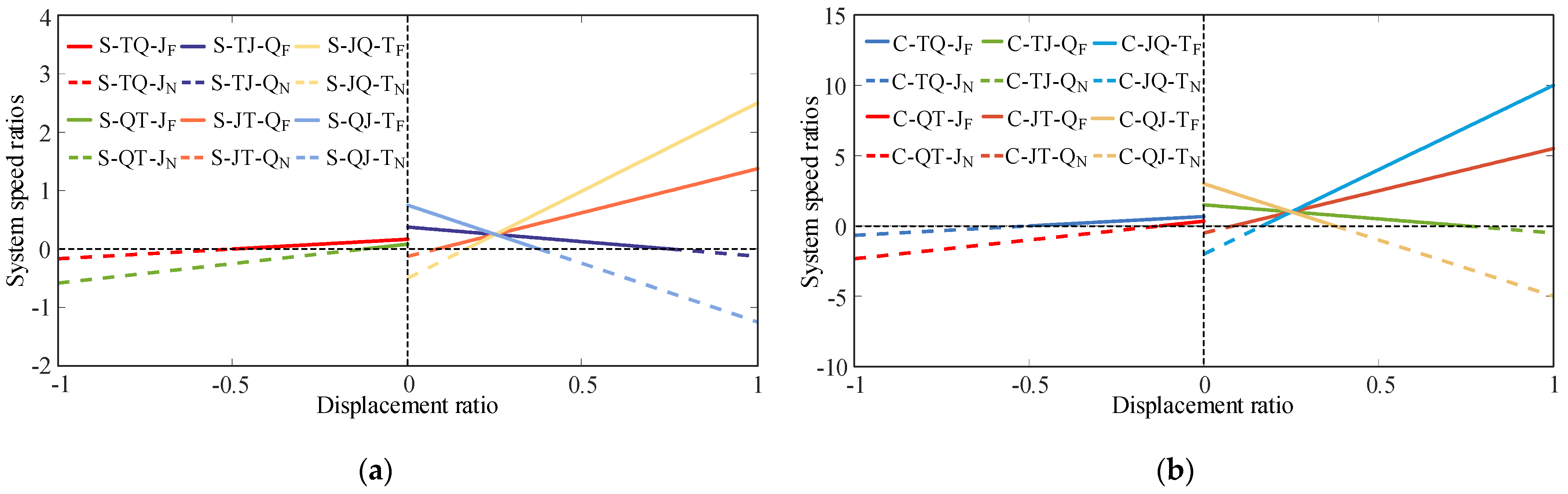

In each DGT connection form, the S-PHTS and C-PHTS also have two configurations with opposite output shaft rotation speeds and power-flow directions. When the displacement ratio of the configuration is allowed to be regulated to 0, the entire power is transmitted to the DGT from the mechanical path, and only a small portion of the power is refluxed via the CLHS; in contrast, when the displacement ratio of the configuration is not allowed to be regulated to 0, the entire power is transmitted to the DGT from the CLHS, and only a small portion of the power is refluxed via the mechanical path. The power-flow transmission direction of the CLHS determines the power-flow transmission direction of the PHTS. When the DGT connection form and the system output shaft rotation speed direction are the same, the reflux-power transmission directions of the S-PHTS and C-PHTS are opposite.

The power-flow transmission characteristics of the system show that the PHTS is equivalent to an energy storage mechanism, and the power input from the power source into the system can be accumulated within the system. In the process of reflux-power accumulation, the system differential pressure of the CLHS increases accordingly. When the stored power in the system reaches the level required to overcome the external resistance, the PHTS can instantaneously release the output torque that exceeds the maximum torque of the power source, thereby achieving increased torque. However, the stored power of the PHTS does not increase indefinitely. When the power stored in the PHTS increases to a certain critical value, the power loss in the system rises rapidly in the form of heat generation, leakage, friction, etc., owing to the influence of the bearings, gears, pump, and motors. When the input power of the power source is equal to the system power loss, the energy stored in the PHTS reaches a steady state, wherein the system has the maximum torque ratio.

5. Feasibility Analysis of the PHTS

The analysis of PHTS characteristics reveals that, among the configurations listed in

Table 4, the ten configurations, except C-QJ-T

F and C-JQ-T

N, have good efficiency characteristics and large torque ratios. To accurately evaluate the aforementioned ten configurations and clearly explain the influence of configuration parameters on transmission characteristics, the upper limit of the system speed ratio of the configurations must be analyzed.

Table 1 shows that all configurations listed in

Table 4 have speed ratio upper limits when the displacement ratio is 0. Among them, the speed ratio upper limit of the C-PHTS is related only to

k, whereas that of the S-PHTS is related to both

k and

i1i2. Therefore, when calculating the speed ratio upper limit of the S-PHTS, the range of

i1i2 values must be considered.

Considering S-QT-J

F as an example, the control range of the displacement ratio

ε of the configuration is [−1/(

ki1i2), 0]. Because |

ε|

≤ 1, the numerical relationship between

k and

i1i2 is

The maximum speed ratio upper limit

ibmax for S-QT-J

F can be expressed as

ibmax can be calculated by incorporating the value of

k into Equation (30).

Note that, in the form of mechanical–hydraulic reflux transmission, the speed ratio upper limit |

ib| of the S-PHTS is positively related to |

ε|

max. When |

ε|

max = 1, the S-PHTS has the maximum speed ratio upper limit. The maximum speed ratio upper limits of the aforementioned ten advantageous configurations are shown in

Table 5.

Table 5 shows that S-TQ-J

F and C-QT-J

F have the smallest speed ratio upper limits. This not only results in a narrow high-efficiency zone of the system, but is also detrimental to improving vehicle comfort. Therefore, this study concludes that the S-TQ-J

F and C-QT-J

F configurations do not possess structural advantages.

Because the planet carrier of C-TJ-QF is directly connected to the power source and the rated rotation speed of diesel engines used in construction vehicles is generally around 2000 rpm, when a vehicle is equipped with C-TJ-QF, the maximum rotation speed of the sun wheel connected to the hydraulic path is essentially above 5000 rpm. When k is increased, the rotation speed of the sun gear further increases and may even exceed 10,000 rpm. Likewise, S-JT-QN has similar problems. While both C-TJ-QF and S-JT-QN exhibit good transmission characteristics, considering the actual operating conditions of construction vehicles, the cost, and the reliability, the practicality of these two configurations is believed to be relatively low.

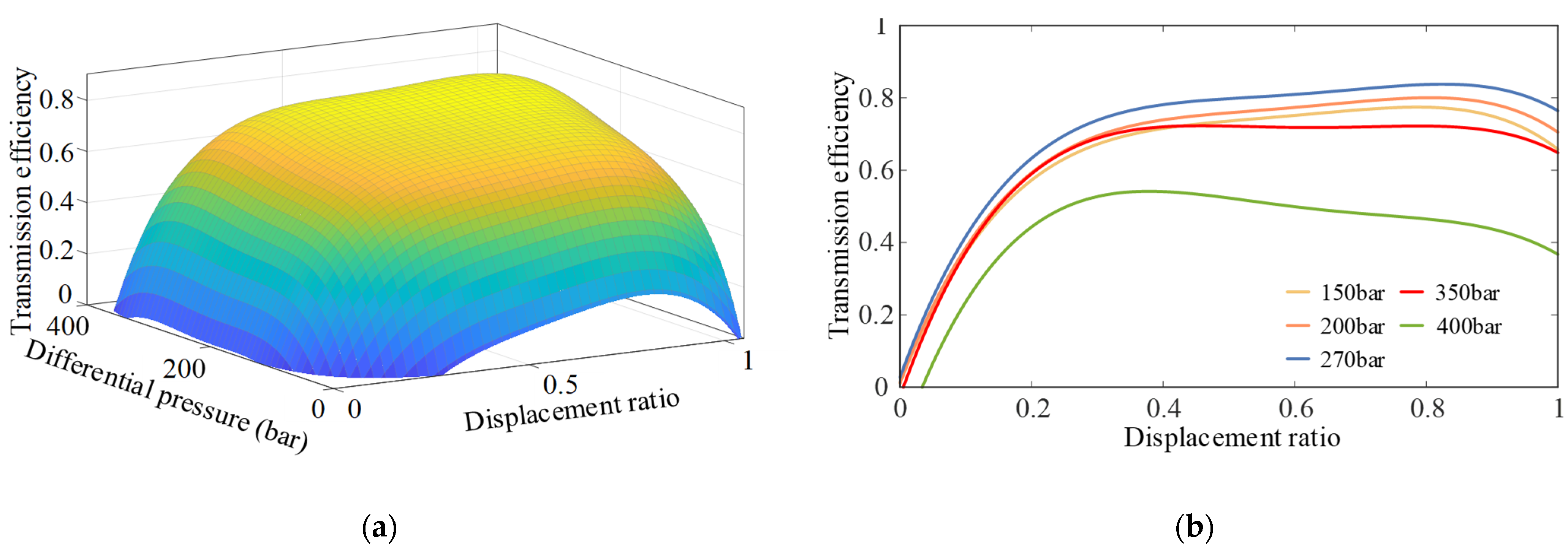

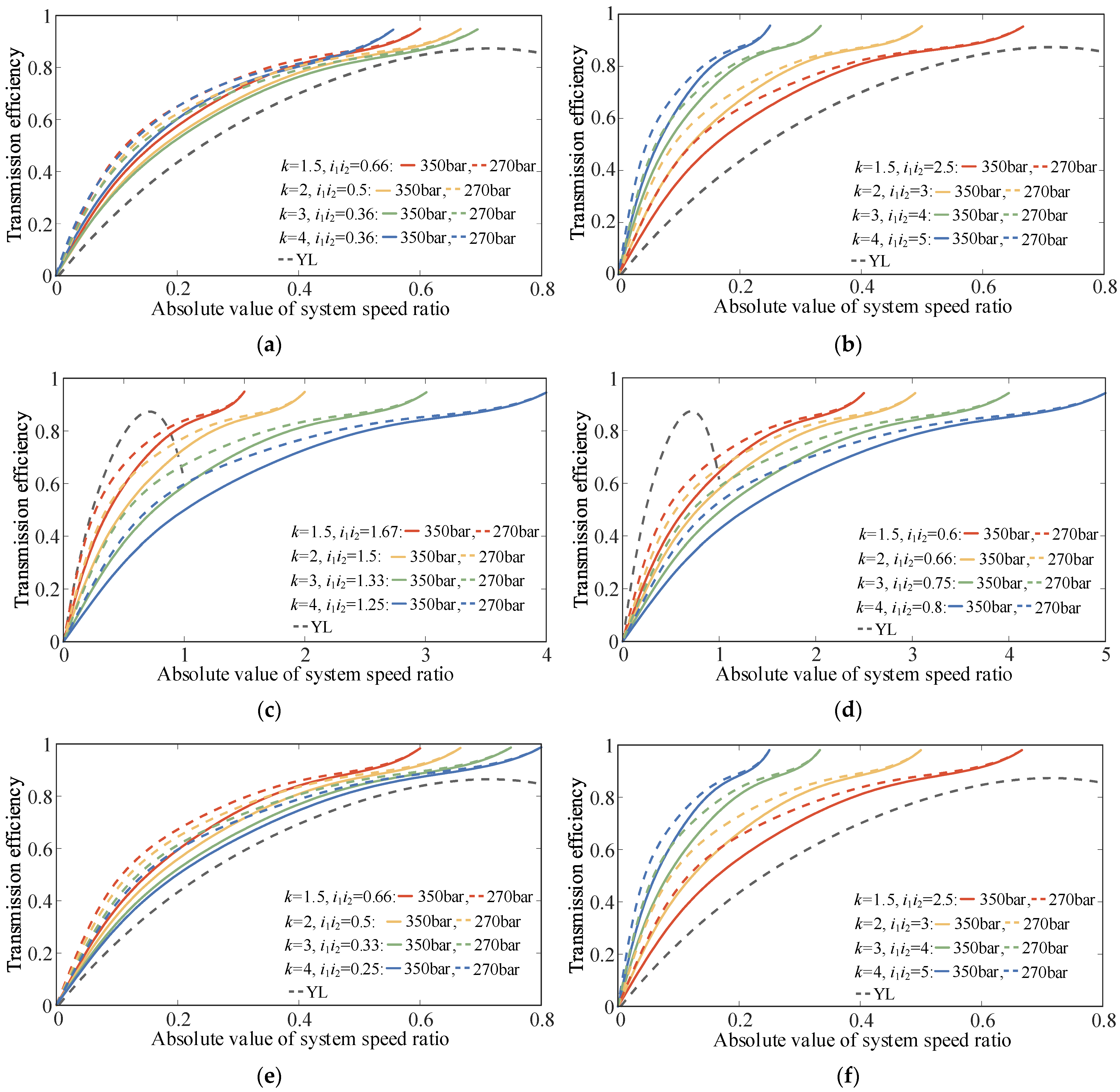

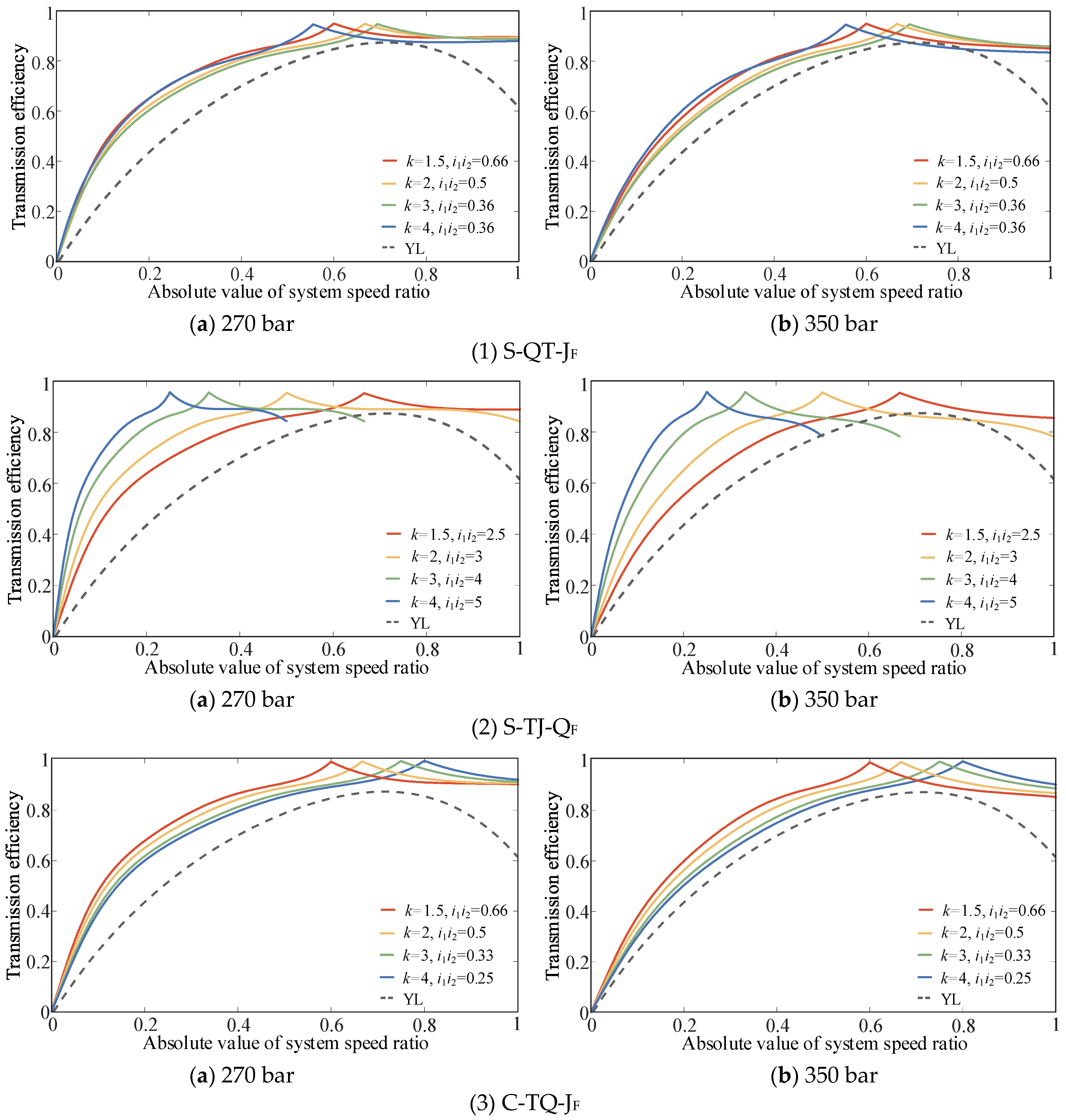

To illustrate the validity of the configuration and determine the optimal configuration, this study considers as an example the large load operating conditions where the pressure difference of the CLHS is stable at 270 and 350 bar. The efficiency characteristics of S-QT-J

F, S-TJ-Q

F, S-QJ-T

F, S-JQ-T

N, C-TQ-J

F, and C-JT-Q

N were compared with those of the torque converter, as shown in

Figure 13.

Figure 13 shows that

k,

i1i2, and

ηP-M significantly impact the transmission efficiency of the PHTS. Compared with the torque converter, S-QJ-T

F and S-JQ-T

N exhibit no efficiency advantages within the same speed ratio range. To enhance the transmission efficiency, these configurations must be used in series with a reducer. In addition, owing to their structural form, S-QJ-T

F and S-JQ-T

N have extremely high requirements for the rated power of the CLHS, which considerably increases the overall cost. Therefore, S-QJ-T

F and S-JQ-T

N are also considered to have no practical value for use.

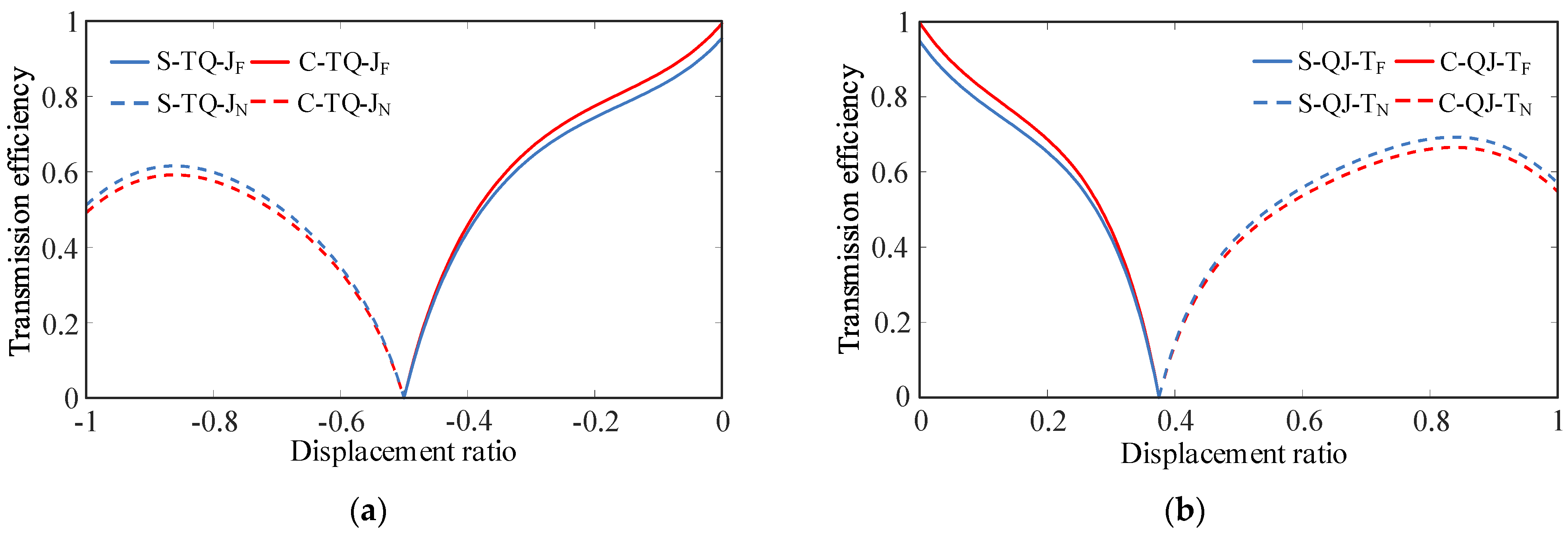

The transmission efficiencies of S-QT-J

F, S-TJ-Q

F, C-TQ-J

F, and C-JT-Q

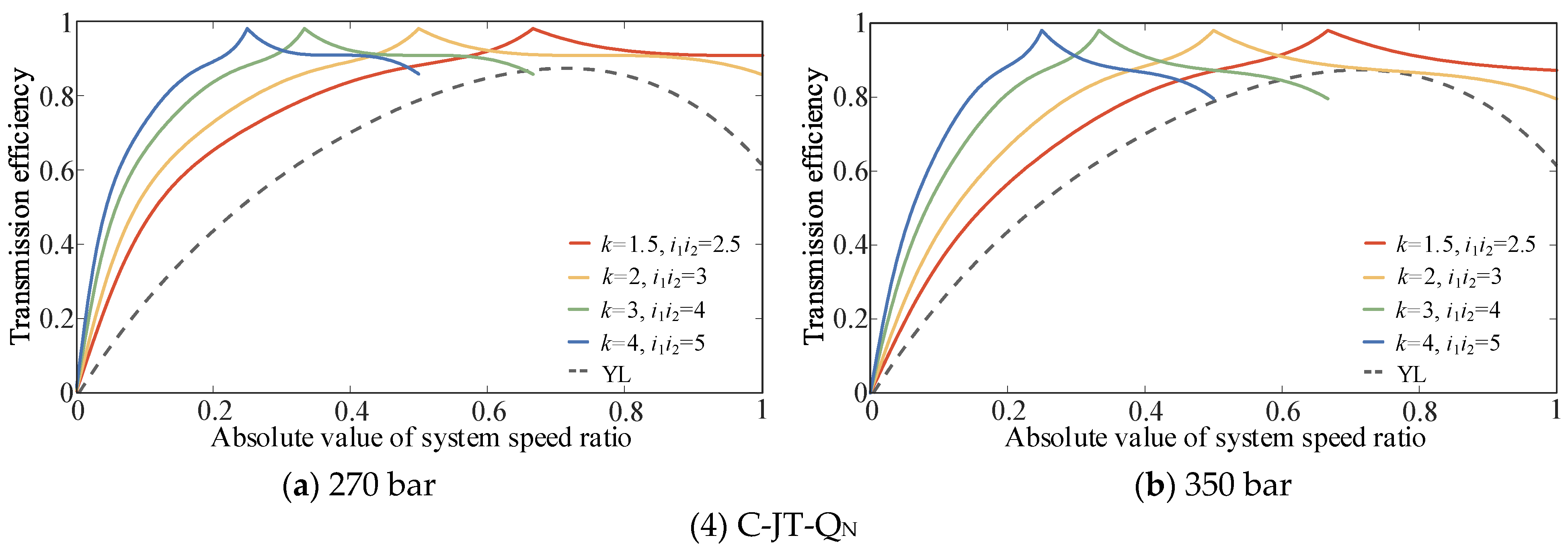

N are relatively high. Even at the lowest efficiency of the CLHS, these four configurations have higher transmission efficiencies within the same speed ratio range compared with the torque converter. However, the speed ratio upper limits of these configurations remain small, and there is a problem of narrow high-efficiency areas. Therefore, simply applying the reflux transmission mode to the transmission system is insufficient. To widen the high-efficiency range of the system without increasing the number of vehicle gears, it is necessary to expand the CLHS displacement ratio control range (switching to bidirectional CLHS) in practical applications and use the split transmission mode to increase the system speed ratio’s upper limit. Considering as an example the advantageous configurations shown in

Figure 13, the efficiency characteristics of the configurations after expanding the CLHS displacement ratio control range are as shown in

Figure 14.

Figure 14 shows that expanding the displacement ratio control range of the CLHS can effectively widen the high-efficiency ranges of S-QT-J

F, S-TJ-Q

F, C-TQ-J

F, and C-JT-Q

N. The reflux transmission mode is applied to the starting stage of the vehicle to avoid engine stalling and increase the torque at low speeds, whereas the split transmission mode is applied to the high-speed driving conditions to widen the high-efficiency range of the system. The orderly combination of reflux and split transmission modes can ensure the power performance of construction vehicles without increasing the number of vehicle gears, improve the transmission efficiency, widen the high-efficiency range, and compensate for the shortcomings of the low transmission efficiency of the torque converter.

6. Conclusions

To significantly improve the transmission efficiency of the vehicle while ensuring the power performance in order to enhance the construction vehicle’s performance, this study applies the power reflux hydro-mechanical transmission system (PHTS) to the starting of a construction vehicle and investigates the PHTS configurations. By analyzing the internal relationship between the configuration and the power-flow transmission form, transmission characteristics, and energy loss mechanism, the following conclusions can be drawn:

(1) The PHTS exhibits a similar transmission performance to the hydrodynamic transmission system, which not only ensures that the engine maintains high-speed operation at zero vehicle speed and avoids stalling, but also improves the vehicle’s ability to start and to overcome obstacles. Reasonable configurations can enable the PHTS to significantly improve the efficiency of the construction vehicle transmission system while ensuring power performance. Expanding the displacement ratio control range of the hydraulic speed regulation mechanism and combining the power reflux transmission mode with the power split transmission mode in an orderly manner can widen the high-efficiency range of the vehicle transmission system without increasing the number of vehicle gears, and can compensate for the shortcomings of the low transmission efficiency of the torque converter.

(2) When the connection forms of the DGT are identical, the C-PHTS exhibits higher transmission efficiency in the mechanical–hydraulic reflux transmission form, whereas the S-PHTS exhibits higher transmission efficiency in the hydraulic–mechanical reflux transmission form. Although the S-PHTS always shows a larger torque ratio and speed ratio upper limit compared with the C-PHTS, it has a higher power requirement for the CLHS owing to the influence of its structural form.

(3) From the analysis results of PHTS transmission characteristics, the four configurations, i.e., S-QT-JF, S-TJ-QF, C-TQ-JF, and C-JT-QN, are considered to have better transmission characteristics and to be suitable for construction vehicles.

This paper proposes a new method of using a hydrostatic external reflux transmission system to replace a hydrodynamic internal reflux transmission system, and provides a guide for a new research direction in the field of hydro-mechanical composite transmission. However, it is limited by page length restrictions for the article. This paper has not yet discussed issues such as matching, optimization, and control methods between PHTS and the vehicle. In the future, based on real prototype vehicles, we plan to further analyze the cooperative operation methods between PHTS and the shifting mechanism, research the design methods for hydrostatic reflux automatic transmission, and explore the dynamic characteristics of PHTS under various starting conditions so as to lay the foundation for the development of control strategies.