Experimental Study of Self-Compacting Mortar Incorporating Recycled Glass Aggregate

Abstract

:1. Introduction

2. Experimental Program

2.1. Materials

2.2. Mixture Proportioning

2.3. Test Program

2.4. Mixing Procedure

2.5. Test Methods

2.5.1. Tests on Fresh SCM-RGA Mixtures

Slump Flow Test

V-funnel Flow Time Test

2.5.2. Tests on Hardened SCM-RGA

Compressive and Flexural Strength

Water Absorption by Immersion

Sorptivity (Capillary Water Absorption)

Expansion due to Alkali–Silica-Reaction (ASR)

3. Results and Discussion

3.1. Fresh Properties of SCM-RGA Mixes

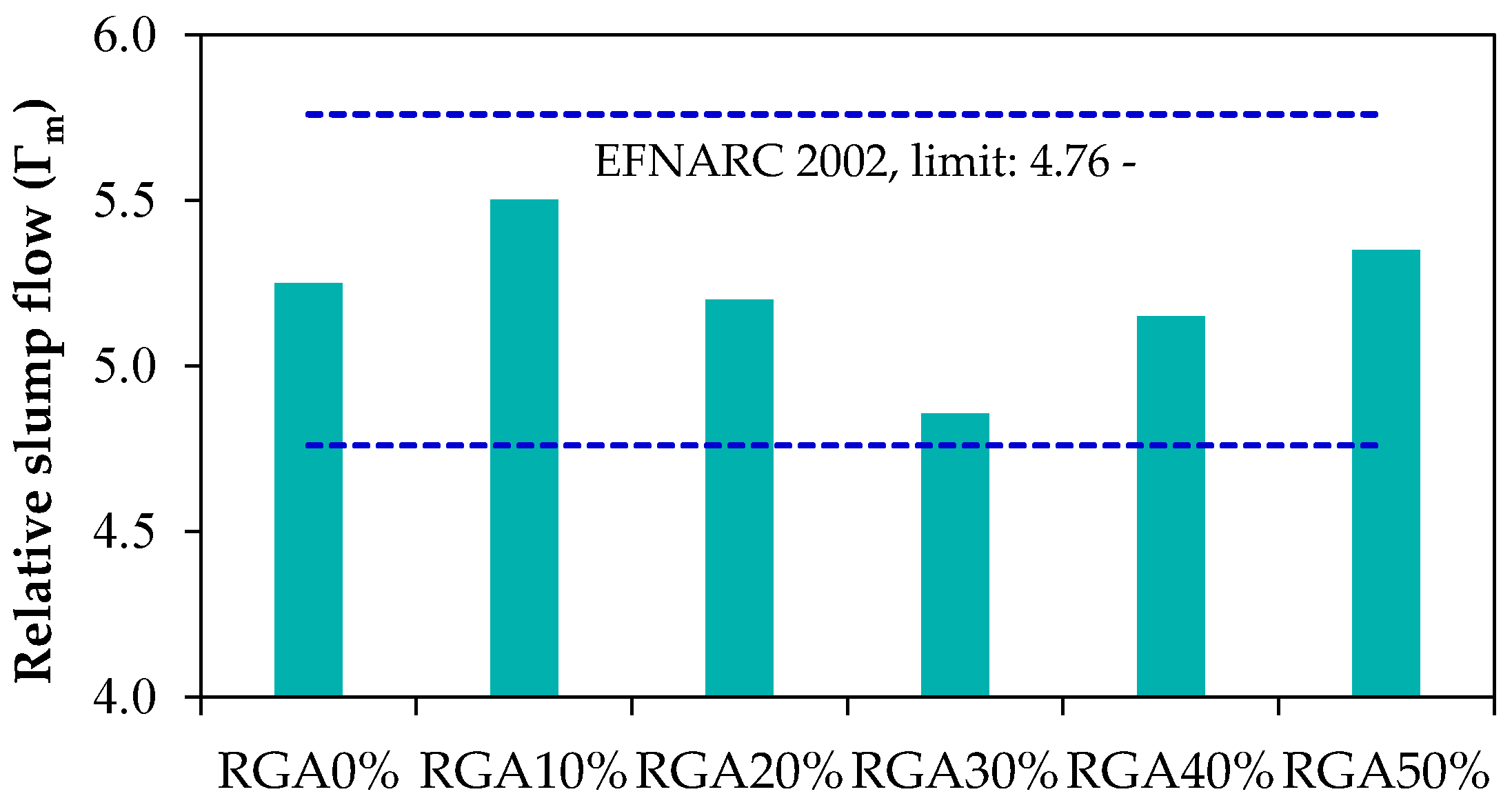

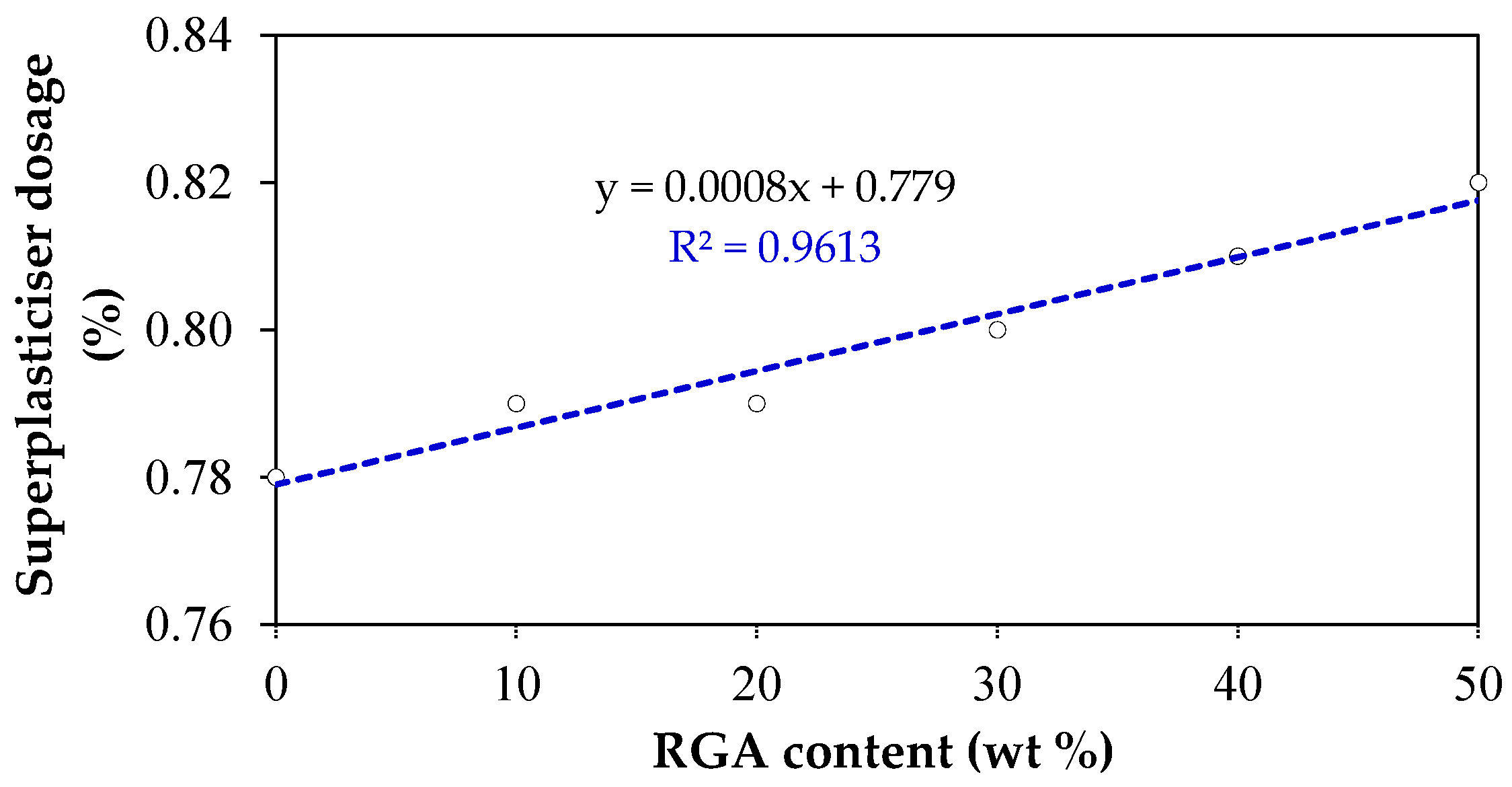

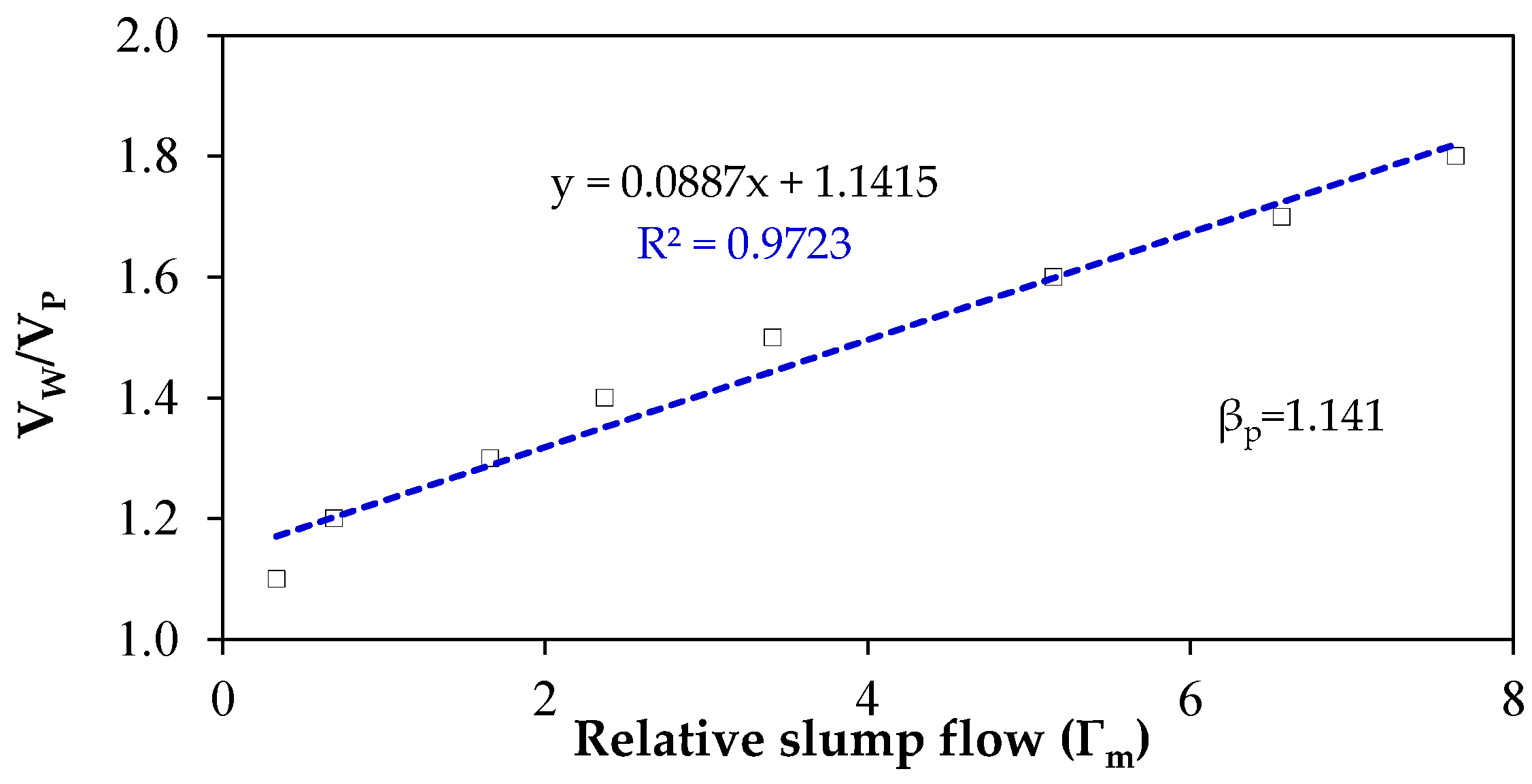

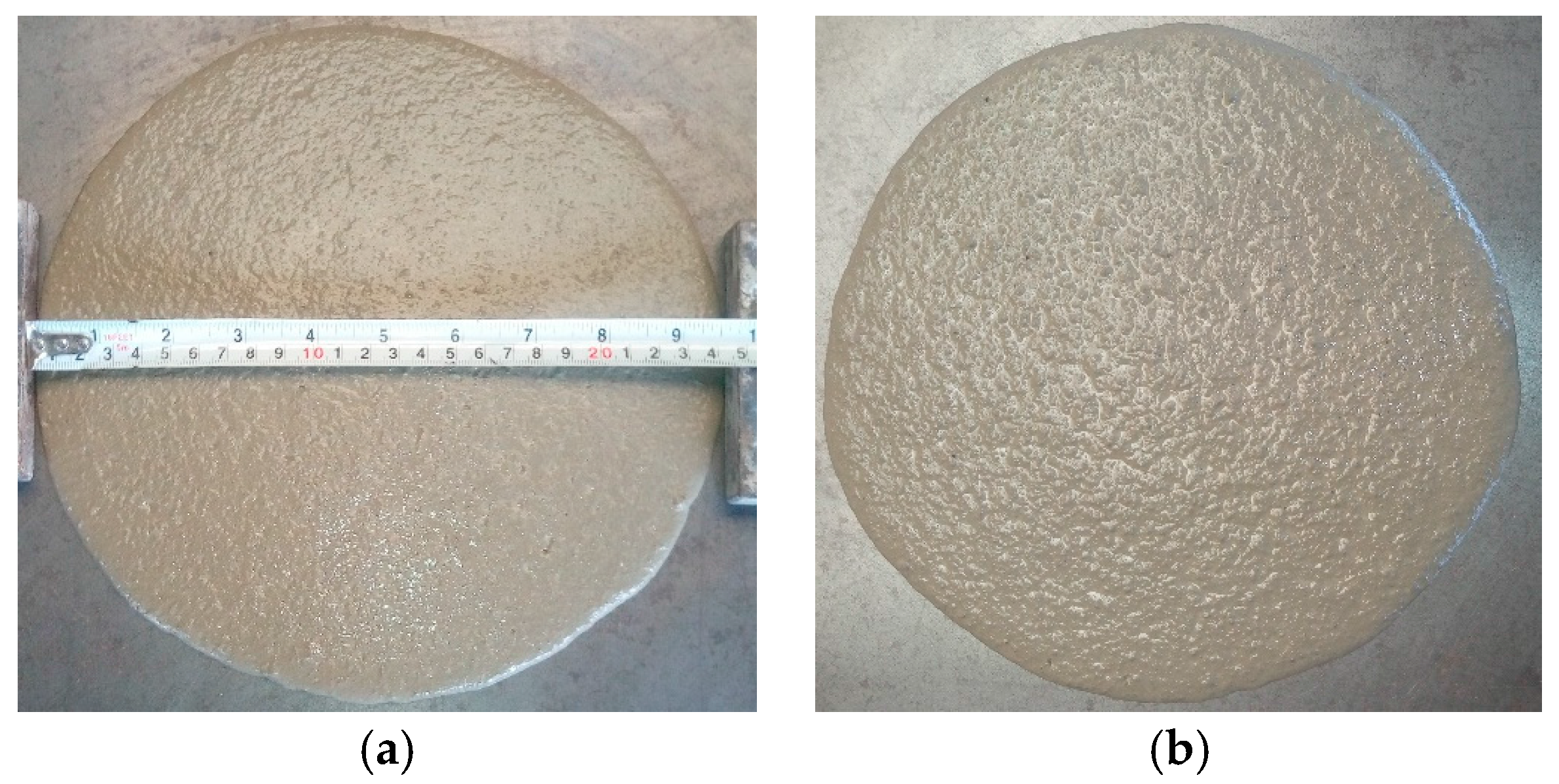

3.1.1. Slump Flow

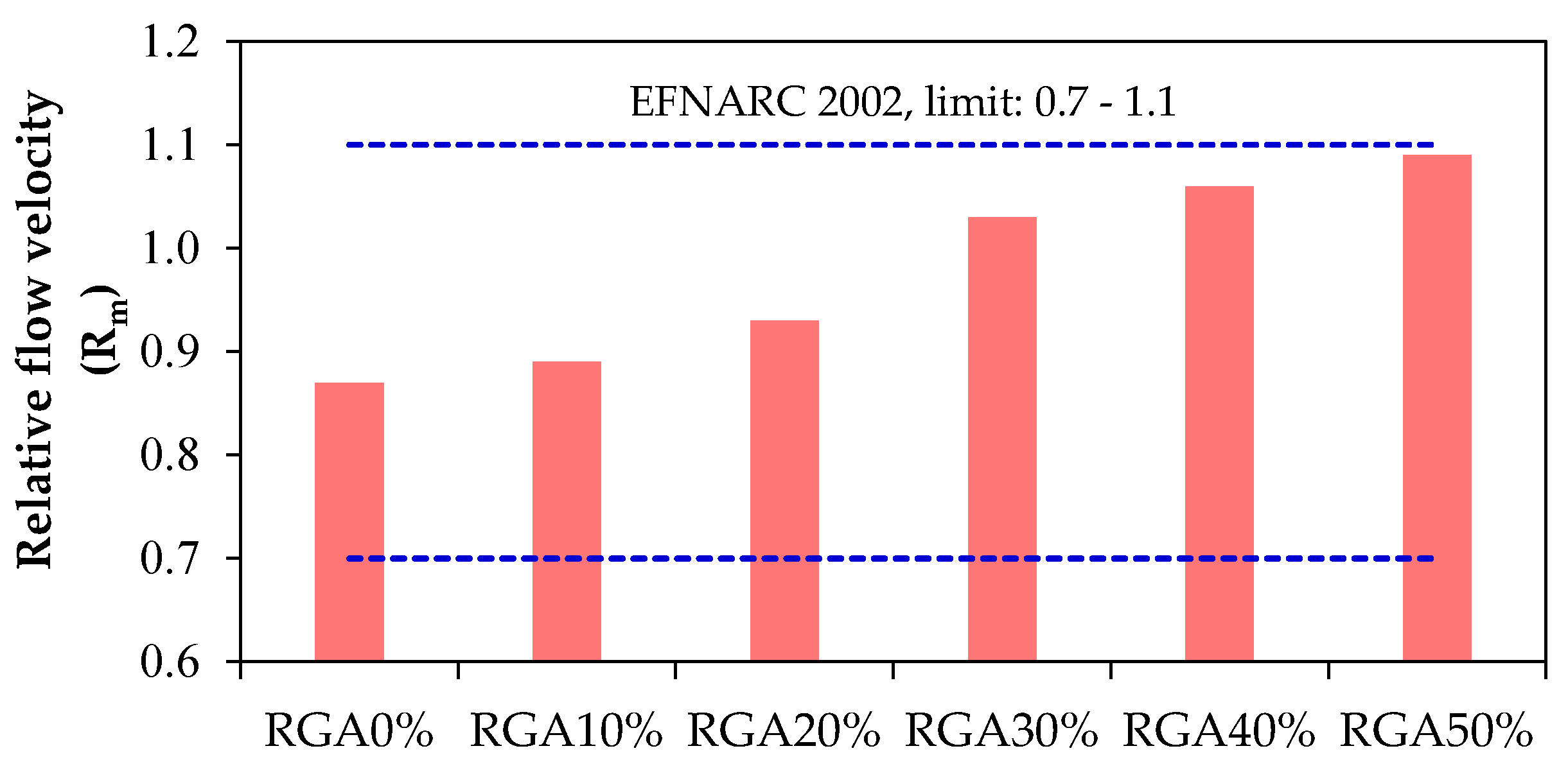

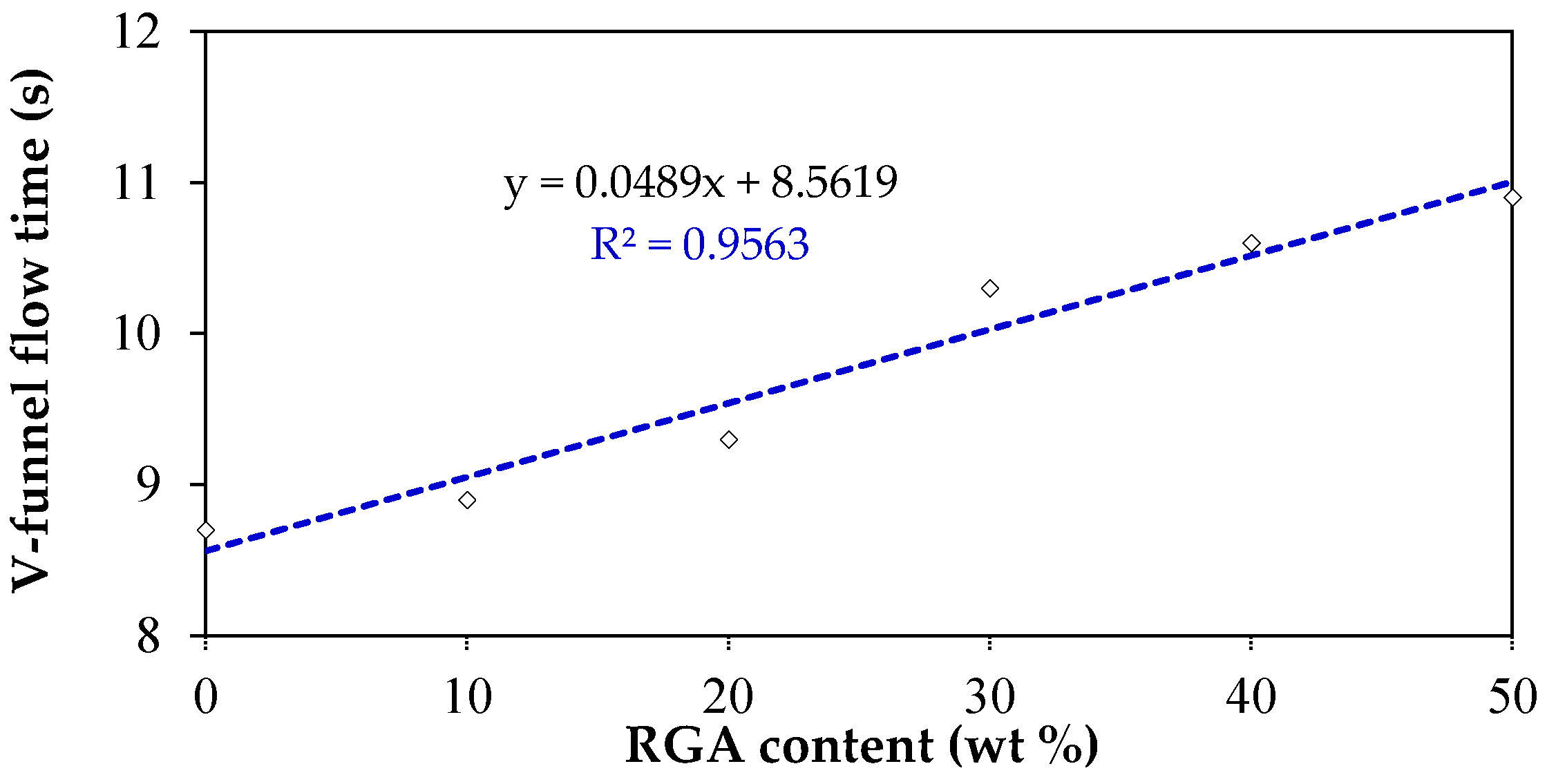

3.1.2. V-funnel Flow Time

3.2. Hardened Properties of SCM-RGA

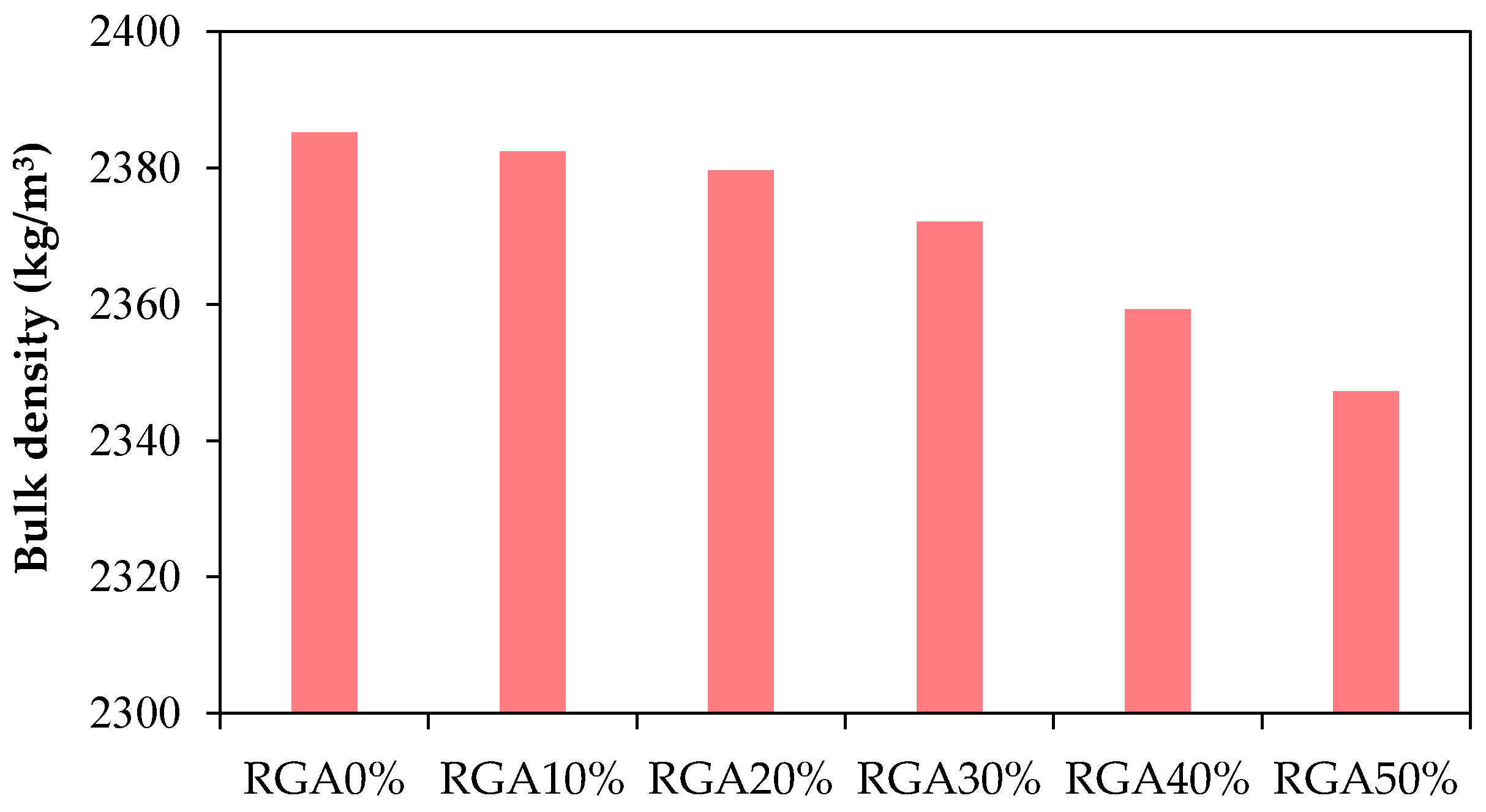

3.2.1. Bulk Density

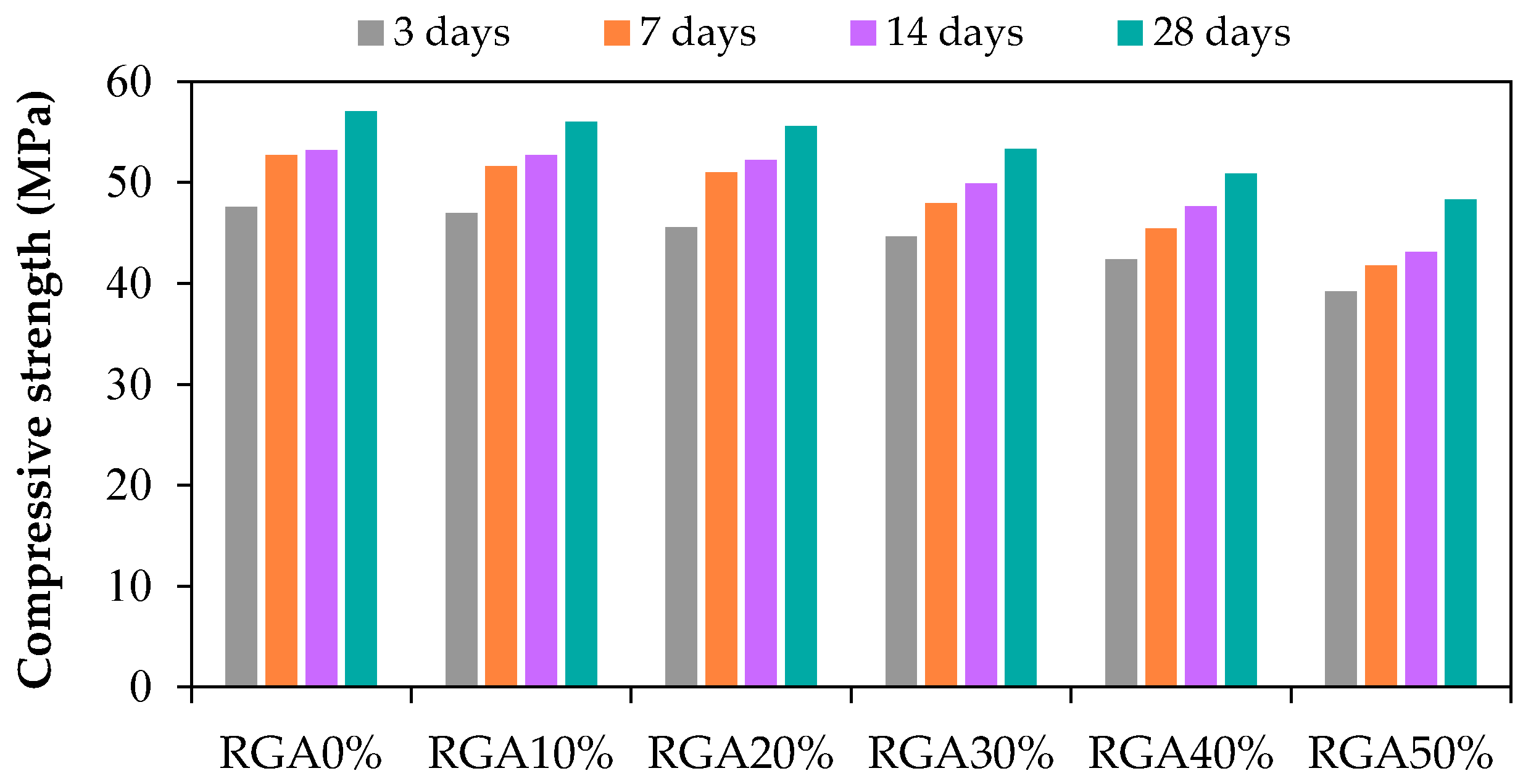

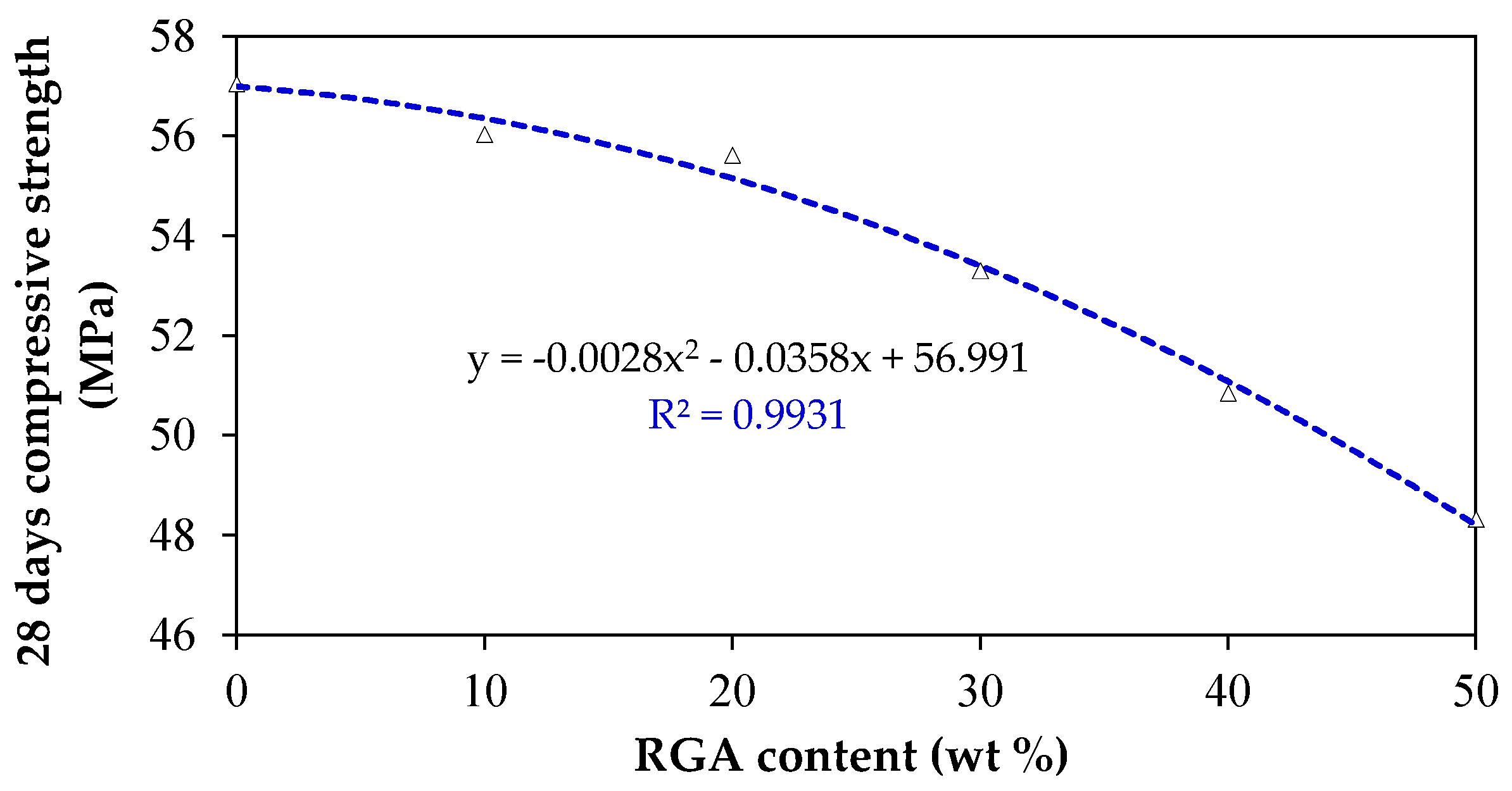

3.2.2. Compressive Strength

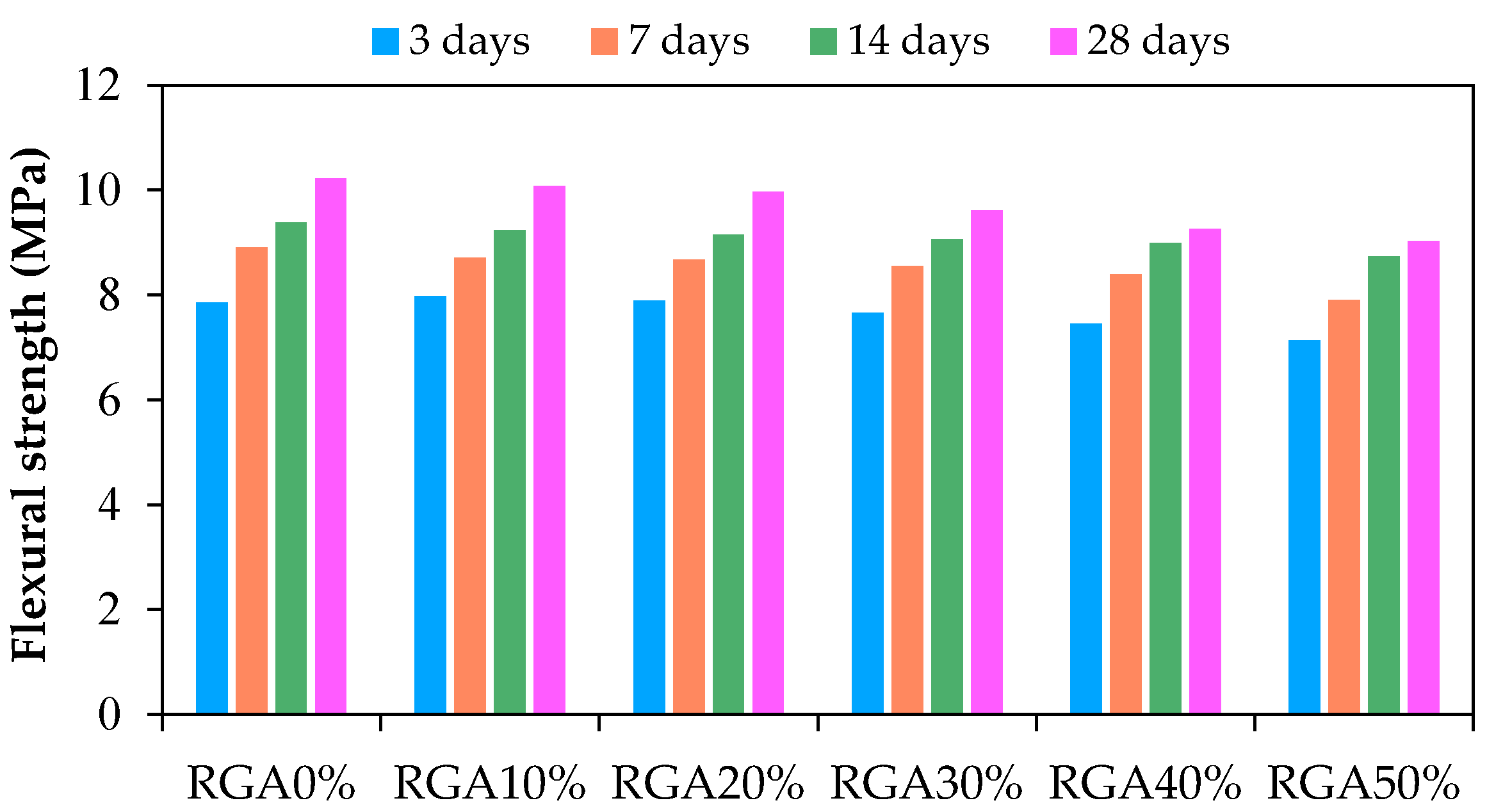

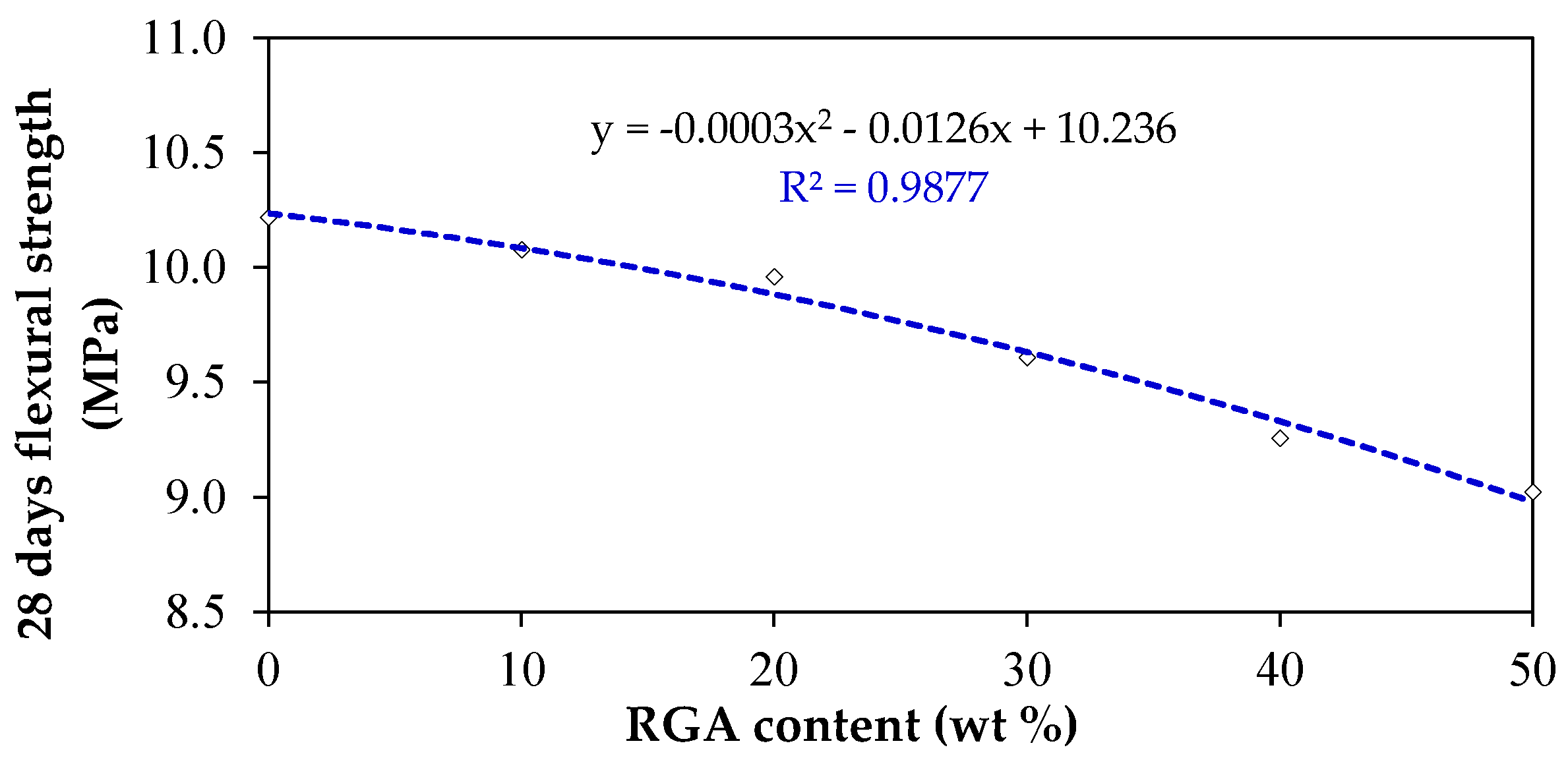

3.2.3. Flexural Strength

3.2.4. Water Absorption

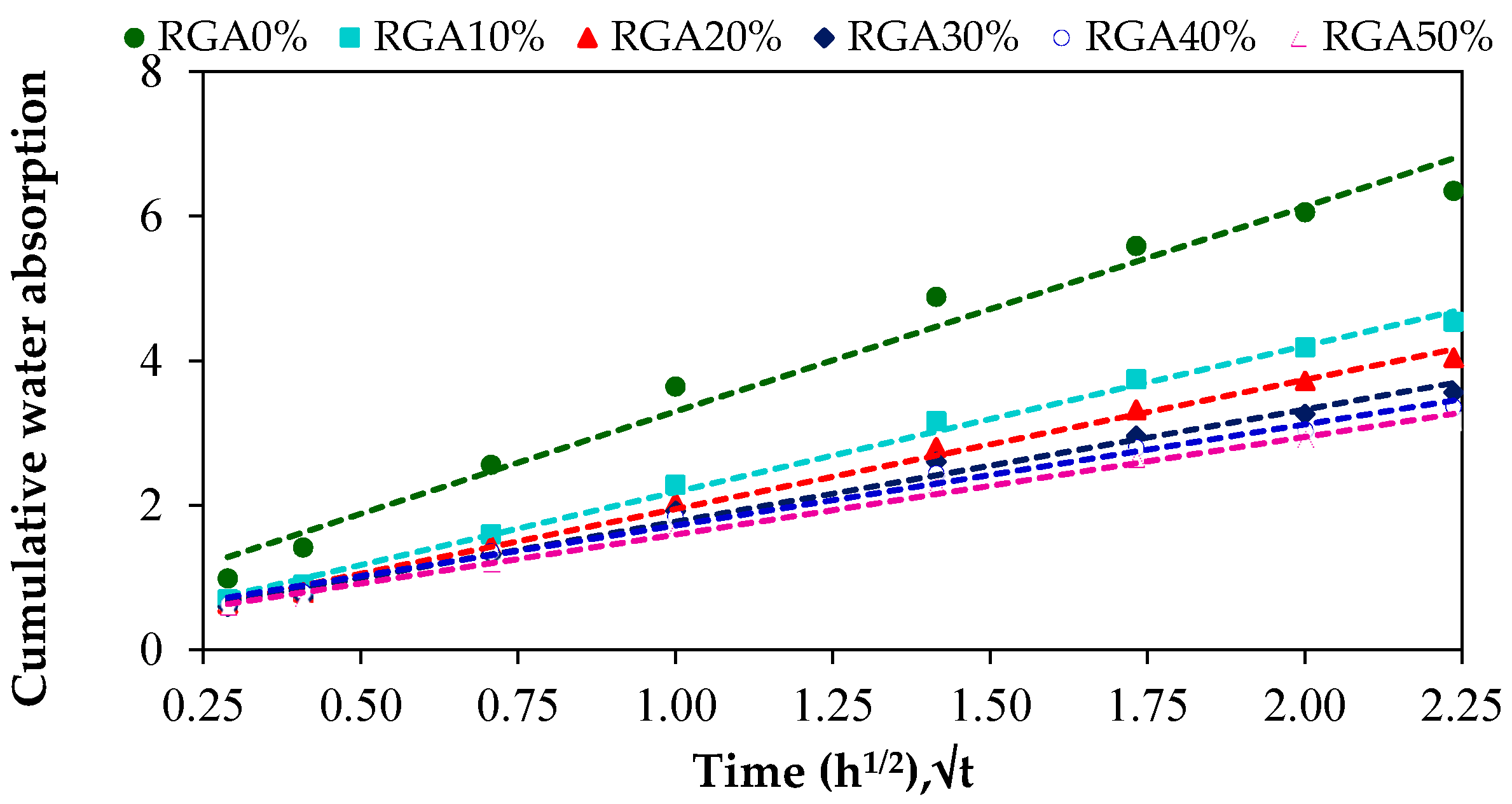

3.2.5. Sorptivity

3.2.6. Expansion due to Alkali–Silica Reaction (ASR)

4. Conclusions

- The slump flow of SCM-RGA mixes decreased and V-funnel flow time increased as the content of glass aggregate increased. At a given water to powder ratio, superplasticiser dosage should be increased as the content of glass aggregate increased to ensure and maintain slump flow and flow time within the acceptable range.

- The density, compressive strength and flexural strength of SCM-RGA mixes decreased with an increase in glass aggregate content. However, up to 30% RGA replacement ratio, the compressive and flexural strength showed 6.57% and 5.97% of reduction compared to reference SCM respectively.

- SCM mixes containing glass aggregate exhibited lower water absorption and sorptivity value when compared to the control SCM. Sorptivity and water absorption decreased when the glass aggregate content increased. At 50% RGA replacement ratio, sorptivity of SCM-RGA is 52.3% lower than the reference SCM. This clearly indicates that concrete containing glass aggregates is more durable than conventional concrete.

- A strong correlation was observed between the compressive and flexural strength of SCM-RGA mixes, that is as compressive strength increased, flexural strength also increased in a power function trend line.

- For SCM containing RGA, good correlation between sorptivity and strength (compressive and flexural values) was observed. The strength of SCM-RGA decreased due to week interfacial bondage between the binding paste matrix and glass aggregate, and the sorptivity also significantly decreased due to relatively lower water permeability nature of glass.

- It was observed that as the content of glass aggregate increased, ASR expansion also increased. Nevertheless, all mixes prepared in this study were potentially innocuous in regard to ASR expansion.

- The experimental evidences showed that glass aggregate can be successfully incorporated in SCM as replacement of fine aggregate without a remarkable effect on workability and strength properties especially up to 30% of glass aggregate content. Thus, contributes towards sustainable solid waste management, saving landfills, conservation of natural resources and environmental protection. The SCM-RGA mixes developed in this study are apt for SCC making, grouting, rehabilitation of structures and production of light transmitting concrete.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Topçu, İ.B.; Canbaz, M. Properties of concrete containing waste glass. Cem. Concr. Res. 2004, 34, 267–274. [Google Scholar] [CrossRef]

- Langer, W.; Drew, L.; Sachs, J. Aggregate and the Environment; American Geological Institute (AGI): Alexandria, VA, USA, 2004; pp. 1–68. ISBN 0-922152-71-3. [Google Scholar]

- Sharifi, Y.; Afshoon, I.; Firoozjaie, Z. Fresh properties of self-compacting concrete containing ground waste glass microparticles as cementing material. J. Adv. Concr. Technol. 2015, 13, 50–66. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Nardinocchi, A.; Donnini, J. Reuse of recycled glass in mortar manufacturing. Eur. J. Environ. Civ. Eng. 2016, 20, 140–151. [Google Scholar] [CrossRef]

- Chandak, S.P. Trends in solid waste management: Issues, challenges and opportunities. In Proceedings of the International Consultative Meeting on Expanding Waste Management Services in Developing Countries, Tokyo, Japan, 18–19 March 2010. [Google Scholar]

- Kasozi, A.; Harro, B.V. Solid Waste Management in Nairobi: A Situation Analysis; Environmental & Process Systems Engineering Group-University of Cape Town, the City Council of Nairobi and the United Nations Environment Programme: Nairobi, Kenya, 2010. [Google Scholar]

- Nunes, S.; Matos, A.M.; Duarte, T.; Figueiras, H.; Sousa-Coutinho, J. Mixture design of self-compacting glass mortar. Cem. Concr. Compos. 2013, 43, 1–11. [Google Scholar] [CrossRef]

- European Federation for Specialist Construction Chemicals and Concrete Systems (EFNARC). Specification and Guidelines for Self-Compacting Concrete; European Federation for Specialist Construction Chemicals and Concrete Systems: Norfolk, UK, 2002; pp. 1–32. ISBN 0953973344. [Google Scholar]

- Okamura, H.; Ozawa, K. Self-compacting high performance concrete. Struct. Eng. Int. 1996, 6, 269–270. [Google Scholar] [CrossRef]

- Okamura, H.; Ozawa, K. Mix design of self compacting concrete. Concr. Libr. JSCE 1995, 25, 107–120. [Google Scholar]

- Midorikawa, T.; Pelova, G.I.I.; Walraven, J.C. Application of ‘The water layer model’ to self-compacting mortar with different size distributions of fine aggregate. Heron 2009, 54, 73–100. [Google Scholar]

- Karataş, M.; Benli, A.; Ergin, A. Influence of ground pumice powder on the mechanical properties and durability of self-compacting mortars. Constr. Build. Mater. 2017, 150, 467–479. [Google Scholar] [CrossRef]

- Mohseni, E.; Miyandehi, B.M.; Yang, J.; Yazdi, M.A. Single and combined effects of nano-SiO2, nano-Al2O3 and nano-TiO2 on the mechanical, rheological and durability properties of self-compacting mortar containing fly ash. Constr. Build. Mater. 2015, 84, 331–340. [Google Scholar] [CrossRef]

- Okamura, H.; Ouchi, M. Self-compacting concrete. J. Adv. Concr. Technol. 2003, 1, 5–15. [Google Scholar] [CrossRef]

- Rizwan, S.A.; Bier, T.A. Blends of limestone powder and fly-ash enhance the response of self-compacting mortars. Constr. Build. Mater. 2012, 27, 398–403. [Google Scholar] [CrossRef]

- Afshinnia, K.; Rangaraju, P.R. Impact of combined use of ground glass powder and crushed glass aggregate on selected properties of portland cement concrete. Constr. Build. Mater. 2016, 117, 263–272. [Google Scholar] [CrossRef]

- Ismail, Z.Z.; AL-Hashmi, E.A. Recycling of waste glass as a partial replacement for fine aggregate in concrete. Waste Manag. 2009, 29, 655–659. [Google Scholar] [CrossRef] [PubMed]

- Limbachiya, M.C. Bulk engineering and durability properties of washed glass sand concrete. Constr. Build. Mater. 2009, 23, 1078–1083. [Google Scholar] [CrossRef]

- Tan, K.H.; Du, H. Use of waste glass as sand in mortar: Part I—Fresh, mechanical and durability properties. Cem. Concr. Compos. 2013, 35, 109–117. [Google Scholar] [CrossRef]

- Ling, T.C.; Poon, C.S.; Kou, S.C. Influence of recycled glass content and curing conditions on the properties of self-compacting concrete after exposure to elevated temperatures. Cem. Concr. Compos. 2012, 34, 265–272. [Google Scholar] [CrossRef]

- Sharifi, Y.; Houshiar, M.; Aghebati, B. Recycled glass replacement as fine aggregate in self-compacting concrete. Front. Struct. Civ. Eng. 2013, 7, 419–428. [Google Scholar] [CrossRef]

- Wright, J.R.; Cartwright, C.; Fura, D.; Rajabipour, F. Fresh and hardened properties of concrete incorporating recycled glass as 100% sand replacement. J. Mater. Civ. Eng. 2014, 26. [Google Scholar] [CrossRef]

- Ali, E.E.; Al-Tersawy, S.H. Recycled glass as a partial replacement for fine aggregate in self compacting concrete. Constr. Build. Mater. 2012, 35, 785–791. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S. Properties of self-compacting concrete prepared with recycled glass aggregate. Cem. Concr. Compos. 2009, 31, 107–113. [Google Scholar] [CrossRef]

- Almesfer, N.; Ingham, J. Effect of Waste Glass on the Properties of Concrete. J. Mater. Civ. Eng. 2014, 26. [Google Scholar] [CrossRef]

- De Castro, S.; De Brito, J. Evaluation of the durability of concrete made with crushed glass aggregates. J. Clean. Prod. 2013, 41, 7–14. [Google Scholar] [CrossRef]

- Sikora, P.; Horszczaruk, E.; Skoczylas, K.; Rucinska, T. Thermal properties of cement mortars containing waste glass aggregate and nanosilica. Procedia Eng. 2017, 196, 159–166. [Google Scholar] [CrossRef]

- Maraghechi, H.; Shafaatian, S.M.H.; Fischer, G.; Rajabipour, F. The role of residual cracks on alkali silica reactivity of recycled glass aggregates. Cem. Concr. Compos. 2012, 34, 41–47. [Google Scholar] [CrossRef]

- Sharifi, Y.; Afshoon, I.; Firoozjaei, Z.; Momeni, A. Utilization of waste glass micro-particles in producing self-consolidating concrete mixtures. Int. J. Concr. Struct. Mater. 2016, 10, 337–353. [Google Scholar] [CrossRef]

- Siad, H.; Lachemi, M.; Sahmaran, M.; Mesbah, H.A.; Hossain, K.M.A.; Ozsunar, A. Potential for using recycled glass sand in engineered cementitious composites. Mag. Concr. Res. 2017, 69, 905–918. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Use of waste glass as sand in mortar: Part II—Alkali-silica reaction and mitigation methods. Cem. Concr. Compos. 2013, 35, 118–126. [Google Scholar] [CrossRef]

- European Committee for Standardization. Composition, Specifications and Conformity Criteria for Common Cements; EN 197-1; European Committee for Standardization: Brussels, Belgium, 2000. [Google Scholar]

- ASTM International. Standard Specification for Concrete Aggregates; ASTM C33-11; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- ASTM International. Flexural Strength of Hydraulic-Cement Mortars; ASTM C348-02; ASTM International: West Conshohocken, PA, USA, 2002. [Google Scholar]

- ASTM International. Standard Test Method for Compressive Strength of Hydraulic-Cement Mortars (Using Portions of Prisms Broken in Flexure); ASTM C349-02; ASTM International: West Conshohocken, PA, USA, 2002. [Google Scholar]

- ASTM International. Standard Test Method for Density, Absorption, and Voids in Hardened Concrete; ASTM C 642-06; ASTM International: West Conshohocken, PA, USA, 2006. [Google Scholar]

- ASTM International. Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes; ASTM C 1585-04; ASTM International: West Conshohocken, PA, USA, 2004. [Google Scholar]

- ASTM International. Standard Test Method for Potential Alkali Reactivity of Cement-Aggregate Combinations (Mortar-Bar Method); ASTM C1260-07; ASTM International: West Conshohocken, PA, USA, 2007. [Google Scholar]

- ASTM International. Standard Practice for Use of Apparatus for the Determination of Length Change of Hardened Cement Paste, Mortar, and Concrete; ASTM C490-07; ASTM International: West Conshohocken, PA, USA, 2007. [Google Scholar]

- Georgiadis, A.S.; Sideris, K.K.; Anagnostopoulos, N.S. Properties of SCC produced with limestone filler or viscosity modifying admixture. J. Mater. Civ. Eng. 2009, 22, 352–360. [Google Scholar] [CrossRef]

- Khaleel, O.R.; Abdul Razak, H. The effect of powder type on the setting time and self compactability of mortar. Constr. Build. Mater. 2012, 36, 20–26. [Google Scholar] [CrossRef]

- Okamura, H.; Ozawa, K.; Ouchi, M. Self-Compacting Concrete. Struct. Concr. 2000, 1, 5–15. [Google Scholar] [CrossRef]

- Tironi, A.; Scian, A.N.; Irassar, E.F. Blended cements with limestone filler and kaolinitic calcined clay: Filler and pozzolanic effects. J. Mater. Civ. Eng. 2017, 29. [Google Scholar] [CrossRef]

- Bentz, D.P.; Ferraris, C.F.; Jones, S.Z.; Lootens, D.; Zunino, F. Limestone and silica powder replacements for cement: Early-age performance. Cem. Concr. Compos. 2017, 78, 43–56. [Google Scholar] [CrossRef] [PubMed]

- Rahma, A.; El Naber, N.; Issa Ismail, S. Effect of glass powder on the compression strength and the workability of concrete. Cogent Eng. 2017, 4. [Google Scholar] [CrossRef]

- Penacho, P.; De Brito, J.; Rosário Veiga, M. Physico-mechanical and performance characterization of mortars incorporating fine glass waste aggregate. Cem. Concr. Compos. 2014, 50, 47–59. [Google Scholar] [CrossRef]

- Choi, S.Y.; Choi, Y.S.; Yang, E.I. Effects of heavy weight waste glass recycled as fine aggregate on the mechanical properties of mortar specimens. Ann. Nucl. Energy 2016, 99, 372–382. [Google Scholar] [CrossRef]

- Ling, T.C.; Poon, C.S. A comparative study on the feasible use of recycled beverage and CRT funnel glass as fine aggregate in cement mortar. J. Clean. Prod. 2012, 29–30, 46–52. [Google Scholar] [CrossRef]

- Ling, T.C.; Poon, C.S. Utilization of recycled glass derived from cathode ray tube glass as fine aggregate in cement mortar. J. Hazard. Mater. 2011, 192, 451–456. [Google Scholar] [CrossRef] [PubMed]

- Medina, C.; Zhu, W.; Howind, T.; Sanchez De Rojas, M.I.; Frias, M. Influence of mixed recycled aggregate on the physical-mechanical properties of recycled concrete. J. Clean. Prod. 2014, 68, 216–225. [Google Scholar] [CrossRef]

- Menéndez, G.; Bonavetti, V.L.; Irassar, E.F. Ternary blend cement concrete. Part II: Transport mechanisms. Mater. Constr. 2007, 57, 31–43. [Google Scholar] [CrossRef]

- Rajabipour, F.; Maraghechi, H.; Fischer, G. Investigating the alkali-silica reaction of recycled glass aggregates in concrete materials. J. Mater. Civ. Eng. 2010, 22, 1201–1208. [Google Scholar] [CrossRef]

- Saccani, A.; Bignozzi, M.C. ASR expansion behavior of recycled glass fine aggregates in concrete. Cem. Concr. Res. 2010, 40, 531–536. [Google Scholar] [CrossRef]

- Yuksel, C.; Ahari, R.S.; Ahari, B.A.; Ramyar, K. Evaluation of three test methods for determining the alkali-silica reactivity of glass aggregate. Cem. Concr. Compos. 2013, 38, 57–64. [Google Scholar] [CrossRef]

| Chemical Composition (%) | Cement | LP | RGA | Fine Aggregate |

|---|---|---|---|---|

| CaO | 63.37 | 47.86 | 10.67 | 4.17 |

| SiO2 | 20.61 | 12.20 | 81.98 | 79.96 |

| Al2O3 | 5.05 | 0.60 | 0.86 | 8.65 |

| Fe2O3 | 3.24 | 0.30 | 0.23 | 1.53 |

| MgO | 0.81 | 0.90 | 5.63 | 0.00 |

| SO3 | 2.75 | 0.00 | 0.19 | 1.27 |

| K2O | 0.52 | — | 0.23 | 2.82 |

| Na2O | 0.15 | — | — | — |

| P2O5 | — | 0.15 | 0.12 | 0.79 |

| C3A | 7.91 | — | — | — |

| Insoluble residue (I.R.) | 1.00 | 0.20 | — | — |

| Loss on ignition (LOI) | 2.90 | 37.65 | — | — |

| Description | Property |

|---|---|

| Appearance/color | Yellowish liquid |

| Density (kg/L) | 1.06 (at +20 °C) |

| pH value | 5.5 ± 0.5 |

| Chemical base | Aqueous solution of modified polycarboxylate |

| Dosage | 0.2–2% by weight of cement |

| Properties | Cement | LP | RGA | Fine Aggregate | |

|---|---|---|---|---|---|

| Specific gravity | 3.15 | 2.80 | 2.32 | 2.37 | |

| Bulk density (kg/m3) | 1433 | 1365 | 1545 | 1610 | |

| Fineness modulus | — | — | 2.70 | 2.35 | |

| Specific surface (cm2/g) | 3197 | 1029 | — | — | |

| Soundness (mm) | 0.30 | — | — | — | |

| Normal consistency (%) | 25.65 | — | — | — | |

| Setting time (min) | Initial | 160 | — | — | — |

| Final | 252 | — | — | — | |

| Compressive strength (N/mm2) | At 2 days | 19.30 | — | — | — |

| At 28 days | 48.94 | — | — | — | |

| Mix Designation | W/P | W/C | Cement (kg/m3) | Limestone Powder (kg/m3) | Water (kg/m3) | Fine Aggregate (kg/m3) | RGA (kg/m3) | SP (kg/m3) |

|---|---|---|---|---|---|---|---|---|

| RGA0% | 0.33 | 0.40 | 623.76 | 138.61 | 252.48 | 1185.00 | — | 5.95 |

| RGA10% | 0.33 | 0.40 | 623.76 | 138.61 | 252.48 | 1066.50 | 118.50 | 6.02 |

| RGA20% | 0.33 | 0.40 | 623.76 | 138.61 | 252.48 | 948.00 | 237.00 | 6.02 |

| RGA30% | 0.33 | 0.40 | 623.76 | 138.61 | 252.48 | 829.50 | 355.50 | 6.10 |

| RGA40% | 0.33 | 0.40 | 623.76 | 138.61 | 252.48 | 711.00 | 474.00 | 6.18 |

| RGA50% | 0.33 | 0.40 | 623.76 | 138.61 | 252.48 | 592.50 | 592.50 | 6.25 |

| Fresh Properties | Mix Designation | EFNARC [8] Criteria | |||||

|---|---|---|---|---|---|---|---|

| RGA0% | RGA10% | RGA20% | RGA30% | RGA40% | RGA50% | ||

| Slump flow (mm) | 250 | 255 | 249 | 242 | 248 | 252 | 250 ± 10 |

| V-funnel flow time (s) | 8.7 | 8.9 | 9.3 | 10.3 | 10.6 | 10.9 | 9 ± 2 |

| Mix Designation | Compressive Strength (MPa) | Flexural Strength (MPa) | ||||||

|---|---|---|---|---|---|---|---|---|

| 3 Days | 7 Days | 14 Days | 28 Days | 3 Days | 7 Days | 14 Days | 28 Days | |

| RGA0% | 47.59 | 52.70 | 53.21 | 57.05 | 7.85 | 8.91 | 9.38 | 10.22 |

| RGA10% | 46.98 | 51.61 | 52.70 | 56.04 | 7.97 | 8.70 | 9.23 | 10.08 |

| RGA20% | 45.54 | 51.01 | 52.21 | 55.62 | 7.89 | 8.67 | 9.14 | 9.96 |

| RGA30% | 44.65 | 47.92 | 49.92 | 53.30 | 7.66 | 8.55 | 9.06 | 9.61 |

| RGA40% | 42.43 | 45.42 | 47.61 | 50.85 | 7.45 | 8.39 | 8.98 | 9.26 |

| RGA50% | 39.24 | 41.79 | 43.13 | 48.33 | 7.13 | 7.91 | 8.73 | 9.02 |

| Mix Designation | Bulk Density (kg/m3) | Water Absorption (%) | Sorptivity (mm/h1/2) |

|---|---|---|---|

| RGA0% | 2385.25 | 7.11 | 2.83 |

| RGA10% | 2382.43 | 7.07 | 2.02 |

| RGA20% | 2379.68 | 6.88 | 1.79 |

| RGA30% | 2372.11 | 6.61 | 1.55 |

| RGA40% | 2359.31 | 6.52 | 1.40 |

| RGA50% | 2347.25 | 6.29 | 1.35 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tuaum, A.; Shitote, S.; Oyawa, W. Experimental Study of Self-Compacting Mortar Incorporating Recycled Glass Aggregate. Buildings 2018, 8, 15. https://doi.org/10.3390/buildings8020015

Tuaum A, Shitote S, Oyawa W. Experimental Study of Self-Compacting Mortar Incorporating Recycled Glass Aggregate. Buildings. 2018; 8(2):15. https://doi.org/10.3390/buildings8020015

Chicago/Turabian StyleTuaum, Awetehagn, Stanley Shitote, and Walter Oyawa. 2018. "Experimental Study of Self-Compacting Mortar Incorporating Recycled Glass Aggregate" Buildings 8, no. 2: 15. https://doi.org/10.3390/buildings8020015