Thermal Conductivity of Straw Bales: Full Size Measurements Considering the Direction of the Heat Flow

Abstract

:1. Introduction

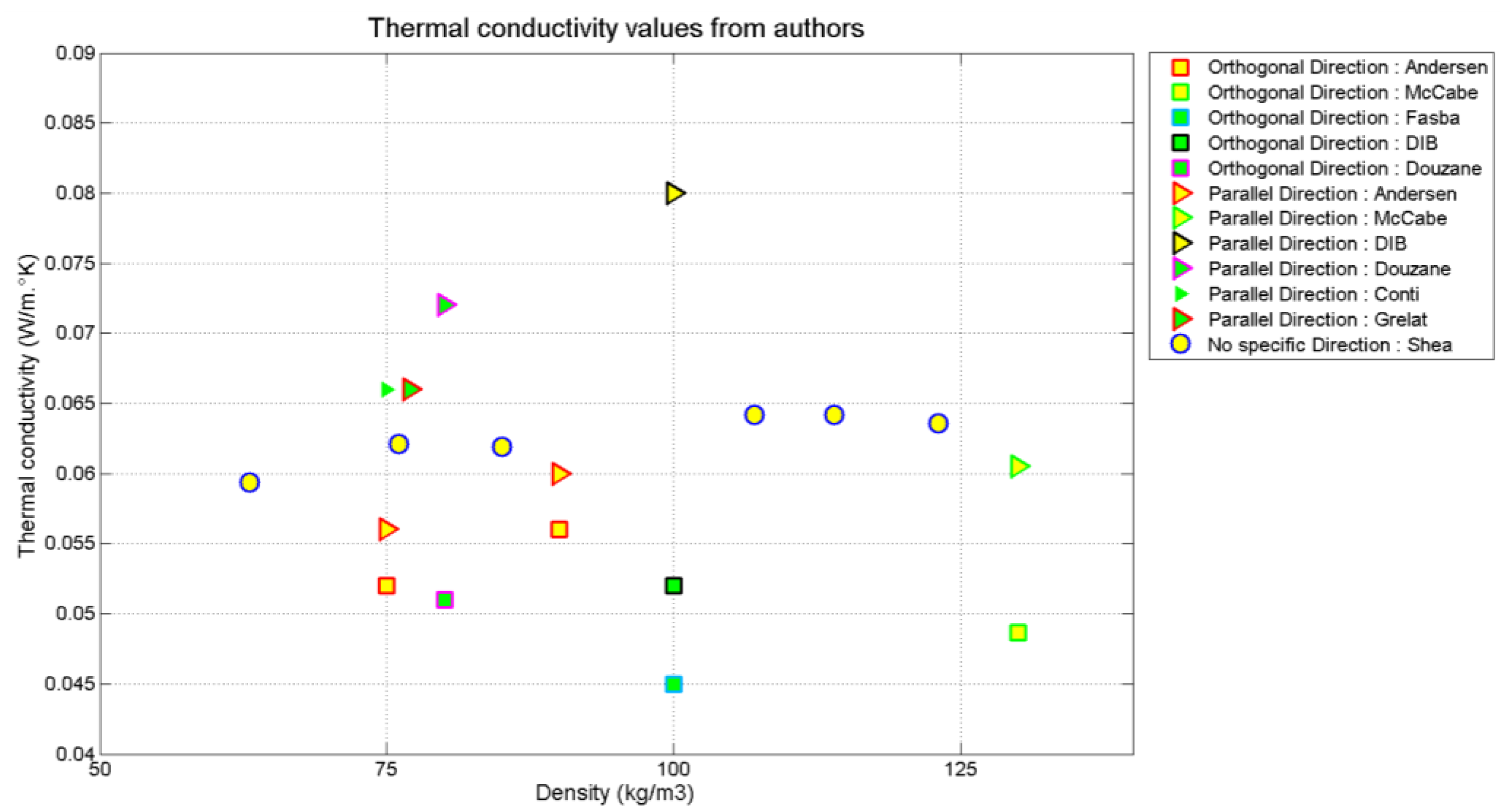

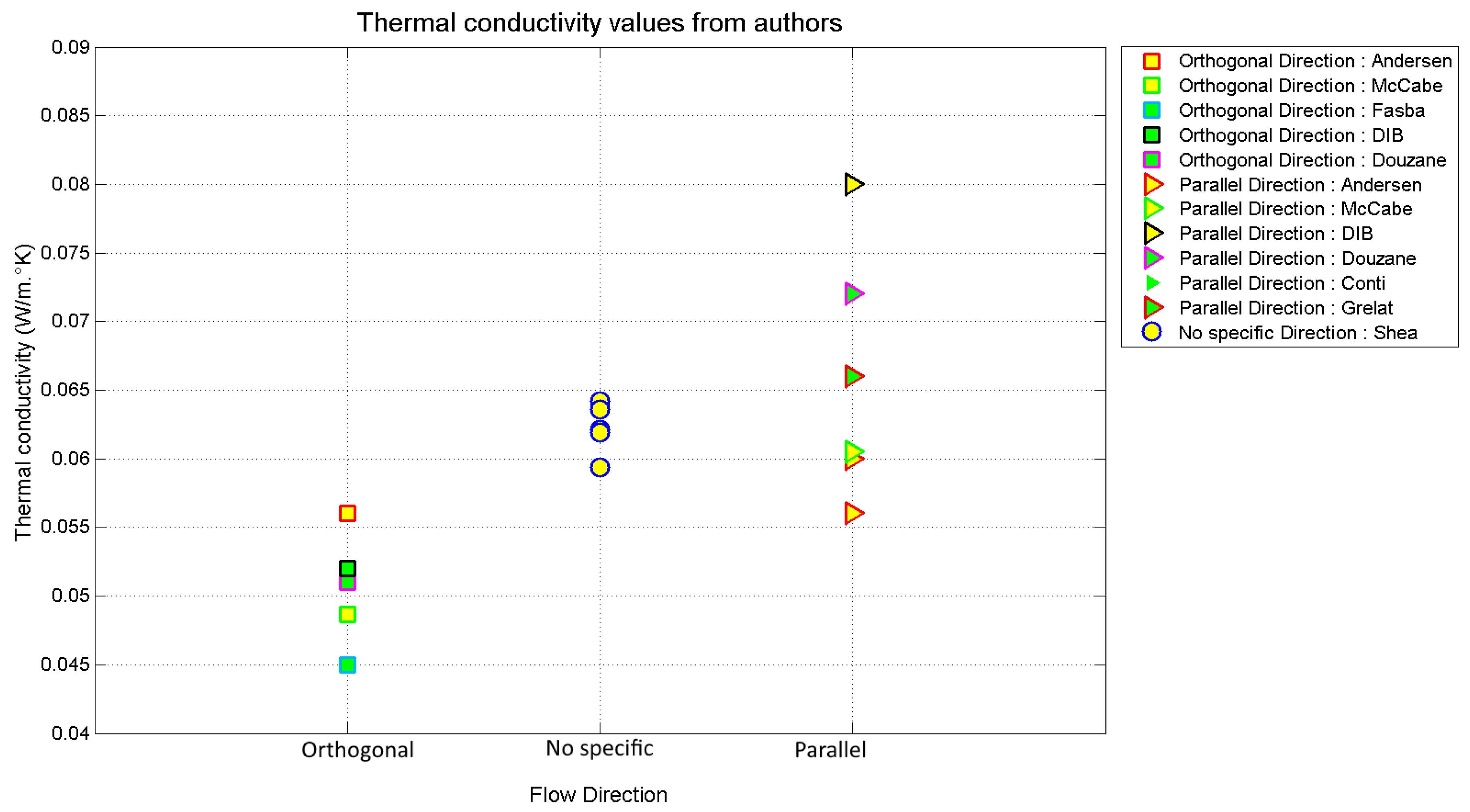

1.1. Overview of Thermal Conductivity Measurements on Straw Bales

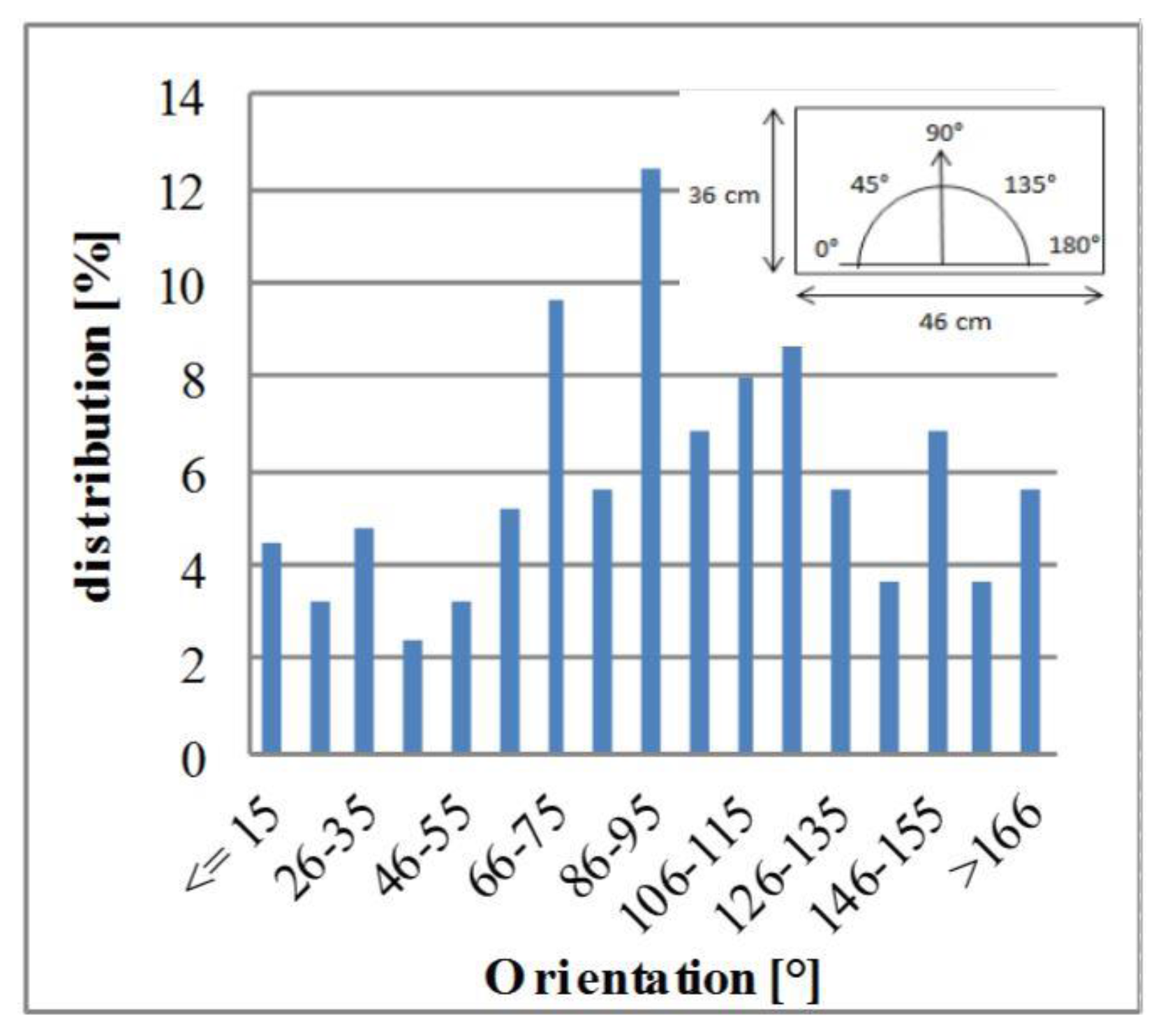

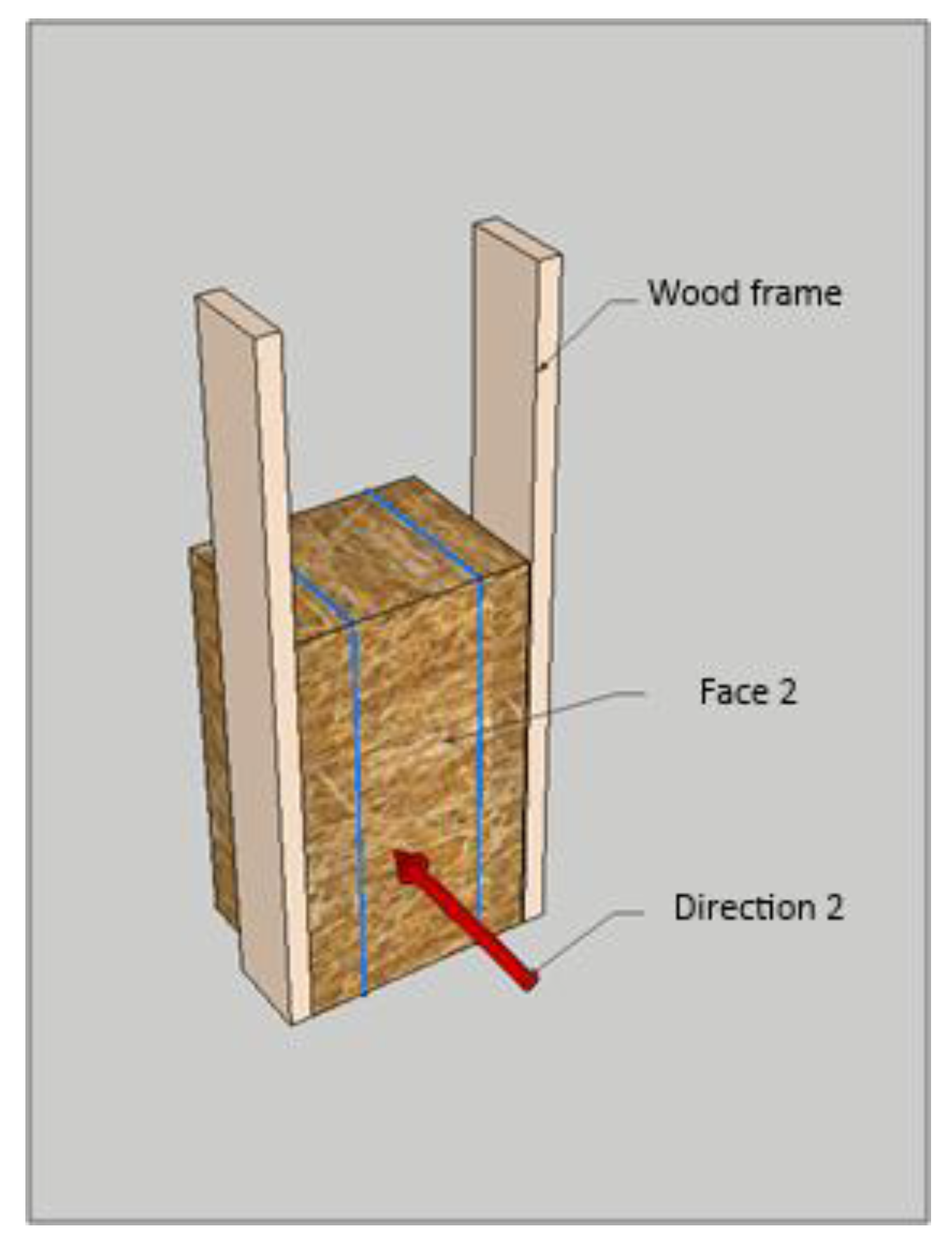

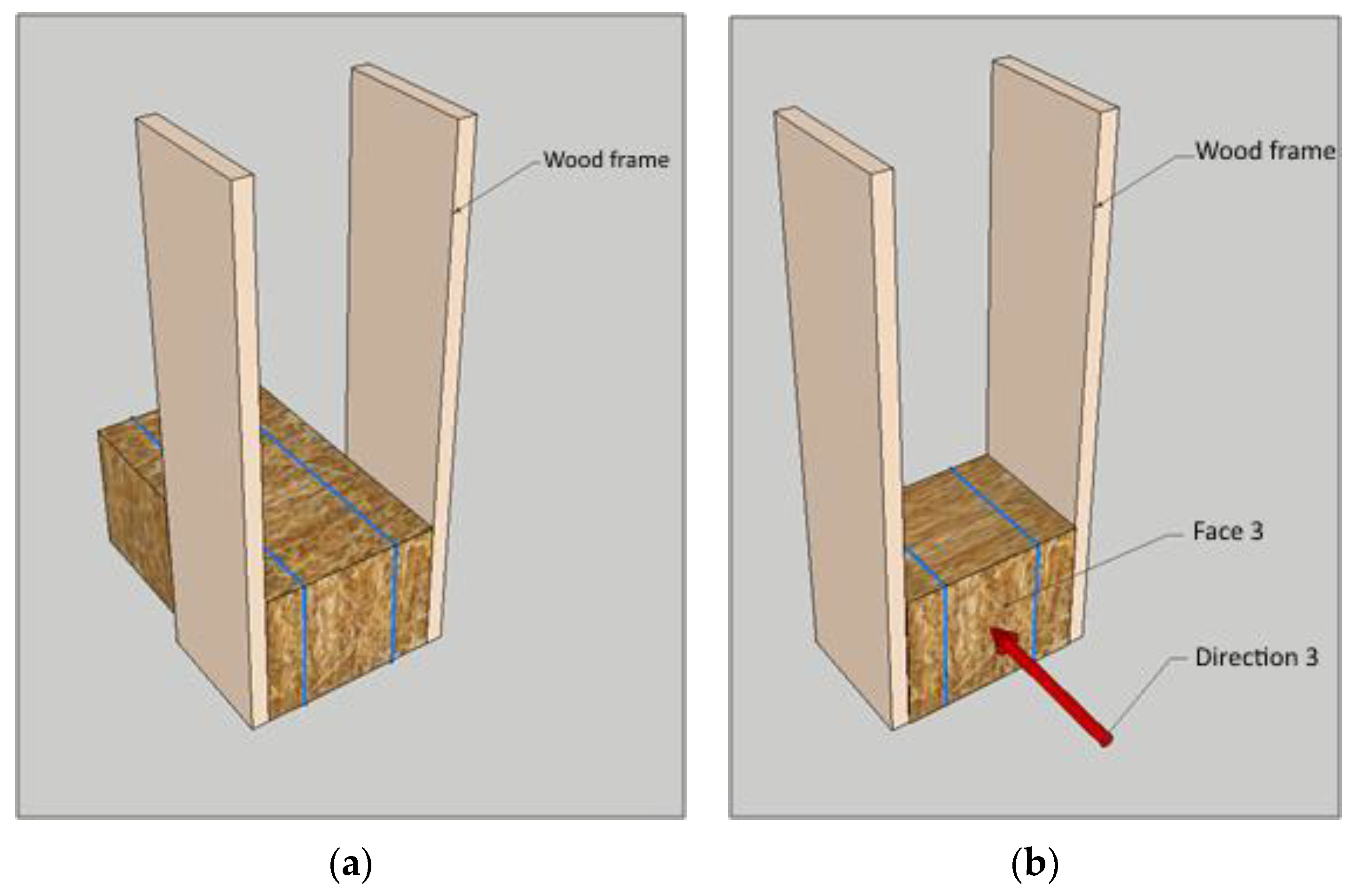

1.2. Straw-Bale Orientation in Vertical Walls

2. Results

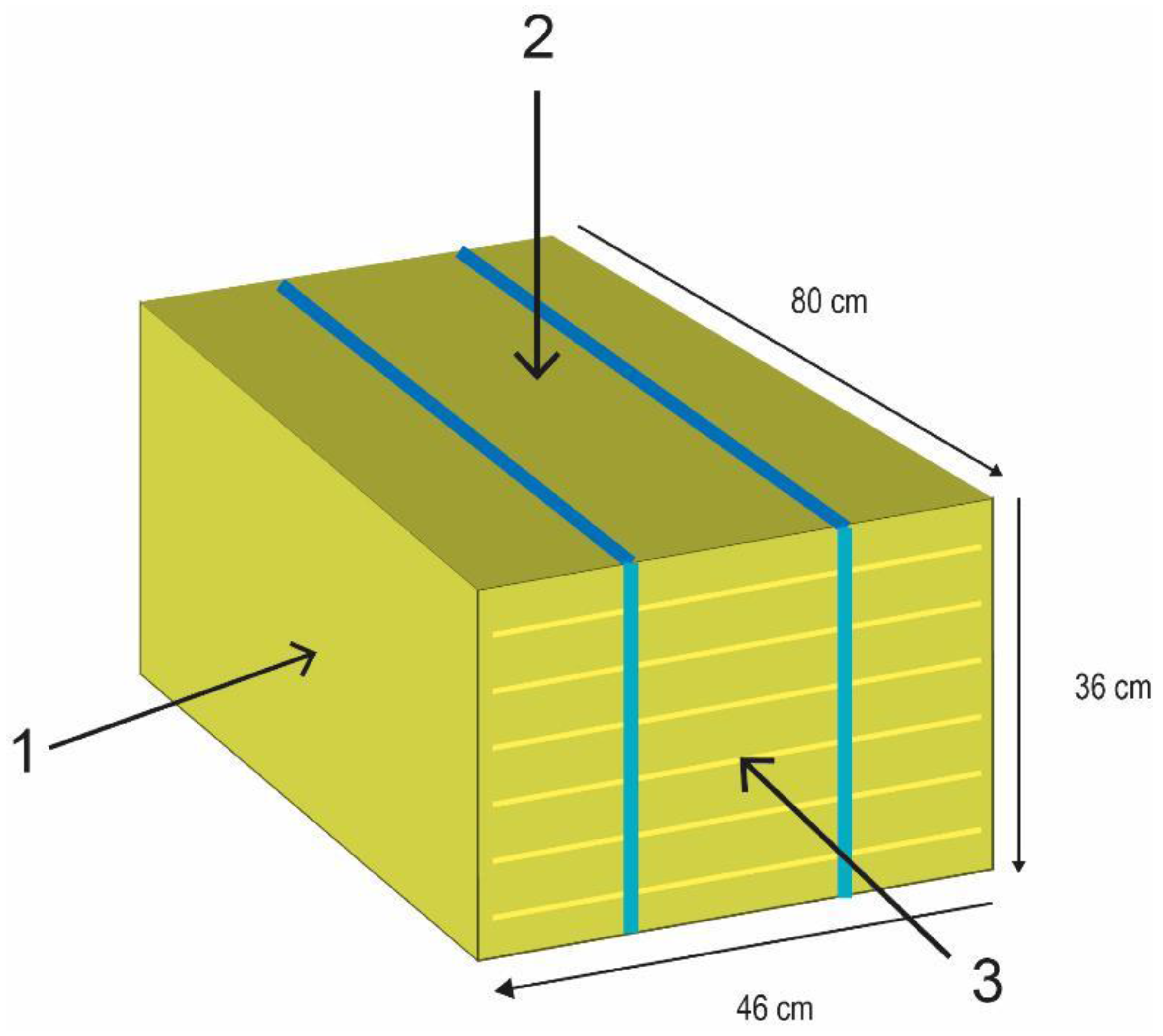

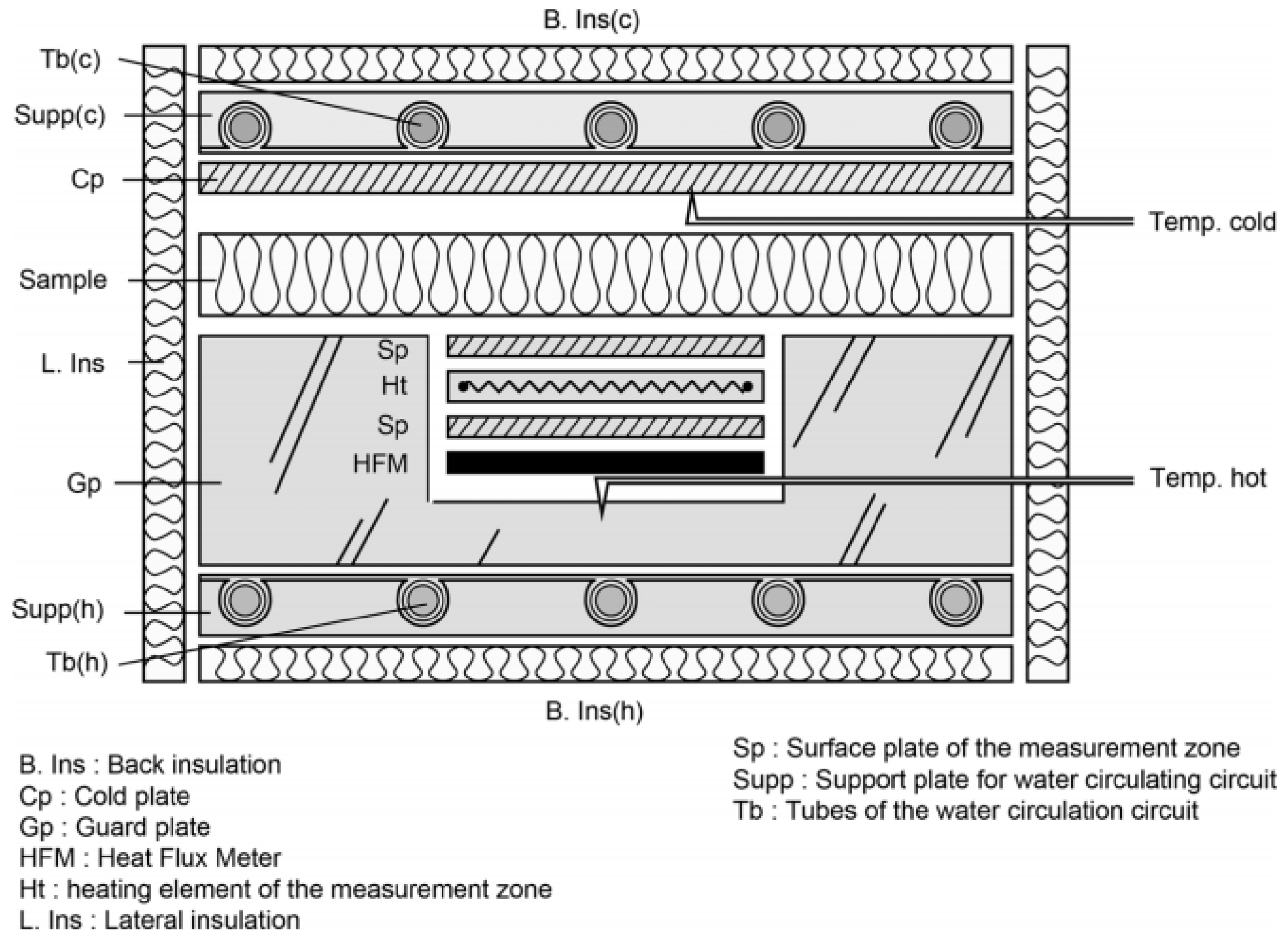

2.1. Measurements and Method

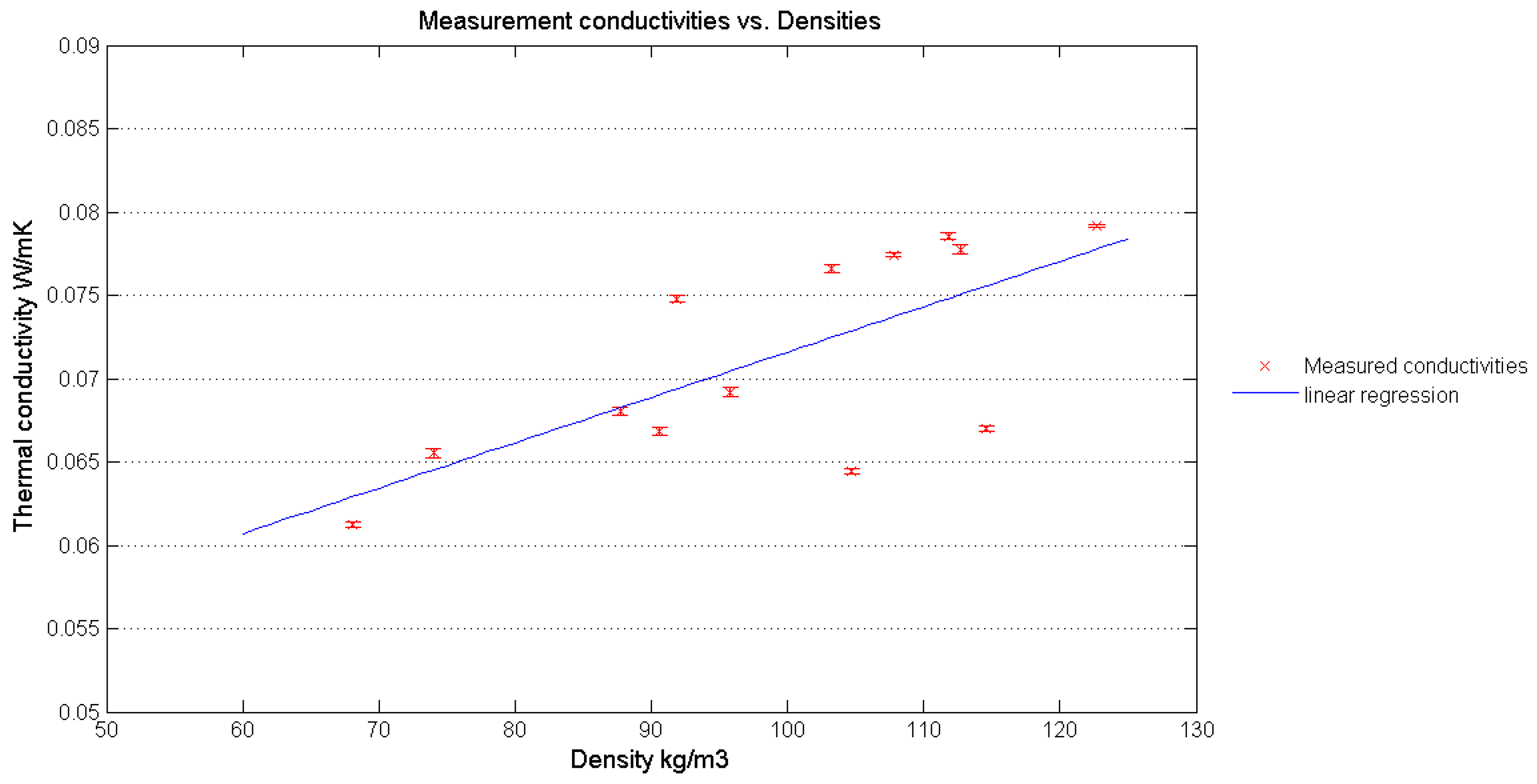

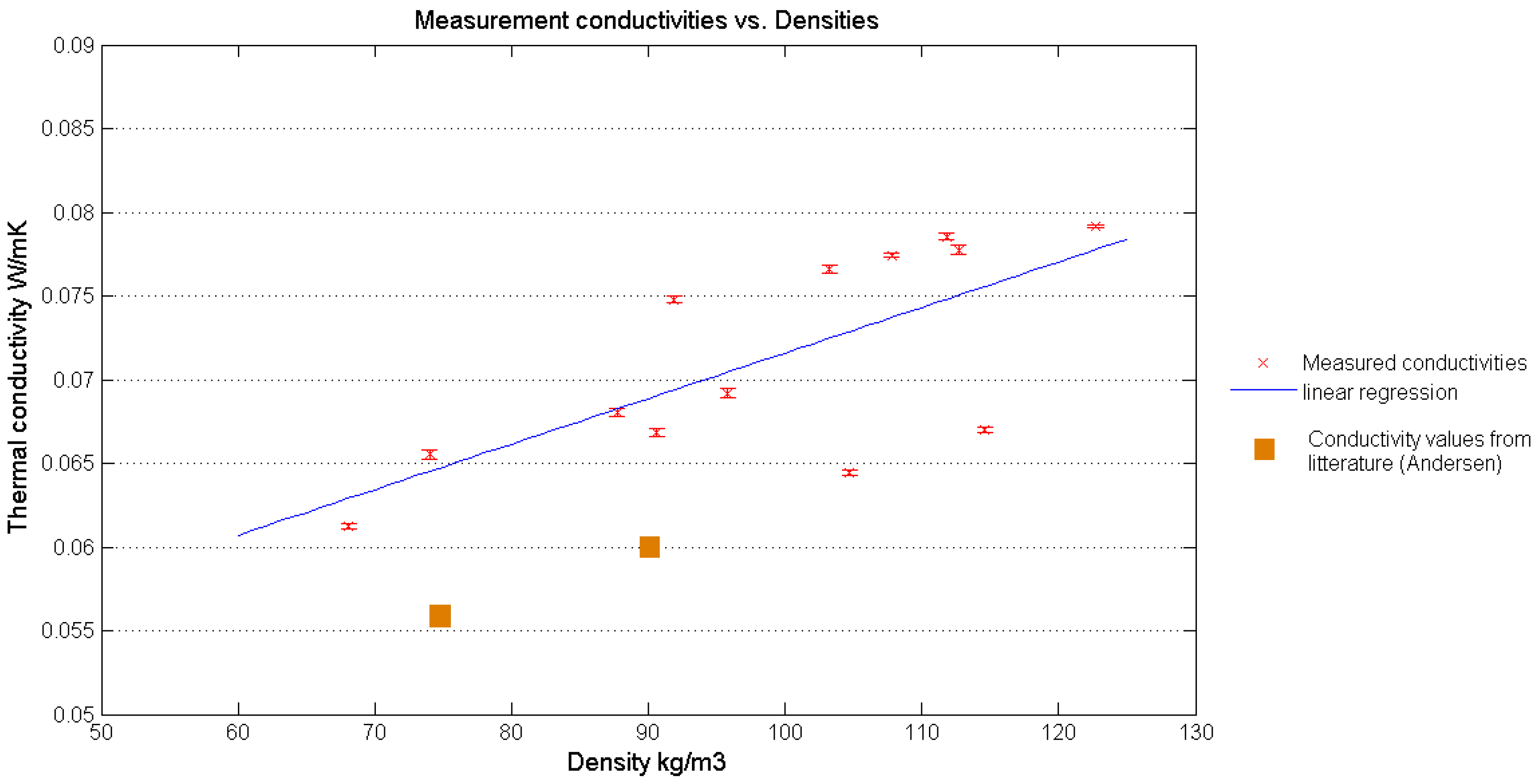

2.2. Thermal Conductivities

- λ = thermal conductivity (W/mK)

- d = density (kg/m3)

- t = thickness (m)

- λ = thermal conductivity (W/Mk)

- d = density (kg/m3)

3. Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- European Straw Bale Gathering—ESBG: Montargis, France, 20–25 August 2015. Available online: www.esbg2015.eu (accessed on 10 September 2016).

- EN ISO 10456:2007 Building Materials and Products—Hygrothermal Properties—Tabulated Design Values and Procedures for Determining Declared and Design Thermal Values; ISO: Geneva, Switzerland, 2007.

- Dubois, S.; Lebeau, F. Design, Construction and Validation of a Guarded Hot Plate Apparatus for Thermal Conductivity Measurement of High Thickness Crop-Based Specimens. Mater. Struct. 2015, 48, 407–421. [Google Scholar] [CrossRef]

- ISO 8302:1991 Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Guarded Hot Plate Apparatus; ISO: Geneva, Switzerland, 1991.

- McCabe, J. Thermal Resistivity of Straw Bales for Construction. Master’s Thesis, University of Arizona, Tucson, AZ, USA, 1993. [Google Scholar]

- Andersen, B.M.; Munch-Andersen, J. Halmballer og Muslinger som Isoleringsmaterialer; Report 2001-06–21; Statens Byggeforskningsinstitut: Copenhagen, Denmark, 2001. [Google Scholar]

- Shea, A.D.; Wall, K.; Walker, P. Evaluation of the thermal performance of an innovative prefabricated natural plant fibre building system. Build. Serv. Eng. Res. Technol. 2013, 344, 369–380. [Google Scholar] [CrossRef]

- Prüfbericht. Wärmeleitfähigkeit nach EN 12667; Forchungsinstitut für Wärmeschutz e.V.: München, Germany, 2010. [Google Scholar]

- Deutsches Institut für Bautechnik (DIB). Available online: https://www.dibt.de/index_eng.html (accessed on 10 September 2016).

- Douzane, O.; Promis, G.; Roucoult, J.-M.; Le, A.-D.T.; Langlet, T. Hygrothermal performance of a straw bale building: In situ and laboratory investigations. J. Build. Eng. 2016, 8, 91–98. [Google Scholar] [CrossRef]

- Conti, L.; Barbari, M.; Monti, M. Steady-State Thermal Properties of Rectangular Straw-Bales (RSB) for Building. Buildings 2016, 6, 44. [Google Scholar] [CrossRef]

- Wei, K.; Lv, C.; Chen, M.; Zhou, X.; Dai, Z.; Shen, D. Development and performance evaluation of a new thermal insulation material from rice straw using high frequency hot-pressing. Energy Build. 2015, 87, 116–122. [Google Scholar] [CrossRef]

- Grelat, A. Using Sustainable Materials as Walling for Individual Housing With Wood Structure; Final report; Centre D’expertise du Batiment et des Travaux Public: Saint-Remy-Les-Chevreuse, France, 2004. [Google Scholar]

- Palumbo, M.; Lacasta, A.M.; Holcroft, N.; Shea, A.; Walker, P. Determination of hygrothermal parameters of experimental and commercial bio-based insulation materials. Constr. Build. Mater. 2016, 124, 269–275. [Google Scholar] [CrossRef]

- Allgemeine bauaufsichliche Zulassung—Wärmedämmstoff aus Strohballen “Baustrohballen”; Technical agreement n° Z-23.11–1595; Deutsches Institut für Bautechnik: Berlin, Germany, 2006.

| Reference | Density (kg/m3) | Orientation | Thermal Conductivity (W/mK) |

|---|---|---|---|

| McCabe, 1993 [5] | 130 | perpendicular | 0.0487 |

| parallel | 0.0605 | ||

| Andersen, 2001 [6] | 75 | perpendicular | 0.052 |

| parallel | 0.056 | ||

| 90 | perpendicular | 0.056 | |

| parallel | 0.06 | ||

| Shea, 2013 [7] | 63 | no specific direction | 0.0594 |

| 76 | 0.0621 | ||

| 85 | 0.0619 | ||

| 107 | 0.0642 | ||

| 114 | 0.0642 | ||

| 123 | 0.0636 | ||

| Fasba, 2003 [8] | 90–110 | perpendicular | 0.045 |

| Douzane, 2016 [10] | 80 | perpendicular | 0.051 |

| parallel | 0.072 | ||

| Conti, 2016 [11] | 75 | parallel | 0.066 |

| Grelat, 2004 [13] | 77 | parallel | 0.066 |

| DIBt, 2006 [9] | 90–110 | perpendicular | 0.052 |

| parallel | 0.08 |

| Thickness (m) | Density (kg/m3) |

|---|---|

| 0.3 | 74 |

| 0.471 | 111.8 |

| 0.488 | 114.6 |

| 0.485 | 91.9 |

| 0.462 | 104.7 |

| 0.386 | 107.8 |

| 0.485 | 122.7 |

| 0.485 | 95.8 |

| 0.486 | 87.7 |

| 0.495 | 103.2 |

| 0.484 | 90.6 |

| 0.481 | 68.1 |

| 0.476 | 112.7 |

| Straw Mass in Apparent Wall Surface kg/m2 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 25 | 30 | 35 | 40 | 45 | 50 | 55 | 60 | 65 | 70 | ||

| Wall width (cm) | 36 | 55.6 | 69.4 | 83.3 | 97.2 | 111.1 | 125.0 | 138.9 | 152.8 | 166.7 | 180.6 | 194.4 |

| 40 | 50.0 | 62.5 | 75.0 | 87.5 | 100.0 | 112.5 | 125.0 | 137.5 | 150.0 | 162.5 | 175.0 | |

| 46 | 43.5 | 54.3 | 65.2 | 76.1 | 87.0 | 97.8 | 108.7 | 119.6 | 130.4 | 141.3 | 152.2 | |

| Straw Mass in Apparent Wall Surface kg/m2 | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 25 | 30 | 35 | 40 | 45 | 50 | 55 | 60 | 65 | 70 | Gain | Average | ||

| Wall width (cm) | 36 | 0.060 | 0.063 | 0.067 | 0.071 | 0.075 | 0.078 | 0.082 | 0.086 | 0.090 | 0.093 | 0.097 | −23% | |

| 40 | 0.058 | 0.061 | 0.065 | 0.068 | 0.072 | 0.075 | 0.078 | 0.082 | 0.085 | 0.089 | 0.092 | −28% | −25% | |

| 46 | 0.056 | 0.059 | 0.062 | 0.065 | 0.068 | 0.071 | 0.074 | 0.077 | 0.080 | 0.083 | 0.086 | −25% | ||

| Gain (%) | −3% | −7% | −8% | −9% | −9% | −10% | −6% | −6% | ||||||

| Average: | −7.4% | |||||||||||||

| Straw Mass in Apparent Wall Surface kg/m2 | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 25 | 30 | 35 | 40 | 45 | 50 | 55 | 60 | 65 | 70 | Gain | Average | ||

| Wall width (cm) | 36 | 5.69 | 5.37 | 5.08 | 4.82 | 4.59 | 4.38 | 30% | ||||||

| 40 | 6.51 | 6.17 | 5.87 | 5.59 | 5.33 | 5.10 | 4.89 | 4.70 | 39% | 34% | ||||

| 46 | 7.40 | 7.07 | 6.76 | 6.48 | 6.22 | 5.98 | 5.76 | 5.55 | 33% | |||||

| Gain (%) | - | 37% | 38% | 39% | 40% | 41% | 42% | 43% | 44% | - | - | |||

| Average: | 40.4% | |||||||||||||

| Straw Mass in Apparent Wall Surface kg/m2 | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 25 | 30 | 35 | 40 | 45 | 50 | 55 | 60 | 65 | 70 | Gain | Average | ||

| Wall width (cm) | 36 | 0.176 | 0.186 | 0.197 | 0.207 | 0.218 | 0.228 | –23% | ||||||

| 40 | 0.154 | 0.162 | 0.170 | 0.179 | 0.187 | 0.196 | 0.204 | 0.213 | –28% | –25% | ||||

| 46 | 0.135 | 0.142 | 0.148 | 0.154 | 0.161 | 0.167 | 0.174 | 0.180 | –25% | |||||

| Gain (%) | - | –27% | –27% | –28% | –29% | –29% | –30% | –30% | –30% | - | - | |||

| Average: | –28.7% | |||||||||||||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Costes, J.-P.; Evrard, A.; Biot, B.; Keutgen, G.; Daras, A.; Dubois, S.; Lebeau, F.; Courard, L. Thermal Conductivity of Straw Bales: Full Size Measurements Considering the Direction of the Heat Flow. Buildings 2017, 7, 11. https://doi.org/10.3390/buildings7010011

Costes J-P, Evrard A, Biot B, Keutgen G, Daras A, Dubois S, Lebeau F, Courard L. Thermal Conductivity of Straw Bales: Full Size Measurements Considering the Direction of the Heat Flow. Buildings. 2017; 7(1):11. https://doi.org/10.3390/buildings7010011

Chicago/Turabian StyleCostes, Jean-Philippe, Arnaud Evrard, Benjamin Biot, Gauthier Keutgen, Amaury Daras, Samuel Dubois, Frédéric Lebeau, and Luc Courard. 2017. "Thermal Conductivity of Straw Bales: Full Size Measurements Considering the Direction of the Heat Flow" Buildings 7, no. 1: 11. https://doi.org/10.3390/buildings7010011

APA StyleCostes, J.-P., Evrard, A., Biot, B., Keutgen, G., Daras, A., Dubois, S., Lebeau, F., & Courard, L. (2017). Thermal Conductivity of Straw Bales: Full Size Measurements Considering the Direction of the Heat Flow. Buildings, 7(1), 11. https://doi.org/10.3390/buildings7010011