4.2. Flexural Tensile Strength Test

Flexural strength testing was done according ASTM C67-07 [

13]. The loading scheme was modified from third-point loading to center-point loading. A total of 5 samples were tested for each of the seven mix designs. A Universal Hydraulic UH Series Shimadzu universal testing machine with a maximum load capacity of 1000 KN was used. The machine was set up with a Linear Variable Differential Transformer (LVDT) displacement sensor to record mid-span deflection as shown in

Figure 7. The values for flexural strength were computed using Equation (2):

where:

S = Modulus of rupture of the block at the plane of failure, PSI (Pound per Square Inch) (MPa);

W = Maximum load indicated by the testing machine, lbs (N);

L = Span length, in (mm);

b = Average width of the block at the plane of failure, in (mm);

d = Average depth of the block at the plane of failure, in (mm).

Figure 7.

(a) Leveling the two supports and centering Linear Variable Differential Transformer (LVDT); (b) Flexural strength test set-up.

Figure 7.

(a) Leveling the two supports and centering Linear Variable Differential Transformer (LVDT); (b) Flexural strength test set-up.

Using center point loading, flexural strength is determined assuming simple, pure bending. In this case the span to depth ratio was approximately 2. Failure of the tested blocks did not always occur at the mid-point. During testing, all the unreinforced blocks experienced sudden failure, while none of the fiber reinforced blocks did, as shown in

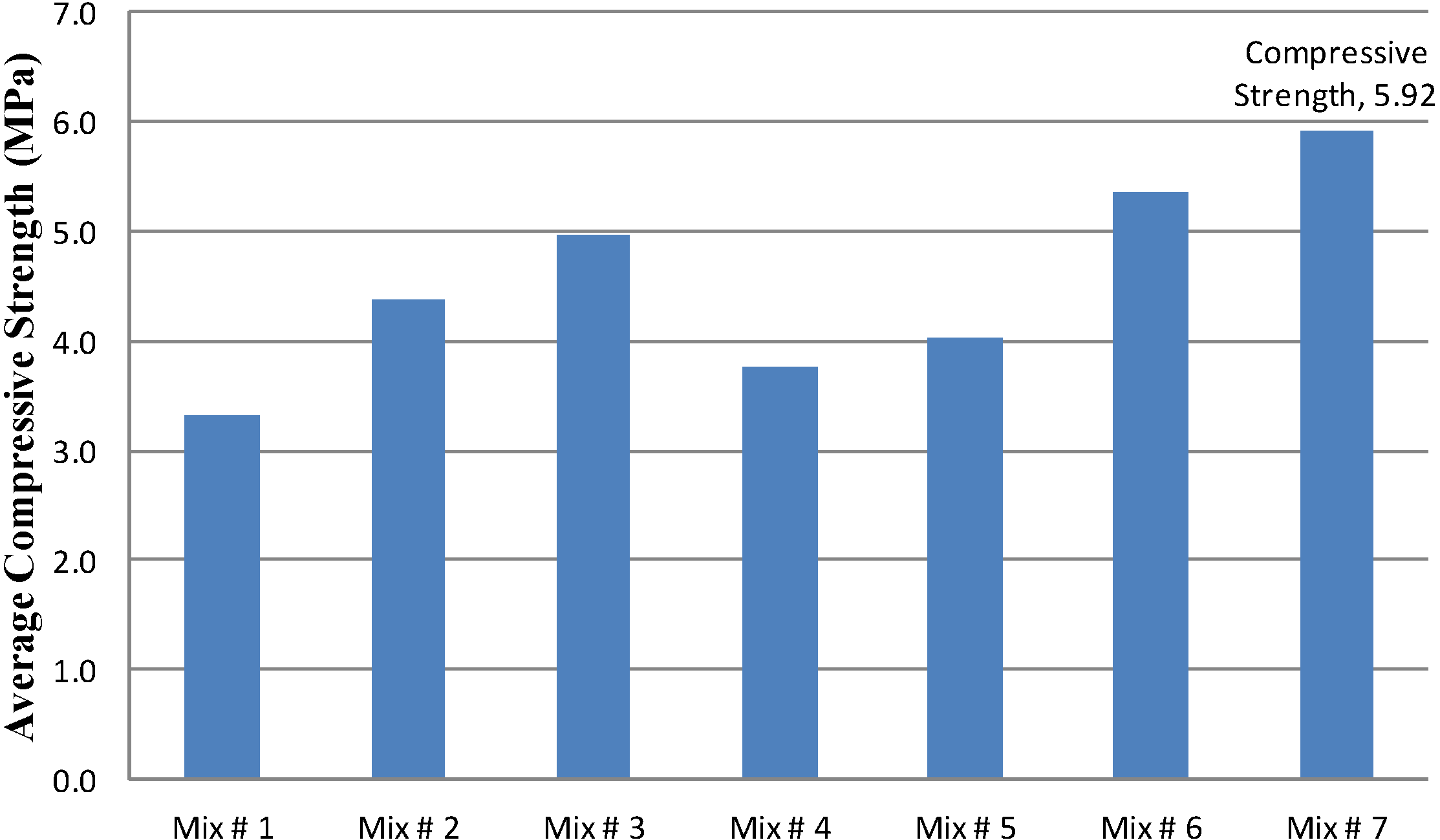

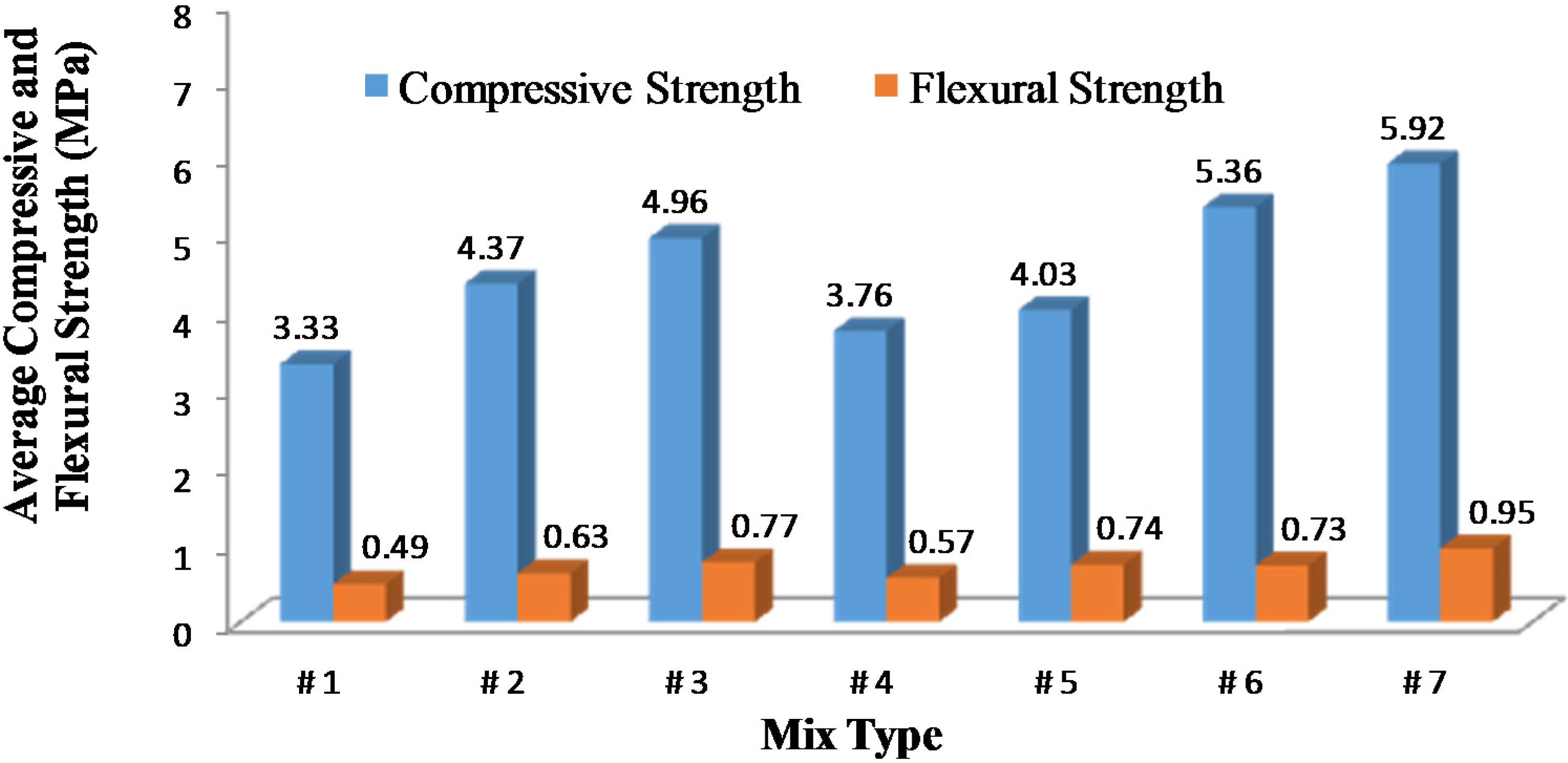

Figure 8. The reinforced GCEBs with treated 50 mm of banana fibers (mix #7) yielded the highest average modulus of rupture (MOR) with a value of 0.95 MPa; also, the average flexural strength and the maximum displacement of the blocks are shown in

Table 6.

Table 7 presents the percentage of increase in flexural strength compared to mix # 1 with a value of 0.49 MPa.

Figure 8.

(a) Plain CEB flexural failure; (b) Reinforced GCEB flexural failure.

Figure 8.

(a) Plain CEB flexural failure; (b) Reinforced GCEB flexural failure.

Table 6.

Average flexural strength and maximum mid-span displacement results of GCEBs.

Table 6.

Average flexural strength and maximum mid-span displacement results of GCEBs.

| Sample Mix | # 1 | # 2 | # 3 | # 4 | # 5 | Avg. Flexural Strength (MPa) | Standard Deviation | Maximum Displacement (mm) |

|---|

| # 1 | 0.57 | 0.62 | 0.40 | 0.41 | 0.57 | 0.49 | 0.10 | 0.8 |

| # 2 | 0.61 | 0.59 | 0.53 | 0.70 | 0.70 | 0.63 | 0.07 | 1.5 |

| # 3 | 0.82 | 0.75 | 0.74 | 0.69 | 0.84 | 0.77 | 0.06 | 2.8 |

| # 4 | 0.46 | 0.73 | 0.43 | 0.66 | 0.58 | 0.57 | 0.13 | 3.0 |

| # 5 | 0.79 | 0.71 | 0.77 | 0.73 | 0.70 | 0.74 | 0.04 | 2.0 |

| # 6 | 0.81 | 0.64 | 0.73 | 0.77 | 0.68 | 0.73 | 0.07 | 2.3 |

| # 7 | 0.88 | 0.96 | 0.99 | 1.00 | 0.94 | 0.95 | 0.05 | 3.4 |

Table 7.

Percentage increase in flexural strength.

Table 7.

Percentage increase in flexural strength.

| Mix Type | % Increase |

|---|

| # 2 | 28% |

| # 3 | 58% |

| # 4 | 17% |

| # 5 | 51% |

| # 6 | 49% |

| # 7 | 94% |

Fibers are known to oppose crack formation in step with increasing stress and also bridge micro cracks from expanding [

15,

16]. The block geometry did not provide enough span to allow for failure to occur at the center of the blocks, which would have allowed for a better assessment of the influence of the fibers. Also, the center point is not always the weakest point in the block, therefore values reported using center-point loading could be higher compared to third-point loading results.

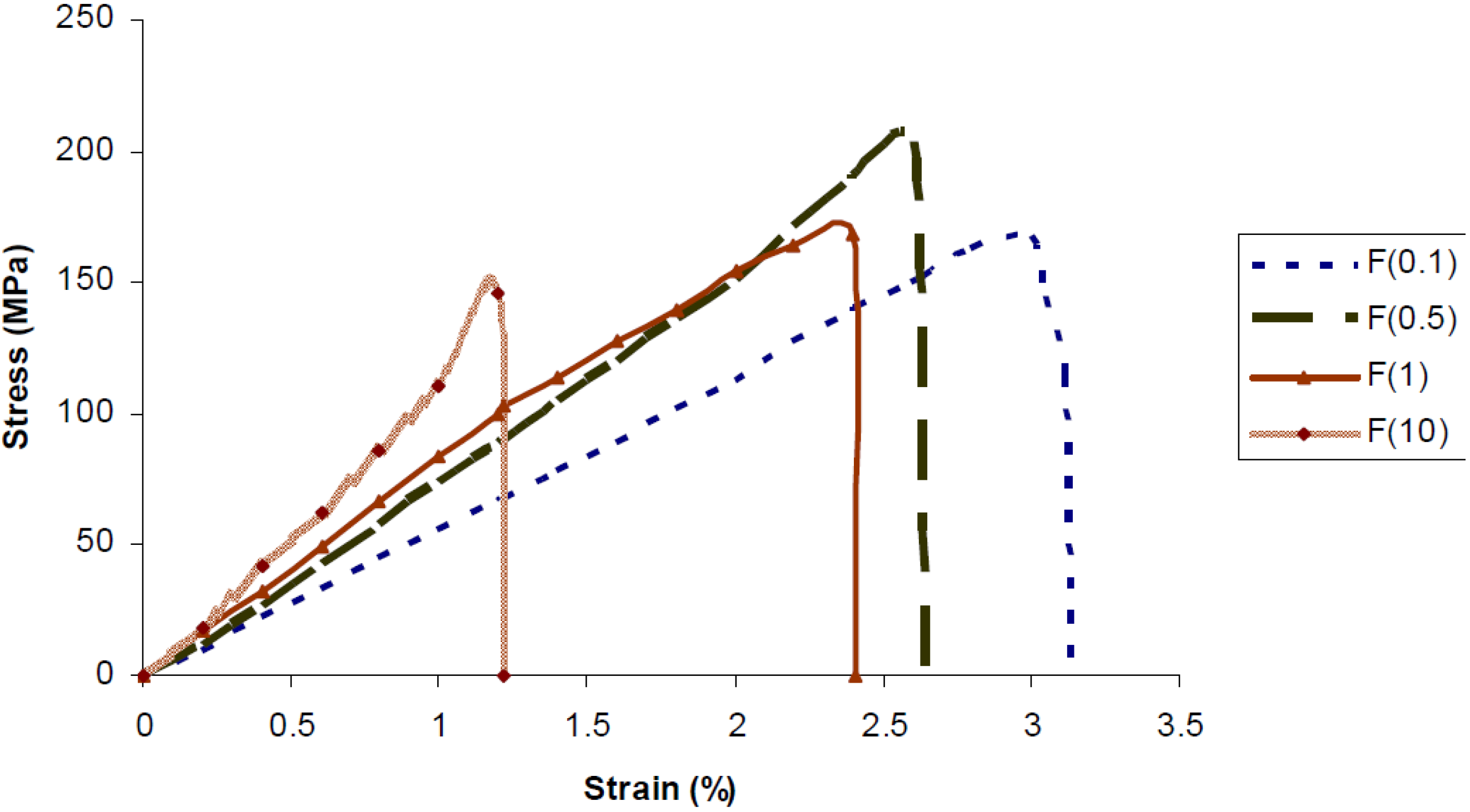

Most of the 35 tested samples’ failures occurred at the mid-point. Each tested sample exhibited linear elastic characteristics prior to initial crack, which typically occurred at peak load. The load-deflection responses of the fiber-reinforced samples were different from the unreinforced ones. Typical load-deflection curves of the tested samples are presented in

Figure 9. In general, the fiber-reinforced blocks performed better in post-initial crack behavior compared to the plain matrix. The results also suggest that the fibers affect the brittle behavior of the matrices. The unreinforced samples exhibited sudden failure in all instances. Most of the fiber-reinforced matrices experienced complete failure at more than 2 mm deflection, while the plain samples experienced complete failure at less than 1 mm displacement. It was also observed that some of the fibers’ cracks bridged. That could explain the cause of gradual failure as shown in

Figure 10.

The fibers at the crack zone bear the tensile stress transferred from the rupture section. Previous studies established a relationship between increased aspect ratio of fibers and the ability of fibers to bridge micro cracks. In this study, the 50 mm fibers had a higher aspect ratio and produced a higher tensile strength in matrices compared to the 25 mm fibers, suggesting that their embedded length was insufficient to develop full tensile capacity. Observations during testing showed that the strength rebound occurred when fibers kicked in. The maximum post-initial crack load for the matrices reinforced with treated 50 mm fibers (mix #7) was the highest peak load recorded for all matrices.

Figure 9.

Typical load-deflection curves for GCEBs Mixes.

Figure 9.

Typical load-deflection curves for GCEBs Mixes.

Figure 10.

Banana fibers bridging the GCEB cracks during failure.

Figure 10.

Banana fibers bridging the GCEB cracks during failure.

The findings point out that extensible banana fibers did not totally pull out of matrices when specimens reached peak strength. It was also noted that gradual fiber slipping and stretching resulted in a high post-peak strength even at high deformation levels. Comparing the results from the different matrices in this study, matrices with different proportions of the shorter fibers (25 mm) did not sustain as much fiber slippage as matrices with only 50 mm fibers. Subsequently, more gradual failure, after initial crack of all the fiber-reinforced matrices, suggests an improved performance in ductility that can be attributed to the banana fibers. Also, both fiber pullout and breakage were observed in GCEBs.

4.3. Water Absorption Test

The specimens from the flexural tests were used for the water absorption test. The water absorption test is basic in nature but may be the most useful in assessing the durability of GCEBs. After 28 days curing, GCEBs were weighed and recorded. This was the dry weight (

Wd). The weighted samples were then totally immersed in a water tank for 24 h. They were then taken out, wiped with a cloth, and reweighed. The weight of each specimen was recorded. This was the wet weight (

Ws). The water absorption of the samples was calculated using Equation (3):

where:

WA = Block water absorption;

Ws = Saturated weight of the block after submersion in cold water;

Wd = Dry weight of the block.

The absorption measures the unit’s total capacity to absorb moisture. The measure of plain-CEB recorded approximately 7.4% water absorption, while the water absorption of the GCEB with banana fibers recorded an average of 10.6%. The final density of the block is 128 PCF (Pound per Cubic Feet). Blocks with banana fibers have a slightly higher water permeability or absorption than plain blocks. The higher water absorption capacity of fiber-reinforced blocks may be attributed to the amount of water absorbed by the cellulose fiber. It can be concluded that fibers increase block permeability to water. The resulting data, however, shows that all the processed GCEBs were either in the 10%–20% water absorption range or below. Therefore, with respect to this parameter, all the GCEBs met the minimum requirements for their use in building construction [

17].